A Comprehensive Study of the Macro-Scale Performance of Graphene Oxide Enhanced Low Carbon Concrete

Abstract

1. Introduction

2. Experimental Program

2.1. Materials

2.2. Methods

3. Results and Discussion

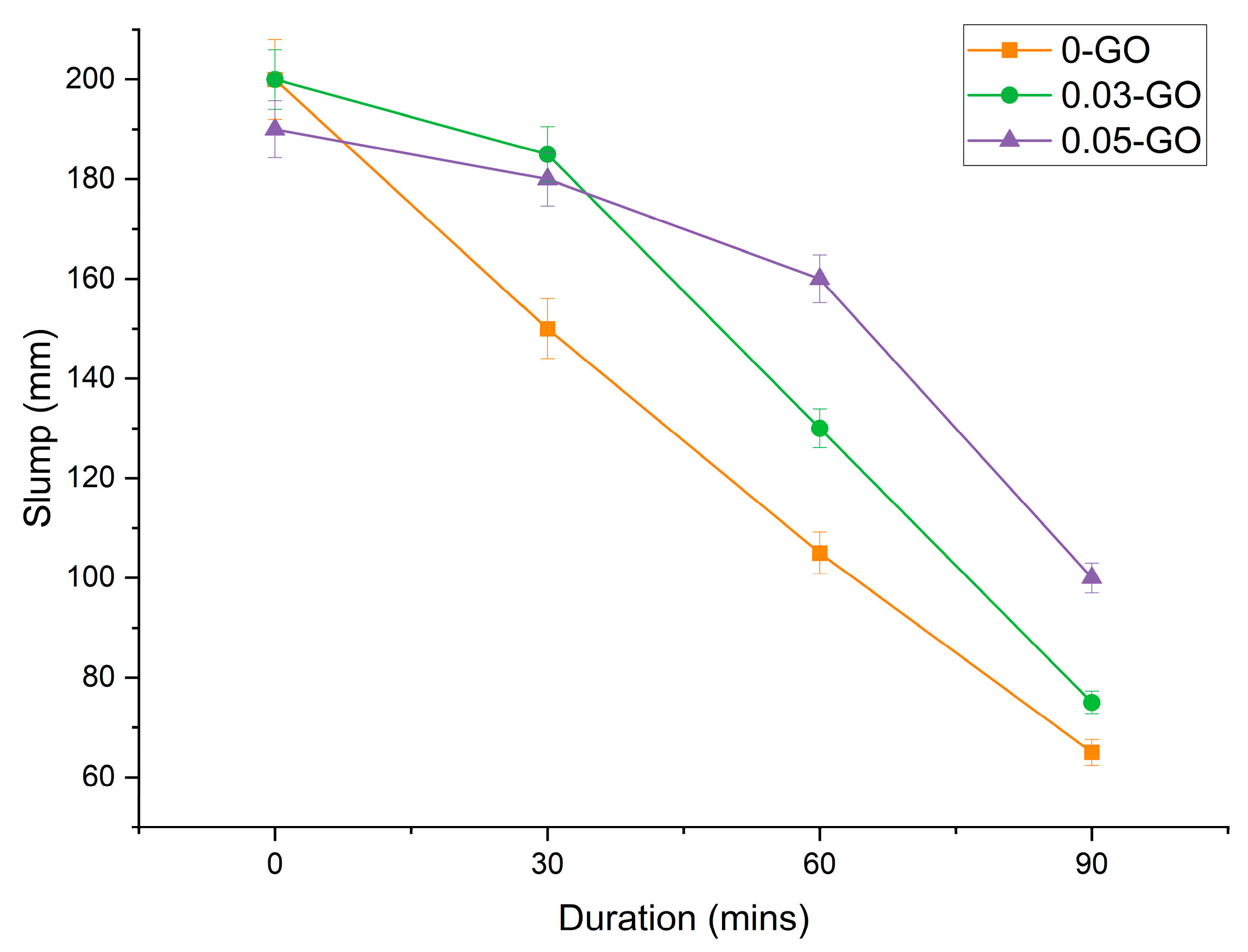

3.1. Slump and Slump Retention Tests

3.2. Air Content and Bleeding

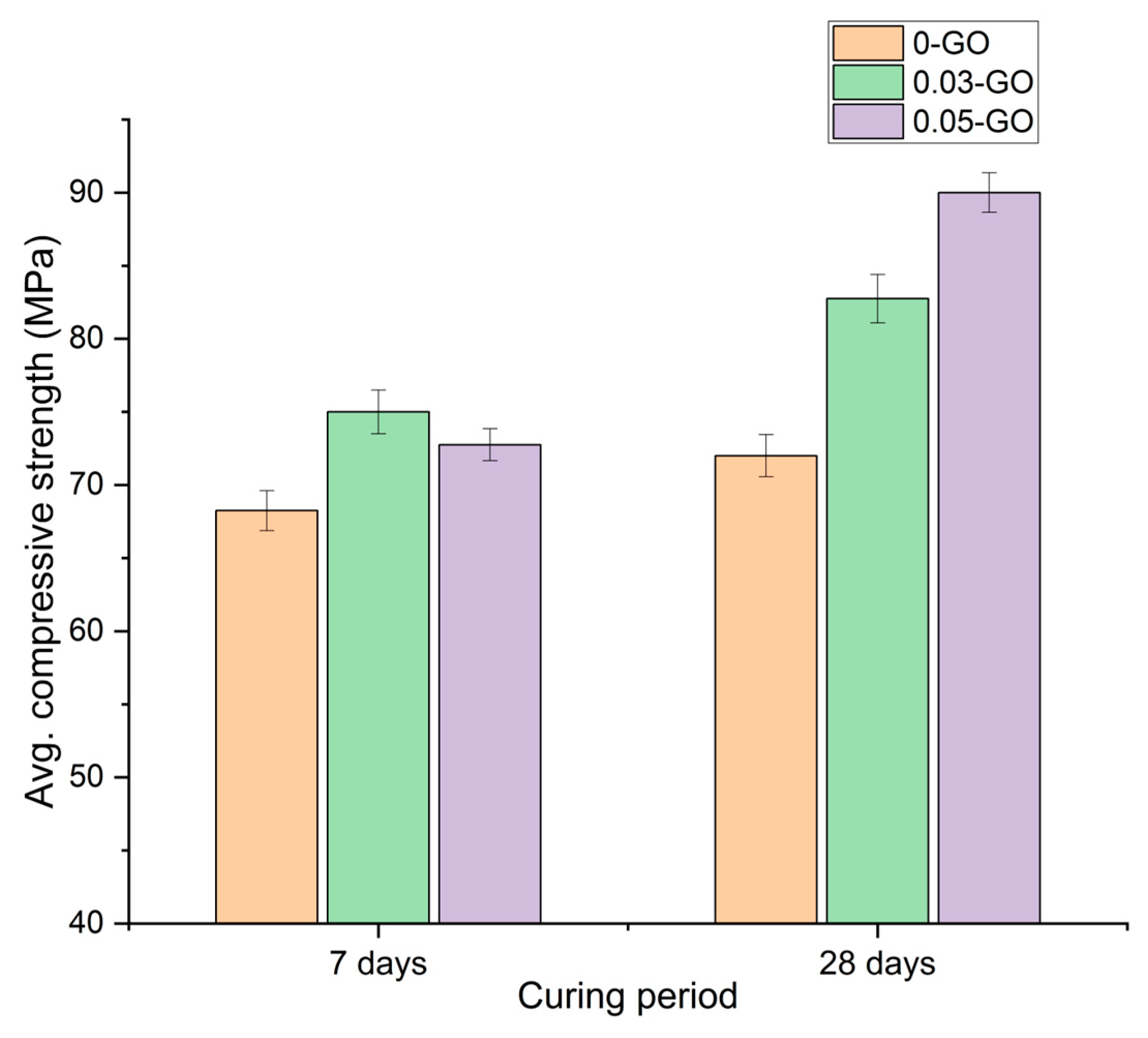

3.3. Compressive Strength

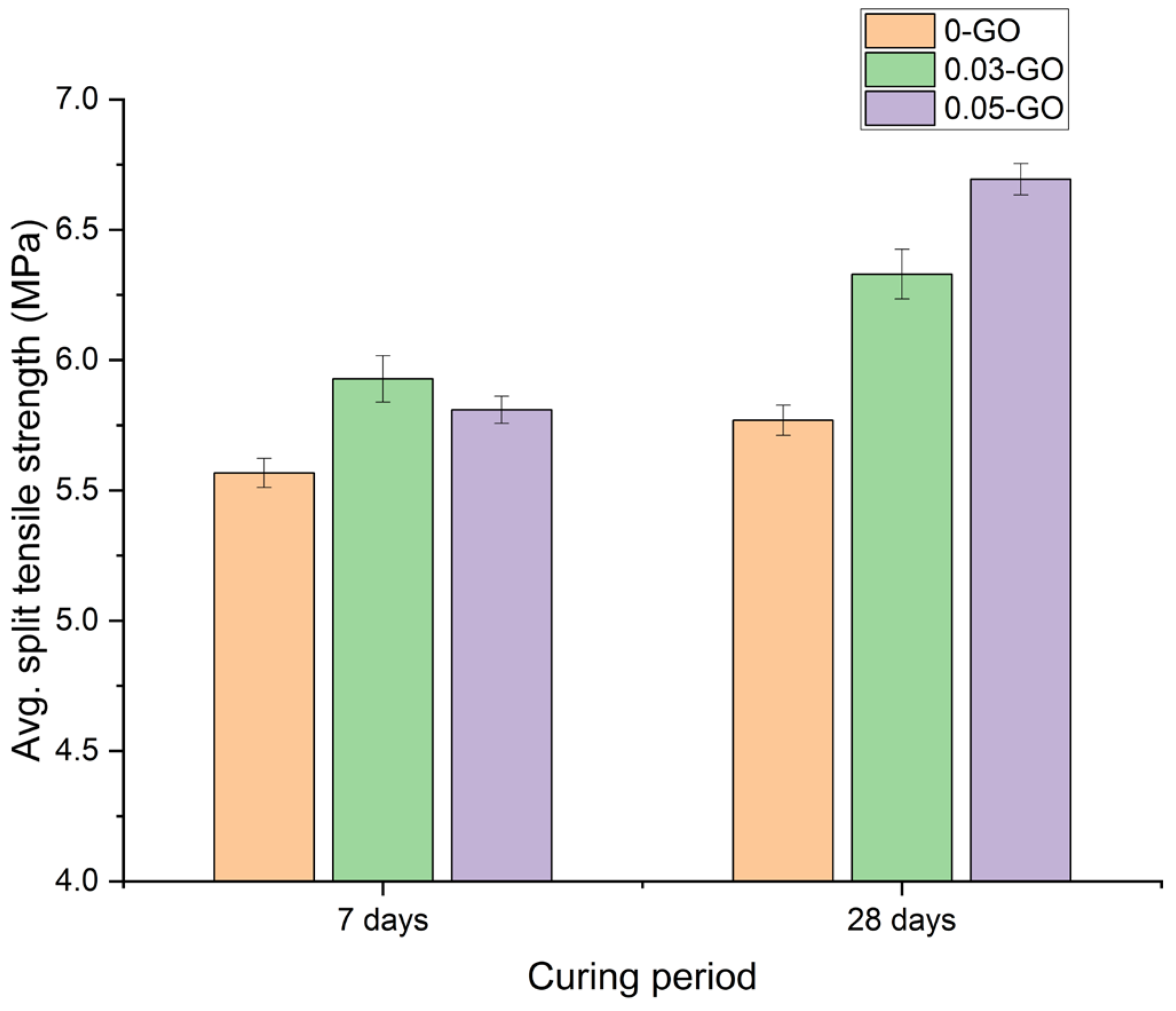

3.4. Tensile Strength

3.5. Flexural Strength (Modulus of Rupture)

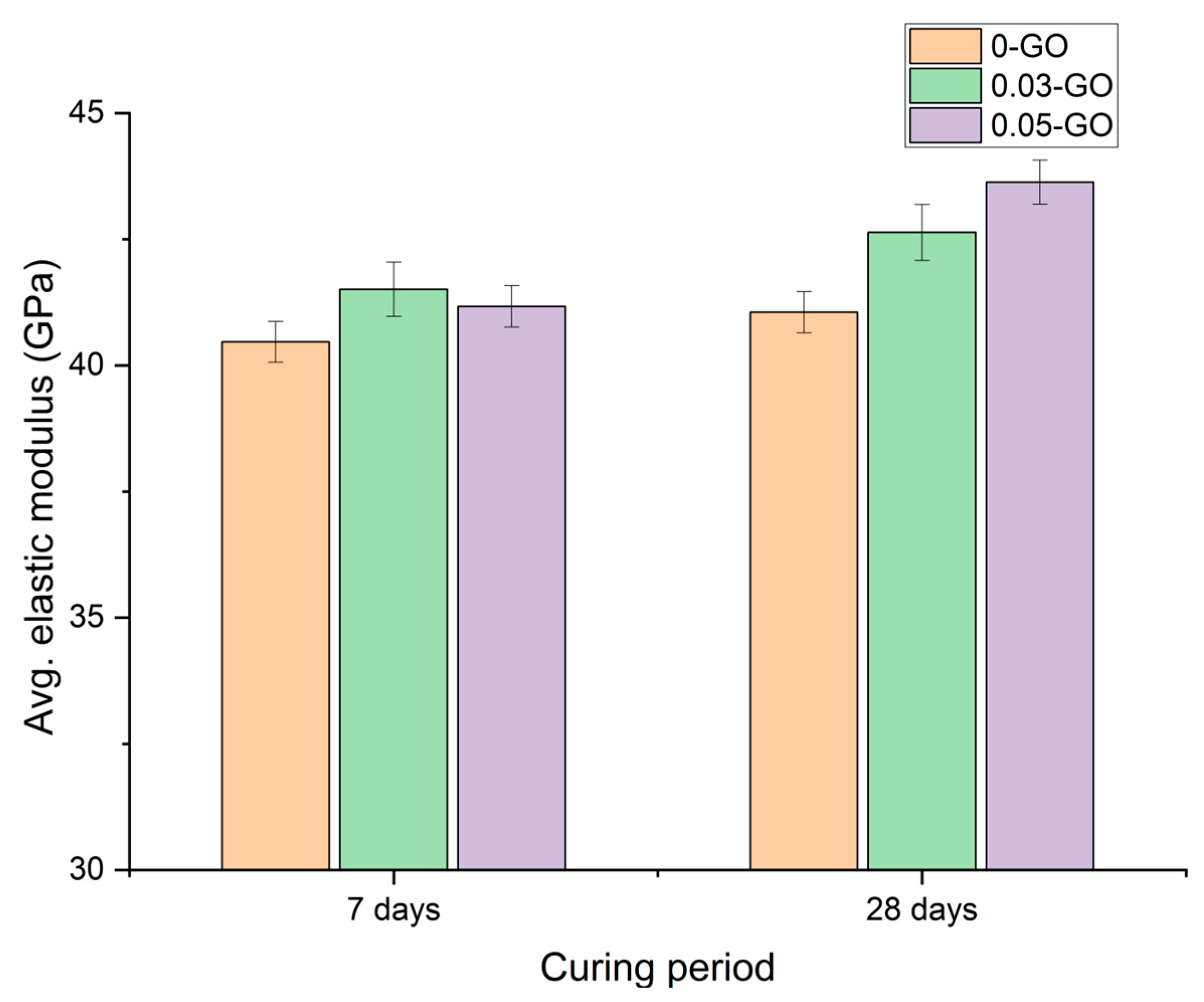

3.6. Modulus of Elasticity

3.7. Drying Shrinkage

3.8. Strength Gain Mechanisms

3.8.1. SEM/EDS Based Microstructural Assessment

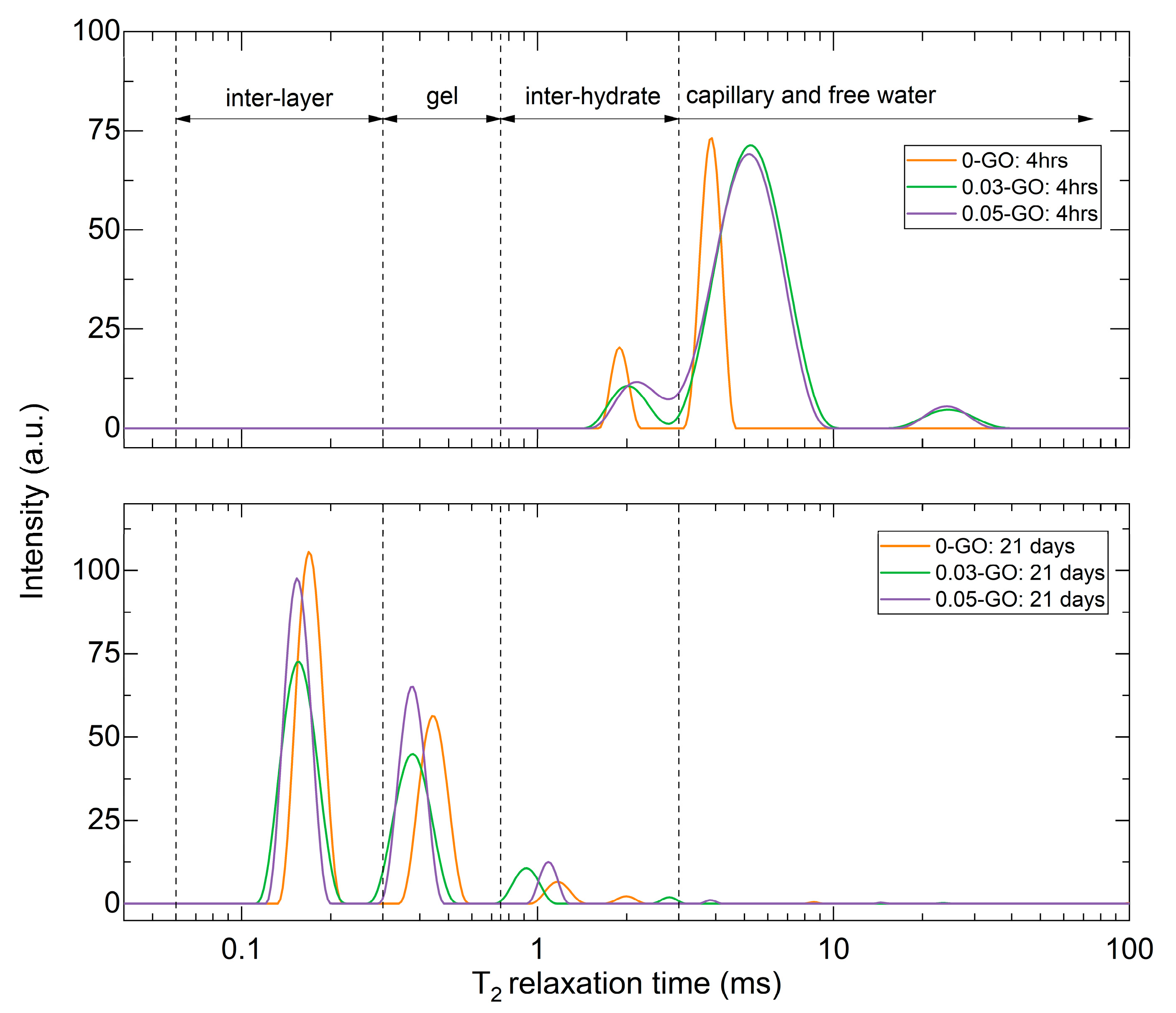

3.8.2. Evolution of Water Phases Through 1H-NMR

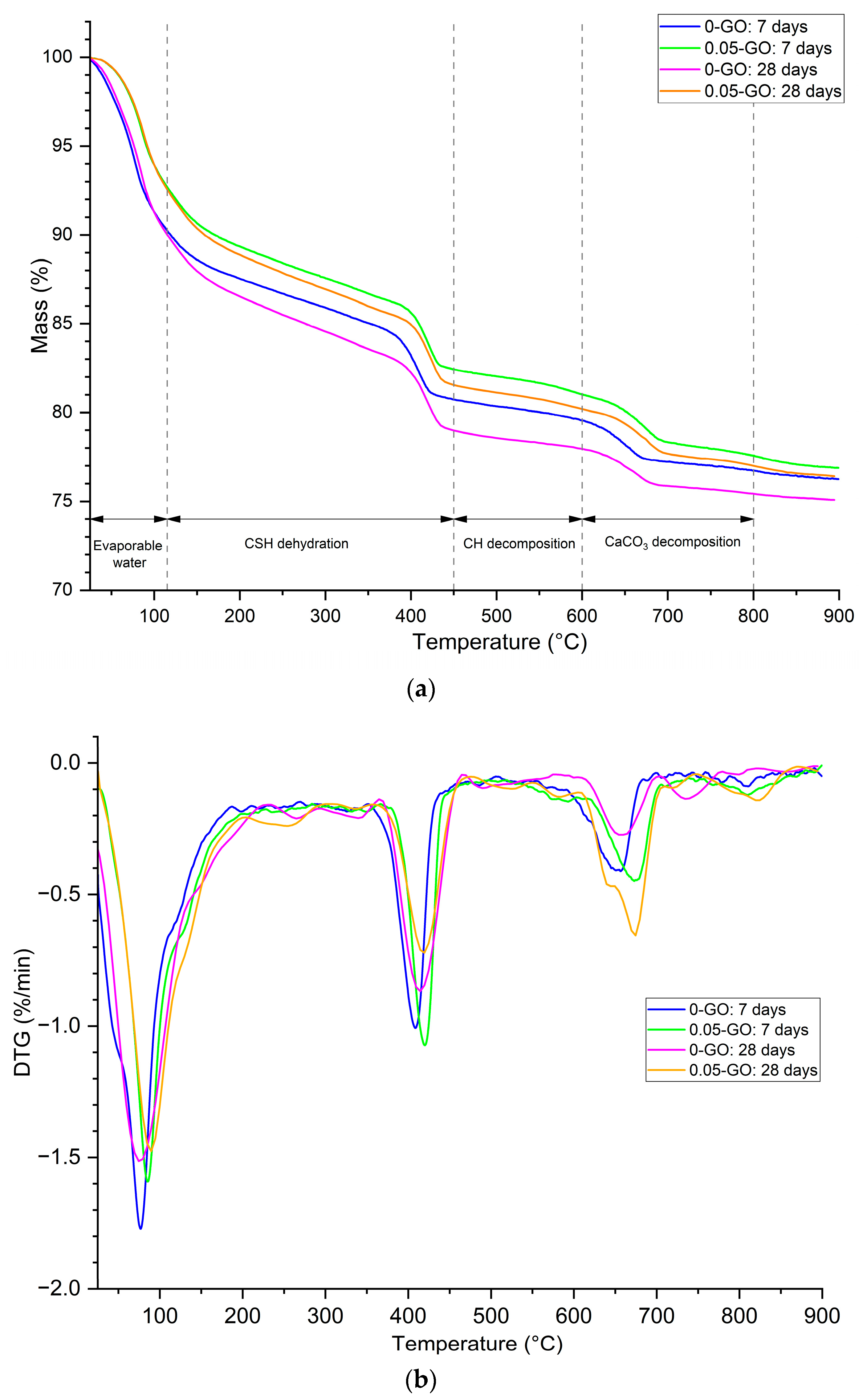

3.8.3. Quantification of Hydration Products Through TGA

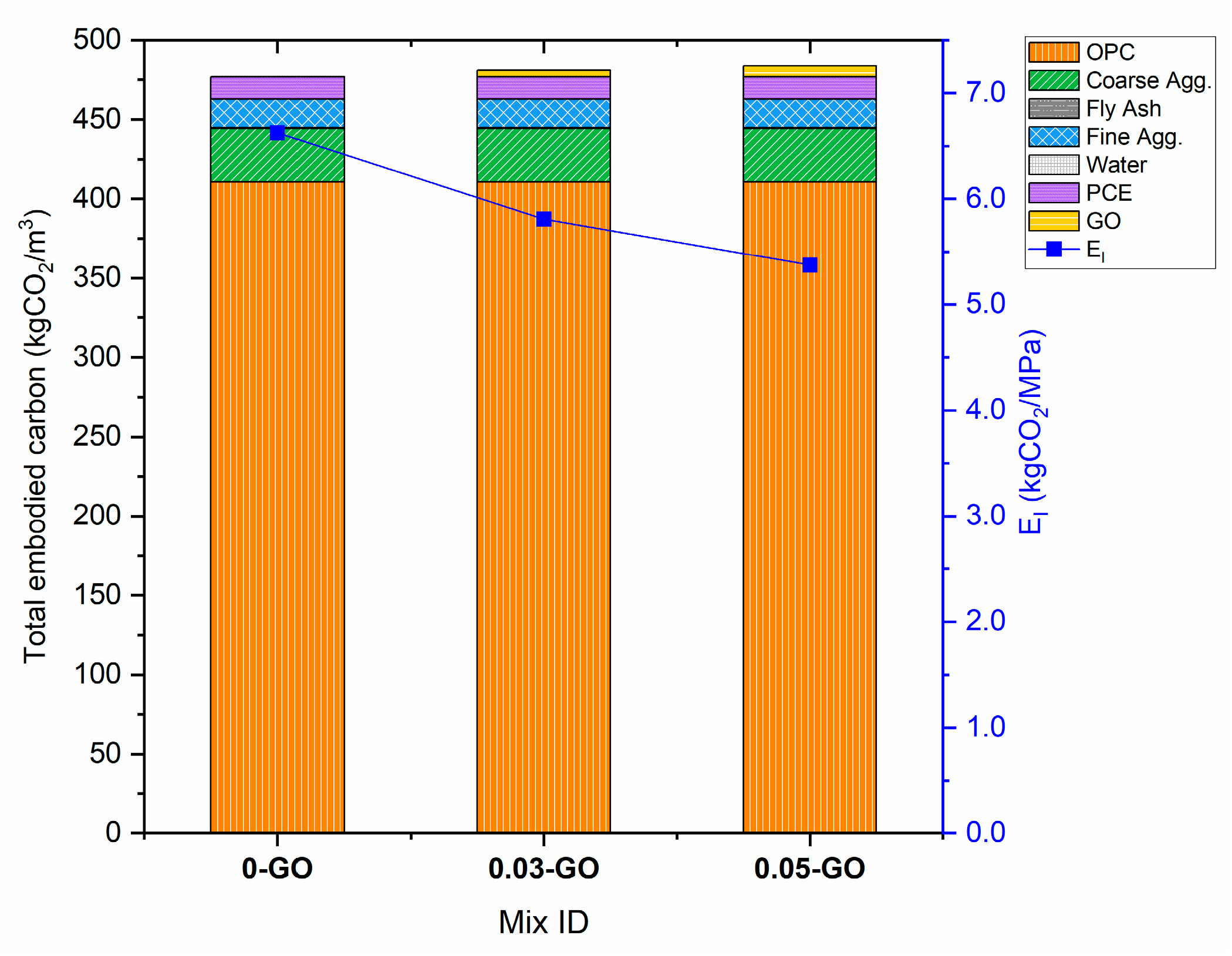

3.9. Calculation of Embodied Carbon and CO2 Index

4. Conclusions and Recommendations for Future Research

- Bleeding, air content, and slump retention were thoroughly assessed in GO-concrete, revealing that controlled mixing of GO-integrated PCE counteract GO-induced workability loss, making practical application more feasible.

- Mechanical strength enhancements were recorded up to 25% in compressive strength with GO dosages of 0.05% bwoc, attributed to accelerated hydration and improved interfacial bonding.

- TGA and 1H-NMR revealed a significant decrease in evaporable water and increases in hydration products in GO mixes, corroborating the microstructural strength gain mechanisms.

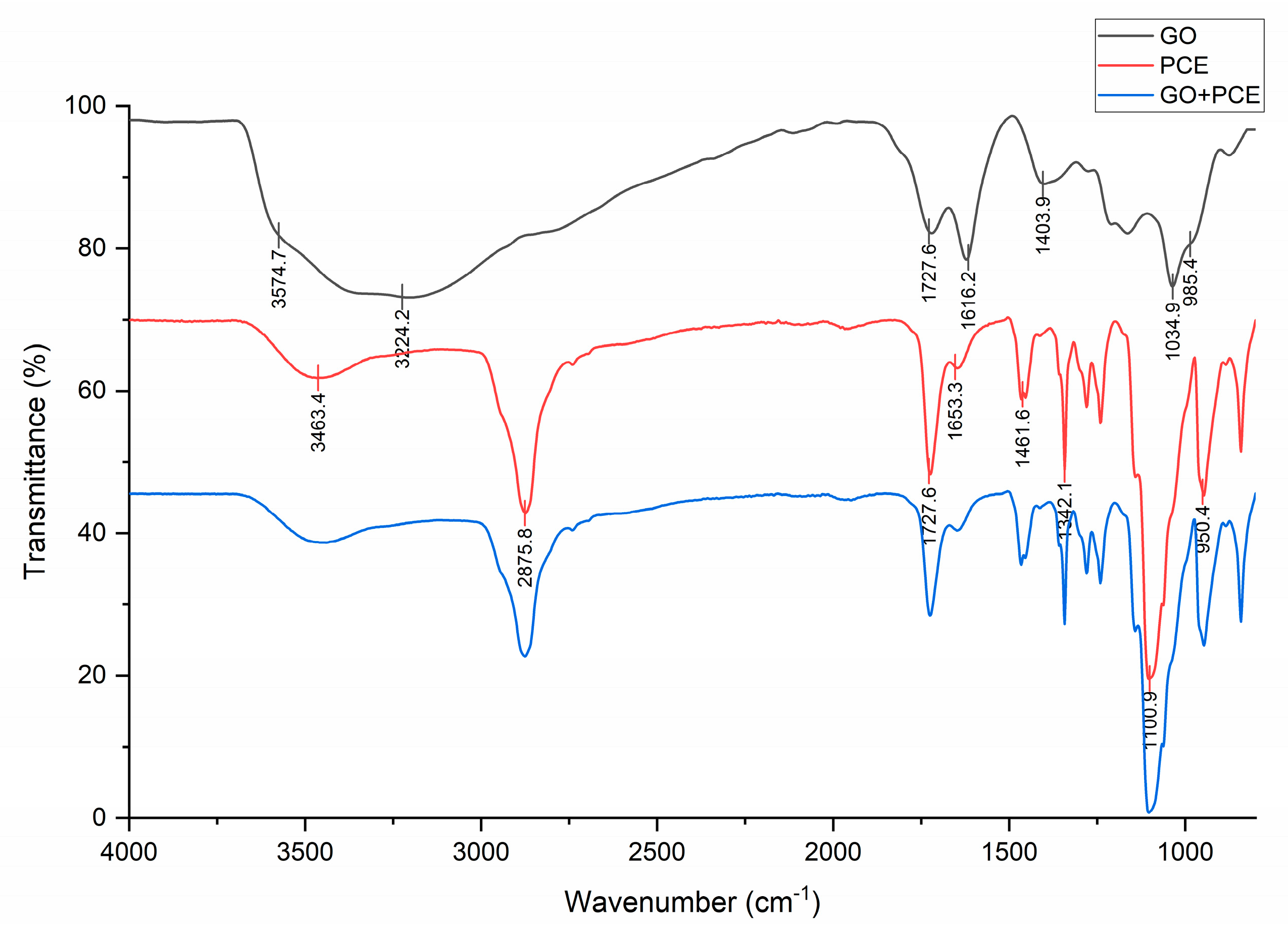

- FTIR analysis confirmed the chemical compatibility between GO and PCE, validating that the non-invasive mixing method preserved PCE functionality, while SEM and EDS analyses demonstrated uniform GO dispersion within the cement matrix, supporting the effectiveness of the mixing approach and its contribution to microstructural enhancement.

- Among the evaluated dosages, the 0.05% GO mix emerged as the most sustainable mix, exhibiting the lowest EI of 5.37 kgCO2/MPa, in contrast to the control mix (0-GO), which recorded a higher EI of 6.62 kgCO2/MPa.

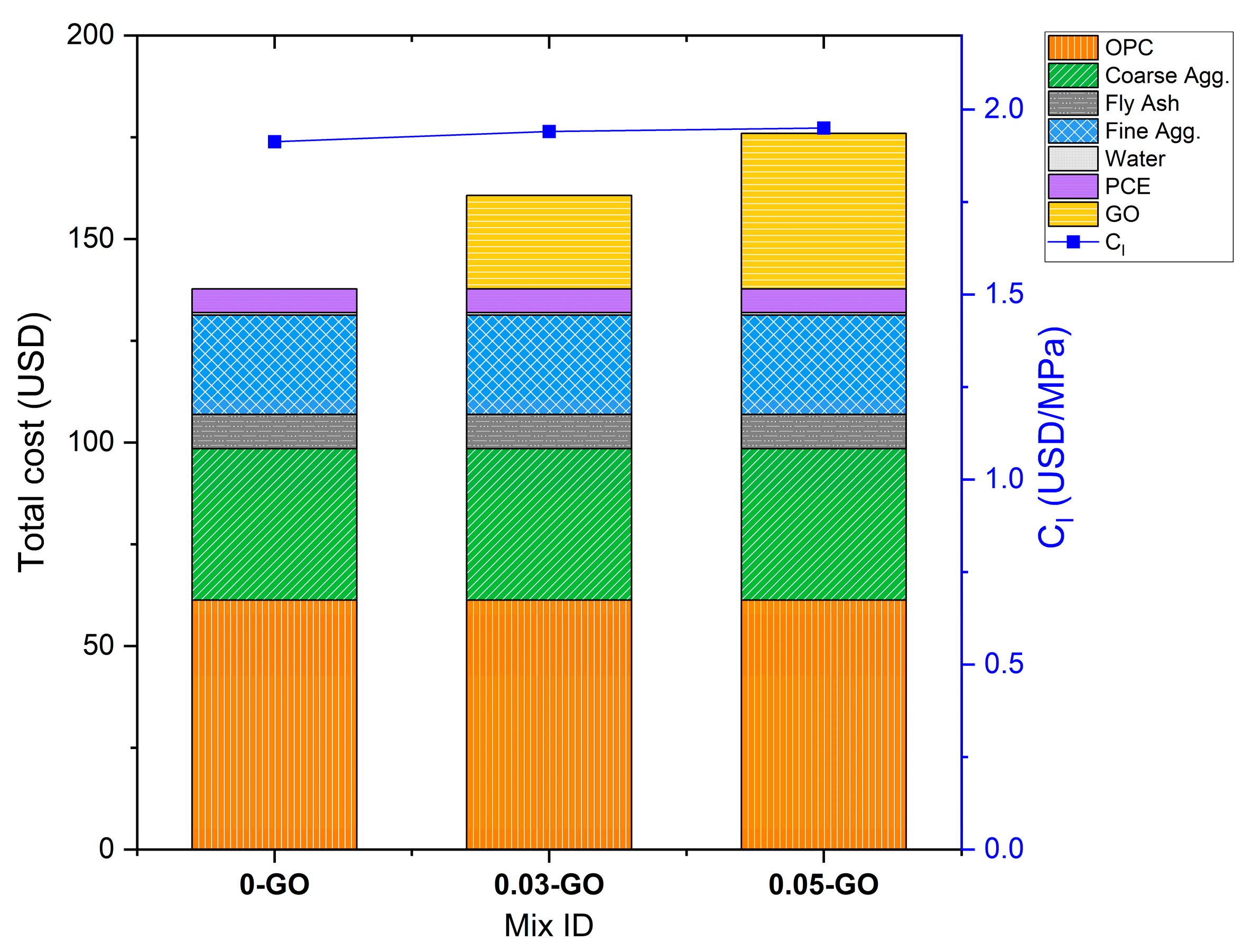

- The cost index (CI) for GO-admixed concretes was marginally elevated relative to the control (0-GO: 1.91, 0.03-GO: 1.94, 0.05-GO: 1.95) and the break-even GO cost threshold was determined to be USD 118.80/kg, with GO prices below this value supporting viable commercialization.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Belaïd, F. How does concrete and cement industry transformation contribute to mitigating climate change challenges? Resour. Conserv. Recycl. Adv. 2022, 15, 200084. [Google Scholar] [CrossRef]

- Pearce, F. Can the World’s Most Polluting Heavy Industries Decarbonize; Yale School of the Environment: New Haven, CT, USA, 2021. [Google Scholar]

- Chen, C.; Xu, R.; Tong, D.; Qin, X.; Cheng, J.; Liu, J.; Zheng, B.; Yan, L.; Zhang, Q. A striking growth of CO2 emissions from the global cement industry driven by new facilities in emerging countries. Environ. Res. Lett. 2022, 17, 044007. [Google Scholar] [CrossRef]

- Andrew, R.M.; Peters, G.P. The Global Carbon Project’s Fossil CO2 Emissions Dataset; Zenodo: Geneva, Switzerland, 2024. [Google Scholar]

- Friedlingstein, P.; O’sullivan, M.; Jones, M.W.; Andrew, R.M.; Bakker, D.C.E.; Hauck, J.; Landschützer, P.; Le Quéré, C.; Luijkx, I.T.; Peters, G.P.; et al. Global carbon budget 2023. Earth Syst. Sci. Data 2023, 15, 5301–5369. [Google Scholar] [CrossRef]

- Barcelo, L.; Kline, J.; Walenta, G.; Gartner, E. Cement and carbon emissions. Mater. Struct. 2014, 47, 1055–1065. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef]

- Ostovari, H.; Müller, L.; Skocek, J.; Bardow, A. From unavoidable CO2 source to CO2 sink? A cement industry based on CO2 mineralization. Environ. Sci. Technol. 2021, 55, 5212–5223. [Google Scholar] [CrossRef] [PubMed]

- Shanmugam, G. 200 Years of Fossil Fuels and Climate Change (1900–2100). J. Geol. Soc. India 2023, 99, 1043–1062. [Google Scholar] [CrossRef]

- Laveglia, A.; Ukrainczyk, N.; De Belie, N.; Koenders, E. Decarbonizing the lime-based construction materials industry: A practical guide for cradle-to-gate life-cycle inventory. Sustain. Prod. Consum. 2023, 40, 194–209. [Google Scholar] [CrossRef]

- Nie, S.; Zhou, J.; Yang, F.; Lan, M.; Li, J.; Zhang, Z.; Chen, Z.; Xu, M.; Li, H.; Sanjayan, J.G. Analysis of theoretical carbon dioxide emissions from cement production: Methodology and application. J. Clean. Prod. 2022, 334, 130270. [Google Scholar] [CrossRef]

- Cheng, D.; Reiner, D.M.; Yang, F.; Cui, C.; Meng, J.; Shan, Y.; Liu, Y.; Tao, S.; Guan, D. Projecting future carbon emissions from cement production in developing countries. Nat. Commun. 2023, 14, 8213. [Google Scholar] [CrossRef] [PubMed]

- Global Cement and Concrete Association. Concrete Future: The GCCA 2050 Cement and Concrete Industry Roadmap for Net Zero Concrete; Global Cement and Concrete Association: London, UK, 2021. [Google Scholar]

- Soomro, M.; Tam, V.W.; Evangelista, A.C.J. Production of cement and its environmental impact. In Recycled Concrete; Elsevier: Amsterdam, The Netherlands, 2023; pp. 11–46. [Google Scholar]

- EPD Australasia. Available online: https://epd-australasia.com (accessed on 18 April 2025).

- Amran, M.; Makul, N.; Fediuk, R.; Lee, Y.H.; Vatin, N.I.; Lee, Y.Y.; Mohammed, K. Global carbon recoverability experiences from the cement industry. Case Stud. Constr. Mater. 2022, 17, e01439. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Kanavaris, F.; Das, B.B.; Idrees, M. Decarbonising cement and concrete production: Strategies, challenges and pathways for sustainable development. J. Build. Eng. 2024, 86, 108861. [Google Scholar] [CrossRef]

- Chaudhury, R.; Sharma, U.; Thapliyal, P.; Singh, L. Low-CO2 emission strategies to achieve net zero target in cement sector. J. Clean. Prod. 2023, 417, 137466. [Google Scholar] [CrossRef]

- Ginigaddara, T.; Mendis, P.; Devapura, P.; Mohotti, D.; Fonseka, I. Innovative low carbon graphene concrete. Concr. Aust. 2022, 48, 33–41. [Google Scholar]

- Meng, S.; Ouyang, X.; Fu, J.; Niu, Y.; Ma, Y. The role of graphene/graphene oxide in cement hydration. Nanotechnol. Rev. 2021, 10, 768–778. [Google Scholar] [CrossRef]

- Ruan, C.; Lin, J.; Chen, S.; Sagoe-Crentsil, K.; Duan, W. Effect of graphene oxide on the pore structure of cement paste: Implications for performance enhancement. ACS Appl. Nano Mater. 2021, 4, 10623–10633. [Google Scholar] [CrossRef]

- Ginigaddara, T.; Ekanayake, J.; Mendis, P.; Devapura, P.; Liyanage, A.; Vaz-Serra, P. An Introduction to High Performance Graphene Concrete. Electron. J. Struct. Eng. 2022, 22, 11–18. [Google Scholar] [CrossRef]

- Verma, P.; Rajib, C.; Chakrabarti, A. Synthesis process and characterization of graphene oxide (GO) as a strength-enhancing additive in concrete. Eur. J. Environ. Civ. Eng. 2024, 28, 2575–2603. [Google Scholar] [CrossRef]

- Dimov, D.; Amit, I.; Gorrie, O.; Barnes, M.D.; Townsend, N.J.; Neves, A.I.; Withers, F.; Russo, S.; Craciun, M.F. Ultrahigh performance nanoengineered graphene–concrete composites for multifunctional applications. Adv. Funct. Mater. 2018, 28, 1705183. [Google Scholar] [CrossRef]

- Shareef, K.; Rawoof, S.A.; Sowjanya, K.J.L. A feasibility study on mechanical properties of concrete with graphene oxide. Lateral 2017, 5, 10micrometer. [Google Scholar]

- Lai, H.; Li, Q.; Wang, X.; Xu, S. A comprehensive morphology study on the carbon nanotube agglomerations in cementitious composite. Carbon 2024, 223, 119014. [Google Scholar] [CrossRef]

- Xu, L.; Liu, K.; Wang, R. Effect and mechanism of carbon nanotubes on the properties of polyacrylate/cement composite cementitious materials. Constr. Build. Mater. 2024, 443, 137687. [Google Scholar] [CrossRef]

- Golewski, G.L.J.T.; Mechanics, A.F. Enhancement fracture behavior of sustainable cementitious composites using synergy between fly ash (FA) and nanosilica (NS) in the assessment based on digital image processing procedure. Theor. Appl. Fract. Mech. 2024, 131, 104442. [Google Scholar] [CrossRef]

- Ma, L.; Sun, M.; Yang, J.; Dai, Q.J. Nanosilica-enhanced geopolymer cementitious materials: Mechanistic insights from experimental and computational simulations. J. Build. Eng. 2024, 98, 111098. [Google Scholar] [CrossRef]

- Filho, A.W.; de Moura, M.R.; Aouada, F.A. Performance of cementitious mortars containing hydrogel–nanoclay hybrid nanocomposite. J. Sol-Gel Sci. Technol. 2024, 115, 263–280. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Ren, Z.; Chou, T.-W. Advances in the science and technology of carbon nanotubes and their composites: A review. Compos. Sci. Technol. 2001, 61, 1899–1912. [Google Scholar] [CrossRef]

- De Volder, M.F.L.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon Nanotubes: Present and Future Commercial Applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [PubMed]

- Singh, L.P.; Karade, S.R.; Bhattacharyya, S.K.; Yousuf, M.M.; Ahalawat, S. Beneficial role of nanosilica in cement based materials—A review. Constr. Build. Mater. 2013, 47, 1069–1077. [Google Scholar] [CrossRef]

- Wei, X.-X.; Pei, C.; Zhu, J.-H. Towards the large-scale application of graphene-modified cement-based composites: A comprehensive review. Constr. Build. Mater. 2024, 421, 135632. [Google Scholar] [CrossRef]

- Salami, B.A.; Mukhtar, F.; Ganiyu, S.A.; Adekunle, S.; Saleh, T.A. Graphene-based concrete: Synthesis strategies and reinforcement mechanisms in graphene-based cementitious composites (Part 1). Constr. Build. Mater. 2023, 396, 132296. [Google Scholar] [CrossRef]

- Li, W.; Qu, F.; Dong, W.; Mishra, G.; Shah, S.P. A comprehensive review on self-sensing graphene/cementitious composites: A pathway toward next-generation smart concrete. Constr. Build. Mater. 2022, 331, 127284. [Google Scholar] [CrossRef]

- Çakır, M.V. The synergistic effect of hybrid nano-silica and GNP additives on the flexural strength and toughening mechanisms of adhesively bonded joints. Int. J. Adhes. Adhes. 2023, 122, 103333. [Google Scholar] [CrossRef]

- Ghazanlou, S.I.; Ghazanlou, S.I.; Ghazanlou, S.I.; Karimi, H.; Azimi, N.; Hosseinpour, S. Multifunctional performance of core–shell rGO@ Fe3O4 on the mechanical, electrical/thermal, EMI, and microstructure properties of cement-based composites. Constr. Build. Mater. 2023, 394, 132182. [Google Scholar] [CrossRef]

- Razaq, A.; Bibi, F.; Zheng, X.; Papadakis, R.; Jafri, S.H.M.; Li, H. Review on graphene-, graphene oxide-, reduced graphene oxide-based flexible composites: From fabrication to applications. Materials 2022, 15, 1012. [Google Scholar] [CrossRef] [PubMed]

- Lv, S.; Wu, L.; Li, Z.; Gao, R.; Liu, L. Investigation of dispersion behavior of GO in aqueous and effect of ultra-low dosage GO on structure and properties of cement-based composites. Constr. Build. Mater. 2022, 350, 128828. [Google Scholar] [CrossRef]

- Zeng, H.; Lai, Y.; Qu, S.; Yu, F. Exploring the effect of graphene oxide on freeze–thaw durability of air-entrained mortars. Constr. Build. Mater. 2022, 324, 126708. [Google Scholar] [CrossRef]

- Reddy, P.V.R.K.; Prasad, D.R. Investigation on the impact of graphene oxide on microstructure and mechanical behaviour of concrete. J. Build. Pathol. Rehabil. 2022, 7, 30. [Google Scholar] [CrossRef]

- Rao, P.; Prakash, J.; Alexander, R.; Shinde, M.; Dasgupta, K. Role of graphene oxide infusion in concrete to elevate strength and fire performance in construction concrete. Diam. Relat. Mater. 2024, 147, 111269. [Google Scholar] [CrossRef]

- Devasena, M.; Karthikeyan, J. Investigation on strength properties of graphene oxide concrete. Int. J. Eng. Sci. Invent. Res. Dev. 2015, 1, 307–310. [Google Scholar]

- Kabus, O.; Butska, L.; Makarenko, O.; Pershina, L.; Tymoshchenko, A. Evaluating the efficiency of the fluidity retention of ready-mix concrete during the transportation of it to the construction site. MATEC Web Conf. 2018, 230, 03005. [Google Scholar] [CrossRef][Green Version]

- Lin, X. Synthesis and performance of a new long-acting slump retention agent at different temperatures. J. Phys. Conf. Ser 2024, 2713, 012005. [Google Scholar] [CrossRef]

- Mondal, S.K.; Welz, A.; Clinton, C.; Khayat, K.; Kumar, A.; Okoronkwo, M.U. Quantifying the Workability of Calcium Sulfoaluminate Cement Paste Using Time-Dependent Rheology. Materials 2022, 15, 5775. [Google Scholar] [CrossRef] [PubMed]

- Tao, Y.; Rahul, A.; Mohan, M.K.; De Schutter, G.; Van Tittelboom, K. Recent progress and technical challenges in using calcium sulfoaluminate (CSA) cement. Cem. Concr. Compos. 2023, 137, 104908. [Google Scholar] [CrossRef]

- Lei, Y.; Boucenna, I.; Thévenet, V.; Brett, W.; Paineau, E.; Ponton, A. The Rheological and Structural Properties of Aqueous Graphene Oxide Dispersions: Concentration and pH Dependence. Langmuir 2024, 40, 16048–16057. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Korayem, A.H.; Li, C.; Liu, Y.; He, H.; Sanjayan, J.G.; Duan, W.H. Incorporation of graphene oxide and silica fume into cement paste: A study of dispersion and compressive strength. Constr. Build. Mater. 2016, 123, 327–335. [Google Scholar] [CrossRef]

- Li, X.; Li, C.; Liu, Y.; Chen, S.J.; Wang, C.; Sanjayan, J.G.; Duan, W.H. Improvement of mechanical properties by incorporating graphene oxide into cement mortar. Mech. Adv. Mater. Struct. 2018, 25, 1313–1322. [Google Scholar] [CrossRef]

- Liu, C.; Huang, X.; Wu, Y.-Y.; Deng, X.; Zheng, Z. The effect of graphene oxide on the mechanical properties, impermeability and corrosion resistance of cement mortar containing mineral admixtures. Constr. Build. Mater. 2021, 288, 123059. [Google Scholar] [CrossRef]

- Chen, Y.; Li, X.; Dong, B.; Du, H.; Yan, R.; Wang, L. High-temperature properties of cement paste with graphene oxide agglomerates. Constr. Build. Mater. 2022, 320, 126286. [Google Scholar] [CrossRef]

- Bhojaraju, C.; Mousavi, S.S.; Brial, V.; DiMare, M.; Ouellet-Plamondon, C.M. Fresh and hardened properties of GGBS-contained cementitious composites using graphene and graphene oxide. Constr. Build. Mater. 2021, 300, 123902. [Google Scholar] [CrossRef]

- Gao, Y.; Jing, H.; Fu, G.; Zhao, Z.; Shi, X. Studies on combined effects of graphene oxide-fly ash hybrid on the workability, mechanical performance and pore structures of cementitious grouting under high W/C ratio. Constr. Build. Mater. 2021, 281, 122578. [Google Scholar] [CrossRef]

- Reddy, P.; Prasad, D.R. A study on workability, strength and microstructure characteristics of graphene oxide and fly ash based concrete. Mater. Today Proc. 2022, 62, 2919–2925. [Google Scholar] [CrossRef]

- Hong, X.; Lee, J.C.; Qian, B. Mechanical properties and microstructure of high-strength lightweight concrete incorporating graphene oxide. Nanomaterials 2022, 12, 833. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Pang, K.; Zhong, R.; Li, J.; Liu, Q.; Zhang, J. Effect of key design parameters on the physical/mechanical properties of coarse aggregated UHPC and its structural response subjected to bending. Constr. Build. Mater. 2024, 448, 138189. [Google Scholar] [CrossRef]

- Reis, E.D.; Resende, H.F.; Christoforo, A.L.; Costa, R.M.; Gatuingt, F.; Poggiali, F.S.J.; Bezerra, A.C.S. Assessment of physical and mechanical properties of concrete with carbon nanotubes pre-dispersed in cement. J. Build. Eng. 2024, 89, 109255. [Google Scholar] [CrossRef]

- Cheng, Z.; Liu, Y.; Wu, J.; Guo, X.; Chen, W.; Gao, Y. Graphene oxide-coated fly ash for high performance and low-carbon cementitious composites. J. Mater. Res. Technol. 2023, 25, 6710–6724. [Google Scholar] [CrossRef]

- de Souza, F.B.; Yao, X.; Gao, W.; Duan, W. Graphene opens pathways to a carbon-neutral cement industry. Sci. Bull. 2022, 67, 5–8. [Google Scholar] [CrossRef] [PubMed]

- Lv, H.; Du, M.; Li, Z.; Xiao, L.; Zhou, S. Cost optimization of graphene oxide-modified ultra-high-performance concrete based on machine learning methods. Inorganics 2024, 12, 181. [Google Scholar] [CrossRef]

- Devapura, P.; Ginigaddara, T.; Udumulla, D.; Mendis, P.; Booy, M.; Herath, N. Effect of Graphene Oxide on Interfacial Transition Zone and Strength Enhancement of Recycled Aggregate Concrete. J. Build. Eng. 2025, 105, 112570. [Google Scholar] [CrossRef]

- Munuera, J.; Britnell, L.; Santoro, C.; Cuéllar-Franca, R.; Casiraghi, C. A review on sustainable production of graphene and related life cycle assessment. 2D Mater. 2021, 9, 012002. [Google Scholar] [CrossRef]

- Papanikolaou, I.; Arena, N.; Al-Tabbaa, A. Graphene nanoplatelet reinforced concrete for self-sensing structures—A lifecycle assessment perspective. J. Clean. Prod. 2019, 240, 118202. [Google Scholar] [CrossRef]

- Surehali, S.; Volaity, S.S.; Simon, A.; Divigalpitiya, R.; Kumar, A.; Neithalath, N. New Generation Graphenes in Cement-Based Materials: Production, Property Enhancement, and Life Cycle Analysis. ACS Sustain. Chem. Eng. 2024, 12, 9193–9206. [Google Scholar] [CrossRef]

- Gutiérrez-Cruz, A.; Ruiz-Hernández, A.R.; Vega-Clemente, J.F.; Luna-Gazcón, D.G.; Campos-Delgado, J. A review of top-down and bottom-up synthesis methods for the production of graphene, graphene oxide and reduced graphene oxide. J. Mater. Sci. 2022, 57, 14543–14578. [Google Scholar] [CrossRef]

- Zeng, H.; Qu, S.; Tian, Y.; Hu, Y.; Li, Y. Recent progress on graphene oxide for next-generation concrete: Characterizations, applications and challenges. J. Build. Eng. 2023, 69, 106192. [Google Scholar] [CrossRef]

- Gholampour, A.; Kiamahalleh, M.V.; Tran, D.N.; Ozbakkaloglu, T.; Losic, D. Revealing the dependence of the physiochemical and mechanical properties of cement composites on graphene oxide concentration. RSC Adv. 2017, 7, 55148–55156. [Google Scholar] [CrossRef]

- ASTM C114-23; Standard Test Methods for Chemical Analysis of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2023.

- Ginigaddara, T.; Devapura, P.; Mendis, P.; Udumulla, P. A Multi-Scale Investigation of Graphene Oxide Enhanced Cementitious Composites through Liquid Phase Characterizations, Mechanical Properties and Microstructural Strength Gain Mechanisms. J. Build. Eng. 2025, 106, 112621. [Google Scholar] [CrossRef]

- ASTM C136/C136M-19; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2019.

- ISO/TS 21356-1:2021; Nanotechnologies—Structural Characterization of Graphene—Part 1: Graphene from Powders and Dispersions. ISO: Geneva, Switzerland, 2021.

- AS 1012.2:2014; Methods of Testing Concrete Preparing Concrete Mixes in the Laboratory. Standards Australia: Sydney, Australia, 2014.

- Poinot, T.; Benyahia, K.; Govin, A.; Jeanmaire, T.; Grosseau, P. Use of ultrasonic degradation to study the molecular weight influence of polymeric admixtures for mortars. Constr. Build. Mater. 2013, 47, 1046–1052. [Google Scholar] [CrossRef]

- Silvestro, L.; Ruviaro, A.S.; Lima, G.T.d.S.; Matos, P.R.d.; Rodríguez, E.; Gleize, P. Sonicação de superplastificante à base de policarboxilato para aplicação em matrizes cimentícias. Rev. IBRACON Estrut. Mater. 2022, 16, e16205. [Google Scholar] [CrossRef]

- AS 1012.3.1:2014; Methods of Testing Concrete—Determination of Properties Related to the Consistency of Concrete—Slump Test. Standards Australia: Sydney, Australia, 2014.

- AS 1012.4.2:2014; Methods of Testing Concrete, Method 4.2: Determination of Air Content of Freshly Mixed Concrete—Measuring Reduction in Air Pressure in Chamber Above Concrete. Standards Australia: Sydney, Australia, 2014.

- AS 1012.6:2014; Methods of Testing Concrete Determination of Bleeding of Concrete. Standards Australia: Sydney, Australia, 2014.

- AS 1012.8.1:2014; Methods of Testing Concrete Method for Making and Curing Concrete—Compression and Indirect Tensile Test Specimens. Standards Australia: Sydney, Australia, 2014.

- AS 1012.8.2:2014; Methods of Testing Concrete Method for Making and Curing Concrete—Flexure Test Specimens. Standards Australia: Sydney, Australia, 2014.

- AS 1012.8.4:2015; Methods of Testing Concrete Method for Making and Curing Concrete—Drying Shrinkage Specimens Prepared in the Field or in the Laboratory. Standards Australia: Sydney, Australia, 2015.

- AS 1012.9:2014; Methods of Testing Concrete Compressive Strength Tests—Concrete, Mortar and Grout Specimens. Standards Australia: Sydney, Australia, 2014.

- AS 1012.10-2000; Methods of Testing Concrete, Method 10: Determination of Indirect Tensile strength of Concrete Cylinders (‘Brazil’ or Splitting Test). Standards Australia: Sydney, Australia, 2000.

- AS 1012.11-2000; Methods of Testing Concrete Determination of the Modulus of Rupture (Reconfirmed 2014). Standards Australia: Sydney, Australia, 2000.

- AS 1012.17-1997; Methods of Testing Concrete Determination of the Static Chord Modulus of Elasticity and Poisson’s Ratio of Concrete Specimens (Reconfirmed 2014). Standards Australia: Sydney, Australia, 1997.

- AS 1012.13:2015; Methods of Testing Concrete Determination of the Drying Shrinkage of Concrete for Samples Prepared in the Field or in the Laboratory. Standards Australia: Sydney, Australia, 2015.

- Aono, Y.; Matsushita, F.; Shibata, S.; Hama, Y. Nano-structural Changes of C-S-H in Hardened Cement Paste during Drying at 50°C. J. Adv. Concr. Technol. 2007, 5, 313–323. [Google Scholar] [CrossRef]

- Mahmoud, A.A.; El-Sayed, A.A.; Aboraya, A.M.; Fathy, I.N.; Abouelnour, M.A.; Elfakharany, M.E.; Fattouh, M.S.; Alahmer, A.E.; Nabil, I.M. Influence of elevated temperature exposure on the residual compressive strength and radiation shielding efficiency of ordinary concrete incorporating granodiorite and ceramic powders. Sci. Rep. 2025, 15, 3572. [Google Scholar] [CrossRef] [PubMed]

- BS EN 15978:2011; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. BSI—British Standards Institution: Brussels, Belgium, 2011.

- Crawford, R.; Stephan, A.; Prideaux, F. Environmental Performance in Construction (EPiC) Database; The University of Melbourne: Melbourne, Australia, 2024. [Google Scholar]

- Grant, T.; Rocha, H. AusLCI (The Australian Life Cycle Inventory Database Initiative) Database Manual; Lifecycles: Melbourne, Australia, 2023. [Google Scholar]

- Zandifaez, P.; Asadi Shamsabadi, E.; Akbar Nezhad, A.; Zhou, H.; Dias-da-Costa, D. AI-Assisted optimisation of green concrete mixes incorporating recycled concrete aggregates. Constr. Build. Mater. 2023, 391, 131851. [Google Scholar] [CrossRef]

- Circular Ecology. Inventory of Carbon & Energy (ICE) Database, Version 3.0; Circular Ecology: Worcester, UK, 2019. [Google Scholar]

- Tran, N.P.; Wang, T.; Nguyen, T.N.; Jin, H.; Ngo, T.D. High-volume recycled glass cementitious and geopolymer composites incorporating graphene oxide. Constr. Build. Mater. 2024, 450, 138476. [Google Scholar] [CrossRef]

- Crawford, R.; Stephan, A.; Prideaux, F. EPiC database—Gravel. In Environmental Performance in Construction (EPiC) Database; The University of Melbourne: Melbourne, Australia, 2019. [Google Scholar]

- Crawford, R.; Stephan, A.; Prideaux, F. EPiC database—Sand. In Environmental Performance in Construction (EPiC) Database; The University of Melbourne: Melbourne, Australia, 2020. [Google Scholar]

- Crawford, R.; Stephan, A.; Prideaux, F. EPiC database—Water. In Environmental Performance in Construction (EPiC) Database; The University of Melbourne: Melbourne, Australia, 2020. [Google Scholar]

- Graphene Labs. Products & Services. Available online: https://graphenelabs.com.au/ (accessed on 12 March 2025).

- Cheng, S.; Chen, K.; Wu, Q.; Chen, X.; Zhao, C.; Wu, Z. Influence of industrial-grade graphene oxide on macro and micro properties of ultra-high performance concrete incorporating recycled fine aggregate. Constr. Build. Mater. 2024, 417, 135427. [Google Scholar] [CrossRef]

- Nguyen, H.D.; Zhang, Q.; Sagoe-Crentsil, K.; Duan, W. Graphene oxide-coated sand for improving performance of cement composites. Cem. Concr. Compos. 2021, 124, 104279. [Google Scholar] [CrossRef]

- Kedir, A.; Gamachu, M.; Alex, A.G.; Faggio, G. Cement-based graphene oxide composites: A review on their mechanical and microstructure properties. J. Nanomater. 2023, 2023, 6741000. [Google Scholar] [CrossRef]

- Abdalla, J.A.; Thomas, B.S.; Hawileh, R.A.; Kabeer, K.S.A. Influence of nanomaterials on the workability and compressive strength of cement-based concrete. Mater. Today Proc. 2022, 65, 2073–2076. [Google Scholar] [CrossRef]

- Secrieru, E.; Mohamed, W.; Fataei, S.; Mechtcherine, V. Assessment and prediction of concrete flow and pumping pressure in pipeline. Cem. Concr. Compos. 2020, 107, 103495. [Google Scholar] [CrossRef]

- Liu, S.; Li, S.; Wang, Q.; Zhang, R.; Liu, X. Effect of Polycarboxylate-Silane Modified Graphene Oxide Composite on the Properties of Cement Pastes. Materials 2022, 15, 5313. [Google Scholar] [CrossRef] [PubMed]

- Harichane, A.; Belalia, F. Influence of Polycarboxylate Superplasticizer on the Calorimetric and Physicomechanical Properties of Mortar. IgMin Res. 2023, 1, 133–135. [Google Scholar]

- Trikkaliotis, D.G.; Christoforidis, A.K.; Mitropoulos, A.C.; Kyzas, G.Z. Graphene oxide synthesis, properties and characterization techniques: A comprehensive review. ChemEngineering 2021, 5, 64. [Google Scholar] [CrossRef]

- Lai, G. Research on synthesis and properties of amphoteric early strength polycarboxylate superplasticizer. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; p. 022056. [Google Scholar]

- Lee, S.; Kim, B.; Seo, J.; Cho, S. Beneficial use of MIBC in metakaolin-based geopolymers to improve flowability and compressive strength. Materials 2020, 13, 3663. [Google Scholar] [CrossRef] [PubMed]

- Anwar, A.; Liu, X.; Zhang, L. To what extent can polycarboxylate superplasticizers enhance the dispersion characteristics of modified graphene oxide in cement? Insights from ultrasonication and high-shear mixing methods. Cem. Concr. Res. 2025, 195, 107881. [Google Scholar] [CrossRef]

- Duan, H.; Zhou, T.; Li, B.; Pang, Y.; Lou, H.; Yang, D.; Qiu, X. Synthesis, performance evaluation, and adsorption–dispersion mechanism of sulfonic acid-terminated long side chain polycarboxylate superplasticizers. Langmuir 2024, 40, 24956–24967. [Google Scholar] [CrossRef] [PubMed]

- Hoogenboom, R.; Muhammad, M.; de Schutter, G.; Lesage, K. The Use of a Polymer Comprising Side Chains Having a Sterically Hindered Amine as Chemical Admixture for a Cementitious Material. US20250145528A1, 8 May 2025. [Google Scholar]

- Hover, K.C.; Bickley, J.; Hooton, R.J.R.R.; Foundation, E. Guide to Specifying Concrete Performance Phase II Report of Preparation of a Performance-based Specification for Cast-In-Place Concrete; NRMCA P2P Steering Committee: Silver Spring, Maryland, 2008. [Google Scholar]

- Mohammed, A.; Sanjayan, J.G.; Duan, W.H.; Nazari, A. Graphene Oxide Impact on Hardened Cement Expressed in Enhanced Freeze–Thaw Resistance. J. Mater. Civ. Eng. 2016, 28, 04016072. [Google Scholar] [CrossRef]

- Lee, S.-J.; Jeong, S.-H.; Kim, D.-U.; Won, J.-P. Graphene oxide as an additive to enhance the strength of cementitious composites. Compos. Struct. 2020, 242, 112154. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Lin, Y.-C.; Chung, J.H.; Chiu, H.-Y.; Yeh, N.-L.; Chang, S.-J.; Chan, C.-H.; Shih, C.-C.; Chen, G.-Y. Enhancing cementitious composites with functionalized graphene oxide-based materials: Surface chemistry and mechanisms. Int. J. Mol. Sci. 2023, 24, 10461. [Google Scholar] [CrossRef]

- Amini, K.; Ghasemi, A.; Amiri, S.S.; Mirvalad, S.; Korayem, A.H. The synergic effects of metakaolin and polycarboxylate-ether on dispersion of graphene oxide in cementitious environments and macro-level properties of graphene oxide modified cement composites. Constr. Build. Mater. 2021, 270, 121462. [Google Scholar] [CrossRef]

- National Ready Mixed Concrete Association (NRMCA). CIP 5—Plastic Shrinkage Cracking; NRMCA: Alexandria, VA, USA, 2021. [Google Scholar]

- Reid (Reid NZ). Hot Weather & Tilt-up Guide; Reid NZ: Auckland, New Zealand, 2022. [Google Scholar]

- Li, X.; Liu, Y.M.; Li, W.G.; Li, C.Y.; Sanjayan, J.G.; Duan, W.H.; Li, Z. Effects of graphene oxide agglomerates on workability, hydration, microstructure and compressive strength of cement paste. Constr. Build. Mater. 2017, 145, 402–410. [Google Scholar] [CrossRef]

- Jing, G.; Wu, J.; Lei, T.; Wang, S.; Strokova, V.; Nelyubova, V.; Wang, M.; Ye, Z. From graphene oxide to reduced graphene oxide: Enhanced hydration and compressive strength of cement composites. Constr. Build. Mater. 2020, 248, 118699. [Google Scholar] [CrossRef]

- Devi, S.C.; Khan, R.A. Compressive strength and durability behavior of graphene oxide reinforced concrete composites containing recycled concrete aggregate. J. Build. Eng. 2020, 32, 101800. [Google Scholar] [CrossRef]

- de Souza, F.B.; Shamsaei, E.; Sagoe-Crentsil, K.; Duan, W. Proposed mechanism for the enhanced microstructure of graphene oxide–Portland cement composites. J. Build. Eng. 2022, 54, 104604. [Google Scholar] [CrossRef]

- Fu, Q.; Wang, Z.; Xue, Y.; Niu, D. Catalysis and regulation of graphene oxide on hydration properties and microstructure of cement-based materials. ACS Sustain. Chem. Eng. 2023, 11, 5626–5643. [Google Scholar] [CrossRef]

- Lv, S.; Ma, Y.; Qiu, C.; Sun, T.; Liu, J.; Zhou, Q. Effect of graphene oxide nanosheets of microstructure and mechanical properties of cement composites. Constr. Build. Mater. 2013, 49, 121–127. [Google Scholar] [CrossRef]

- Mowlaei, R.; Lin, J.; de Souza, F.B.; Fouladi, A.; Korayem, A.H.; Shamsaei, E.; Duan, W. The effects of graphene oxide-silica nanohybrids on the workability, hydration, and mechanical properties of Portland cement paste. Constr. Build. Mater. 2021, 266, 121016. [Google Scholar] [CrossRef]

- Zeng, H.; Lai, Y.; Qu, S.; Yu, F. Effect of graphene oxide on permeability of cement materials: An experimental and theoretical perspective. J. Build. Eng. 2021, 41, 102326. [Google Scholar] [CrossRef]

- Abdulkadir, I.; Mohammed, B.S.; Ali, M.O.A.; Liew, M.S. Effects of graphene oxide and crumb rubber on the fresh properties of self-compacting engineered cementitious composite using response surface methodology. Materials 2022, 15, 2519. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Kothiyal, N.; Chitkara, M. Enhanced mechanical performance of cement nanocomposite reinforced with graphene oxide synthesized from mechanically milled graphite and its comparison with carbon nanotubes reinforced nanocomposite. RSC Adv. 2016, 6, 103993–104009. [Google Scholar] [CrossRef]

- Fan, L.; Zheng, J.; Wu, C.; Wang, H.; Li, F.; Song, F. Graphene oxide at carbon nanotubes/cement matrix abnormally enhance its hydration products and interlayer stress transfer at an important hydration accelerated period: Experimental study and molecular dynamics simulation. Colloids Surfaces A Physicochem. Eng. Asp. 2025, 717, 136830. [Google Scholar] [CrossRef]

- Yang, H.; Zhu, E.; Liu, L. Analysis of the Effect of Pore Structure on the Mechanical Properties of Concrete Based on the Meso Numerical Model. Appl. Sci. 2022, 12, 5428. [Google Scholar] [CrossRef]

- Muthukumarana, T.; Arachchi, M.; Somarathna, H.; Raman, S. A review on the variation of mechanical properties of carbon fibre-reinforced concrete. Constr. Build. Mater. 2023, 366, 130173. [Google Scholar] [CrossRef]

- Jonnalagadda, S.; Vemuri, S. Choosing Conventional Concrete, Ultra-High Performance Concrete or Steel as Material of Construction: An Opinion. Eur. Mod. Stud. J. 2023, 7, 280–288. [Google Scholar] [CrossRef]

- Marí, A.R.; Bairán, J.M.; Duarte, N. Long-term deflections in cracked reinforced concrete flexural members. Eng. Struct. 2010, 32, 829–842. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Y.; Ming, X.; Zhao, H.; Sun, Z.; Li, Z.; Sun, G. Optimizing concrete performance with polymer-cement networks: Enhanced flexural strength and crack resistance. Mater. Today Commun. 2025, 42, 111068. [Google Scholar] [CrossRef]

- Bagheri, A.; Negahban, E.; Asad, A.; Abbasi, H.A.; Raza, S.M. Graphene oxide-incorporated cementitious composites: A thorough investigation. Mater. Adv. 2022, 3, 9040–9051. [Google Scholar] [CrossRef]

- Guan, X.; Yu, L.; Li, H. Experimental study on fracture mechanics of cementitious materials reinforced by graphene oxide–silica nanocomposites. Constr. Build. Mater. 2022, 325, 126758. [Google Scholar] [CrossRef]

- Krystek, M.; Pakulski, D.; Patroniak, V.; Górski, M.; Szojda, L.; Ciesielski, A.; Samorì, P. High-Performance Graphene-Based Cementitious Composites. Adv. Sci. 2019, 6, 1801195. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.; Fan, D.; Yang, S. Modelling and Experimentation on Mechanical Properties of Graphene-Oxide Cement. MATEC Web Conf. 2019, 274, 05004. [Google Scholar] [CrossRef]

- Gilbert, I. Shrinkage, cracking and deflection-the serviceability of concrete structures. Electron. J. Struct. Eng. 2001, 1, 15–37. [Google Scholar] [CrossRef]

- Menu, B.; Jolin, M.; Bissonnette, B. Studies on the Influence of Drying Shrinkage Test Procedure, Specimen Geometry, and Boundary Conditions on Free Shrinkage. Adv. Mater. Sci. Eng. 2017, 2017, 9834159. [Google Scholar] [CrossRef]

- Cement Concrete Aggregates Australia (CCAA). Concrete Testing and Quality Assurance; CCAA: Mascot, Australia, 2020. [Google Scholar]

- Ullah, M.; Imtiazi, S.B.A.; Khushnood, R.A.; Pervaiz, E.; Ahmed, W.; Ullah, A.; Qureshi, Z.A. Synthesis, characterization and application of graphene oxide in self consolidating cementitious systems. Constr. Build. Mater. 2021, 296, 123623. [Google Scholar] [CrossRef]

- Kumar, S.; Bheel, N.; Zardari, S.; Alraeeini, A.S.; Almaliki, A.H.; Benjeddou, O. Effect of graphene oxide on mechanical, deformation and drying shrinkage properties of concrete reinforced with fly ash as cementitious material by using RSM modelling. Sci. Rep. 2024, 14, 18675. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Xu, Y.; Hua, J.; Wang, X.; Huang, L.; Zhou, X. Mechanical Properties and Shrinkage Behavior of Concrete-Containing Graphene-Oxide Nanosheets. Materials 2020, 13, 590. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Li, W.; Wang, K.; Zhao, H.; Shah, S.P. Hydration and microstructure of cement paste mixed with seawater–an advanced investigation by SEM-EDS method. Constr. Build. Mater. 2023, 392, 131925. [Google Scholar] [CrossRef]

- Sargam, Y.; Wang, K.J.C.; Research, C. Quantifying dispersion of nanosilica in hardened cement matrix using a novel SEM-EDS and image analysis-based methodology. Cem. Concr. Res. 2021, 147, 106524. [Google Scholar] [CrossRef]

- Xiong, G.; Ren, Y.; Wang, C.; Zhang, Z.; Zhou, S.; Kuang, C.; Zhao, Y.; Guo, B.; Hong, S. Effect of power ultrasound assisted mixing on graphene oxide in cement paste: Dispersion, microstructure and mechanical properties. J. Build. Eng. 2023, 69, 106321. [Google Scholar] [CrossRef]

- Kowalczyk, R.M.; Gajewicz, A.M.; McDonald, P.J. The mechanism of water–isopropanol exchange in cement pastes evidenced by NMR relaxometry. RSC Adv. 2014, 4, 20709–20715. [Google Scholar] [CrossRef]

- Moraes, T.B. Transformada inversa de laplace para analise de sinais de ressonância magnética nuclear de baixo campo. Química Nova 2021, 44, 1020–1027. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, J.; Su, X.; Liu, L.; Chen, Z.; Zhu, J.; Shi, C. Investigation of early hydration of cement by hydrogen nuclear magnetic resonance (1H NMR): New insights into paramagnetic effect. J. Build. Eng. 2024, 98, 111362. [Google Scholar] [CrossRef]

- Muller, A.C.A. Characterization of Porosity & CSH in Cement Pastes by 1H NMR. Ph.D. Thesis, EPFL, Lausanne, Switzerland, 2014. [Google Scholar]

- Murali, M.; Alaloul, W.S.; Mohammed, B.S.; Musarat, M.A.; Salaheen, M.A.; Al-Sabaeei, A.M.; Isyaka, A. Utilizing graphene oxide in cementitious composites: A systematic review. Case Stud. Constr. Mater. 2022, 17, e01359. [Google Scholar] [CrossRef]

- Li, X.; Lu, Z.; Chuah, S.; Li, W.; Liu, Y.; Duan, W.H.; Li, Z. Effects of graphene oxide aggregates on hydration degree, sorptivity, and tensile splitting strength of cement paste. Compos. Part A Appl. Sci. Manuf. 2017, 100, 1–8. [Google Scholar] [CrossRef]

- Smith, S.C.; Rodrigues, D.F. Carbon-based nanomaterials for removal of chemical and biological contaminants from water: A review of mechanisms and applications. Carbon 2015, 91, 122–143. [Google Scholar] [CrossRef]

- Trikkaliotis, D.G.; Mitropoulos, A.C.; Kyzas, G.Z. Low-cost route for top-down synthesis of over- and low-oxidized graphene oxide. Colloids Surf. A Physicochem. Eng. Asp. 2020, 600, 124928. [Google Scholar] [CrossRef]

- Ramli, R.; Hidayat, R. Graphene Oxide Based on Biomass Waste: Synthesis and Applications. In Graphene-A Wonder Material for Scientists and Engineers; IntechOpen: London, UK, 2022. [Google Scholar]

- Bahmei, F.; Bahramifar, N.; Ghasemi, S.; Younesi, H.; Weil, M. Comparison of environmental impacts in the production of graphene from biomass waste and the Hummers’ method. J. Clean. Prod. 2025, 497, 145145. [Google Scholar] [CrossRef]

- Alcaraz, L.; Díaz-Guerra, C.; Fernández-Martínez, R.; Gómez-Mancebo, M.B.; Sotillo, B.; Llorente, I.; López, F.A. Second life of recycled graphite for sustainable production of multilayer graphene related materials with multiple potential applications. Mater. Charact. 2024, 209, 113695. [Google Scholar] [CrossRef]

- Ribeiro, J.S.; Freitas, M.B.; Freitas, J.C. Recycling of graphite and metals from spent Li-ion batteries aiming the production of graphene/CoO-based electrochemical sensors. J. Environ. Chem. Eng. 2021, 9, 104689. [Google Scholar] [CrossRef]

| Mix ID | OPC | Fly Ash | Water | Coarse Aggregates | Fine Aggregates | PCE * | GO |

|---|---|---|---|---|---|---|---|

| 0-GO | 464 | 116 | 175 | 940 | 740 | 3.050 | 0 |

| 0.03-GO | 464 | 116 | 175 | 940 | 740 | 3.050 | 0.174 |

| 0.05-GO | 464 | 116 | 175 | 940 | 740 | 3.050 | 0.290 |

| Portland Clinker | Limestone (CaCO3) | Residue Ashes | Slags, Ferrous Metal, Blast Furnace | Gypsum (CaSO4 2H2O) |

|---|---|---|---|---|

| >87.5% | <7.5% | <7.5% | <7.5% | <5% |

| Property | Value | Experimental Method | Ref. |

|---|---|---|---|

| Particle size of graphite | 100–200 µm | Sieve Analysis | [72] |

| d-spacing | 0.8447 nm | X-ray diffraction (XRD) | [73] |

| ID/IG | 0.8255 | Raman spectroscopy | [73] |

| Carbon: Oxygen (C/O) | 1.67 | X-ray Photoelectron Spectroscopy (XPS) | [73] |

| Oxygen content | 36.31% | XPS | [73] |

| Material | CO2 Emissions (kgCO2-eq) | Cost per kg (USD) |

|---|---|---|

| OPC | 0.885 [93] | 0.13 [93] |

| Fly Ash | 0.004 [94] | 0.07 [95] |

| Coarse Aggregate | 0.036 [96] | 0.04 [93] |

| Fine Aggregate | 0.024 [97] | 0.03 [93] |

| PCE | 4.610 [95] | 1.91 [95] |

| Water | 0.001 [98] | 0.003 [93] |

| GO | 23.2 [19] | 118.80 [99] |

| Time | 0 min | 15 min | 30 min | 45 min | 60 min | 90 min |

|---|---|---|---|---|---|---|

| 0-GO | 0 | 0 | 0 | 0 | 0 | 0 |

| 0.03-GO | 0 | 0 | 0 | 0 | 0 | 0 |

| 0.05-GO | 0 | 0 | 0 | 0 | 0 | 0 |

| Segment | Equation | 0-GO: 7 Days | 0.05-GO: 7 Days | 0-GO: 28 Days | 0.05-GO: 28 Days |

|---|---|---|---|---|---|

| Evaporable water (~25–115 °C) | Equation (1) | 9.76 | 7.30 | 9.96 | 7.40 |

| CSH dehydration (115–450 °C) | Equation (2) | 9.51 | 10.25 | 11.05 | 11.04 |

| CH decomposition (450–600 °C) | Equation (3) | 1.18 | 1.42 | 1.03 | 1.35 |

| CaCO3 decomposition (600–800 °C) | Equation (4) | 2.83 | 3.44 | 2.53 | 3.20 |

| Total Hydration Products (%) | 13.52 | 15.11 | 14.59 | 15.59 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ginigaddara, T.; Devapura, P.; Vimonsatit, V.; Booy, M.; Mendis, P.; Satsangi, R. A Comprehensive Study of the Macro-Scale Performance of Graphene Oxide Enhanced Low Carbon Concrete. Constr. Mater. 2025, 5, 47. https://doi.org/10.3390/constrmater5030047

Ginigaddara T, Devapura P, Vimonsatit V, Booy M, Mendis P, Satsangi R. A Comprehensive Study of the Macro-Scale Performance of Graphene Oxide Enhanced Low Carbon Concrete. Construction Materials. 2025; 5(3):47. https://doi.org/10.3390/constrmater5030047

Chicago/Turabian StyleGinigaddara, Thusitha, Pasadi Devapura, Vanissorn Vimonsatit, Michael Booy, Priyan Mendis, and Rish Satsangi. 2025. "A Comprehensive Study of the Macro-Scale Performance of Graphene Oxide Enhanced Low Carbon Concrete" Construction Materials 5, no. 3: 47. https://doi.org/10.3390/constrmater5030047

APA StyleGinigaddara, T., Devapura, P., Vimonsatit, V., Booy, M., Mendis, P., & Satsangi, R. (2025). A Comprehensive Study of the Macro-Scale Performance of Graphene Oxide Enhanced Low Carbon Concrete. Construction Materials, 5(3), 47. https://doi.org/10.3390/constrmater5030047