Marshall-Based Thermal Performance Analysis of Conventional and Polymer-Modified Asphalt Binders

Abstract

1. Introduction

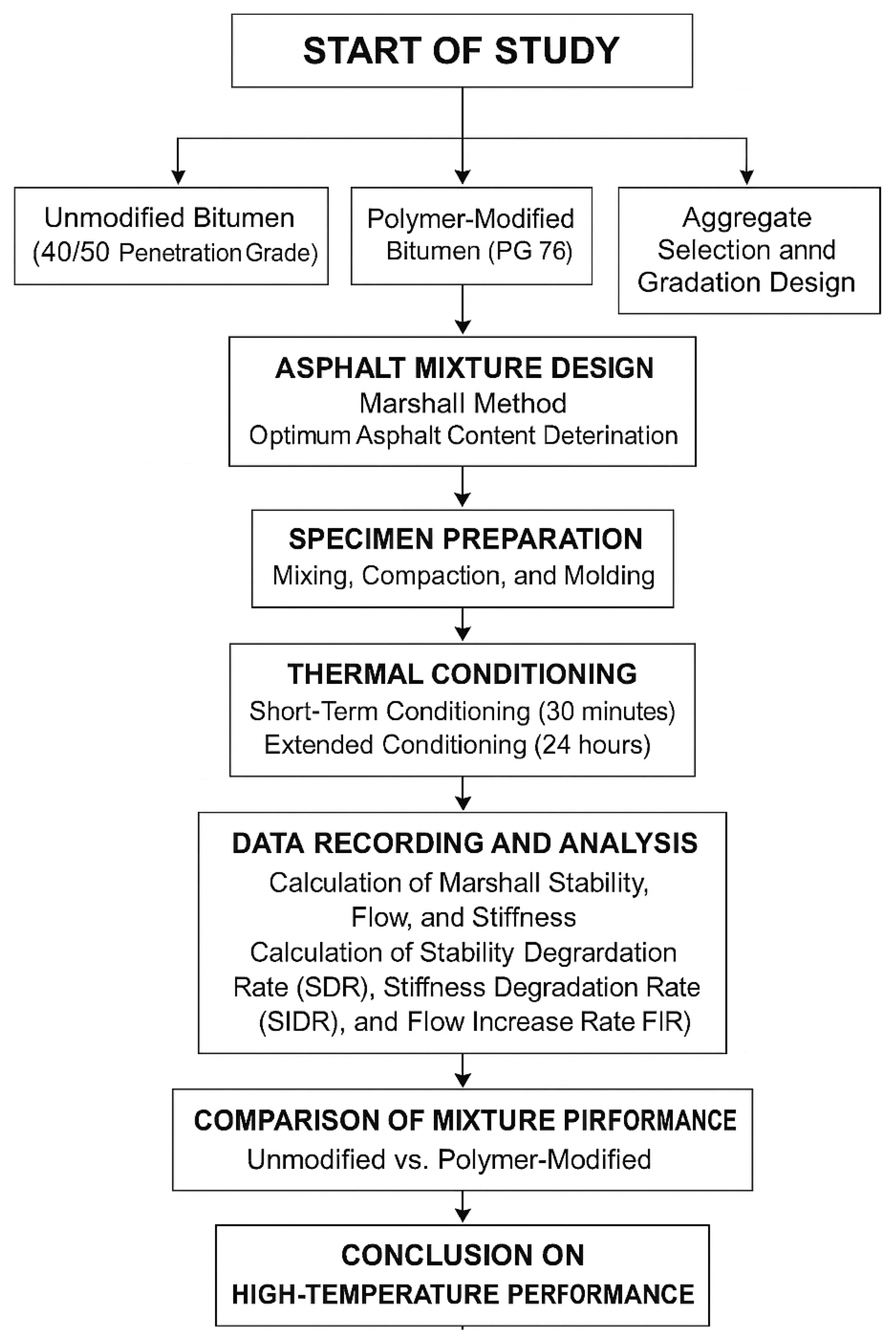

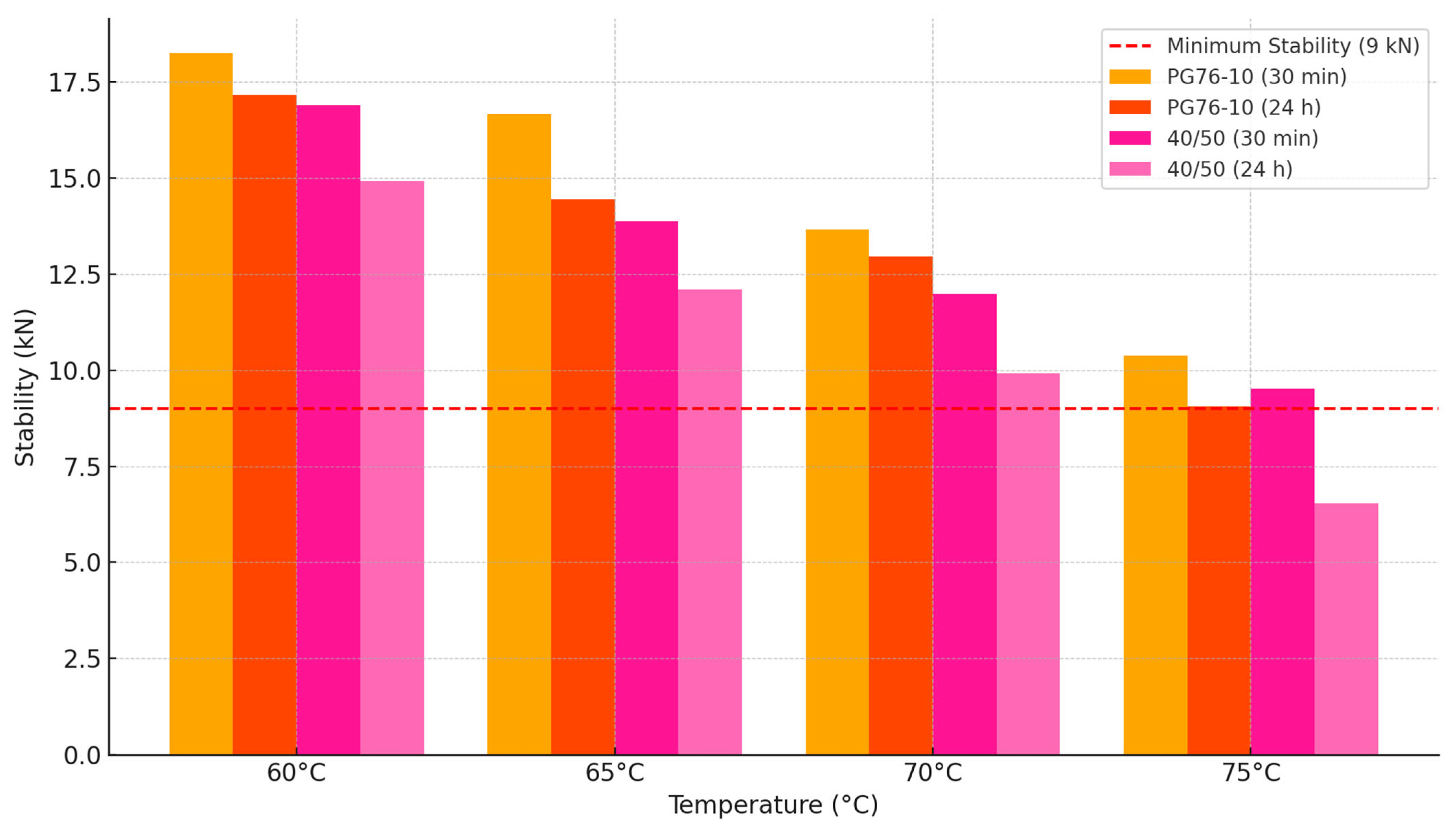

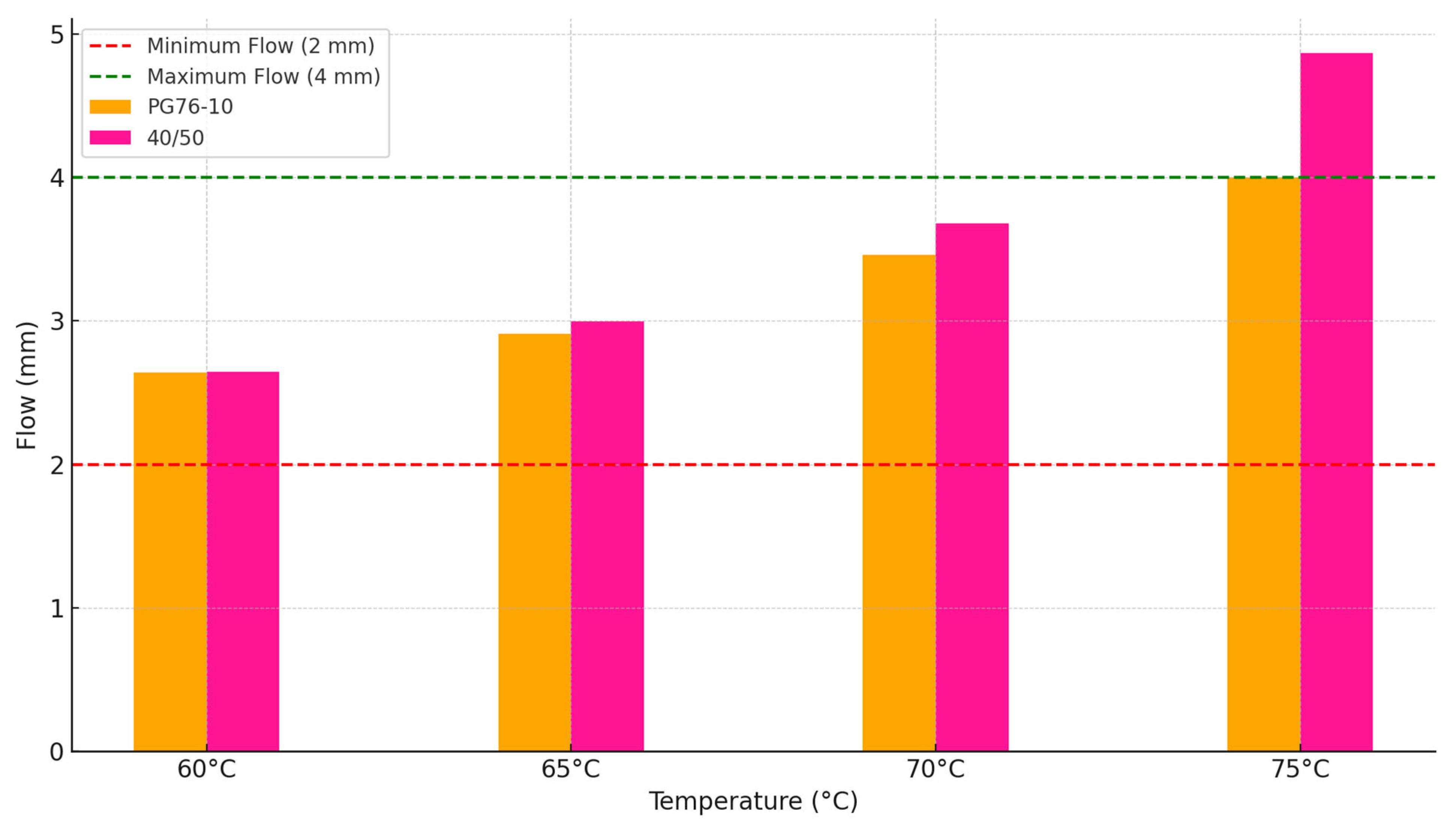

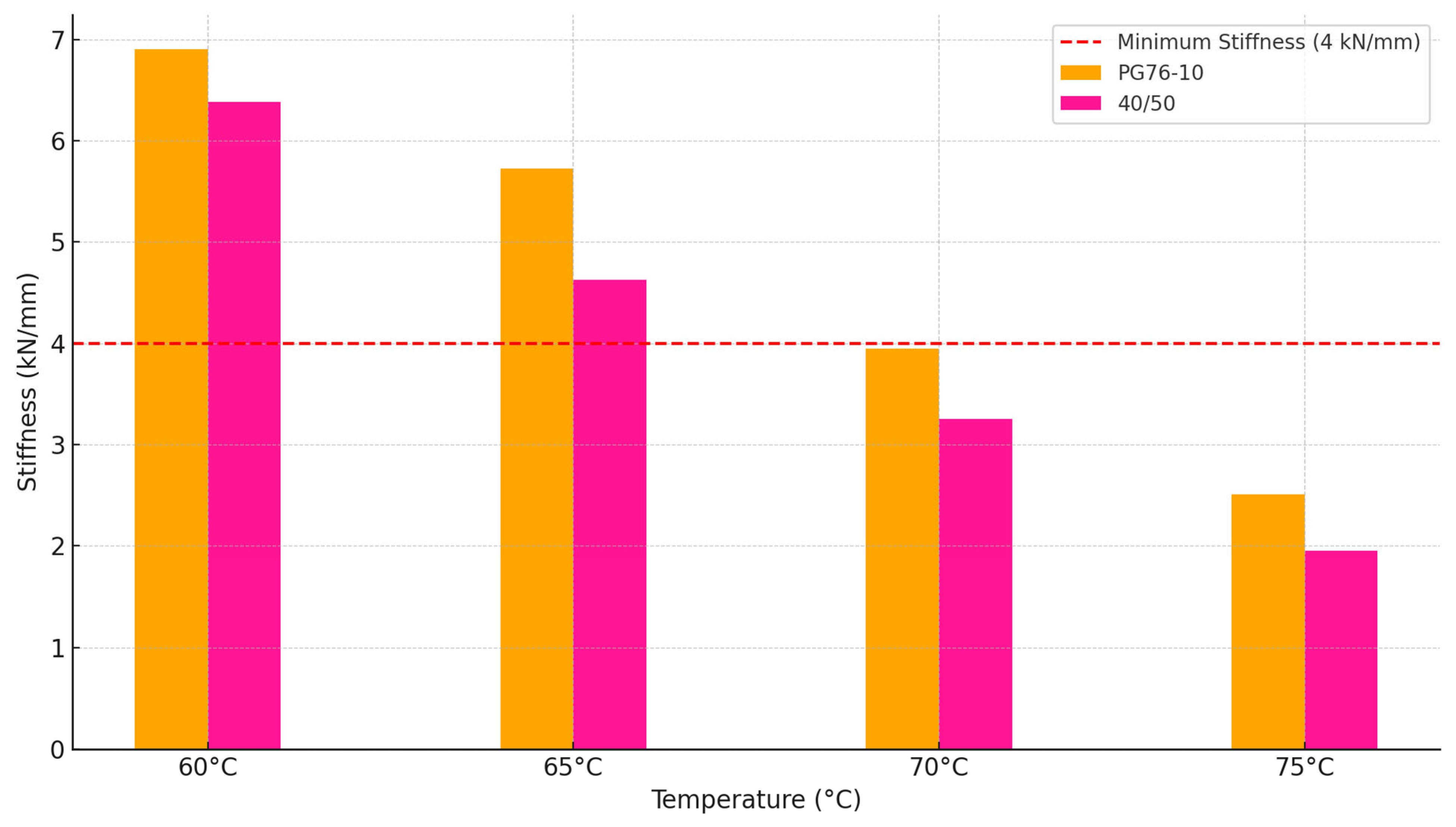

- Evaluate the effects of elevated temperatures (60 °C, 65 °C, 70 °C, and 75 °C) on the Marshall stability, flow, and stiffness of both mixture types.

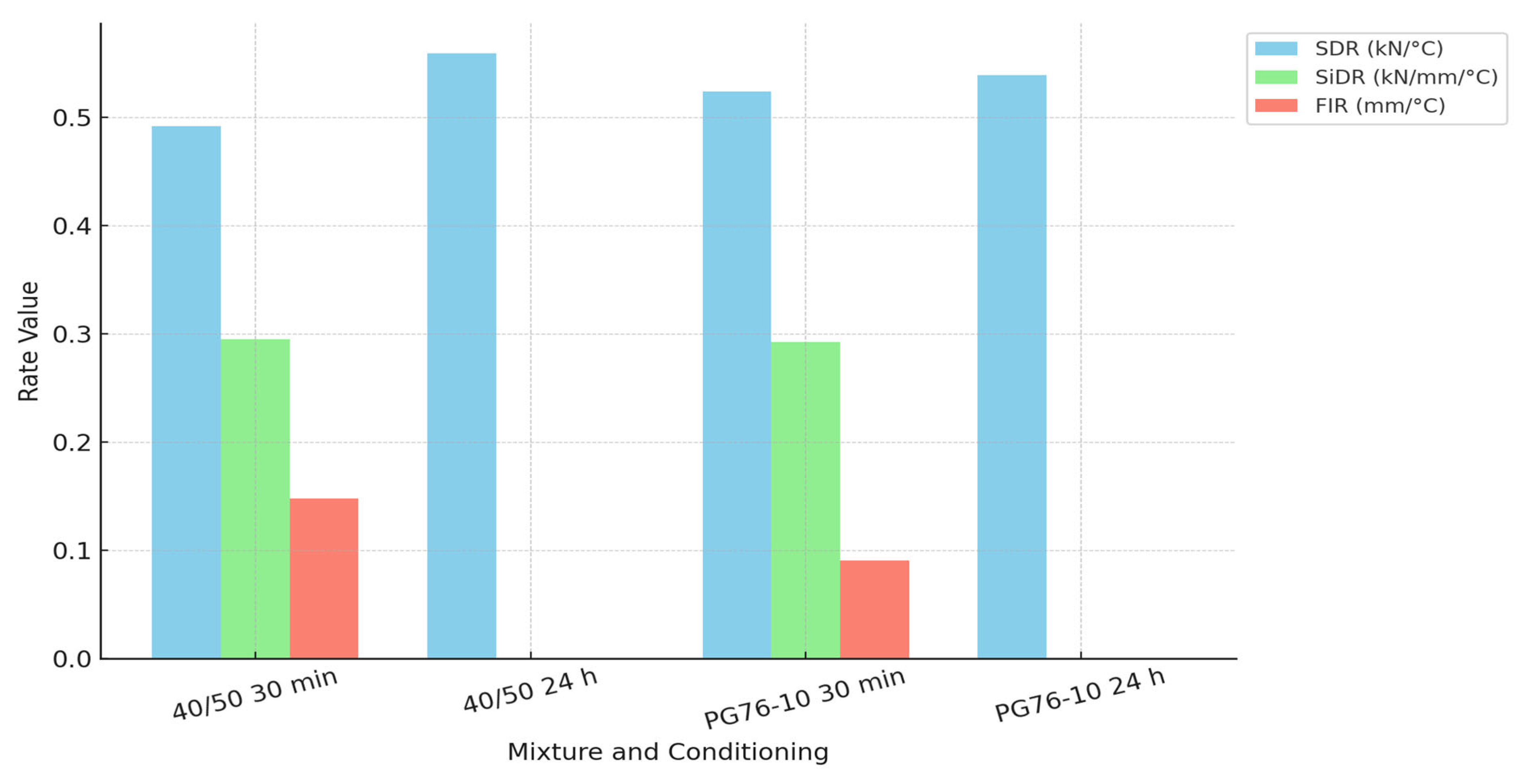

- Analyze the influence of short-term (30 min) and extended (24 h) conditioning on the mechanical performance at high temperatures.

- Calculate and compare the stability degradation rate (SDR), stiffness degradation rate (SiDR), and flow increase rate (FIR) for each mixture to quantify thermal susceptibility.

- Determine the relative suitability of polymer-modified asphalt binders for improving pavement durability and service life under extreme climatic conditions typical of Iraq and other hot regions.

2. Literature Review

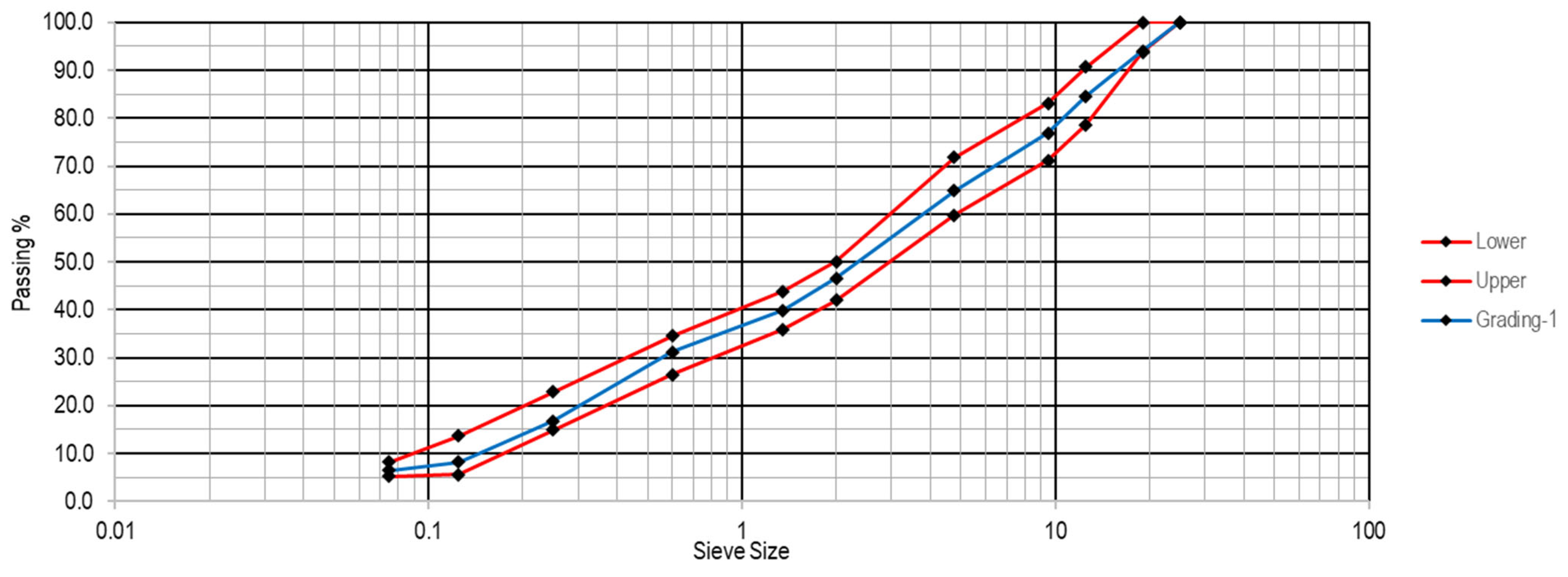

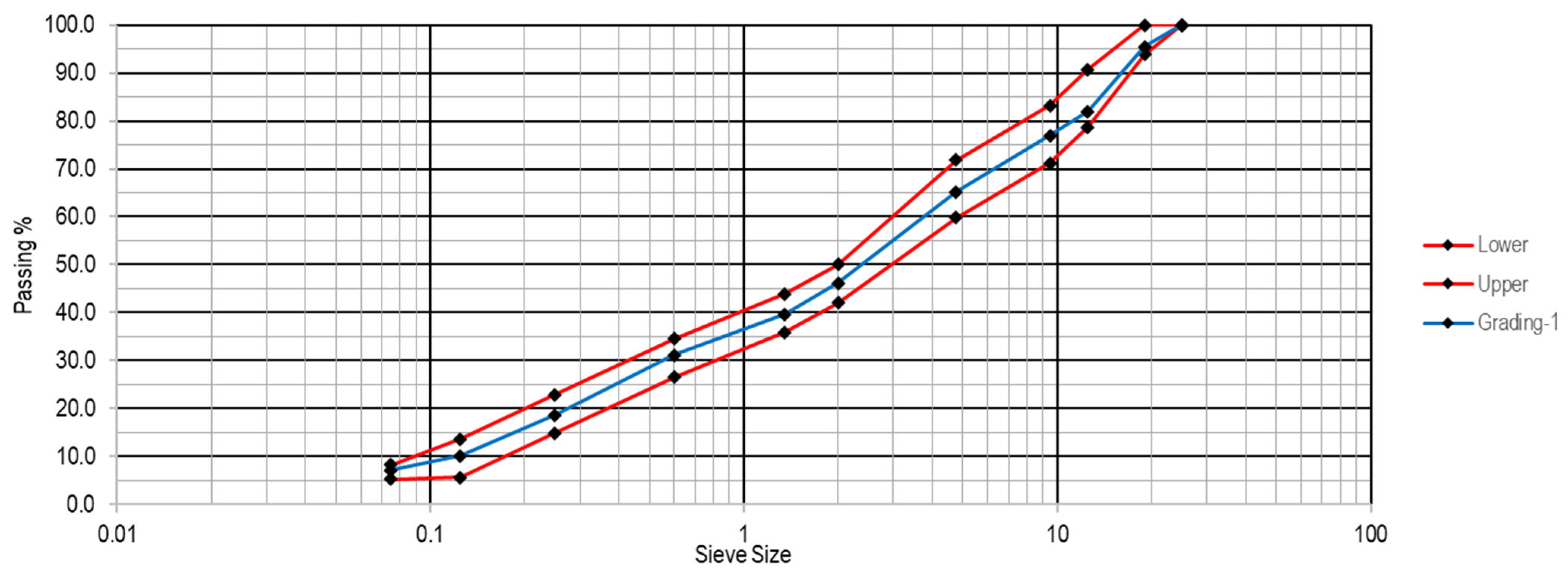

3. Materials and Methods

4. Results and Discussion

5. Conclusions

6. Limitations and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Deng, Z.; Li, W.; Dong, W.; Sun, Z.; Kodikara, J.; Sheng, D. Multifunctional asphalt concrete pavement toward smart transport infrastructure: Design, performance and perspective. Compos. Part B Eng. 2023, 265, 110937. [Google Scholar] [CrossRef]

- Almusawi, A.; Nasraldeen, S.T.; Albdairi, M.; Norri, H.H. Viscoelastic and Fatigue Performance of Modified Bitumen Using Polymer and Bio-Based Additives: A Comparative Study. Buildings 2025, 15, 306. [Google Scholar] [CrossRef]

- Al-Atroush, M. Structural behavior of the geothermo-electrical asphalt pavement: A critical review concerning climate change. Heliyon 2022, 8, e12107. [Google Scholar] [CrossRef]

- Abouelsaad, A.; White, G. Review of Asphalt Mixture Ravelling Mechanisms, Causes and Testing. Int. J. Pavement Res. Technol. 2022, 15, 1448–1462. [Google Scholar] [CrossRef]

- Penki, R.; Rout, S.K. Next-generation bitumen: A review on challenges and recent developments in bio-bitumen preparation and usage. Biomass- Convers. Biorefinery 2023, 13, 9583–9600. [Google Scholar] [CrossRef]

- Walubita, L.F.; Mahmoud, E.; Fuentes, L.; Prakoso, A.; Lee, S.I.; Souliman, M.; Komba, J.J. Correlating the asphalt-binder high-temperature properties (DSR) to HMA permanent deformation (RLPD) and field rutting: A laboratory-field study. Constr. Build. Mater. 2020, 262, 120761. [Google Scholar] [CrossRef]

- Amani, M.J.; Alampoor, A.; Piri, M.; Golroo, A.; Rezaeimanesh, M. A Review on the Impact of Pavement Condition on Traffic Safety. Available online: https://doi.org/10.2139/ssrn.5050295 (accessed on 9 June 2025).

- Yang, Q.; Lin, J.; Wang, X.; Wang, D.; Xie, N.; Shi, X. A review of polymer-modified asphalt binder: Modification mechanisms and mechanical properties. Clean. Mater. 2024, 12, 100255. [Google Scholar] [CrossRef]

- Ishaq, M.A.; Giustozzi, F. Effect of polymers and micro fibres on the thermo-chemical and rheological properties of polymer modified binders. Aust. J. Civ. Eng. 2023, 21, 34–49. [Google Scholar] [CrossRef]

- Lv, Q.; Huang, W.; Zheng, M.; Sadek, H.; Zhang, Y.; Yan, C. Influence of gradation on asphalt mix rutting resistance measured by Hamburg Wheel Tracking test. Constr. Build. Mater. 2020, 238, 117674. [Google Scholar] [CrossRef]

- Almusawi, A.; Shoman, S.; Lupanov, A.P. Assessment of the effectiveness and the initial cost efficiency of hot recycled asphalt using polymer modified bitumen. Case Stud. Constr. Mater. 2023, 18, e02145. [Google Scholar] [CrossRef]

- Jaf, H.; Mamhusseini, A.A. Enhancing Asphalt Mix Performance through the Incorporation of Crumb. Eurasian J. Sci. Eng. 2024, 10, 138–149. [Google Scholar] [CrossRef]

- Hassan, W. Climate change projections of maximum temperatures for southwest Iraq using statistical downscaling. Clim. Res. 2021, 83, 187–200. [Google Scholar] [CrossRef]

- Vysotskaya, M.; Kharlamov, E.; Denisov, V.; Kurlykina, A. PMB quality problems based on its morphology and used equipment. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 135, p. 03035. [Google Scholar] [CrossRef]

- Binti Joohari, I.; Giustozzi, F. Hybrid Polymerisation: An Exploratory Study of the Chemo-Mechanical and Rheological Properties of Hybrid-Modified Bitumen. Polymers 2020, 12, 945. [Google Scholar] [CrossRef] [PubMed]

- Mokoena, R.; Mturi, G.; Maritz, J.; Mateyisi, M.; Klein, P. African Case Studies: Developing Pavement Temperature Maps for Performance-Graded Asphalt Bitumen Selection. Sustainability 2022, 14, 1048. [Google Scholar] [CrossRef]

- Gong, Z.; Zhang, L.; Wu, J.; Xiu, Z.; Wang, L.; Miao, Y. Review of regulation techniques of asphalt pavement high temperature for climate change adaptation. J. Infrastruct. Preserv. Resil. 2022, 3, 9. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Boom, Y.J.; Giustozzi, F. Sustainable Polymers from Recycled Waste Plastics and Their Virgin Counterparts as Bitumen Modifiers: A Comprehensive Review. Polymers 2021, 13, 3242. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, L.; Zhai, J.; Huang, W. A review of design methods for cold in-place recycling asphalt mixtures: Design processes, key parameters, and evaluation. J. Clean. Prod. 2022, 370, 133530. [Google Scholar] [CrossRef]

- Sargand, S.; Kim, S. Performance evaluation of polymer modified and unmodified Superpave mixes. In Proceedings of the Second International Symposium on Maintenance and Rehabilitation of Pavements and Technological Control. Segundo Simposio Sobre Manutencao e Rehabilitacao de Pavimentos e Controle Technologico. Auburn, AL, USA, 29 April–1 August 2001, Auburn University; University of Mississippi; ASCE; IRF; DOTRSPA; NAPA; FREMIX Fresagem de Pavimentos, 2001; no. 01-147. Available online: https://trid.trb.org/View/701383 (accessed on 9 June 2025).

- Ali, M.F.; Siddiqui, M.N. Changes in asphalt chemistry and durability during oxidation and polymer modification. Pet. Sci. Technol. 2001, 19, 1229–1249. [Google Scholar] [CrossRef]

- Pérez-Lepe, A.; Martínez-Boza, F.J.; Gallegos, C. High temperature stability of different polymer-modified bitumens: A rheological evaluation. J. Appl. Polym. Sci. 2007, 103, 1166–1174. [Google Scholar] [CrossRef]

- Von Quintus, H.L.; Mallela, J.; Buncher, M. Quantification of Effect of Polymer-Modified Asphalt on Flexible Pavement Performance. Transp. Res. Rec. J. Transp. Res. Board 2007, 2001, 141–154. [Google Scholar] [CrossRef]

- Shaffie, E.; Ahmad, J.; Abdul Rahman, M.Y. Temperature Effects on Stripping Performance of Superpave Design Mix. Sci. Res. J. 2008, 5, 11–20. [Google Scholar] [CrossRef]

- Reyes Lizcano, F.A.; Lizarazo, C.M.; Figueroa, A.S.; Candia, M.; Flintsch, G.W. Dynamic characterization of hot-mix asphalt mixtures using modified and conventional asphalts in Colombia. Presented at the 88th Annual Meeting of the Transportation Research Board (TRB), Washington, DC, USA, 11–15 January 2009; Available online: https://www.researchgate.net/publication/279861315_Dynamic_Characterization_of_Hot-Mix_Asphalt_Mixtures_Using_Modified_and_Conventional_Asphalts_in_Colombia (accessed on 9 June 2025).

- Yao, Z.; Zhao, D.; Lei, M. Evaluation of Polymer-Modified Hot-Mix Asphalt: Laboratory Characterization. J. Mater. Civ. Eng. 2009, 21, 163–170. [Google Scholar] [CrossRef]

- Khan, K.M.; Asghar, A. Performance of Pavements under Extreme Loading and Temperature Conditions using Polymer Modified Bitumen. Univ. Eng. Technol. Taxila Tech. J. 2013, 18, 52. Available online: https://www.proquest.com/openview/e845a40c68643a77e6844dcd49688a41/1?cbl=2032486&pq-origsite=gscholar (accessed on 9 June 2025).

- Al-sabagh, A.M.; Abdel_Hai, F.; Abd El Rhman, A.M.; EL-Shafie, M.; Ibrahim, I.M.; Mohammedy, M.M. A Study on Marshall Properties for Polymer Modified Bitumen in Diffferent Molar Ratios. Al-Azhar Bull. Sci. 2014, 25, 23–38. [Google Scholar] [CrossRef]

- Kabbash, O.M. The Design of Hot Mixture Thin Surfacing Containing Asbuton Modified Bitumen Fro Hot and Erid Region. Ph.D. Thesis, UNS (Sebelas Maret University), Surakarta, Indonesia, 2014. [Google Scholar]

- Micaelo, R.; Gameiro, A.; Quaresma, L.; Picado-Santos, L. Production of Hot-Mix Asphalt with PMB: Compactability and mechanical behaviour characterization. In Proceedings of the 8th RILEM Inter-National Symposium on Testing and Characterization of Sustainable and Innovative Bituminous Materials, Ancona, Italy, 7–9 October 2015; Springer: Dordrecht, The Netherlands, 2016; pp. 231–242. [Google Scholar] [CrossRef]

- Albrka, S.I.; Ismail, A.; Yusoff, N.; Alhamali, D.I.; Musbah, A. Performance properties of ASA polymer modified asphalt binders and mixtures. J. Eng. Sci. Technol. 2016, 11, 1155–1164. Available online: https://jestec.taylors.edu.my/Vol%2011%20issue%208%20August%202016/11_8_7.pdf (accessed on 9 June 2025).

- Jan, H.; Aman, M.Y.; Tawab, M.; Ali, K.; Ali, B. Performance evaluation of hot mix asphalt concrete by using polymeric waste polyethylene. In Modeling, Simulation, and Optimization; Springer: Berlin/Heidelberg, Germany, 2018; pp. 91–99. [Google Scholar] [CrossRef]

- Asmael, N.M.; Waheed, M.Q. Investigation of using polymers to improve asphalt pavement performance. Am. Sci. Res. J. Eng. Technol. Sci. (ASRJETS) 2018, 39, 38–48. Available online: https://asrjetsjournal.org/index.php/American_Scientific_Journal/article/view/3768 (accessed on 9 June 2025).

- Khurshid, M.B.; Qureshi, N.A.; Hussain, A.; Iqbal, M.J. Enhancement of Hot Mix Asphalt (HMA) Properties Using Waste Polymers. Arab. J. Sci. Eng. 2019, 44, 8239–8248. [Google Scholar] [CrossRef]

- Gc, H.; Souliman, M.I.; Zeiada, W.; Isied, M. Mechanistic Assessment of Fatigue Performance and Cost Analysis of Pavement Overlays: Comparison between Conventional Hot Mixed Asphalt, Asphalt Rubber, and Polymer-Modified Mixtures. Adv. Civ. Eng. Mater. 2019, 8, 611–622. [Google Scholar] [CrossRef]

- Sarnowski, M.; Kowalski, K.J.; Król, J.B.; Radziszewski, P. Influence of Overheating Phenomenon on Bitumen and Asphalt Mixture Properties. Materials 2019, 12, 610. [Google Scholar] [CrossRef]

- Yan, K.; You, L.; Wang, D. High-Temperature Performance of Polymer-Modified Asphalt Mixes: Preliminary Evaluation of the Usefulness of Standard Technical Index in Polymer-Modified Asphalt. Polymers 2019, 11, 1404. [Google Scholar] [CrossRef]

- Mu, Y.; Fu, Z.; Liu, J.; Li, C.; Dong, W.; Dai, J. Evaluation of High-Temperature Performance of Asphalt Mixtures Based on Climatic Conditions. Coatings 2020, 10, 535. [Google Scholar] [CrossRef]

- Amin, I.; Alabasey, R.; Azam, A.; EL-Badawy, S.M.; Gabr, A. Evaluation of Polymer Modified Asphalt Mixtures in Pavement Construction. MEJ-Mansoura Eng. J. 2015, 40, 74–82. Available online: https://journals.ekb.eg/article_104955_42d4c391e1766c5c3cdcb8c83f69c48f.pdf (accessed on 9 June 2025). [CrossRef]

- Yu, J.Y.; Zhang, H.L.; Sun, P.; Zhao, S.F. Laboratory performances of nano-particles/polymer modified asphalt mixtures developed for the region with hot summer and cold winter and field evaluation. Road Mater. Pavement Des. 2020, 21, 1529–1544. [Google Scholar] [CrossRef]

- Chen, C.; Wu, H.; Zhang, W.; Mao, Y.; Zhang, C. Investigation of High Temperature Performance and Viscosity Characteristics of Modified and Unmodified Color Asphalt. Exp. Tech. 2022, 46, 317–333. [Google Scholar] [CrossRef]

- Singh, B.; Kumar, P. Investigating the performance of polymer and warm mix modified asphalt binders and mixtures. Int. J. Pavement Eng. 2022, 23, 3691–3705. [Google Scholar] [CrossRef]

- Badry, M.M.; Dulaimi, A.; Shanbara, H.K.; Al-Busaltan, S.; Abdel-Wahed, T. Effect of Polymer on the Properties of Bitumen and Pavement Layers, Case Study: Expressway No. 1, Republic of Iraq. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1090, p. 012032. [Google Scholar] [CrossRef]

- Rincón-Estepa, J.A.; González-Salcedo, E.V.; Rondón-Quintana, H.A.; Reyes-Lizcano, F.A.; Bastidas-Martínez, J.G. Mechanical Behavior of Low-Density Polyethylene Waste Modified Hot Mix Asphalt. Sustainability 2022, 14, 4229. [Google Scholar] [CrossRef]

- Joni, H.H.; AL-Rubaie, A.H. Enhancement of the Rutting Resistance of Asphalt Mixtures at Different High Temperatures Using Waste Polyethylene Polymer. Eng. Technol. J. 2022, 40, 1432–1440. [Google Scholar] [CrossRef]

- Yin, F.; West, R.; Powell, B.; DuBois, C. Short-Term Performance Characterization and Fatigue Damage Prediction of Asphalt Mixtures Containing Polymer-Modified Binders and Recycled Plastics. Transp. Res. Rec. J. Transp. Res. Board 2023, 2679, 742–759. [Google Scholar] [CrossRef]

- Gu, M. Analysis of the Discriminability of High-Temperature Performance Indices of Modified Asphalt Mixtures. In Proceedings of the International Conference on Innovative Solutions in Hydropower Engineering and Civil Engineering, HECE 2022, Hangzhou, China, 25–27 September 2022; Springer Nature Singapore: Singapore, 2022; pp. 243–251. [Google Scholar] [CrossRef]

- Tahmoorian, F.; Liyanapathirana, S.; Yeaman, J.; Egwurube, J. Performance of Hot-Mix Asphalt and Modified Binders Containing Polyethylene. J. Transp. Eng. Part B Pavements 2023, 149, 04023001. [Google Scholar] [CrossRef]

- Saleh, M.; Ahmed, N.; Moghaddam, T.B.; Hashemian, L. Towards a high-performance asphalt concrete for extreme climatic conditions using asphaltenes and polyethylene terephthalate fibres. Constr. Build. Mater. 2024, 420, 135573. [Google Scholar] [CrossRef]

- Ullah, S.; Qabur, A.; Ullah, A.; Aati, K.; Abdelgiom, M.A. Enhancing High-Temperature Performance of Flexible Pavement with Plastic-Modified Asphalt. Polymers 2024, 16, 2399. [Google Scholar] [CrossRef] [PubMed]

- Junus, S.; Renreng, I.; Syahid, M.; Hayat, A. Identifying the Effect of Polymer Composition in Hot Mix Asphalt Modification. East.-Eur. J. Enterp. Technol. 2024, 128, 20–30. [Google Scholar] [CrossRef]

- Oyelere, A.; Wu, S.; Rodriguez, E. Evaluation of High-Temperature Rheological and Aging Characteristics in Asphalt Binders Modified with Recycled High-Density Polyethylene and Recycled Polypropylene. Adv. Civ. Eng. Mater. 2024, 13, 134–150. [Google Scholar] [CrossRef]

- İbiş, A.B.; Şengöz, B.; Almusawi, A.; Özdemir, D.K.; Topal, A. Mechanical Characteristics of Environmentally Friendly Permeable Pavement: Enhanced Porous Asphalt. Jordan J. Civ. Eng. 2024, 18, 212–223. [Google Scholar] [CrossRef]

- Dimter, S.; Šimun, M.; Zagvozda, M.; Rukavina, T. Laboratory Evaluation of the Properties of Asphalt Mixture with Wood Ash Filler. Materials 2021, 14, 575. [Google Scholar] [CrossRef]

- Mushtaq, F.; Huang, Z.; Shah, S.A.; Zhang, Y.; Gao, Y.; Azab, M.; Hussain, S.; Anwar, M.K. Performance Optimization Approach of Polymer Modified Asphalt Mixtures with PET and PE Wastes: A Safety Study for Utilizing Eco-Friendly Circular Economy-Based SDGs Concepts. Polymers 2022, 14, 2493. [Google Scholar] [CrossRef]

- Habbouche, J.; Hajj, E.Y.; Sebaaly, P.E.; Piratheepan, M. A critical review of high polymer-modified asphalt binders and mixtures. Int. J. Pavement Eng. 2020, 21, 686–702. [Google Scholar] [CrossRef]

- Dalhat, M.A.; Al-Adham, K. Review on laboratory preparation processes of polymer modified asphalt binder. J. Traffic Transp. Eng. Engl. Ed. 2023, 10, 159–184. [Google Scholar] [CrossRef]

- Pfeiffer, J.P.; Van Doormaal, P.M. The rheological properties of asphaltic bitumens. J. Inst. Pet. Technol. 1936, 22, 414–440. [Google Scholar]

| Author(s) | Year | Objective/Focus | Methodology/Tools | Key Findings |

|---|---|---|---|---|

| Sargand and Kim [20] | 2001 | Compare PMB and unmodified Superpave mixes in terms of rutting/fatigue resistance | APA, triaxial repeated load, flexural fatigue | PMB improves rutting and fatigue resistance; gradation has a minor effect |

| Ali and Siddiqui [21] | 2001 | Study chemical and performance changes with oxidation and polymer modification | Chemical and physical analysis | PMB improves high-temperature resistance; chemical composition affects properties |

| Pérez-Lepe et al. [22] | 2007 | Assess phase separation and rheology in PMB | Rheological tests, microscopy | Reactive polymers more stable; HDPE shows mechanical gains but instability |

| Quintus et al. [23] | 2007 | Evaluate long-term effects of PMA on pavement | Pavement data analysis | PMA reduces cracking and improves service life |

| Shaffie et al. [24] | 2008 | Evaluate binder and temperature effects on stripping | AASHTO TP4, resilient modulus | Rubber PMB improves moisture resistance; temperature reduces strength |

| Lizcano et al. [25] | 2009 | Assess SBS-modified mixes under dynamic loading | Nottingham Asphalt Tester | PMB reduces thermal susceptibility; higher resistance to deformation |

| Zhao et al. [26] | 2009 | Evaluate polymer impact on pavement failures | Superpave and wheel-tracking tests | PMB enhances high- and low-temperature performance |

| Khan and Asghar [27] | 2013 | Examine PMB vs. conventional asphalt under stress | UTM 5P, lab-prepared mixes | PMB shows better performance under heavy loads and high temperatures |

| Al-Sabagh et al. [28] | 2014 | Evaluate polymer ratios for optimal performance | SEM, TGA, chemical testing | PMB improves performance; two polymers suitable for road applications |

| Kabbash et al. [29] | 2016 | Assess modified thin surfacing mixes | Additives, asphalt specimen testing | SBS stable at different temperatures; Retona 55 performs better |

| Micaelo et al. [30] | 2016 | Examine mixing/compaction temperature influence | HSRV-E, Superpave | No single optimal temperature; compaction affects performance |

| Albrka et al. [31] | 2016 | Evaluate ASA-modified asphalt | Dynamic creep, conventional tests | 5% ASA content optimal; improved binder and mixture behavior |

| Jan et al. [32] | 2017 | Assess PE waste as asphalt modifier | AASHTO, Marshall tests | Waste plastic improves stability; softening point increases |

| Asmael and Waheed [33] | 2018 | Test tensile and deformation resistance | Indirect tensile, retained stability | Polystyrene effective in cold; phenol resin improves hot resistance |

| Khurshid et al. [34] | 2019 | Examine recycled plastic effects on HMA | Marshall, wheel-tracking tests | HDPE most effective; CR most cost-efficient |

| Gc et al. [35] | 2019 | Assess performance and cost of overlays | FlexPAVE, cost models | PMB extends service life; better fatigue resistance |

| Sarnowski et al. [36] | 2019 | Study binder degradation via overheating | Overheating degradation index (ODI) | PMBs degrade faster with overheating; sensitivity 20 °C lower |

| Yan et al. [37] | 2019 | Validate technical indexes under extreme heat | DSR, MSCR, ZSV tests | TB-APAO and WTR-APAO outperform SBS; traditional indexes inadequate |

| Mu et al. [38] | 2020 | Evaluate rutting under real climate temperatures | Rutting test, modified depth formula | Temperature-rutting rate better than dynamic stability; additives help |

| Amin et al. [39] | 2020 | Examine PMA’s effect on rutting, durability | Marshall, viscometer, penetration | 4% PMA optimal; improves stability and service life |

| Yu et al. [40] | 2020 | Evaluate nano + polymer performance | Dynamic, rutting, wheel tracking | Nanomaterials improve both low- and high-temperature resistance |

| Chen et al. [41] | 2021 | Assess SBS-modified color asphalt | RTFOT, PAV, DSR, Brookfield | SBS improves bonding and viscosity; aging affects color |

| Singh and Kumar [42] | 2021 | Investigate mixed modification benefits | Marshall, binder tests | Polymer + warm mix improves workability and performance |

| Badry et al. [43] | 2021 | Field validation of polymer-modified pavement | Site and lab testing | PMB improves penetration, stiffness, and road durability |

| Rincón-Estepa et al. [44] | 2022 | Use LDPE for environmental and strength benefits | Marshall, ITS, Cantabro | 5% LDPE optimal; increases stiffness in hot climates |

| Joni and Al-Rubaie [45] | 2022 | Evaluate effect of LDPE on rutting depth | Marshall, rutting depth tests | 4% PE reduces rutting by >80%; improves Marshall stability |

| Yin et al. [46] | 2023 | Predict fatigue and cracking in modified mixes | FlexPAVE, rheological and mix tests | PMB improves elasticity; recycled PE reduces cracking resistance |

| M Gu. [47] | 2023 | Analyze usefulness of indexes in PMB evaluation | CRITIC, entropy weight method | CSI and RD best reflect PMB high-temperature performance |

| Tahmoorian et al. [48] | 2023 | Examine recycled PE effect on binder behavior | Binder property tests | PE enhances durability; waste PE is a viable modifier |

| Saleh et al. [49] | 2024 | Combine PET fiber and asphaltenes | Superpave, modulus, ITS | 0.15% PET fiber improves fracture energy and rutting |

| Ullah et al. [50] | 2024 | Compare LDPE, PP, ABS in asphalt | Wheel tracking, bitumen testing | LDPE best for rut depth; PMA improves resistance significantly |

| Junus et al. [51] | 2024 | Identify optimal polymer content | Compression strength tests | 5% synthetic rubber at 200 °C shows highest strength |

| Oyelere et al. [52] | 2024 | Evaluate rutting and aging in recycled plastic-modified asphalt | Rheology, aging tests | rPP shows best stability; both enhance rut resistance |

| No. | Test Description | Test Method (ASTM) | Result | Specification Limits |

|---|---|---|---|---|

| 1 | Penetration at 25 °C (100 g, 5 s) (1/10 mm) | D5 | 46 | 40–50 |

| 2 | Flash Point (°C) | D92 | >250 | ≥250 |

| 3 | Ductility at 25 °C (5 cm/min) (cm) | D113 | >100 | ≥100 |

| 4 | Ductility after T.F.O.T. at 25 °C (cm) | D113 | 95 | – |

| 5 | Retained Penetration after T.F.O.T. (%) | D5 | 55.2 | ≥55 |

| 6 | Penetration Drop after Heating (%) | D5 | 17 | ≤20 |

| 7 | Density (kg/m3) | D71, D3289 | 1025 | 1010–1060 |

| 8 | Change of Weight after Heating (%) | D6 | 0.28 | ≤0.5 |

| 9 | Softening Point R.B. (°C) | D36 | 58 | 52–60 |

| 10 | Increase of Softening Point after Heating (°C) | D36 | 6 | ≤10 |

| 11 | Solubility in Organic Solvents (%) | D2042 | 99.3 | ≥99 |

| 12 | Bitumen Content (%) | D4 | 99.8 | ≥99.5 |

| Property | Test Method | PG(T) [°C] | Result | Specification | Status |

|---|---|---|---|---|---|

| Original Binder | |||||

| Max. Pavement Temperature (7-day average) (°C) | – | – | <76 | <76 | Pass |

| Min. Pavement Design Temperature (°C) | – | – | >−10 | >−10 | Pass |

| Min. Flash Point Temperature (°C) | AASHTO T48 | – | 230 | >230 | Pass |

| Test Temperature at which Viscosity shall be Maximum 3 (Pa·s) | AASHTO T316 | 135 | 2.044 | Max 3.0 Pa-s | Pass |

| G*/Sin δ (kPa) | ASTM D7175 | 76 | 2.59 | ≥1.0 kPa | Pass |

| Rolling Thin Film Oven (RTFO), ASTM D2872 | |||||

| Maximum percent of Mass loss (%) | ASTM D2872 | 163 | 1 | Max 1% | Pass |

| Multiple-Stress Creep Recovery (MSCR) Standard Traffic “E” Grade Jnr 3.2 Jnr diff max 75% | ASTM D7405 | 76 | <0.5 | Max 0.5 kPa−1 | Pass |

| Pressurized Aging Vessel (PAV) (110 °C), ASTM D6521 | |||||

| G*/Sin δ for “H, V & E” grade | ASTM D7175 | 37 | <6000 | Max 6000 kPa | Pass |

| S @ 60/Sec (MPa) | ASTM D6648 | 0 | 148.5 | Max 300 MPa | Pass |

| M-value @ 60/Sec | ASTM D6648 | 0 | 0.392 | Min 0.300 | Pass |

| Grade (PG) | 76/-10 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaleel, M.M.; Albdairi, M.; Almusawi, A. Marshall-Based Thermal Performance Analysis of Conventional and Polymer-Modified Asphalt Binders. Constr. Mater. 2025, 5, 40. https://doi.org/10.3390/constrmater5020040

Jaleel MM, Albdairi M, Almusawi A. Marshall-Based Thermal Performance Analysis of Conventional and Polymer-Modified Asphalt Binders. Construction Materials. 2025; 5(2):40. https://doi.org/10.3390/constrmater5020040

Chicago/Turabian StyleJaleel, Mustafa Mohammed, Mustafa Albdairi, and Ali Almusawi. 2025. "Marshall-Based Thermal Performance Analysis of Conventional and Polymer-Modified Asphalt Binders" Construction Materials 5, no. 2: 40. https://doi.org/10.3390/constrmater5020040

APA StyleJaleel, M. M., Albdairi, M., & Almusawi, A. (2025). Marshall-Based Thermal Performance Analysis of Conventional and Polymer-Modified Asphalt Binders. Construction Materials, 5(2), 40. https://doi.org/10.3390/constrmater5020040