Structural Build-Up of Cement Pastes: A Comprehensive Overview and Key Research Directions

Abstract

1. Introduction

2. Origins and Mechanisms

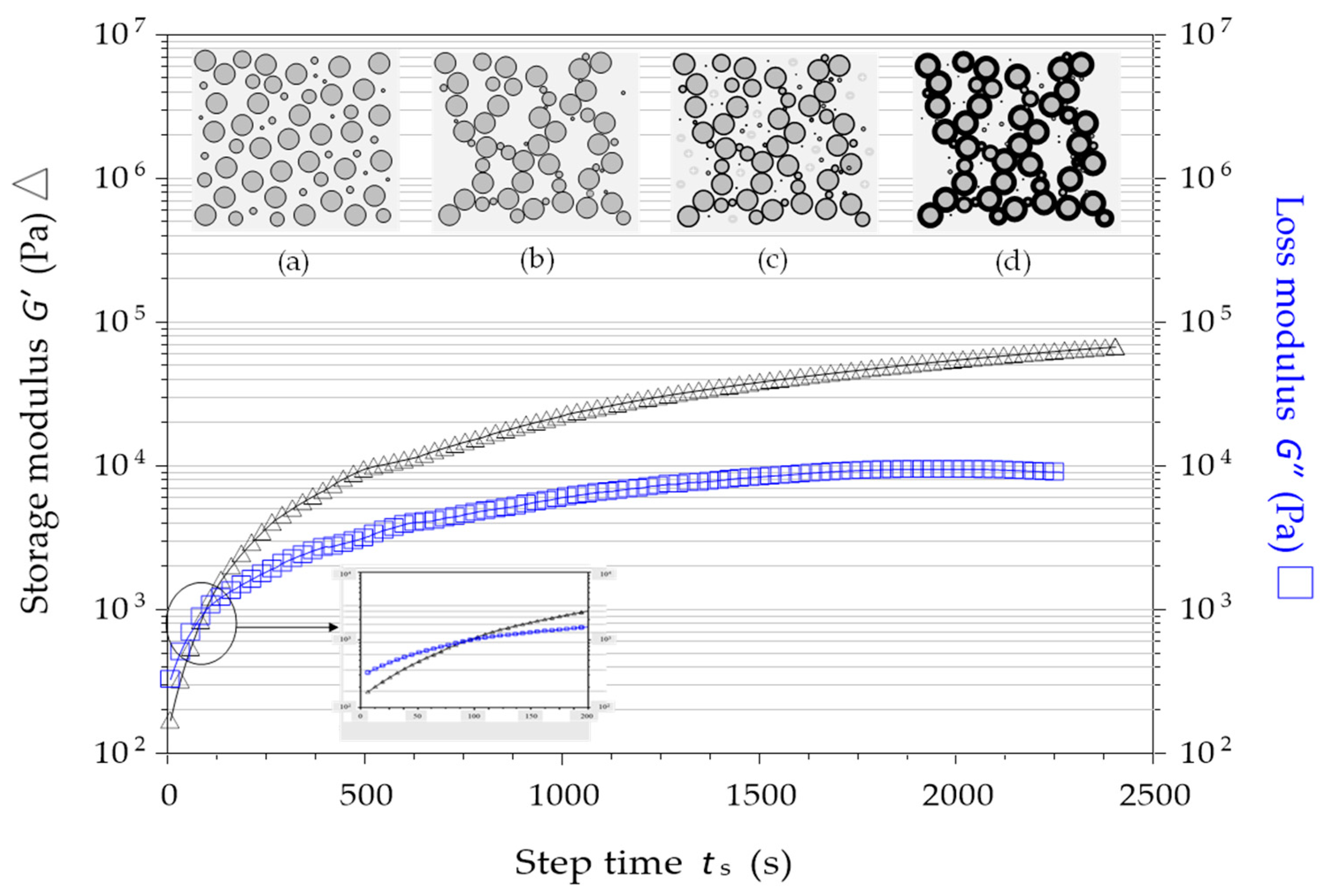

- The first stage corresponds to the non-linear evolution of the storage modulus with time. The mechanisms taking place in this stage are complex. Just after the end of mixing, colloidal interactions between cement particles drive the formation of a network (Figure 1a). According to Han et al. [23], in cementitious pastes characterized by a high ionic strength and a low zeta potential, the attractive Van der Waals forces tend to dominate over the electrostatic forces. This behavior can be attributed to the significant screening effect caused by the high concentration of ions in the solution, which reduces the range and magnitude of the electrostatic interactions between particles. As a result, the attractive Van der Waals forces, which are short-range and non-specific, become the primary drivers of particle interactions. Thus, the attractive Van der Waals forces enable the particles to come together and form a percolated colloidal structure able to withstand minimum stress. This network provides the foundation for the material’s subsequent structural evolution. Furthermore, the initial reaction of C3A can also contribute to the initial increase in the storage modulus. This first stage seems mainly controlled by percolation, notably in cement pastes with a low solid volume fraction or in the presence of admixtures;

- In the second stage, the storage modulus increases linearly with time. The mechanisms behind this increase are a subject of debate and do not achieve a consensus because of the interplay of the roles of particle interaction, cement hydration, and hydration product interaction. One of the most widely accepted hypotheses is that the observed increase in the storage modulus at this stage results from the formation of early hydration products, such as calcium–silicate–hydrate (C-S-H) [25] and ettringite, which create rigid bridges between the cement particles [24]. These hydration products act as mechanical connectors, reinforcing the initial network and transforming it into a more rigid and interconnected framework [27,28];

- The third stage overlaps with the acceleration period of cement hydration and the onset of setting. In this stage marked by an exponential increase in the storage modulus, the inter-particle connections are further strengthened through the continued hydration and densification of the microstructure. The network becomes increasingly rigid as more hydration products fill the pore space. This rigidification [29] is mainly due to the increase in the contact area between cement particles due to the precipitation of C-S-H.

3. Measurement Methods

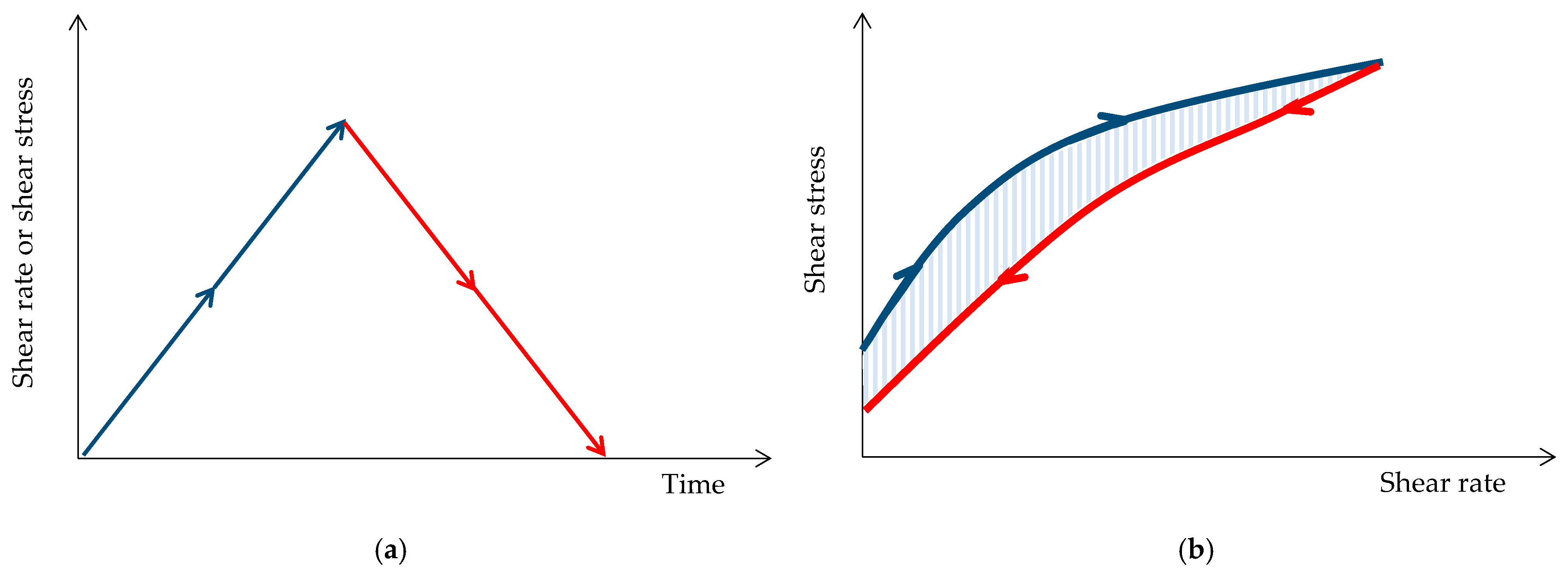

3.1. Hysteresis Loop Test

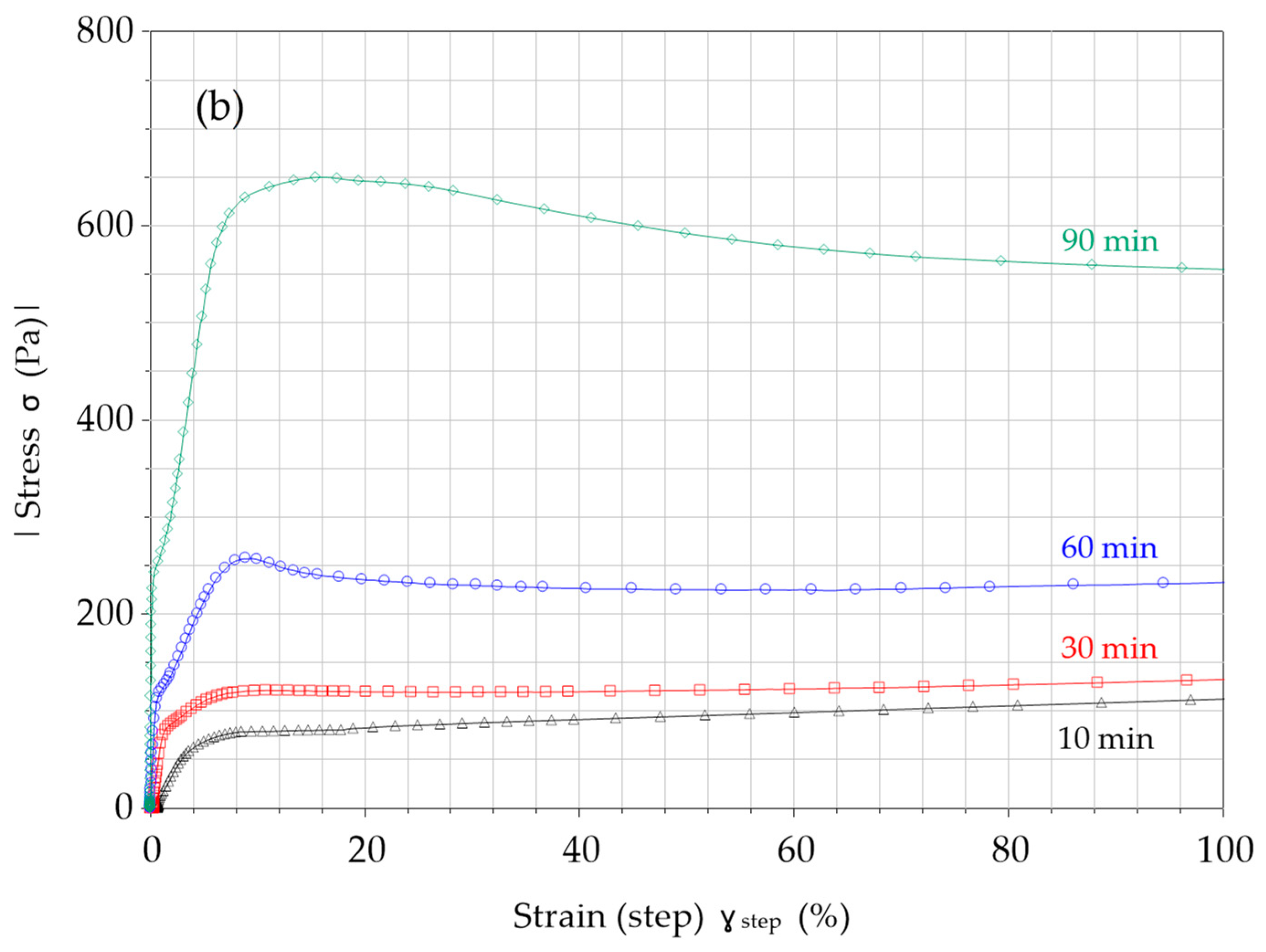

3.2. Static Yield Stress Measurements

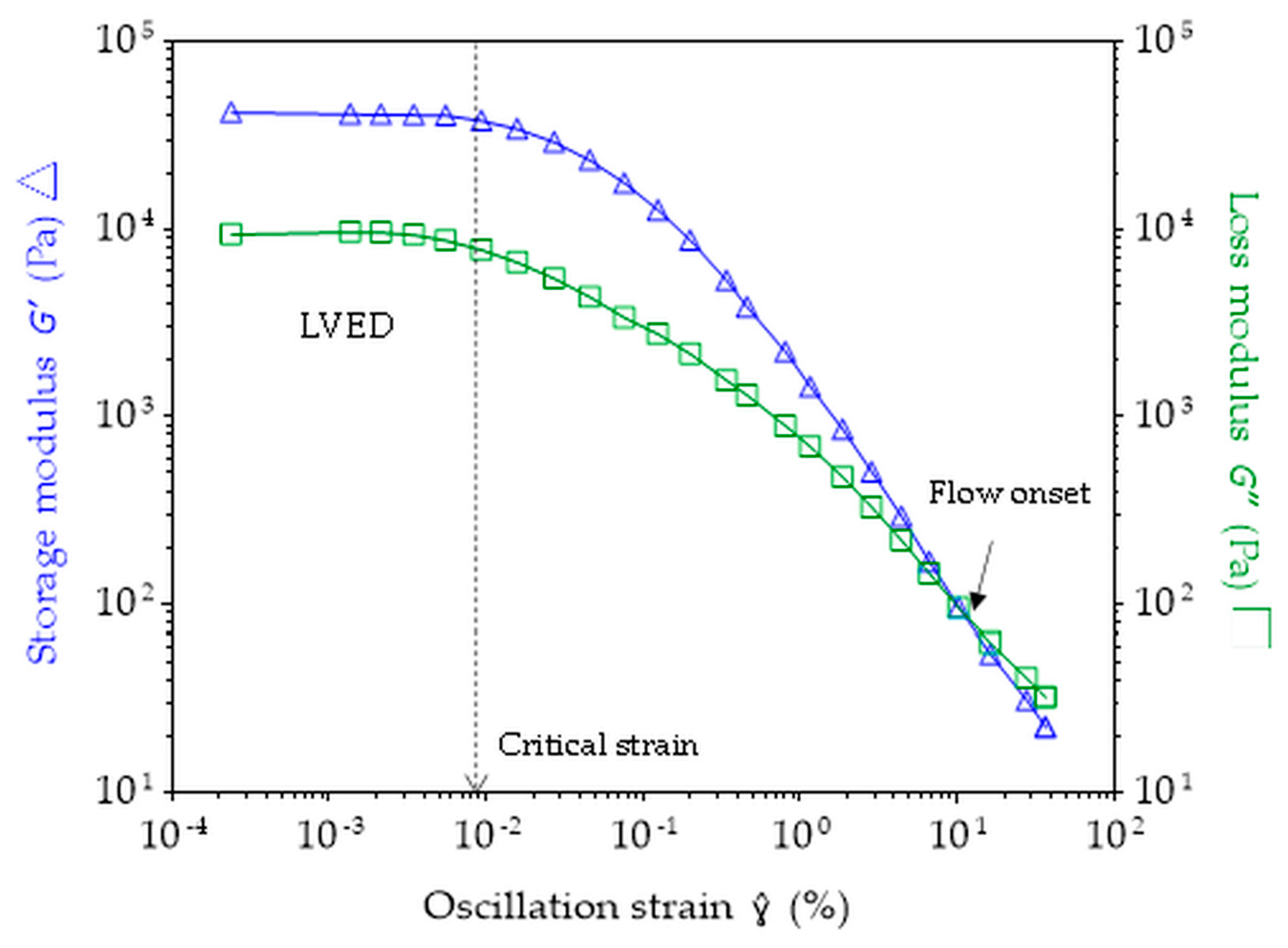

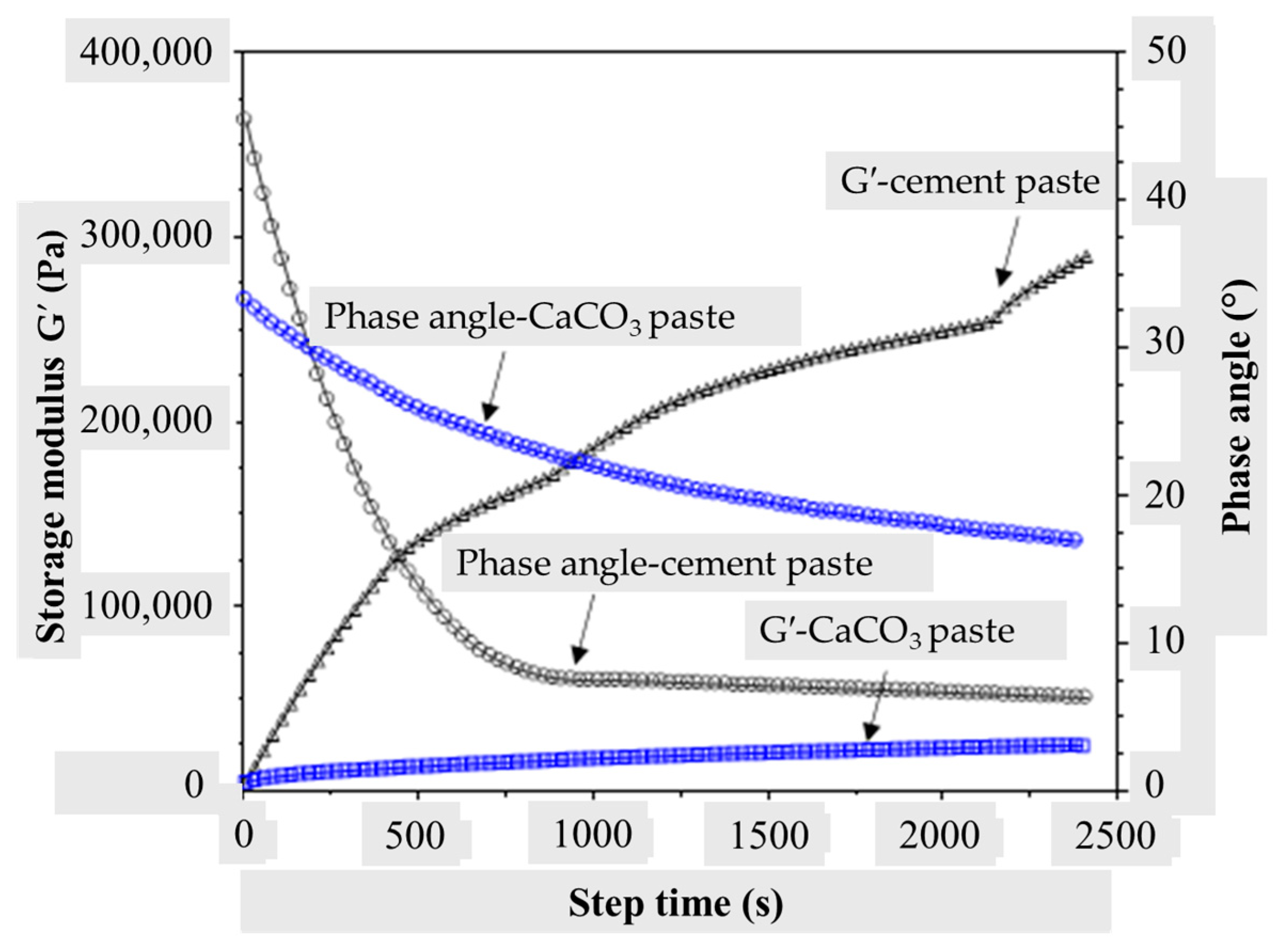

3.3. Small-Amplitude Oscillatory Shearing (SAOS)

4. Structural Build-Up Influencing Factors

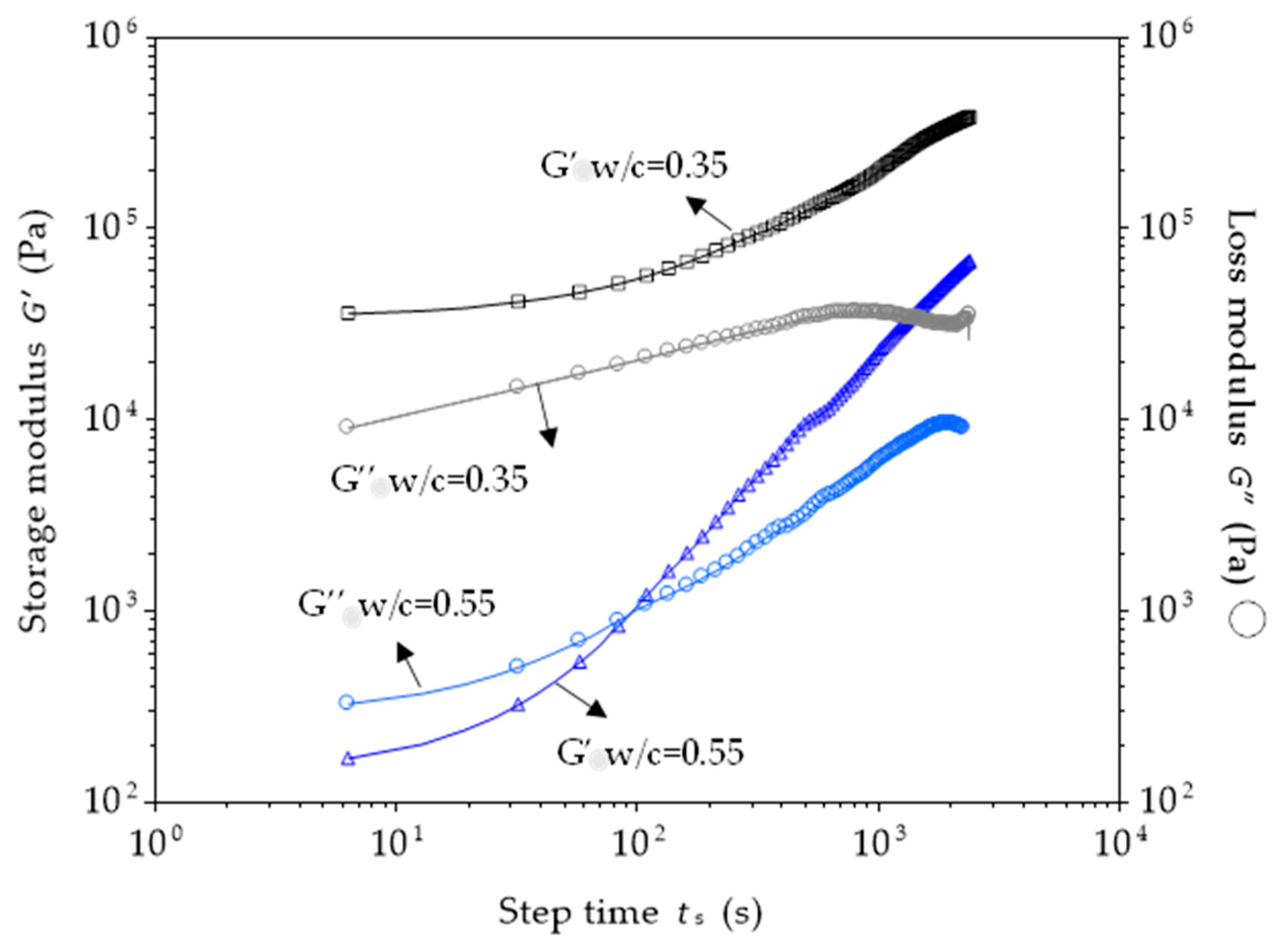

4.1. Solid Volume Fraction (Or Water-to-Binder Ratio)

4.2. Supplementary Cementitious Materials (SCMs)

4.3. Admixtures

4.4. Temperature

5. Conclusions

- The structural build-up is divided into three main stages. These stages are driven by colloidal interactions between cement particles, cement hydration, and inter-particle connection;

- Cement hydration and the formation of hydration products such as ettringite and C-S-H play a crucial role in the evolution of structural build-up. However, further investigation is needed into the effect of the dormant period, during which the dissolution of cement particles supersaturates the pore solution and increases its ionic strength. This condition can affect the structural build-up by promoting particle flocculation and the precipitation of hydrates on the surface of the particles;

- The measurement methods of structural build-up are strongly influenced by the shear rate, shearing time, and disruptive shear technique. The oscillatory shear has a more significant effect on dispersing concentrated cement suspensions than the rotational shear;

- A higher w/b ratio, plasticizers, and superplasticizers decrease the structural build-up, while VMAs, SCMs, mineral admixtures, and temperature have the opposite effect. However, the effect of mineral admixtures is dose dependent. They enhance the structural build-up up to a certain dosage threshold, beyond which a further increase may lead to a reduction in structural build-up;

- The effect of the w/b ratio on structural build-up becomes more complex when SCMs are used, as variations in rheological properties are also influenced by SCM properties such as water demand, morphology, structure, and reactivity;

- The effect of mineral admixtures such as silica fume, ground slag, fly ash, attapulgite, nano calcium carbonate, and nano silica on structural build-up is more pronounced when the w/b ratio decreases;

- The effect of temperature is primarily linked to its role as a hydration accelerator, but it is strongly influenced by the w/b ratio and other mix properties, such as cement fineness and SCMs.

6. Research Needs

Author Contributions

Funding

Conflicts of Interest

References

- Helal, Z.; Salim, H.; Ahmad, S.S.E.; Elemam, H.; Mohamed, A.I.H.; Elmahdy, M.A.R. Sustainable Bacteria-Based Self-Healing Steel Fiber Reinforced Concrete. Case Stud. Constr. Mater. 2024, 20, e03389. [Google Scholar] [CrossRef]

- Çaparoğlu, N.; Altun, Ö.B.; Mardani, A. Effect of Urea on the Thixotropic Behavior of Mixtures Containing Calcium Aluminate Cement and Portland Cement. Int. J. Pavement Eng. 2025, 26, 2466053. [Google Scholar] [CrossRef]

- Hassan, A.; Alomayri, T.; Noaman, M.F.; Zhang, C. 3D Printed Concrete for Sustainable Construction: A Review of Mechanical Properties and Environmental Impact. Arch. Comput. Methods Eng. 2025, 1–31. [Google Scholar] [CrossRef]

- Roussel, N. Rheological Requirements for Printable Concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Jiao, D.; Shi, C.; Yuan, Q.; An, X.; Liu, Y.; Li, H. Effect of Constituents on Rheological Properties of Fresh Concrete-A Review. Cem. Concr. Compos. 2017, 83, 146–159. [Google Scholar] [CrossRef]

- Peng, Y.; Unluer, C. Advances in Rheological Measurement and Characterization of Fresh Cement Pastes. Powder Technol. 2023, 429, 118903. [Google Scholar] [CrossRef]

- Roussel, N.; Bessaies-Bey, H.; Kawashima, S.; Marchon, D.; Vasilic, K.; Wolfs, R. Recent Advances on Yield Stress and Elasticity of Fresh Cement-Based Materials. Cem. Concr. Res. 2019, 124, 105798. [Google Scholar] [CrossRef]

- Roussel, N. Rheology of Fresh Concrete: From Measurements to Predictions of Casting Processes. Mater. Struct. 2007, 40, 1001–1012. [Google Scholar] [CrossRef]

- Kwon, S.; Park, C.; Jeong, J.; Jo, S.D.; Lee, S.H. Prediction of Concrete Pumping: Part II—Analytical Prediction and Experimental Verification. ACI Mater. J. 2013, 110, 657–667. [Google Scholar] [CrossRef]

- Wallevik, O.H.; Wallevik, J.E. Rheology as a Tool in Concrete Science: The Use of Rheographs and Workability Boxes. Cem. Concr. Res. 2011, 41, 1279–1288. [Google Scholar] [CrossRef]

- El Bitouri, Y. The Effect of Temperature on the Structural Build-Up of Cement Pastes. CivilEng 2023, 4, 1198–1213. [Google Scholar] [CrossRef]

- El Bitouri, Y.; Azéma, N. On the “Thixotropic” Behavior of Fresh Cement Pastes. Eng 2022, 3, 677–692. [Google Scholar] [CrossRef]

- Khayat, K.H.; Meng, W.; Vallurupalli, K.; Teng, L. Rheological Properties of Ultra-High-Performance Concrete—An Overview. Cem. Concr. Res. 2019, 124, 105828. [Google Scholar] [CrossRef]

- Rubio-Hernández, F.-J. Rheological Behavior of Fresh Cement Pastes. Fluids 2018, 3, 106. [Google Scholar] [CrossRef]

- Kawashima, S.; Wang, K.; Ferron, R.D.; Kim, J.H.; Tregger, N.; Shah, S. A Review of the Effect of Nanoclays on the Fresh and Hardened Properties of Cement-Based Materials. Cem. Concr. Res. 2021, 147, 106502. [Google Scholar] [CrossRef]

- Reiter, L.; Wangler, T.; Roussel, N.; Flatt, R.J. The Role of Early Age Structural Build-up in Digital Fabrication with Concrete. Cem. Concr. Res. 2018, 112, 86–95. [Google Scholar] [CrossRef]

- Sha, S.; Mantellato, S.; Weckwerth, S.A.; Zhang, Z.; Shi, C.; Flatt, R.J. Do Superplasticizers Work the Way We Think? New Insights from Their Effect on the Percolation Threshold of Limestone Pastes. Cem. Concr. Res. 2023, 172, 107235. [Google Scholar] [CrossRef]

- Perrot, A.; Lecompte, T.; Khelifi, H.; Brumaud, C.; Hot, J.; Roussel, N. Yield Stress and Bleeding of Fresh Cement Pastes. Cem. Concr. Res. 2012, 42, 937–944. [Google Scholar] [CrossRef]

- El Bitouri, Y.; Azéma, N. Contribution of Turbidimetry on the Characterisation of Cement Pastes Bleeding. Adv. Cem. Res. 2022, 35, 180–190. [Google Scholar] [CrossRef]

- Zhu, L.; Zhao, Z.; Zhao, Y.; Xiang, Y.; Guan, X. Study on the Enhancement of Thixotropic Properties of Steel Slag-Based Digital Concrete by Metakaolin. Case Stud. Constr. Mater. 2025, 22, e04293. [Google Scholar] [CrossRef]

- Ye, H.; Zhang, J.; Gao, X.; Ling, J.; Zhu, X.; Jiao, D. Showing the Role of Weakly-Bound Particles Flocculation in the Reversibility of Thixotropic Behavior for Fresh Cement Paste. Constr. Build. Mater. 2024, 411, 134624. [Google Scholar] [CrossRef]

- Tao, Y.; Chen, X.; Zhang, Y.; De Schryver, R.; Jiang, W. Modeling Thixotropic Behavior of Fresh Cement Pastes. Mater. Lett. 2024, 371, 136884. [Google Scholar] [CrossRef]

- Han, K.; Guo, T.; Shu, X.; Shi, J.; Ran, Q. Structural Build-up of Cement Pastes-Underlying Mechanisms Considering the Particle Packing, Colloidal Interactions and Hydration Kinetics. Constr. Build. Mater. 2024, 438, 137030. [Google Scholar] [CrossRef]

- Roussel, N.; Ovarlez, G.; Garrault, S.; Brumaud, C. The Origins of Thixotropy of Fresh Cement Pastes. Cem. Concr. Res. 2012, 42, 148–157. [Google Scholar] [CrossRef]

- Yuan, Q.; Lu, X.; Khayat, K.H.; Feys, D.; Shi, C. Small Amplitude Oscillatory Shear Technique to Evaluate Structural Build-up of Cement Paste. Mater. Struct. 2017, 50, 112. [Google Scholar] [CrossRef]

- Jiao, D.; De Schryver, R.; Shi, C.; De Schutter, G. Thixotropic Structural Build-up of Cement-Based Materials: A State-of-the-Art Review. Cem. Concr. Compos. 2021, 122, 104152. [Google Scholar] [CrossRef]

- Huang, T.; Li, B.; Yuan, Q.; Shi, Z.; Xie, Y.; Shi, C. Rheological Behavior of Portland Clinker-Calcium Sulphoaluminate Clinker-Anhydrite Ternary Blend. Cem. Concr. Compos. 2019, 104, 103403. [Google Scholar] [CrossRef]

- Mantellato, S.; Palacios, M.; Flatt, R.J. Relating Early Hydration, Specific Surface and Flow Loss of Cement Pastes. Mater. Struct./Mater. Constr. 2019, 52, 5. [Google Scholar] [CrossRef]

- Nachbaur, L.; Mutin, J.C.; Nonat, A.; Choplin, L. Dynamic Mode Rheology of Cement and Tricalcium Silicate Pastes from Mixing to Setting. Cem. Concr. Res. 2001, 31, 183–192. [Google Scholar] [CrossRef]

- Michel, L.; Reiter, L.; Sanner, A.; Flatt, R.J.; Kammer, D.S. Structural Build-up at Rest in the Induction and Acceleration Periods of Portland Cement. Cem. Concr. Res. 2024, 186, 107665. [Google Scholar] [CrossRef]

- Zingg, A.; Holzer, L.; Kaech, A.; Winnefeld, F.; Pakusch, J.; Becker, S.; Gauckler, L. The Microstructure of Dispersed and Non-Dispersed Fresh Cement Pastes—New Insight by Cryo-Microscopy. Cem. Concr. Res. 2008, 38, 522–529. [Google Scholar] [CrossRef]

- Huang, T.; Yuan, Q.; He, F.; Xie, Y. Understanding the Mechanisms behind the Time-Dependent Viscoelasticity of Fresh C3A–Gypsum Paste. Cem. Concr. Res. 2020, 133, 106084. [Google Scholar] [CrossRef]

- El Bitouri, Y. Deformation Capacity of Fresh Cement Pastes. Korea-Aust. Rheol. J. 2024, 36, 99–108. [Google Scholar] [CrossRef]

- Yahia, A.; Perrot, A.; Feys, D.; Khayat, K.H.; Sonebi, M.; Kawashima, S.; Schimdt, W. Viscoelastic Properties of Fresh Cement Paste: Measuring Procedures and Influencing Parameters. RILEM Tech. Lett. 2023, 8, 23–30. [Google Scholar] [CrossRef]

- Banfill, P.F.G. Rheological Methods for Assessing the Flow Properties of Mortar and Related Materials. Constr. Build. Mater. 1994, 8, 43–50. [Google Scholar] [CrossRef]

- Mostafa, A.M.; Yahia, A. New Approach to Assess Build-up of Cement-Based Suspensions. Cem. Concr. Res. 2016, 85, 174–182. [Google Scholar] [CrossRef]

- Shaughnessy, R.; Clark, P.E. The Rheological Behavior of Fresh Cement Pastes. Cem. Concr. Res. 1988, 18, 327–341. [Google Scholar] [CrossRef]

- Roussel, N. Steady and Transient Flow Behaviour of Fresh Cement Pastes. Cem. Concr. Res. 2005, 35, 1656–1664. [Google Scholar] [CrossRef]

- Roussel, N.; Lemaître, A.; Flatt, R.J.; Coussot, P. Steady State Flow of Cement Suspensions: A Micromechanical State of the Art. Cem. Concr. Res. 2010, 40, 77–84. [Google Scholar] [CrossRef]

- Barnes, H.A. The Yield Stress—A Review or ‘παντα ρει’-Everything Flows? J. Non-Newton. Fluid Mech. 1999, 81, 133–178. [Google Scholar] [CrossRef]

- Barnes, H.A.; Walters, K. The Yield Stress Myth? Rheol. Acta 1985, 24, 323–326. [Google Scholar] [CrossRef]

- Mahaut, F.; Chateau, X.; Coussot, P.; Ovarlez, G. Yield Stress and Elastic Modulus of Suspensions of Noncolloidal Particles in Yield Stress Fluids. J. Rheol. 2008, 52, 287–313. [Google Scholar] [CrossRef]

- Liddel, P.V.; Boger, D.V. Yield Stress Measurements with the Vane. J. Non-Newton. Fluid Mech. 1996, 63, 235–261. [Google Scholar] [CrossRef]

- El Bitouri, Y.; Azéma, N. Potential Correlation Between Yield Stress and Bleeding. In Proceedings of the SP-349: 11th ACI/RILEM International Conference on Cementitious Materials and Alternative Binders for Sustainable Concrete, Virtual, 7–10 June 2021; American Concrete Institute: Farmington Hills, MI, USA, 2022; Volume 349, pp. 479–494. [Google Scholar]

- Dzuy, N.Q.; Boger, D.V. Direct Yield Stress Measurement with the Vane Method. J. Rheol. 1985, 29, 335–347. [Google Scholar] [CrossRef]

- Flatt, R.J.; Bowen, P. Yodel: A Yield Stress Model for Suspensions. J. Am. Ceram. Soc. 2006, 89, 1244–1256. [Google Scholar] [CrossRef]

- El Bitouri, Y.; Azéma, N.; Le Saoût, G.; Lauten, R.A.; De Weerdt, K. Effect of Plasticizer on Hydration and Rheological Behavior of Cement Pastes. CivilEng 2022, 3, 748–759. [Google Scholar] [CrossRef]

- El Bitouri, Y. Rheological Behavior of Cement Paste: A Phenomenological State of the Art. Eng 2023, 4, 1891–1904. [Google Scholar] [CrossRef]

- Feys, D.; Cepuritis, R.; Jacobsen, S.; Lesage, K.; Secrieru, E.; Yahia, A. Measuring Rheological Properties of Cement Pastes: Most Common Techniques, Procedures and Challenges. RILEM Tech. Lett. 2017, 2, 129–135. [Google Scholar] [CrossRef]

- Fourmentin, M.; Ovarlez, G.; Faure, P.; Peter, U.; Lesueur, D.; Daviller, D.; Coussot, P. Rheology of Lime Paste—A Comparison with Cement Paste. Rheol. Acta 2015, 54, 647–656. [Google Scholar] [CrossRef]

- Billberg, P. Form Pressure Generated by Self-Compacting Concrete: Influence of Thixotropy and Structural Behaviour at Rest. Ph.D. Thesis, KTH, Civil and Architectural Engineering, Stockholm, Sweden, 2006. [Google Scholar]

- Zhang, Z.Z.; Jia, Z.; Shi, J.; Jiang, Y.; Banthia, N.; Zhang, Y. Clarifying and Quantifying the Driving Force for the Evolution of Static Yield Stress of Cement Pastes. Cem. Concr. Res. 2023, 167, 107129. [Google Scholar] [CrossRef]

- Yuan, Q.; Zhou, D.; Khayat, K.H.; Feys, D.; Shi, C. On the Measurement of Evolution of Structural Build-up of Cement Paste with Time by Static Yield Stress Test vs. Small Amplitude Oscillatory Shear. Test. Cem. Concr. Res. 2017, 99, 183–189. [Google Scholar] [CrossRef]

- Roussel, N. Correlation between Yield Stress and Slump: Comparison between Numerical Simulations and Concrete Rheometers Results. Mater. Struct./Mater. Constr. 2006, 39, 501–509. [Google Scholar] [CrossRef]

- Roussel, N.; Stefani, C.; Leroy, R. From Mini-Cone Test to Abrams Cone Test: Measurement of Cement-Based Materials Yield Stress Using Slump Tests. Cem. Concr. Res. 2005, 35, 817–822. [Google Scholar] [CrossRef]

- Zhang, K.K.; Mezhov, A.; Schmidt, W. Chemical and Thixotropic Contribution to the Structural Build-up of Cementitious Materials. Constr. Build. Mater. 2022, 345, 128307. [Google Scholar] [CrossRef]

- Chen, M.; Yang, L.; Zheng, Y.; Li, L.; Wang, S.; Huang, Y.; Zhao, P.; Lu, L.; Cheng, X. Rheological Behaviors and Structure Build-up of 3D Printed Polypropylene and Polyvinyl Alcohol Fiber-Reinforced Calcium Sulphoaluminate Cement Composites. J. Mater. Res. Technol. 2021, 10, 1402–1414. [Google Scholar] [CrossRef]

- Jiao, D.; De Schutter, G. Insights into the Viscoelastic Properties of Cement Paste Based on SAOS Technique. Constr. Build. Mater. 2022, 357, 129320. [Google Scholar] [CrossRef]

- Lei, W.-G.; Struble, L.J. Microstructure and Flow Behavior of Fresh Cement Paste. J. Am. Ceram. Soc. 1997, 80, 2021–2028. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, Z.; Yan, D.; Lai, H.; Ma, X.; Lai, J.; Liu, Y.; Zhong, L.; Chen, Z.; Zhang, X.; et al. Study on Rheological, Adsorption and Hydration Properties of Cement Slurries Incorporated with EPEG-Based Polycarboxylate Superplasticizers. Front. Mater. 2024, 11, 1358630. [Google Scholar] [CrossRef]

- Conte, T.; Chaouche, M. Rheological Behavior of Cement Pastes under Large Amplitude Oscillatory Shear. Cem. Concr. Res. 2016, 89, 332–344. [Google Scholar] [CrossRef]

- Mostafa, A.M.; Yahia, A. Performance Evaluation of Different Rheometric Shearing Techniques to Disperse Concentrated Cement Suspension. Appl. Rheol. 2015, 25, 23–31. [Google Scholar] [CrossRef]

- Khayat, K.H.; Assaad, J.J. Effect of w/cm and High-Range Water-Reducing Admixture on Formwork Pressure and Thixotropy of Self-Consolidating Concrete. ACI Mater. J. 2006, 103, 186–193. [Google Scholar] [CrossRef]

- Kwasny, J.; Sonebi, M.; Plasse, J.; Amziane, S. Influence of Rheology on the Quality of Surface Finish of Cement-Based Mortars. Constr. Build. Mater. 2015, 89, 102–109. [Google Scholar] [CrossRef]

- Navarrete, I.; Kurama, Y.; Escalona, N.; Lopez, M. Impact of Physical and Physicochemical Properties of Supplementary Cementitious Materials on Structural Build-up of Cement-Based Pastes. Cem. Concr. Res. 2020, 130, 105994. [Google Scholar] [CrossRef]

- Ma, S.; Huang, C.; Baah, P.; Nantung, T.; Lu, N. The Influence of Water-to-Cement Ratio and Superabsorbent Polymers (SAPs) on Solid-like Behaviors of Fresh Cement Pastes. Constr. Build. Mater. 2021, 275, 122160. [Google Scholar] [CrossRef]

- Zhi-quan, Y.; Yi, D.; Ya-peng, M.; Ying-yan, Z.; Yi, Y.; Yan-hui, G.; Bi-hua, Z.; Shi-hou, L.; Jian-kun, S.; Jun-zhi, C.; et al. Comprehensive Effect of the Time and Water-Cement Ratio on the Rheological Properties of Power-Law Cement Grouts. Geofluids 2021, 2021, 6636708. [Google Scholar] [CrossRef]

- Mao, Y.; Drissi, S.; Hu, X.; Zhang, J.; Shi, C. Effect of Wet Carbonated Recycled Cement Paste Powder on the Rheology of Cement Paste. Cem. Concr. Res. 2024, 181, 107553. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, H.; Wang, D.; Wang, H.; Chen, G. Rheological Properties of Cement Paste Containing Ground Fly Ash Based on Particle Morphology Analysis. Crystals 2022, 12, 524. [Google Scholar] [CrossRef]

- Kirby, G.H.; Lewis, J.A. Rheological Property Evolution in Concentrated Cement-Polyelectrolyte Suspensions. J. Am. Ceram. Soc. 2002, 85, 2989–2994. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Kankal, M.; Nacar, S.; Felekoğlu, B.; Ramyar, K. Assessment of Cement Characteristics Affecting Rheological Properties of Cement Pastes. Neural Comput. Appl. 2021, 33, 12805–12826. [Google Scholar] [CrossRef]

- Kong, X.; Zhang, Y.; Hou, S. Study on the Rheological Properties of Portland Cement Pastes with Polycarboxylate Superplasticizers. Rheol. Acta 2013, 52, 707–718. [Google Scholar] [CrossRef]

- Han, K.; Guo, T.; Shu, X.; Ran, Q.; Guo, Y.; Shi, J. Insight into the Role of Early C3A Hydration in Structural Build-up of Cement Paste. Cem. Concr. Res. 2024, 175, 107354. [Google Scholar] [CrossRef]

- Mork, J.H.; Gjoerv, O.E. Effect of Gypsum-Hemihydrate Ratio in Cement on Rheological Properties of Fresh Concrete. ACI Mater. J. 1997, 94, 142–146. [Google Scholar] [CrossRef]

- Dils, J.; Boel, V.; De Schutter, G. Influence of Cement Type and Mixing Pressure on Air Content, Rheology and Mechanical Properties of UHPC. Constr. Build. Mater. 2013, 41, 455–463. [Google Scholar] [CrossRef]

- García-Maté, M.; Santacruz, I.; De la Torre, Á.G.; León-Reina, L.; Aranda, M.A.G. Rheological and Hydration Characterization of Calcium Sulfoaluminate Cement Pastes. Cem. Concr. Compos. 2012, 34, 684–691. [Google Scholar] [CrossRef]

- Huang, L.; Yan, P.; Liu, Y. Effect of Alkali Content in Cement on the Fluidity and Structural Build-up of Plasticized Cement Pastes. Constr. Build. Mater. 2020, 253, 119180. [Google Scholar] [CrossRef]

- Assaad, J.; Journal, K.K. Assessment of Thixotropy of Self-Consolidating Concrete and Concrete-Equivalent-Mortar-Effect of Binder Composition and Content. ACI Mater. J. 2004, 101, 400–408. [Google Scholar]

- Mardani-Aghabaglou, A.; Son, A.E.; Felekoglu, B.; Ramyar, K. Effect of Cement Fineness on Properties of Cementitious Materials Containing High Range Water Reducing Admixture. J. Green Build. 2017, 12, 142–167. [Google Scholar] [CrossRef]

- Sha, F.; Kong, H.; Zhang, L.; Meng, Q.; Wang, Q. Rheological Properties of CEMI Type Microfine Cement Slurry with Different Fineness. Constr. Build. Mater. 2023, 404, 133253. [Google Scholar] [CrossRef]

- Zhang, L.; Zuo, W.; Qian, T.; Xu, W.; Jiang, Z.; She, W. Viscosity Transition from Dilute to Concentrated Cementitious Suspensions: The Effect of Colloidal Interactions and Flocs Percolation. Mater. Struct./Mater. Constr. 2022, 55, 244. [Google Scholar] [CrossRef]

- Li, Q.; Fan, Y.; Shah, S.P. Rheological Properties and Structural Build-Up of Cement Based Materials with Addition of Nanoparticles: A Review. Buildings 2022, 12, 2219. [Google Scholar] [CrossRef]

- Baldino, N.; Gabriele, D.; Lupi, F.R.; Seta, L.; Zinno, R. Rheological Behaviour of Fresh Cement Pastes: Influence of Synthetic Zeolites, Limestone and Silica Fume. Cem. Concr. Res. 2014, 63, 38–45. [Google Scholar] [CrossRef]

- Vance, K.; Kumar, A.; Sant, G.; Neithalath, N. The Rheological Properties of Ternary Binders Containing Portland Cement, Limestone, and Metakaolin or Fly Ash. Cem. Concr. Res. 2013, 52, 196–207. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, Y.; Xiao, J.; Shi, J.; Chen, Y.; Pang, B.; Wu, M.; Liu, G.; Yang, Y. Study on Dynamic and Static Structural Build-up of Fresh Cement Paste with Limestone Powder Based on Structural Kinetics Model. Constr. Build. Mater. 2021, 305, 124598. [Google Scholar] [CrossRef]

- Martins, R.M.; Bombard, A.J.F. Rheology of Fresh Cement Paste with Superplasticizer and Nanosilica Admixtures Studied by Response Surface Methodology. Mater. Struct./Mater. Constr. 2012, 45, 905–921. [Google Scholar] [CrossRef]

- Song, P.; Wang, X.; Wang, Y.; Zhou, J.; Qiu, H.; Rahimi, A.; Ingham, J. Assess the Interaction of Water Reducers and Accelerators on the Rheological and Early Hydration Properties of Cement-Based Materials. J. Mater. Res. Technol. 2025, 36, 806–822. [Google Scholar] [CrossRef]

- Zhang, H.; Gan, X.; Lu, Z.; Li, L.; Lu, L. Polycarboxylate Superplasticizer-Modified Graphene Oxide: Dispersion and Performance Enhancement in Cement Paste. Nanomaterials 2025, 15, 419. [Google Scholar] [CrossRef]

- Ma, B.; Peng, Y.; Tan, H.; Jian, S.; Zhi, Z.; Guo, Y.; Qi, H.; Zhang, T.; He, X. Effect of Hydroxypropyl-Methyl Cellulose Ether on Rheology of Cement Paste Plasticized by Polycarboxylate Superplasticizer. Constr. Build. Mater. 2018, 160, 341–350. [Google Scholar] [CrossRef]

- González-Aviña, J.V.; Hosseinpoor, M.; Yahia, A.; Durán-Herrera, A. Synergistic Effects of Superplasticizers and Biopolymer-Based Viscosity-Modifying Admixtures on the Rheology of Cement-Based Systems. Cem. Concr. Compos. 2024, 154, 105807. [Google Scholar] [CrossRef]

- Heikal, M.; Morsy, M.S.; Aiad, I. Effect of Treatment Temperature on the Early Hydration Characteristics of Superplasticized Silica Fume Blended Cement Pastes. Cem. Concr. Res. 2005, 35, 680–687. [Google Scholar] [CrossRef]

- Teng, L.; Wei, J.; Khayat, K.H.; Assaad, J.J. Effect of Competitive Adsorption between Specialty Admixtures and Superplasticizer on Structural Build-up and Hardened Property of Mortar Phase of Ultra-High-Performance Concrete. Cem. Concr. Compos. 2023, 141, 105130. [Google Scholar] [CrossRef]

- Kwan, A.K.H.; Fung, W.W.S. Roles of Water Film Thickness and SP Dosage in Rheology and Cohesiveness of Mortar. Cem. Concr. Compos. 2012, 34, 121–130. [Google Scholar] [CrossRef]

- Boutouam, Y.; Hayek, M.; Bouarab, K.; Yahia, A. A Comprehensive Review of Plant-Based Biopolymers as Viscosity-Modifying Admixtures in Cement-Based Materials. Appl. Sci. 2024, 14, 4307. [Google Scholar] [CrossRef]

- González-Aviña, J.V.; Hosseinpoor, M.; Yahia, A.; Durán-Herrera, A. New Biopolymers as Viscosity-Modifying Admixtures to Improve the Rheological Properties of Cement-Based Materials. Cem. Concr. Compos. 2024, 146, 105409. [Google Scholar] [CrossRef]

- Boukhatem, A.; Bouarab, K.; Yahia, A. Kappa (κ)-Carrageenan as a Novel Viscosity-Modifying Admixture for Cement-Based Materials—Effect on Rheology, Stability, and Strength Development. Cem. Concr. Compos. 2021, 124, 104221. [Google Scholar] [CrossRef]

- Boukhatem, A.; Bouarab, K.; Yahia, A. Effect of (κ)- and (ι)-Carrageenans on Rheology and Strength Development of Cement-Based Materials. ACI Mater. J. 2022, 119, 207–219. [Google Scholar] [CrossRef]

- Ma, S.; Qian, Y.; Kawashima, S. Experimental and Modeling Study on the Non-Linear Structural Build-up of Fresh Cement Pastes Incorporating Viscosity Modifying Admixtures. Cem. Concr. Res. 2018, 108, 1–9. [Google Scholar] [CrossRef]

- Li, Q.; Fan, Y. Effect of Nano-Metakaolin on the Thixotropy of Fresh Cement Paste. Constr. Build. Mater. 2022, 353, 129062. [Google Scholar] [CrossRef]

- Ghafari, E.; Ghahari, S.A.; Feng, Y.; Severgnini, F.; Lu, N. Effect of Zinc Oxide and Al-Zinc Oxide Nanoparticles on the Rheological Properties of Cement Paste. Compos. Part B Eng. 2016, 105, 160–166. [Google Scholar] [CrossRef]

- Morsy, M.S.; Shoukry, H.; Mokhtar, M.M.; Ali, A.M.; El-Khodary, S.A. Facile Production of Nano-Scale Metakaolin: An Investigation into Its Effect on Compressive Strength, Pore Structure and Microstructural Characteristics of Mortar. Constr. Build. Mater. 2018, 172, 243–250. [Google Scholar] [CrossRef]

- Shan, Y.; Zhuang, S.; Yu, X. Understanding the Impact of Ultrafine Phosphorus Slag on the Workability of Cement Paste. Powder Technol. 2025, 455, 120800. [Google Scholar] [CrossRef]

- Safanelli, N.; Effting, C.; Schackow, A.; Miranda, K.W.; de Matos, P.R. Rheology of Cement Pastes with Superplasticizer and Nanocellulose Crystals. Ambiente Construído 2025, 25, e140029. [Google Scholar] [CrossRef]

- Pathak, S.; Vesmawala, G.; Hulagabali, M.M. Effect on Use of Nano TiO2 on Rheological Behavior and Strength of Cement Paste: An Experimental Study. Asian J. Civ. Eng. 2025, 26, 2275–2285. [Google Scholar] [CrossRef]

- Li, Q.; Fan, Y. Rheological Evaluation of Nano-Metakaolin Cement Pastes Based on the Water Film Thickness. Constr. Build. Mater. 2022, 324, 126517. [Google Scholar] [CrossRef]

- Makwana, D.; Bellani, J.; Verma, H.K.; Khatri, D.; Shah, M. Emergence of Nano Silica for Oil and Gas Well Cementing: Application, Challenges, and Future Scope. Environ. Sci. Pollut. Res. 2021, 28, 37110–37119. [Google Scholar] [CrossRef]

- Kohandelnia, M.; Hosseinpoor, M.; Yahia, A.; Belarbi, R. New Insight on Rheology of Self-Consolidating Earth Concrete (SCEC). Powder Technol. 2023, 424, 118561. [Google Scholar] [CrossRef]

- Senff, L.; Hotza, D.; Lucas, S.; Ferreira, V.M.; Labrincha, J.A. Effect of Nano-SiO2 and Nano-TiO2 Addition on the Rheological Behavior and the Hardened Properties of Cement Mortars. Mater. Sci. Eng. A 2012, 532, 354–361. [Google Scholar] [CrossRef]

- Li, Q.; Fan, Y.; Zhao, Y.; Liang, Z. Early-Age Properties Evaluation of Nano-Metakaolin Cement Paste Based on Electrochemical Impedance Spectroscopy. Buildings 2022, 12, 1763. [Google Scholar] [CrossRef]

- Quanji, Z.; Lomboy, G.R.; Wang, K. Influence of Nano-Sized Highly Purified Magnesium Alumino Silicate Clay on Thixotropic Behavior of Fresh Cement Pastes. Constr. Build. Mater. 2014, 69, 295–300. [Google Scholar] [CrossRef]

- Jiao, D.; Lesage, K.; Yardimci, M.Y.; El Cheikh, K.; Shi, C.; De Schutter, G. Structural Evolution of Cement Paste with Nano-Fe3O4 under Magnetic Field-Effect of Concentration and Particle Size of Nano-Fe3O4. Cem. Concr. Compos. 2021, 120, 104036. [Google Scholar] [CrossRef]

- Kawashima, S.; Chaouche, M.; Corr, D.J.; Shah, S.P. Rate of Thixotropic Rebuilding of Cement Pastes Modified with Highly Purified Attapulgite Clays. Cem. Concr. Res. 2013, 53, 112–118. [Google Scholar] [CrossRef]

- Yuan, Q.; Zhou, D.; Li, B.; Huang, H.; Shi, C. Effect of Mineral Admixtures on the Structural Build-up of Cement Paste. Constr. Build. Mater. 2018, 160, 117–126. [Google Scholar] [CrossRef]

- Huang, H.; Huang, T.; Yuan, Q.; Zhou, D.; Deng, D.; Zhang, L. Temperature Dependence of Structural Build-up and Its Relation with Hydration Kinetics of Cement Paste. Constr. Build. Mater. 2019, 201, 553–562. [Google Scholar] [CrossRef]

- Lothenbach, B.; Winnefeld, F.; Alder, C.; Wieland, E.; Lunk, P. Effect of Temperature on the Pore Solution, Microstructure and Hydration Products of Portland Cement Pastes. Cem. Concr. Res. 2007, 37, 483–491. [Google Scholar] [CrossRef]

- Mezhov, A.; Robens-Radermacher, A.; Zhang, K.; Kühne, H.-C.; Unger, J.F.; Schmidt, W. Temperature Impact on the Structural Build-Up of Cementitious Materials–Experimental and Modelling Study. In RILEM Bookseries; Springer: Cham, Switzerland, 2022; Volume 37, pp. 330–336. [Google Scholar]

- Link, J.; Sowoidnich, T.; Pfitzner, C.; Gil-Diaz, T.; Heberling, F.; Lützenkirchen, J.; Schäfer, T.; Ludwig, H.-M.; Haist, M. The Influences of Cement Hydration and Temperature on the Thixotropy of Cement Paste. Materials 2020, 13, 1853. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary Cementitious Materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Dada, H.; Soualhi, H.; Belaidi, A.S.E.; Kadri, E.-H.; Benabed, B. A Study of the Rheological Behaviour of Eco-Friendly Mortar Made with Metakaolin and Marble Powder at Various Ambient Temperatures. Eur. J. Environ. Civ. Eng. 2023, 27, 1088–1103. [Google Scholar] [CrossRef]

- Çelikten, S.; Atabey, İ.İ.; Bayer Öztürk, Z. Cleaner Environment Approach by the Utilization of Ceramic Sanitaryware Waste in Portland Cement Mortar at Ambient and Elevated Temperatures. Iran. J. Sci. Technol. Trans. Civ. Eng. 2022, 46, 4291–4301. [Google Scholar] [CrossRef]

- Sharma, A.; Gupta, S.; Noman Husain, M.; Chaudhary, S. Factors Affecting the Rheology of Cement-based Composites: A Review. J. Am. Ceram. Soc. 2025, 108, e20429. [Google Scholar] [CrossRef]

- McCarthy, M.J.; Dhir, R.K.; Caliskan, S.; Ashraf, M.K. Influence of Self-Compacting Concrete on the Lateral Pressure on Formwork. Proc. Inst. Civ. Eng.-Struct. Build. 2012, 165, 127–138. [Google Scholar] [CrossRef]

- Perrot, A.; Rangeard, D.; Pierre, A. Structural Built-up of Cement-Based Materials Used for 3D-Printing Extrusion Techniques. Mater. Struct. 2016, 49, 1213–1220. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Early Age Mechanical Behaviour of 3D Printed Concrete: Numerical Modelling and Experimental Testing. Cem. Concr. Res. 2018, 106, 103–116. [Google Scholar] [CrossRef]

- Pan, T.; Jiang, Y.; He, H.; Wang, Y.; Yin, K. Effect of Structural Build-Up on Interlayer Bond Strength of 3D Printed Cement Mortars. Materials 2021, 14, 236. [Google Scholar] [CrossRef] [PubMed]

- Boukhatem, A.; Bouarab, K.; Yahia, A. Kappaphycus Alvarezii Seaweed as Novel Viscosity- Modifying Admixture for Cement-Based Materials. ACI Mater. J. 2023, 120, 15–28. [Google Scholar] [CrossRef]

- Mostafa, A.M.; Diederich, P.; Yahia, A. Effectiveness of Rotational Shear in Dispersing Concentrated Cement Suspensions. J. Sustain. Cem.-Based Mater. 2015, 4, 205–214. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiao, J.; Han, K.; Wang, J.; Hu, X. Study on the Structural Build-up of Cement-Ground Limestone Pastes and Its Micro-Mechanism. Constr. Build. Mater. 2020, 263, 120656. [Google Scholar] [CrossRef]

- Megid, W.A.; Khayat, K.H. Effect of Structural Buildup at Rest of Self-Consolidating Concrete on Mechanical and Transport Properties of Multilayer Casting. Constr. Build. Mater. 2019, 196, 626–636. [Google Scholar] [CrossRef]

- Han, F.; Pu, S.; Zhou, Y.; Zhang, H.; Zhang, Z. Effect of Ultrafine Mineral Admixtures on the Rheological Properties of Fresh Cement Paste: A Review. J. Build. Eng. 2022, 51, 104313. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hayek, M.; El Bitouri, Y.; Bouarab, K.; Yahia, A. Structural Build-Up of Cement Pastes: A Comprehensive Overview and Key Research Directions. Constr. Mater. 2025, 5, 31. https://doi.org/10.3390/constrmater5020031

Hayek M, El Bitouri Y, Bouarab K, Yahia A. Structural Build-Up of Cement Pastes: A Comprehensive Overview and Key Research Directions. Construction Materials. 2025; 5(2):31. https://doi.org/10.3390/constrmater5020031

Chicago/Turabian StyleHayek, Mahmoud, Youssef El Bitouri, Kamal Bouarab, and Ammar Yahia. 2025. "Structural Build-Up of Cement Pastes: A Comprehensive Overview and Key Research Directions" Construction Materials 5, no. 2: 31. https://doi.org/10.3390/constrmater5020031

APA StyleHayek, M., El Bitouri, Y., Bouarab, K., & Yahia, A. (2025). Structural Build-Up of Cement Pastes: A Comprehensive Overview and Key Research Directions. Construction Materials, 5(2), 31. https://doi.org/10.3390/constrmater5020031