Utilization of Different Types of Plastics in Concrete Mixtures

Abstract

1. Introduction

- (1)

- (2)

- The influence of different plastic powder types on cement hydration, where all powders have similar particle size and size distribution.

- The influence of plastic aggregates on mortar density and compressive and flexural strength, where plastic particles have the same fineness modulus, moisture content, no contamination, and the same degradation level (single-use plastic).

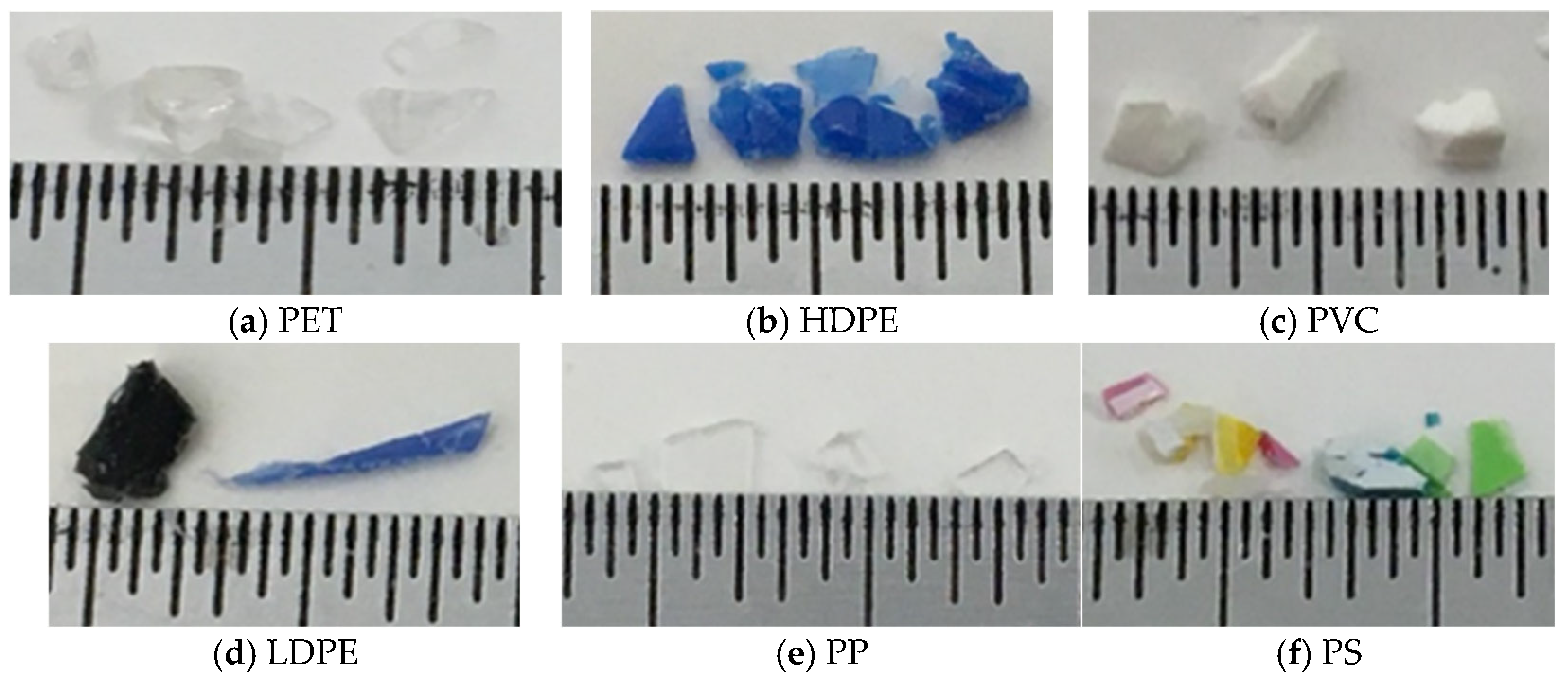

2. Materials

3. Methods

4. Results and Discussion

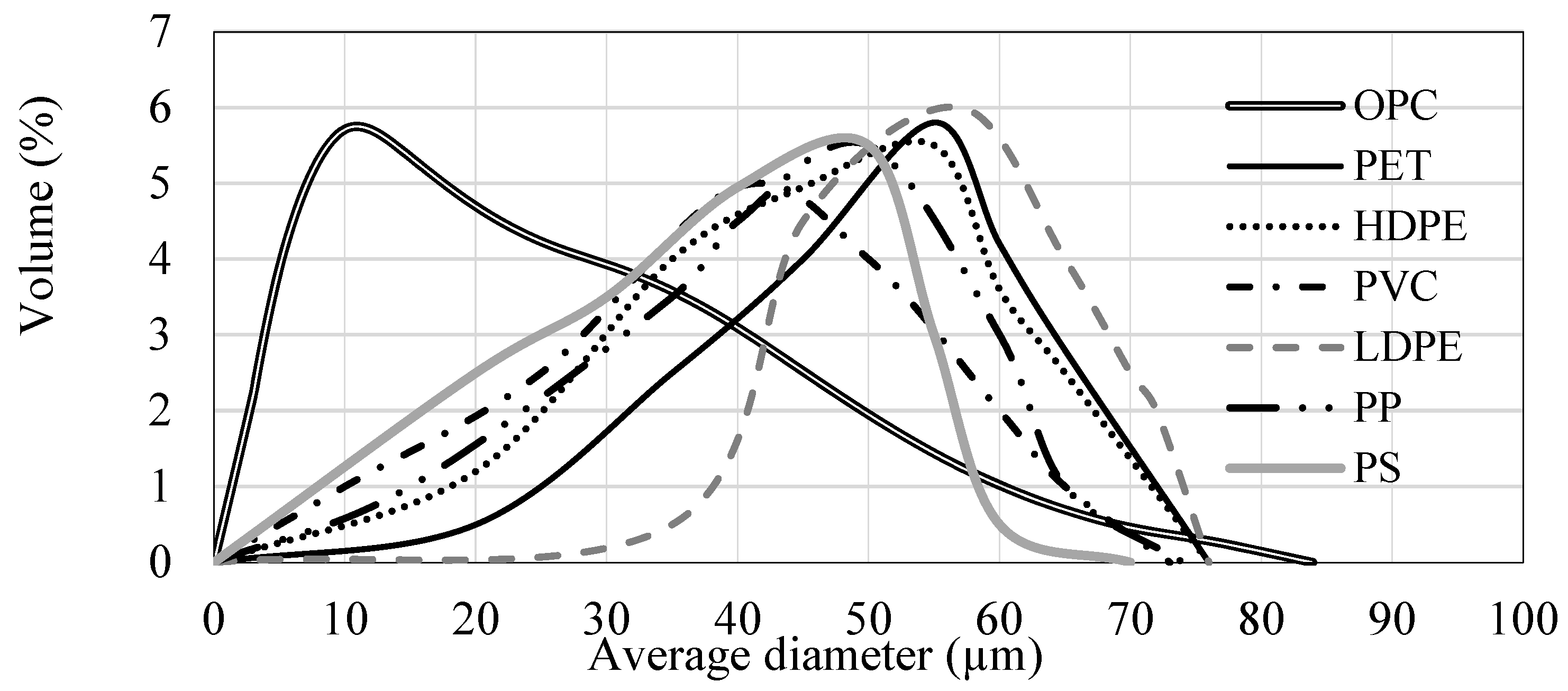

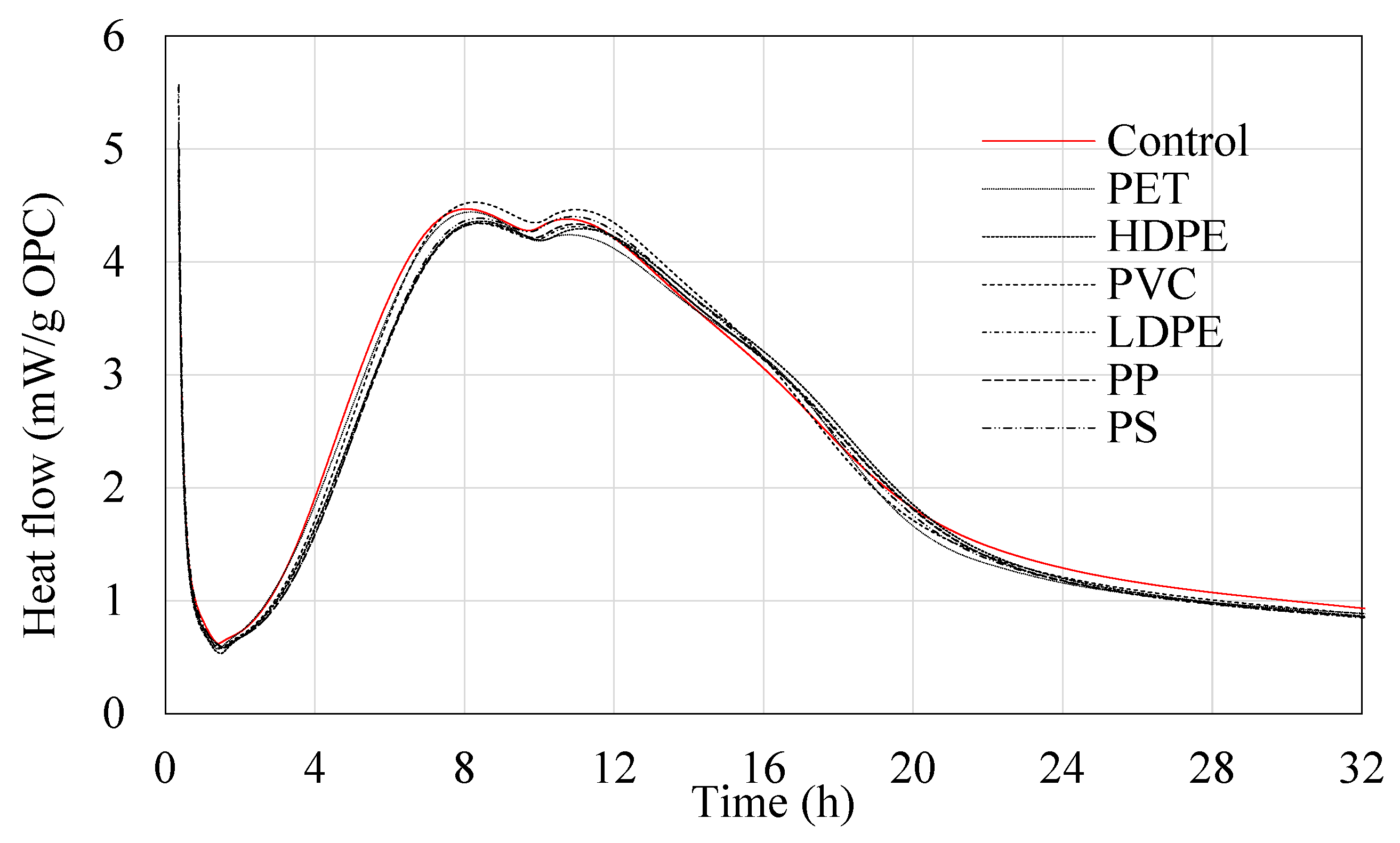

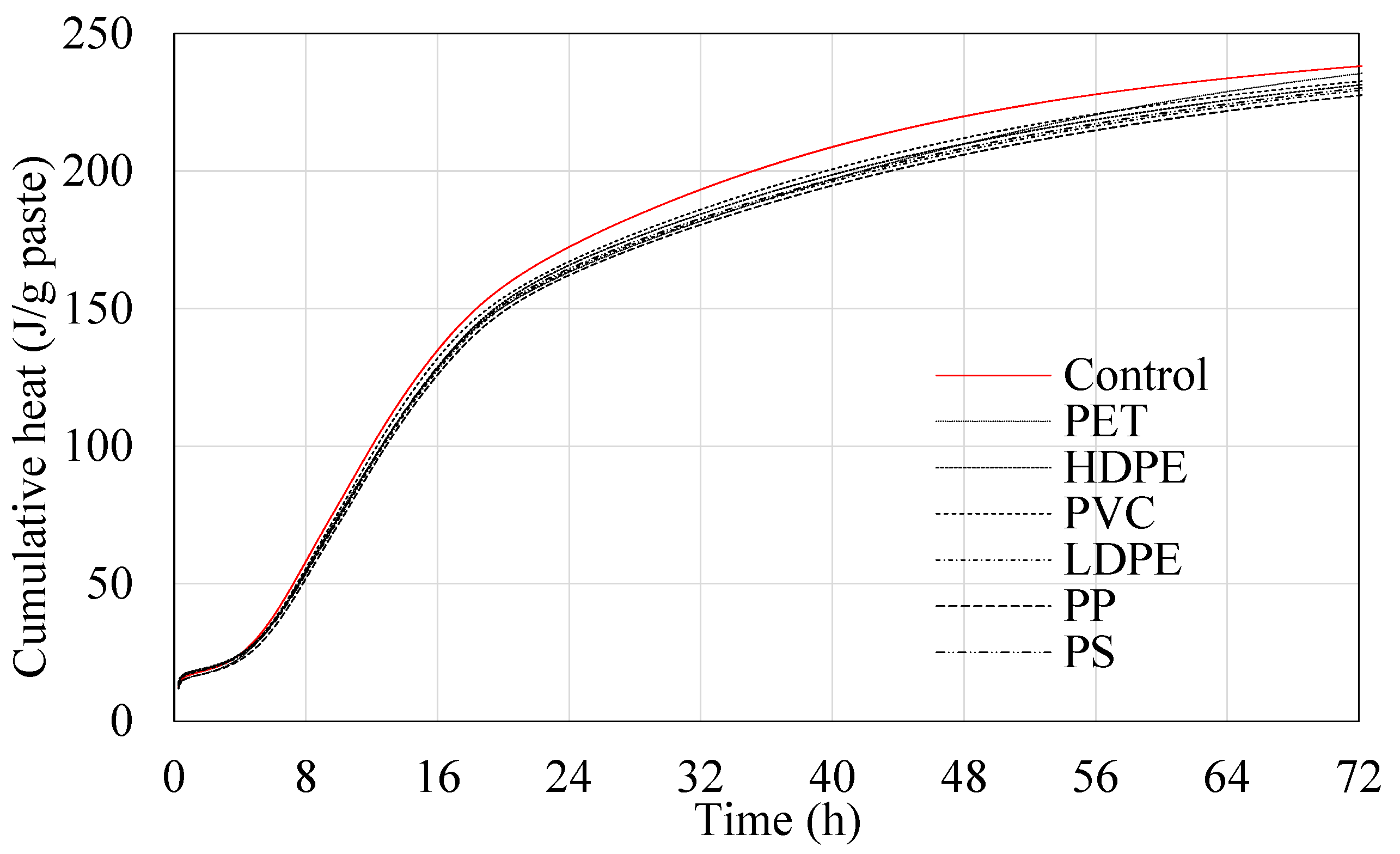

4.1. Effect of Plastic Powder on Cement Hydration

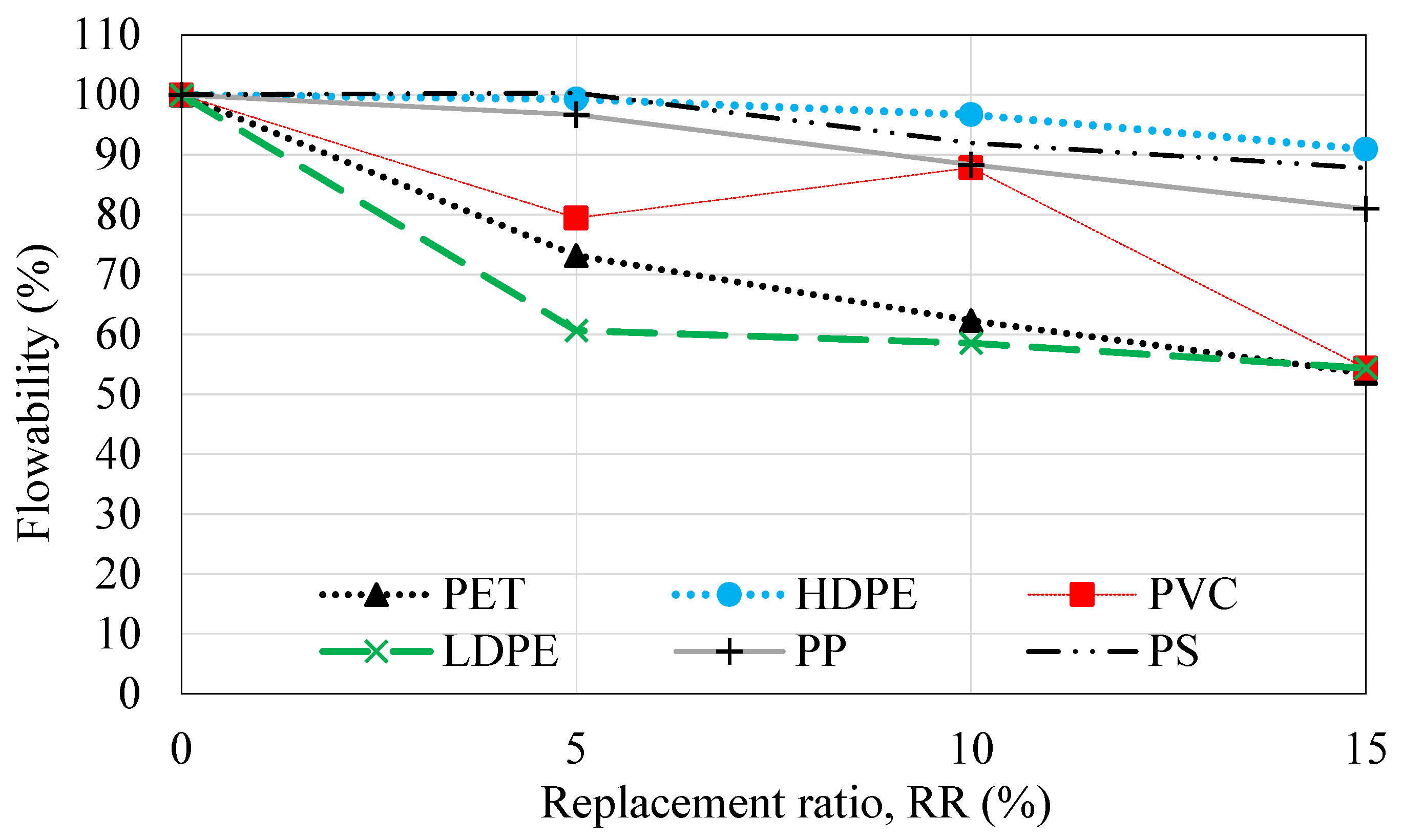

4.2. Effect of Plastic Fine Aggregate on Mortar Flowability

4.3. Effect of Plastic Fine Aggregate on Mortar Dry Density

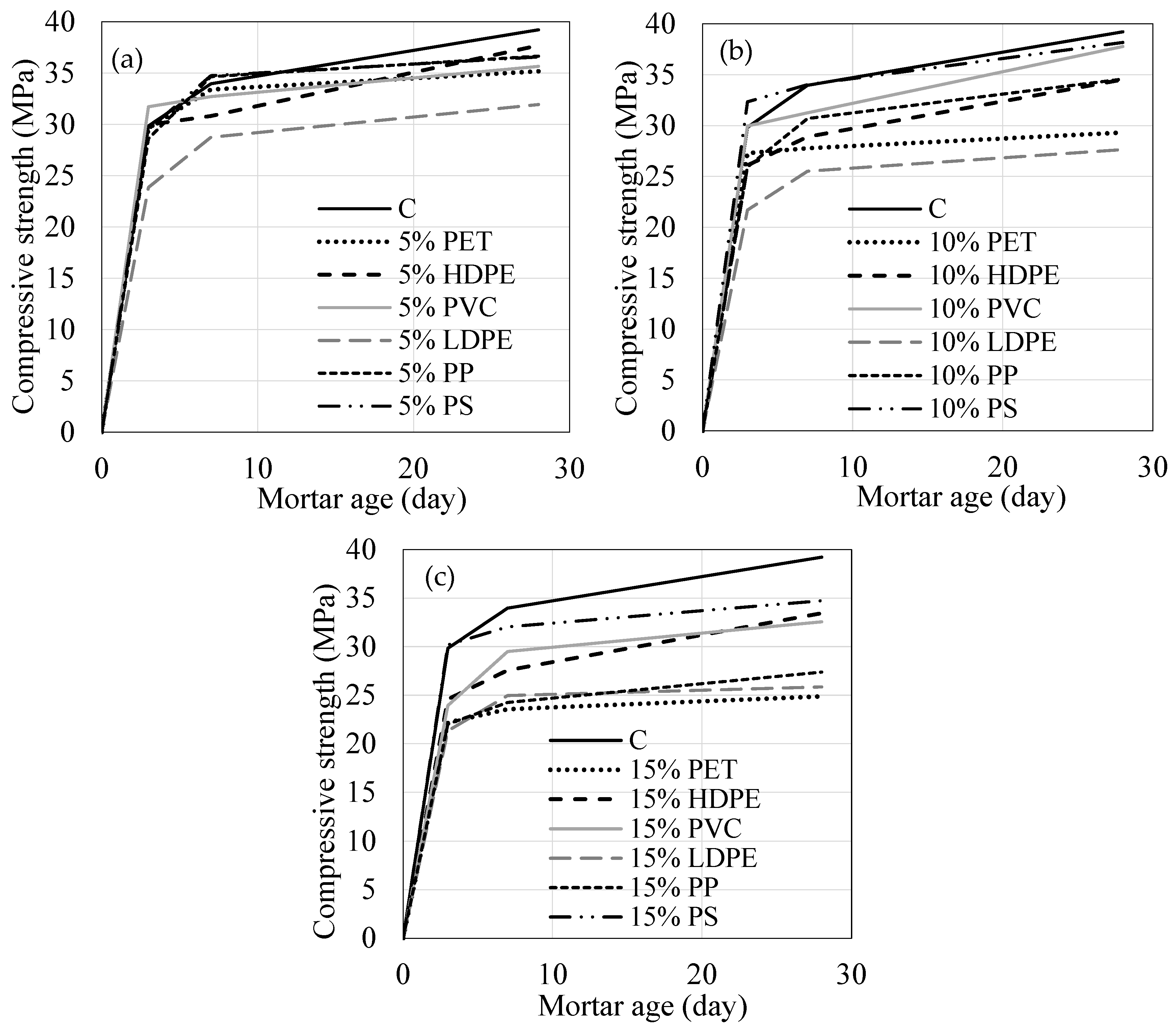

4.4. Effect of Plastic Fine Aggregate on Mortar Compressive Strength

4.5. Effect of Plastic Fine Aggregate on Mortar Flexural Strength

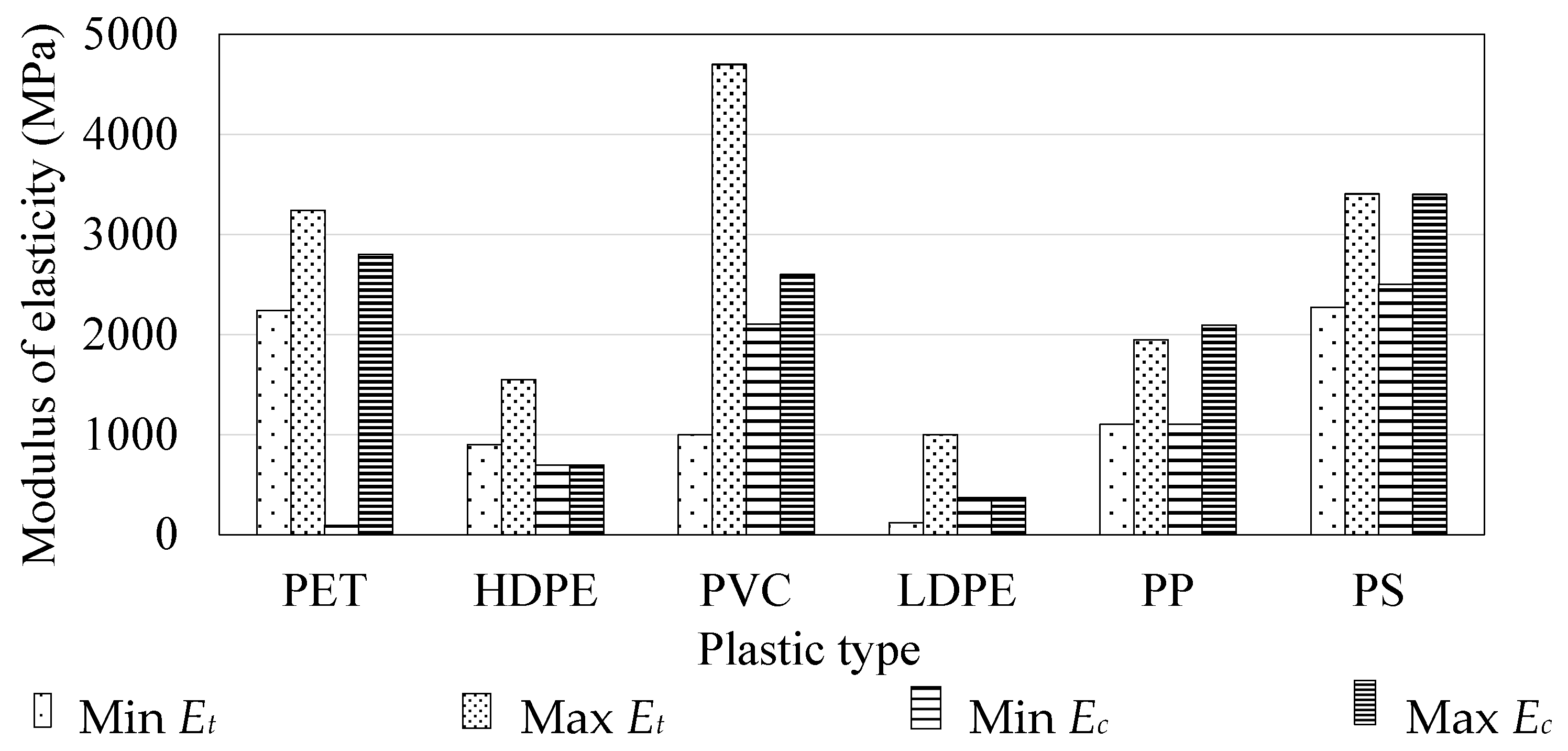

4.6. Parameters Affecting Strength of Mortars Containing Plastic Particles

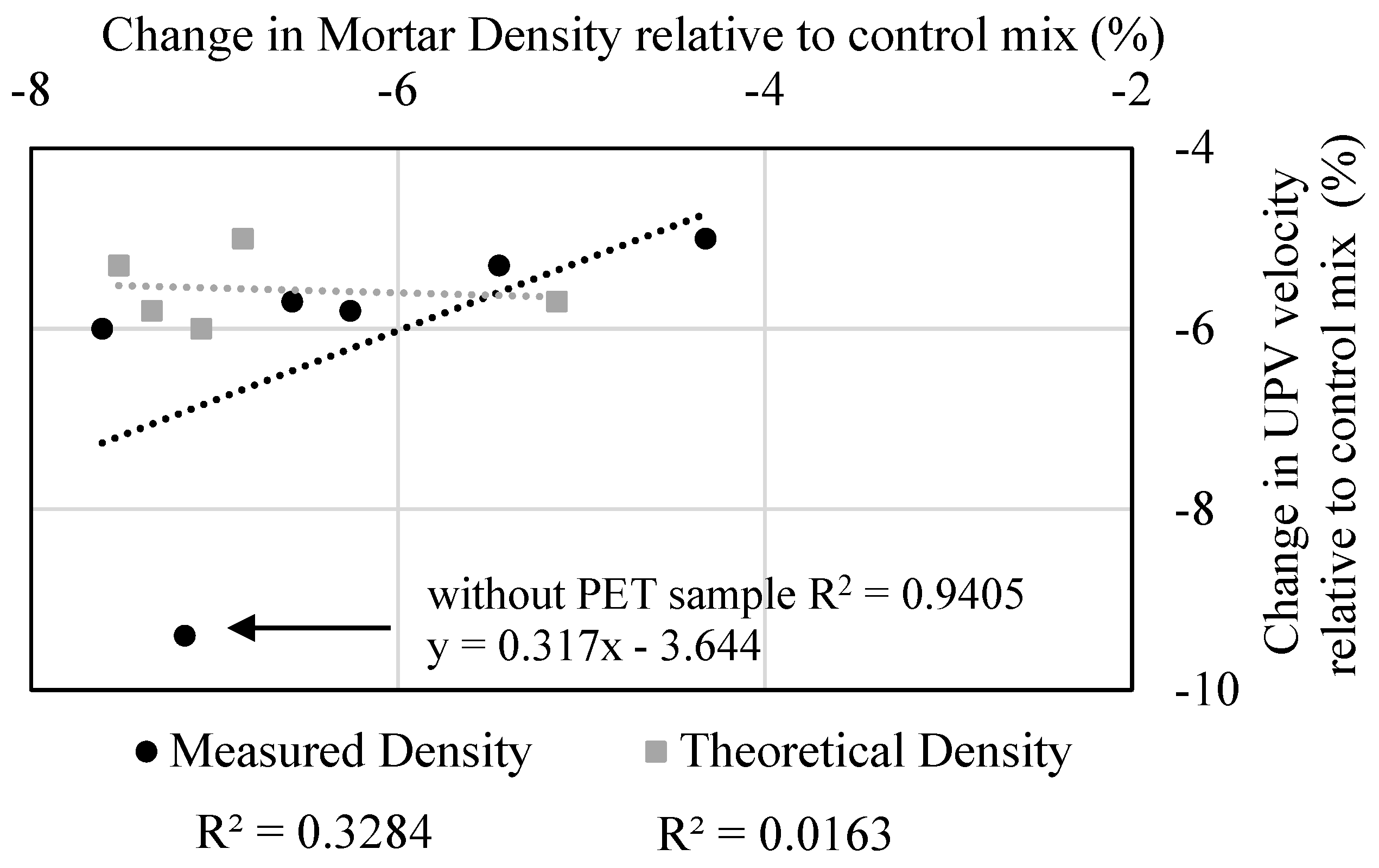

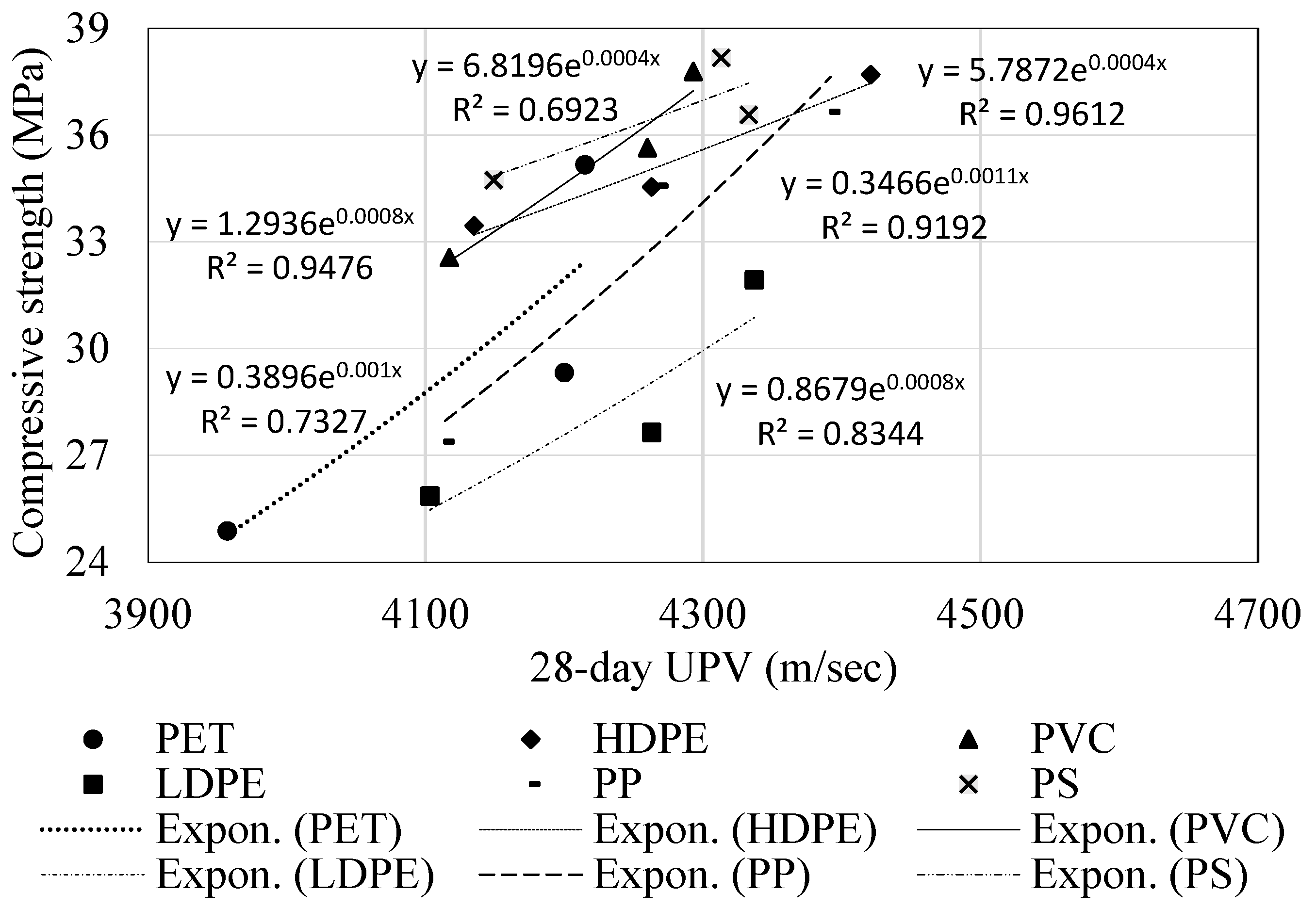

4.7. Effect of Plastic Fine Aggregate on Ultrasonic Pulse Velocity

5. Conclusions

- Plastic powders with a maximum particle size of 75 µm had little effect on early-age hydration reactions and hydration kinetics.

- Mortars with different plastic fine aggregates and RRs showed a wide range of flowability, with PET and LDPE mortars having the lowest flowability. Particle shape strongly affected flowability, and flowability directly influenced hardened mortar properties (density and compressive and flexural strength) due to resulting compaction quality.

- Mortar compressive and flexural strengths declined with increasing content of the plastic fine aggregate.

- After 28 days of curing, with the exception of the LDPE sample, which had slightly reduced strength, replacement ratios of 5% of NFA with PFA had almost no effect on compressive strengths. Only PET and LDPE had compressive strengths significantly lower than that of the control when using a 10% RR.

- Among the different types of plastic-aggregate mortars, incorporating PS fine aggregate resulted in the highest mechanical strength. Meanwhile, the lowest strengths resulted in PET and LDPE mortars.

- The ratio of flexural to compressive strength ranged from 8 to 13%.

- The mechanical strength of the polymer-modified mortar was not directly impacted by the mechanical strength of the polymer type used as a fine aggregate.

- UPV was shown to reflect changes in the porosity of the mortars, rather than changes in mortar density resulting simply from the substitution of sand with low-density plastics.

- UPV measurements revealed that as the amount of PFA increased, the compressive strength of the mortar decreased and porosity increased.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- U.S. Environmental Protection Agency. Greenhouse Gases Equivalencies Calculator: Calculations and References; Environmental Protection Agency: Washington, DC, USA, 2022. [Google Scholar]

- Naik, T.; Singh, S.; Huber, C.; Brodersen, B. Use of post-consumer waste plastics in cement-based composites. Cem. Concr. Res. 1996, 26, 1489–1492. [Google Scholar] [CrossRef]

- Tasong, W.; Lynsdale, C.; Cripps, J. Aggregate-cement paste interface. Part I. Influence of aggregate geochemistry. Cem. Concr. Res. 1999, 29, 1019–1025. [Google Scholar] [CrossRef]

- Choi, Y.; Moon, D.; Kim, Y.; Lachemi, M. Characteristics of mortar and concrete containing fine aggregate manufactured from recycled waste polyethylene terephthalate bottles. Constr. Build. Mater. 2009, 23, 2829–2835. [Google Scholar] [CrossRef]

- Correia, J.; Lima, J.; Brito, J. Post-fire mechanical performance of concrete made with selected plastic waste aggregates. Cem. Concr. Compos. 2014, 53, 187–199. [Google Scholar] [CrossRef]

- Guendouz, M.; Debieb, F.; Boukendakdji, O.; Kadri, E.; Bentchikou, M.; Soualhi, H. Use of plastic in sand concrete. J. Mater. Environ. Sci. 2016, 7, 382–389. [Google Scholar]

- Ceran, O.; Simsek, B.; Uygunoglu, T.; Sara, O. PVC concrete composites: Comparative study with other polymer concrete in terms of mechanical, thermal, and electrical properties. J. Mater. Cycles Waste Manag. 2019, 21, 818–828. [Google Scholar] [CrossRef]

- Zulkernain, N.; Gani, P.; Chuan, N.; Uvarajan, T. Utilisation of plastic waste as aggregate in construction materials: A review. Constr. Build. Mater. 2021, 296, 123669. [Google Scholar] [CrossRef]

- Schaefer, C.; Patil, K.; Ortega, M.; Soriano, C.; Buyukozturk, O.; White, A.; Short, M. Irradiated recycled plastic as a concrete additive for improved chemo-mechanical properties and lower carbon footprint. Waste Manag. 2018, 71, 426–439. [Google Scholar] [CrossRef]

- Liu, T.; Nafees, A.; Javed, M.F.; Aslam, F.; Alabduljabbar, H.; Xiong, J.J.; Malik, M.Y. Comparative study of mechanical properties between irradiated and regular plastic waste as a replacement of cement and fine aggregate for manufacturing of green concrete. Ain Shams Eng. J. 2022, 13, 101563. [Google Scholar] [CrossRef]

- Grigoriadis, K.; Bañuls-Ciscar, J.; Caverzan, A.; Negro, P.; Senaldi, C.; Ceccone, G. Use of irradiated PET plastic waste for partially replacing cement in concrete. Waste Manag. 2023, 170, 193–203. [Google Scholar] [CrossRef]

- Bahij, S.; Omary, S.; Feugeas, F.; Faqiri, A. Fresh and hardened properties of concrete containing different forms of plastic waste: A review. Waste Manag. 2020, 113, 157–175. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, A.A.; Najla’a, H.; Jaber, M.H.; Hassan, R.F.; Hussein, H.H.; Al-Salim, N.H. Experimental investigation of flexural and shear behaviors of reinforced concrete beam containing fine plastic waste aggregates. Structures 2022, 43, 834–846. [Google Scholar] [CrossRef]

- Hamada, H.M.; Al-Attar, A.; Abed, F.; Beddu, S.; Humada, A.M.; Majdi, A.; Thomas, B.S. Enhancing sustainability in concrete construction: A comprehensive review of plastic waste as an aggregate material. Sustain. Mater. Technol. 2024, 40, 00877. [Google Scholar] [CrossRef]

- Guo, Y.C.; Li, X.M.; Zhang, J.; Lin, J.X. A review on the influence of recycled plastic aggregate on the engineering properties of concrete. J. Build. Eng. 2023, 79, 107787. [Google Scholar] [CrossRef]

- Safi, B.; Saidi, M.; Aboutaleb, D.; Maallem, M. The use of plastic waste as fine aggregate in the self-compacting mortars: Effect on physical and mechanical properties. Constr. Build. Mater. 2013, 43, 436–442. [Google Scholar] [CrossRef]

- Frigione, M. Recycling of PET bottles as fine aggregate in concrete. Waste Manag. 2010, 30, 1101–1106. [Google Scholar] [CrossRef]

- Senhadji, Y.; Siad, H.; Escadeillas, G.; Benosman, A.S.; Chihaoui, R.; Mouli, M.; Lachemi, M. Physical, mechanical and thermal properties of lightweight composite mortars containing recycled polyvinyl chloride. Constr. Build. Mater. 2019, 195, 198–207. [Google Scholar] [CrossRef]

- Harihanandh, M.; Karthik, P. Feasibility study of recycled plastic waste as fine aggregates in concrete. Mater. Today Proc. 2022, 52, 1807–1811. [Google Scholar] [CrossRef]

- Rahmani, E.; Dehestani, M.; Beygi, M.; Allahyari, H.; Nikbin, I. On the mechanical properties of concrete containing waste PET particles. Constr. Build. Mater. 2013, 47, 1302–1308. [Google Scholar] [CrossRef]

- Cordoba, L.; Barrera, G.; Diaz, C.; Nunez, F.; Yanez, A. Effects on mechanical properties of recycled PET in cement-based composite. Int. J. Polym. Sci. 2013, 2013, 763–776. [Google Scholar]

- Azhdarpour, A.; Nikoudel, M.; Taheri, M. The effect of using polyethylene terephthalate particles on physical and strength-related properties of concrete: A laboratory evaluation. Constr. Build. Mater. 2016, 109, 55–62. [Google Scholar] [CrossRef]

- Vaillancourt, C.; Sorelli, L. Characterization of concrete composites with recycled plastic aggregates from post-consumer material streams. Constr. Build. Mater. 2018, 182, 561–572. [Google Scholar] [CrossRef]

- Ferreira, L.; Brito, J.; Saikia, N. Influence of curing conditions on the mechanical performance of concrete containing recycled plastic aggregate. Constr. Build. Mater. 2012, 36, 196–204. [Google Scholar] [CrossRef]

- Islam, M.; Meherier, M.; Islam, A. Effects of waste pet as coarse aggregate on the fresh and hardened properties of concrete. Constr. Build. Mater. 2016, 125, 946–951. [Google Scholar] [CrossRef]

- Tang, W.; Lo, Y.; Nadeem, A. Mechanical and drying shrinkage properties of structural-graded polystyrene aggregate concrete. Cem. Concr. Compos. 2008, 30, 403–409. [Google Scholar] [CrossRef]

- Chen, C.; Jaffe, N.; Koppitz, M.; Weimer, W.; Polocoser, A. Concrete mixture with plastic as fine aggregate replacement. Int. J. Adv. Mech. Civ. Eng. 2015, 2, 49–53. [Google Scholar]

- Sáez del Bosque, I.; Zhu, W.; Howind, T.; Matías, A.; Sánchez De Rojas, M.; Medina, C. Properties of interfacial transition zones (ITZS) in concrete containing recycled mixed aggregate. Cem. Concr. Compos. 2017, 81, 25–34. [Google Scholar] [CrossRef]

- Hannawi, K.; Prince, W.; Bernard, S. Effect of thermoplastic aggregates incorporation on physical, mechanical and transfer behavior of cementitious materials. Waste Biomass Valor. 2010, 1, 251–259. [Google Scholar] [CrossRef]

- Quiroga, P.; Fowler, D. The Effects of Aggregates Characteristics on the Performance of Portland Cement Concrete; Research Report ICAR 104-1F; Aggregates Foundation for Technology, Research, and Education National Sand, Stone, and Gravel Association: Alexandria, VA, USA, 2003. [Google Scholar]

- Li, X.; Ling, T.; Mo, K. Functions and Impacts of Plastic/Rubber Wastes as Eco-Friendly Aggregate in Concrete—A Review. Constr. Build. Mater. 2020, 240, 117869. [Google Scholar] [CrossRef]

- ASTM-C128-17; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM-C136-17; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2021.

- Akay, M. Introduction to Polymer Science and Technology, 1st ed.; Ventus Publishing: Eire, CO, USA, 2015; ISBN 978-87-403-0087-1. [Google Scholar]

- Guerra, E.; Lima, E. Handbook of Polymer Synthesis, Characterization, and Processing, 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013; ISBN 978-04-706-3032-7. [Google Scholar]

- van Krevelen, D.W.; te Nijenhuis, K. Properties of Polymers, 4th ed.; Linacre House: Oxford, UK, 2009; ISBN 978-0-08-054819-7. [Google Scholar]

- Gesoglu, M.; Guneyisi, E.; Nansu, O.; Etli, S.; Alhassan, M. Mechanical and fracture characteristics of self-compacting concretes containing different percentages of plastic waste powder. Constr. Build. Mater. 2017, 140, 562–569. [Google Scholar] [CrossRef]

- Khan, M.; Huat, H.; Dun, M.; Sutanto, M.; Jarghouyeh, E.; Zoorob, S. Effect of irradiated and non-irradiated waste PET based cementitious grouts on flexural strength of semi-flexible pavement. Materials 2019, 12, 4133. [Google Scholar] [CrossRef] [PubMed]

- ASTM-C1437-17; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM-C109-17; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM-C39-17; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM-C348-17; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2021.

- Pierre, F.; Philibert, A.; Giroux, B.; Rivard, P. Concrete quality designation based on ultrasonic pulse velocity. Constr. Build. Mater. 2016, 125, 1022–1027. [Google Scholar] [CrossRef]

- ASTM-597-17; Standard Test Method for Pulse Velocity Through Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- Abduallah, R.M.A. Recycling Plastic Materials in Concrete Infrastructure. Ph.D. Thesis, Ohio State University, Columbus, OH, USA, 2021. [Google Scholar]

- Bentz, D.; Barrett, T.; Igor De la Varga, W.; Weiss, J. Relating compressive strength to heat release in mortars. Adv. Civ. Eng. Mater. 2012, 1, 20120002. [Google Scholar] [CrossRef]

- Ge, Z.; Wang, K.; Sandberg, P.; Ruiz, J. Characterization and performance prediction of cement-based materials using a simple isothermal calorimeter. J. Adv. Concr. Technol. 2009, 7, 355–366. [Google Scholar] [CrossRef]

- Zhiping, L.; Dagang, L.; Xiaojian, G. Analysis of correlation between hydration heat release and compressive strength for blended cement pastes. Constr. Build. Mater. 2020, 260, 120436. [Google Scholar]

- Sule, J.; Emmanuel, S.; Joseph, I.; Ibhadobe, O.; Buba, Y. Use of waste plastics in cement-based composite for lightweight concrete production. Int. J. Res. Eng. Technol. 2017, 2, 44–54. [Google Scholar]

- Dawood, A.; Al-khazrahi, H.; Falih, R. Physical and mechanical properties of concrete containing pet wastes as a partial replacement for fine aggregates. Case Stud. Constr. Mater. 2021, 14, e00482. [Google Scholar] [CrossRef]

- Vakkar, V.; Gupta, R.; Kumar, N. Study on partial replacement of pulverized plastic as fine aggregate in rigid pavements. Int. Res. J. Eng. Technol. 2019, 6, 56–72. [Google Scholar]

- Albano, C.; Camacho, N.; Hernandez, M.; Matheus, A.; Gutierrez, A. Influence of content and particle size of waste PET bottles on concrete behavior at different w/c ratios. Waste Manag. 2009, 29, 2707–2716. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Gu, L.; Gholampour, A. Short-term mechanical properties of concrete containing recycled polypropylene coarse aggregates under ambient and elevated temperature. J. Mater. Civ. Eng. 2017, 29, 04017191. [Google Scholar] [CrossRef]

- Zvonaric, M.; Barisic, I.; Galic, M.; Minazek, K. Influence of laboratory compaction method on compaction and strength characteristics of unbound and cement-bound mixtures. Appl. Sci. 2021, 11, 4750. [Google Scholar] [CrossRef]

- Budhu, M. Soil Mechanics Fundamental, 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2015; ISBN 978-0-470-57795-0. [Google Scholar]

- Tesinova, P. Advances in Composite Materials: Analysis of Natural and Man-Made Materials; Intechopen: London, UK, 2011; ISBN 978-9-533-07449-8. [Google Scholar]

- Vergara, L.; Miralles, R.; Gosálbez, J.; Juanes, F.J.; Ullate, L.G.; Anaya, J.J.; Izquierdo, M.A.G. NDE ultrasonic methods to characterise the porosity of mortar. NDT E Int. 2001, 34, 557–562. [Google Scholar] [CrossRef]

- Lafhaj, Z.; Goueygou, M.; Djerbi, A.; Kaczmarek, M. Correlation between porosity, permeability and ultrasonic parameters of mortar with variable water/cement ratio and water content. Cem. Concr. Res. 2006, 36, 625–633. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Almeshal, I.; Magbool, H.M.; Alabduljabbar, H.; Alyousef, R. Performance of sustainable concrete containing different types of recycled plastic. J. Clean. Prod. 2021, 328, 129517. [Google Scholar] [CrossRef]

- Mohammed, A.A. Compressive strength-ultrasonic pulse velocity relationship of concrete containing plastic waste. In Proceedings of the 3rd International Conference on Recent Innovations in Engineering (ICRIE 2020), Duhok, Iraq, 9–10 September 2020; p. 012010. [Google Scholar]

- Alfahdawi, I.H.; Osman, S.A.; Hamid, R.; Al-Hadithi, A.I. Modulus of elasticity and ultrasonic pulse velocity of concrete containing polyethylene terephthalate (PET) waste heated to high temperature. J. Eng. Sci. Technol. 2018, 13, 3577–3592. [Google Scholar]

- Demirboga, R.; Türkmen, İ.; Karakoc, M.B. Relationship between ultrasonic velocity and compressive strength for high-volume mineral-admixtured concrete. Cem. Concr. Res. 2004, 34, 2329–2336. [Google Scholar] [CrossRef]

| Material | Specific Gravity (SG) | Fineness Modulus (FM) | Water Absorption (%) |

|---|---|---|---|

| Sand | 2.65 | - | 0.81 |

| PET | 1.30 | 3.20 | 0.10 |

| HDPE | 0.72 | 3.20 | 0.00 |

| PVC | 1.37 | 3.20 | 0.03 |

| LDPE | 0.80 | 3.20 | 0.01 |

| PP | 0.76 | 3.20 | 0.00 |

| PS | 0.90 | 3.20 | 0.02 |

| Mix | w/c | Water (kg/m3) | Volume Replacement Ratio, RR | Cement (kg/m3) | Aggregates (kg/m3) | |

|---|---|---|---|---|---|---|

| Sand | Plastic | |||||

| C | 0.485 | 254 | 0% | 525 | 1442 | 0 |

| PET | 0.485 | 254 | 5% | 525 | 1370 | 35 |

| 10% | 525 | 1298 | 71 | |||

| 15% | 525 | 1226 | 106 | |||

| HDPE | 0.485 | 254 | 5% | 525 | 1370 | 20 |

| 10% | 525 | 1298 | 39 | |||

| 15% | 525 | 1226 | 59 | |||

| PVC | 0.485 | 254 | 5% | 525 | 1370 | 37 |

| 10% | 525 | 1298 | 75 | |||

| 15% | 525 | 1226 | 112 | |||

| LDPE | 0.485 | 254 | 5% | 525 | 1370 | 22 |

| 10% | 525 | 1298 | 43 | |||

| 15% | 525 | 1226 | 64 | |||

| PP | 0.485 | 254 | 5% | 525 | 1370 | 21 |

| 10% | 525 | 1298 | 42 | |||

| 15% | 525 | 1226 | 62 | |||

| PS | 0.485 | 254 | 5% | 525 | 1370 | 24 |

| 10% | 525 | 1298 | 49 | |||

| 15% | 525 | 1226 | 73 | |||

| Mortar Density (kg/m3) | |||||||

|---|---|---|---|---|---|---|---|

| RR | Cement | PET | HDPE | PVC | LDPE | PP | PS |

| 0% | Theoretical | 2210 | 2210 | 2210 | 2210 | 2210 | 2210 |

| Experimental | 2220 | 2220 | 2220 | 2220 | 2220 | 2220 | |

| Difference | 0.5% | 0.5% | 0.5% | 0.5% | 0.5% | 0.5% | |

| Air Content | 3.5% | 3.5% | 3.5% | 3.5% | 3.5% | 3.5% | |

| 5% | Theoretical | 2174 | 2158 | 2176 | 2160 | 2158 | 2163 |

| Experimental | 2160 | 2168 | 2160 | 2127 | 2188 | 2203 | |

| Difference | −0.6% | 0.5% | −0.7% | −1.6% | 1.4% | 1.8% | |

| Air Content | 4.6% | 3.5% | 4.7% | 5.5% | 2.6% | 2.2% | |

| 10% | Theoretical | 2137 | 2106 | 2141 | 2110 | 2108 | 2116 |

| Experimental | 2121 | 2149 | 2139 | 2076 | 2129 | 2138 | |

| Difference | −0.8% | 2.0% | −0.1% | −1.6% | 1.0% | 1.1% | |

| Air Content | 4.7% | 2.0% | 4.0% | 5.5% | 3.0% | 3.0% | |

| 15% | Theoretical | 2100 | 2053 | 2106 | 2063 | 2057 | 2068 |

| Experimental | 2061 | 2099 | 2074 | 2051 | 2081 | 2124 | |

| Difference | −1.9% | 2.2% | −1.6% | −0.6% | 1.1% | 2.7% | |

| Air Content | 5.75% | 1.8% | 5.5% | 4.5% | 2.8% | 1.4% | |

| Mix | RR | Compressive Strength | Flexural Strength | K | ||

|---|---|---|---|---|---|---|

| Value (MPa) | Change % | Value (MPa) | Change % | |||

| C | 0% | 39.2 ± 1.8 | − | 4.41 ± 0.11 | − | 11% |

| PET | 5% | 35.1 ± 1.2 | −10 | 3.46 ± 0.42 | −21 | 10% |

| 10% | 29.3 ± 0.6 | −25 | 2.91 ± 0.08 | −34 | 10% | |

| 15% | 24.9 ± 1.6 | −37 | 1.85 ± 0.01 | −58 | 8% | |

| HDPE | 5% | 37.7 ± 1.0 | −4 | 3.50 ± 0.14 | −20 | 9% |

| 10% | 34.5 ± 2.4 | −12 | 3.30 ± 0.05 | −25 | 10% | |

| 15% | 33.5 ± 0.8 | −15 | 3.32 ± 0.05 | −26 | 10% | |

| PVC | 5% | 35.7 ± 0.8 | −9 | 4.54 ± 0.31 | 3 | 13% |

| 10% | 37.8 ± 1.7 | −4 | 4.01 ± 0.12 | −9 | 11% | |

| 15% | 32.6 ± 2.1 | −17 | 3.26 ± 0.13 | −26 | 10% | |

| LDPE | 5% | 31.9 ± 1.3 | −19 | 4.03 ± 0.54 | −11 | 13% |

| 10% | 27.6 ± 0.1 | −30 | 3.29 ± 0.24 | −25 | 12% | |

| 15% | 25.9 ± 0.9 | −34 | 2.75 ± 0.07 | −37 | 11% | |

| PP | 5% | 36.7 ± 2.6 | −7 | 3.96 ± 0.12 | −10 | 11% |

| 10% | 34.6 ± 2.2 | −12 | 3.33 ± 0.47 | −22 | 10% | |

| 15% | 27.4 ± 0.8 | −30 | 2.95 ± 0.02 | −33 | 11% | |

| PS | 5% | 36.6 ± 1.0 | −7 | 4.43 ± 0.08 | 0 | 12% |

| 10% | 38.2 ± 1.8 | −3 | 3.87 ± 0.08 | −12 | 10% | |

| 15% | 34.7 ± 1.4 | −11 | 3.41 ± 0.21 | −23 | 10% | |

| RR | UPV Change by Mortar Type (%) | |||||

|---|---|---|---|---|---|---|

| PET | HDPE | PVC | LDPE | PP | PS | |

| 5% | −3.5 | 1.2 | −2.5 | −0.7 | 0.6 | −0.8 |

| 10% | −3.8 | −1.8 | −1.7 | −2.4 | −2.3 | −1.2 |

| 15% | −9.4 | −5.3 | −5.7 | −6.0 | −5.8 | −5.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abduallah, R.; Burris, L.; Castro, J.; Sezen, H. Utilization of Different Types of Plastics in Concrete Mixtures. Constr. Mater. 2025, 5, 39. https://doi.org/10.3390/constrmater5020039

Abduallah R, Burris L, Castro J, Sezen H. Utilization of Different Types of Plastics in Concrete Mixtures. Construction Materials. 2025; 5(2):39. https://doi.org/10.3390/constrmater5020039

Chicago/Turabian StyleAbduallah, Ramzi, Lisa Burris, Jose Castro, and Halil Sezen. 2025. "Utilization of Different Types of Plastics in Concrete Mixtures" Construction Materials 5, no. 2: 39. https://doi.org/10.3390/constrmater5020039

APA StyleAbduallah, R., Burris, L., Castro, J., & Sezen, H. (2025). Utilization of Different Types of Plastics in Concrete Mixtures. Construction Materials, 5(2), 39. https://doi.org/10.3390/constrmater5020039