Earthen Construction: Acceptance among Professionals and Experimental Durability Performance

Abstract

1. Introduction

2. Earthen Buildings That Stand the Test of Time

3. Main Benefits of Earthen Construction

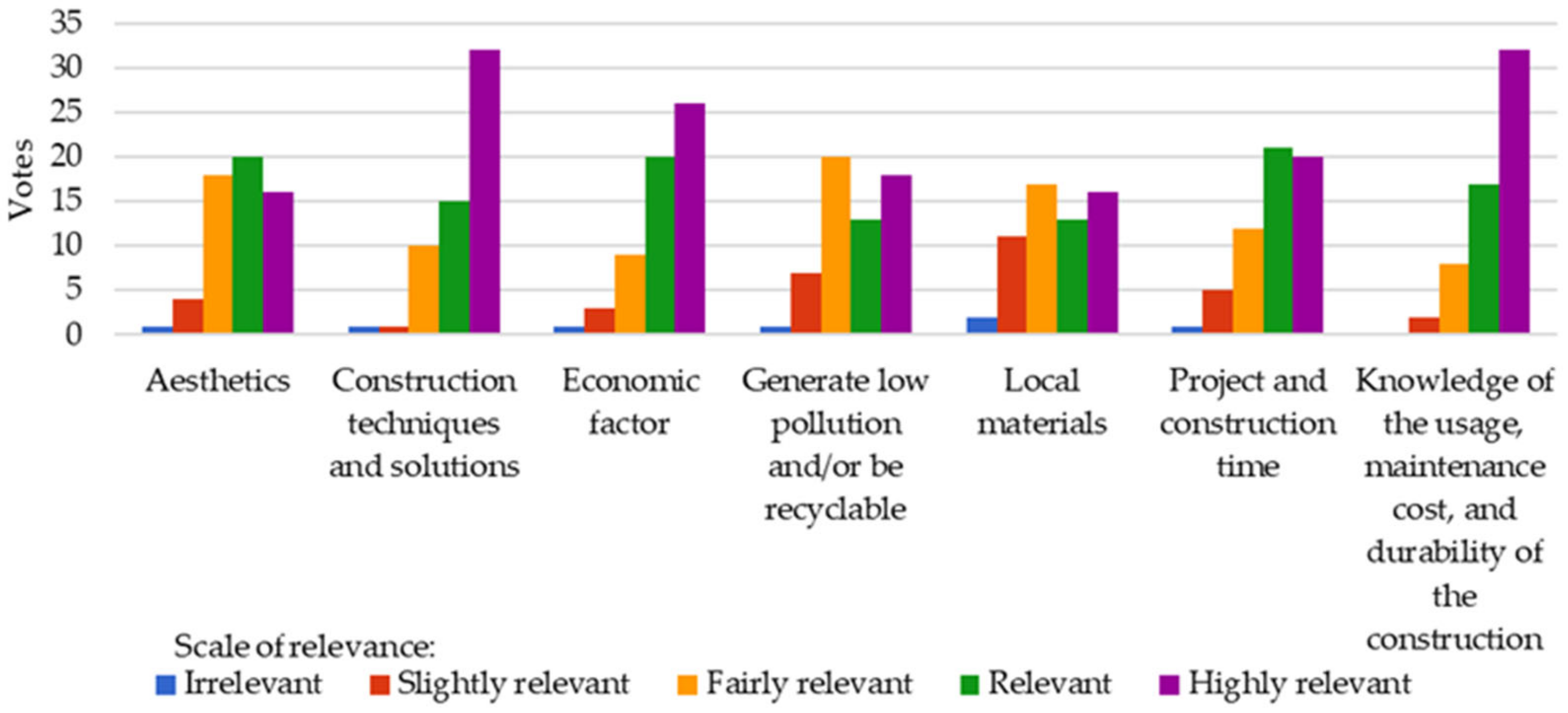

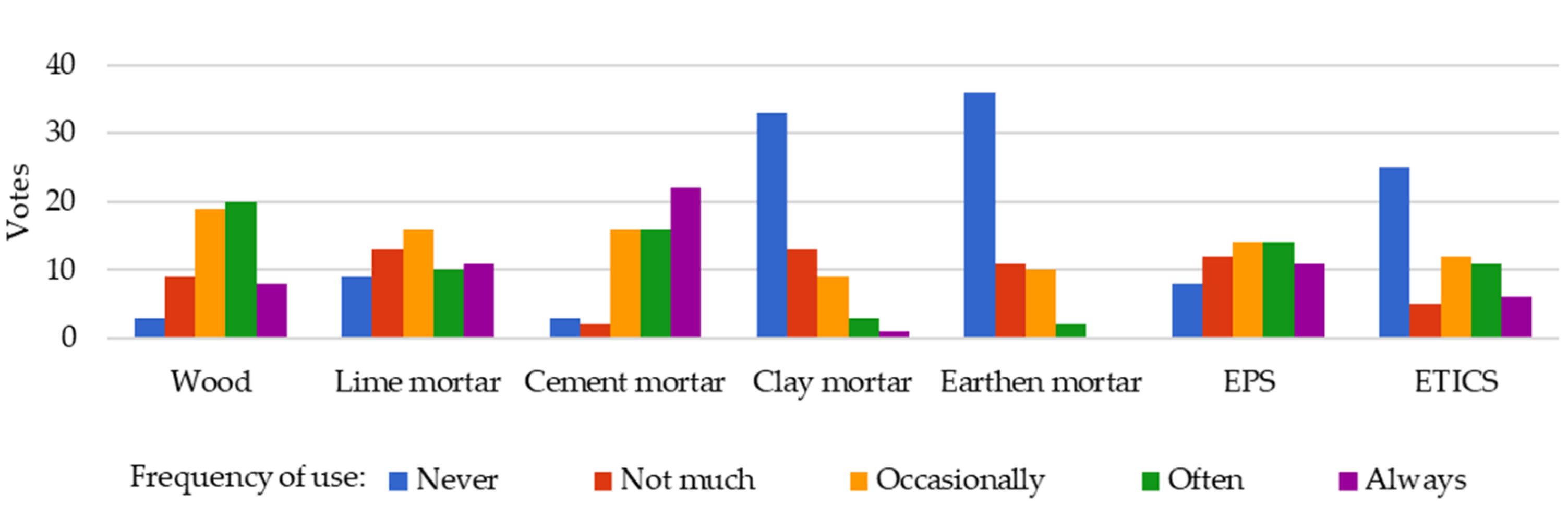

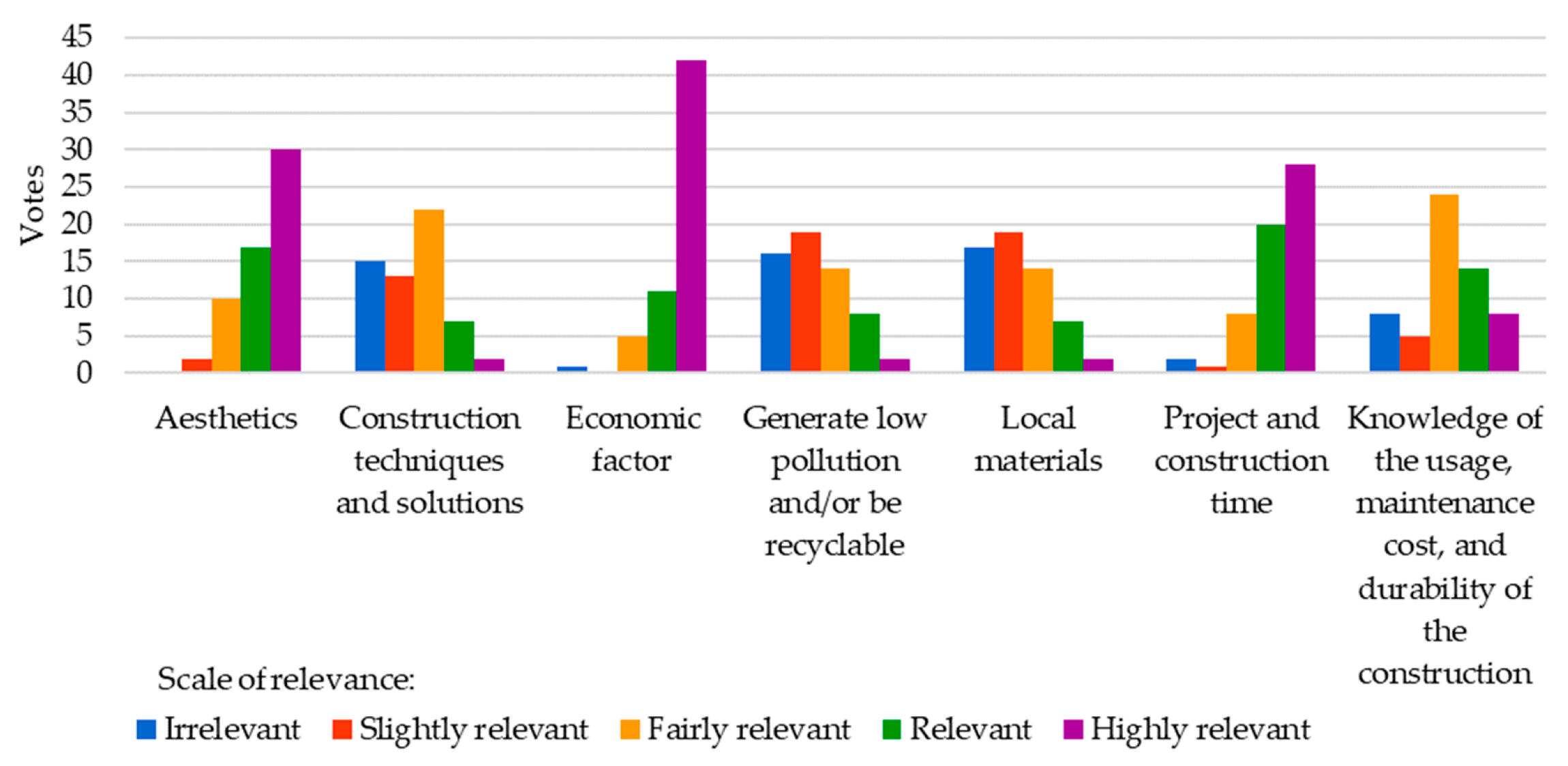

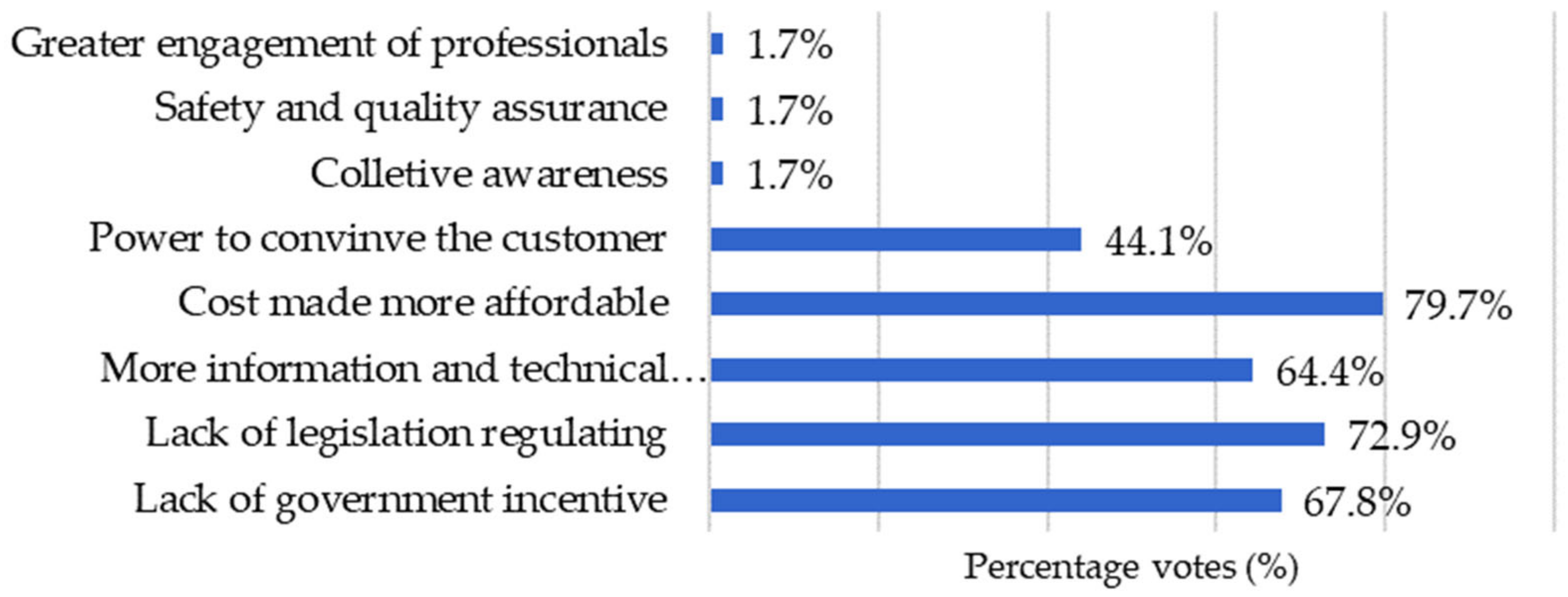

4. Assessment of Interest in Earthen Construction and Other Sustainable Materials

5. Durability Assessment of Earthen Construction

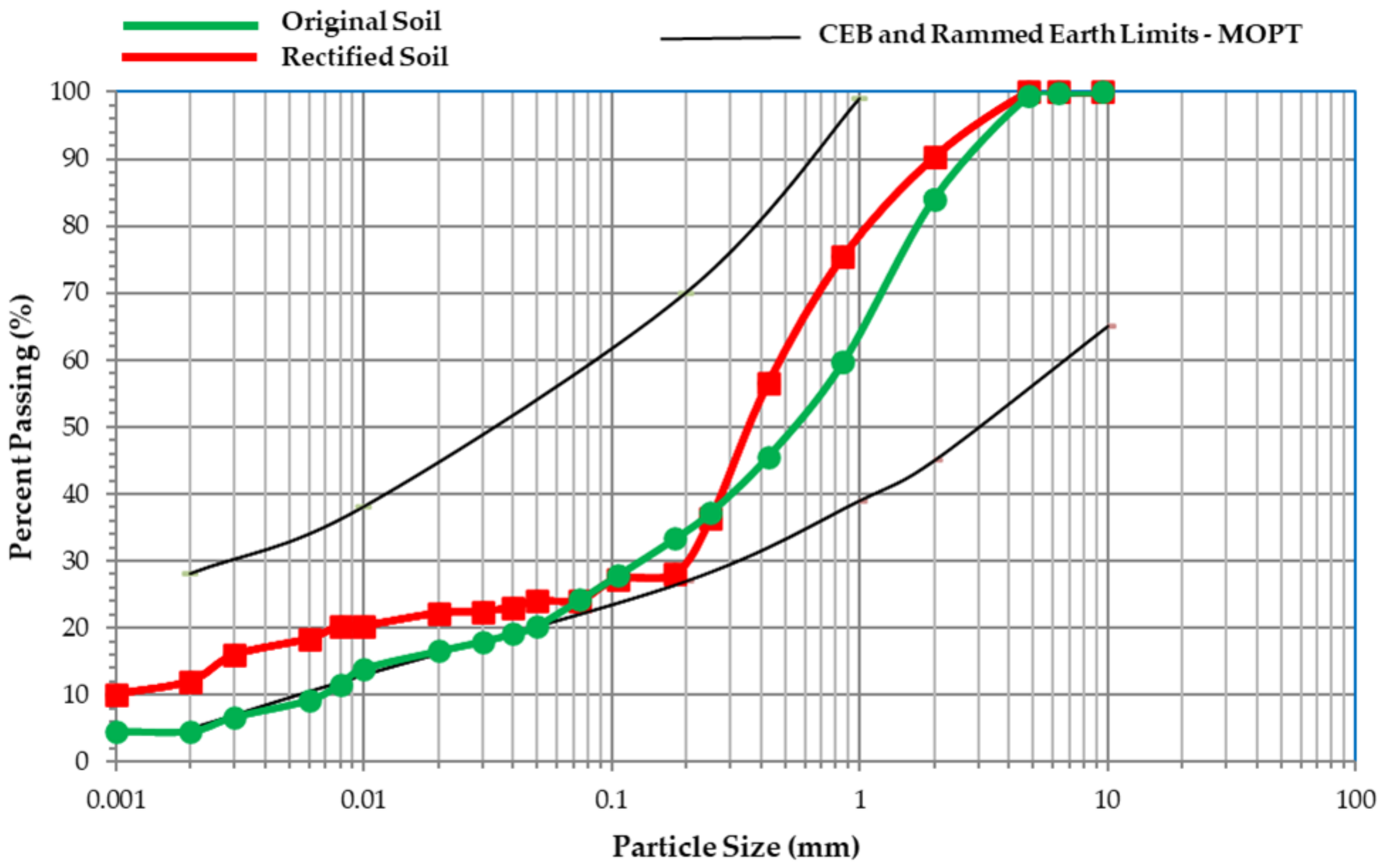

5.1. Materials and Composition of the Specimens

5.2. Performed Tests

5.2.1. Accelerated Erosion

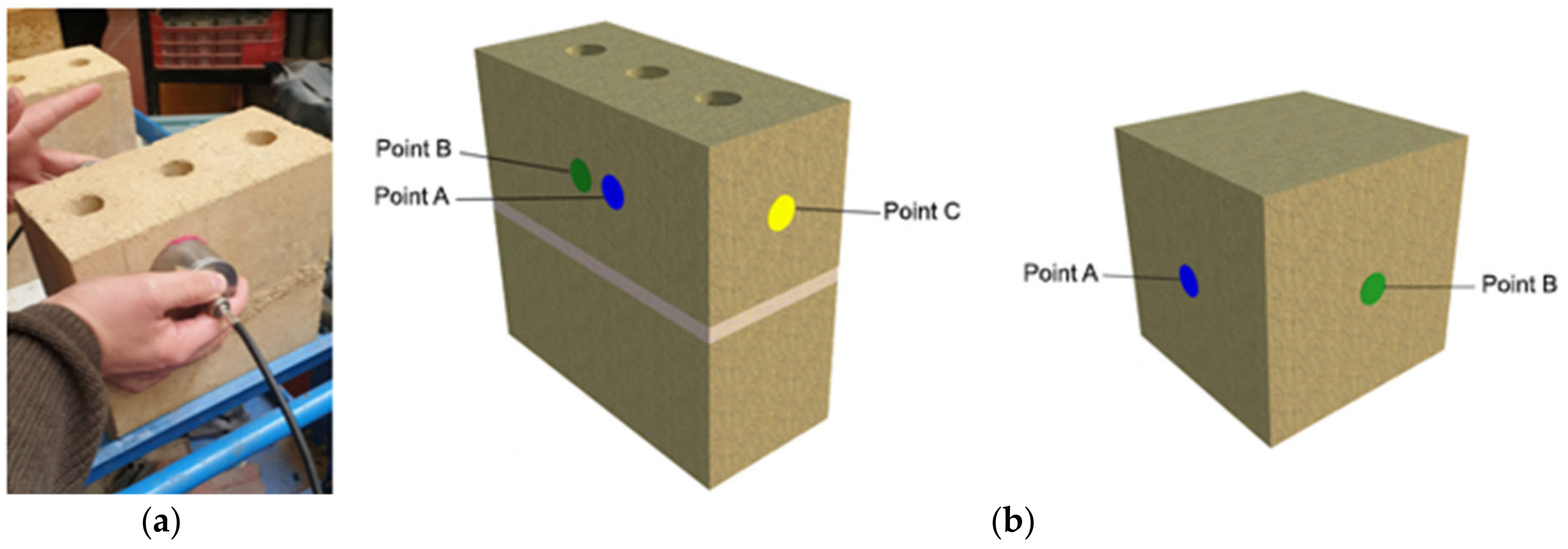

5.2.2. Ultrasonic Velocity

5.2.3. Compressive Strength

5.3. Test Results

5.3.1. Accelerated Erosion

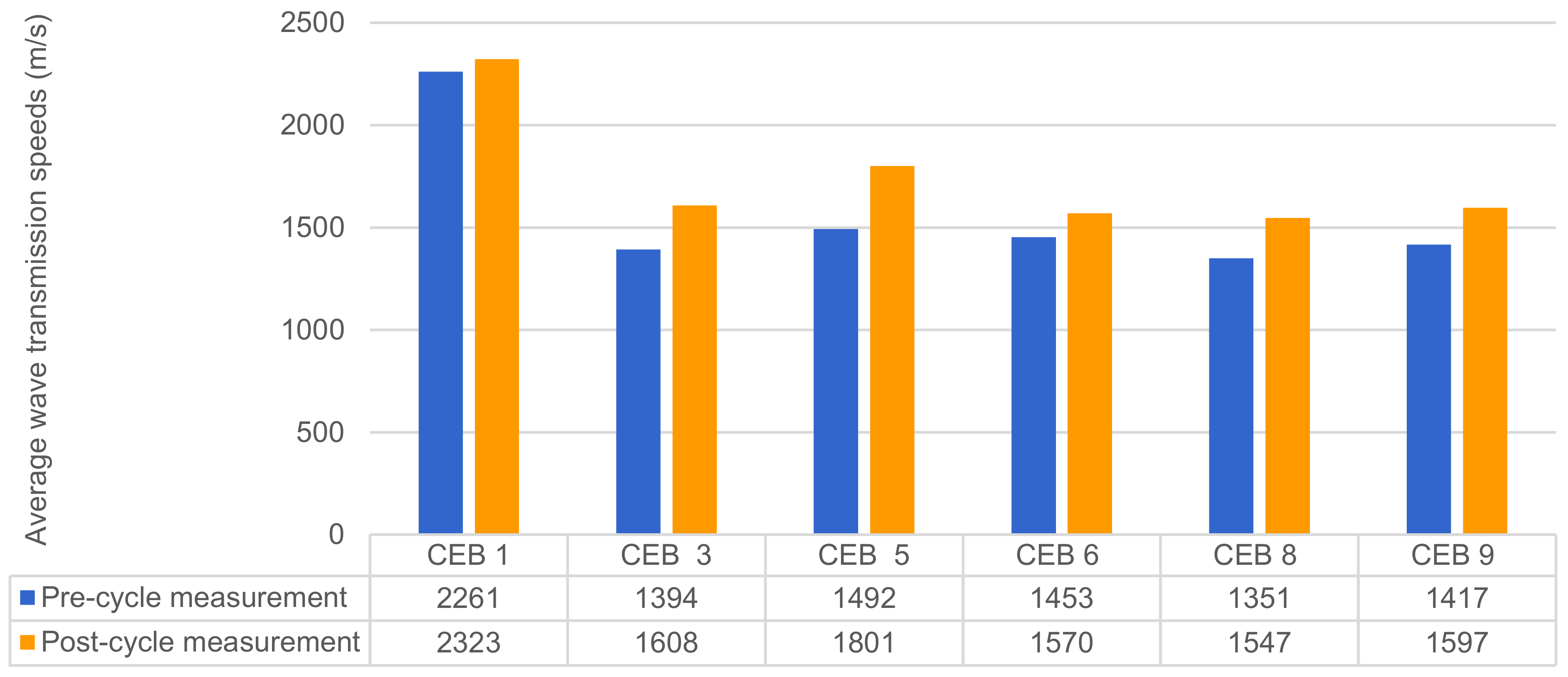

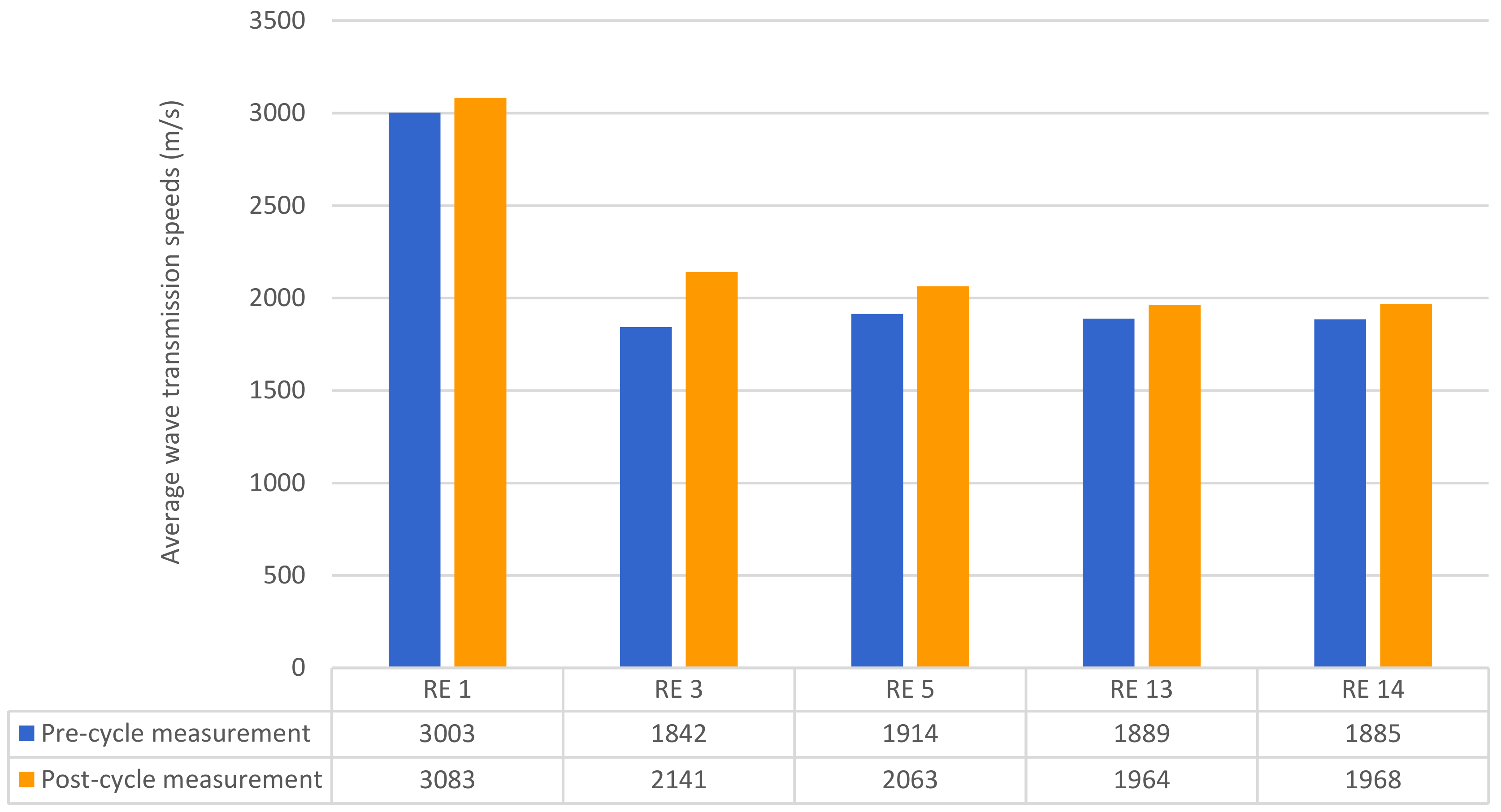

5.3.2. Ultrasonic Velocity

5.3.3. Compressive Strength

5.4. Relation between Ultrasonic Analysis Results and Compressive Strength

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nina, J.F.; Eires, R.M.G. Durabilidade da Construção em Terra—Contributo para uma Melhor Aceitação Deste Material Sustentável. Dissertação de Mestrado, Universidade do Minho, Guimarães, Portugal, 2022. Available online: https://hdl.handle.net/1822/81503 (accessed on 27 February 2023).

- Minke, G. Building with Earth—Design and Technology of a Sustainable Architecture; Birkhäuser—Publishers for Architecture: Basel, Switzerland; Berlin, Germany; Boston, MA, USA, 2006. [Google Scholar]

- Les Dernier, D.D. Pre-Cast Rammed Earth. 2022. Available online: https://www.rammedearthworks.com/blog/2016/1/30/pre-cast-rammed-earth (accessed on 26 February 2023).

- Jalali, S.; Eires, R. Inovações Científicas de Construção em Terra Crua; Ensino, Investigação e Desenvolvimento (EIDAO 08): Guimarães, Portugal, 2008. [Google Scholar]

- Fernandes, M. Técnicas de Construção em Terra. 2006. 10ª Mesa Redonda de Primavera-TERRA: FORMA DE CONSTRUIR. Available online: http://www.restapia.es/files/14804 (accessed on 26 February 2023).

- Neves, C.; Faria, O.B. Técnicas de Construção com Terra. Bauru—SP: FEB-UNESP/PROTERRA. 2011. Available online: www.redproterra.org (accessed on 26 February 2023).

- Peixoto, M.V.S. Avaliação da Integridade Mecânica em Paredes de Taipa de Pilão—Utilizando a Técnica do Ultrassom; Universidade Federal de Minas Gerais—Escola de Belas Artes: Belo Horizonte, Brazil, 2017. [Google Scholar]

- Holland, O. Pritzker Prize 2022: Francis Kéré Becomes First African to Win ‘Nobel of Architecture’. CNN Style, 15 March 2022. Available online: https://edition.cnn.com/style/article/pritzker-prize-2022-francis-kere/index.html (accessed on 29 March 2022).

- Alfarra, J. Discover the Great Mosque of Djenne, Mali—Middle East Monitor. MEMO—Middle East Monitor, 12 July 2021. Available online: https://www.middleeastmonitor.com/20210704-discover-the-great-mosque-of-djenne-mali/ (accessed on 22 December 2022).

- Eires, R. Construção em Terra: Desempenho Melhorado com Incorporação de Biopolímeros. January 2012. Available online: http://repositorium.sdum.uminho.pt/handle/1822/21010 (accessed on 2 December 2021).

- Fernandes, M. A Taipa no Mundo. Actas do 6º ATP | 9º SIACOT. digitAR, nº. 1, 2013; pp. 14–21. Available online: https://impactum-journals.uc.pt/digitar/article/view/_1_2 (accessed on 26 February 2023). [CrossRef]

- Gomes, M.I.; Santos, T.; Pereira, C.; Faria, P. Construção com Base em Terra: Contributo Para a Ecoeficiência na Construção; Universidade Nova de Lisboa’s Repository: Lisboa, Portugal, 2019. [Google Scholar]

- DIN 4102-1; Fire Behaviour of Building Materials and Elements. Deutsches Institut für Normung: Berlin, Germany, 1998.

- Toftum, J.; Jgrgensen, A.S.; Fanger, P.O. Upper limits of air humidity for preventing warm respiratory discomfort. Energy Build. 1998, 28, 15–23. [Google Scholar] [CrossRef]

- Toftum, J.; Jørgensen, A.S.; Fanger, P.O. Upper limits for indoor air humidity to avoid uncomfortably humid skin. Energy Build. 1998, 28, 1–13. [Google Scholar] [CrossRef]

- Tsutsumi, H.; Tanabe, S.I.; Harigaya, J.; Iguchi, Y.; Nakamura, G. Effect of humidity on human comfort and productivity after step changes from warm and humid environment. Build. Environ. 2007, 42, 4034–4042. [Google Scholar] [CrossRef]

- Paasi, J.; Nurmi, S.; Vuorinen, R.; Strengell, S.; Maijala, P. Performance of ESD protective materials at low relative humidity. J. Electrost. 2001, 51, 429–434. [Google Scholar] [CrossRef]

- Wolkoff, P.; Kjærgaard, S.K. The dichotomy of relative humidity on indoor air quality. Environ. Int. 2007, 33, 850–857. [Google Scholar] [CrossRef] [PubMed]

- Medjelekh, D.; Ulmet, L.; Gouny, F.; Fouchal, F.; Nait-Ali, B.; Maillard, P.; Dubois, F. Characterization of the coupled hygrothermal behavior of unfired clay masonries: Numerical and experimental aspects. Build. Environ. 2016, 110, 89–103. [Google Scholar] [CrossRef]

- Jannat, N.; Cullen, J.; Abdullah, B.; Al-Mufti, R.L.; Karyono, K. Thermophysical Properties of Sawdust and Coconut Coir Dust Incorporated Unfired Clay Blocks. Constr. Mater. 2022, 2, 16. [Google Scholar] [CrossRef]

- Lindemann, N. What’s the average survey response rate? Pointerpro, 9 August 2021. Available online: https://pointerpro.com/blog/average-survey-response-rate/ (accessed on 22 December 2022).

- CTCV. Estudo de Mercado e Inovação sobre Materiais para a Construção Sustentável. 2012. Available online: www.centrohabitat.net (accessed on 26 February 2023).

- Laboratório Nacional de Engenharia Civil. LNEC E 196-1966: Análise Granulométrica. In Especificação LNEC; Laboratório Nacional de Engenharia Civil: Lisbon, Portugal, 1966. [Google Scholar]

- Muguda, S.; Hughes, P.N.; Augarde, C.E.; Perlot, C.; Gallipoli, D.; Bruno, A.W. Geotechnical characterisation of recycled biopolymer-stabilised earthen materials. In Proceedings of the 17th European Conference on Soil Mechanics and Geotechnical Engineering (ECSMGE 2019), Reykjavik, Iceland, 1–6 September 2019. [Google Scholar] [CrossRef]

- NP EN 197-1; Norma Portuguesa. ISO: Geneva, Switzerland, 2001. Available online: https://pdfcoffee.com/np-en-197-12001-pdf-free.html (accessed on 16 December 2021).

- CIMPOR. Ficha Técnica CEM II A-L 42,5R. 3653, September 2019. Available online: https://www.cimpor.com/documents/20124/34190/FICHA_T%C3%89CNICA_CEM_II_A-L_42%2C5R_DEZEMBRO_2022.pdf/4ddf1bc3-6cd3-2804-d8e0-ff06c4c3239b?t=1669714750083 (accessed on 26 February 2023).

- DIN EN 459-1; Building Lime - Part 1: Definitions, Specifications and Conformity Criteria. European Standards: Plzen, Czech Republic, July 2015. Available online: https://www.en-standard.eu/din-en-459-1-building-lime-part-1-definitions-specifications-and-conformity-criteria/ (accessed on 5 March 2023).

- Van Lengen, J. Manual do Arquiteto Descalço; Livraria do Arquiteto: Porto Alegre, Brazil, 2004. [Google Scholar]

- Leis, T.; Folache, P.; Barahona, F.; Jürmann, K. Tadelakt Estônia, Espanha e Portugal. 2016. Available online: www.compalha.pt (accessed on 18 December 2021).

- EN 1015-3; Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar. European Committee for Standardization: Brussels, Belgium, 1999.

- ASTM D559–03; United States: Standard Guide for Design of Earthen Wall Building Systems. American Society for Testing and Materials: West Conshohocken, PA, USA, 2003.

- Rezende, M.L.D.S.; Eires, R.; Camões, A.; Jesus, C.M.G. Desenvolvimento e Avaliação de um Simulador de Chuvas para Teste Acelerado de Degradação; REVISTA do Departamento de Engenharia Civil da Universidade do Minho: Braga, Portugal, 2016; Volume 53, pp. 17–28. [Google Scholar]

- NBR 13554; Solo-Cimento: Ensaio de Durabilidade por Molhagem e Secagem. ABNT—Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 1996.

- PROCEQ. Operating Instructions Pundit Lab/Pundit Lab+ Ultrasonic Instrument. Schwerszenbach, 2017. Available online: https://www.manualslib.com/manual/1266051/Proceq-Pundit-Lab.html#manual (accessed on 26 February 2023).

- EN 12504-4; Testing Concrete—Part 4: Determination of Ultrasonic Pulse Velocity. CEN: Dublin, Ireland, 2004. Available online: https://www.en-standard.eu/bs-en-12504-4-2021-testing-concrete-in-structures-determination-of-ultrasonic-pulse-velocity/ (accessed on 20 December 2021).

- EN 772-1; Ensaio Compressão. Normas Portuguesas. Laboratório Nacional de Engenharia Civil: Lisbon, Portugal, 2002.

- DIN 18945:2013-08; Earth Blocks—Terms and Definitions, Requirements, Test Methods. Normenausschuss Bauwesen (NABau): Berlin, Germany, 2013. Available online: https://infostore.saiglobal.com/en-us/standards/din-18945-2013-436386_saig_din_din_985181/ (accessed on 26 February 2023).

- Daniel, R.; Vitor, S.; Paulina, F. Caracterização de Blocos de Terra Comprimida. TEST&E 2016. Available online: https://run.unl.pt/bitstream/10362/19305/1/CN%20-%20Ribeiro%20et%20al_normas%20blocos%20terra_TESTE2016.pdf (accessed on 26 February 2023).

- Fabbri, A.; Morel, J.; Gallipoli, D. Assessing the performance of earth building materials: A review of recent developments. RILEM Tech. Lett. 2018, 3, 46–58. Available online: https://letters.rilem.net/index.php/rilem/article/view/71/75 (accessed on 26 February 2023). [CrossRef]

- Aubert, J.E.; Fabbri, A.; Morel, J.C.; Maillard, P. An earth block with a compressive strength higher than 45 MPa! Constr. Build. Mater. 2013, 47, 366–369. [Google Scholar] [CrossRef]

- XP P13-901; Compressed Earth Blocks fo Walls and Partitions: Definitions-Specifications-Test Methods-Delivery Acceptance Conditions. Normalisation Francaise: Paris, France, 2001.

- Song, Z.; Zhang, D.; Mao, Y.; Mu, Y.; Zhang, K.; Zhang, Q. Behavior of Lime-Stabilized Red Bed Soil after Cyclic Wetting-Drying in Triaxial Tests and SEM Analysis. Adv. Mater. Sci. Eng. 2020, 2020, 4230519. [Google Scholar] [CrossRef]

- Garzón, E.; Cano, M.; ÒKelly, B.C.; Sánchez-Soto, P.J. Effect of lime on stabilization of phyllite clays. Appl. Clay Sci. 2016, 123, 329–334. [Google Scholar] [CrossRef]

- Mathew, P.K.; Rao, S.N. Effect of Lime on Cation Exchange Capacity of Marine Clay. J. Geotech. Geoenviron. Eng. 1997, 123, 183–185. [Google Scholar] [CrossRef]

- Dash, S.K.; Hussain, M. Lime Stabilization of Soils: Reappraisal. J. Mater. Civ. Eng. 2012, 24, 707–714. [Google Scholar] [CrossRef]

- UNE 41410; Compressed Earth Blocs for Walls and Partitions. Definitions, Specifications and Test Methods. European Standards: Plzen, Czech Republic, 2008. Available online: https://www.en-standard.eu/une-41410-2008-compressed-earth-blocs-for-walls-and-partitions-definitions-specifications-and-test-methods/ (accessed on 26 February 2023).

- Lourenco, P.B. The Australian Earth Building Handbook; HB 195; SAI Global Limited: Sydney, Austrália, 2002; Available online: www.saiglobal.com/shop (accessed on 26 February 2023).

- Misseri, G.; Rovero, L. Rammed earth as bi-modulus material: Experimental and analytical investigations through Euler-Bernoulli and Timoshenko beam models. Int. J. Mason. Res. Innov. 2022, 7, 482–503. Available online: http://creativecommons.org/licenses/by/4.0/ (accessed on 26 February 2023). [CrossRef]

- De Abreu, C.G. Caracterização de Betão Com Terra Através de Provetes Laminares; Universidade de Lisboa: Lisboa, Portugal, 2013. [Google Scholar]

| Compressed Earth Blocks—CEBs | RE Specimens | |||||

| Identification | Stabilization | Finishing | Identification | Stabilization | Finishing | |

| Face A | Face B | |||||

| CEB 1 | cement | - | RE 1 | cement | - | - |

| CEB 2 | cement | - | RE 2 | cement | - | - |

| CEB 3 | hydrated lime | - | RE 3 | hydrated lime | - | - |

| CEB 4 | hydrated lime | - | RE 4 | hydrated lime | - | - |

| CEB 5 | quicklime | traditional varnish | RE 5 | quicklime | - | - |

| CEB 6 | quicklime | - | RE 6 | quicklime | - | - |

| CEB 7 | quicklime | - | RE 7 | no addition | - | - |

| CEB 8 | quicklime | soaping | RE 8 | no addition | - | - |

| CEB 9 | quicklime | quicklime/aloe paint | RE 9 | no addition | w/QL plaster | w/HL plaster |

| RE 10 | no addition | w/QL plaster + pigmented lime paint | w/QL plaster + oil painting | |||

| RE 11 | no addition | w/HL plaster + pigmented lime paint | w/HL plaster + oil painting | |||

| RE 12 | no addition | w/HL plaster + traditional varnish | traditional varnish | |||

| RE 13 | quicklime | soaping | - | |||

| RE 14 | quicklime | quicklime/aloe painting | - | |||

| Measuring Distance (mm) | ||

|---|---|---|

| Points | CEB | RE specimen |

| A | 105 | 150 |

| B | 105 | 150 |

| C | 220 | - |

| Qualitative Visual and Pachymeter Evaluation | ||||

|---|---|---|---|---|

| Wetting and Drying Cycles | ||||

| A | B | 1st Cycle | 2nd Cycle | 3rd Cycle |

| CEB 1 | 1 |  |  |  |

| 2 | No relevant changes were observed in the specimen body, and the overall dimensions of the model also remained the same. | |||

| 3 | Insignificant or non-existent | Insignificant or non-existent | Insignificant or non-existent | |

| CEB 3 | 1 |  |  |  |

| 2 | Material loss occurred mainly near the laying plaster and on existing vertical marks. The specimen’s edges had pre-existing material losses. | There was a slight increase in the degradation previously reported, especially around the laying plaster, which has been gradually disintegrating since the last cycle. | The CEBs in the sample separated because the laying plaster that held them together weakened. The analysis focused on the CEB at the top of the sample, which exhibited more changes during testing. | |

| 3 | - | The overall dimensions are approximately 90mm long and just over 10mm deep. | - | |

| CEB 9 | 1 |  |  |  |

| 2 | The specimen has experienced gradual paint loss with superficial wear, a small section of complete detachment, and yellowed areas of paint. | No significant degradation reported from the previous cycle. | There has been no progression of surface degradation since the previous cycle. | |

| 3 | The paint loss is almost 16mm long, with a depth of just over 1mm. The other changes of the exposed face spread to practically the entire surface. | |||

| Qualitative Visual and Pachymeter Evaluation | ||||

|---|---|---|---|---|

| Wetting and Drying Cycles | ||||

| A | B | 1st Cycle | 2nd Cycle | 3rd Cycle |

| RE 1 | 1 |  |  |  |

| 2 | The specimen showed no noticeable changes during the cycles. | |||

| 3 | Insignificant or non-existent | Insignificant or non-existent | Insignificant or non-existent | |

| RE 3 | 1 |  |  |  |

| 2 | The specimen experienced mass loss and fine aggregate exposure in areas where roughness existed from its manufacturing. | Small increase in degradation in the same areas already affected by water in the previous cycle. | Small increase in length and depth of areas already worn during cycles. | |

| 3 | Approximate maximum damage dimensions: 6.00mm long and 3.50mm deep. | - | The overall dimensions are 91.86mm long and 4.46mm deep. | |

| RE 8 | 1 |  | - | - |

| 2 | Loss of much of the volume in 15 min of water jet exposure. | - | - | |

| 3 | Loss of almost 50% of volume | - | - | |

| Relationship between CEBs Results | ||

|---|---|---|

| Specimens | Results | |

| Typology | Average transmission speed variation (%) | Compressive strength (MPa) |

| CEB 1 | 2.74 | 9.6 |

| CEB 3 | 15.37 | 3.4 |

| CEB 5 | 20.76 | 2.8 |

| CEB 6 | 8.09 | 4.2 |

| CEB 8 | 14.49 | 3.9 |

| CEB 9 | 12.69 | 4.0 |

| Relationship between the Results of RE Specimens | ||

|---|---|---|

| Specimens | Results | |

| Typology | Average transmission speed variation (%) | Compressive strength (MPa) |

| RE 1 | 2.66 | 10.8 |

| RE 3 | 16.19 | 3.5 |

| RE 5 | 7.80 | 3.3 |

| RE 13 | 3.97 | 2.7 |

| RE 14 | 4.41 | 3.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nina, J.F.; Eires, R.; Oliveira, D.V. Earthen Construction: Acceptance among Professionals and Experimental Durability Performance. Constr. Mater. 2023, 3, 143-163. https://doi.org/10.3390/constrmater3020010

Nina JF, Eires R, Oliveira DV. Earthen Construction: Acceptance among Professionals and Experimental Durability Performance. Construction Materials. 2023; 3(2):143-163. https://doi.org/10.3390/constrmater3020010

Chicago/Turabian StyleNina, Juliana F., Rute Eires, and Daniel V. Oliveira. 2023. "Earthen Construction: Acceptance among Professionals and Experimental Durability Performance" Construction Materials 3, no. 2: 143-163. https://doi.org/10.3390/constrmater3020010

APA StyleNina, J. F., Eires, R., & Oliveira, D. V. (2023). Earthen Construction: Acceptance among Professionals and Experimental Durability Performance. Construction Materials, 3(2), 143-163. https://doi.org/10.3390/constrmater3020010