Abstract

The building and construction industry consumes a significant amount of natural resources alongside contributing to the generation of waste materials. Addressing the dual challenge of waste management and recycling in this sector is imperative. This study begins with a bibliometric assessment to identify waste materials used as insulation in building and construction systems. The assessment of 2627 publications revealed mattress waste materials were seldom considered. The aim of this research focuses on exploring alternative methods for repurposing mattress materials in construction, aiming to mitigate waste generation. While various materials are being recycled for building applications, this research emphasises the potential of incorporating recycled polyurethane foam (PUF) from mattresses as insulation products. A transient plane source (TPS) was employed to determine the thermal conductivity of waste mattress PUF obtained from a recycling plant in Victoria, Australia. The results exhibited promising thermal resistance, with a mean value of 0.053 Wm/K. However, optimal thermal performance was observed with increased thickness, suggesting that a thickness of 215mm aligns with industry standards for building fabric systems. Further research is required to comprehensively analyse moisture resistance and fire retardation of waste mattress materials. This paper presents key findings of current trends, limitations, and future research directions to the use of waste mattress PUF as an insulation material.

1. Introduction

As national economies continue to advance rapidly, the global challenges of energy scarcity and environmental deterioration are escalating. Over the past four decades, the demand for energy in buildings has increased by an annual rate of 1.8%, and projections indicate a surge from 2790 million tonnes of oil equivalent (Mtoe) in 2010 to more than 4400 Mtoe by 2050 [1]. Consequently, energy conservation has emerged as the fifth major energy resource, alongside coal, oil, natural gas, and nuclear energy, garnering heightened attention from numerous governments worldwide [2]. The innovation of novel thermal insulation materials stands as a primary strategy to curtail energy consumption and adapt to the varying methods of construction [3,4]. Thermal insulation products refer to building materials that contain material property compositions to resist heat flow. The materials heat resistance can improve the indoor thermal environment whilst minimising the heating and cooling pressures of the building. Installing appropriate insulation can significantly reduce the energy consumption that is used for heating and cooling [5]. Insulation can be sub-categorised between organic and inorganic materials [6]. Organic materials include natural or renewable resources and are a lot more attractive to use in construction due to their positive environmental effects, their recycabililty, and benefitting from low resource production techniques. Lower amounts of energy are often required to extract the materials when compared to inorganic material manufacturing. However, inorganic insulation often offers higher thermal performance, lower costs, and higher fire resistance [7].

Insulation properties can vary with each material used. The physical composition or cell structure of the material defines the insulation value and therefore the purpose of that material in the building application. Common insulation materials include fibreglass, polyester, natural wool, glass wool, rockwool, and polystyrene [7,8,9,10]. Polystyrene has two variants: expanded polystyrene (EPS) and extruded polystyrene (XPS). EPS is created by evaportating the pentane gas added in the polystyrene grains, resulting in a closed cell foam. The higher density increases the insulation properties; however, EPS has no sound absorbing qualities and is very flammable, so chemicals are added to make it fire retardant. EPS is often used as external cladding as well as floor insulation in timber sub floor construction [11]. XPS is created by melting polyester grains into an extruder with a blowing agent. This material is similar to EPS insulation, though it absorbs less moisture. With less moisture absorbtion, it contributes to the variation of the thermal conductivity [12]. Rockwool is produced by melting several types of rock, such as dolostone, basalt, and diabase, at 1600 °C. The remaining fibers are bound together using resin, food grade starches, and oils. It is often used in cavity insulation as it has a high thermal resistance, though water condensation negatively affects this material [12]. Natural wool, also commonly known as sheeps wool, is an organic insulating product, though it can mixed or blended with polyester and textile products. The thermal performance of this material varies between the seasons of summer and winter. It performs poorly in warmer temperatures compared to colder temperatures, where its thermal properties perform very well. It is important to note that the sound absorbtion is siginicantly high compared to most other insulating products. Higher levels of moisture in the material can produce a higher rate of thermal conductivity [12].

Fibreglass is produced by mixing sand and recycled glass [13]. The fibers transform and are bound together with the addition of resin. It has similar thermal properties to rock wool, but the thermal resistance is not affected by water condensation. This is a very common insulation product, but it can create occupational health and safety issues during installation [12]. Fibreglass has dominated the construction industry, with more than a 50% market share, because of its simple application in residential timber framed systems. The product of fibreglass spray foam represents approximately a quarter of the demand, however the majority of spray foam insulation is used in commerical construction [14]. Recycled textiles such as polyester have been utilised in recent years as an insulation material due to the large quantities of waste being produced [15]. Recycled textile materials, including polyester and polyurethane, can create an effective thermal property rating as well as an effective sound absorbing quality [16]. Bespoke composite materials can be utilised in building and construction as insulation. It is important to note that the minimum standards of thermal resistance of novel materials can be met. However, when high thermal performance is required, other material elements in the construction envelope would need to be considered to meet the required thermal resisant criteria [17].

Spray polyurethane foam (SPUF) is currently used as an insulation material; however, there are severe negative environmental impacts that can be created through its use [18]. The blowing agents in the foam accounted for approximately 38 million tonnes of carbon emissions in 2010. The emissions of these blowing agents occur during the manufacturing process, installation, use phase, and end of life phase. When reviewing the qualities of each material that can be used as a building construction insulation product, the important factors are how the material is measured and that variables are minimised [5]. Research has been conducted on wall materials, focusing on phase-change energy storage (PCES) technology. A study provided an experimental program focusing on wall systems utilising PCES. The results demonstrated the potential application in wall systems for warmer climates, but an innovative approach is still required for optimal application in colder regions [19]. Villasmil et al. [20] conducted a study on thermal insulation materials for thermal energy storage systems, highlighting the advantages of different materials for various applications. This study demonstrated that novel materials such as vacuum panels and aerogels can be economically beneficial in construction systems. Jelle [21] assessed the advantages, disadvantages, limitations, and possibilities of thermal insulation materials under different conditions. This research focused on both traditional and innovative building insulation materials, highlighting further research areas. To improve sustainable practices in the building and construction industry, it is imperative to adopt the principles of the circular economy [22]. This refers to the circularity of waste materials being redeveloped and utilised to supplement the extraction of raw materials. For example, researchers have focused on integrating waste cardboard and plastics in building and construction composite materials [23,24,25,26]. This demonstrated the potential application of using novel waste materials in common construction systems. Currently, waste mattress foam is not utilised in the construction industry. Components of mattress systems are recycled, such as steel, timber, and ticking materials. However, the polyurethane foam used in mattresses is difficult to re-purpose due to contamination, fire safety, and end of life use.

Therefore, it is critical to research current waste materials and search for their alternative use in the building and construction industry. The utilisation of novel waste materials can reduce the need to extract virgin resources and minimise the accumulation of waste in landfill areas. Moreover, integrating waste materials as a source for insulation products can reduce the creation of carbon emissions sourced from the manufacturing of common insulation materials. This study will review waste sources used as insulation, alongside current commercially available insulation materials. An experimental program was utilised to conduct the thermal conductivity of waste mattress foam. A comparative analysis was also conducted to determine if waste mattress materials are a viable source of insulation materials.

2. Materials and Methods

2.1. Bibliometric Analysis

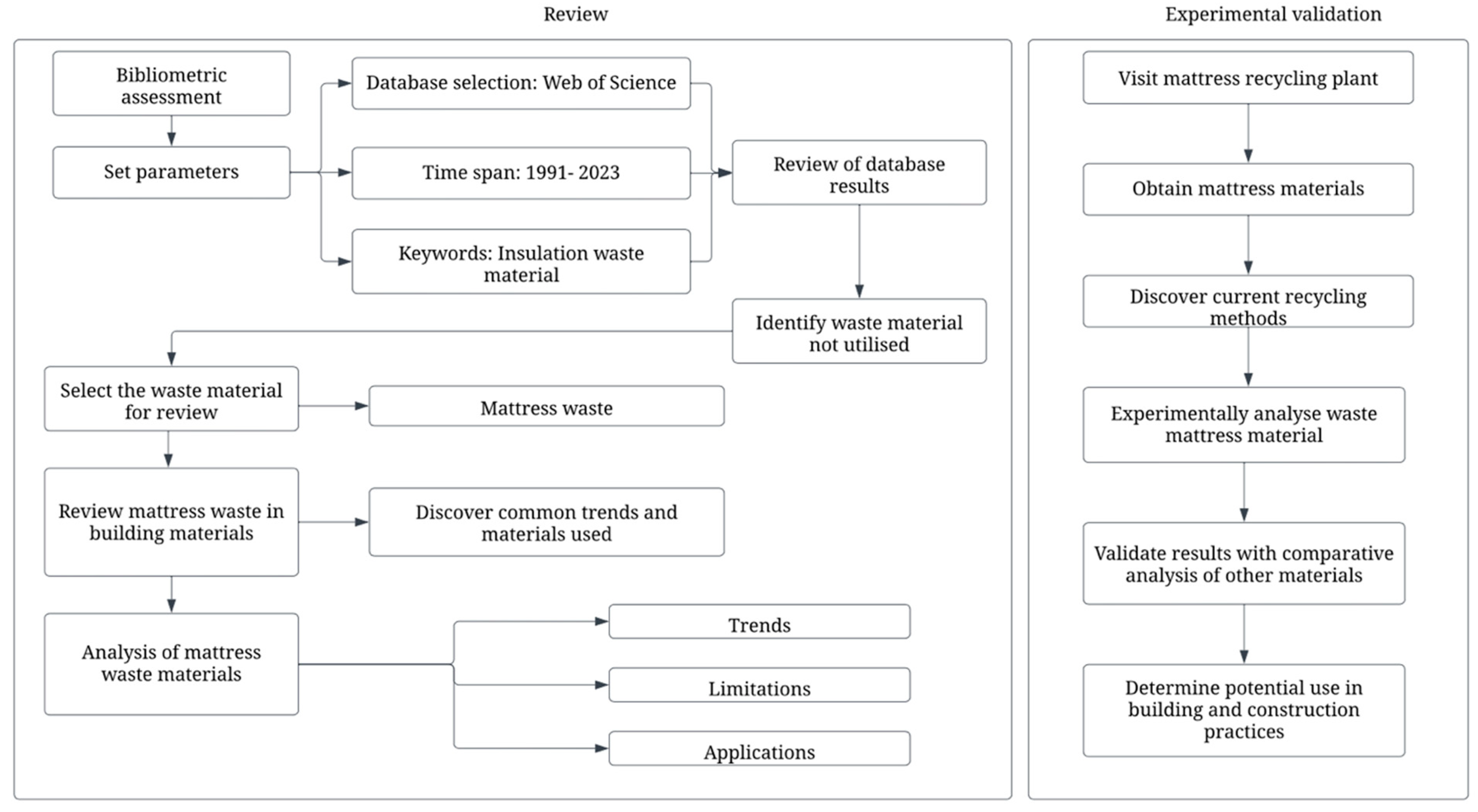

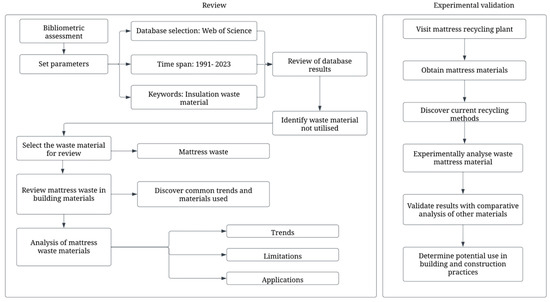

This study begins by analysing insulation materials along with their associated waste origins, exploring the evolving trends within the building and construction industry via a bibliometric analysis. Employing Bibliometrix, a bibliographic analysis tool, this assessment involves a detailed quantitative mapping of published literature. The generated insights aid in recognising research patterns, identifying literature gaps, and establishing benchmarks [27]. The exploration of publications primarily relied on Web of Science (WOS), a widely utilised abstract and citation database known for its extensive coverage, global content, citation tracking, and analytical tools. The main criteria used was “Insulation waste materials”. The analysis spans the total time coverage listed by the WOS database, from 1991 to 2023, encompassing journal articles, book chapters, and conference proceedings. This methodological approach is illustrated in Figure 1. The culmination of this research is a systematic overview of the current literature and insights from the bibliometric analysis. The study aims to highlight potential waste materials that could be integrated within insulation systems, fostering further research toward the sustainability of the construction industry.

Figure 1.

Methodology.

2.2. Experimental Program

A site visit was undertaken at a resource recovery centre to collect waste samples for further experimental testing. To determine the suitability of the waste material for insulation purposes, the transient plane source (TPS) was used to ascertain the thermal conductivity values. Results measured using TPS are typically successful due to the nature of the non-destructive method and small sample sise requirements.

Transient Plane Source (TPS)

The TPS thermal characterisation technique can determine the thermal properties of various materials. The TPS machine is prominent because of its ability to measure the thermal conductivity as well as the thermal diffusivity of complex materials simultaneously [28]. Table 1 details the specifications of the TPS used in the experimental program. The TPS sensor is a double spiral of nickel wire in between two polyimide films acting as insulating plates; this is treated as a sensor because of the electrical conducting pattern. To measure the thermal conductivity, the disk is sandwiched between two thin layers of material that is covered with an insulation material on the outer sides while an electrical current is transferred through the disk. The electrical current is strong enough to increase the temperature of the disk while maintaining the ability to record the temperature increase of the material. The measurement of the thermal conductivity in the material defines the property of the material to conduct heat [29]. A key advantage of using a TPS is that it is a non-destructive method. The contact between the material and the disk as well as the differences in various material properties do not influence the measurements of results. The hot disk sensor has very high resistance to heat; this is also mirrored with the compact size of the testing samples, and the measurements can be recorded with great sensitivity and accuracy [29].

Table 1.

TPS specifications (Hot disk TPS 2500 S Model). Adapted from [28].

The approximate temperature that will be conducted is between 30–50 °C. The materials used in this study will each be measured approximately ten times to ensure the relative parameters are in working order. Once the results are obtained over the course of the experiment, the average mean will be taken to give the most accurate result. Equation (1) represents the meaning of thermal conductivity for the material samples [28]. The variables associated with the materials in this equation are detailed as “(1)” and “(2)”. He, Y. [29] has detailed the theory behind the measurement using TPS.

q = Conduction of heat transfer

k = Thermal conductivity of the material

A = Area of perpendicular to the heat flow

T = Temperature of hot disks

L = Distance of conduction of heat transfer is occurring

Equation (1) Thermal conductivity.

3. Bibliometric Results

The primary findings obtained through the bibliometric assessment are detailed in Table 2. This evaluation encompassed 2627 documents derived from 935 unique sources. On average, each document had 4.5 authors, calculated based on author appearances across these documents, totaling 8667 authors. This illustrates a robust focus on the subject, evident from the collaboration among multiple authors.

Table 2.

Main information.

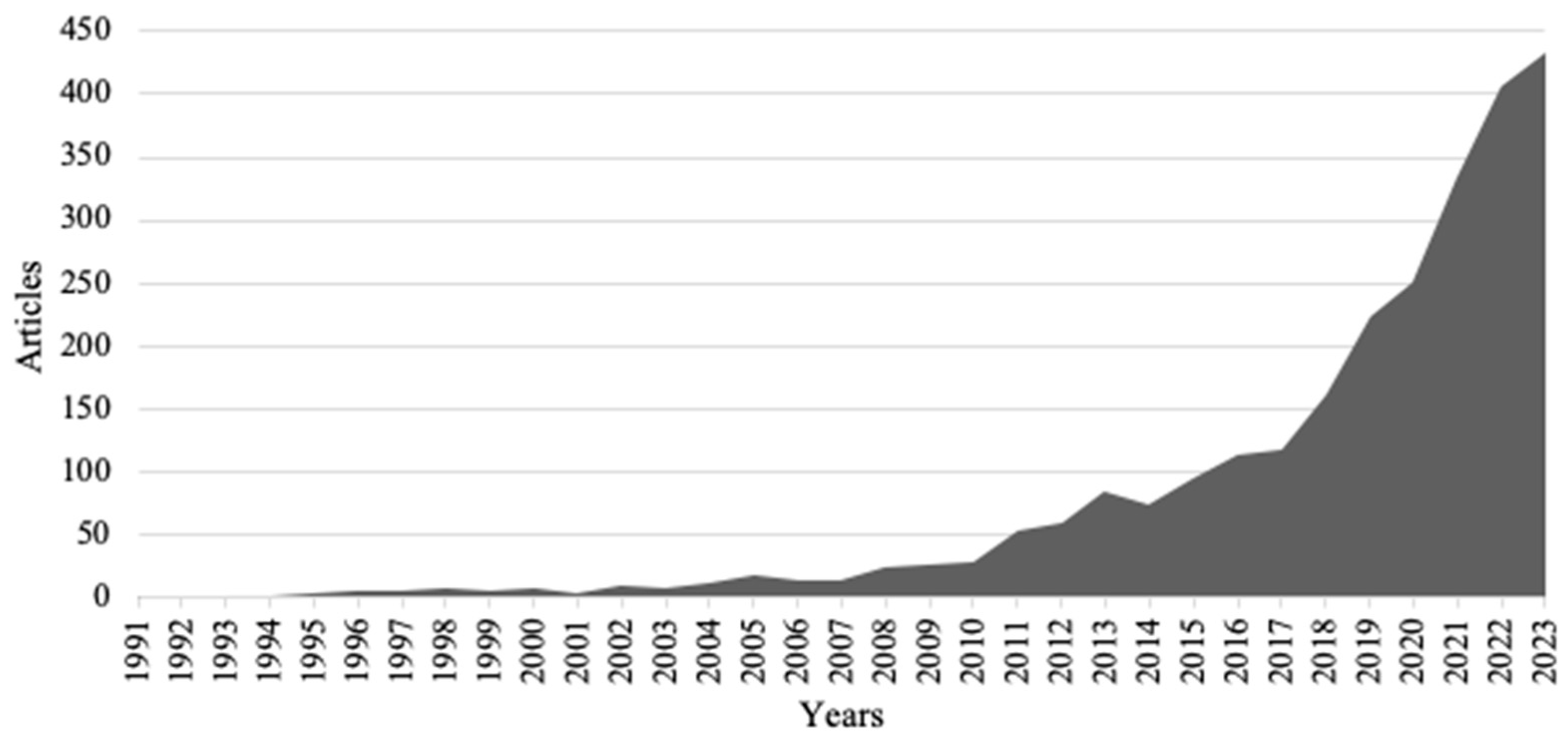

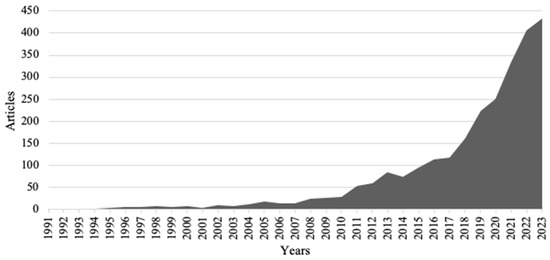

Journal articles constituted most publications, totaling 1987, followed by 151 review papers. Figure 2 visually represents the annual scientific publications spanning from 1991 to 2023, indicating a noticeable surge in publications since 2020. Specifically, there has been a substantial 87% increase in publications on the topic of waste materials in the building and construction industry since 2013. This demonstrates the surge in research focus and publications in the last decade compared to the 30 years prior.

Figure 2.

Annual publications.

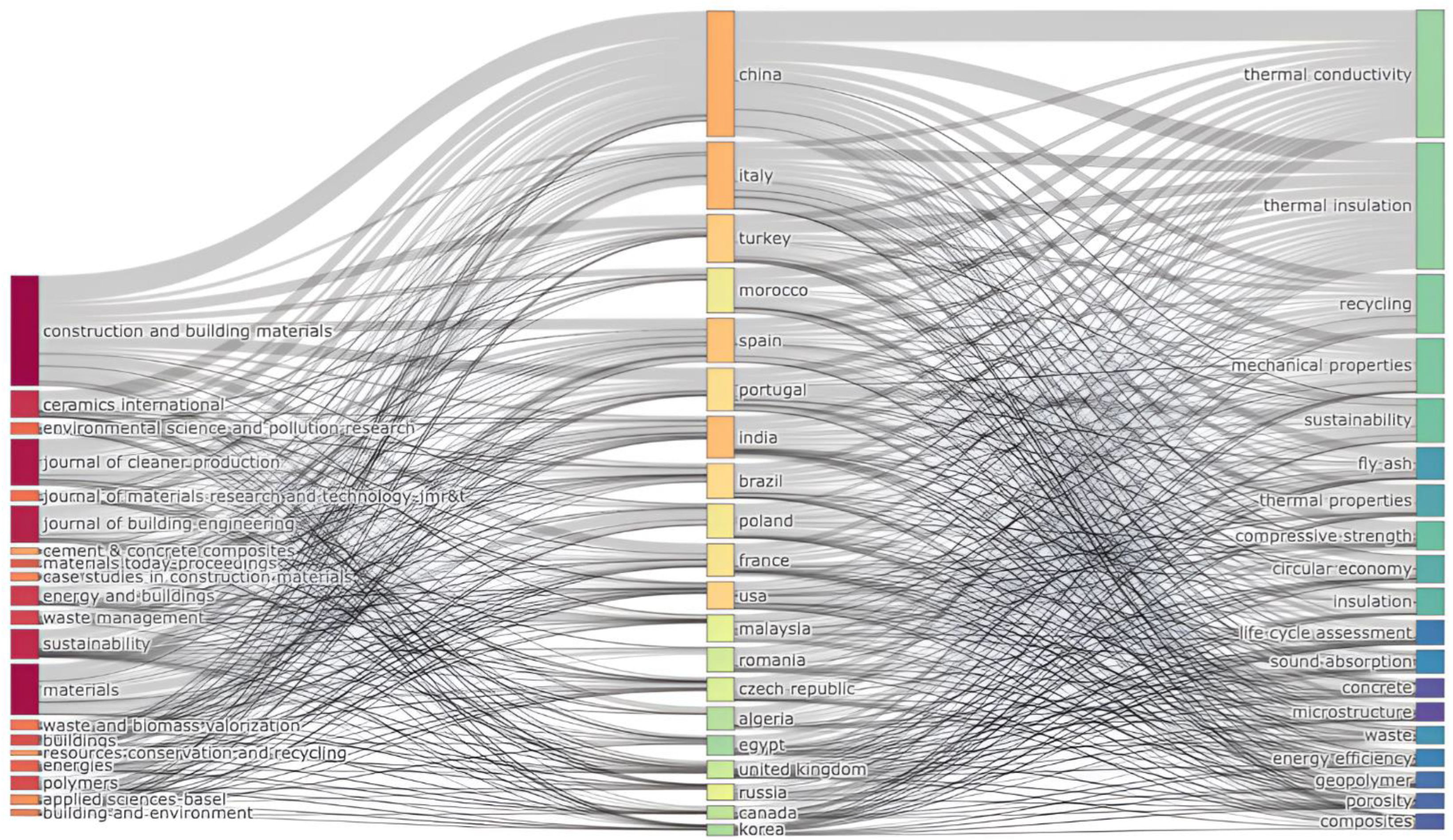

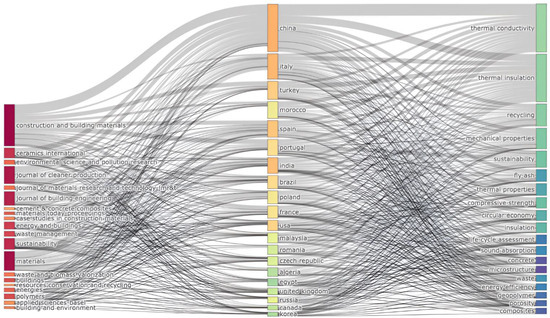

Figure 3 illustrates a three-plot Sankey plot, also known as a Sankey diagram or Sankey chart. This is a graphical representation used to illustrate the flow of research source vs. country of origin vs. research focus. The thickness of the lines represents the strength of the relationship between the two entities. The results indicate that the Journal of Construction and Building Materials is the predominant source. China has produced the most publications that focus on waste insulation materials, specifically focusing on thermal conductivity. This coincides with the predominantly experimental research published in the journals. Recycling methods of waste materials are a prominent research focus, with other key research areas such as sustainability and the circular economy becoming more popular in recent years. The physical characteristics of waste insulation materials are a dominant trend. Microstructure, porosity, sound absorption, and thermal properties are key focal points in research publications. The life cycle assessment of waste insulation materials is less a focus of research, and life cycle costing of waste insulation materials remains seldom considered from the analysis output. Additionally, Figure 3 corroborates the findings listed in Figure 4 and Figure 5 to detail the origin of sources and highlight prominent research being conducted in their different countries.

Figure 3.

Sankey-plot.

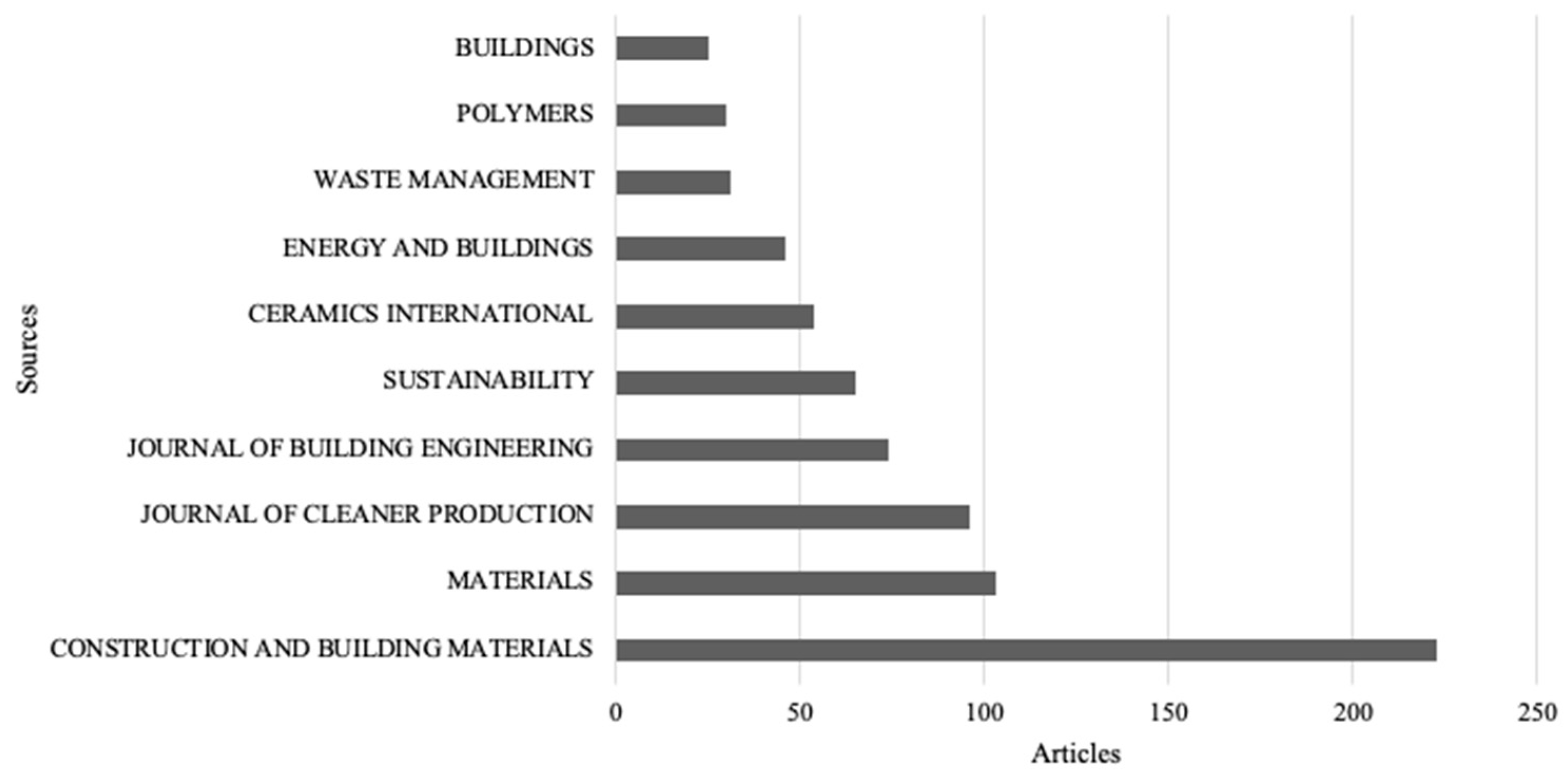

Figure 4.

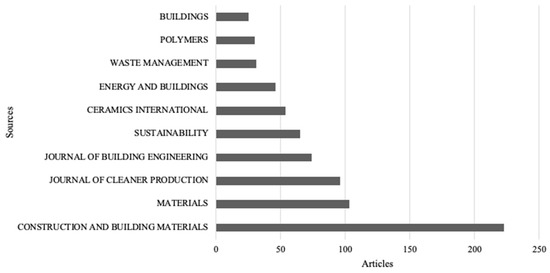

Publication sources.

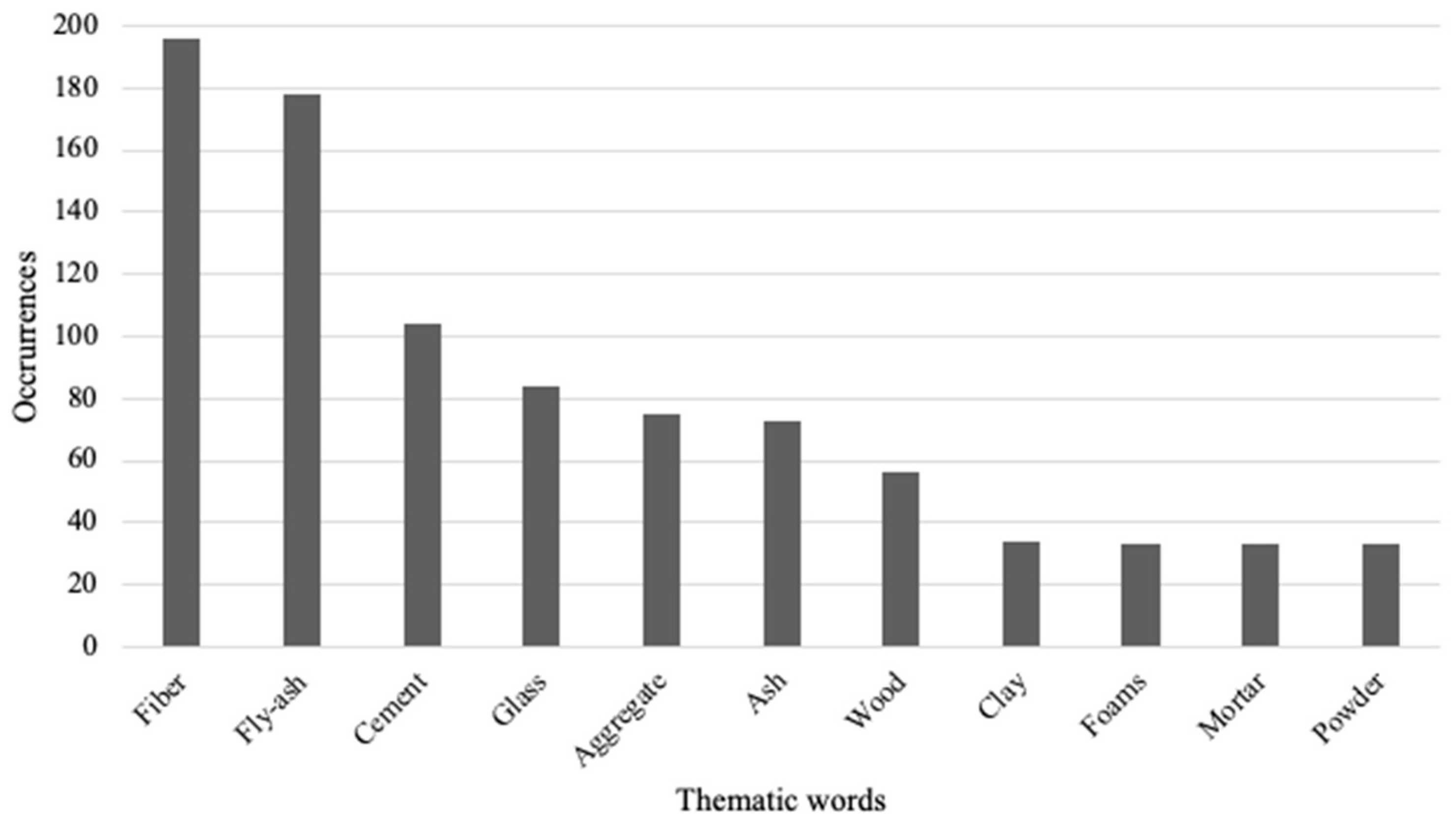

Figure 5.

Thematic word occurrences.

Figure 4 depicts the frequently published sources during the analysed time-period. The Journal of Building and Construction Materials emerges as the predominant source of publications. This journal encourages research that emphasises experimental methodologies, showcasing innovative approaches aimed at enhancing the building and construction industry. The prevalence of publications in both the Journal of Materials and the Journal of Construction and Building Materials in these sources underscores the specialised methods employed, specifically focusing on experimental material designs and alternative materials within their scope.

Figure 5 outlines the thematic occurrences of keywords related to insulation waste materials derived from the analysis of 2627 documents. Fibre materials emerge as the most extensively researched area, evidenced by a high volume of publications focusing on waste-related fibre materials. This is highlighted through the frequent appearances of glass, wood, and foam materials. Moreover, fibre-based materials have been a dominant source of experimental research toward integration within insulation materials. However, foam waste offers a potential source for insulation materials. The source of the fibres is not detailed in the thematic word occurrences; however, potential waste sources could be derived from cardboard fibres and recycled demolition materials [30,31,32,33,34]. Additionally, fly ash and cements used in concrete were also a common theme occurrence due to the term “waste”. As highlighted in other review papers, these materials have been a popular research focus over the last decade [35]. Conversely, research publications on municipal waste materials like powder, clay, and foam are comparatively fewer, indicating a gap in exploration and documentation within these material categories.

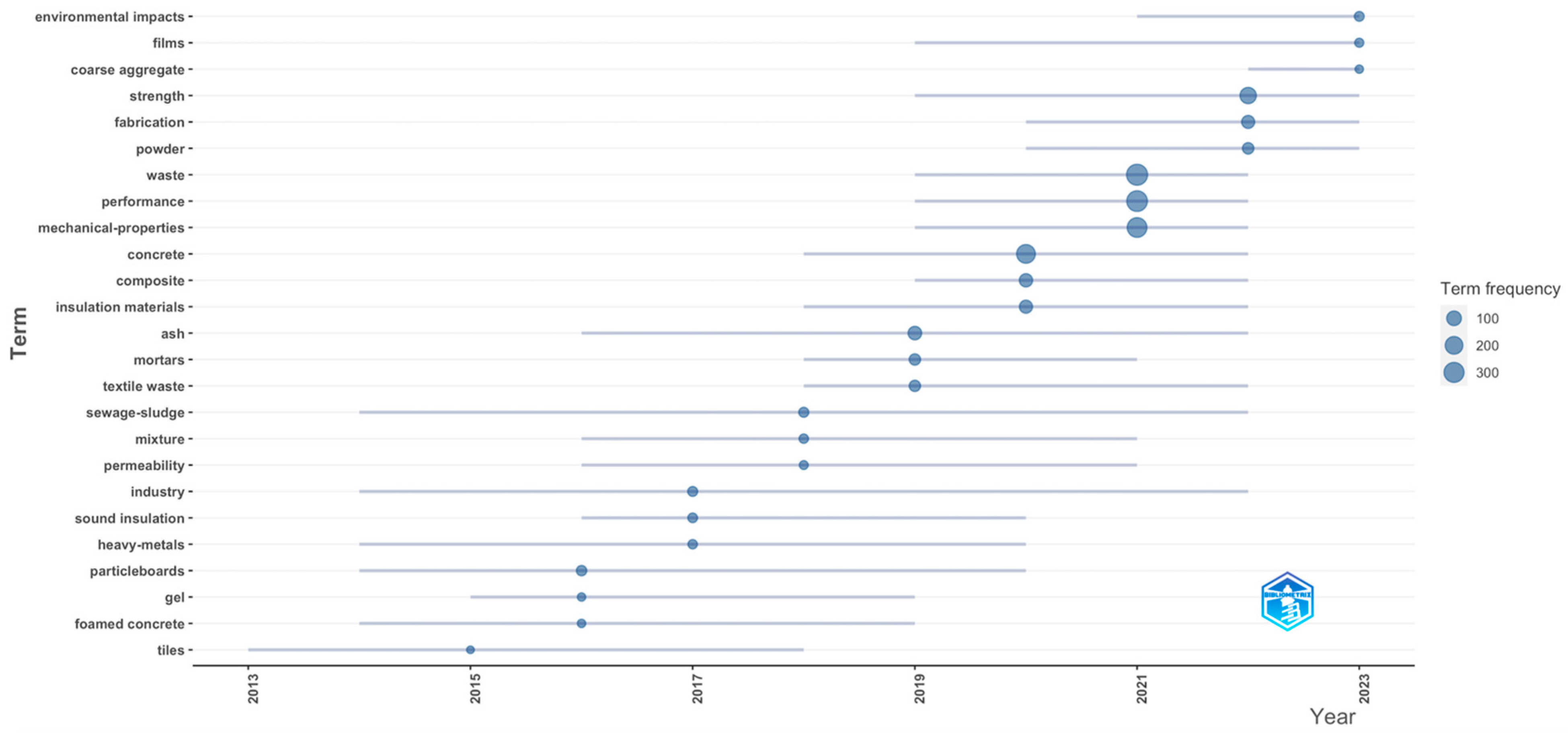

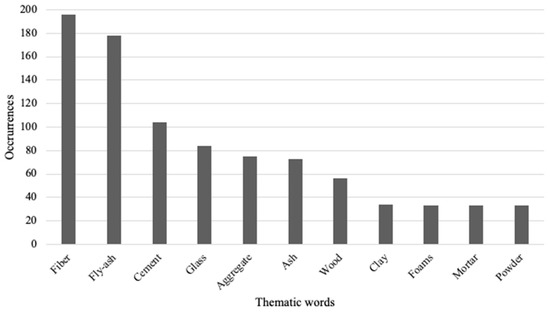

Figure 6 presents the evolving research trends corresponding to publication years within the last decade. The varying sizes of the circles represent the frequency of each research topic. This visualisation highlights three prominent research areas that have garnered focus. Over the years, trends and limitations have shifted, prompting adjustments in research focus to align with the changing landscape. Notably, the current trending topics, observed from 2023, are environmental effects, films, and coarse aggregates. Moreover, this trend coincides with the dominant research focus in 2021, where significant numbers of publications were based on waste and the mechanical performance of materials. Common industrial waste stream materials have been extensively researched, with the beneficial effects being highlighted in recent years [36].

Figure 6.

Research trends.

Summary of Bibliometric Assessment

The comprehensive bibliometric analysis has uncovered the following findings and observations:

- Foam, mortar, and clay emerged as the least researched waste insulation materials.

- Mechanical testing encompassing thermal conductivity evaluations holds significant research emphasis.

- Fibre and fly ash waste materials have been researched extensively.

- Recycling and sustainability remain a pivotal driving force behind waste material research.

- The Journal of Building and Construction Materials remains the primary source of waste material-related research.

- Research on mattress waste was not published within the analysis.

The outcomes of the bibliometric analysis offer valuable guidance for emerging researchers, aiding in identifying influential journal sources and directing research efforts toward areas with potentially higher impact. Notably, the assessment highlighted substantial research conducted on fibre waste-related materials, while foam waste received significantly less attention in comparison. Considering the diverse array of waste products, this review will systematically concentrate on lesser researched municipal solid waste materials, specifically targeting foam mattress waste materials. The aim of the study is to analyse foam mattress waste materials that could be redirected from landfill and integrated within insulation materials used in the building and construction industry.

4. Mattress Waste

In Australia, the accumulation of waste materials is increasing. Between 2014–2015, 64 million tonnes (Mt) of waste were generated; in 2020–2021, waste increased to 75.8 Mt [37]. The largest contributor was building and demolition materials equating to 25.2 Mt. In total, this was equivalent to 2.95 tonnes per capita. The increase in waste generation is often attributed to the growing population. The ever-growing demand on mattresses does not stop, therefore the accumulation of waste material continues to increase in landfill areas. In the United Kingdom (UK), approximately 75% of mattress waste results in landfill. This equates to approximately 7.5 million units annually [38]. Mattress waste creates extensive problems for local councils due to the disposal at local waste management centres. Recycling mattresses is problematic due to the time, costs, and suitable applications. This often results in mattresses being landfilled, causing negative environmental effects. Nationwide in Australia, approximately two million mattresses are sold every year, resulting in 1.6 to 1.8 million mattresses being disposed of. Approximately half of those mattresses go to landfill, which equates to 900,000 cubic metres added to landfill per year [39]. The remaining mattresses are reused, stockpiled, or illegally dumped. With the appropriate collection and processing systems, mattresses are almost completely recyclable. These statistics represent an opportunity to create a new product with those used mattress materials [40]. The Waste Management and Resource Recovery Association of Australia has specifically emphasised the importance of appropriate separation and collection systems that must be put in place to avoid landfill [41]. Every tonne of recycled mattress material produces an estimated 1.5 tonnes of carbon emission equivalent (CO2-e) savings in greenhouse gas (GHG) material and approximately 25 cubic metres (M3) of landfill space preserved [42]. This demonstrates that the development toward recycling mattress materials in other areas is critical to reduce detrimental effects on the environment. It is important to note that the development toward novel waste materials used in the building and construction industry requires significant research and development. Therefore, highlighting a potential use for mattress waste can create additional pathways to integrate the material in other building and construction systems.

4.1. Thermal Insulation Materials

Materials exhibit various thermal properties that significantly influence their behaviour in different environmental temperatures. Thermal conductivity, a fundamental property, describes a material’s ability to conduct heat, with higher conductivity facilitating faster heat transfer. Conversely, materials with low thermal conductivity offer better insulation against heat flow. Specific heat capacity represents the amount of heat required to raise the temperature of a unit mass of the material by 1 °C, influencing its ability to store and release heat [43]. Thermal conductivity is critical when evaluating insulation materials, as it directly affects their effectiveness in resisting heat flow. Low thermal conductivity signifies efficient insulation, as it impedes the transfer of heat through the material, thereby maintaining desired temperatures within a space. Insulation materials with high thermal conductivity, on the other hand, are less effective at retaining heat and may result in increased energy consumption for heating or cooling purposes. Therefore, selecting insulation materials with low thermal conductivity is essential for enhancing energy efficiency and reducing heat loss in buildings, appliances, and industrial applications [44]. By minimising heat transfer, these materials contribute to maintaining comfortable indoor environments while also lowering energy costs and mitigating environmental impacts. Table 3 details the variance in thermal conductivity between common insulation materials.

Table 3.

Materials and the variance of thermal conductivity.

The density of a material plays a crucial role in determining its thermal conductivity. Generally, materials with higher density tend to have higher thermal conductivity. This relationship arises from the fact that denser materials have more closely packed molecules or particles, allowing for more efficient transfer of thermal energy through the material. In such materials, thermal energy can propagate more easily due to the shorter distances between particles, leading to greater conductivity. Conversely, materials with lower density typically have more air or void spaces between particles, which inhibit the transfer of heat and result in lower thermal conductivity [45]. This is because air is a poor conductor of heat compared to solid materials. Therefore, when selecting insulation materials, it is important to consider not only their insulating properties but also their density, as higher-density materials may offer better thermal conductivity but could be less effective at insulating against heat transfer.

Table 4 details various materials alongside their minimum and maximum thermal conductivity and density values. As shown, increasing the density often increases the thermal conductivity. Therefore, materials with a low density can offer increased positive insulation properties. These findings demonstrate that foam materials such as polyurethane foam (PUF) found in mattresses can be beneficial to reduce the heat transference in building envelopes.

Table 4.

Common insulation materials and their variable measurements.

4.2. Physical Properties of Mattress Materials

Parts of mattress materials are recycled, but not all materials are being utilised. Currently, some types of foam, fibres, and other soft materials are cut, compressed, and used in carpet underlay, oil filters, mats, and furniture upholstery stuffing. The metal springs are sent to scrap recyclers and sold to steel mills to be melted down and used in various applications such as roof sheets [42]. Mattress foams can vary dramatically in physical properties as they relate to the response of compressive loads, which is the critical criteria when selecting a mattress. However, different forms of foam can have a variety of physical properties that can lead to other uses. Three common mattress foams include memory foam (viscoelastic foam), latex foam, and PUF. The design of the mattress has not evolved dramatically in the past fifty years, with a standard mattress comprising two foam layers. Typically, PUF with a steel spring system is sandwiched between the two layers. The metal and foam are then covered with a strapping material that is comprised of cotton or wool to secure the individual pieces together. Once adhesives are applied, the materials are sewn together, and this creates the mattress. Components of the mattress are not accessible for replacement; due to this limitation there has been a rise in the development of other foam products such as latex and memory foams to eradicate the use of metal spring mattresses [47]. The construction components of mattresses are shown in Table 5.

Table 5.

Breakdown of mattress properties. Adapted from [42].

4.3. Mattress Foams

4.3.1. Memory Foam

Viscoelastic foam is commonly known as memory foam. It is a chemically adjusted, flexible PUF that is formulated to increase density and viscosity. Viscoelastic foam has an open cell structure to create a breathable mattress. However, it can also be formulated to have a tighter cell structure. Viscosity is measured via shear or tensile stresses. There is an increased density with memory foam, creating a heavier mattress. This type of foam reacts specifically to heat and pressure, which is why it is popular in the mattress industry [48]. Viscoelastic foam is thermally optimal in temperatures between 26–40 °C. This is in direct correlation to compressive loads. The density of the material is affected due to thermal variations and has a poor thermal conductivity response in freezing temperatures. In colder temperatures, the material will become more rigid whereas other foams will be less affected. Attempts to improve the thermal performance have been attempted with the incorporation of other chemicals, although this has proved to be insufficient as this decreases the performance of viscosity [49]. As such, using viscoelastic foam as a thermal insulating product in building and construction systems will be insufficient. This is due to the breakdown of the cell structure in colder temperatures.

4.3.2. Latex

Latex mattresses are created from natural latex or synthetic latex. Natural latex is often referred to as a natural rubber that is formed from the liquid extracted from rubber trees [50]. Synthetic latex is comprised of styrene butadiene rubber (STB) obtained from the polymerisation of styrene and butadiene [51]. Due to the cell structure of latex, the combustible properties are significantly high compared to other foams used in mattresses. Full latex mattresses are usually multilayered latex foam panels with open holes to allow for elements of breathability, flexibility, comfort, noiselessness, and antibacterial qualities. Latex material is easily ignited and, once ignited, fire can spread quickly, producing a toxic smoke. Therefore, this factor eliminates the material being used viably as a construction material [52].

4.3.3. Polyurethane Foam (PUF)

PUF belongs to the thermosetting group of plastics and is formed with a combination of chemicals. The basic chemical compound comprises of polyols, toluene, diisocyanate, water, amine catalysts, tin catalysts, and methylene chloride as blowing agents [53]. Other additives will enhance the foam properties with colour, fire retardation, and anti-fungal and UV protection. Initially, the propellant gas used was R11, however, it became illegal to use R11 gas. This was then replaced with carbon dioxide or pentane gas. This alternative selection of gas led to an increase in the thermal conductivity in the material [54]. It is important to note that density values can change when creating the foam, with adjustment of chemicals in the formation process. This is the reason that when selecting a mattress, the density can differ significantly [48]. PUF is commonly used in mattresses because of its durability, comfort, and support. The cell structure of PUF is crucial, as it contains various cavities and interconnecting pores. This creates crucial mechanical and acoustic values. Materials with an open cell structure typically absorb sound or noise [55]. The sound absorption, fire retardation, and thermal resistant properties of PUF provides a significant input for the application toward thermal insulation in building construction.

5. Current Research Utilising Mattress Waste

Research publications with the term “mattress” are predominantly associated with journals focusing on medical and musculoskeletal investigations. However, Table 6 demonstrates a few articles that have focused on utilising mattress waste in alternative applications. It is important to note that research has been published on raw materials that can be integrated within mattresses.

Table 6.

Mattress waste foam in research applications.

6. Recycling Mattress Waste

The implementation of an effective waste management system is critical to recycle mattresses. There is significant physical demand to disassemble each mattress due to the interwoven materials that bind the mattress together. It is important to minimise the process of handling each mattress. Minimising manual labour will decrease the number of hours involved in the process while also eliminating double handling issues. Engaging in correct supervision of waste handling activities is critical for the occupational health and safety of employees. Environmental factors concerning the level of air pollution as well as water and noise pollution should be examined while the recycling process is underway to ensure that mattresses are not further contaminating the environment. The process of recycling a mattress is complex because of its size, weight, range of different materials, and feasibility of the extraction process. There are two types of methods: manual labour and machine operated.

Manual recycling involves the use of sharp instruments to pierce the mattress layers and physical human resources to carry out the work. This is a slow process as well as also creating safety hazards due to the potential infectious mattresses and air borne pollutants from the various materials. Although this method was common, the involvement of technology has created different machines that can carry out the work. Dismantling and shredding is also another process that involves manual handling to recover non-steel materials; the mattress is loaded into a machine that cuts the mattress to retrieve the steel and the steel is then baled and collected for the steel mills. An alternative machine used in the process is called a loader ripper; this machine places the mattress on a conveyor belt and tears the mattress apart, then separates the layers accordingly for recycling. This eliminates manual handling altogether [61]. In Australia, Boomerang Alliance conducted a report on several leading mattress recycling companies in Melbourne, with the conclusion that TIC Group is a leading mattress recycling company. The companies included Bed Collect (largely refurbishes mattresses), Jubilee Trial, Kush-Inn (based at Wyndham Landfill), TIC Mattress Recycling (TIC), and WM Group (based at Knox Transfer Station). TIC Group scored an average of 4.5 while the average of the other companies were approximately 2.7 out of 5 [42]. The report cross referenced the companies on criteria such as:

- Regulatory compliance

- OH&S Management

- Level of Recycling

- Accuracy of Environmental Claims

- Accuracy of Operational Description

- Pollution Controls

- Fire Hazards

- Management Control

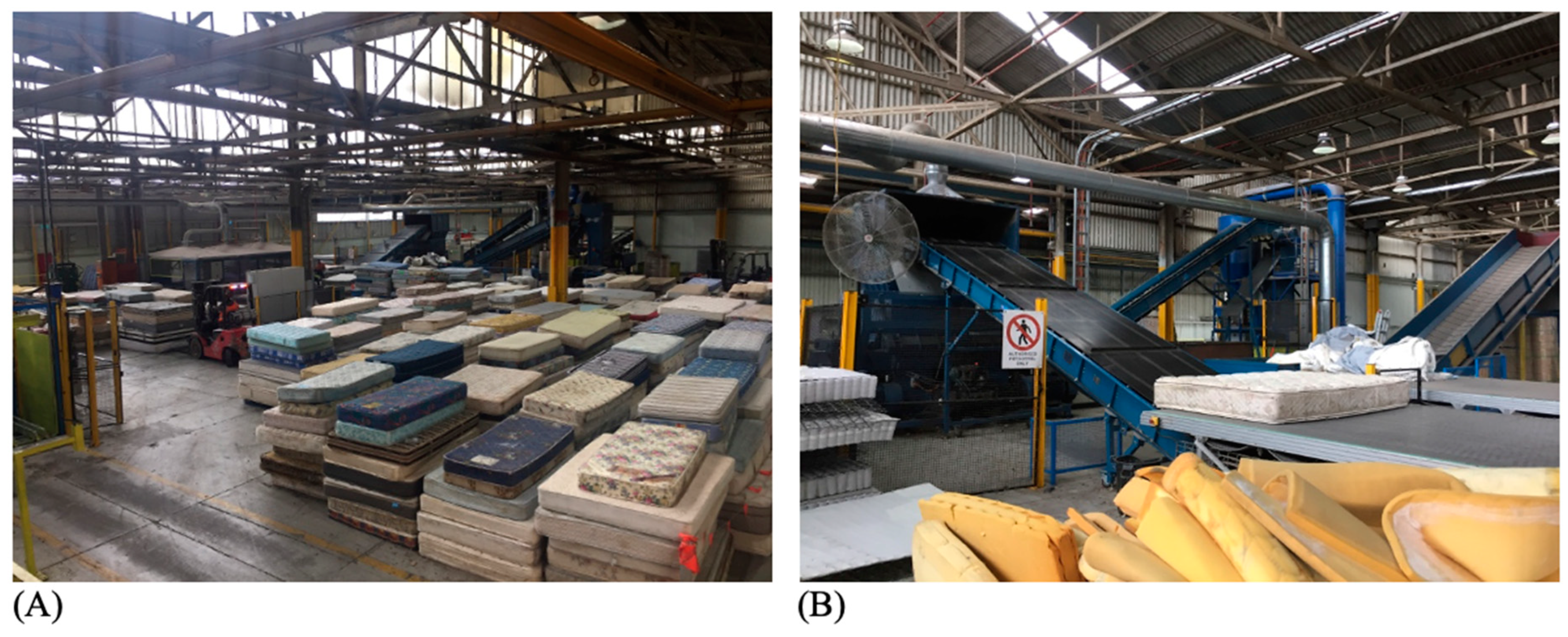

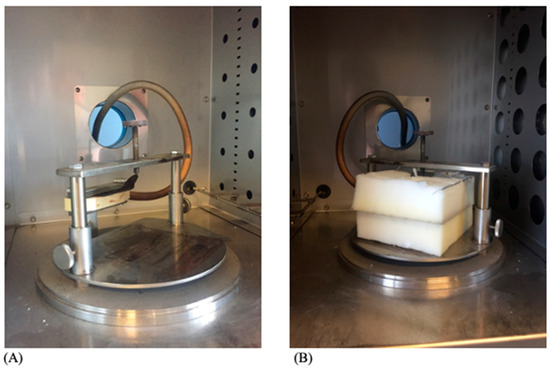

TIC Group Site Visit

A site visit was conducted at the leading mattress recycling company, TIC Group [62,63]. TIC facilitated a site walkthrough of operations, providing samples of materials while also answering questions. The site visit information is shown in Table 7, and Figure 7 represents the TIC Group mattress recycling plant. The processing steps of recycling at TIC Group are:

Table 7.

TIC Group Results.

Figure 7.

TIC Group Recycling Plant (A) Mattress (B) Conveyor belt.

- Collection of mattresses.

- Mattresses loaded onto a conveyor belt.

- A machine cuts the sides of the mattress.

- Workers open the mattress and remove foam.

- Foam is bundled and collected by various companies for further recycling.

- The leftover mattress is loaded into the ripper/shredder.

- The remaining materials are loaded into two skip bins: one for scrap metal and one for landfill.

It is important to note that approximately 2–3 tonnes of the shredded flock (ticking) go to landfill per day. With further research on PUF and the potential to incorporate the shredded textiles into insulation, this provides an opportunity to reach 100% recyclability of mattress material.

7. Experimental Results

The TPS measures a wide range of materials; however, due to the variations in cell structures, there has been concern regarding the accuracy in results with lower density materials. Theoretically, heat can transfer faster through open cell structures, thus creating inaccurate results for actual insulating values. However, the analysis of numerical results exposes that even significant thermal transportation through low density material has almost no influence on the accuracy of the measurement. Therefore, the results of thermal conductivity from the TPS for low density materials corresponds to the equivalent material insulating values [64].

When measuring the insulating properties of PUF, the critical factor is having a low output of power alongside a long measurement in time. This is different compared to conducting materials where a high output of power is measured alongside a short measurement in time. This factor used in the application of the TPS is important for valuing the thermal properties of the corresponding material; however, the PUF also has associated variables. The ageing effects on the material must be considered, as well as variations in density, temperature, moisture, and contamination. Making note of the visual variations as well as other measurable differences is critical when conducting the experiment using the TPS [65].

TPS

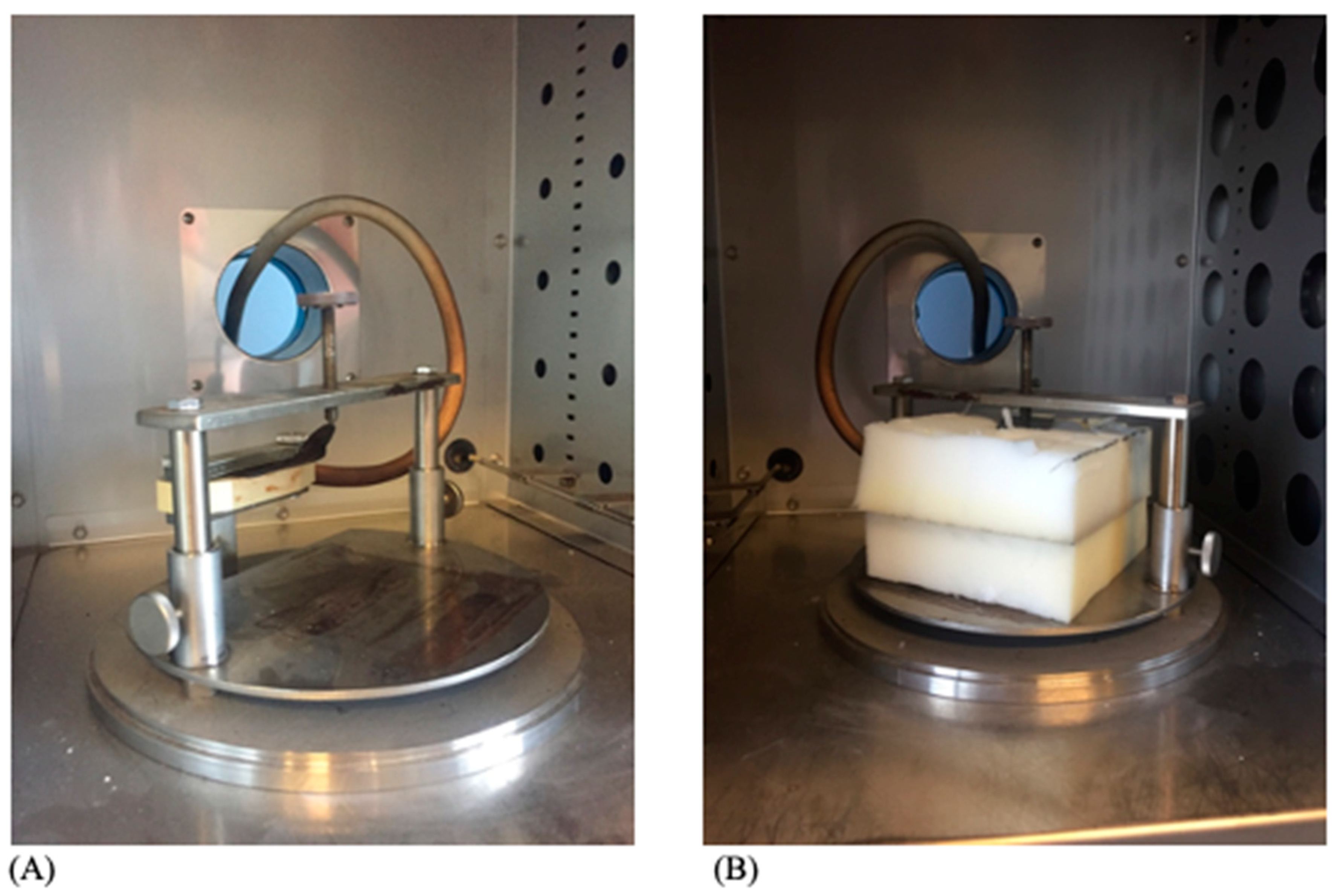

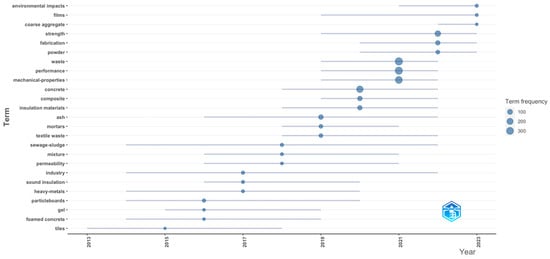

The preliminary steps to undertake the experiment were to enter the experimental parameters. This included measuring the sample sizes, entering the probing depth, setting the internal temperature of the machine, setting the heating power, and entering the measurement time. As shown in Figure 8, the equipment used was the TPS 7.

Figure 8.

TPS 7.

The collection of mattress waste (polyurethane foam) was obtained from the site visit for the TPS experiment. The following PUF sample sizes were collected:

- 10 cm × 10 cm × 10 mm

- 10 cm × 10 cm × 20 mm

- 10 cm × 10 cm × 30 mm

Listed within the user guide of the TPS was a summary of experimental parameters for various materials, as shown in Table 8. The summary provided a commencement point when selecting times and heating power of the transient recordings. This also provided suitable radii of the Hot Disk sensors that were studied for the PUF. As shown in Table 8, the low-conducting material parameters were the most suitable for PUF. Figure 9 demonstrates the internal view of pre- and post-material insertion.

Table 8.

Summary of Experimental Parameters of TPS 7.

Figure 9.

Internal view of the TPS (A) Pre-material, (B) PUF Samples.

When recording the results from the experiment, it was possible to use a benchmark reading provided to measure the accuracy of the results. The Temperature Coefficient of Resistivity (TCR) benchmark values for the TPS are shown in Table 9. Fortunately, due to the possible application of the PUF being used as a building insulation, the TCR values do not vary dramatically within the desired temperatures of 0 °C to 50 °C.

Table 9.

Approximate TCR values for the TPS.

The experiment included three separate sample size thicknesses of 10 mm, 20 mm, and 30 mm. The results of the raw data are shown in Table 10, Table 11 and Table 12. The theoretically correct data is shown in Table 13.

Table 10.

TPS raw data results; 10 mm Samples.

Table 11.

TPS raw data results; 20 mm Samples.

Table 12.

TPS raw data results; 30 mm Samples.

Table 13.

Theoretically correct data.

The mean thermal conductivity of the 10 mm raw data samples is 0.044935 W/m K; however, there is no theoretically correct data available for use. This is due to the correlating probing depth used within the experiment of the 10 mm samples. The probing depth should not exceed the measurement of the samples used, as the Table highlights that the raw data collected should not be used for theoretical purposes. The sensor’s probing depth is typically determined by the size and design of the sensor used within the TPS. The sensor matches the thickness or depth of the samples being tested. It is critical that the probing depth of the sensor does not exceed the thickness of the samples. As shown in Table 10, Table 11 and Table 12, the probing depth varies between each experimental sample. The mean thermal conductivity of the raw data 20 mm samples is 0.046781 W/m K; however, when compared to the 10 mm samples, there were two theoretically correct data available for use. This is due to the correlating probing depth used within the experiment of the 20 mm samples; therefore, the probing depth should not exceed 20 mm for theoretically correct data. As shown in the data collection of the raw data and theoretically correct data, there is significant variance between measurements. Focusing on the latter measurements will be included in an accurate representation of the materials.

Table 13 highlights the theoretically correct data used from the raw data collected from the experiment above. The theoretically correct data correlate to the data that closely align with the expected results. When the experimental data closely match the theoretical predictions, they demonstrate the accuracy and reliability of the data produced. The total temperature recordings varied from approximately 38 °C to 42 °C throughout the whole duration of the experiment. The most optimal comparison was recorded with 30 mm and 20 mm samples. The average thermal conductivity of the mattress waste samples produced is 0.053 W/ m K, as shown in Table 13. It is important to note the standard deviation of the results produced is between 0.043–0.065. This indicates similar thermal behavior with commercially available materials, as exhibited in Table 4.

The density of mattress material is required for comparison analysis of commercially available insulation materials. The density values for the samples experimented on are shown in Table 14.

Table 14.

Density Value of mattress samples.

8. Comparitive Analysis of Materials

To effectively analyse the future use of recycled mattress material as a thermal insulating product, it is critical to have a comparison of the effective thermal insulating products currently used in the industry. Table 15 highlights the density of the material with kilograms in weight per m3. A thermal conductivity test is the measure of the material’s ability to resist heat transfer. Specific heat is the energy required to increase the material in temperature by 1 °C in the unit of kj/kg k. Water vapour diffusion is the movement of water vapours through the cell structure of the material.

Table 15.

Material comparitive analysis. Adapted from [12].

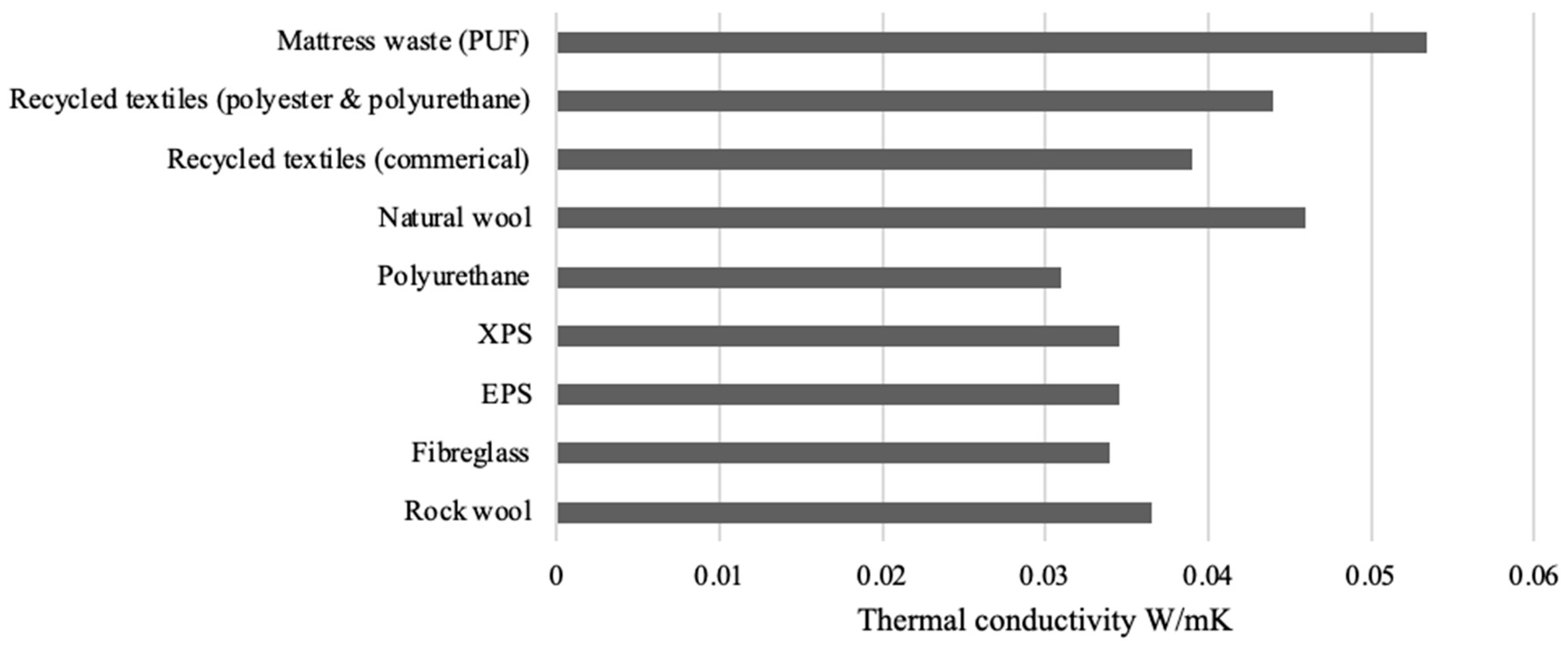

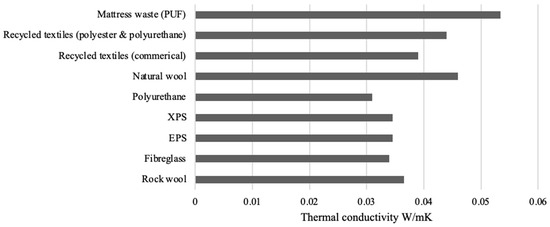

As shown in Table 15, the density of the material can vary significantly; however, despite this large variance, the thermal conductivity does not alter drastically. It highlights the possibility of using recycled mattress materials as an insulating product or mixing a blend of mateirals in a mattress to create an independent product. Figure 10 graphically depicts the thermal conductivity of commercial materials and the investigated PUF mattress waste. As shown, the mattress waste material has a higher thermal conductivity value compared to commercially available insulation materials. Polyurethane and fibreglass materials demonstrate the lowest average. Despite the waste material having the highest thermal conductivity, there are still opportunities to use it as an insulation product within building envelope systems.

Figure 10.

Thermal conductivity of various materials.

9. Limitations, and Possible Applications of Mattress Waste

9.1. Limitations

PUF is a highly flammable material, and this therefore limits its possible applications. When PUF is burning, there is a release of hydrogen cyanide (HCN) and isocyanates, which are very poisonous [66]. However, applying eco-friendly additives can reduce the associated fire hazards and expand its marketing potential. Flame-retardant polymer-based materials can minimise health risks. The additives create a glass like coating on the surface of the material to ensure the material does not combust or begin to burn [67]. Marques et al. [68] investigated PUF composites containing recycled Polyethylene terephthalate (PET) and alumina trihydrate (ATH). Their findings demonstrated that PET and ATH can replace up to 55% of the PUF residue. This has been shown to enhance safety and efficiently be used as an insulation material. The combination of these materials does not alter the cell structure dramatically, which enables the positive physical attributes PUF to remain effective as an insulation material. It should be noted that the higher percentage of PET additives results in a lower compression strength in the material. However, this is a secondary concern, as the primary application of insulation concerns the thermal properties [68]. Moreover, composites containing PUF with altering percentages of PET and ATH demonstrate that there is a reduction in the ignition response when additional materials are used with PUF in a composite design [68]. This demonstrates positive outcomes when utilising alternative materials and can promote further research opportunities.

9.2. Application

Insulation materials can be further characterised with their accoustic values via the sound transmission they permeate or the rate of sound wave absorption. Sound transmission refers to materials that are of a solid nature or closed cell structure, with sound waves ricocheting off the surface and forcing the sound waves to return. The key factor of the quality in sound transmission material is the actual mass of material. The heavier the mass in the material, the more likely a significantly improved sound transmission is created. Sound absorbtion refers to sound waves hitting the surface of the material and dissipating into the cell structure of the material. Materials with open cell structures are usually good sound absorbers; however, those materials are not usually optimal insulators due to the vastness of the open cells in the material [12]. PUF cell structure can vary depending on its application. As a rigid foam with a closed cell structure, it has a high insulating value. However, due to the open cell structure of PUF, it has a lower insulating value with mild acoustic qualities. When combined with recycled textiles of polyester or cotton, the acoustic values and insulating properties can rise signinficantly [69]. Applying the PUF derived from mattresses directly as an insulation product would be the most optimal solution; however, further material engineering is required to compete with current insulation materials on the market. To create an advanced form of blended PUF insulating product using other materials, physical polymer waste mechanics would need to be implemented. This process involves turning the polyurethane into flakes, granules, or powder and then using it in a new material [70].

The re-bonding process can be simple with PUF as it is low cost and generally environmentally friendly; however, the largest defect is the output of performance of the final product. This is why it is widely used for carpet underlay, car lining, furniture, and other cheap components [71]. The re-grind or powdering process is currently being used in the construction industry, though it is not a widely used. The application is incorporated using the polyurethane powder and added to concrete; this improves the concrete adiabatic effects. Polyurethane waste grinded to certain particle sizes can also be added to the building in the roof construction systems; in Japan, the ground down waste is being used for mortar and light aggregate [71].

The National Construction Code in Australia [72] requires insulating materials to achieve an R-value for building envelope systems. For example, the roof and walls must achieve an R-value of 4.1 and 2.8, respectively, in regions 1–7. The Australian Standards (AS/NZS 4559.1 [73]) provide the calculations to demonstrate the R-value. The results indicate that PUF may be used with the 90% confidence level required. Typical residential wall systems in Australia include a depth of 90 mm [74]. Common insulation products are then fabricated to this measurement. As shown in Table 16, recycled PUF does not meet the minimum requirements of a 90 mm wall system; however, there is an opportunity to incorporate PUF into the building envelope as a part of that total R-value requirement. Moreover, minimum roof/ceiling R-values are 4.1. There is an opportunity to meet this requirement using recycled PUF mattress materials at 240 mm. Typical ceiling insulation is manufactured to a thickness of 130–250 mm [75]. The recycled mattress PUF can be applied as an insulation product with the required R-values, meeting products currently used in the building construction industry.

Table 16.

R-value of mattress PUF materials.

10. Conclusions and Future Studies

The building and construction industry across the globe significantly contributes to waste materials resulting in landfill. The recycling problems associated with mattresses is a simultaneous growing problem. Incorporating recycled PUF from mattresses as an insulation product can offer the opportunity to decrease the waste generated. This study highlighted the gap in research when analysing sources of waste materials to be utilised as potential insulation products. In conjunction with the review, the study experimentally investigated the thermal conductivity of waste PUF derived from mattresses. Samples were obtained from a site visit to a mattress recycling plant in Victoria, Australia. The thermal conductivity results demonstrated that waste mattress PUF has a thermal resistant mean of 0.053 W/(m K). This indicated that the waste mattress PUF could be used as an insulation product due to these thermal properties. However, the thermal resistance is only optimal when the PUF is thicker in dimension. The optimal thickness of PUF is measured at 215 mm in order to meet the current industry requirements of those building fabric systems. Further exploration of the fire behaviour and application of eco-friendly flame-retardant chemicals are required on waste mattress PUF. Due to the effective cell structure of PUF, there are also advantageous sound-proof characteristics with the material. Moreover, an opportunity to blend PUF with various recycled textiles could create an enhanced product for insulating measures.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request.

Conflicts of Interest

The author declares no conflicts of interest.

References

- Nejat, P.; Jomehzadeh, F.; Taheri, M.M.; Gohari, M.; Abd Majid, M.Z. A global review of energy consumption, CO 2 emissions and policy in the residential sector (with an overview of the top ten CO2 emitting countries). Renew. Sustain. Energy Rev. 2015, 43, 843–862. [Google Scholar] [CrossRef]

- Li, C.; Chen, Z.; Dong, W.; Lin, L.; Zhu, X.; Liu, Q.; Zhang, Y.; Zhai, N.; Zhou, Z.; Wang, Y.; et al. A review of silicon-based aerogel thermal insulation materials: Performance optimization through composition and microstructure. J. Non-Cryst. Solids 2021, 553, 120517. [Google Scholar] [CrossRef]

- Omrany, H.; Ghaffarianhoseini, A.; Ghaffarianhoseini, A.; Raahemifar, K.; Tookey, J. Application of passive wall systems for improving the energy efficiency in buildings: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 62, 1252–1269. [Google Scholar] [CrossRef]

- Cuce, E.; Harjunowibowo, D.; Cuce, P.M. Renewable and sustainable energy saving strategies for greenhouse systems: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 64, 34–59. [Google Scholar] [CrossRef]

- Su, X.; Luo, Z.; Li, Y.; Huang, C. Life cycle inventory comparison of different building insulation materials and uncertainty analysis. J. Clean. Prod. 2016, 112, 275–281. [Google Scholar] [CrossRef]

- Schritt, H.; Pleissner, D. Recycling of organic residues to produce insulation composites: A review. Clean. Waste Syst. 2022, 3, 100023. [Google Scholar] [CrossRef]

- Aditya, L.; Mahlia, T.M.I.; Rismanchi, B.; Ng, H.M.; Hasan, M.H.; Metselaar, H.S.C.; Muraza, O.; Aditiya, H.B. A review on insulation materials for energy conservation in buildings. Renew. Sustain. Energy Rev. 2017, 73, 1352–1365. [Google Scholar] [CrossRef]

- Tariku, F.; Shang, Y.; Molleti, S. Thermal performance of flat roof insulation materials: A review of temperature, moisture and aging effects. J. Build. Eng. 2023, 76, 107142. [Google Scholar] [CrossRef]

- Füchsl, S.; Rheude, F.; Röder, H. Life cycle assessment (LCA) of thermal insulation materials: A critical review. Clean. Mater. 2022, 5, 100119. [Google Scholar] [CrossRef]

- Zhao, J.; Li, S. Life cycle cost assessment and multi-criteria decision analysis of environment-friendly building insulation materials—A review. Energy Build. 2022, 254, 111582. [Google Scholar] [CrossRef]

- Ha, Y.; Jeon, J. Thermogravimetric analysis and pyrolysis characterization of expanded–polystyrene and polyurethane–foam insulation materials. Case Stud. Therm. Eng. 2024, 54, 104002. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Krüger, E.L.; Suetake, G.; Matoski, A. Evaluation of the thermal performance of insulation sheets in fiberglass security booths. Build. Environ. 2018, 136, 1–10. [Google Scholar] [CrossRef]

- Shrestha, S.S.; Biswas, K.; Desjarlais, A.O. A protocol for lifetime energy and environmental impact assessment of building insulation materials. Environ. Impact Assess. Rev. 2014, 46, 25–31. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Sasi, S.; Yaghoubi, E.; Joseph, P.; Vrcelj, Z. Microstructural attributes and physiochemical behaviours of concrete incorporating various synthetic textile and cardboard fibres: A comparative review. J. Build. Eng. 2024, 86, 108690. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Braulio-Gonzalo, M.; Bovea, M.D. Environmental and cost performance of building’s envelope insulation materials to reduce energy demand: Thickness optimisation. Energy Build. 2017, 150, 527–545. [Google Scholar] [CrossRef]

- Danny Harvey, L.D. Net climatic impact of solid foam insulation produced with halocarbon and non-halocarbon blowing agents. Build. Environ. 2007, 42, 2860–2879. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, C.; Liu, M.; Li, X.; Liu, T.; Liu, Z. Thermal insulation performance of buildings with phase-change energy-storage wall structures. J. Clean. Prod. 2024, 438, 140749. [Google Scholar] [CrossRef]

- Villasmil, W.; Fischer, L.J.; Worlitschek, J. A review and evaluation of thermal insulation materials and methods for thermal energy storage systems. Renew. Sustain. Energy Rev. 2019, 103, 71–84. [Google Scholar] [CrossRef]

- Jelle, B.P. Traditional, state-of-the-art and future thermal building insulation materials and solutions—Properties, requirements and possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef]

- Haigh, R. A Decade Review of Research Trends Using Waste Materials in the Building and Construction Industry: A Pathway towards a Circular Economy. Waste 2023, 1, 935–959. [Google Scholar] [CrossRef]

- Haigh, R. The mechanical behaviour of waste plastic milk bottle fibres with surface modification using silica fume to supplement 10% cement in concrete materials. Constr. Build. Mater. 2024, 416, 135215. [Google Scholar] [CrossRef]

- Haigh, R.; Joseph, P.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. Thermal Characterizations of Waste Cardboard Kraft Fibres in the Context of Their Use as a Partial Cement Substitute within Concrete Composites. Materials 2022, 15, 8964. [Google Scholar] [CrossRef] [PubMed]

- Haigh, R.; Bouras, Y.; Sandanayake, M.; Vrcelj, Z. The mechanical performance of recycled cardboard kraft fibres within cement and concrete composites. Constr. Build. Mater. 2022, 317, 125920. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. A review of the mechanical and durability performance of kraft-fibre reinforced mortar and concrete. Construction and Building Materials 2021, 297, 123759. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. bibliometrix: An R-tool for comprehensive science mapping analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Ashraf, A.A. Thermal Conductivity Measurement by Hot Disk Analyser: Measurement of Thermal Conductivity and Diffusivity of Different Materials by the Transient Plane Source Method Using Hot Disk Thermal Constants Analyzer. 2014. [Google Scholar] [CrossRef]

- He, Y. Rapid thermal conductivity measurement with a hot disk sensor. Thermochim. Acta 2005, 436, 122–129. [Google Scholar] [CrossRef]

- Haigh, R. A comparitive analysis of the mechanical properties with high volume waste cardboard fibres within concrete composite materials. In Proceedings of the Australasian Structural Engineering Conference: ASEC 2022, Melbourne, Australia, 9–10 November 2022; Engineers Australia: Melbourne, Australia, 2022; pp. 397–406. [Google Scholar]

- Özçelikci, E.; Oskay, A.; Bayer, İ.R.; Şahmaran, M. Eco-hybrid cement-based building insulation materials as a circular economy solution to construction and demolition waste. Cem. Concr. Compos. 2023, 141, 105149. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. A life cycle assessment of cardboard waste in low stress grade concrete applications. Environ. Manag. 2024, 354, 120428. [Google Scholar] [CrossRef] [PubMed]

- Haigh, R.; Bouras, Y.; Sandanayake, M.; Vrcelj, Z. Economic and environmental optimisation of waste cardboard kraft fibres in concrete using nondominated sorting genetic algorithm. J. Clean. Prod. 2023, 426, 138989. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. The durability performance of waste cardboard kraft fibre reinforced concrete. J. Build. Eng. 2023, 67, 106010. [Google Scholar] [CrossRef]

- Sandanayake, M.; Bouras, Y.; Haigh, R.; Vrcelj, Z. Current Sustainable Trends of Using Waste Materials in Concrete—A Decade Review. Sustainability 2020, 12, 9622. [Google Scholar] [CrossRef]

- John, N.J.; Khan, I.; Patel, A. Evaluation of the crushing characteristics of industrial waste aggregates as construction materials. Constr. Build. Mater. 2023, 403, 133111. [Google Scholar] [CrossRef]

- Pickin, J.; Wardle, C.; O’Farrell, K.; Stovell, L.; Nyunt, P.; Guazzo, S.; Lin, Y.; Caggiati-Shortell, G.; Chakma, P.; Edwards, C.; et al. National Waste Report 2022; The Department of Climate Change, Energy, the Environment and Water: Canberra, Australia, 2022.

- Circular_for_Resource_and_Waste_Professionals. 73% of People Would Pay More for Easy-To-Recycle Mattresses. 2023. Available online: https://www.circularonline.co.uk/news/73-of-people-would-pay-more-for-easy-to-recycle-mattresses/#:~:text=He%20said%3A%20%E2%80%9CWith%207.5%20million,adopting%20a%20circular%20economy%20approach (accessed on 9 January 2024).

- Wanless_Waste_Management. Mattress Recycling. A Study by QUT and Wanless Waste Management. 2023. Available online: https://wanless.com.au/mattress-recycling/ (accessed on 18 February 2024).

- The Senate of Australia Parlament. Never Waste a Crisis: The Waste and Recycling Industry in Australia; Environment and Communications References Committee: Canberra, Australia, 2018.

- Waste_Management_Resource_Recovery_Association_Australia. Time for Change. WMRR Roadmap to 2025 for Energy from Waste. 2020. Available online: https://www.bioenergyaustralia.org.au/news/time-for-change-wmrr-roadmap-to-2025-for-energy-from-waste (accessed on 17 February 2024).

- Lazzaro, D.W.a.A. Mattress recycling & disposal. In The Collection, Recycling and Disposoal of Used Mattresses in Victoria; Boomerang Alliance: Surry Hills, NSW, Australia, 2016. [Google Scholar]

- Khoza, M.M.; Huan, Z.; Sithebe, T.; Vasudeva, V. Experimental study of specific heat capacity and thermal conductivity of Al2O3-nanotransformer oil. Mater. Today Proc. 2023, 92, 1289–1294. [Google Scholar] [CrossRef]

- Hou, J.; Liu, Z.-A.; Zhang, L. Influence and sensitivity evaluation of window thermal parameters variations on economic benefits of insulation materials for building exterior walls—A case study for traditional dwelling in China. Therm. Sci. Eng. Prog. 2023, 46, 102207. [Google Scholar] [CrossRef]

- Lakatos, Á.; Lucchi, E. Thermal performances of Super Insulation Materials (SIMs): A comprehensive analysis of characteristics, heat transfer mechanisms, laboratory tests, and experimental comparisons. Int. Commun. Heat Mass Transf. 2024, 152, 107293. [Google Scholar] [CrossRef]

- Domínguez-Muñoz, F.; Anderson, B.; Cejudo-López, J.M.; Carrillo-Andrés, A. Uncertainty in the thermal conductivity of insulation materials. Energy Build. 2010, 42, 2159–2168. [Google Scholar] [CrossRef]

- Ergonomic_Life_International. The History of Mattress Design. 2024. Available online: https://ergonomiclifeinternational.co/2017/04/28/the-history-of-mattress-design/ (accessed on 17 February 2024).

- Defonseka, C. Practical Guide to Flexible Polurethane Foams. Smithers Rapra: Shrewsbury, UK, 2013. [Google Scholar]

- Loeblein, M.; Bolker, A.; Ngoh, Z.L.; Li, L.; Wallach, E.; Tsang, S.H.; Pawlik, M.; Verker, R.; Atar, N.; Gouzman, I.; et al. Novel timed and self-resistive heating shape memory polymer hybrid for large area and energy efficient application. Carbon 2018, 139, 626–634. [Google Scholar] [CrossRef]

- Banerjee, S.L.; Potluri, P.; Singha, N.K. Antimicrobial cotton fibre coated with UV cured colloidal natural rubber latex: A sustainable material. Colloids Surf. A Physicochem. Eng. Asp. 2019, 566, 176–187. [Google Scholar] [CrossRef]

- Garrido, M.A.; Font, R.; Conesa, J.A. Thermochemical study of the briquetting process of mattress foams. Fuel Process. Technol. 2017, 159, 88–95. [Google Scholar] [CrossRef]

- Huang, D.; Zhang, M.; Shi, L.; Peng, L.; Yuan, Q.; Wang, S. Fire behaviors of single and laminated natural latex foam. Int. J. Therm. Sci. 2019, 136, 278–286. [Google Scholar] [CrossRef]

- Sternberg, J.; Sequerth, O.; Pilla, S. Structure-property relationships in flexible and rigid lignin-derived polyurethane foams: A review. Mater. Today Sustain. 2024, 25, 100643. [Google Scholar] [CrossRef]

- Papadopoulos, A.M. State of the art in thermal insulation materials and aims for future developments. Energy Build. 2005, 37, 77–86. [Google Scholar] [CrossRef]

- Gwon, J.G.; Kim, S.K.; Kim, J.H. Sound absorption behavior of flexible polyurethane foams with distinct cellular structures. Mater. Des. 2016, 89, 448–454. [Google Scholar] [CrossRef]

- Veses, A.; Sanahuja-Parejo, O.; Martinez, I.; Callen, M.S.; Lopez, J.M.; Garcia, T.; Murillo, R. A pyrolysis process coupled to a catalytic cracking stage: A potential waste-to-energy solution for mattress foam waste. Waste Manag. 2021, 120, 415–423. [Google Scholar] [CrossRef]

- Arning, K.; van Heek, J.; Ziefle, M. Acceptance profiles for a carbon-derived foam mattress. Exploring and segmenting consumer perceptions of a carbon capture and utilization product. J. Clean. Prod. 2018, 188, 171–184. [Google Scholar] [CrossRef]

- Garrido, M.A.; Gerecke, A.C.; Heeb, N.; Font, R.; Conesa, J.A. Isocyanate emissions from pyrolysis of mattresses containing polyurethane foam. Chemosphere 2017, 168, 667–675. [Google Scholar] [CrossRef]

- Andreea Hegyi, C.D.; Henriette, S. Sheep wool thermal insulating mattresses behaviour in the water vapours presence. In Proceedings of the Procedia Manufacturing 2020, 13th International Conference Interdisciplinarity in Engineering (INTER-ENG 2019), Targu Mures, Romania, 3–4 October 2019. [Google Scholar]

- Rajkishore Nayak, S.H.; Asis, P.; Long, T.V.; Nguyen, R.A.; Shanks, R.P.; Mac, F. Sustainable reuse of fashion waste as flame-retardant mattress filing with ecofriendly chemicals. Clean. Prod. 2020, 251, 119620. [Google Scholar] [CrossRef]

- Australian_Bedding_Stewardship_Council_Limited. Mattress Recycling Study. Stocks, Flows and Feasibility. 2021. Available online: https://www.accc.gov.au/system/files/public-registers/documents/Application%20Attachment%20H%20-%20Mattress%20Recycling%20Study%3A%20Stocks%20flows%20and%20feasibility%20-%2026.05.22%20-%20PR%20-%20AA1000613%20ABSC.pdf (accessed on 17 February 2024).

- Waste_Initiatives. TIC Group. 2024. Available online: https://wasteinitiatives.com.au/project/tic-group-recycling/ (accessed on 30 January 2024).

- TIC_Group. Sustainability through Innovation. 2024. Available online: https://ticgroup.com.au/ (accessed on 8 February 2024).

- Coquard, R.; Coment, E.; Flasquin, G.; Baillis, D. Analysis of the hot-disk technique applied to low-density insulating materials. Int. J. Therm. Sci. 2013, 65, 242–253. [Google Scholar] [CrossRef]

- Al-Ajlan, S.A. Measurements of thermal properties of insulation materials by using transient plane source technique. Appl. Therm. Eng. 2006, 26, 2184–2191. [Google Scholar] [CrossRef]

- Son, M.H.; Kim, Y.; Jo, Y.H.; Kwon, M. Assessment of chemical asphyxia caused by toxic gases generated from rigid polyurethane foam (RPUF) fires. Forensic Sci. Int. 2021, 328, 111011. [Google Scholar] [CrossRef] [PubMed]

- Abu-Jdayil, B.; Mourad, A.-H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Marques, D.V.; Barcelos, R.L.; Silva, H.R.T.; Egert, P.; Parma, G.O.C.; Girotto, E.; Consoni, D.; Benavides, R.; Silva, L.; Magnago, R.F. Recycled polyethylene terephthalate-based boards for thermal-acoustic insulation. J. Clean. Prod. 2018, 189, 251–262. [Google Scholar] [CrossRef]

- Tiuc, A.-E.; Vermeşan, H.; Gabor, T.; Vasile, O. Improved Sound Absorption Properties of Polyurethane Foam Mixed with Textile Waste. Energy Procedia 2016, 85, 559–565. [Google Scholar] [CrossRef]

- Simón, D.; Borreguero, A.M.; de Lucas, A.; Rodríguez, J.F. Recycling of polyurethanes from laboratory to industry, a journey towards the sustainability. Waste Manag. 2018, 76, 147–171. [Google Scholar] [CrossRef]

- Yang, W.; Dong, Q.; Liu, S.; Xie, H.; Liu, L.; Li, J. Recycling and Disposal Methods for Polyurethane Foam Wastes. Procedia Environ. Sci. 2012, 16, 167–175. [Google Scholar] [CrossRef]

- Australian_Building_Codes_Board. National Construction Code. 2024. Available online: https://ncc.abcb.gov.au (accessed on 22 January 2024).

- AS/NZS-4859.1; Materials for Thermal Insulation of Buildings. Australia Standards: Sydney, Australia, 2002.

- Your_Home. Lightweight Framing. 2024. Available online: https://www.yourhome.gov.au/materials/lightweight-framing (accessed on 19 February 2024).

- Earthwool. Earthwool Ceiling (Roof) Insulation Batts. 2020. Available online: https://www.iisinsulation.com.au/insulation/earthwool-insulation/earthwool-ceiling-roof-insulation-batts/# (accessed on 21 February 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).