1. Introduction

For over 10,000 years, the oldest mortars discovered are in Galilee, located in the modern-day state of Israel, using binders such as aerial lime and gypsum. Mortars using hydraulic lime as a binder were used in Jerusalem cisterns built during the Phoenician era [

1].

In Portugal, at the beginning of the 19th century, the main binder was Portland cement, which replaced hydraulic lime and hydrated lime, due to its reduced curing time, ease of use and storage, and better mechanical behaviour. However, Portland cement performs poorly when applied to old buildings, due to its high stiffness and susceptibility to cracking [

2,

3].

Usually, in old buildings, it is necessary to renovate part or all of the coatings, due to their high state of degradation [

4].

In recent times, and as a result of several studies, hydraulic lime has been seen as a suitable binder for obtaining high-grade coatings for old buildings.

Nanomaterials assume increasingly important roles in civil construction and in the most diverse areas of science [

5]. Recent advances in nanotechnology that break certain limitations existing in construction materials enable products with new functionalities and significant contributions to environmental, sustainable, and rehabilitation issues [

6].

Nanotechnology is considered one of the most promising technologies of the future. The quantum mechanical properties of materials at the nanoscale (less than 100 nanometres) are important for the development of new products and applications. TiO

2 has been one of the most studied by the scientific and industrial community due to its characteristics of surface self-cleaning and purification of some atmospheric pollutants [

7]. Nanofibers with silver and copper are useful for protection against mould in buildings, serving as alternatives to classical methods (spraying biocides and paints) to protect against biological deterioration. Two major advantages ought to be highlighted—their low cost and simple or effortless application. Experimentally excellent results were obtained [

8].

Some proposals refer to photocatalytic coatings with the addition of silver and silica nanoparticles in order to reduce the contamination of microorganisms in buildings [

9].

Fungi are found everywhere, including inside buildings. The genera

Alternaria,

Cladosporium, and

Epicoccum are those that are predominately found in communities in moderate-to-humid climatic zones [

10]. The decline in the quality of both building surfaces and the environment is largely due to the development of fungi on the surface, in cracks, and inside the pores of walls and ceilings.

Most studies analyse and characterise the composition of fungi communities in a simplistic way. Most of the studies refer to old buildings [

11]. In these studies, fungi were collected in various types of materials: cementitious renders, concrete, plaster, plasterboard, etc.

Symptoms such as sore throat, rhinitis, and cough are most common in buildings where there is fungal contamination, especially in damp areas. In addition to the allergic problems mentioned, fungal development also poses aesthetic and hygiene problems.

In a study carried out in Wales, they found that in homes ‘contaminated’ predominantly with

Penicillium and

Cladosporium, 30 to 40% of users suffer from asthma [

12]. Fungi genera such as

Cladosporium,

Penicillium, and

Aspergillus were the ones most frequently detected according to a study carried out in the São Paulo region of Brazil [

13].

There are few data or case studies on fungi development inside buildings; for instance, in Portugal, some studied identified species of fungi in monuments, but outside buildings, as in the study carried out in Sé Catedral de Lamego [

14].

In a study carried out in the towns of Sendim, Vila Real, and Porto in northern Portugal, in houses with walls and ceilings covered with plaster, plasterboard, and tin plaster, fungi of the genera

Aspergillus,

Penicillium,

Cladosporium, and

Alternaria were detected [

15]. The fungus

Cladosporium was collected and used in the investigated samples of this study, as it is considered one of the most ‘aggressive’ (develops and damages materials very fast) fungi.

With current efforts to improve the internal environment of buildings, the use of biocides is the most used solution to remedy and prevent the appearance of mould. Most biocides used with antifungal characteristics are harmful to people, animals, and the environment. Consequently, we need to find biocides with better environmental performance.

For buildings, the complete assessment of their sustainability includes construction, use, maintenance, repair, modernisation, rehabilitation, and finally, dismantling and demolition or recycling. Therefore, life cycle analysis (LCA) in buildings, as it involves many products and companies, becomes a task of considerable complexity. The longer the life cycle, the better. More recent methods of LCA include incorporating economic analysis in their evaluation, which is an important factor for any approach in construction, including sustainable principles. The increase in sustainable alternatives will influence the construction industry [

16]. Inventory analysis can be extremely complex and involve tens or hundreds of unit processes. The more rigorous the LCA methods are, the more data will be needed, leading to large expenses in collecting and updating them.

Some methods aim to simplify LCA for practical use. These methods are not comprehensive, but they play essential roles in making buildings more sustainable.

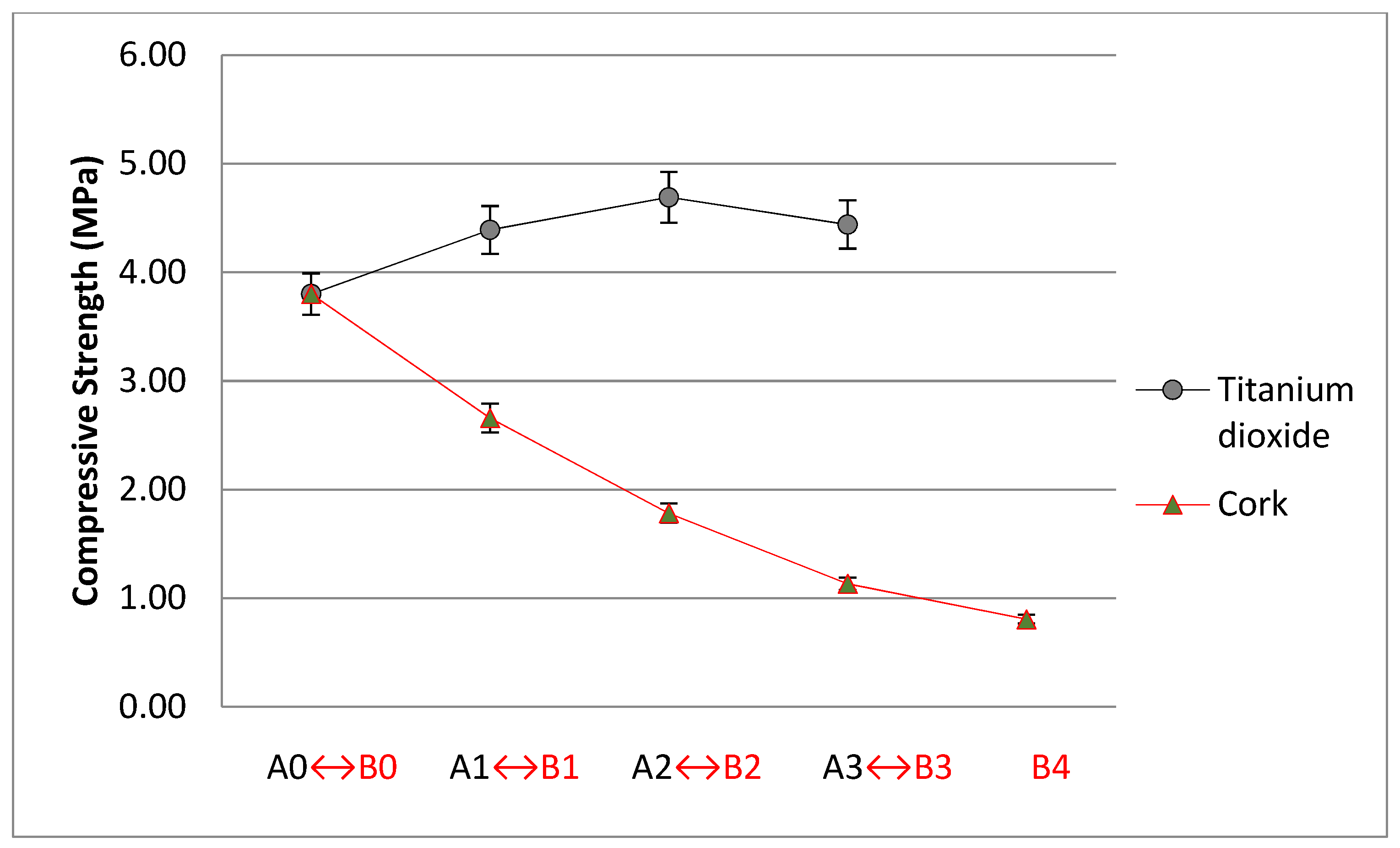

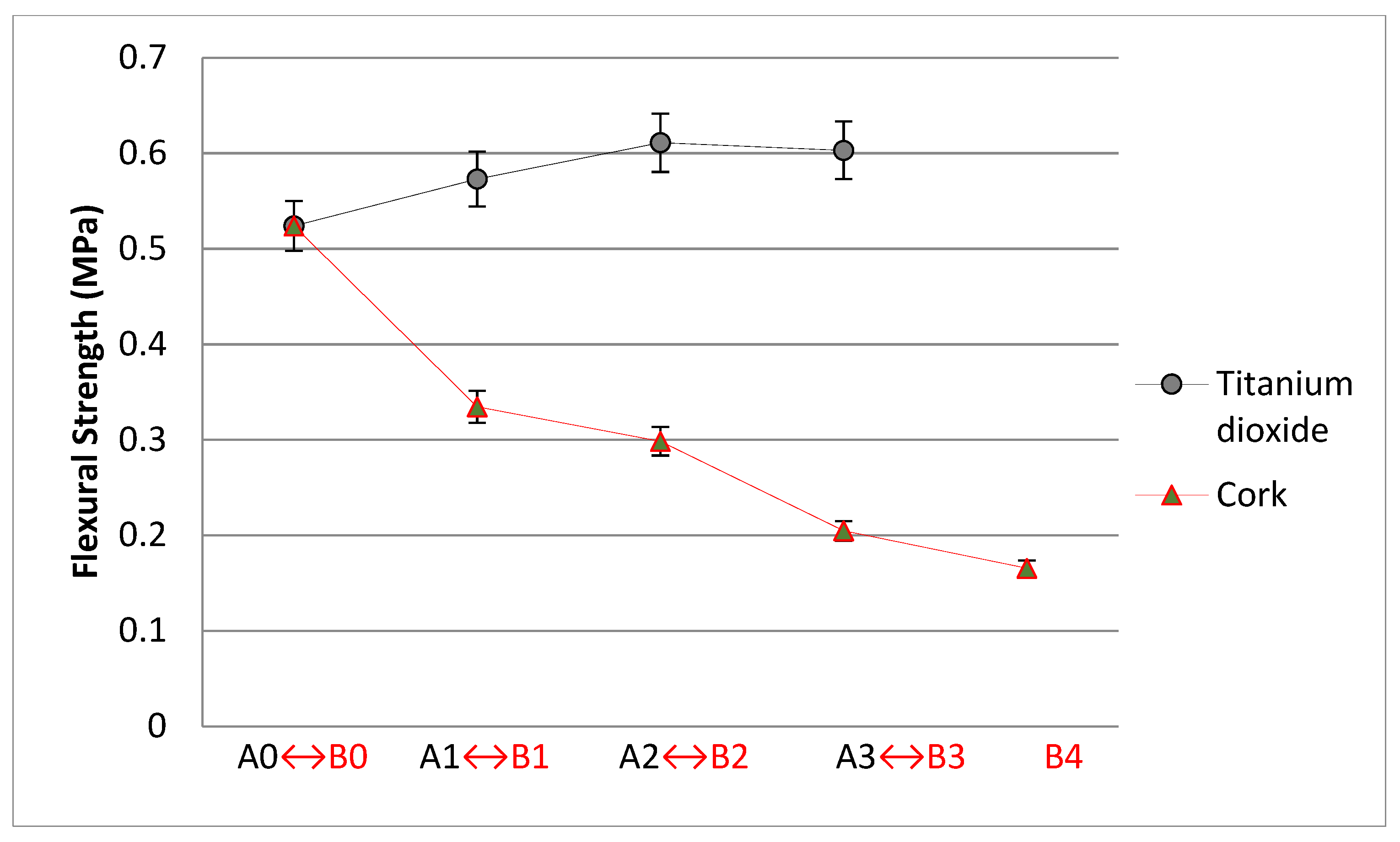

The mechanical and physical properties of mortars for interior coatings of buildings, with additives with TiO

2 and microgranulated cork, were analysed in several studies [

17,

18]. In

Section 2 of this study, the formulations and results of the mechanical tests performed are presented.

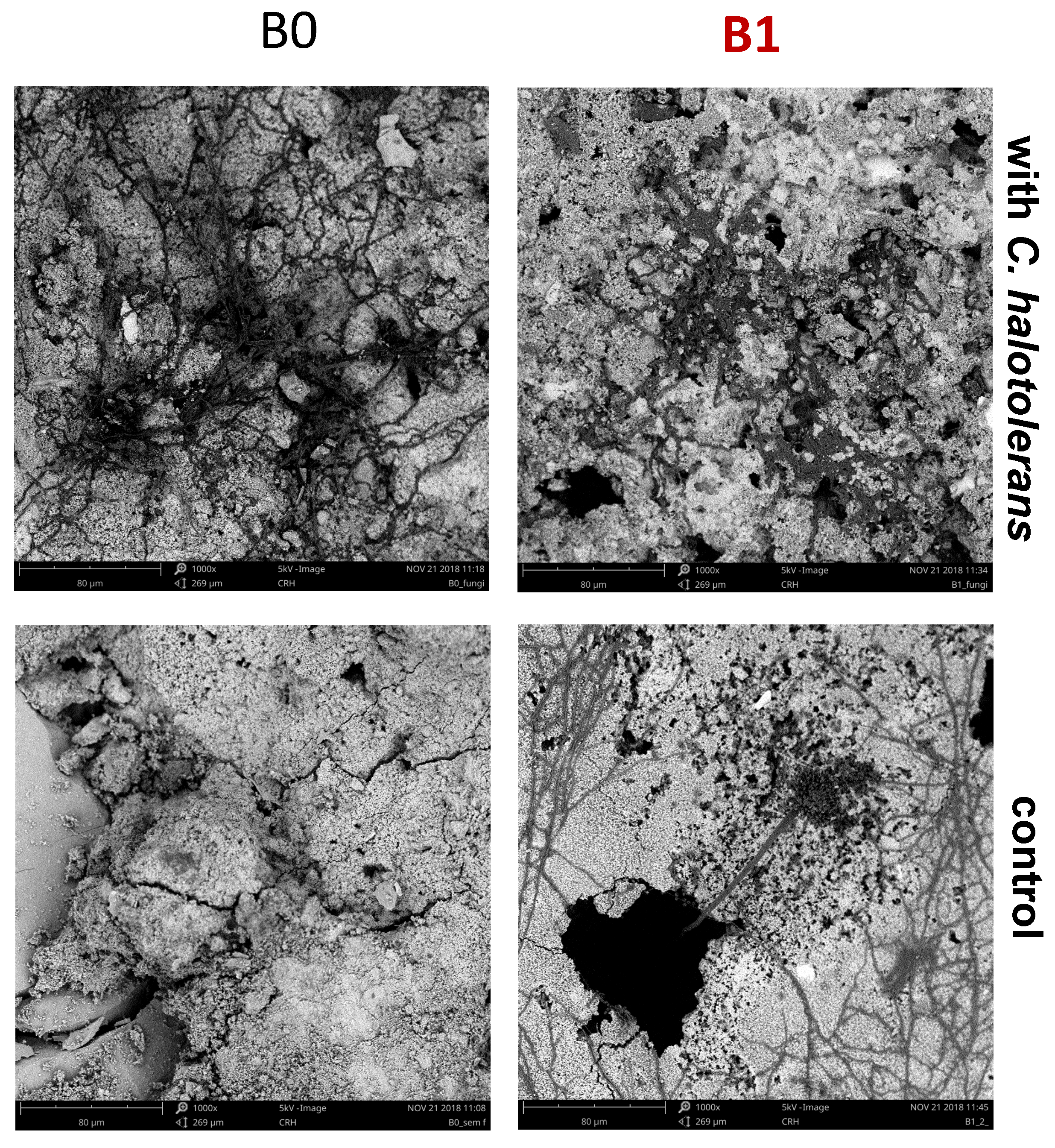

Section 3 summarises and compares the results of microscopic observation of the evolution of fungi in two mortar samples at 118 days. These two sections serve to frame (we do not detail the analyses) the main objective of this study, which is the analysis of the sustainable properties of the mortars presented.

4. Methodology

The novelty of this study is investigating the life cycle analysis (LCA) of nano- and micro-additive mortars in which good antifungal properties have been verified [

17,

18], and to observe if these can help to reduce the ecological footprint in buildings.

To be able to use foreign methodologies for decision-making support and sustainability assessment, it is necessary to make prior adjustments to the parameters, weights, and references. These modifications are indispensable due to the difference that exists in the construction technology and quality standards of the interior environment between Portugal and most European countries.

The methodology for assessing the relative sustainability of construction technologies (MARS-SC) [

22,

23] was used in this study, as it adapts better to the construction method and Portuguese culture. The sustainability categories of environmental, functional, and economic features are the basis of this methodology [

23]. It is a methodology that allows simplifying the analysis and verifying the sustainability of alternative solutions (in this study, mortars with additives) in relation to existing solutions (in this study, mortars without additives).

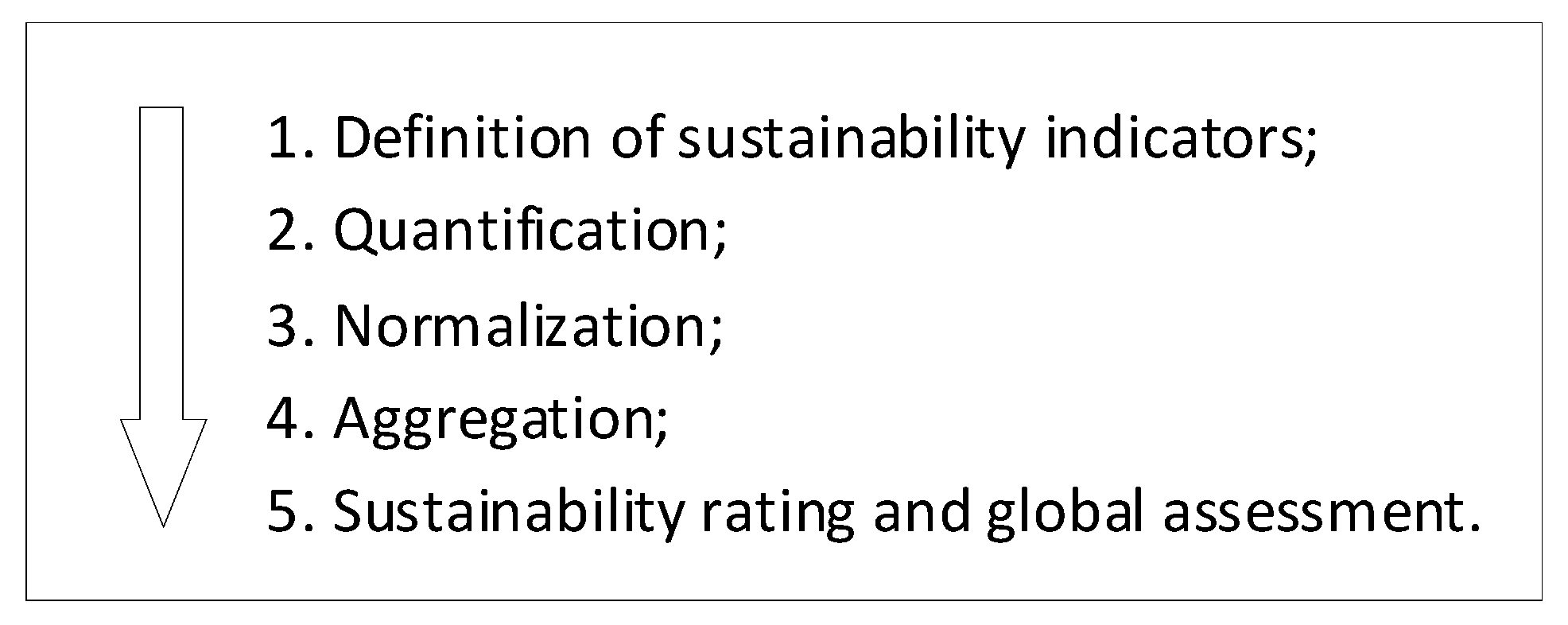

4.1. Functional Units and System Limits

The object of analysis in this study was a hydraulic, lime-based mortar used as an internal coating material. The chosen methodology was MARS-SC because it permits the assessment of different phases of the mortar sample’s life cycle [

22,

23]. As a cradle-to-grave study of mortars has considerable limitations, since the use, recycling, and disposal of mortar result in identical environmental impacts, it was decided to limit this study to the incorporated environmental impacts (cradle to gate) and those arising from transport to the site and its mixture. We used 1 m

3 of mortar as a functional unit. The MARS-SC methodology was processed in five steps (

Figure 6).

Figure 7 displays, in a simplified way, the processes that were included in the LCA analysis and the boundaries of the study. Additionally, we adapted the system to the investigated mortar compositions.

4.2. Inventory Analysis

In this phase, data collection and calculation procedures occurred to quantify system inputs and outputs, which is called the inventory phase. To complete an inventory, it is essential to quantify the emissions associated with the different stages of the life cycle, the raw materials, and energy consumption for the product.

To quantify the sustainability indicators, it is first necessary to develop an inventory analysis [

23]. To quantify inputs (materials, energy, and chemicals) and outputs (e.g., waste) from the adopted product system, an inventory was used according to [

25].

Table 3 shows the data obtained for the material inventory and transport phases considered for the formulation of each mortar.

4.3. Environmental Impact Assessment

With life cycle impact assessment (LCIA) methods, we converted inventory data into environmental impact data.

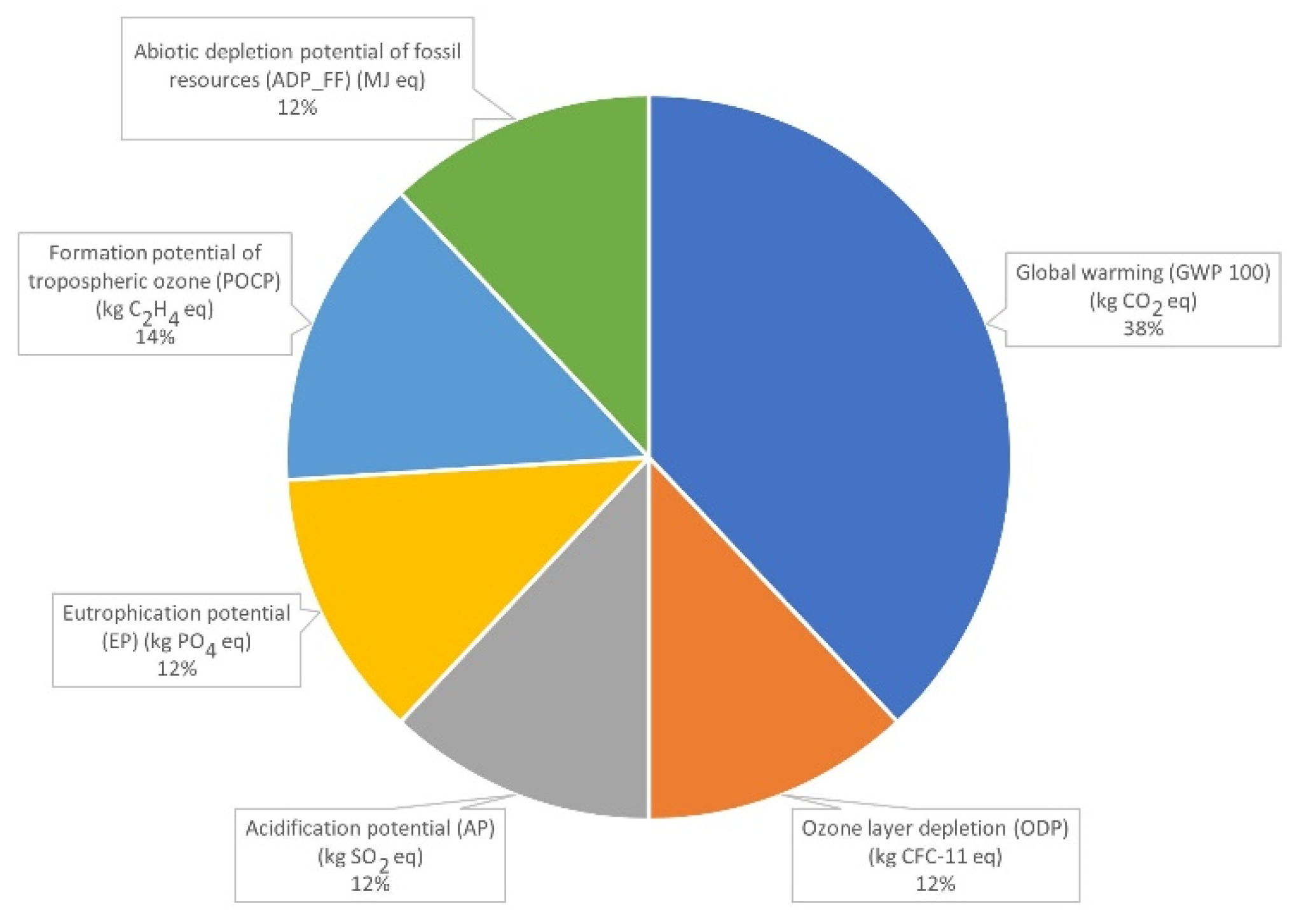

The MARS-SC method subdivides environmental performance into six categories: (i) global warming; (ii) destruction of the ozone layer; (iii) acidification; (iv) eutrophication; (v) tropospheric ozone; (vi) abiotic depletion of fossil resources (

Table 4). The type of product or construction element and the objectives of the study affect the definition of sustainability indicators.

The lifecycle impact methods available in the bibliography and in the open LCA software were used in this study and are described as follows:

- (a)

The method used in CML2 baseline 2000 V3.2 is problem oriented (midpoint in the environmental mechanism). For each problem, there are quantified characterisation factors. An emission identified in the life cycle impact is converted into a contribution to the effect of an environmental problem by multiplying it by an equivalent factor.

- (b)

The cumulative energy demand V1.08 method is a widely used indicator with energy efficiency parameters and screening for the environmental impacts of processes and is used to compare the primary energy demand (energy that has not undergone a transformation process).

4.3.1. Normalisation

To avoid scaling effects in the junction of parameters within each indicator, and to solve the problem of some parameters becoming ‘bigger-is-better’ types, while others ‘smaller-is-better’ types, the parameters were normalised. Normalisation was carried out using [

26] Equation (1).

where

is the ith parameter value.

and

are the best and worst value of the sustainability parameter i among the analysed products. Therefore, the normalisation transforms the values to a reduced scale between 0 (worst value) and 1 (best value), leaving dimensionless indicators [

23].

4.3.2. Aggregation and Global Assessment

Equation (2) allows us to calculate the aggregation of each environmental variable of the indicator and transform it into a general indicator that describes the environmental performance (ND

A).

where

is the normalised indicator within the sustainability for the environmental performance, wi the weight of the ith indicator, and ND

A is the result of aggregation of the environmental performance. The sum of all weights must equal 1 [

23]. For aggregation, this study considered the weights in

Figure 8. The MARS-SC indicates this approach for the Portuguese context, which the large part of the international scientific community in the area follows [

22]. As specific weights are used in the assessment of overall environmental performance, this methodology can be applied in other contexts.

Additionally, known as a sustainable profile, the results are presented on a ‘radar’ diagram. In the ‘radar’ diagram, the number of rays is equal to the number of indicators analysed. The overall performance of each mortar, in each sustainable profile, was monitored and compared with that of the reference mortar.

6. Conclusions

In this study, seven mortars with different dosages of nano-TiO2 and microgranulated cork additives were studied and compared with a simple mortar.

The results displayed that the potential environmental impact of mortar, especially in terms of CO2 emissions, is due to its lime content. Although the results are limited, we can conclude that as these mortars have antifungal properties, their durability will be higher, and therefore, their environmental impact will be much lower than that of a simple mortar. Further, we found that the mortar with the best antifungal performance is A2, and this sample also obtained a good environmental performance.

The best environmental performance is obtained with B1 mortar.

By analysing the mechanical results, we verified that A2 and B1 mortars have good performances and have applicability in construction.

Through this study, we can conclude that nano- and micro-additive mortars with TiO2 and cork obtain better environmental performance than currently used mortars.