Abstract

Due to routine maintenance of aircraft on the concrete pavement at army airbases, a large part of the pavement surface is often found saturated with different hydrocarbon-based oil, fuel, and fluid. In addition, the pavement concrete is subjected to the aircraft’s exhaust temperature during operation. This study examined the resistance ability of 3 different cementitious materials: (i) epoxy, (ii) fly ash (FA) based geopolymer with various alkali to fly ash (AL/FA) ratios and (iii) Portland cement (PC) mortar under a simulated airfield circumstance. The mortar specimens were repetitively exposed to a mixture of synthetic engine oil, hydraulic fluids, jet fuel and elevated temperatures (175 °C) for 5 months simultaneously. During the exposures, geopolymer and PC mortar both suffered saponification. The degree of saponification of geopolymer samples is found to be highly reliant on the AL/FA ratios. On the contrary, the epoxy mortar was found to be resistant to saponification. It was also found that the PC mortar developed numerous thermal cracks but epoxy and geopolymer did not experience any visual thermal cracks under the same conditions.

1. Introduction

Concrete pavements at airfields that house aircraft are often found saturated with hydrocarbon-based synthetic engine lubricant, hydraulic fluid and jet fuel. Additionally, rigid pavements are repetitively subjected to high thermal exhaust of auxiliary power units (APUs) of aircraft for a short period. As reported, the F/A-18 aircraft’s exhaust can heat the surface of concrete pavement to 175 °C in 10–12 min [1,2,3]. Consequently, the Portland cement (PC) concrete pavements at airbases worldwide have been suffering rapid surface degradation, which is termed as scaling of surface [1,2,3,4,5,6]. As stated, surface scaling is a detachment of aggregates and/or small pieces of hardened cement mortar from the top surface due to the combined action of synthetic hydrocarbon oils and repeated thermal exposures [3,5]. The depth of surface scaling could vary from 6 mm to 25 mm [1,3,7,8]. Concrete pavements at Australian airbases have also been facing the same issue since F/A-18 aircraft were introduced at their airbases [9,10].

According to the US Army Corps of Engineers [11], alkali-activated cement should be a better performing binder than ordinary cement to repair army airbases. Moreover, many studies mentioned that epoxy modified cement mortar or epoxy sand mortar exhibits excellent resistance to aggressive environments [7,12]. Therefore, this study examined the resistance of geopolymer and epoxy mortar to a reproduced airfield operating condition.

Geopolymer could be an eco-friendly cementitious material depending on the raw materials [13,14]. It is considered to be a superior substitute to ordinary PC when environmental and technical points are considered [15,16,17,18,19]. It has already been used in the construction of the Global Change Institute (GCI) building at the University of Queensland (UQ) in Australia [20,21,22]. Recently, some heavy-duty rigid pavements at a commercial airport in Brisbane were also constructed using geopolymer concrete. However, the research about the durability of geopolymer concrete/mortar against airfield conditions is still scarce.

Geopolymer is an inorganic polymer that is usually produced by alkaline activation of aluminosilicate (powder materials) [17,23,24]. Sodium or potassium hydroxide are usually used as alkali hydroxides, and sodium or potassium silicate ( or () are generally used as alkali silicates to activate the aluminosilicate powder. Usually, fly ash (FA) is considered as a preferred source of aluminosilicate to manufacture geopolymer concrete/mortar because FA contains a significant amount of acidic oxides, such as and which are effortlessly able to react with alkalis [25].

To date, the precise mechanism of geopolymer reaction is still being explored and evolving as a great interest of research [26]. When alkali hydroxides and silicates are added to FA, the inorganic spherical aluminosilicates are dissolved into the alkali solutions and a step-by-step geo-polymerization (exothermic reactions) occurs. As mentioned [27,28], the steps involve polycondensation of hypothetical monomers, i.e., orthosialate ions ; usually from monomers to dimers, trimers, tetramer, and higher molecules. This process eventually yields the polymeric covalent bonds: poly-siloxonate poly-sialate and poly-sialate disiloxo , which are solid, hard, and stable materials [18,29]. However, quartz and mullite of FA are usually less reactive and could partly involve in the reaction process and remain as relict mineralogy of FA [18]. Depending on the climate, curing conditions, and mix design, the solidification of geopolymer usually varies from a couple of hours to some days [18,29,30].

The hardened product (metallic-poly-sialate-siloxo), which is the backbone of geopolymer, has high resistance to alkaline and acidic environments at ambient temperatures [27,31,32,33,34,35]. Moreover, many studies stated that geopolymer has better thermal resistance compared to typical PC [21,36,37,38,39,40,41,42,43].

Epoxy resin is broadly used in construction industries as it offers better resistance to chemicals compared to ordinary cement [7,44,45,46]. Although epoxy is an expensive material, due to its excellent durability characteristics against adverse conditions, it is often chosen as an additive material to cement mortar. As reported, considering the cost–performance ratio, epoxy can be used as a single binder in concrete/mortar where chemical resistance is needed [7,12]. Thus, this study used epoxy as a single binder to produce a mortar intended to repair degraded concrete at airfields. A small amount of silica fume (SF) was added to epoxy mortar to improve its performance under airfield conditions; as SF considerably decreases the permeability, thermal conductivity, spalling, and thermal cracking of concrete material [47,48,49,50]. Moreover, spherical SF usually holds an abundance of silanol groups on the surface. Silanol groups and silicate compounds easily react with epoxy groups. As a result, the 3D cross-linked structures of epoxy resin get densified. The dense epoxy-silica product shows higher compressive strength and better stability at elevated temperatures [51,52].

Some previous experimental studies demonstrated reasons for the rapid surface degradation (scaling) mechanism of ordinary PC concrete at army airbase [2,3,4]. These studies revealed that typical PC is highly attacked by synthetic hydrocarbon oils/fluids at elevated temperatures and causes saponification on the surface of the pavement concrete. However, the solution to the problem is still unanswered. Therefore, the present study systematically examined the durability of three binding materials (geopolymer, epoxy and plain PC) under a replicated airfield condition. The visual observation, residual compressive strength, loss of mass and chemical degradation of the specimens were considered as performance indicators to compare. The findings of the study will help find suitable cementitious materials to repair/resurface existing military airbase rigid pavements. Moreover, the study illuminates the influence of alkali to FA ratios (AL/FA) on the durability of geopolymer under airfield environments.

2. Raw Materials and Specimen Preparation

2.1. Geopolymer Ingredients and Preparation

A solution (16 M) was prepared from 98% pure NaOH flakes supplied by Redox Pty Ltd. and used in the present study. Sodium silicate ( solution (laboratory-grade D) with = 2.0 was procured and used in the preparation of geopolymer mixes. solution was made one day before activating the fly ash (FA). The FA of class F was utilized as a source of aluminosilicate materials. Australian river sand (FM = 2.20) that had a water absorption capacity of 0.56% and specific gravity (Sp. g.) of 2.62, was utilized as fine aggregates. Drinkable tap water with water to fly ash ratio (W/FA) = 0.45 was used to prepare all geopolymer mixes. The mix ratio and characteristics of the geopolymer are listed in Table 1. After mixing, 50 mm size of geopolymer mortar cubes were cast and cured at 80 °C for a day.

Table 1.

The mix designs and properties of the geopolymer mortar used [10].

2.2. Epoxy and PC Mortar Ingredients and Preparation

Two-part epoxy was utilized to prepare the epoxy mortar. Part A was a diglycidyl ether of bisphenol A (DGEBA), and Part B was cycloaliphatic amine (hardener). The properties (physical) of the epoxy used in the study are presented in Table 2. Australian cement (general-purpose) was used to produce the PC mortar. The same sand type that was used for geopolymer mortar was used to produce PC and epoxy mortar as well. The mix proportions of the constituents and the characteristics of the PC and epoxy mortar are presented in Table 3.

Table 2.

The physical characteristics of the epoxy [7].

Table 3.

The mix proportion and the characteristics of the epoxy and PC mortar [10].

Firstly, dry sand and silica fume (SF) were mixed up in an automatic mixture machine for 2–3 min to produce the epoxy mortar. Secondly, water was poured into the dry mixture and mixing continued for a further 2 min. Thirdly, premixed two-part epoxy was poured and mixing continued for an extra 2–3 min. After casting, to prevent moisture loss, all epoxy specimens were wrapped up with wet fabric and polyethene sheets for a day.

A total of 81 mortar cubes (50 mm) were prepared where 27 cubes were used for each group of the mortars (geopolymer, epoxy and PC). Firstly, 15 cubes of each mortar type were tested to investigate the compressive strength for time and considered as a control specimen. Secondly, 12 cubes from each mortar type were exposed to the replicated aircraft operating conditions to evaluate the residual strength. Finally, 36 more geopolymer cubes with various alkali to fly ash (AL/FA) ratios e.g., 0.5, 0.6, 0.7 and 0.8 were also prepared and exposed to the condition to examine the effect of the AL/FA ratios on the resilience of the geopolymer.

3. Durability Test Program

Geopolymer, epoxy and PC mortar were systematically exposed to two different airbase conditions for 5 months to rank their resistance to the exposure conditions. The subsequent sections elucidate the exposure scenario.

3.1. Cyclic Exposure to Synthetic Oil, Fluid, Fuel and Elevated Temperatures

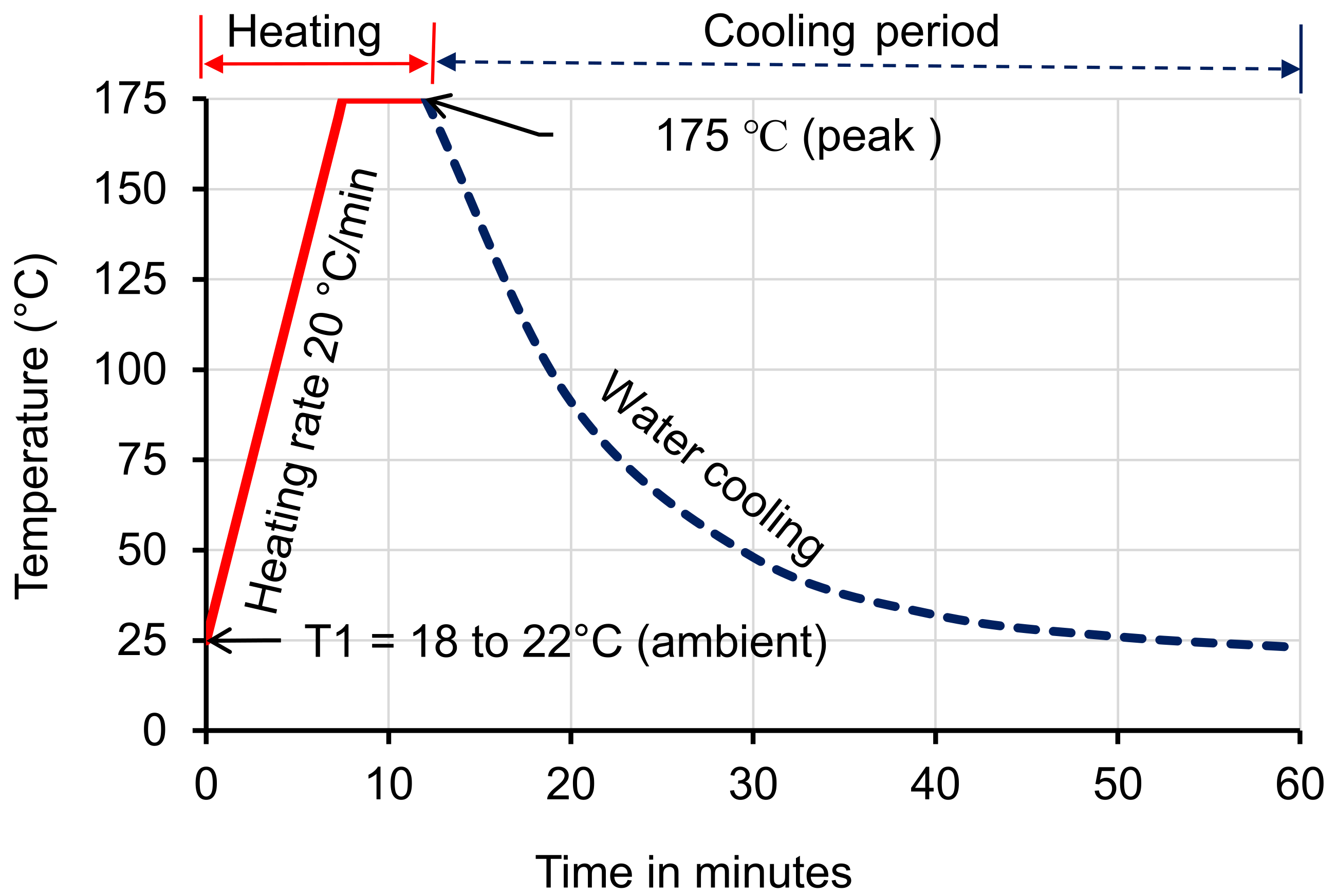

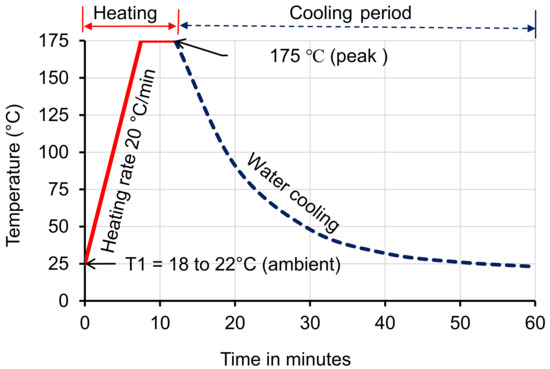

A total of 12 cube samples from each mortar type (geopolymer, epoxy and plain PC) at age of 3-day were exposed to hydrocarbon-based synthetic oil, fluid, and elevated thermal cycles, simultaneously. AeroShell Turbine Oil 500 (a synthetic hindered ester oil with some additives), AeroShell Fluid 31 (a synthetic hydrocarbon-based hydraulic fluid) and jet fuel (mostly kerosine) were secured from Skyfuel Australia Pty. Ltd. (The Oaks, NSW, Australia). An equal amount of these oils and fluid were sprayed on the surface of the cube specimens once daily except at weekends for 5 months. Moreover, the hydrocarbon-treated mortar cubes were exposed to the heating and cooling cycle, as shown in Figure 1. A convection oven was used for heating and the heat-treated samples were submerged in a water tub for cooling down to room temperatures. Water cooling was selected to simulate precipitation effects on the pavements at airbases. Heating and cooling cycles of the mortar samples were conducted 2–3 times a week. After every 20 cycles, 3 exposed mortar specimens from each mortar type were tested under compressive load to investigate the loss of the compressive strength.

Figure 1.

Thermal cycle implemented to reproduce military airfield’s heating and cooling condition [1,5].

3.2. Cyclic Exposures to Elevated Temperature Only

To calculate the mass loss of the mortar specimens due to high thermal exposures, 9 cubes (3 from each group) were exposed to 175 °C for 12 min. Hence, after every heating phase, specimens were kept outside to cool down to ambient temperatures, and mass losses were recorded.

4. Result and Discussion

4.1. Visual Observations after Exposure to the Replicated Conditions

The PC mortar samples suffered saponification and developed numerous wide cracks due to chemicals (hydrocarbons) and thermal attacks simultaneously, as shown in Figure 2a. As previously reported, concrete usually faces saponification (formation of soap bubbles and salty compounds) when repeatedly subjected to hydrocarbon-based oils/fluids at elevated temperatures [1,3]. Aircraft engine lubricating oil, jet fuel and hydraulic fluid usually comprises free alcohol, long chain of hydrocarbons in the form of and , an abundance of esters of fatty acids and phosphate esters [2,5]. Esters of fatty acid are easily converted into alcohol and carboxylic acid when hydrolysed. Carboxylic acid attacks of PC at elevated temperature and produces calcium carboxylates, which are soaps [2,53]. As the chemical attack leads to the development of soaps, it is termed saponification of concrete. Occurring saponification in concrete triggered degradation of microstructures and covalent bonds of cement paste. At the same time, high thermal exposure caused numerous cracks in the mortar cubes by developing vapor pressure in the pores of the degraded cement paste.

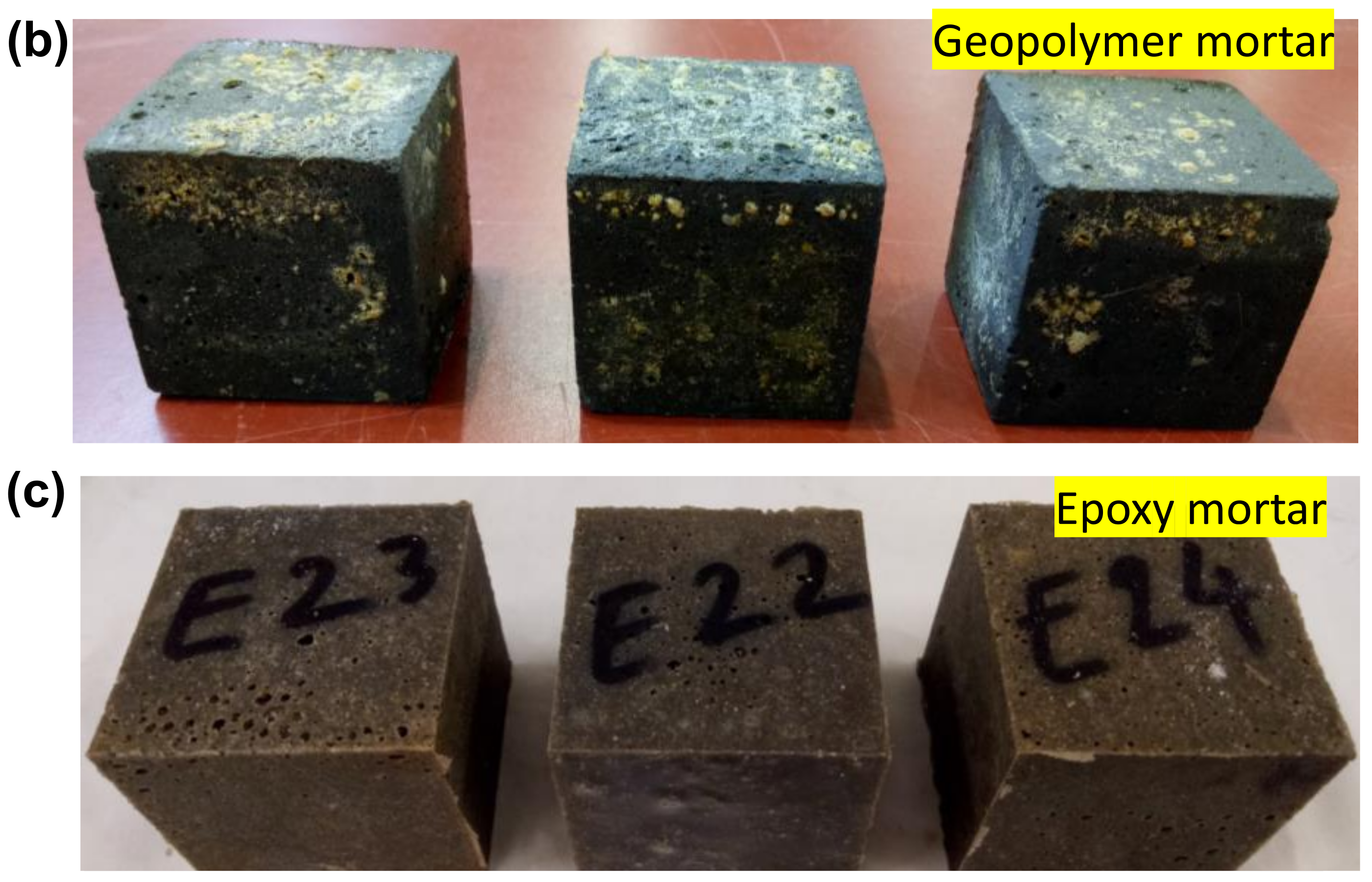

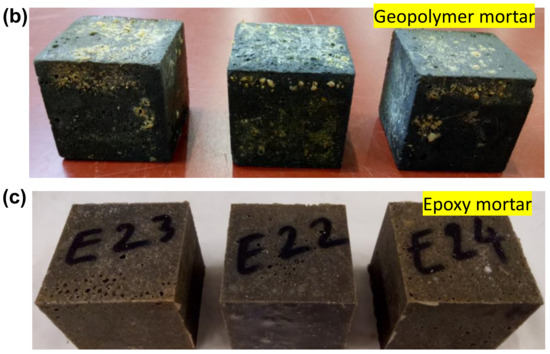

Figure 2.

Appearance of the (a) plain PC [10], (b) geopolymer [54] and (c) epoxy mortar cubes after 80 cycles of exposure to hydrocarbon-based synthetic oil, fluids, fuel and high temperature simultaneously.

Geopolymer mortar also faced saponification during the same exposure but did not develop cracks, as shown in Figure 2b. Esters of fatty acid reacted with free in geopolymer at high temperatures and produced sodium carboxylate, which is also a salt, and the process is known as saponification [54]. This implies geopolymer is also susceptible to saponification like ordinary PC mortar when exposed to synthetic hydrocarbon-based oil at elevated temperatures. However, probably due to stronger microstructures or more heat resistance ability than PC mortar, geopolymer did not experience thermal crack.

The epoxy sand mortar neither suffered saponification nor cracking under the same exposure conditions. The surface of epoxy mortar looked glossy before the exposures and remained glossy after the exposures, no obvious change on the surface of epoxy mortar cubes were observed, as shown in Figure 2c. It indicates epoxy mortar should be more durable under airbase operating circumstances than other mortars used in the study.

4.2. Residual Compressive Strength of the Exposed Specimens

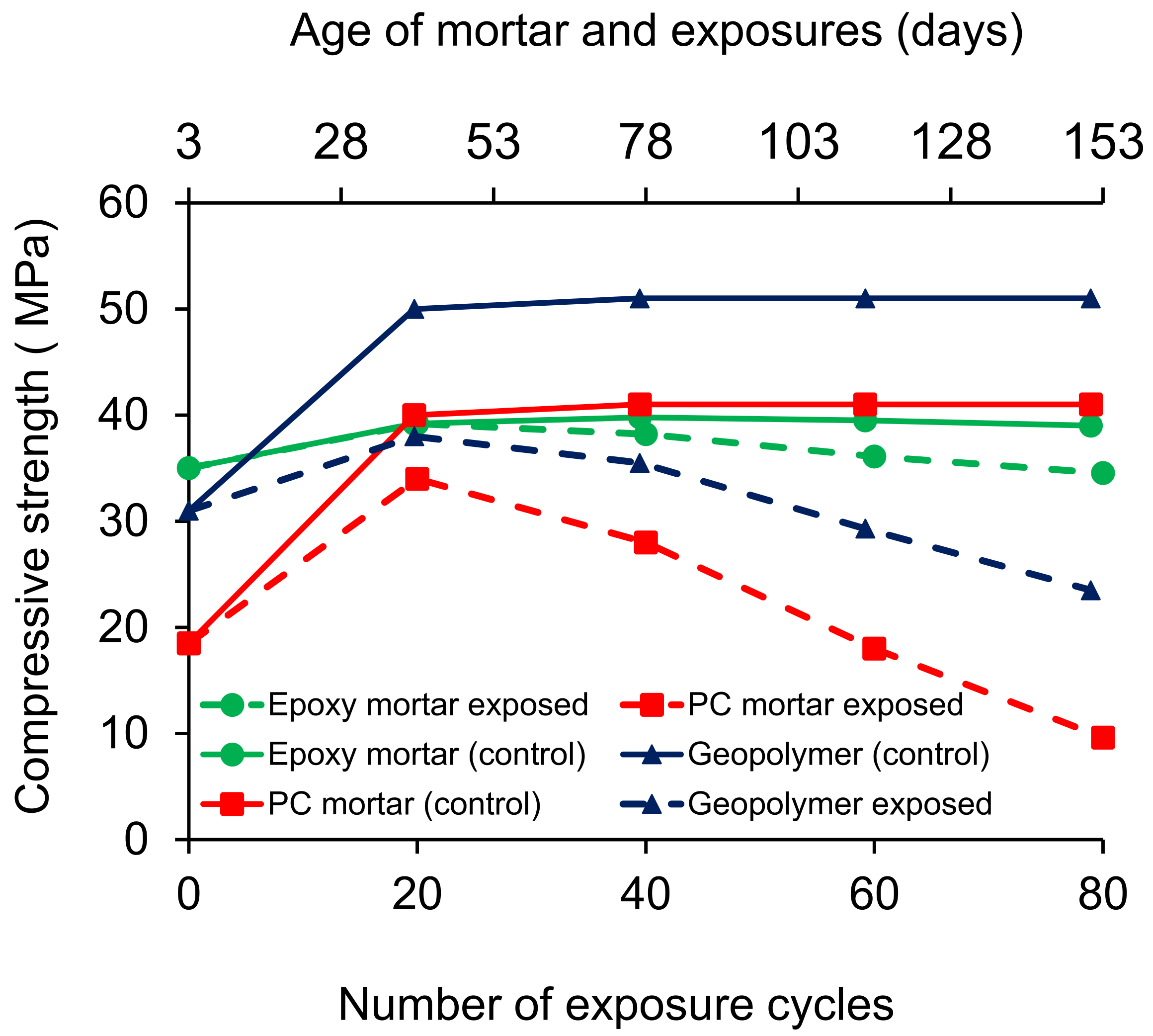

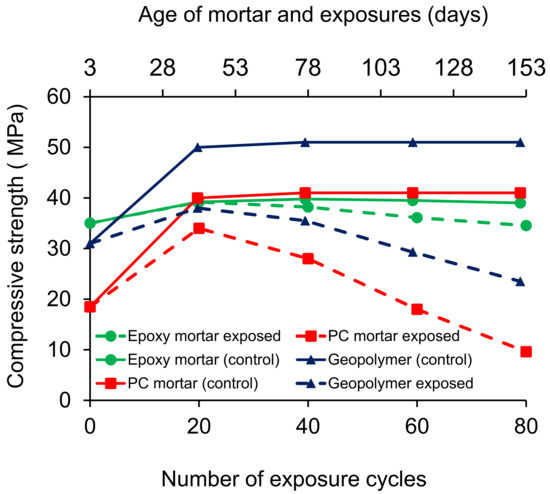

Figure 3 shows the gain and reduction of compressive strength of the control and exposed mortars, respectively. Since all mortars cubes were exposed to the replicated airbase conditions when they were only 3-day old, mortar cubes gained compressive strength even up to 20 cycles of exposure. Later, they started losing their strength due to subsequent exposure cycles; while the unexposed mortar cubes (the control samples) showed a slightly gaining of compressive strength over the period.

Figure 3.

Drop in the compressive strength of the mortar samples during the cyclic exposures over 150 days.

After 80 cycles of exposure, the plain PC, geopolymer and epoxy sand mortar lost approximately 80%, 53% and 11.50% of the compressive strength than that of the control mortar specimens, respectively. Although geopolymer showed significantly better resistance than the PC mortar, the epoxy mortar exhibited the highest resilience against the severe adverse effect of military airbase working conditions.

Airbase overlay pavement design requires a minimum of 19 MPa compressive strength of concrete [55]. Geopolymer and epoxy mortar both were able to uphold more compressive strength than the minimum requirement even after 80 cycles of exposure. However, after the same exposure cycles, the PC mortar failed to do so. Therefore, epoxy mortar is a preferable choice for patch repairing or small resurfacing of the degraded part of the airfield rigid pavements. Despite its technical benefits, the epoxy mortar could be an expensive solution when a large area of the rigid pavements needs to be resurfaced. In such cases, geopolymer can be selected to construct and repair rigid pavements at airfields as it offered superior resistance to airfield circumstances compared to ordinary PC mortar.

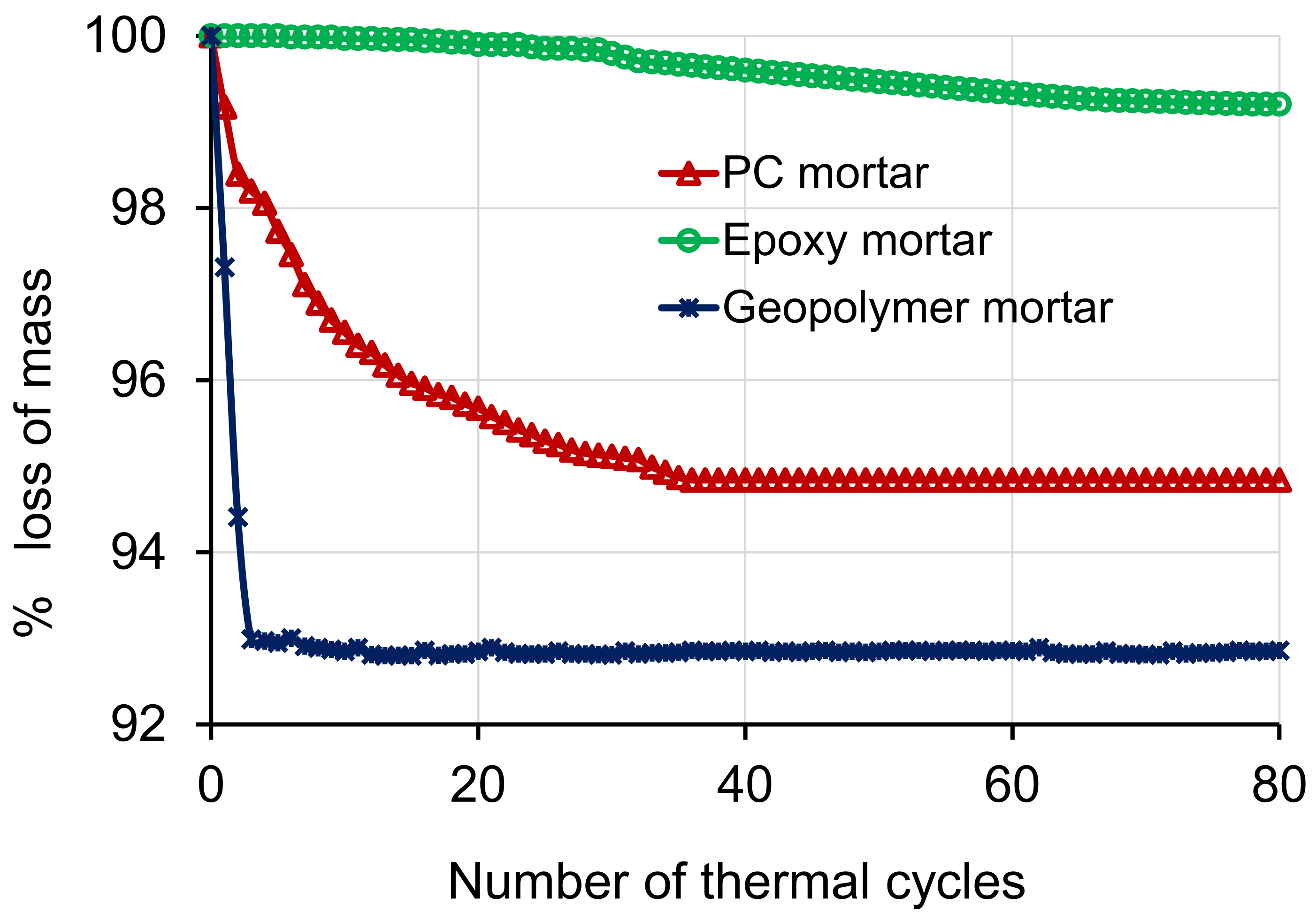

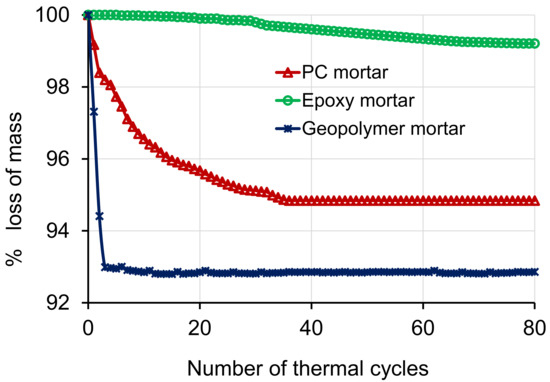

4.3. Mass Loss Due to Cyclic Thermal Exposures

Figure 4 presents the mass loss behaviour of the PC, epoxy and geopolymer mortar when exposed to thermal cycles only. After 80 cycles of high thermal exposure, the PC, epoxy and geopolymer lost approximately 5%, 1% and 7% of the mass, respectively. Due to the high volume of initial water (free) in the PC mortar for hydration and geopolymer for the polymerization reactions, they lost a significantly higher amount of mass than that of the epoxy mortar. As reported, epoxy mortar starts losing its epoxy groups at 220 °C and the loss becomes substantial at 320 °C [56]. This implies the epoxy chain (crosslink) did not start losing moisture at 175 °C; however, geopolymer and PC gel showed a significant reduction in the mass during the high thermal exposures.

Figure 4.

Mass loss of the PC, epoxy and geopolymer mortar when subjected to thermal cycles only.

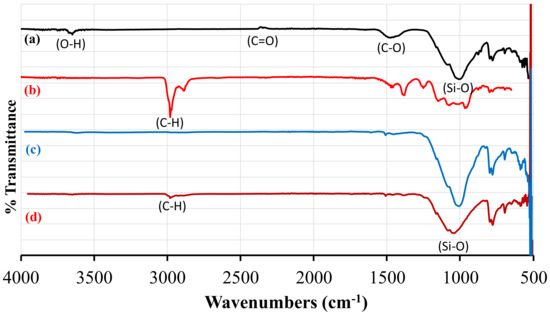

4.4. FTIR Analysis of the Specimens

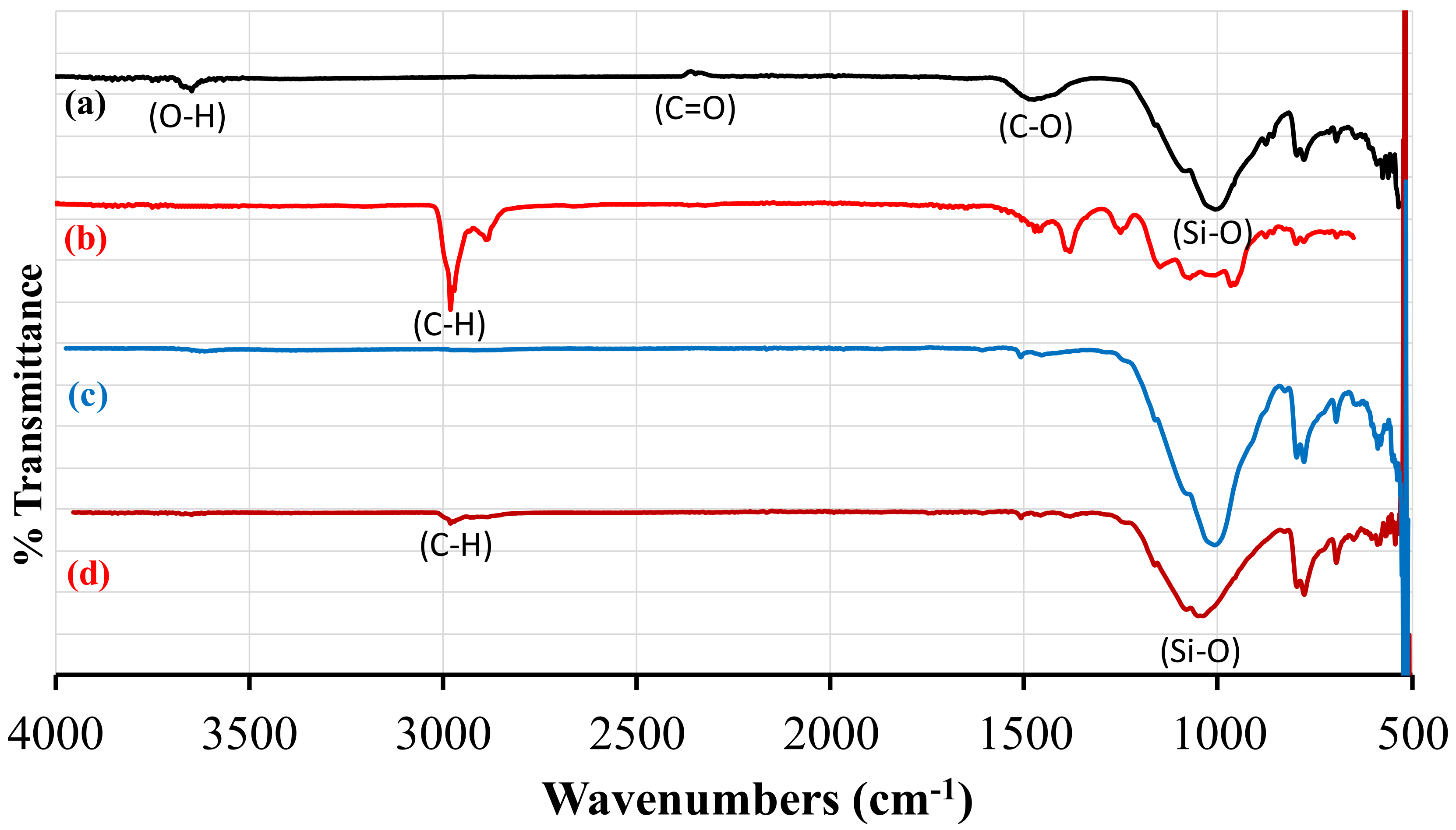

Figure 5 shows FTIR spectrums of the PC and epoxy mortar before and after exposures. It is observed that groups and bonds of PC mortar are attacked by esters of fatty acids and phosphate esters of synthetic hydrocarbon oils used. As a result, saponification occurred in the ordinary PC mortar significantly. On the other hand, bonds in epoxy sand mortar remained almost unchanged even after 80 cycles of exposures to the hydrocarbon-based synthetic oil, fluid, fuel and thermal cycles simultaneously.

Figure 5.

FTIR spectrums of (a) PC mortar (control), (b) PC mortar exposed, (c) epoxy mortar (control) and (d) epoxy mortar exposed.

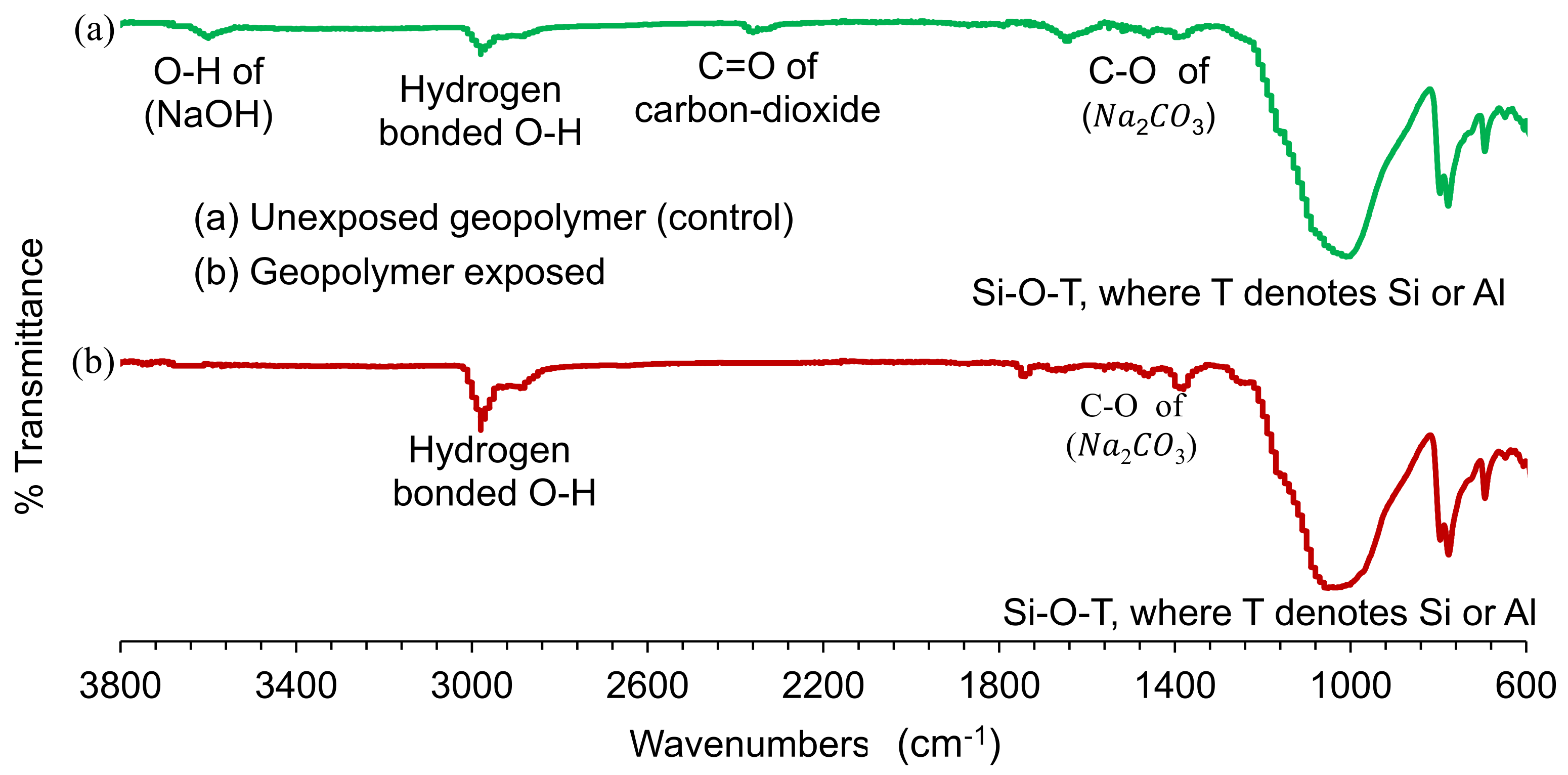

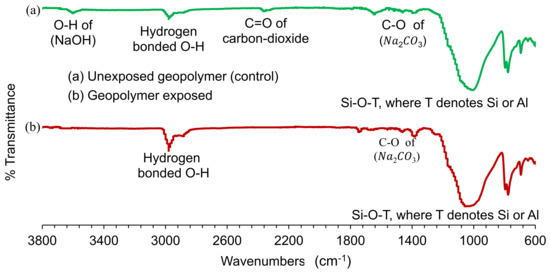

Figure 6b shows the FTIR spectrums of geopolymer before and after exposure to the conditions. Like PC mortar, geopolymer also lost ions and bonds due to the repeated attack of esters of fatty acids at elevated temperatures. These chemical attacks resulted in saponification in the geopolymer surface. Moreover, the peak for the bonds in geopolymer is observed to slightly move from the previous (original) position to a higher wavenumber. This signifies the covalent bonds in geopolymer were degraded and lost their molecular mass during the exposure period. Based on the chemical analysis, epoxy mortar is found to be the most suitable overlay material to repair airfield pavements.

Figure 6.

FTIR spectrums of the (a) unexposed geopolymer specimens (control) and (b) the geopolymer mortar exposed.

4.5. Influence of Alkali to Fly Ash (AL/FA) Ratio

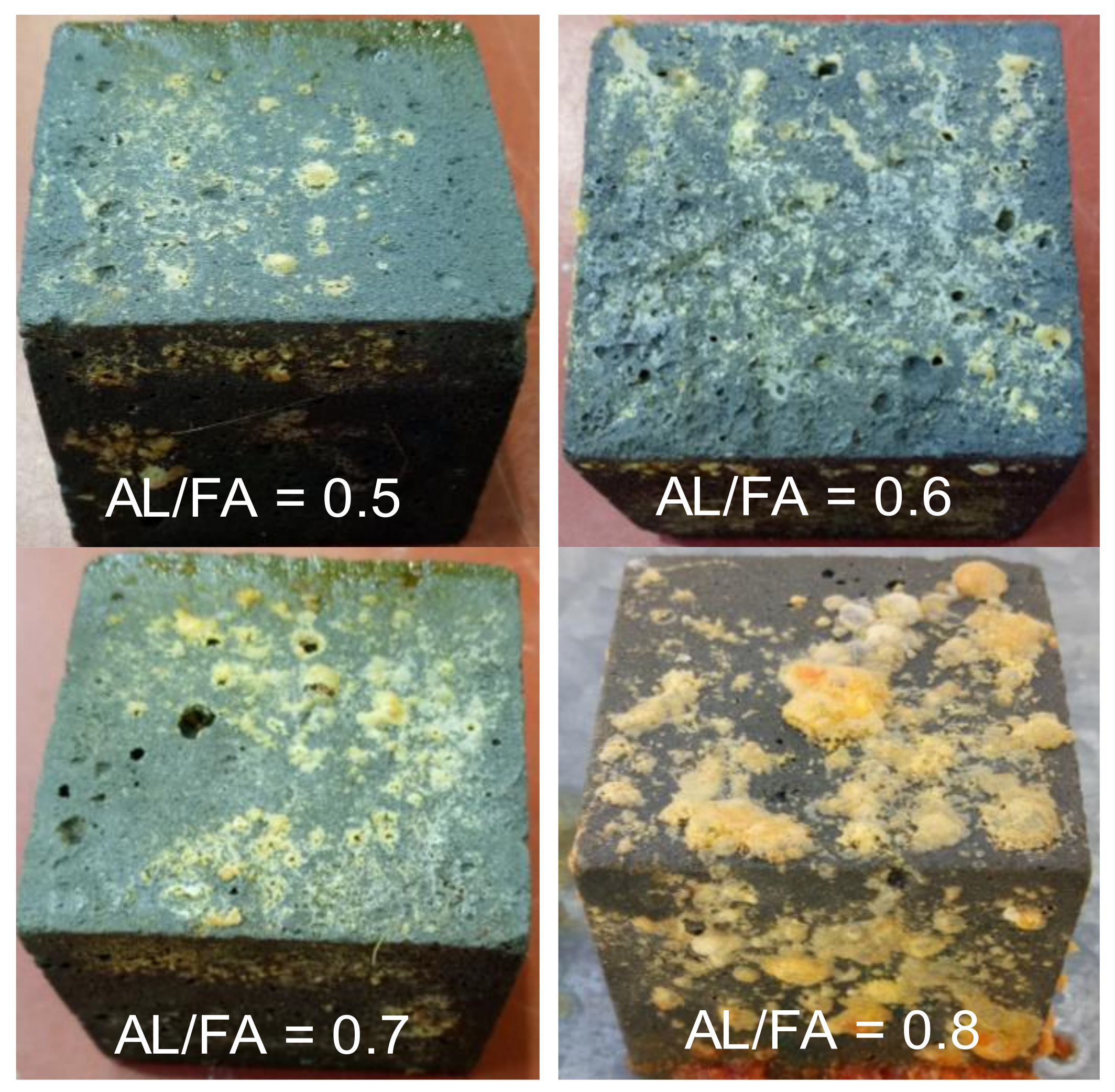

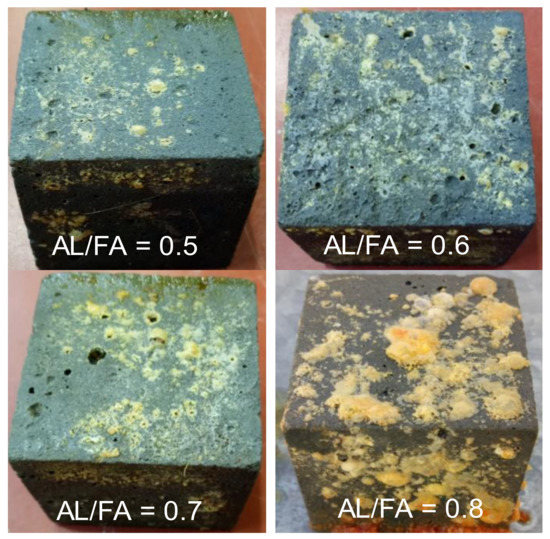

Geopolymer specimens with a higher AL/FA ratio were observed to suffer a higher degree of saponification than the geopolymer with a lower dose of AL/FA ratio, as presented in Figure 7. Upon the 80 cycles of exposure, geopolymer samples with AL/FA ratios of 0.5, 0.6, 0.7 and 0.8 lost approximately 33%, 40%, 49%, and 53% of the compressive strength, respectively, compared to that of the reference specimen.

Figure 7.

The appearance of geopolymer mortar cubes with various AL/FA ratios after 80 cycles of exposure to the simulated airfield condition.

A higher dose of AL/FA of geopolymer contributed to a higher amount of unreacted alkalis (AL) in the geopolymer matrix. As a result, unreacted AL freely reacted with hydrocarbon-based oil/fluid/fuel causing significant saponification. Therefore, a lower ratio of AL/FA is recommended for the construction/repair of airfield rigid pavements. It also should be noted that a lower dose of AL/FA resulted in lower strength (compressive) of geopolymer mortar.

5. Conclusions

This study examined the durability of geopolymer with various AL/FA ratios, epoxy and PC mortar while cyclically exposed to a reproduced airfield condition over 5 months. During the repeated exposures, geopolymer and PC mortar both went through the saponification process. Saponification of FA-based geopolymer was found to be highly dependent on alkali to fly ash (AL/FA) ratio as geopolymer mortar samples with a higher dose of AL/FA showed a higher degree of saponification. Nevertheless, the epoxy mortar did not suffer saponification under the same condition. In regards to cracking, the PC mortar developed numerous thermal cracks but epoxy and geopolymer did not experience any visual thermal cracks due to cyclic thermal exposures.

After 5 months of cyclic exposure, epoxy mortar specimens held the highest percentage of compressive strength compared to geopolymer and PC mortar. Based on the chemical analysis and mass moss criterion, epoxy mortar samples showed the best resistance to the replicated airfield condition. Therefore, the present study considers that epoxy can be the first choice as a single binder for patch repairing or small resurfacing of the airfield rigid pavements as it offered the highest resistance to the aircraft operating circumstances.

However, epoxy might not be a suitable option for a larger application (construct and/or repair) at airfields as it is expensive. In such a case, FA-based geopolymer (with AL/FA ratio is 0.5 or less) can be used because geopolymer with AL/FA ratio of 0.5 was observed to suffer insignificant saponification and upheld approximately 67% of the compressive strength even after 5 months of cyclic exposures to airfield conditions.

Author Contributions

Conceptualization, S.K.S. and S.A.-D.; methodology, S.K.S. and S.A.-D.; validation, M.A.; formal analysis, S.K.S.; investigation, S.K.S.; resources S.K.S. and S.A.-D.; writing—original draft preparation, S.K.S.; writing—review and editing, E.O.G. and M.S.; visualization, S.K.S. and M.M.H.; supervision, S.A.-D. and M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Department of Defence, Commonwealth government of Australia.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors thank Jim Baxter, SEIT, UNSW Canberra ACT 2612 Australia for his generous support to the experimental investigations. Also, the authors would like to acknowledge Barry Gray, School of Science, UNSW Canberra for his assistance to conduct chemical analysis.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shill, S.K.; Al-Deen, S.; Ashraf, M. Concrete durability issues due to temperature effects and aviation oil spillage at military airbase–A comprehensive review. Constr. Build. Mater. 2018, 160, 240–251. [Google Scholar] [CrossRef]

- McVay, M.C.; Smithson, L.D.; Manzione, C. Chemical damage to airfield concrete aprons from heat and oils. Mater. J. 1993, 90, 253–258. [Google Scholar]

- McVay, M.; Rish, J., III; Sakezles, C.; Mohseen, S.; Beatty, C. Cements resistant to synthetic oil, hydraulic fluid, and elevated temperature environments. Mater. J. 1995, 92, 155–163. [Google Scholar]

- Hironaka, M.C.; Malvar, L.J. Jet exhaust damaged concrete. Concr. Int. 1998, 20, 32–35. [Google Scholar]

- Shill, S.K.; Al-Deen, S.; Ashraf, M. Saponification and scaling in ordinary concrete exposed to hydrocarbon fluids and high temperature at military airbases. Constr. Build. Mater. 2019, 215, 765–776. [Google Scholar] [CrossRef]

- Hossain, M.M.; Al-Deen, S.; Hassan, M.K.; Shill, S.K.; Kader, M.A.; Hutchison, W. Mechanical and thermal properties of hybrid fibre-reinforced concrete exposed to recurrent high temperature and aviation oil. Materials 2021, 14, 2725. [Google Scholar] [CrossRef]

- Shill, S.K.; Al-Deen, S.; Ashraf, M.; Hutchison, W.; Hossain, M.M. Performance of amine cured epoxy and silica fume modified cement mortar under military airbase operating conditions. Constr. Build. Mater. 2020, 232, 117280. [Google Scholar] [CrossRef]

- Shill, S.K.; Al-Deen, S.; Ashraf, M.; Rashed, M.; Hutchison, W. Consequences of aircraft operating conditions at military airbases: Degradation of ordinary mortar and resistance mechanism of acrylic and silica fume modified cement mortar. Road Mater. Pavement Des. 2022, 23, 98–111. [Google Scholar] [CrossRef]

- Shill, S.K.; Al-Deen, S.; Ashraf, M.; Hossain, M.M. Residual properties of conventional concrete repetitively exposed to high thermal shocks and hydrocarbon fluids. Constr. Build. Mater. 2020, 252, 119072. [Google Scholar] [CrossRef]

- Shill, S.K.; Al-Deen, S.; Ashraf, M.; Elahi, M.A.; Subhani, M.; Hutchison, W. A comparative study on the performance of cementitious composites resilient to airfield conditions. Constr. Build. Mater. 2021, 282, 122709. [Google Scholar] [CrossRef]

- Malone, P.G.; Randall, C.A., Jr.; Kirkpatrick, T. Potential Applications of Alkali-Activated Alumino-Silicate Binders in Military Operations; Army Engineer Waterways Experiment Station Vicksburg Ms Geotechnical Lab, Department of the Army: Vicksburg, MI, USA, 1985. [Google Scholar]

- Levchik, S.V.; Weil, E.D. Thermal decomposition, combustion and flame-retardancy of epoxy resins—a review of the recent literature. Polym. Int. 2004, 53, 1901–1929. [Google Scholar] [CrossRef]

- Parathi, S.; Nagarajan, P.; Pallikkara, S.A. Ecofriendly geopolymer concrete: A comprehensive review. Clean Technol. Environ. Policy 2021, 23, 1701–1713. [Google Scholar] [CrossRef]

- Imtiaz, L.; Rehman, S.K.U.; Memon, S.A.; Khan, M.K.; Javed, M.F. A review of recent developments and advances in eco-friendly geopolymer concrete. Appl. Sci. 2020, 10, 7838. [Google Scholar] [CrossRef]

- Temuujin, J.; van Riessen, A.; MacKenzie, K. Preparation and characterisation of fly ash based geopolymer mortars. Constr. Build. Mater. 2010, 24, 1906–1910. [Google Scholar] [CrossRef]

- Palomo, A.; Grutzeck, M.; Blanco, M. Alkali-activated fly ashes: A cement for the future. Cem. Concr. Res. 1999, 29, 1323–1329. [Google Scholar] [CrossRef]

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S. Geopolymer concrete: A review of some recent developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications, 4th ed.; Institut Geopolymere: Saint-Quentin, France, 2015. [Google Scholar]

- Mellado, A.; Catalán, C.; Bouzón, N.; Borrachero, M.; Monzó, J.; Payá, J. Carbon footprint of geopolymeric mortar: Study of the contribution of the alkaline activating solution and assessment of an alternative route. RSC Adv. 2014, 4, 23846–23852. [Google Scholar] [CrossRef]

- Glasby, T.; Day, J.; Genrich, R.; Aldred, J. EFC geopolymer concrete aircraft pavements at Brisbane West Wellcamp Airport. In Proceedings of the 27th Concrete Institute of Australia Conference, Melbourne, Australia, 30 August–2 September 2015. [Google Scholar]

- Ali, A.M.; Sanjayan, J.; Guerrieri, M. Performance of geopolymer high strength concrete wall panels and cylinders when exposed to a hydrocarbon fire. Constr. Build. Mater. 2017, 137, 195–207. [Google Scholar]

- Aldred, J.; Day, J. Is geopolymer concrete a suitable alternative to traditional concrete. In Proceedings of the 37th Conference on Our World in Concrete & Structures, Singapore, 29–31 August 2012; pp. 29–31. [Google Scholar]

- Davidovits, J.; Sawyer, J.L. Early High-Strength Mineral Polymer. U.S. Patent 4,509,985, 9 April 1985. [Google Scholar]

- Khale, D.; Chaudhary, R. Mechanism of geopolymerization and factors influencing its development: A review. J. Mater. Sci. 2007, 42, 729–746. [Google Scholar] [CrossRef]

- Xie, Z.; Xi, Y. Hardening mechanisms of an alkaline-activated class F fly ash. Cem. Concr. Res. 2001, 31, 1245–1249. [Google Scholar] [CrossRef]

- Hamaideh, A.; Al-Qarallah, B.; Hamdi, M.R.; Mallouh, S.A.A.; Alshaaer, M. Synthesis of geopolymers using local resources for construction and water purification. J. Water Resour. Prot. 2014, 06, 507–513. [Google Scholar] [CrossRef][Green Version]

- Bakharev, T. Resistance of geopolymer materials to acid attack. Cem. Concr. Res. 2005, 35, 658–670. [Google Scholar] [CrossRef]

- Bakharev, T. Durability of geopolymer materials in sodium and magnesium sulfate solutions. Cem. Concr. Res. 2005, 35, 1233–1246. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers: Inorganic polymeric new materials. J. Therm. Anal. Calorim. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Guo, X.; Shi, H.; Dick, W.A. Compressive strength and microstructural characteristics of class C fly ash geopolymer. Cem. Concr. Compos. 2010, 32, 142–147. [Google Scholar] [CrossRef]

- Abdulkareem, O.A.; al Bakri, A.M.; Kamarudin, H.; Nizar, I.K.; Ala’eddin, A.S. Effects of elevated temperatures on the thermal behavior and mechanical performance of fly ash geopolymer paste, mortar and lightweight concrete. Constr. Build. Mater. 2014, 50, 377–387. [Google Scholar] [CrossRef]

- Roy, D.; Arjunan, P.; Silsbee, M. Effect of silica fume, metakaolin, and low-calcium fly ash on chemical resistance of concrete. Cem. Concr. Res. 2001, 31, 1809–1813. [Google Scholar] [CrossRef]

- Koenig, A.; Herrmann, A.; Overmann, S.; Dehn, F. Resistance of alkali-activated binders to organic acid attack: Assessment of evaluation criteria and damage mechanisms. Constr. Build. Mater. 2017, 151, 405–413. [Google Scholar] [CrossRef]

- Temuujin, J.; Minjigmaa, A.; Lee, M.; Chen-Tan, N.; van Riessen, A. Characterisation of class F fly ash geopolymer pastes immersed in acid and alkaline solutions. Cem. Concr. Compos. 2011, 33, 1086–1091. [Google Scholar] [CrossRef]

- Sindhunata; Provis, J.L.; Lukey, G.C.; Xu, H.; van Deventer, J.S. Structural evolution of fly ash based geopolymers in alkaline environments. Ind. Eng. Chem. Res. 2008, 47, 2991–2999. [Google Scholar] [CrossRef]

- Sabbatini, A.; Vidal, L.; Pettinari, C.; Sobrados, I.; Rossignol, S. Control of shaping and thermal resistance of metakaolin-based geopolymers. Mater. Des. 2017, 116, 374–385. [Google Scholar] [CrossRef]

- Tchakouté, H.K.; Rüscher, C.H.; Kong, S.; Kamseu, E.; Leonelli, C. Thermal behavior of metakaolin-based geopolymer cements using sodium waterglass from rice husk ash and waste glass as alternative activators. Waste Biomass Valorization 2017, 8, 573–584. [Google Scholar] [CrossRef]

- Colangelo, F.; Cioffi, R.; Roviello, G.; Capasso, I.; Caputo, D.; Aprea, P.; Liguori, B.; Ferone, C. Thermal cycling stability of fly ash based geopolymer mortars. Compos. Part B Eng. 2017, 129, 11–17. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Kodur, V.; Wu, B.; Cao, L.; Wang, F. Thermal behavior and mechanical properties of geopolymer mortar after exposure to elevated temperatures. Constr. Build. Mater. 2016, 109, 17–24. [Google Scholar] [CrossRef]

- Kürklü, G. The effect of high temperature on the design of blast furnace slag and coarse fly ash-based geopolymer mortar. Compos. Part B Eng. 2016, 92, 9–18. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rodríguez, E.D.; de Gutierrez, R.M.; Gordillo, M.; Provis, J.L. Mechanical and thermal characterisation of geopolymers based on silicate-activated metakaolin/slag blends. J. Mater. Sci. 2011, 46, 5477. [Google Scholar] [CrossRef]

- Junaid, M.T.; Kayali, O.; Khennane, A. Response of alkali activated low calcium fly-ash based geopolymer concrete under compressive load at elevated temperatures. Mater. Struct. 2017, 50, 50. [Google Scholar]

- Aslani, F. Thermal performance modeling of geopolymer concrete. J. Mater. Civ. Eng. 2015, 28, 04015062. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A.; Sapidis, G.; Papastergiadis, E. Fundamental properties of epoxy resin-modified cement grouts. Constr. Build. Mater. 2016, 125, 184–195. [Google Scholar] [CrossRef]

- Aggarwal, L.; Thapliyal, P.; Karade, S. Properties of polymer-modified mortars using epoxy and acrylic emulsions. Constr. Build. Mater. 2007, 21, 379–383. [Google Scholar] [CrossRef]

- Elalaoui, O.; Ghorbel, E.; Ouezdou, M.B. Influence of flame retardant addition on the durability of epoxy based polymer concrete after exposition to elevated temperature. Constr. Build. Mater. 2018, 192, 233–239. [Google Scholar] [CrossRef]

- Phan, L.T.; Carino, N.J. Effects of test conditions and mixture proportions on behavior of high-strength concrete exposed to high temperatures. ACI Mater. J. 2002, 99, 54–66. [Google Scholar]

- Behnood, A.; Ziari, H. Effects of silica fume addition and water to cement ratio on the properties of high-strength concrete after exposure to high temperatures. Cem. Concr. Compos. 2008, 30, 106–112. [Google Scholar] [CrossRef]

- Demirboǧa, R. Influence of mineral admixtures on thermal conductivity and compressive strength of mortar. Energy Build. 2003, 35, 189–192. [Google Scholar] [CrossRef]

- Smith, B.G. Durability of silica fume concrete exposed to chloride in hot climates. J. Mater. Civ. Eng. 2001, 13, 41–48. [Google Scholar] [CrossRef]

- Chruściel, J.J.; Leśniak, E. Modification of epoxy resins with functional silanes, polysiloxanes, silsesquioxanes, silica and silicates. Prog. Polym. Sci. 2015, 41, 67–121. [Google Scholar] [CrossRef]

- Ahmad, Z.; Al-Sagheer, F. Novel epoxy–silica nano-composites using epoxy-modified silica hyper-branched structure. Prog. Org. Coat. 2015, 80, 65–70. [Google Scholar] [CrossRef]

- Demirbaş, A. Biodiesel fuels from vegetable oils via catalytic and non-catalytic supercritical alcohol transesterifications and other methods: A survey. Energy Convers. Manag. 2003, 44, 2093–2109. [Google Scholar] [CrossRef]

- Shill, S.K.; Al-Deen, S.; Ashraf, M.; Hutchison, W. Resistance of fly ash based geopolymer mortar to both chemicals and high thermal cycles simultaneously. Constr. Build. Mater. 2020, 239, 117886. [Google Scholar] [CrossRef]

- United States. Department of the Army. Army Airfield and Heliport Rigid and Overlay Pavement Design; Headquarters, Department of the Army: Arlington, VA, USA, 1968. [Google Scholar]

- Grassie, N.; Guy, M.I.; Tennent, N.H. Degradation of epoxy polymers: Part 1—Products of thermal degradation of bisphenol-A diglycidyl ether. Polym. Degrad. Stab. 1985, 12, 65–91. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).