Assessment of the Potential for Delayed Ettringite Formation in Heat Cured Mortars and Concrete Using Australian Materials

Abstract

1. Introduction

- Duration of the precure time prior to the heat cure cycle—typically 4 h is used as the length of the precure, however, in laboratory experiments shorter precure times have exacerbated expansion associated with DEF; longer precure times reduce the risk of DEF.

- Temperature and duration of the curing cycle—70 °C is a widely reported threshold temperature, although some data have been reported suggesting the observation of DEF at lower curing temperatures; increasing the duration of the heat curing cycle also increases the risk. Higher temperatures (>90 °C) and longer heat cure cycles (>10 h) result in significantly greater risk of expansion associated with DEF and have been the focus of much of the laboratory research.

- Moisture—a relative humidity of >90% is required [7]. The precipitation of ettringite and the transport of sulphate ions in the concrete occurs through the pore solution. Generally, DEF is not observed for concretes which are dry.

- Calcium aluminate (C3A) content—DEF occurs for a C3A content >7%, although DEF has also been observed for C3A contents as low as 5%. As C3A is a reactant in the formation of sulphoaluminates such as ettringite, C3A is required in reasonable proportions for DEF.

- Sulphate content (represented by SO3)—DEF occurs for a SO3 content >3%. Similarly, sulphate is a reactant in the precipitation of ettringite.

- Sulphur trioxide to aluminium oxide molar ratio ([SO3]/[Al2O3])—DEF is at its pessimum when the [SO3]/[Al2O3] ≈ 1.1.

- Alkali content—elevated alkali contents in the pore solution promotes DEF. The presence of alkali (Na+, K+) ions in the pore solution increase the solubility of sulphate ions leading to the decomposition of early ettringite. Leaching of alkali content at a later stage, in the hardened state, is also responsible for accelerating DEF.

2. Materials and Methods

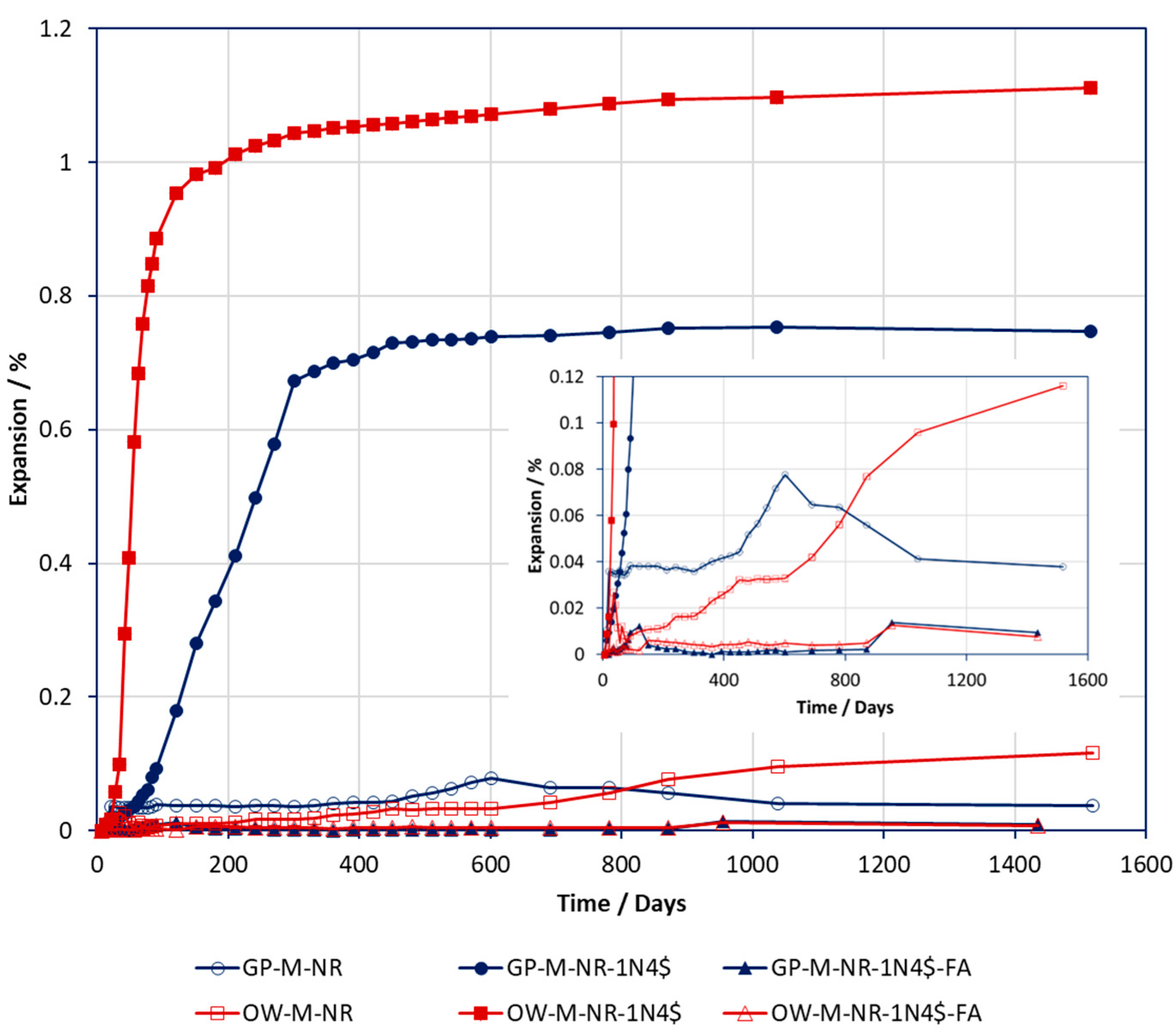

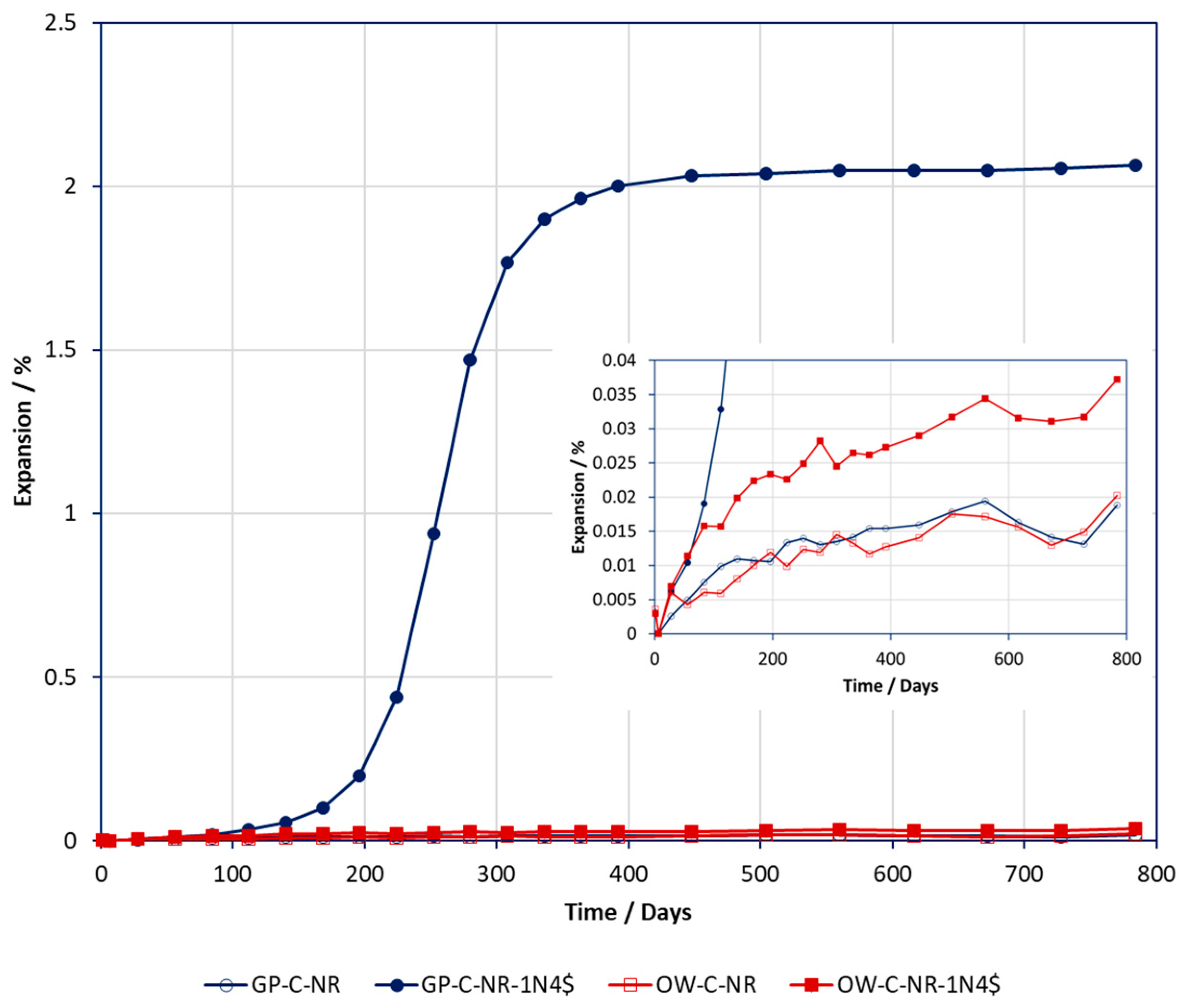

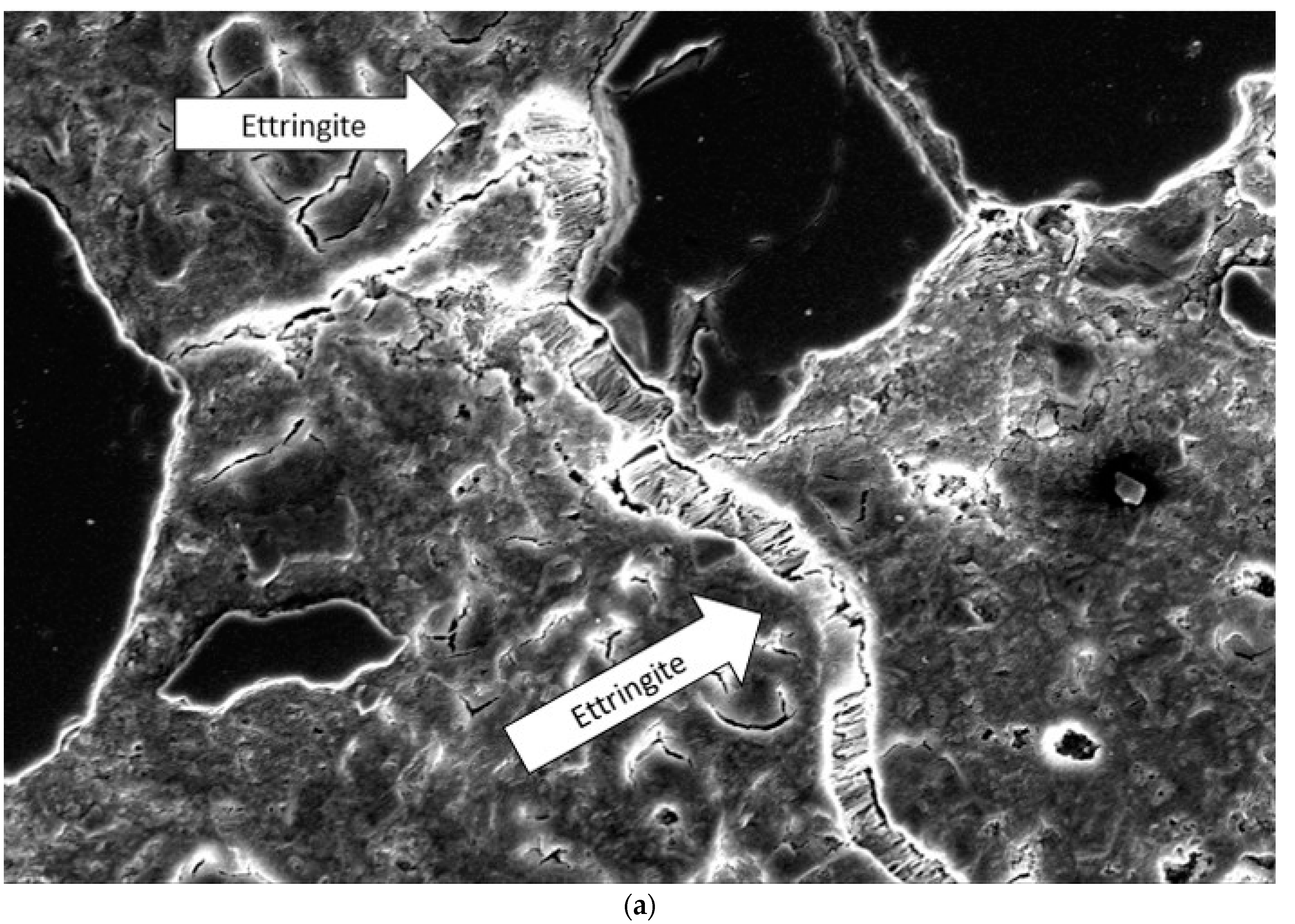

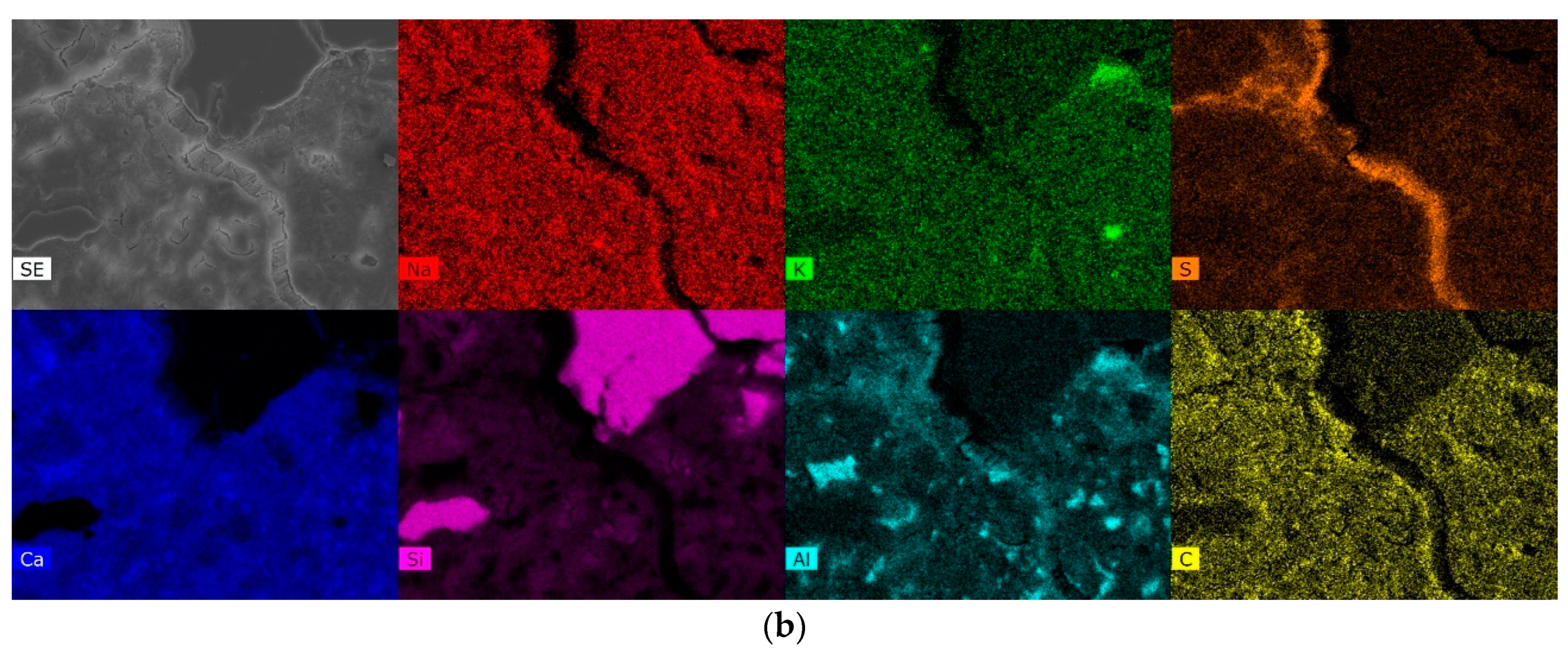

3. Results

4. Discussion

5. Conclusions

- For DEF to be observed, an elevated non-conforming alkali and sulphate content in the cement is required (1% Na2Oe and 4% SO3) in heat cured mortars and concretes at 90 °C.

- For heat cured mortars and concretes using cement (GP and OW in this study) conforming to AS 3972 (<3.5% SO3) and ATIC-SP43 (<0.6% Na2Oe), the risk of deleterious DEF is low. A lower specified SO3 limit (<3.0%) may be desirable when elevated temperature curing is carried out as specified by TfNSW B80.

- For heat cured mortars containing binary binder compositions incorporating 25% FA, no expansion was observed either when conforming or non-conforming (1.0% Na2Oe, 4% SO3) binders were used. For non-conforming binders where expansion was observed, the incorporation of FA in the blended cement mitigated deleterious DEF. Concretes manufactured with blended cements containing 25% FA have a very low risk of DEF even if the concrete temperature rises to 90 °C.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Godart, B. Pathology, Assessment and Treatment of Structures Affected by Delayed Ettringite Formation. Struct. Eng. Int. 2017, 27, 362–369. [Google Scholar] [CrossRef]

- Heinz, D.; Ludwig, U. Mechanism of secondary ettringite formation in mortars and concretes subjected to heat treatment. Am. Concr. Inst. Spec. Publ. 1987, 2, 2059–2072. [Google Scholar]

- Ramu, Y.K. Influence of Cement Composition and Curing Regimes on the Susceptibility of Heat-Cured Cementitious Systems to Delayed Ettringite Formation. PhD Thesis, University of Technology Sydney, Ultimo, Australia, June 2020. Available online: http://hdl.handle.net/10453/142373 (accessed on 1 July 2023).

- Taylor, H.F.W.; Famy, C.; Scrivener, K.L. Delayed ettringite formation. Cem. Concr. Res. 2001, 31, 683–693. [Google Scholar] [CrossRef]

- Leklou, N.; Aubert, J.-E.; Escadeillas, G. Influence of various parameters on heat-induced internal sulphate attack. Eur. J. Environ. Civ. Eng. 2013, 17, 141–153. [Google Scholar] [CrossRef]

- Zhang, Y.; Pan, Y.; Zhang, D. A literature review on delayed ettringite formation: Mechanism, affect factors and suppressing methods. Mag. Concr. Res. 2021, 73, 325–342. [Google Scholar] [CrossRef]

- Martin, R.P.; Bonnet, A.; Renaud, J.C.; Chlela, R.; Toutlemonde, F.; Sauvaget, C. Influence of moisture on the development of delayed ettringite formation. Mag. Concr. Res. 2023, 75, 747–754. [Google Scholar] [CrossRef]

- Paul, A.; Rashidi, M.; Kim, J.Y.; Jacobs, L.J.; Kurtis, K.E. The impact of sulfate-and sulfide-bearing sand on delayed ettringite formation. Cem. Concr. Compos. 2022, 125, 104323. [Google Scholar] [CrossRef]

- Kawabata, Y.; Ueda, N.; Miura, T.; Multon, S. The influence of restraint on the expansion of concrete due to delayed ettringite formation. Cem. Concr. Compos. 2021, 121, 104062. [Google Scholar] [CrossRef]

- Gu, Y.; Martin, R.P.; Metalssi, O.O.; Fen-Chong, T.; Dangla, P. Pore size analyses of cement paste exposed to external sulfate attack and delayed ettringite formation. Cem. Concr. Res. 2019, 123, 105766. [Google Scholar] [CrossRef]

- Pichelin, A.; Carcasses, M.; Cassagnabère, F.; Multon, S.; Nahas, G. Sustainability, transfer and containment properties of concrete subject to delayed ettringite formation (DEF). Cem. Concr. Compos. 2020, 113, 103738. [Google Scholar] [CrossRef]

- Yammine, A.; Hamdadou, M.; Leklou, N.; Bignonnet, F.; Choinska-Colombel, M. Effect of recycled concrete aggregates and recycled filler on delayed ettringite formation: An experimental study compared to chemical modelling. Cem. Concr. Compos. 2022, 132, 104636. [Google Scholar] [CrossRef]

- Kelham, S. The effect of cement composition and fineness on expansion associated with delayed ettringite formation. Cem. Concr. Compos. 1996, 18, 171–179. [Google Scholar] [CrossRef]

- Odler, I.; Chen, Y. Effect of cement composition on the expansion of heat-cured cement pastes. Cem. Concr. Res. 1995, 25, 853–862. [Google Scholar] [CrossRef]

- Pourchet, S.; Regnaud, L.; Perez, J.P.; Nonat, A. Early C3A hydration in the presence of different kinds of calcium sulphate. Cem. Concr. Res. 2009, 39, 989–996. [Google Scholar] [CrossRef]

- Transport for NSW (TfNSW) Specification D&C B80. Concrete Work for Bridges, Edition 3, Revision 6, May 2023. Available online: https://standards.transport.nsw.gov.au/_entity/annotation/fa4dc857-cdfe-ed11-8f6d-000d3ae011f9 (accessed on 1 July 2023).

- Transport and Main Roads Specifications MRTS70. Concrete. The State of Queensland (Department of Transport and Main Roads), July 2022. Available online: https://www.tmr.qld.gov.au/-/media/busind/techstdpubs/Specifications-and-drawings/Specifications/2-Bridges-and-Structures/MRTS70.pdf?la=en (accessed on 1 July 2023).

- Main Roads Western Australia. Specification 820. Concrete for Structures. Clause 820.71. The Government of Western Australia, 25 July 2023. Available online: https://www.mainroads.wa.gov.au/globalassets/technical-commercial/technical-library/specifications/800-series-bridge-major-structures/specification-820-concrete-for-structures.pdf (accessed on 1 July 2023).

- Glasser, F.P. The role of sulphate mineralogy and cure temperature in delayed ettringite formation. Cem. Concr. Compos. 1996, 18, 187–193. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Taylor, H.F.W. Delayed ettringite formation: A microstructural and microanalytical study. Adv. Cem. Res. 1993, 5, 139–146. [Google Scholar] [CrossRef]

- Ramu, Y.K.; Thomas, P.; Sirivivatnanon, V. Pore Solution Chemistry of Expansive Heat Cured Cementitious Systems. In Proceedings of the 4th International RILEM conference on Microstructure Related Durability of Cementitious Composites (Microdurability 2020), Delft, The Netherlands, 29 April–25 May 2021; pp. 212–219. Available online: https://www.rilem.net/agenda/4th-international-rilem-conference-on-microstructure-related-durability-of-cementitious-composites-1301 (accessed on 1 July 2023).

- Thomas, M.D.A.; Hooton, R.D.; Ramlochan, T. Use of pore solution analysis in design for concrete durability. Adv. Cem. Res. 2010, 22, 203–210. [Google Scholar]

- Divet, L.; Randriambololona, R. Delayed ettringite formation: The effect of temperature and basicity on the interaction of sulphate and CSH phase. Cem. Concr. Res. 1998, 28, 357–363. [Google Scholar] [CrossRef]

- Shimada, Y.; Young, J.F. Thermal stability of ettringite in alkaline solutions at 80 °C. Cem. Concr. Res. 2004, 34, 2261–2268. [Google Scholar] [CrossRef]

- Diamond, S. Delayed Ettringite Formation–Processes and Problems. Cem. Concr. Compos. 1996, 18, 205–215. [Google Scholar] [CrossRef]

- Miura, T.; Maruyama, I.; Nakamura, H.; Yamamoto, Y. Feedback system of ion transfer through cracks during deterioration of mortar due to sulphate attack evaluated by RBSM-truss network model. J. Adv. Concr. Technol. 2017, 15, 610–626. [Google Scholar] [CrossRef][Green Version]

- Shao, Y.; Lyansdale, C.; Lawrence, C.D.; Sharp, J.H. Deterioration of heat-cured mortars due to the combined effect of delayed ettringite formation and freeze/thaw cycles. Cem. Concr. Compos. J. 1997, 27, 1761–1771. [Google Scholar] [CrossRef]

- Jebli, M.; Jamin, F.; Pelissou, C.; Lhopital, E.; El Youssoufi, M.S. Characterization of the expansion due to the delayed ettringite formation at the cement paste-aggregate interface. Constr. Build. Mater. 2021, 289, 122979. [Google Scholar] [CrossRef]

- Thomas, M.; Folliard, K.; Drimalas, T.; Ramlochan, T. Diagnosing delayed ettringite formation in concrete structures. Cem. Concr. Res. 2008, 38, 841–847. [Google Scholar] [CrossRef]

- Ramu, Y.K.; Sirivivatnanon, V.; Thomas, P.; Dhandapani, Y.; Vessalas, K. Evaluating the im-pact of curing temperature in delayed ettringite formation using electrochemical impedance spectroscopy. Constr. Build. Mater. 2021, 282, 122726. [Google Scholar] [CrossRef]

- Ramu, Y.K.; Thomas, P.S.; Sirivivatnanon, V.; Vessalas, K. Non-expansive delayed ettringite formation in low sulphate and low alkali cement mortars. Aust. J. Civ. Eng. 2022, 21, 68–79. [Google Scholar] [CrossRef]

- AS 3972-2010; General Purpose and Blended Cements. Standards Australia: Sydney, Australia, 2010.

- Australian Technical Infrastructure Committee Specifications, ATIC-SPEC Section: SP43. Cementitious Materials for Concrete. Issue 6, 11 July 2019. Available online: http://www.atic.net.au/wp-content/uploads/2021/01/ATIC-SP43-11July2019.pdf (accessed on 1 July 2023).

- Mak, J.; Vessalas, K.; Thomas, P.; Baweja, D. Evaluation of Factors Pertaining to Delayed Ettringite Formation in Steam Cured Precast Concrete Members. In Proceedings of the New Zealand Concrete Industry Conference 2012, Hamilton, New Zealand, 11–13 October 2012. [Google Scholar]

- AS 5100.5:2017; Bridge Design, Part 5: Concrete. Standards Australia: Sydney, Australia, 2017.

- AS 1597.2-2013; Precast Reinforced Concrete Box Culverts Large Culverts (Exceeding 1200 mm Span or 1200 mm Height and up to and Including 4200 mm Span and 4200 mm Height). Standards Australia: Sydney, Australia, 2013.

- Department for Infrastructure and Transport. Master Specification ST-SC-S4 Low Pressure Steam Curing of Precast Units. The Government of South Australia, Version 2, September 2019. Available online: https://www.dit.sa.gov.au/__data/assets/pdf_file/0006/551454/MASTER_SPECIFICATION_-_PART_ST-SC-S4_-_LOW_PRESSURE_STEAM_CURING_OF_PRECAST_UNITS.DOCX.pdf (accessed on 1 July 2023).

- VicRoads Code of Practice RC 610. Structural Concrete. 600 Series Bridgeworks. The Government of Victoria, February 2020. Available online: https://webapps.vicroads.vic.gov.au/VRNE/csdspeci.nsf/webscdocs/9D7325ADAD6BB912CA25851200151FF5?OpenDocument (accessed on 1 July 2023).

- AS 2758.1:2014; Aggregates and Rock for Engineering Purposes Concrete Aggregates. Standards Australia: Sydney, Australia, 2014.

- AS 2350.12-2006; Methods of Testing Portland, Blended and Masonry Cements, Method 12: Preparation of a Standard Mortar and Moulding of Specimens. Standards Australia: Sydney, Australia, 2006.

- AS 1012.8.4:2015; Methods of Testing Concrete Method for Making and Curing Concrete—Drying Shrinkage Specimens Prepared in the Field or in the Laboratory. Standards Australia: Sydney, Australia, 2015.

- N 1992-1-2:2004; Eurocode 2: Design of Concrete Structures—Part 1-2: General Rules—Structural Fire Design. European Committee for Standardization: Brussels, Belgium, 2004.

- Kawabata, Y.; Takahashi, H.; Watanabe, S. The long-term suppression effects of fly ash and slag on the expansion of heat-cured mortar due to delayed ettringite formation. Constr. Build. Mater. 2021, 310, 125235. [Google Scholar] [CrossRef]

- Yamazaki, Y.; Tsuruta, K.; Uehara, M. Effect of Alkali-silica Reaction on Delayed Ettringite Formation in Concrete. Q. Rep. RTRI 2020, 61, 192–197. [Google Scholar] [CrossRef]

- Shayan, A.; Ivanusec, I. An experimental clarification of the association of delayed ettringite formation with alkali-aggregate reaction. Cem. Concr. Compos. 1996, 18, 161–170. [Google Scholar] [CrossRef]

- Shayan, A.; Quick, G.W. Microscopic features of cracked and uncracked concrete railway sleepers. Mater. J. 1992, 89, 348–361. [Google Scholar]

- Joshi, N.R.; Matsumoto, A.; Asamoto, S.; Miura, T.; Kawabata, Y. Investigation of the mechanical behaviour of concrete with severe delayed ettringite formation expansion focusing on internal damage propagation under various compressive loading patterns. Cem. Concr. Compos. 2022, 128, 104433. [Google Scholar] [CrossRef]

| State | Road Authority Specification | Steam Curing Temperature Conditions |

|---|---|---|

| Australia | Standards Australia, AS 5100.5 Clause 4.11 [35] | Concrete temperature ≤ 75 °C except where analysis has been performed that justifies a particular maximum temperature for the concrete. |

| Australia | Standards Australia, AS 1597.2 2013, Clause Appendix C5.3 maximum temperature [36] | The maximum enclosure temperature shall be ≤70 °C. No mention of concrete temperature. |

| New South Wales | Transport for NSW QA Specification B80 Concrete Work for Bridges, 2021 Clause: 7.12.4 [16] | Maximum temperature of the concrete ≤ 70 °C |

| Queensland | Transport and Main Roads Specifications MRTS70 Concrete, 2022 Clause: 16.7.4 [17] | The enclosure temperature must be ≤70 °C. Core concrete temperature must be ≤80 °C. |

| South Australia | Structures—Master Specification ST-SC-S4 Low Pressure Steam Curing of Precast Units Clause 5.3 DPTI: Design Standards Structural 2015 Clause 6.2.1(e) [37] | The enclosure temperature must be ≤70 °C. Concrete temperature ≤ 82 °C |

| Victoria/Tasmania | VicRoads Specification 2020 Clause 610.24(g) [38] | The enclosure temperature must be ≤70 °C. Concrete temperature must be ≤75 °C. |

| Western Australia | Concrete for Structures—Main Roads Specification 820, 2023 Clause: 820.71 [18] | The curing temperature must be ≤70 °C |

| Oxide% | CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | MgO | K2O | Na2O | LOI | Total | Na2Oe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| GP-M | 64.2 | 19.7 | 4.8 | 3.1 | 2.4 | 0.9 | 0.4 | 0.2 | 4.1 | 99.9 | 0.46 |

| OW-M | 65.7 | 22.8 | 4.4 | 0.2 | 3.0 | 0.7 | 0.3 | 0.1 | 2.2 | 99.6 | 0.30 |

| FA-M | 3.88 | 55.46 | 24.42 | 6.91 | 0.19 | 1.22 | 0.77 | 0.88 | 2.52 | 98.7 | N/A |

| GP-C | 64.1 | 19.4 | 4.9 | 3.0 | 2.6 | 1.2 | 0.45 | 0.17 | 4.0 | 100.1 | 0.47 |

| OW-C | 65.1 | 20.2 | 5.4 | 0.7 | 3.2 | 1.2 | 0.42 | 0.07 | 3.8 | 100.4 | 0.35 |

| FA-C | 3.6 | 58 | 26.3 | 7.2 | 0.2 | 1.1 | 0.84 | 0.3 | 0.9 | 100.4 | N/A |

| Compound | GP-M | OW-M | GP-C | OW-C |

|---|---|---|---|---|

| C3S% | 49.9 | 56.3 | 52.7 | 48.6 |

| C2S% | 18.3 | 22.9 | 15.9 | 21.2 |

| C3A% | 7.4 | 11.2 | 7.9 | 13.1 |

| C4AF% | 9.4 | 0.8 | 9.1 | 2.1 |

| Material | Binder | Aggregate (Total) | Coarse Sand | Fine Sand | Water |

|---|---|---|---|---|---|

| Mix proportion by mass | 1 | 3.0 | 2.5 | 0.5 | 0.45 |

| Material | Binder | Aggregate (Total) | Coarse Agg. | Fine Agg. | Water | WR | Slump |

|---|---|---|---|---|---|---|---|

| Content (kg/m3) | 450 | 1830 | 1190 | 640 | 180 | 1.25 | 120 mm |

| Mix proportion by mass | 1 | 4.1 | 2.6 | 1.4 | 0.40 | 0.003 | N/A |

| Mix | 1 Year/% | 2 Year/% |

|---|---|---|

| GP-M-NR | 0.04 | 0.06 |

| GP-M-NR-1N4$ | 0.70 | 0.74 |

| OW-M-NR | 0.02 | 0.04 |

| OW-M-NR-1N4$ | 1.05 | 1.08 |

| GP-M-NR-1N4$-FA | 0.00 | 0.00 |

| OW-M-NR-1N4$-FA | 0.00 | 0.00 |

| GP-C-NR | 0.02 | 0.01 |

| GP-C-NR-1N4$ | 1.96 | 2.06 |

| OW-C-NR | 0.01 | 0.01 |

| OW-C-NR-1N4$ | 0.03 | 0.03 |

| GP-C-R | 0.03 | 0.07 |

| GP-C-R-1N4$ | 1.16 | 1.42 |

| OW-C-R | 0.02 | 0.03 |

| OW-C-R-1N4$ | 0.03 | 0.04 |

| GP-C-R-1N4$-FA | 0.01 | 0.01 |

| OW-C-R-1N4$-FA | 0.00 | 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thomas, P.; Ramu, Y.K.; Martin, L.; Vessalas, K.; Sirivivatnanon, V. Assessment of the Potential for Delayed Ettringite Formation in Heat Cured Mortars and Concrete Using Australian Materials. Constr. Mater. 2023, 3, 529-542. https://doi.org/10.3390/constrmater3040033

Thomas P, Ramu YK, Martin L, Vessalas K, Sirivivatnanon V. Assessment of the Potential for Delayed Ettringite Formation in Heat Cured Mortars and Concrete Using Australian Materials. Construction Materials. 2023; 3(4):529-542. https://doi.org/10.3390/constrmater3040033

Chicago/Turabian StyleThomas, Paul, Yogesh Kumar Ramu, Liam Martin, Kirk Vessalas, and Vute Sirivivatnanon. 2023. "Assessment of the Potential for Delayed Ettringite Formation in Heat Cured Mortars and Concrete Using Australian Materials" Construction Materials 3, no. 4: 529-542. https://doi.org/10.3390/constrmater3040033

APA StyleThomas, P., Ramu, Y. K., Martin, L., Vessalas, K., & Sirivivatnanon, V. (2023). Assessment of the Potential for Delayed Ettringite Formation in Heat Cured Mortars and Concrete Using Australian Materials. Construction Materials, 3(4), 529-542. https://doi.org/10.3390/constrmater3040033