1. Introduction

Asphalt binder, the main component in road construction, is a thermoplastic (viscous-elastic) at high temperatures, typically above 25 °C, acts as a semi-solid or liquid material, while in intermediate to low temperatures, typically below 25 °C, it tends to become brittle [

1,

2,

3]. The sensitivity of asphalt binders to temperature and aging is the primary source of problems encountered in asphalt mixes over their service life. In recent years, rutting, fatigue cracking, and stripping are the main deteriorates resulting from enlarged traffic flows, bigger and hefty cars, and greater tire pressures, which intensified the condition severity on the pavement structure [

4,

5,

6,

7].

In attempts to mitigate these challenges, current researchers have applied various additives for asphalt binder modification. These modifications have primarily focused on enhancing mechanical performance through the use of rubbers, polymers, and bonding improvers. However, these additives have faced challenges, such as storage instability due to high-temperature susceptibility and low homogeneity with asphalt binder [

8,

9,

10,

11,

12,

13]. Therefore, recent advances in nanotechnology have prompted the exploration of various nanomaterials, including nano-titanium, nano-silica, nano-alumina, nano-clays, and other additives to improve asphalt binder’s physicochemical properties. This technology, widely used across different industries worldwide, presents innovative opportunities in engineering and material property enhancement [

14,

15,

16,

17].

Investigators conducted various studies with enormous types of nano-sized materials to boost the physiochemical properties of bituminous materials. One study conducted by Yao H. et al. examined the rheological properties of Performance Grade (PG 58-34) with particular ratios of modified nano-clay. The results showed enhancements in resistance to fatigue cracking and rutting [

18]. These properties were enhanced again with another study conducted by Yao H. et al., using carbon microfiber-modified nano-clay [

19]. Furthermore, reference [

20] used nano-silica to investigate the chemical and rheological properties of nano-modified binders. The findings indicated a decrease in viscosity and rutting susceptibility and an improvement in the dynamic modulus and flow number. Therefore, the enhancement in fatigue cracking performance and anti-aging characteristics and rutting was achieved by the study. This has been approved by other studies [

20,

21]. Also, Nano-CuO modifications have demonstrated improved aging resistance and increased specific heat capacity of asphalt binders, along with reduced temperature and moisture susceptibility, as achieved by [

22]. Incorporating nano-alumina into low-styrene-butadiene-styrene (SBS) content polymer-modified bitumen (PMB) significantly enhanced the rheological properties at both intermediate and high temperatures, as carried out by Kadhim et al. Additionally, this modification resulted in a stable system under storage conditions with excellent anti-aging resistance [

23].

Despite various studies on asphalt binder modification, there is inadequate research on the direct application of composite nanomaterials including Nano-Silica, Nano-Alumina, and Nano-Copper Oxide without additional additives. This gap is critical, as identifying the isolated impact of these nanomaterials on asphalt binder performance can lead to cost-effective and effectual modifications.

In this regard, can composite nanomaterials, without other additives, develop the physiochemical and durability properties of non-modified asphalt binder grade 60/70? Given the study aims and objectives, the integration of composite nanomaterials (Nano-Silica, Nano-Alumina, and Nano-Copper Oxide) into a non-modified asphalt binder can substantially enhance its physiochemical and durability properties due to the unique synergistic effects of these materials. Nano-Silica is involved because of its capability to enhance stiffness and aging resistance due to its high surface area and reactivity. Nano-Alumina is known for its thermal stability and capacity to improve high-temperature performance and rutting resistance. Nano-Copper Oxide contributes to enhanced oxidative resistance and long-term durability through its ability to mitigate the effects of thermal aging. Together, these nanomaterials are hypothesized to interact with the asphalt binder matrix at the nanoscale, forming a more homogeneous and durable structure capable of withstanding various stresses and environmental conditions. To confirm this theory, a series of tests were conducted, including penetration, temperature susceptibility, Dynamic Shear Rheometer (DSR), Rolling Thin Film Oven Test (RTFOT), and Bending Beam Rheometer (BBR). Each test was designed to assess specific properties such as stiffness, aging resistance, and temperature susceptibility.

2. Materials and Methods

2.1. Materials

In this study, a 60/70 penetration grade asphalt binder, supplied by the Directorate of Roads and Bridges—Duhok, KRI, was used. Conventional tests according to AASHTO standards were conducted to analyze the rheological properties of the original asphalt binder, as detailed in

Table 1. Additionally, the performance grade (PG) was determined as PG 64-16. Three different nanomaterials, namely Nano-Silica (SiO

2), Nano-Alumina (Al

2O

3), and Nano-Copper Oxide (CuO), were used to modify the asphalt binder, all of which were ordered from Hebei Suoyi New Material Technology Co., Ltd.—China. The nanomaterial properties are presented in

Table 2.

2.2. Sample Preparation

2.2.1. Nanomaterials Mixing Dosages

To assess the impact of nanomaterials, all three nanomaterials were combined together as a composite nanomaterial. To create the composite nanomaterial batch, the three nanomaterials were mixed together in four percent trial amounts. The first trial consisted of equal amounts of each nanomaterial at 33.33% each. Subsequent trials adjusted the mixing amounts to 25%, 25%, and 50% for the remaining three trials, with each nanomaterial at 50% in turn and the others at 25%. For clarity in the result analysis, each of the four trial mixes was named as presented in

Table 3. The composite nanomaterials were then prepared by weighing the desired amounts of 2%, 4%, and 6% by weight of the binder. A sensitive balance with a precision of 0.01 g was utilized for this part of the work.

2.2.2. Mixing Process

Firstly, to create composite nanomaterials, as all the utilized nanos were in powder forms, a mechanical mixing approach was employed to blend the nanos and achieve homogeneity of the composite. The process began with the accurate weighing of each nanomaterial powder, followed by their combination using mechanical blending, which involved using a high-speed mixer to ensure intimate contact and even distribution of the powders. This method helps to break down any agglomerates and promote a uniform blend of the nanomaterials. Then, an oven was used to heat the original asphalt binder to a temperature slightly above the softening point to become liquid for pouring into the mixing container. Each measured amount of nanomaterial was gradually and carefully added into the heated binder within a high shear mixer, operating at a low speed of 5000 rpm for 5 min to control floating particles and bubbles, prevent clumping, and ensure homogeneity and dispersion of the nanomaterials throughout the asphalt binder. The speed was then increased to 18,000 rpm for 15 min, with consideration given to maintaining the mixing temperature within the range of 162 ± 1 °C. After mixing and achieving proper dispersion, the modified asphalt binder was cooled and handled in sealed containers for further tests and applications.

2.3. Aging Process

The aging process of asphalt binder primarily involves exposure to various environmental and operational conditions over time, resulting from oxidation and volatilization mechanisms [

29,

30]. Short-term aging arises throughout the storing, mixing, transporting, and paving processes [

31]. To simulate this process in the laboratory, the rolling thin film oven (RTFOT) test was conducted in accordance with ASTM D 2872. Furthermore, the pressure aging vessel (PAV) test, as per ASTM D 6521, was carried out to assess the long-term aging of the asphalt binder, reflecting its performance during service [

32,

33].

2.4. Physical Properties of Binde

The binder used underwent conventional laboratory tests before and after the aging process, including ductility, softening point, penetration, and thermal susceptibility. The ductility test measures the asphalt binder’s ability to deform under tensile stress before breaking, performed at a speed of 5 cm/minute and a temperature of 25 °C, in accordance with AASHTO T-51 [

34]. Also, the temperature at which a bituminous sample softens to a specified degree under heat influence is determined by the softening point (SP) test. This test is crucial for understanding the temperature susceptibility and thermal characteristics of asphalt binder, which are essential factors in determining its suitability for use in asphalt pavements [

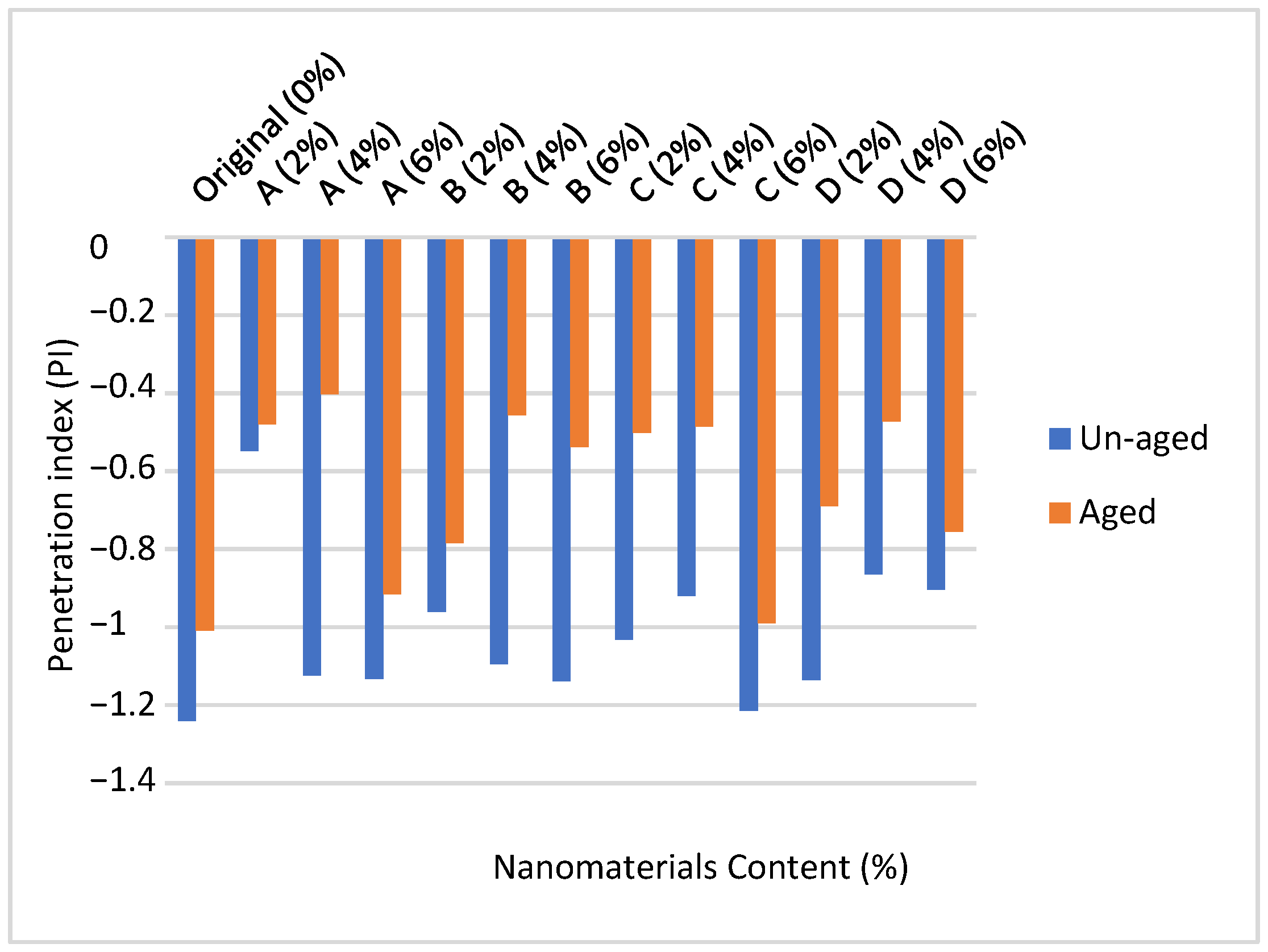

35]. The SP test is conducted according to AASHTO T-53. The penetration test is carried out at a temperature of 25 °C, with a load of 100 g and a time of 5 s, following AASHTO T-49. Rotational viscosity testing is conducted in accordance with AASHTO T-316-13. Finally, the penetration index (PI), which indicates the thermal susceptibility of the asphalt binder, can be determined from the softening point and penetration result data [

34]. A higher PI value indicates lower susceptibility of the asphalt binder to temperature variations. Hence, considering temperature susceptibility, a higher PI value is preferable. The PI value, which varies between −3 (highly susceptible) and +7 (lowly susceptible), can be calculated using Equation (1) [

35,

36,

37].

where PI = Penetration Index, SP = Softening point (°C), and Pen

25 = Penetration value at 25 °C.

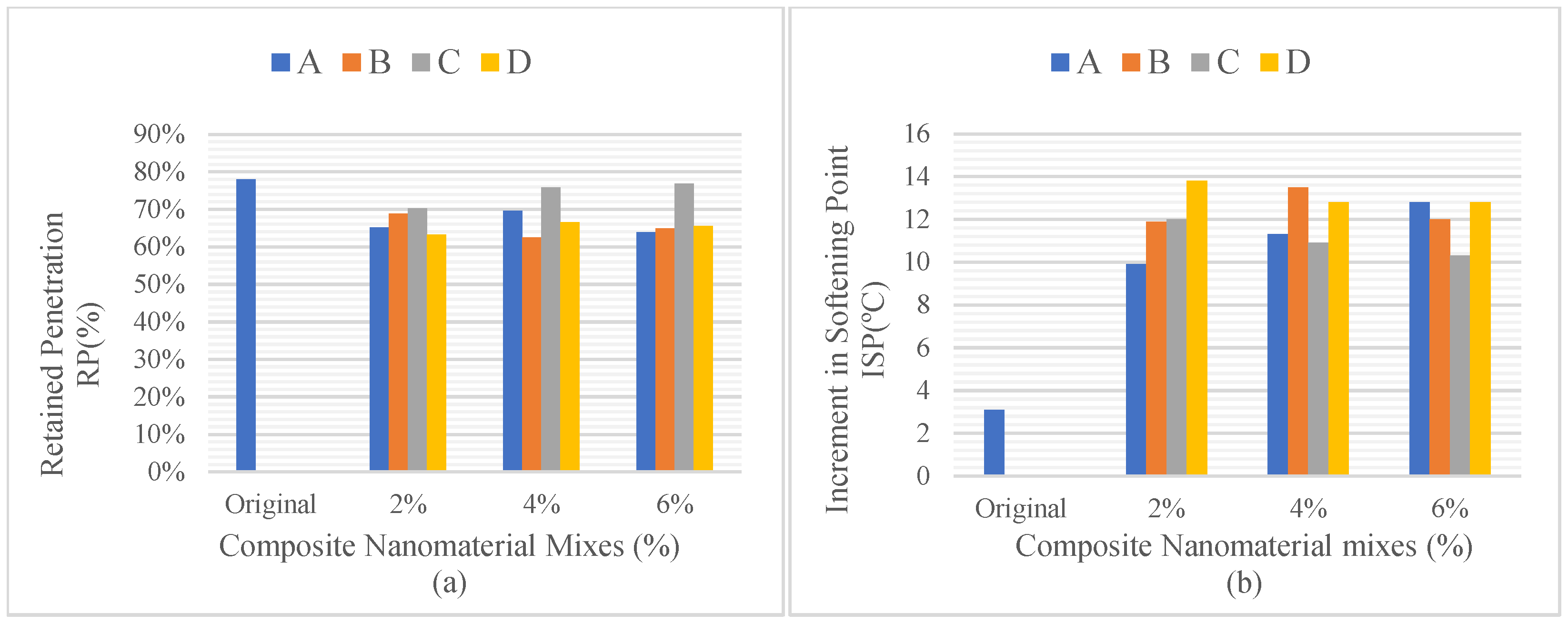

To resist short-term aging, investigations focus on the increment in the softening point (ISP) and the retained penetration (RP) [

38]. ISP represents the difference between the aged and unaged softening points, while RP indicates the percentage of aged penetration to unaged penetration. These parameters are calculated using Equations (2) and (3), respectively.

As the asphalt binder ages, its penetration value decreases, and simultaneously, its softening point and viscosity increase. Generally, for aging resistance of asphalt binder, higher ISP and lower RP values are indicative of better aging resistance. Therefore, a higher ISP and lower RP value help to reverse further aging of the asphalt binder [

39,

40].

2.5. Storage Stability

This test, which is conducted according to ASTM D7173-20 guidelines, indicates the ability of asphalt binder, particularly the modified asphalt binder, to remain homogeneous and maintain its properties during storage at elevated temperatures [

41]. This is crucial for ensuring that the binder does not phase-separate into different components over time, which can negatively affect its performance when used in pavement construction. One common method to assess this stability is the softening point test. In this test, an asphalt binder sample is stored at elevated temperatures for a specified period, and then divided into top and bottom sections. The softening point is measured for both sections. Significant differences in the softening points between the top and bottom layers (ΔT) suggest that the binder has undergone phase separation during storage, indicating poor storage stability. This test helps in identifying the tendency of asphalt binders to maintain a homogeneous composition, ensuring reliable performance in practical applications [

38].

2.6. Dynamic Rheologic Parameters

2.6.1. Dynamic Shear Rheometer (DSR) Test

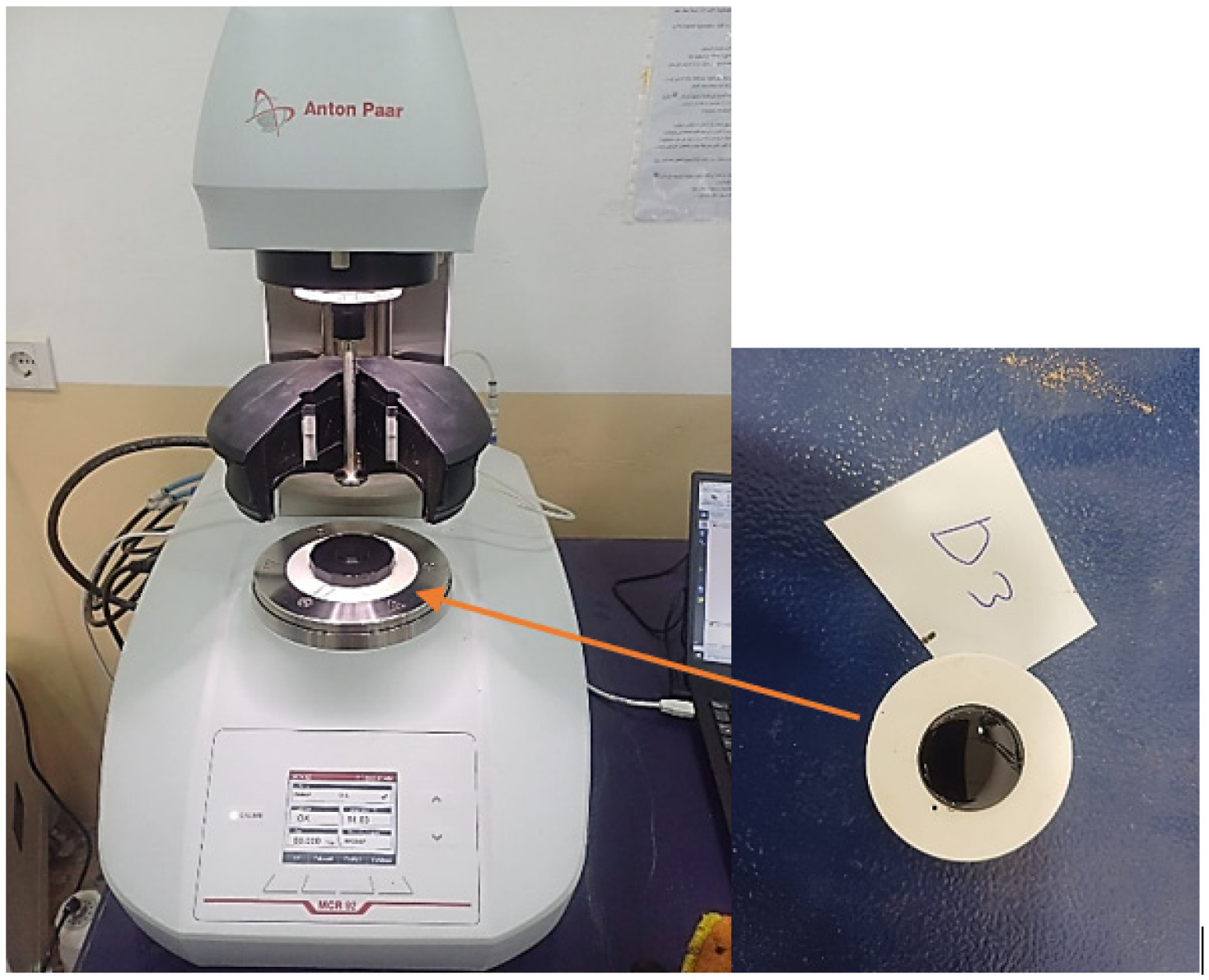

Concerning the rheological characteristics of the binder at intermediate to high temperatures, a dynamic shear rheometer tester, (Anton Paar RheoCompass™) produced by Santner Foundation, Graz, Austria, as shown in

Figure 1, was utilized in accordance with AASHTO T315 [

42]. The DSR test provides two key parameters: the complex shear modulus (G*) and the phase angle (δ) [

43]. These parameters aim to assess the elastic and viscous behaviors of the modified binder samples, which undergo frequent shearing, causing deformation. G* is the comprehensive measure of a specimen’s resistance to deformation, while δ, describing the relationship between components of viscous and elastic behaviors, characterizes the shift between the resultant shear strain and the applied shear stress [

31,

38,

44]. Fatigue cracking and rutting are two indicators obtained from the (G*) and (δ) results [

45]. A greater value of the phase angle (δ) indicates a more viscous asphalt binder, with values typically ranging from 0° to 90° [

46,

47].

2.6.2. Bending Beam Rheometer Test (BBR)

This test was performed on both original and modified asphalt binders following the guidelines of AASHTO T313, as shown in

Figure 2, to evaluate the asphalt binders’ thermal cracking susceptibility. This test aids in evaluating the stiffness and relaxation characteristics of asphalt binders at cold temperatures, which is essential for predicting their performance in cold climates [

6,

16,

22,

48,

49].

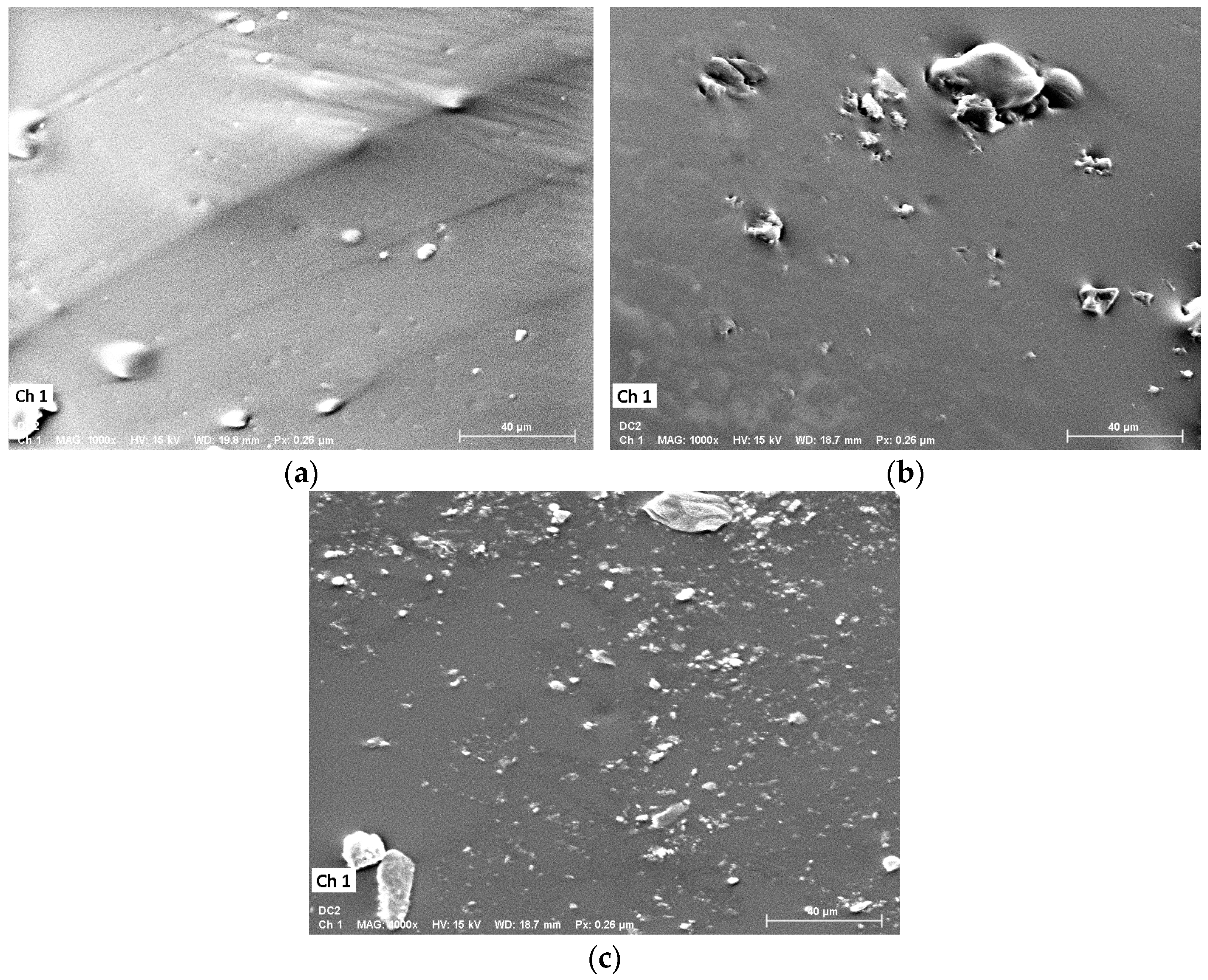

2.7. Dispersion of Nanomaterials in Binder

The scanning electron microscope (SEM) was used to examine the surface morphology of the samples and evaluate the dispersion of nanomaterials within the asphalt binder matrix. SEM imaging, performed at a magnification of 1000×, provided detailed insights into the physical structure and surface characteristics, enabling the identification of any agglomerations or voids. This analysis helped confirm the effectiveness of the mixing process in achieving a uniform distribution of nanomaterials throughout [

50,

51,

52,

53].

3. Results and Discussion

3.1. Conventional Tests

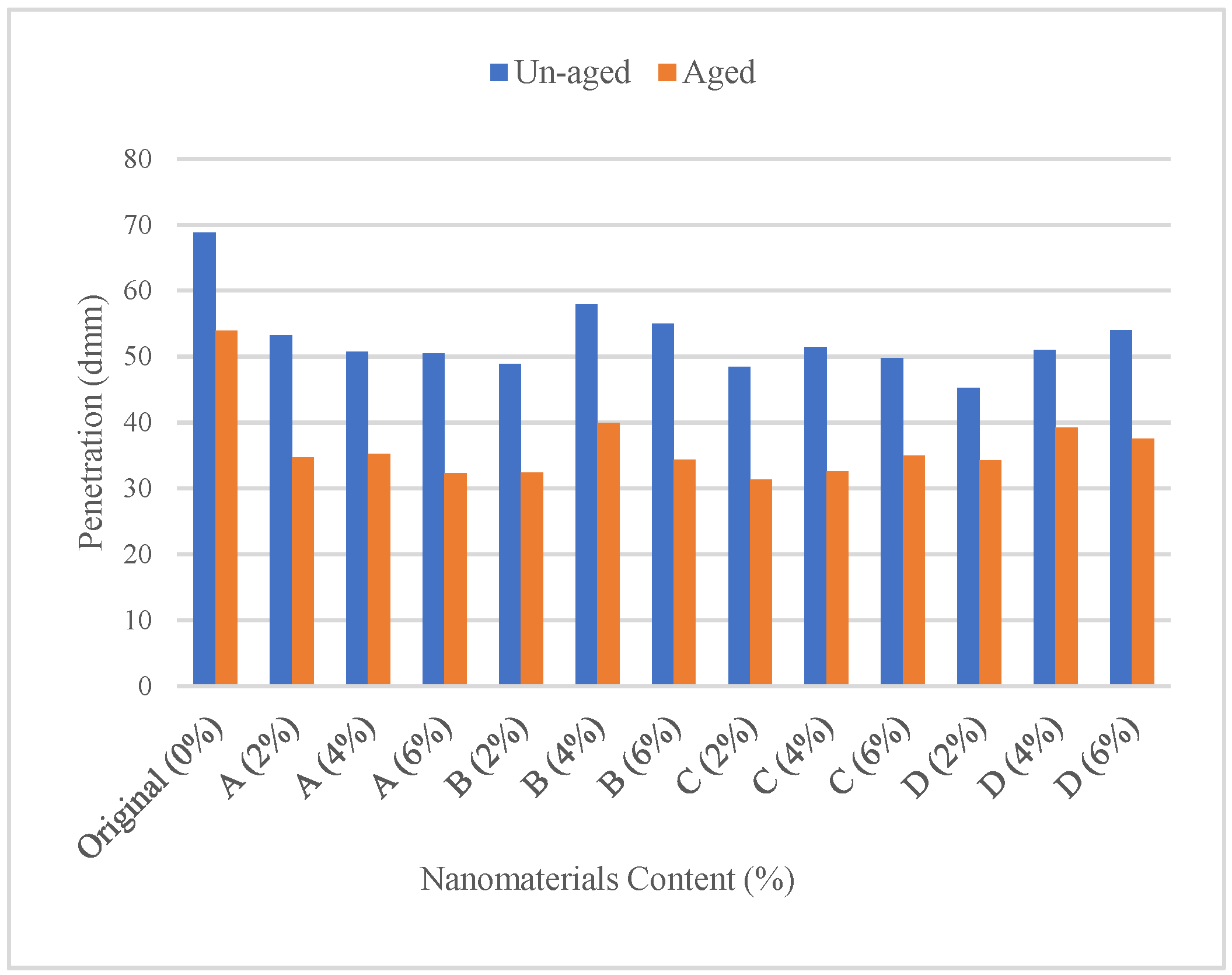

Incorporating nanomaterials into the asphalt binder throughout the previously mentioned procedure has resulted in recognizable improvements in physical properties. The effects of the nanomaterial dosages on aged and unaged samples for penetration, softening point, and thermal susceptibility are shown in

Figure 3,

Figure 4 and

Figure 5, respectively.

From

Figure 3, the penetration test results show a significant reduction in penetration for both un-aged and aged asphalt binders with the addition of A, B, C, and D nanomaterial mixes at different concentrations: 2%, 4%, and 6%. The original binder shows the highest penetration value, indicating a softer consistency. In contrast, binders modified with nanomaterials demonstrate lower penetration values, suggesting increased stiffness. This stiffening effect is more pronounced in aged samples, highlighting the role of nanomaterials in enhancing the resistance to aging. These findings are consistent with the studies in [

54,

55,

56,

57]. Consequently, the results can suggest that the best ratio for the penetration-modified binder is 2% of the mix D as the original asphalt binder grade transferred from 60/70 to 40/50. Conversely, for age-modified binders, the penetration values are nearly stable across all mix ratios and improved better compared to the un-aged ones.

From the results shown in

Figure 4a,b, the original binder shows the highest RP%, and lower ISP indicating better aging resistance. As the percentage of nanomaterial increases, a fluctuation in RP% and ISP values was observed for mix A, B, and D, while an increase in RP% and decrease in ISP values was observed for mix C. Among the modified mixes, mix C at 6% represents the best aging resistance as it yields the lower ISP and higher RP values.

From the results shown in

Figure 5, un-aged asphalt binders exhibit lower susceptibility to temperature than aged ones compared to original asphalt binder. The PI value decreases with the increase in nanomaterials content for un-aged A and B mixes while there are fluctuations in PI values for C and D mixes due to the variation in molecular weights of the utilized nanos. Consequently, the highest temperature susceptibility is observed with the 2% ratio of mix A for unaged, modified asphalt binder and with the 4% ratio of mix A for aged ones.

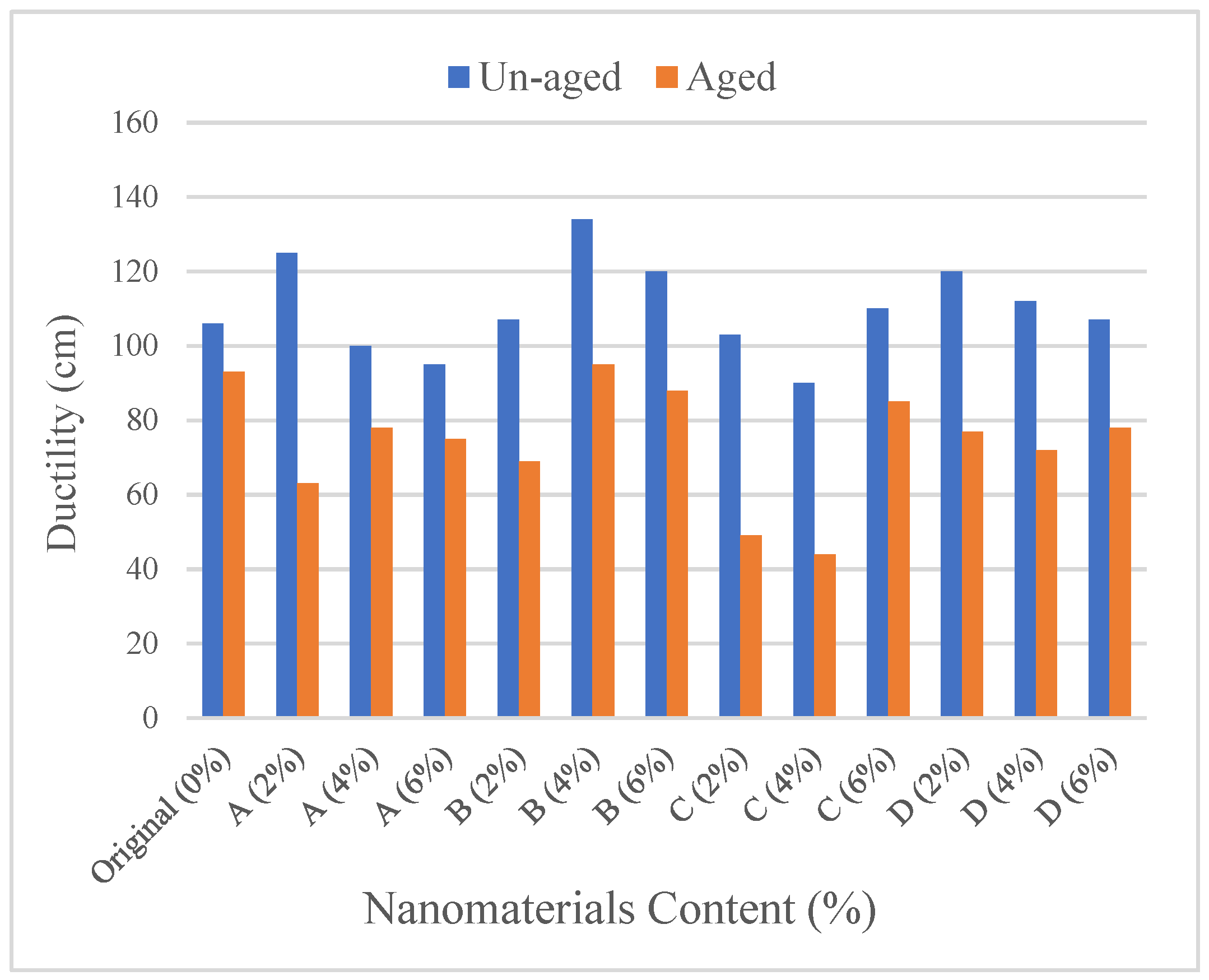

The ductility test results are utilized to assess the anti-deformation and anti-cracking characteristics of modified asphalt binders. As depicted in

Figure 6, for unaged, modified asphalt binders, advances in ductility can be observed with certain contents of composite nanomaterials. Compared to the original binder, mixes consisting of 4% of mix B, 2% of mix A, 2% of mix D, and 6% of mix C showed the most significant enhancement among each mix in modified asphalt binders. This suggests the enhanced ability of the modified asphalt binders to withstand low-temperature performance and resist cracking before the aging process. Conversely, ductility decreased after short-term (RTFOT) aging for all mix contents except 4% of mix B.

Figure 7 illustrates the impact of composite nanomaterial contents on the high-temperature storage stability of modified asphalt binders, measured by the temperature difference (ΔT) between the top and bottom sections after storage. The results show that as the nanomaterial content increases, ΔT also rises, indicating a greater temperature difference and potentially less uniform binder storage. Mixes D and B exhibited the highest ΔT, reaching approximately 2.6 °C and 2 °C, respectively, at 6% content, while mixes A and C displayed more moderate increases. This indicates that mixes A and C contributed to better storage stability compared to mixes D and B. Overall, mix C provided the best high-temperature storage stability among the tested mixes, particularly at higher concentrations. This is due to its higher content of nano-silica, which has a lower molecular weight than the others, as shown in

Table 2. The same impact of nano-silica contribution was observed in a study conducted by [

41].

3.2. Dynamic Rheologic Tests

3.2.1. Dynamic Shear Rheometer Test (DSR)

This test was carried out on aged and unaged modified asphalt binders.

Figure 8 and

Figure 9 represent the plots illustrating the complex shear modulus and phase angle at elevated temperatures for various ratios of composite nanomaterial-modified asphalt binder mixes, for both unaged and aged samples, respectively. The rise in temperature has led to a decrease in the complex shear modulus while simultaneously causing an increase in the phase angle values. Consequently, as the temperature increased, the asphalt binder exhibited greater viscosity. However, compared to the original asphalt binder at the same testing temperatures, the G* values increased, and the δ values decreased for all modified asphalt binders. This implies an improvement in the stiffness and elastic properties of the modified asphalt binders observed in both unaged and aged samples. The observed stiffening effect of nano-silica aligns with the findings reported by [

10,

42,

58], and the effect of nano-alumina is consistent with the results in [

54,

56].

3.2.2. Bending Beam Rheometer (BBR)

This test evaluates the low-temperature characteristics of modified asphalt binders, such as stiffness and resistance to cracking. These properties are crucial for ensuring the durability of asphalt pavements in cold climates over long-term performance. However, concerning stiffness, the findings presented in

Figure 10 show minor improvements in some nanomaterial contents compared to the original asphalt binders, but overall, the results have met the SuperPave criteria, which is less than 300 MPa. Regarding the m-value parameter, all samples at −6 °C have met the requirement, which was more than 0.3, but failed at −12 °C. The sample B-2% obtained the lowest creep stiffness and the highest m-value at −6 °C, indicating fewer low-temperature cracks.

3.3. Nanomaterials Dispersion

The SEM images prove that the mixing technique employed effectively ensures a uniform dispersion of nanomaterials across all samples. At a 2% nanomaterial content, as shown in

Figure 11a, the nanomaterials are well-dispersed with no visible agglomeration, indicating an optimal interaction between the nanomaterials and the asphalt binder matrix. Similarly,

Figure 11b highlights that at a 4% content, the dispersion remains consistent, with only minor indications of clustering. However, at a higher content of 6% (

Figure 11c), small agglomerations begin to form, likely due to the saturation of the binder matrix, which reduces the efficiency of dispersion. This suggests that while higher concentrations of nanomaterials can potentially enhance the binder’s properties, they may also lead to diminishing returns in dispersion quality due to particle aggregation.

4. Conclusions

This study demonstrates significant improvements in the physiochemical and durability properties of asphalt binders modified with composite nanomaterials, including Nano-Silica, Nano-Alumina, and Nano-Copper Oxide. The findings confirm that incorporating these nanomaterials enhances key characteristics, such as penetration, aging resistance, and temperature susceptibility, suggesting their potential for improving asphalt binder performance. Specifically, the addition of nanomaterials at optimized concentrations (e.g., 6% mix C for aged and unaged samples) resulted in improved temperature susceptibility, with modifications showing reduced penetration values and better resistance to aging compared to unmodified binders. This is attributed to the effective dispersion and interaction of the nanomaterials within the binder matrix, which helps enhance its stability and performance. Also, composite nanomaterials, especially mix C, demonstrate superior performance for high-temperature storage stability, as they contain elevated nano-silica concentration compared to other mixes.

Further mechanical testing, including Dynamic Shear Rheometer (DSR) and Bending Beam Rheometer (BBR) tests, confirmed that the modified asphalt binders exhibited enhanced stiffness and elasticity. This led to a reduction in rutting deformation and increased resistance to low-temperature cracking, particularly with mix B at 2% and other compositions. The modified binders displayed improved long-term durability and resistance to construction-related stresses, as well as the ability to withstand high temperatures and low-temperature cracking. Although some samples showed minor shortcomings at extremely low temperatures, the results indicate that the nanomaterial-modified binders are suitable for applications in regions with fluctuating temperature conditions.

To conclude, the differing behaviors of Samples A, B, C, and D can be attributed to the type and proportion of composite nanomaterials used. Sample A exhibited optimal performance at lower dosages (2% and 4%), demonstrating enhanced temperature sensitivity and aging resistance. Sample B, with higher dosages, showed significant improvements in stiffness and durability. Samples C and D displayed intermediate performance due to the combined influence of material composition and interaction effects. These variations highlight the importance of tailoring nanomaterial combinations and dosages to achieve desired binder properties.

Overall, composite nanomaterials demonstrate great potential to improve the mechanical and durability properties of asphalt binders. The positive impacts observed, especially in resisting rutting and aging, highlight the viability of these modified binders for road construction, particularly in areas with high traffic loads and variable climate conditions.

Author Contributions

Conceptualization, B.R.O. and G.J.K.; methodology, B.R.O.; validation, B.R.O. and G.J.K.; formal analysis, B.R.O. and G.J.K.; investigation, B.R.O.; resources, B.R.O. and G.J.K.; data curation, B.R.O. and G.J.K.; writing—original draft preparation, B.R.O.; writing—review and editing, B.R.O. and G.J.K.; visualization, B.R.O. and G.J.K.; supervision, G.J.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

All supporting information and data have been included in this article and are available on request in other formats.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Arabani, M.; Sadeghnejad, M.; Haghanipour, J.; Hassanjani, M.H. The influence of rice bran oil and nano-calcium oxide into bitumen as sustainable modifiers. Case Stud. Constr. Mater. 2024, 21, e03458. [Google Scholar] [CrossRef]

- Carraher, C.E., Jr. Seymour/Carraher’s Polymer Chemistry; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Hunter, R.N.; Self, A.; Read, J. The Shell Bitumen Handbook; ICE Publishing: London, UK, 2015; Volume 514. [Google Scholar]

- Airey, G.D. Rheological evaluation of ethylene vinyl acetate polymer modified bitumens. Constr. Build. Mater. 2002, 16, 473–487. [Google Scholar] [CrossRef]

- Apostolidis, P.; Liu, X.; Kasbergen, C.; Scarpas, A.T. Synthesis of Asphalt Binder Aging and the State of the Art of Antiaging Technologies. Transp. Res. Rec. 2017, 2633, 147–153. [Google Scholar] [CrossRef]

- He, R.; Wu, S.; Wang, X.; Wang, Z.; Chen, H. Temperature Sensitivity Characteristics of SBS/CRP-Modified Bitumen after Different Aging Processes. Materials 2018, 11, 2136. [Google Scholar] [CrossRef]

- Ramadhansyah, P.J.; Masri, K.A.; Norhidayah, A.H.; Hainin, M.R.; Muhammad Naqiuddin, M.W.; Haryati, Y.; Satar, M.K.I.M.; Juraidah, A. Nanoparticle in Asphalt Binder: A State-of-The-Art Review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 712, 012023. [Google Scholar] [CrossRef]

- Abdel-Wahed, T.; Rashwan, N.K.; Maurice, A.E. The physical properties of bitumen modified with ilmenite and bentonite nanoparticles. HBRC J. 2020, 16, 335–350. [Google Scholar] [CrossRef]

- Ahmad Faizul, M.F.R. The Physical and Engineering Properties of 80/100 Bitumen with Carbon Black Additive. Bachelor’s Thesis, Universiti Teknologi PETRONAS, Seri Iskandar, Malaysia, 2013. [Google Scholar]

- Alhamali, D.I.; Wu, J.; Liu, Q.; Hassan, N.A.; Yusoff, N.I.M.; Ali, S.I.A. Physical and Rheological Characteristics of Polymer Modified Bitumen with Nanosilica Particles. Arab. J. Sci. Eng. 2016, 41, 1521–1530. [Google Scholar] [CrossRef]

- Kalantar, Z.N.; Karim, M.R.; Mahrez, A. A review of using waste and virgin polymer in pavement. Constr. Build. Mater. 2012, 33, 55–62. [Google Scholar] [CrossRef]

- Mohammad Asib, A.S.; Rahman, R.; Romero, P.; Hoepfner, M.P.; Mamun, A. Physicochemical characterization of short and long-term aged asphalt mixtures for low-temperature performance. Constr. Build. Mater. 2022, 319, 126038. [Google Scholar] [CrossRef]

- Porto, M.; Caputo, P.; Loise, V.; Eskandarsefat, S.; Teltayev, B.; Oliviero Rossi, C. Bitumen and Bitumen Modification: A Review on Latest Advances. Appl. Sci. 2019, 9, 742. [Google Scholar] [CrossRef]

- Taherkhani, H.; Bayat, R. Applied Nanomaterials in Enhancing the Properties of Asphalt Mixtures. Casp. J. Appl. Sci. Res. 2015, 4, 36–40. [Google Scholar]

- Teizer, J.; Venugopal, M.; Teizer, W.; Felkl, J. Nanotechnology and Its Impact on Construction: Bridging the Gap Between Researchers and Industry Professionals. J. Constr. Eng. Manag. 2012, 138, 594–604. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, A.N.; Amirkhanian, S.N. Long-term ageing influence on rheological characteristics of asphalt binders containing carbon nanoparticles. Int. J. Pavement Eng. 2011, 12, 533–541. [Google Scholar] [CrossRef]

- Yu, Q. Application of nanomaterials in alkali-activated materials. In Nanotechnology in Eco-Efficient Construction; Elsevier: Amsterdam, The Netherlands, 2019; pp. 97–121. [Google Scholar]

- Yao, H.; You, Z.; Li, L.; Shi, X.; Goh, S.W.; Mills-Beale, J.; Wingard, D. Performance of asphalt binder blended with non-modified and polymer-modified nanoclay. Constr. Build. Mater. 2012, 35, 159–170. [Google Scholar] [CrossRef]

- Yao, H.; You, Z.; Li, L.; Goh, S.W.; Lee, C.H.; Yap, Y.K.; Shi, X. Rheological properties and chemical analysis of nanoclay and carbon microfiber modified asphalt with Fourier transform infrared spectroscopy. Constr. Build. Mater. 2013, 38, 327–337. [Google Scholar] [CrossRef]

- Fini, E.H.; Hajikarimi, P.; Rahi, M.; Moghadas Nejad, F. Physiochemical, rheological, and oxidative aging characteristics of asphalt binder in the presence of mesoporous silica nanoparticles. J. Mater. Civ. Eng. 2016, 28, 04015133. [Google Scholar] [CrossRef]

- You, Z.; Mills-Beale, J.; Foley, J.M.; Roy, S.; Odegard, G.M.; Dai, Q.; Goh, S.W. Nanoclay-modified asphalt materials: Preparation and characterization. Constr. Build. Mater. 2011, 25, 1072–1078. [Google Scholar] [CrossRef]

- Amini, N.; Hayati, P. Effects of CuO nanoparticles as phase change material on chemical, thermal and mechanical properties of asphalt binder and mixture. Constr. Build. Mater. 2020, 251, 118996. [Google Scholar] [CrossRef]

- Kadhim, H.J.; Modarres, A.; Al-Busaltan, S. Rheological and microstructural properties of nano-composite bitumen modified by nano-alumina and low-SBS content. Case Stud. Constr. Mater. 2024, 20, e03244. [Google Scholar] [CrossRef]

- ASTM D946M-15; Standard Specification for Penetration-Graded Asphalt Binder for Use in Pavement Construction. ASTM International: West Conshohocken, PA, USA, 2015.

- AASHTO T-049; Standard Method of Test for Penetration of Bituminous Materials. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2019.

- AASHTO T-051; Standard Method of Test for Ductility of Asphalt Materials. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2018.

- AASHTO T-053; Standard Method of Test for Softening Point of Bitumen (Ring-and-Ball Apparatus). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2018.

- AASHTO T-316-13; Standard Method of Test for Viscosity Determination of Asphalt Binder Using Rotational Viscometer. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2013.

- Zare-Shahabadi, A.; Shokuhfar, A.; Ebrahimi-Nejad, S. Preparation and rheological characterization of asphalt binders reinforced with layered silicate nanoparticles. Constr. Build. Mater. 2010, 24, 1239–1244. [Google Scholar] [CrossRef]

- Mousavi, M.; Aldagari, S.; Fini, E.H. Adsorbing Volatile Organic Compounds within Bitumen Improves Colloidal Stability and Air Quality. ACS Sustain. Chem. Eng. 2023, 11, 9581–9594. [Google Scholar] [CrossRef]

- Lee, S.-J.; Amirkhanian, S.N.; Shatanawi, K.; Kim, K.W. Short-term aging characterization of asphalt binders using gel permeation chromatography and selected Superpave binder tests. Constr. Build. Mater. 2008, 22, 2220–2227. [Google Scholar] [CrossRef]

- Oliviero Rossi, C.; Caputo, P.; Ashimova, S.; Fabozzi, A.; D’Errico, G.; Angelico, R. Effects of Natural Antioxidant Agents on the Bitumen Aging Process: An EPR and Rheological Investigation. Appl. Sci. 2018, 8, 1405. [Google Scholar] [CrossRef]

- Lee, S.-J.; Amirkhanian, S.; Park, N.-W.; Kim, K. Characterization of warm mix asphalt binders containing artificially long-term aged binders. Constr. Build. Mater. 2009, 23, 2371–2379. [Google Scholar] [CrossRef]

- Zhang, L.; Gao, X.; Wang, W.; Wang, H.; Zheng, K. Laboratory Evaluation of Rheological Properties of Asphalt Binder Modified by Nano-TiO2/CaCO3. Adv. Mater. Sci. Eng. 2021, 2021, 5522025. [Google Scholar] [CrossRef]

- Wang, W.; Cheng, Y.; Tan, G.; Liu, Z.; Shi, C. Laboratory investigation on high- and low-temperature performances of asphalt mastics modified by waste oil shale ash. J. Mater. Cycles Waste Manag. 2018, 20, 1710–1723. [Google Scholar] [CrossRef]

- Ashish, P.K.; Singh, D. Study on understanding functional characteristics of multi-wall CNT modified asphalt binder. Int. J. Pavement Eng. 2020, 21, 1069–1082. [Google Scholar] [CrossRef]

- Gunay, T. Investigation of physical properties of base and SBS modified bitumens by rheological test methods. Rev. De La Construcción. J. Constr. 2022, 21, 281–294. [Google Scholar] [CrossRef]

- Galooyak, S.S.; Dabir, B.; Nazarbeygi, A.E.; Moeini, A. Rheological properties and storage stability of bitumen/SBS/montmorillonite composites. Constr. Build. Mater. 2010, 24, 300–307. [Google Scholar] [CrossRef]

- Jahromi, S.G.; Khodaii, A. Effects of nanoclay on rheological properties of bitumen binder. Constr. Build. Mater. 2009, 23, 2894–2904. [Google Scholar] [CrossRef]

- Crucho, J.; Picado-Santos, L.; Neves, J.; Capitão, S. A Review of Nanomaterials’ Effect on Mechanical Performance and Aging of Asphalt Mixtures. Appl. Sci. 2019, 9, 3657. [Google Scholar] [CrossRef]

- Albayati, A.H.; Latief, R.H.; Al-Mosawe, H.; Wang, Y. Nano-Additives in Asphalt Binder: Bridging the Gap between Traditional Materials and Modern Requirements. Appl. Sci. 2024, 14, 3998. [Google Scholar] [CrossRef]

- Yao, H.; You, Z.; Li, L.; Lee, C.; Wingard, D.; Yap, Y.K.; Shi, X.; Goh, S.W. Properties and Chemical Bonding of Asphalt and Asphalt Mixtures Modified with Nanosilica. J. Mater. Civ. Eng. 2012, 25, 1619–1630. [Google Scholar] [CrossRef]

- Baldino, N.; Gabriele, D.; Lupi, F.R.; Oliviero Rossi, C.; Caputo, P.; Falvo, T. Rheological effects on bitumen of polyphosphoric acid (PPA) addition. Constr. Build. Mater. 2013, 40, 397–404. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, A.N.; Amirkhanian, S.N. Influence of Carbon Nanoparticles on the Rheological Characteristics of Short-Term Aged Asphalt Binders. J. Mater. Civ. Eng. 2011, 23, 423–431. [Google Scholar] [CrossRef]

- Bachir, S.D.; Dekhli, S.; Mokhtar, A.K. Rheological properties and storage stability of SEBS polymer modified bitumens. Int. J. Eng. Sci. Technol. 2013, 5, 1031–1038. [Google Scholar]

- Golestani, B.; Nam, B.H.; Moghadas Nejad, F.; Fallah, S. Nanoclay application to asphalt concrete: Characterization of polymer and linear nanocomposite-modified asphalt binder and mixture. Constr. Build. Mater. 2015, 91, 32–38. [Google Scholar] [CrossRef]

- Shah, P.M.; Mir, M.S. Application of nanotechnology in pavement engineering: A review. Can. J. Civ. Eng. 2020, 47, 1037–1045. [Google Scholar] [CrossRef]

- Karki, B. Effect of Nanomaterials on Binder and Mix Performance; The University of North Dakota: Grand Forks, ND, USA, 2017. [Google Scholar]

- Cheraghian, G.; Wistuba, M.P.; Kiani, S.; Barron, A.R.; Behnood, A. Rheological, physicochemical, and microstructural properties of asphalt binder modified by fumed silica nanoparticles. Sci. Rep. 2021, 11, 11455. [Google Scholar] [CrossRef]

- Abdalfattah, I.A.; Mogawer, W.S.; Stuart, K. Quantification of the degree of blending in hot-mix asphalt (HMA) with reclaimed asphalt pavement (RAP) using Energy Dispersive X-Ray Spectroscopy (EDX) analysis. J. Clean. Prod. 2021, 294, 126261. [Google Scholar] [CrossRef]

- Jiang, Y.; Gu, X.; Zhou, Z.; Ni, F.; Dong, Q. Laboratory Observation and Evaluation of Asphalt Blends of Reclaimed Asphalt Pavement Binder with Virgin Binder using SEM/EDS. Transp. Res. Rec. 2018, 2672, 69–78. [Google Scholar] [CrossRef]

- Zhu, X.; Yuan, Y.; Li, L.; Du, Y.; Li, F. Identification of interfacial transition zone in asphalt concrete based on nano-scale metrology techniques. Mater. Des. 2017, 129, 91–102. [Google Scholar] [CrossRef]

- Lin, P.-C.; Lin, S.; Wang, P.C.; Sridhar, R. Techniques for physicochemical characterization of nanomaterials. Biotechnol. Adv. 2014, 32, 711–726. [Google Scholar] [CrossRef] [PubMed]

- Ali, S.I.A.; Ismail, A.; Yusoff, N.I.M.; Hassan, N.A.; Ibrahim, A.N.H. Characterization of the performance of aluminum oxide nanoparticles modified asphalt binder. J. Teknol. 2016, 78. [Google Scholar] [CrossRef]

- Badgujar, P. Imprint of Nano-silica particles on Ageing of Bitumen. Int. J. Res. Appl. Sci. Eng. Technol. 2018, 6, 238–242. [Google Scholar] [CrossRef]

- Al-Mansob, R.A.; Ismail, A.; Rahmat, R.A.O.K.; Borhan, M.N.; Alsharef, J.M.A.; Albrka, S.I.; Karim, M.R. The performance of Epoxidised Natural Rubber modified asphalt using nano-alumina as additive. Constr. Build. Mater. 2017, 155, 680–687. [Google Scholar] [CrossRef]

- Zghair, H.; Joni, H.; Hassan, M. Rheological Characteristics of Nano Silica Modified Asphalt Binder Material. In Proceedings of the 2019 International Engineering Conference (IEC), Erbil, Iraq, 23–25 June 2019; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar]

- Al-Sabaeei, A.M.; Napiah, M.; Sutanto, M.; Alaloul, W.; Md Yusoff, N.I.; Imran Khan, M.; Modibbo Saeed, S. Physicochemical, rheological and microstructural properties of Nano-Silica modified Bio-Asphalt. Constr. Build. Mater. 2021, 297, 123772. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).