Performance Evaluation of Recycled Fibers in Asphalt Mixtures

Abstract

1. Introduction

Objective

2. Materials and Methods

2.1. Virgin Aggregates and Reclaimed Asphalt Pavement (RAP)

2.2. Asphalt Binder

2.3. Recycled Fibers

2.4. Fillers

2.5. Asphalt Emulsion

2.6. Selection of Air Void Levels for Performance Testing

2.7. Mix Design Phase Using a Balanced Mix Design (BMD) Approach

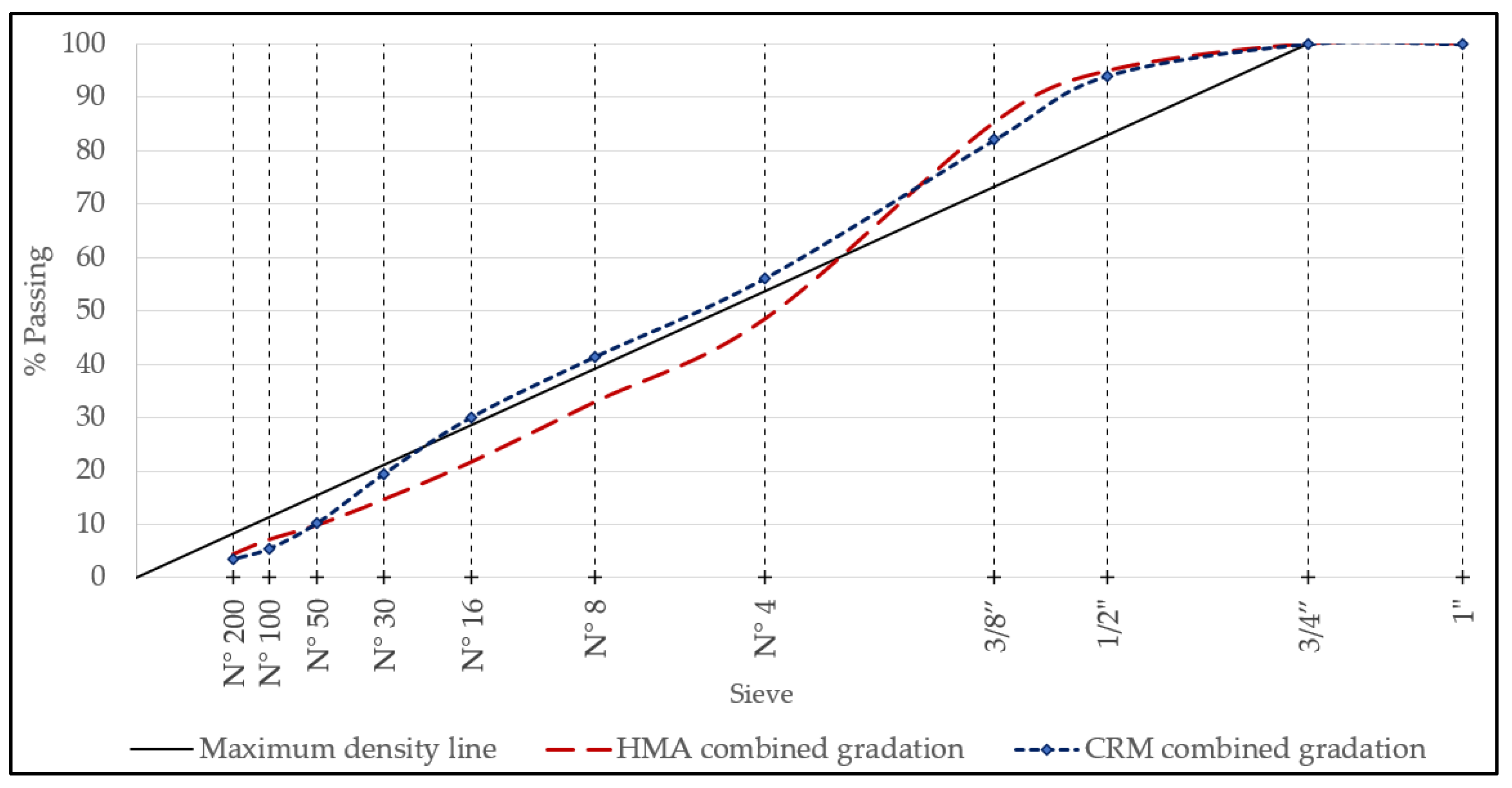

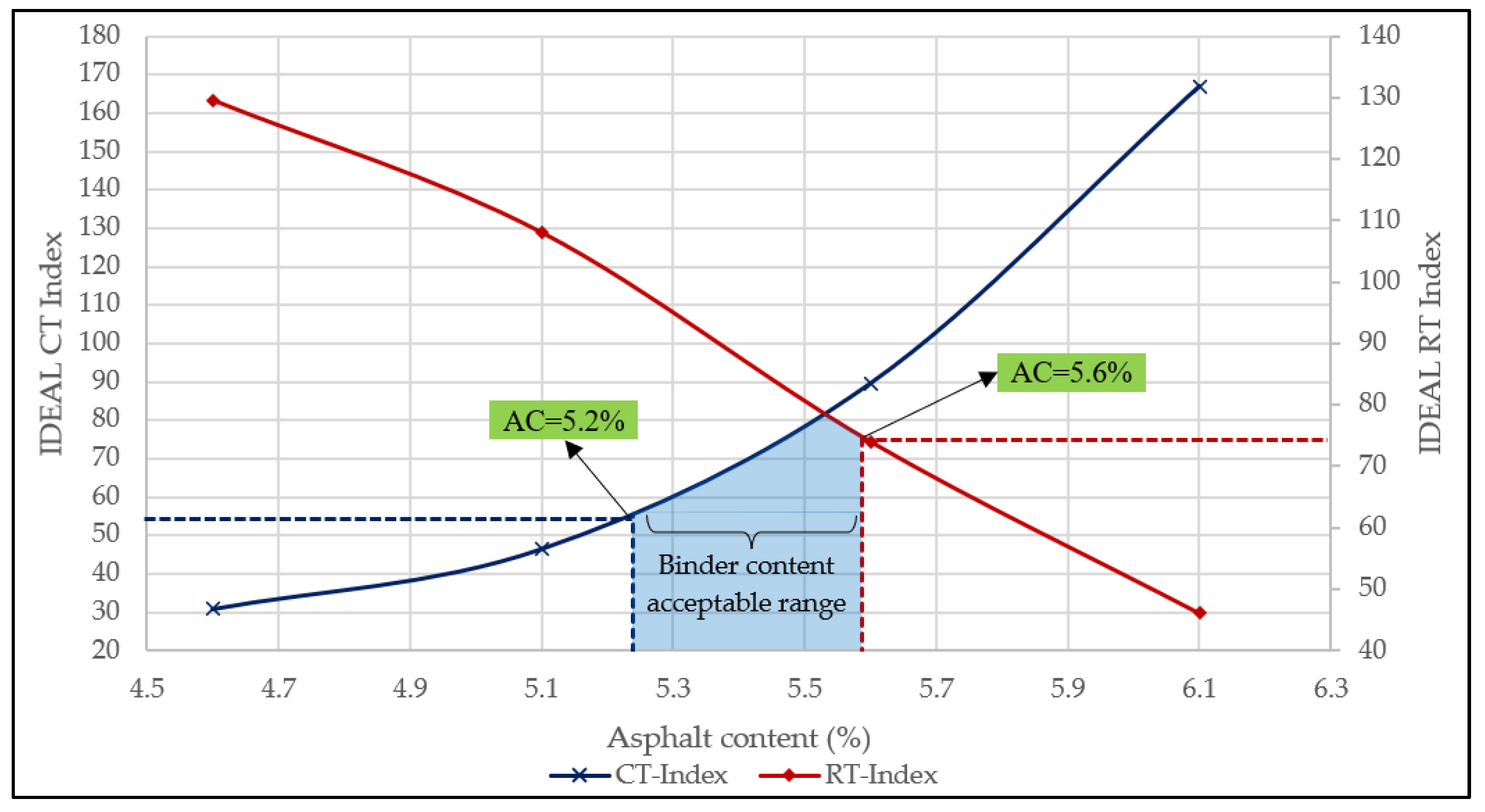

2.7.1. BMD Approach for HMA

2.7.2. BMD Approach for CRMs

2.8. Index-Based Performance Evaluation

2.8.1. Indirect Tensile Asphalt Cracking Test (IDEAL-CT)—ASTM D8225-19 [38]

2.8.2. Indirect Tensile Asphalt Rutting Test (IDEAL-RT)—ASTM D8360-22 [39]

2.9. Inclusion of Recycled Additives

3. Results and Discussion

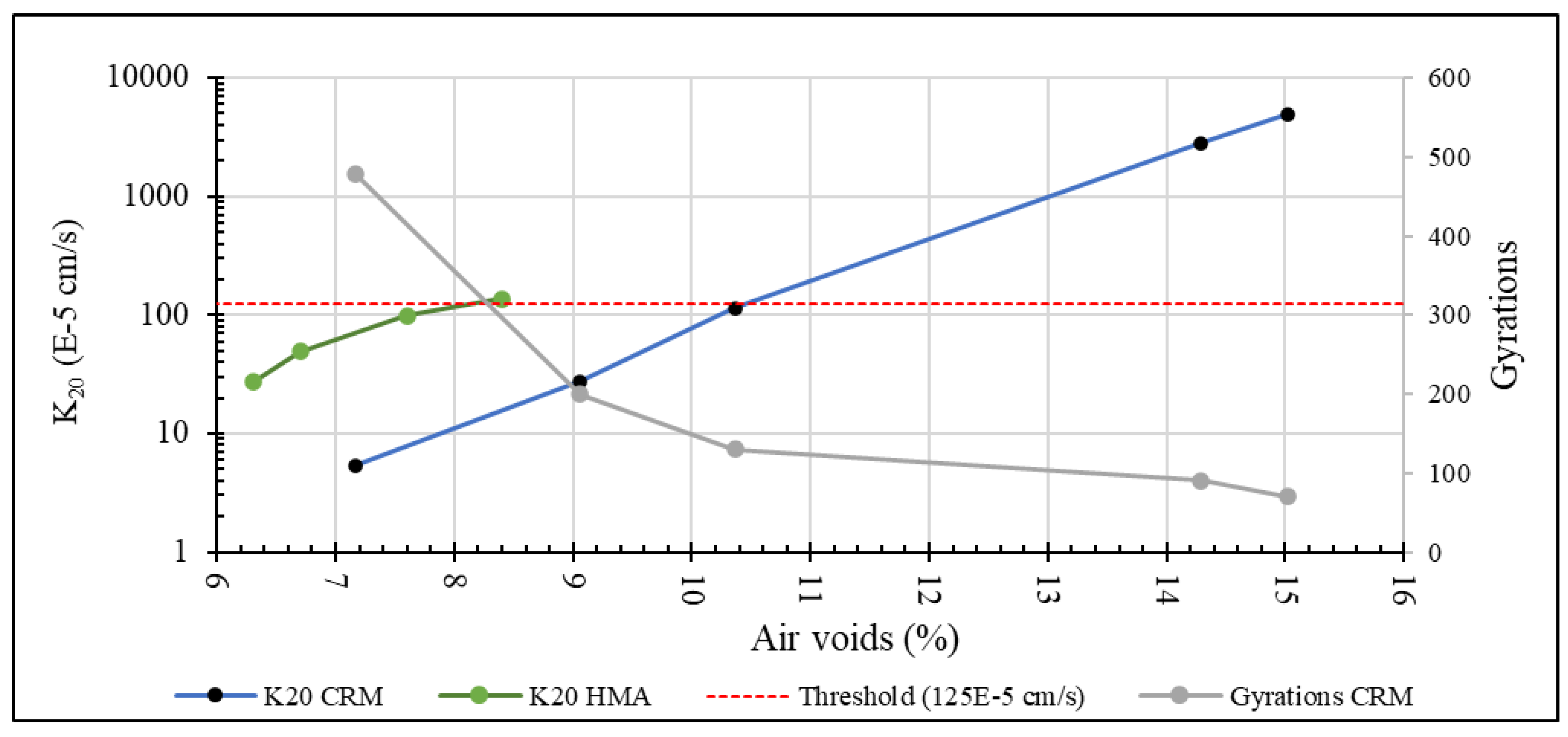

3.1. Permeability Test Results for CRMs

3.2. Balanced Mix Design Results

3.2.1. Hot-Mix Asphalt BMD Results

3.2.2. Cold-Recycled Mixture BMD Results

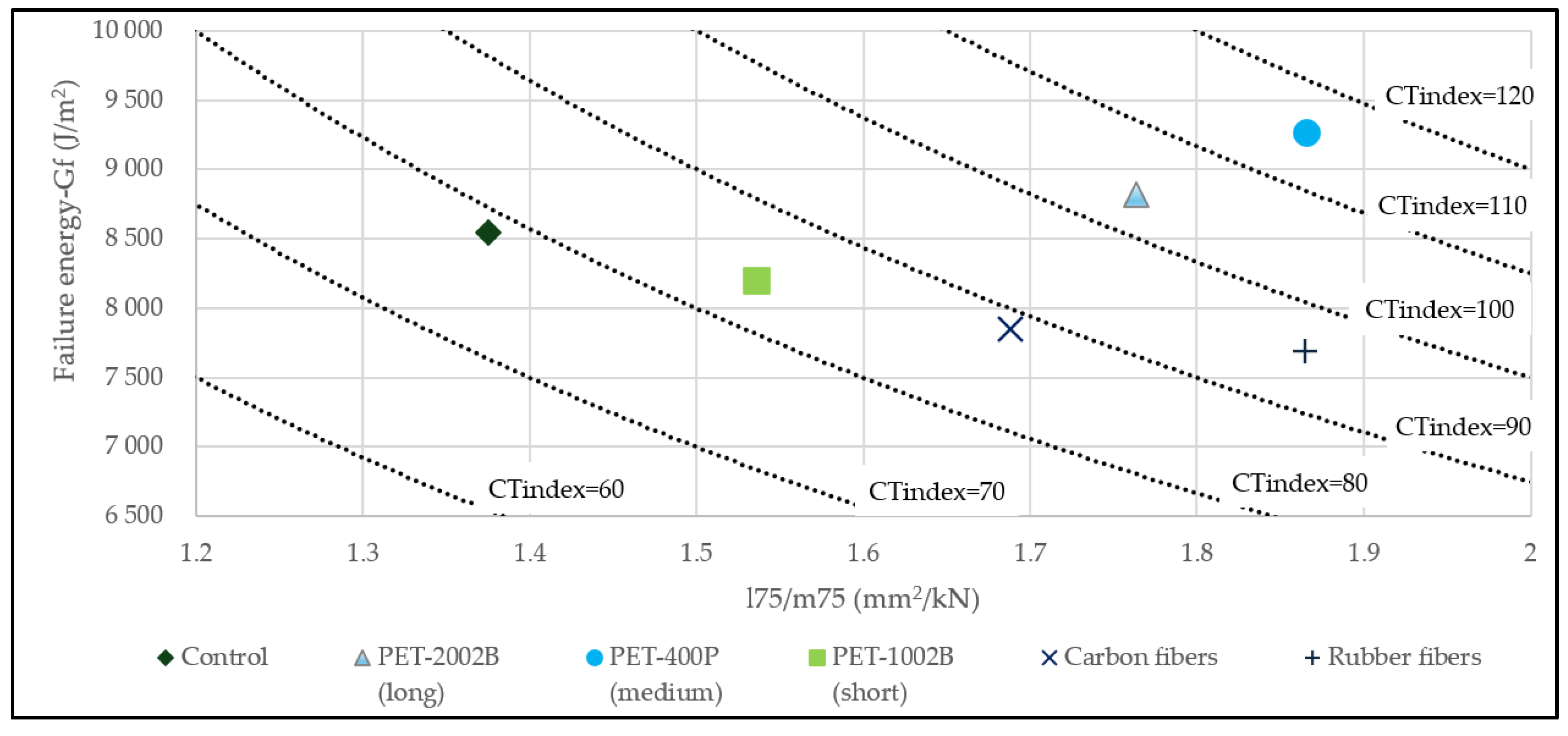

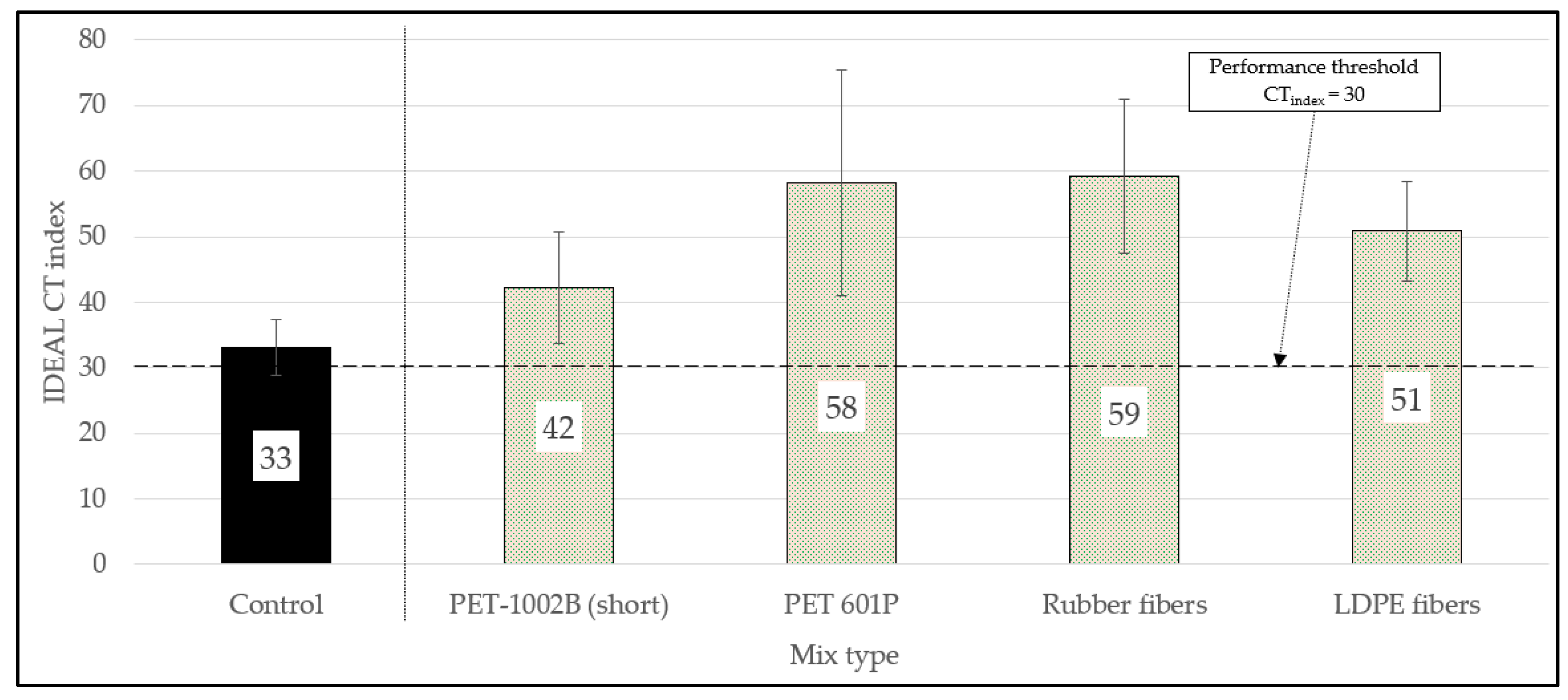

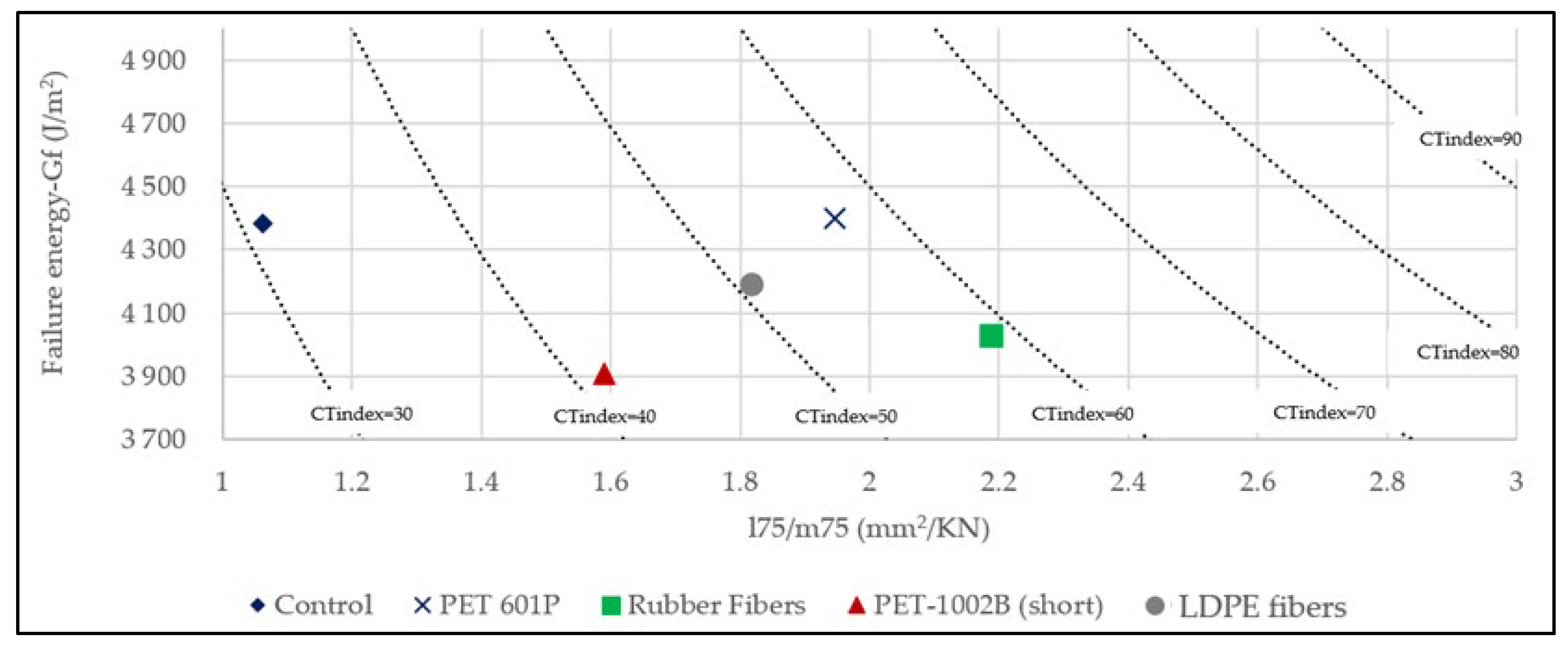

3.3. IDEAL-CT Results

3.3.1. Hot-Mix Asphalt Cracking Resistance Results

3.3.2. Cold-Recycled Mix Cracking Resistance Results

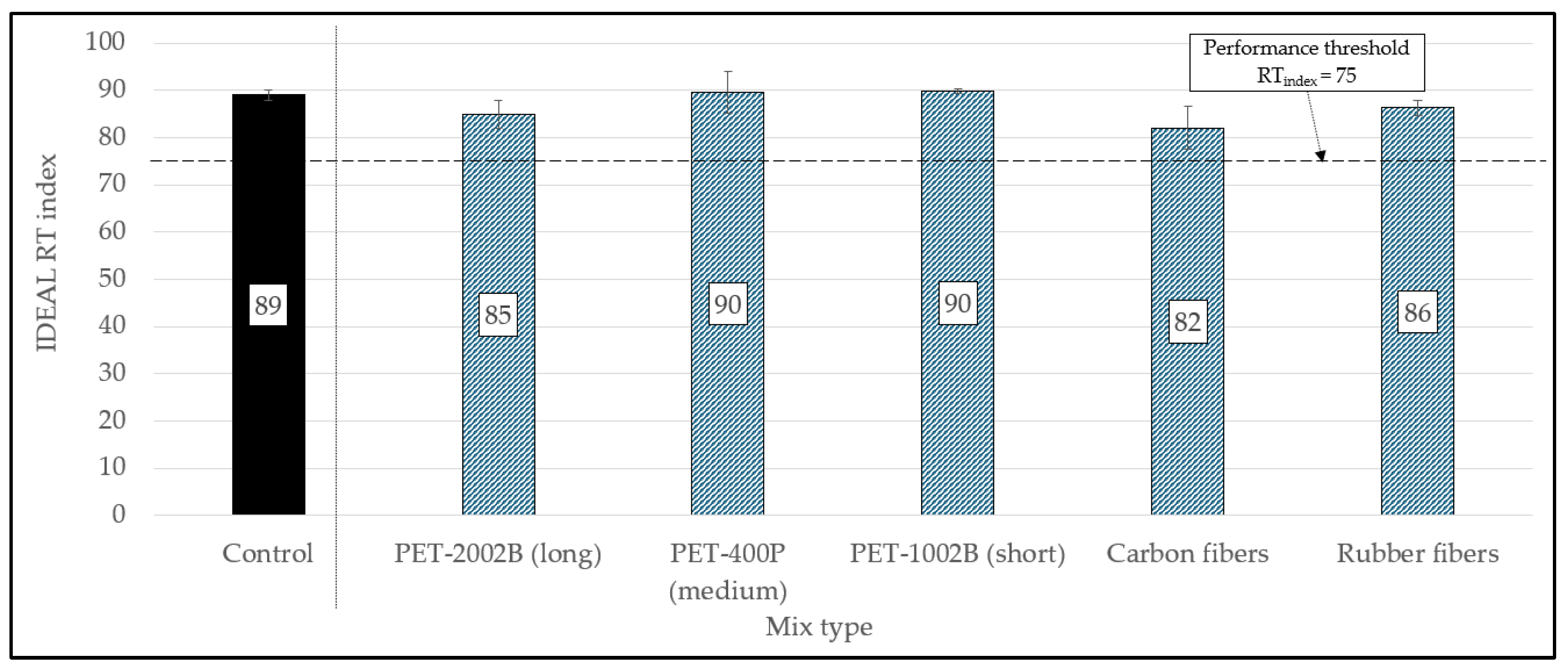

3.4. IDEAL-RT Results

3.4.1. Hot-Mix Asphalt Rutting Resistance Results

3.4.2. Cold-Recycled Mix Rutting Resistance Results

4. Conclusions

- It was determined that the permeability of the studied CRMs with 10% air voids met the recommended threshold typically used for HMA, while the number of gyrations in the SGC remained within a practical range (fewer than 200) for fabricating CRM specimens.

- The BMD procedure enhanced the performance of both types of asphalt concrete by increasing the binder/emulsion content, leading to mixtures with improved cracking resistance while maintaining adequate rutting resistance. For the HMA, the optimum binder content varied from 4.6% to 5.4 ± 0.2%, while for the CRMs, the balanced zone was established between 4.9% and 5.5%.

- For the HMA, samples with rubber fibers failed to meet the air void content of 7 ± 0.5% due to a bouncing effect after removing compaction loads, resulting in more air voids, which could affect the index-based results. However, this effect was not observed for the CRM samples.

- Regarding cracking resistance, the HMA fiber-reinforced mixtures exhibited a higher CT index value. Medium PET and long PET fibers showed the highest increase in this parameter. On the other hand, the CRM-reinforced samples also experienced an increase in cracking resistance, where the PET fibers showed a CT index up to 75% higher than the control.

- Based on the IDEAL-CT interaction diagram, both HMA and CRM fiber-reinforced samples exhibited a less steep post-peak slope; HMA samples maintain the same levels of failure energy as the conventional mixture, but CRMs exhibited a reduction in this parameter; fiber-reinforced mixtures exhibited a less brittle behavior of the mix and better resistance to cracking after the initiation of the crack.

- Regarding rutting resistance, the results of the IDEAL-RT exhibited opposite tendencies between the two types of evaluated asphalt concrete. For the HMA, the evaluated recycled fibers exhibited similar performance to the conventional mix, while for the CRMs, the inclusion of recycled fibers led to a significant reduction in the rutting resistance of the mix; however, CRM samples were compacted at a higher air void content which could affect the results.

- PET fiber mixtures performed better overall against cracking and rutting compared to both conventional mixtures (HMA and CRM), suggesting they could be a viable alternative for enhancing mix performance with recycled materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Williams, B.A.; Willis, J.R.; Shacat, J. Annual Asphalt Pavement Industry Survey on Recycled Materials and Warm-Mix Asphalt Usage: 2022, 13th Annual Survey (IS 138); National Asphalt Pavement Association: Greenbelt, MA, USA, 2024. [Google Scholar] [CrossRef]

- Habbouche, J.; Hajj, E.Y.; Sebaaly, P.E.; Piratheepan, M. A critical review of high polymer-modified asphalt binders and mixtures. Int. J. Pavement Eng. 2020, 21, 686–702. [Google Scholar] [CrossRef]

- Li, H.; Cui, C.; Temitope, A.A.; Feng, Z.; Zhao, G.; Guo, P. Effect of SBS and crumb rubber on asphalt modification: A review of the properties and practical application. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 836–863. [Google Scholar] [CrossRef]

- Jia, H.; Sheng, Y.; Guo, P.; Underwood, S.; Chen, H.; Kim, Y.R.; Ma, Q. Effect of synthetic fibers on the mechanical performance of asphalt mixture: A review. J. Traffic Transp. Eng. (Engl. Ed.) 2023, 10, 331–348. [Google Scholar] [CrossRef]

- Yin, F.; West, R.; Powell, B.; DuBois, C.J. Short-Term Performance Characterization and Fatigue Damage Prediction of Asphalt Mixtures Containing Polymer-Modified Binders and Recycled Plastics. Transp. Res. Rec. 2023, 2000, 141–148. [Google Scholar] [CrossRef]

- Environmental Protection Agency (EPA). Facts and Figures About Materials, Waste and Recycling; Environmental Protection Agency (EPA): Washington, DC, USA, 2020. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/advancing-sustainable-materials-management (accessed on 5 July 2024).

- Asphalt Institute. Asphalt Cold Mix Manual (MS-14), 3rd ed.; Asphalt Institute: Lexington, KY, USA, 1989. [Google Scholar]

- Flores, G.; Gallego, J.; Miranda, L.; Marcobal, J.R. Design methodology for in situ cold recycled mixtures with emulsion and 100% RAP. Constr. Build. Mater. 2019, 216, 496–505. [Google Scholar] [CrossRef]

- Dong, S.; Wang, D.; Hao, P.; Zhang, Q.; Bi, J.; Chen, W. Quantitative assessment and mechanism analysis of modification approaches for cold recycled mixtures with asphalt emulsion. J. Clean. Prod. 2021, 323, 129163. [Google Scholar] [CrossRef]

- Pakes, A.; Edil, T.; Sanger, M.; Olley, R.; Klink, T. Environmental benefits of cold-in-place recycling. Transp. Res. Record. 2018, 2672, 11–19. [Google Scholar] [CrossRef]

- Dittenber, D.B.; GangaRao, H.V. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Herráiz, T.R.; Herráiz, J.I.; Domingo, L.M.; Domingo, F.C. Posidonia oceanica used as a new natural fibre to enhance the performance of asphalt mixtures. Constr. Build. Mater. 2016, 102, 601–612. [Google Scholar] [CrossRef]

- Musa, N.F.; Aman, M.Y.; Shahadan, Z.; Taher, M.N.; Noranai, Z. Utilization of synthetic reinforced fiber in asphalt concrete—A review. Int. J. Civ. Eng. Technol. 2019, 10, 678–694. [Google Scholar]

- Shanbara, H.K.; Ruddock, F.; Atherton, W. A laboratory study of high-performance cold mix asphalt mixtures reinforced with natural and synthetic fibers. Constr. Build. Mater. 2018, 172, 166–175. [Google Scholar] [CrossRef]

- Slebi-Acevedo, C.J.; Lastra-González, P.; Pascual-Muñoz, P.; Castro-Fresno, D. Mechanical performance of fibers in hot mix asphalt: A review. Constr. Build. Mater. 2019, 200, 756–769. [Google Scholar] [CrossRef]

- McDaniel, R. NCHRP Synthesis 475: Fiber additives in asphalt mixtures. In National Academies of Sciences, Engineering, and Medicine; The National Academies Press: Washington, DC, USA, 2015. [Google Scholar] [CrossRef]

- Ahmed, N.; Saleh, M.; Moghaddam, T.B.; Hashemian, L. Investigating the influence of polyethylene terephthalate fibers with different lengths on the cracking resistance of high-performance asphalt concrete. Can. J. Civ. Eng. 2024, 51, 1145–1157. [Google Scholar] [CrossRef]

- Ma, J.; Hesp, S.A. Effect of recycled polyethylene terephthalate (PET) fiber on the fracture resistance of asphalt mixtures. Constr. Build. Mater. 2022, 342, 127944. [Google Scholar] [CrossRef]

- Kim, M.J.; Kim, S.; Yoo, D.Y.; Shin, H.O. Enhancing mechanical properties of asphalt concrete using synthetic fibers. Constr. Build. Mater. 2018, 178, 233–243. [Google Scholar] [CrossRef]

- Pirmohammad, S.; Shokorlou, Y.M.; Amani, B. Laboratory investigations on fracture toughness of asphalt concrete reinforced with carbon and kenaf fibers. Eng. Fract. Mech. 2020, 226, 106875. [Google Scholar] [CrossRef]

- West, R.; Rodezno, C.; Leiva, F.; Yin, F. Development of a Framework for Balanced Mix design. Project NCHRP 2018. 20-07. Available online: https://onlinepubs.trb.org/onlinepubs/nchrp/docs/NCHRP20-07(406)_Revised_final_report.pdf (accessed on 17 May 2024).

- Kmetz, M.; Timm, D.; Rodezno, C.; Tran, N.; Yin, F. Laboratory Characterization of Additive-Modified Asphalt Concrete Mixtures. Transp. Res. Rec. 2024, 2678, 03611981231224742. Available online: https://etd.auburn.edu//handle/10415/9024 (accessed on 13 December 2024). [CrossRef]

- Noorvand, H.; Brockman, S.C.; Mamlouk, M.; Kaloush, K. Effect of aramid fibers on balanced mix design of asphalt concrete. CivilEng 2021, 3, 21–34. [Google Scholar] [CrossRef]

- West, R.; Yin, F. Guidance on Progressing through BMD Approaches. In Balanced Mix Design, Special Report BMD SR-228; National Asphalt Pavement Association NAPA: Greenbelt, MD, USA, 2024. [Google Scholar]

- Zhou, F.; Hu, S.; Newcomb, D. Development of a performance-related framework for production quality control with ideal cracking and rutting tests. Constr. Build. Mater. 2020, 261, 120549. [Google Scholar] [CrossRef]

- Fazli, A.; Rodriguez, D. Sustainable Reuse of waste tire textile fibers (WTTF) as reinforcements. Polymers 2022, 14, 3933. [Google Scholar] [CrossRef]

- Ghos, S.; Sumter, C.R.; Arevalo, P.C.; Ali, S.A.; Zaman, M.; Hobson, K.R.; Kalicki, G.; Metzer, D. Performance of Asphalt Mixes Containing Postconsumer Recycled Plastic using Balanced Mix Design Approach and Dry Process. Transp. Res. Rec. 2022, 2676, 720–732. [Google Scholar] [CrossRef]

- Usman, N.; Masirin, M.I.M.; Ahmad, K.A.; Ali, A.S.B. Application of recycled polyethylene terephthalate fiber in asphaltic mix for fatigue life improvement. In GCEC 2017: Proceedings of the 1st Global Civil Engineering Conference 1; Springer: Singapore, 2019; pp. 1401–1413. [Google Scholar] [CrossRef]

- Lee, K.W.; Brayton, T.E.; Mueller, M.; Singh, A. Rational mix-design procedure for cold in-place recycling asphalt mixtures and performance prediction. J. Mater. Civ. Eng. 2016, 28, 04016008. [Google Scholar] [CrossRef]

- Gao, L.; Ni, F.; Luo, H.; Charmot, S. Characterization of air voids in cold in-place recycling mixtures using X-ray computed tomography. Constr. Build. Mater. 2015, 84, 429–436. [Google Scholar] [CrossRef]

- Cooley, L.A., Jr.; Prowell, B.; Brown, E.R. Issues Pertaining to the Permeability Characteristics of Coarse-Graded SuperPave Mixes; NCAT Report 02–06; NCAT: Auburn, AL, USA, July 2002. [Google Scholar]

- Florida Department of Transportation. Florida Method of Test for Measurement of Water Permeability of Compacted Asphalt Paving Mixtures; Designation: FM 5-565; Florida Department of Transportation: Tallahassee, FL, USA, 2015. [Google Scholar]

- Asphalt Recycling; Reclaiming Association ARRA. Recommended Design Guidelines for Cold Central Plant Recycling (CCPR) Using Bituminous Recycling Agents CR201; Asphalt Recycling & Reclaiming Association ARRA: Glen Ellyn, IL, USA, 2023. [Google Scholar]

- Chen, C.; Taylor, A.; Moore, N. Validation of Rapid Rutting Test Procedures Using Plant Mixtures from the 2021 NCAT Test Track. National Center for Asphalt Technology. Asph. Technol. News. Spring 2023, 35, 10–11. [Google Scholar]

- Vivanco Sala, D.; Tran, N.; Yin, F.; Bowers, B.F. Evaluating impact of corrected optimum asphalt content and benchmarking cracking resistance of Georgia mixtures for balanced mix design implementation. Transp. Res. Rec. 2022, 2676, 13–29. [Google Scholar] [CrossRef]

- Diefenderfer, B.K.; Boz, I.; Bowers, B.F. Evaluating cracking tests for performance-based design concept for cold recycled mixtures. In Proceedings of the International Airfield and Highway Pavements Conference, Chicago, IL, USA, 21–24 July 2019; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 220–229. [Google Scholar]

- Bowers, B.F.; Diefenderfer, B.K.; Wollenhaupt, G.; Stanton, B.; Boz, I. Laboratory properties of a rejuvenated cold recycled mixture produced in a conventional asphalt plant. In Proceedings of the International Airfield and Highway Pavements Conference, Chicago, IL, USA, 21–24 July 2019; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 100–108. [Google Scholar]

- ASTM D8225-19; Standard Test Method for Determination of Cracking Tolerance Index of Asphalt Mixture Using the Indirect Tensile Cracking Test at Intermediate Temperature. American Society for Testing and Materials ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D8360-22; Standard Test Method for Determination of Rutting Tolerance Index of Asphalt Mixture Using the Ideal Rutting Test. American Society for Testing and Materials ASTM International: West Conshohocken, PA, USA, 2022.

| Binder | Test | Result |

|---|---|---|

| Original binder | Dynamic shear G*/sin δ (kPa) | 1.37 |

| Rotational viscosity @135 °C (Pa.s) | 0.408 | |

| Rotational viscosity @165 °C (Pa.s) | 0.115 | |

| Flashpoint (°C) | 320 | |

| RTFOT Residue | Dynamic shear G*/sin δ (kPa) | 3.73 |

| PAV Residue | Dynamic shear G*sin δ (kPa) | 4303 |

| Mixing temperature (°C) | 152–158 | |

| Compaction temperature (°C) | 141–146 | |

| Fiber | Dimensions * | Density (g/cm3) ** | Tensile Strength (MPa) ** | Modulus of Elasticity (GPa) ** | Melting Point (°C) ** |

|---|---|---|---|---|---|

| Carbon | Average length = 25.4 mm Diameter = 7 µm | 1.37 [19] | 4900 [19] | 230 [19] | 1000 [19] |

| Rubber | Average length = 29 mm Diameter = 2.2 mm | 0.83 [26] | 600 [26] | 2.7 [26] | 256 [26] |

| LDPE fibers | Average length = 40 mm Width = 2.0 mm | 0.92 [27] | 11 [27] | 0.52 [27] | 110 [27] |

| PET-2002B (long) | Average length = 63.5 mm Aspect ratio = 200 denier | 1.35 [28] | 192.4 [28] | 3.9 [28] | 250 [28] |

| PET-400P (medium) | Average length = 44.5 mm Aspect ratio = 40 denier | ||||

| PET-1002B (short) | Average length = 38.1 mm Aspect ratio = 100 denier | ||||

| PET-601P | Average length = 57.1 mm Aspect ratio = 60 denier |

| Identification | CSS–1H | |

|---|---|---|

| Properties | Unit | Value |

| Presence of sieve, grit | % | 0.02 |

| Residue, metler | % | 63.64 |

| Particle size distribution, mv | μm | 9.91 |

| Particle size distribution, >90% | μm | 18.76 |

| Storage stability (24 h) | % | 0.61 |

| Settlement (5 days) | % | 3.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leiva-Villacorta, F.; Cerdas-Murillo, A. Performance Evaluation of Recycled Fibers in Asphalt Mixtures. Constr. Mater. 2024, 4, 839-855. https://doi.org/10.3390/constrmater4040045

Leiva-Villacorta F, Cerdas-Murillo A. Performance Evaluation of Recycled Fibers in Asphalt Mixtures. Construction Materials. 2024; 4(4):839-855. https://doi.org/10.3390/constrmater4040045

Chicago/Turabian StyleLeiva-Villacorta, Fabricio, and Alvaro Cerdas-Murillo. 2024. "Performance Evaluation of Recycled Fibers in Asphalt Mixtures" Construction Materials 4, no. 4: 839-855. https://doi.org/10.3390/constrmater4040045

APA StyleLeiva-Villacorta, F., & Cerdas-Murillo, A. (2024). Performance Evaluation of Recycled Fibers in Asphalt Mixtures. Construction Materials, 4(4), 839-855. https://doi.org/10.3390/constrmater4040045