Development of Thermally Insulating Gypsum Boards Blended with Quartzite and Fiberglass Waste

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Optimal Dosage Definition

2.3. Sample Preparation

2.4. Fresh State Properties

2.5. Hardened-State Testing Properties

3. Results and Discussion

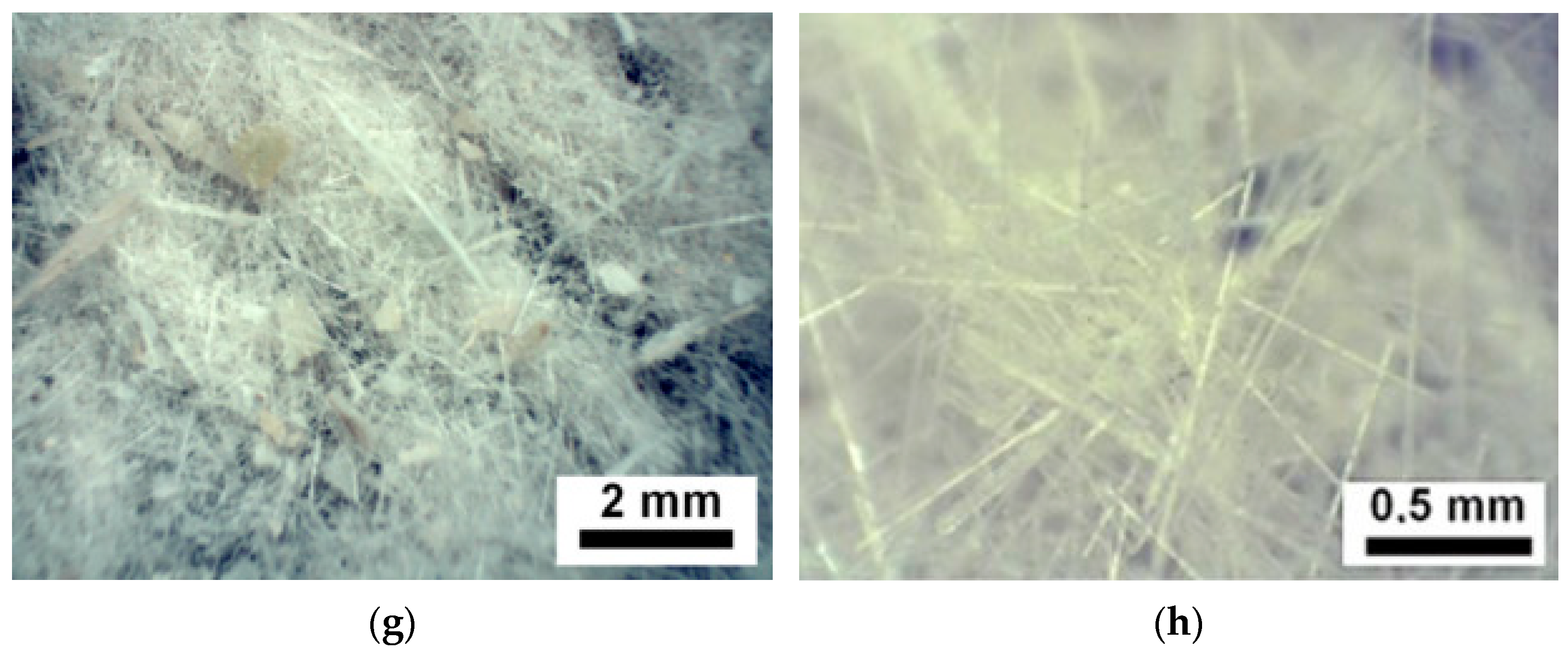

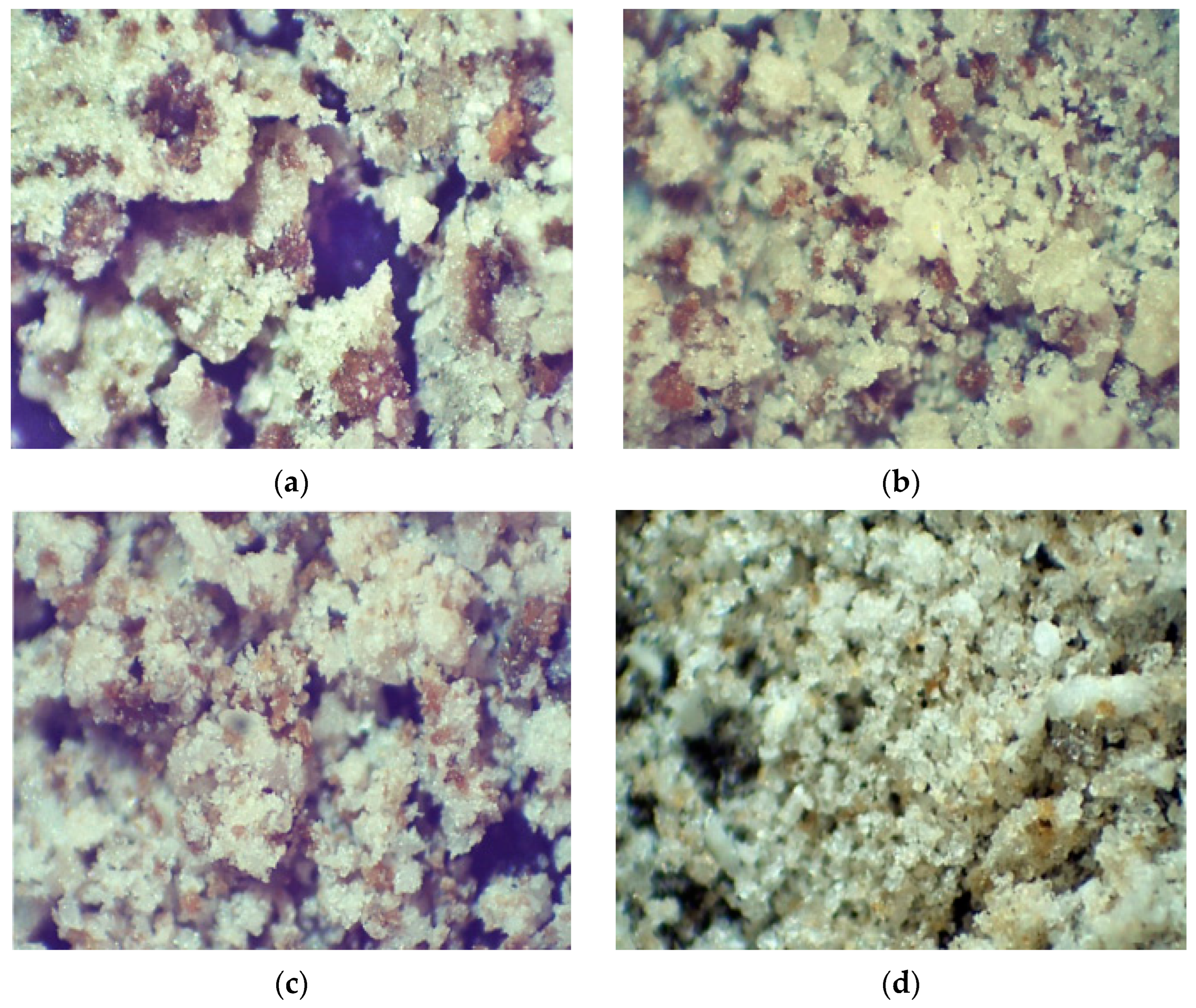

3.1. Materials Characterization

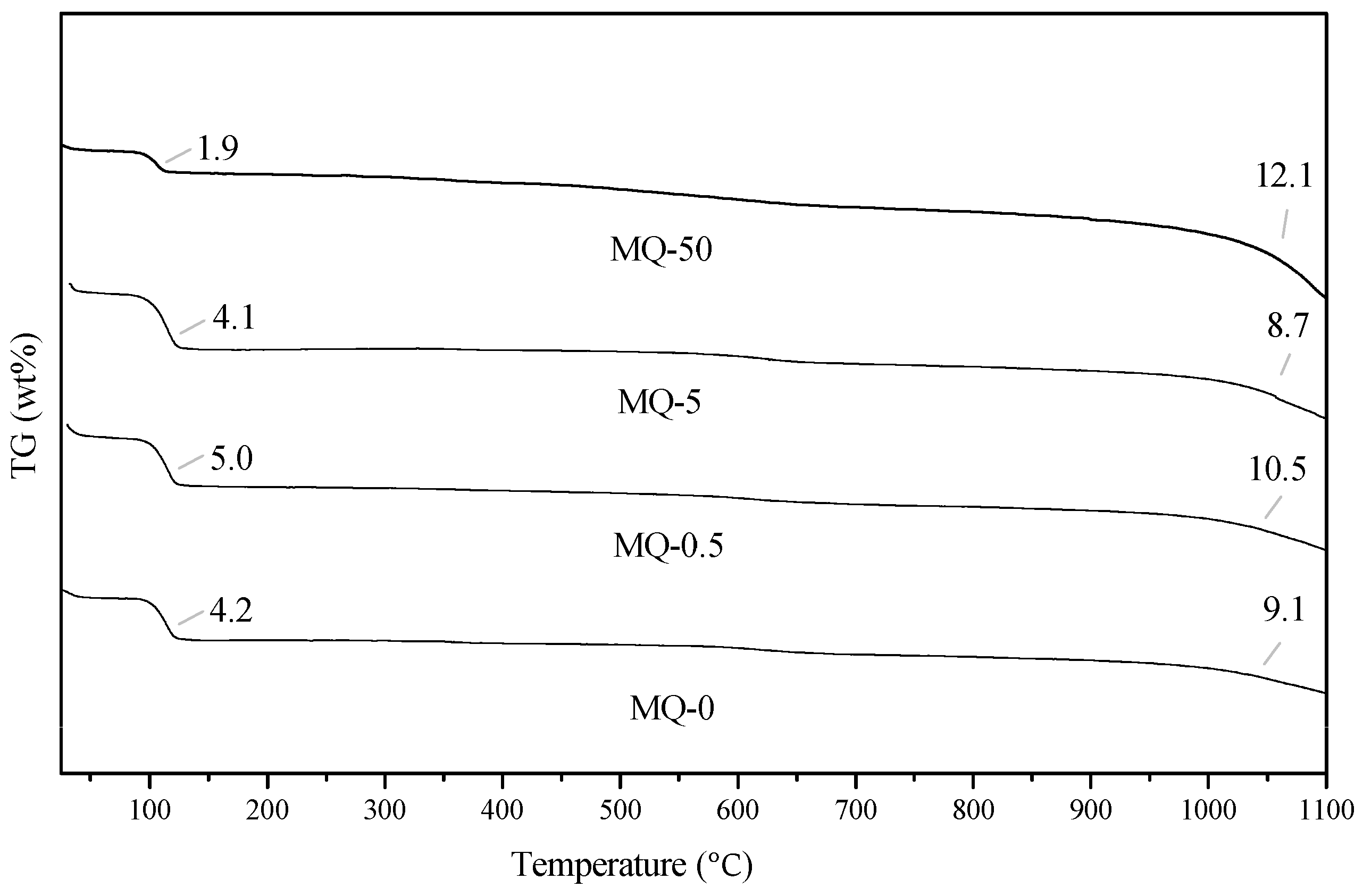

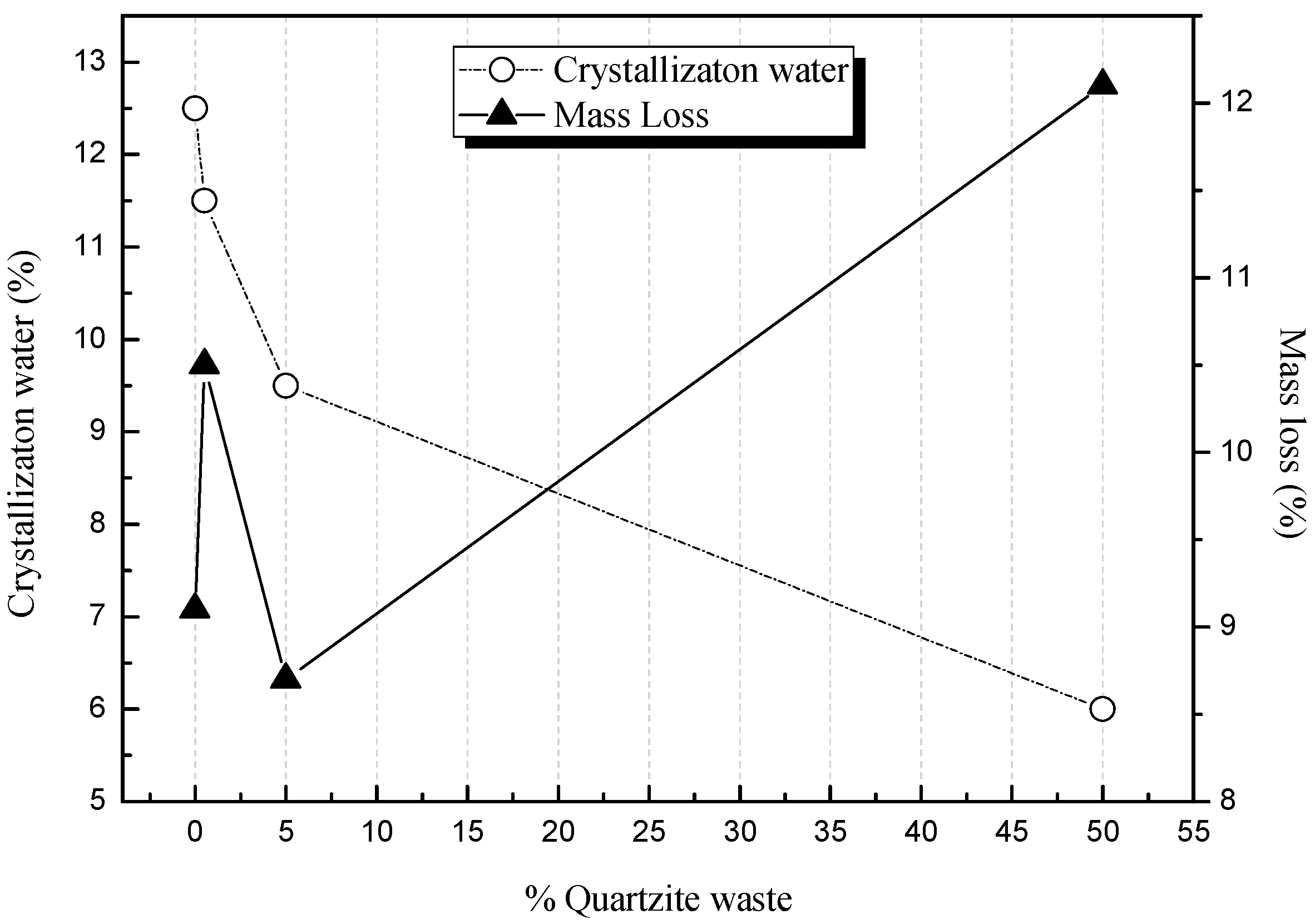

3.2. Optimal Dosage for the Composite

3.3. Properties in the Fresh State

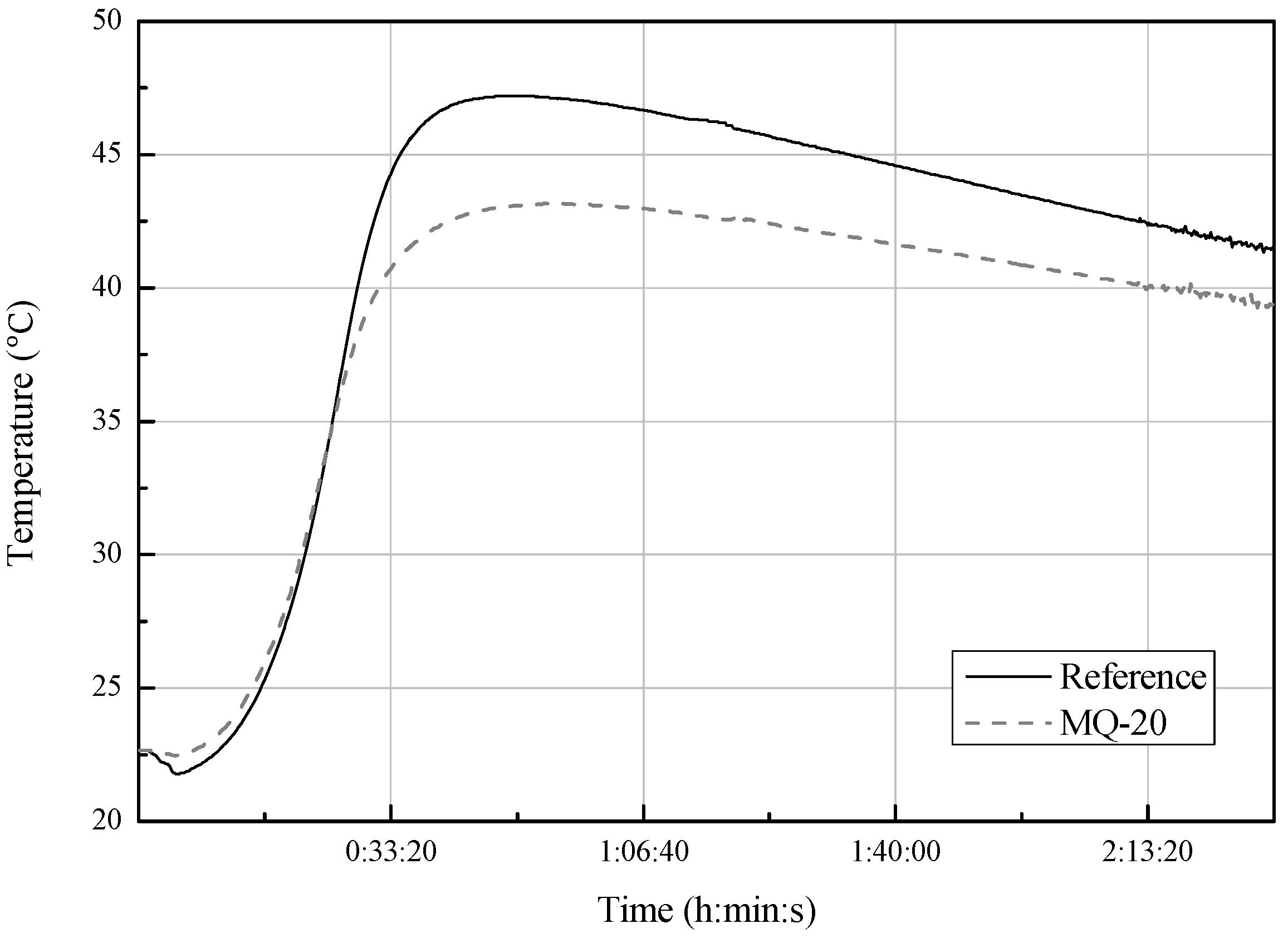

3.4. Hardened-State Properties

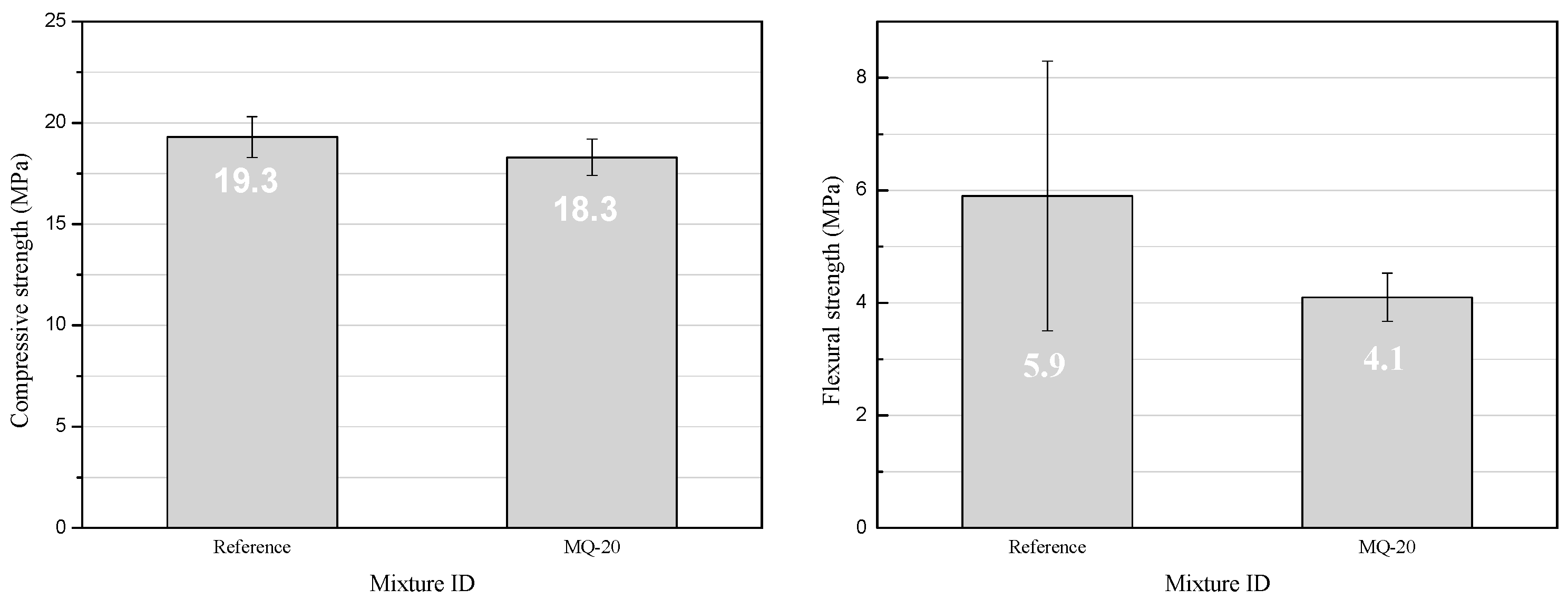

3.4.1. Mechanical Properties

3.4.2. Physical and Chemical Properties

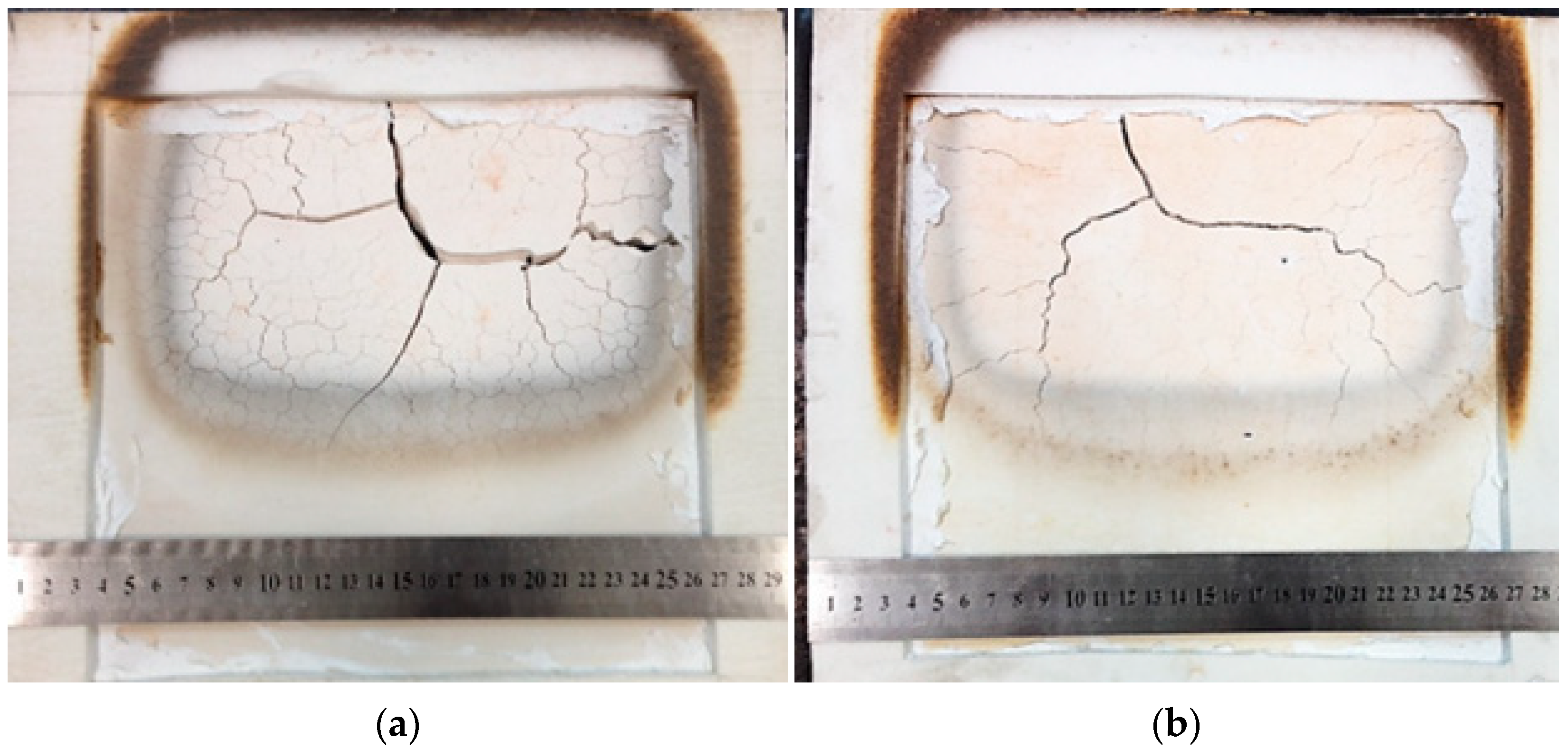

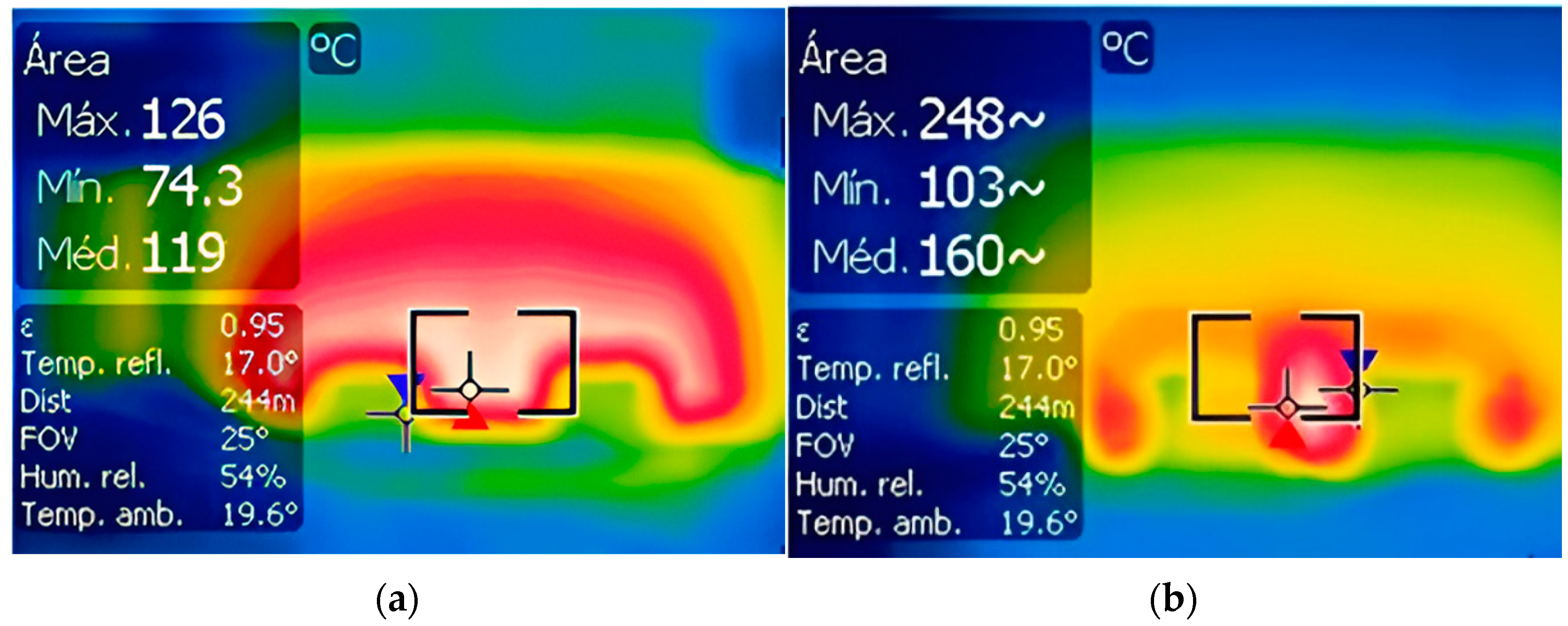

3.4.3. Thermal Properties and Fire Resistance

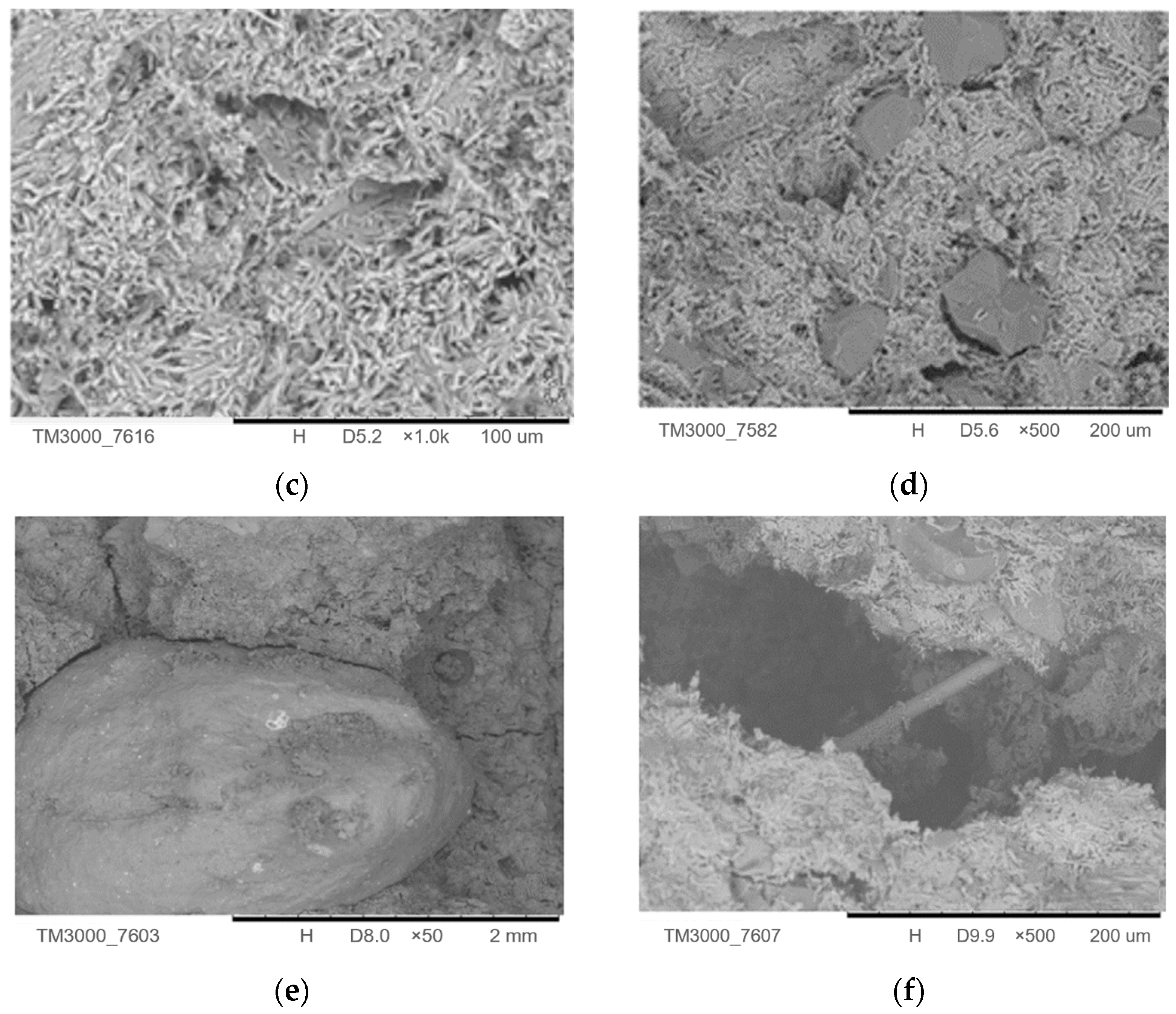

3.4.4. Microstructure

4. Conclusions

- (a)

- The experimental design to determine the optimal dosage indicated that a 20% quartz waste content, as a replacement for commercial gypsum, is suitable. This dosage was selected based on the criteria of the (i) quartz waste consumption, (ii) free water loss, and (iii) crystallization water;

- (b)

- The MQ-20 specimens exhibited lower flexural and compressive strength values (a reduction of up to ~30% in flexural strength). Nevertheless, the obtained results remain above the standard requirements for gypsum boards, and the fracture behavior underwent a transformation due to the addition of fiberglass waste;

- (c)

- The thermal conductivity of the MQ-20 specimens was slightly lower than that of the reference specimens (from 0.58 to 0.54 W/(m·K)). The use of quartz and fiberglass waste significantly reduced the size and number of cracks developed in the boards during the fire test. This can be attributed to the increased porosity of the board and the presence of fiber particles, which help mitigate the crack propagation caused by the deterioration of gypsum crystals.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| QW | Quartzite Waste |

| FW | Fiberglass Waste |

| EC | Expanded Clay |

| ASTM | American Society for Testing and Materials |

| TG/DTA | Thermogravimetric Analysis/Differential Thermal Analysis |

| W/G | Water/Gypsum Ratio |

| ITZ | Interfacial Transition Zone |

| XRF | X-ray Fluorescence |

| SEM | Scanning Electron Microscopy |

| XRD | X-ray Diffraction |

| MPa | Megapascal (Unit of Pressure) |

| W/(m·K) | Watts per meter-Kelvin (Unit of Thermal Conductivity) |

References

- Mahpour, A.R.; Sadrolodabaee, P.; Ardanuy, M.; Haurie, L.; Lacasta, A.M.; Rosell, J.R.; Claramunt, J. Serviceability parameters and social sustainability assessment of flax fabric reinforced lime-based drywall interior panels. J. Build. Eng. 2023, 76, 107406. [Google Scholar] [CrossRef]

- Gonçalves, R.; Martinho, A.; Oliveira, J. Evaluating the potential use of recycled glass fibers for the development of gypsum-based composites. Constr. Build. Mater. 2022, 321, 126320. [Google Scholar] [CrossRef]

- Feng, Y.C.; Zhao, F.Q.; Xu, H. Recycling and utilization of waste glass fiber reinforced plastics. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2016; Volume 67, p. 07012. [Google Scholar]

- Baux, C.; Mélinge, Y.; Lanos, C.; Jauberthie, R. Enhanced Gypsum Panels for Fire Protection. J. Mater. Civ. Eng. 2008, 20, 71–77. [Google Scholar] [CrossRef]

- Wang, S.; Pancheti, J.; Xi, Y.; Mahendran, M. Lightweight composite gypsum boards with clay mineral and glass fibre for enhanced fire-resistance. Compos. Part B Eng. 2023, 266, 111044. [Google Scholar] [CrossRef]

- Singh, S.; Dalbehera, M.M.; Kumar, A.A.; Maiti, S.; Balam, N.B.; Bisht, R.S.; Panigrahi, S.K. Elevated temperature and performance behaviour of rice straw as waste bio-mass based foamed gypsum hollow blocks. J. Build. Eng. 2023, 69, 106220. [Google Scholar] [CrossRef]

- del Río-Merino, M.; Vidales-Barriguete, A.; Piña-Ramírez, C.; Vitiello, V.; Cruz-Astorqui, J.S.; Castelluccio, R. A review of the research about gypsum mortars with waste aggregates. J. Build. Eng. 2022, 45, 103338. [Google Scholar] [CrossRef]

- Ferrández, D.; Álvarez, M.; Zaragoza-Benzal, A.; Cobo-González, Á.; Santos, P. Development and Characterization of Innovative Hemp–Gypsum Composites for Application in the Building Industry. Appl. Sci. 2024, 14, 2229. [Google Scholar] [CrossRef]

- Sheng, D.D.C.V.; Ramegowda, N.S.; Guna, V.; Reddy, N. Groundnut shell and coir reinforced hybrid bio composites as alternative to gypsum ceiling tiles. J. Build. Eng. 2022, 57, 104892. [Google Scholar] [CrossRef]

- Wu, H.; Liu, X.; Wang, C.; Zhang, Y.; Ma, Z. Micro-properties and mechanical behavior of high-ductility engineered geopolymer composites (EGC) with recycled concrete and paste powder as green precursor. Cem. Concr. Compos. 2024, 152, 105672. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Z.; Liu, X.; Zhang, Y.; Ma, Z. Elucidating the role of recycled concrete aggregate in ductile engineered geopolymer composites: Effects of recycled concrete aggregate content and size. J. Build. Eng. 2024, 95, 110150. [Google Scholar] [CrossRef]

- López, F.A.; Martín, M.I.; Alguacil, F.J.; Rincón, J.M.; Centeno, T.A.; Romero, M. Thermolysis of fibreglass polyester composite and reutilisation of the glass fibre residue to obtain a glass–ceramic material. J. Anal. Appl. Pyrolysis 2012, 93, 104–112. [Google Scholar] [CrossRef]

- Ribeiro, R.P.; Nieves, L.J.J.; Bernardin, A.M. Effect of fiberglass waste and fly ash addition on the mechanical performance of Portland cement paste. Clean. Mater. 2023, 7, 100176. [Google Scholar] [CrossRef]

- Silva, M.; Leão, V.; Reis, E. Incorporation of quartzite fines in the production of red ceramics. J. Clean. Prod. 2021, 288, 125098. [Google Scholar] [CrossRef]

- Martins, L.M.; Marques, K.M.; Elói, F.P.d.F.; Mendes, L.A.; Peixoto, R.A.F.; Mendes, J.C. Thermal insulating coating mortars with mining and steel residues and the proposition of a “thermal insulating admixture”. J. Mater. Cycles Waste Manag. 2024, 26, 1432–1449. [Google Scholar] [CrossRef]

- Danish, P.; Ganesh, G.M. Study on influence of Metakaolin and waste marble powder on self-compacting concrete – A state of the art review. Mater. Today Proc. 2021, 44, 1428–1436. [Google Scholar] [CrossRef]

- de Souza, A.M.; de Carvalho, J.M.F.; Salgado, I.L.; Santos, C.F.R.; Ferreira, F.A.; Pedroti, L.G.; Lara, R.C.; Peixoto, R.A.F. Influence of filler/cement and powder/total solids on the mixture design of self-compacting micro-concretes containing waste from the ornamental stone industry. Constr. Build. Mater. 2023, 407, 133445. [Google Scholar] [CrossRef]

- de Carvalho, J.M.F.; de Melo, T.V.; Fontes, W.C.; Batista, J.O.d.S.; Brigolini, G.J.; Peixoto, R.A.F. More eco-efficient concrete: An approach on optimization in the production and use of waste-based supplementary cementing materials. Constr. Build. Mater. 2019, 206, 397–409. [Google Scholar] [CrossRef]

- Alkhaly, Y.R.; Abdullah; Husaini; Hasan, M. Characteristics of reactive powder concrete comprising synthesized rice husk ash and quartzite powder. J. Clean. Prod. 2022, 375, 134154. [Google Scholar] [CrossRef]

- Ciocan, C.; Annels, C.; Fitzpatrick, M.; Couceiro, F.; Steyl, I.; Bray, S. Glass reinforced plastic (GRP) boats and the impact on coastal environment – Evidence of fibreglass ingestion by marine bivalves from natural populations. J. Hazard. Mater. 2024, 472, 134619. [Google Scholar] [CrossRef]

- Ardebili, A.A.; Sáez, P.V.; Cortina, M.G.; Cruz, D.M.T.; Sáiz, Á.R.; Atanes-Sánchez, E. Mechanical characterization of gypsum mortars with waste from the automotive sector. Constr. Build. Mater. 2023, 370, 130675. [Google Scholar] [CrossRef]

- ASTM C25; Standard Test Methods for Chemical Analysis of Limestone, Quicklime, and Hydrated Lime. ASTM International: West Conshohocken, PA, USA, 2021.

- Roces, E.; Muñiz-Menéndez, M.; González-Galindo, J.; Estaire, J. Lightweight expanded clay aggregate properties based on laboratory testing. Constr. Build. Mater. 2021, 313, 125486. [Google Scholar] [CrossRef]

- ASTM C127-24; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM C472; Standard Test Methods for Physical Testing of Gypsum, Gypsum Plasters, and Gypsum Concrete. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C1396; Standard Specification for Gypsum Board. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C473; Standard Test Methods for Physical Testing of Gypsum Panel Products. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C1629; Standard Classification for Abuse-Resistant Nondecorated Interior Gypsum Panel Products and Fiber-Reinforced Cement Panels. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C518; Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM E119; Standard Test Methods for Fire Tests of Building Construction and Materials. ASTM International: West Conshohocken, PA, USA, 2023.

- Gou, M.; Zhao, M.; Zhou, L.; Zhao, J.; Hou, W.; Ma, W.; Hou, Z. Hydration and mechanical properties of FGD gypsum-cement-mineral powder composites. J. Build. Eng. 2023, 69, 106288. [Google Scholar] [CrossRef]

- Barbosa, W.; Ramalho, R.D.; Portella, K. Influence of gypsum fineness in the first hours of cement paste: Hydration kinetics and rheological behaviour. Constr. Build. Mater. 2018, 184, 304–310. [Google Scholar] [CrossRef]

- Gentile, V.; Libralato, M.; Fantucci, S.; Shtrepi, L.; Autretto, G. Enhancement of the hygroscopic and acoustic properties of indoor plasters with a Super Adsorbent Calcium Alginate BioPolymer. J. Build. Eng. 2023, 76, 107147. [Google Scholar] [CrossRef]

- Zhernovsky, I.V.; Cherevatova, A.V.; Voitovich, E.V.; Kozhukhova, N.I.; Evtushenko, E.I. High-temperature phase transformations in CaO-SO3-SiO2-H2O system with nanosized component. Int. J. Appl. Eng. Res. 2016, 11, 7732–7735. [Google Scholar]

- Jia, R.; Wang, Q.; Feng, P. A comprehensive overview of fibre-reinforced gypsum-based composites (FRGCs) in the construction field. Compos. Part B Eng. 2021, 205, 108540. [Google Scholar] [CrossRef]

- Yang, J.; Chen, B.; Wu, X.; Xu, G. Quantitative analysis of steel fibers on UHPFRC uniaxial tensile behavior using X-CT and UTT. Constr. Build. Mater. 2023, 368, 130349. [Google Scholar] [CrossRef]

- Khan, S.A.; Hussain, F.; Amjad, H.; Khushnood, R.A. A scientometric review of the synthesis and application of expanded clay aggregate in cementitious composites. Constr. Build. Mater. 2024, 437, 136654. [Google Scholar] [CrossRef]

- Javangula, H.; Lineberry, Q. Comparative studies on fire-rated and standard gypsum wallboard. J. Therm. Anal. Calorim. 2014, 116, 1417–1433. [Google Scholar] [CrossRef]

- Yue, K.; Liang, B.; Liu, J.; Li, M.; Pu, Y.; Lu, W.; Han, Z.; Li, Z. Fire resistance of light wood frame walls sheathed with innovative gypsum-particle composite: Experimental investigations. J. Build. Eng. 2022, 45, 103576. [Google Scholar] [CrossRef]

- Mélinge, Y.; Lanos, C.; Nguyen, K.; Daiguebonne, C.; Guillou, O.; Freslon, S. One-Dimensional-Time Study of the Dehydration of Plasterboards Under Standard Fire Condition (ISO 834): Thermo-Chemical Analysis. J. Fire Sci. 2010, 29, 299–316. [Google Scholar] [CrossRef]

- Engbrecht, D.C.; Hirschfeld, D.A. Thermal analysis of calcium sulfate dihydrate sources used to manufacture gypsum wallboard. Thermochim. Acta 2016, 639, 173–185. [Google Scholar] [CrossRef]

- Kappert, E.J.; Bouwmeester, H.J.; Benes, N.E.; Nijmeijer, A. Kinetic Analysis of the Thermal Processing of Silica and Organosilica. J. Phys. Chem. B 2014, 118, 5270–5277. [Google Scholar] [CrossRef]

- Jafari, B.; Rezaei, E.; Dianat, M.J.; Abbasi, M.; Hashemifard, S.A.; Khosravi, A.; Sillanpää, M. Development of a new composite ceramic membrane from mullite, silicon carbide and activated carbon for treating greywater. Ceram. Int. 2021, 47, 34667–34675. [Google Scholar] [CrossRef]

- Bouguerra, A. Temperature and moisture dependence on the thermal conductivity of wood-cement-based composite: Experimental and theoretical analysis. J. Phys. D: Appl. Phys. 1999, 32, 2797–2803. [Google Scholar] [CrossRef]

- Zaragoza-Benzal, A.; Ferrández, D.; Santos, P.; Atanes-Sánchez, E. Upcycling EPS waste and mineral wool to produce new lightweight gypsum composites with improved thermal performance. Constr. Build. Mater. 2024, 449, 138464. [Google Scholar] [CrossRef]

- ISO 834-1; International Standard Fire-Resistance Tests—Elements of Building Construction. Part 1: General Requirements; International Organization for Standardization: Geneva, Switzerland, 1999.

- Ahmed, W.; Lim, C.W.; Akbar, A. Influence of Elevated Temperatures on the Mechanical Performance of Sustainable-Fiber-Reinforced Recycled Aggregate Concrete: A Review. Buildings 2022, 12, 487. [Google Scholar] [CrossRef]

- Shalwan, A.; Alajmi, A.; Yousif, B.F. Theoretical Study of the Effect of Fibre Porosity on the Heat Conductivity of Reinforced Gypsum Composite Material. Polymers 2022, 14, 3973. [Google Scholar] [CrossRef]

- Zhou, H.; Puttige, A.R.; Nair, G.; Olofsson, T. Thermal behaviour of a gypsum board incorporated with phase change materials. J. Build. Eng. 2024, 94, 109928. [Google Scholar] [CrossRef]

- Yuan, Z.; Jia, Y. Mechanical properties and microstructure of glass fiber and polypropylene fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2021, 266, 121048. [Google Scholar] [CrossRef]

- Rosas, M.H.; Chileno, N.G.C.; Campos, A.A.; Rocha, J.H.A. Analysis of concrete mechanical properties when adding type-E glass fibers. J. Build. Pathol. Rehabilitation 2023, 8, 1–12. [Google Scholar] [CrossRef]

| Mixture ID | Material (g) | ||||

|---|---|---|---|---|---|

| Gypsum | Expanded Clay | Fiberglass Waste | Quartzite Waste | Water | |

| Reference | 1080.0 | 0.0 | 0.0 | 0.0 | 464.4 |

| MQ-0 | 966.6 | 108.0 | 5.4 | 0.0 | 367.3 |

| MQ-0.5 | 961.2 | 108.0 | 5.4 | 5.4 | 365.3 |

| MQ-5 | 912.6 | 108.0 | 5.4 | 54.0 | 346.8 |

| MQ-50 | 426.6 | 108.0 | 5.4 | 540.0 | 162.1 |

| MQ-20 * | 750.6 | 108.0 | 5.4 | 216.0 | 285.2 |

| Element (%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Gypsum | 58.19 | 0.13 | 40.76 | 0.48 | 0.25 | 0.13 | - | - | - | - | - |

| Quartzite Waste | - | - | 0.14 | 22.07 | 74.53 | 0.11 | 2.20 | 0.14 | 0.46 | 0.16 | 0.13 |

| Fiberglass Waste | - | - | 21.3 | 13.2 | 55.0 | 3.3 | 0.1 | 0.2 | - | 1.0 | - |

| Mixture ID | Free Water (%) | Crystallization Water (%) |

|---|---|---|

| Reference | 1.40 | 12.50 |

| MQ-0 | 2.84 | 11.50 |

| MQ-0.5 | 2.74 | 9.50 |

| MQ-5 | 2.44 | 9.00 |

| MQ-50 | 1.86 | 6.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

R. Mol, R.M.; H. Rosas, M.; D. C. e Silva, K.; F. Peixoto, R.A. Development of Thermally Insulating Gypsum Boards Blended with Quartzite and Fiberglass Waste. Constr. Mater. 2025, 5, 30. https://doi.org/10.3390/constrmater5020030

R. Mol RM, H. Rosas M, D. C. e Silva K, F. Peixoto RA. Development of Thermally Insulating Gypsum Boards Blended with Quartzite and Fiberglass Waste. Construction Materials. 2025; 5(2):30. https://doi.org/10.3390/constrmater5020030

Chicago/Turabian StyleR. Mol, Rosana M., Marialaura H. Rosas, Keoma D. C. e Silva, and Ricardo A. F. Peixoto. 2025. "Development of Thermally Insulating Gypsum Boards Blended with Quartzite and Fiberglass Waste" Construction Materials 5, no. 2: 30. https://doi.org/10.3390/constrmater5020030

APA StyleR. Mol, R. M., H. Rosas, M., D. C. e Silva, K., & F. Peixoto, R. A. (2025). Development of Thermally Insulating Gypsum Boards Blended with Quartzite and Fiberglass Waste. Construction Materials, 5(2), 30. https://doi.org/10.3390/constrmater5020030