3.1. Stratigraphy

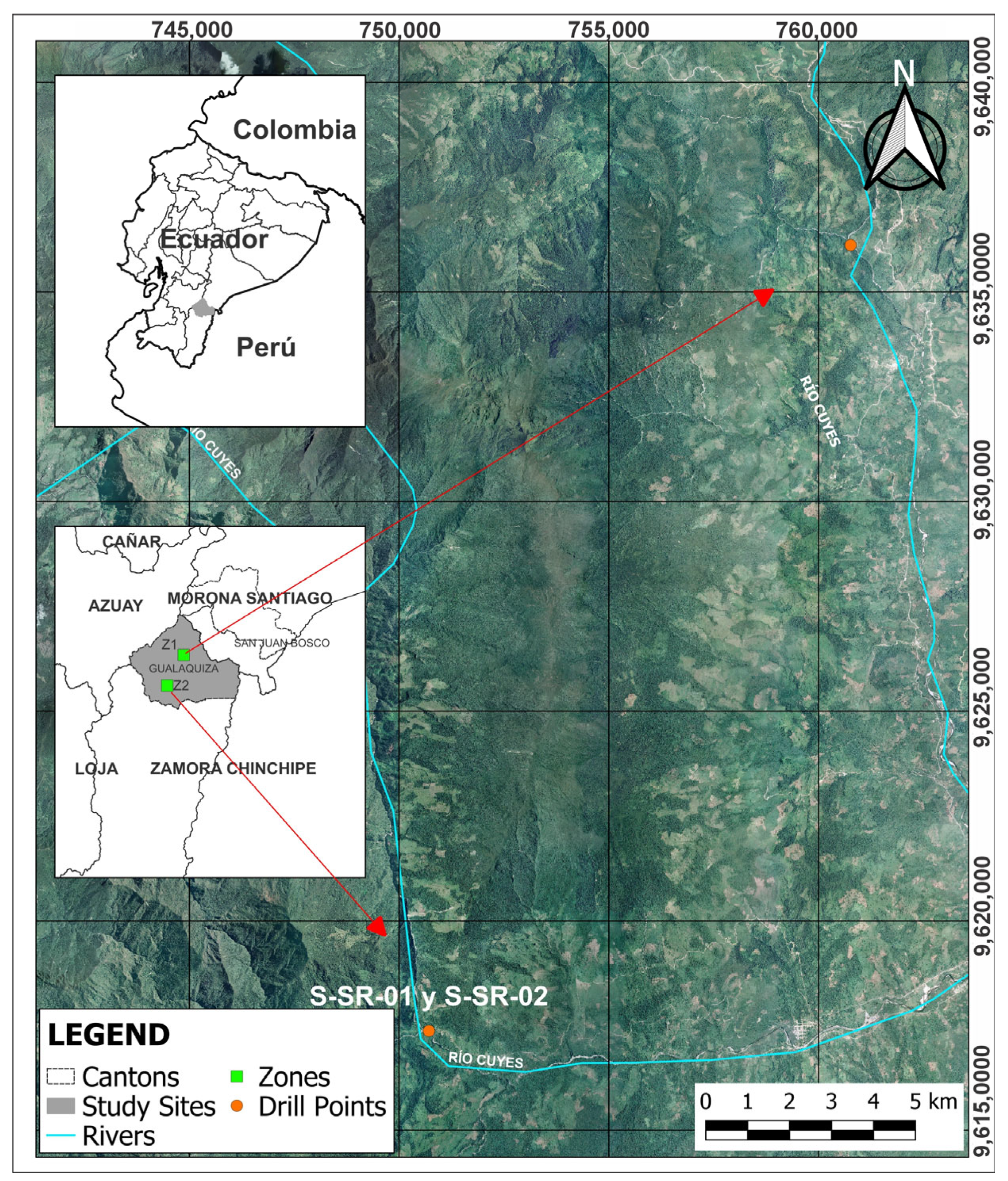

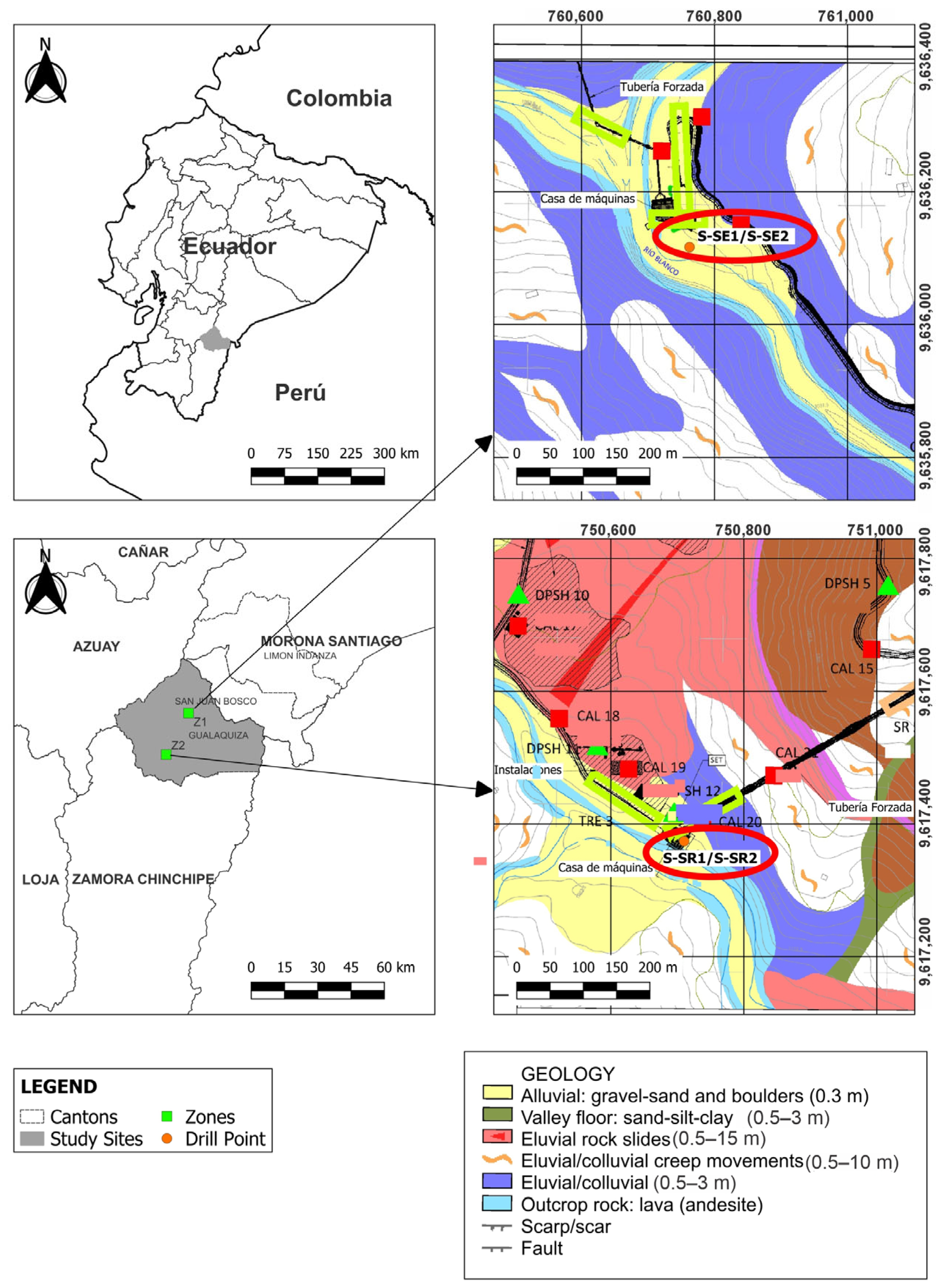

For the characterisation of the obtained drilling cores, a geotechnical logging of the sample boxes was conducted, which allowed for the identification of the lithological and structural characteristics of the materials. In the El Rosario area, intrusive igneous rocks were identified and classified as diorites and granites, while the second borehole predominantly featured volcanic igneous rock, represented by basalt, andesite, and diorite/granite. In the Santa Rosa area, the first borehole revealed a volcanic igneous composition with andesite, diorite/granite, and basalt, followed by a metamorphic rock from the chert subgroup, subsequently accompanied by volcanic igneous rock composed of andesite and basalt, as summarised in

Table 2.

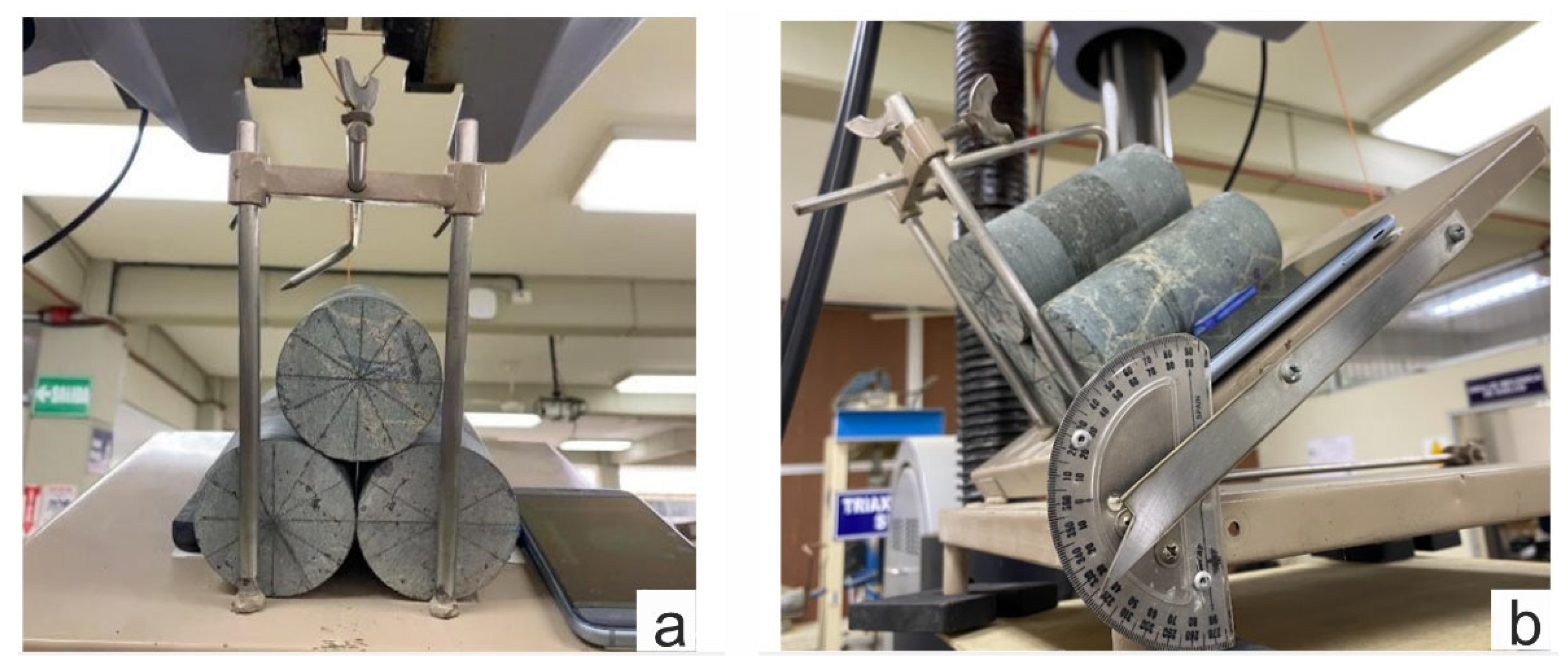

Additionally, the samples for laboratory tests were prepared following the procedures established in specific technical standards. For the unconfined compressive strength test, ASTM D7012-14 standard was followed [

21], which specifies the methods for determining the uniaxial compressive strength and the modulus of elasticity of rocks. In the case of the indirect tensile test or Brazilian test, the ASTM D3967-16 standard was employed [

22], which defines the procedures for measuring tensile strength by applying diametral load. Meanwhile, the point load test was conducted following the guidelines of the ASTM D5731-16 standard [

23], which regulates the determination of the strength of rocks through point loads. Finally, the tilt test, used to determine the basic friction angle between the rocks’ contact surfaces, was conducted per the ASTM C1444-00 standard [

20].

The preparation of the samples included cutting and conditioning the specimens to ensure their compatibility with each test’s geometric and physical requirements. This process maximised the results’ reliability, providing accurate and consistent data for subsequent geotechnical analysis. Compliance with these standards ensures the standardisation of procedures and contributes to the quality and precision of the studies conducted.

3.2. RMR and Q Index

Based on the geomechanical classifications of the RMR and Q index, the following main characteristics of the evaluated rocks were identified. The diorite/granite at a depth of 11.20 m showed an RMR of 96 and a Q index of 96, classifying it as an excellent-quality rock. Meanwhile, the basalt at 17.35 m achieved an RMR of 60 and a Q index of 5.00, indicating good rock quality. In the case of andesite, at a depth of 26.90 m, an RMR of 83 and a Q index of 190.00 were recorded, also classifying it as excellent quality. Finally, the samples of diorite/granite at 8.90 m exhibited significantly lower values, with an RMR of 23 and a Q index of 0.03, indicating low quality due to discontinuities and alterations.

The results obtained for the El Rosario area are presented in

Table 3. These values were obtained from boreholes, not outcrops.

The following results were obtained in Santa Rosa, as shown in

Table 4.

Different quality levels were identified in the analysis of the obtained samples according to the RMR and Q index values. The samples with excellent quality, those with a Q index above 10 or an RMR greater than 80, include cases such as sample S-SR-02 at a depth of 20.20 m, which presented a Q index of 12.17 and an unspecified RMR, classifying it as good quality. Simultaneously, another measurement yielded an RMR of 73 and a similarly high Q index of 12.17, placing it in the excellent-quality category. Additionally, sample S-SR-01 at a depth of 24.30 m showed a Q index of 7.78, indicating very high quality.

Regarding igneous rocks, such as diorite/granite and andesite, high RMR and Q index values were observed, as in the case of granite at 11.20 m, with an RMR of 96 and a Q index of 190. These characteristics reflect high strength and low fracturing, classifying them as excellent-quality rocks. On the other hand, igneous rocks like basalt and andesite, with RMR values of between 50 and 80 and Q indices of between 1 and 10, are considered good quality. A representative example is sample S-SE-02 at 26.00 m, which presented a Q index of 26.00, confirming its good mechanical behaviour.

Finally, metamorphic rocks, such as chert, exhibited the lowest RMR and Q index values, as seen in the sample at 15.20 m, which recorded an RMR of 4.56 and a Q index of 0.74. This indicates lower strength and greater susceptibility to fracturing, classifying them as low-quality rocks.

3.3. Unconfined Compression

The unconfined compression test was conducted to determine the uniaxial compressive strength (UCS) of different lithologies in the study areas of “El Rosario” and “Santa Rosa”.

The results, organised in

Table 5, show that the intrusive rocks of diorite/granite exhibited a strength that varied between 89.3 MPa and 125.8 MPa, indicating that they are strong rocks, with average applied loads ranging from 279.8 kN to 393.0 kN. On the other hand, the basalt, with a strength exceeding 120 MPa and an average of 131.7 MPa, was classified as a high-strength rock, demonstrating consistency in the quality of the samples, with an average load of 412.0 kN. Andesite exhibited a more variable strength, fluctuating between 41.4 MPa and 90.4 MPa, which classifies it as moderately resistant, with average applied loads reaching up to 250.0 kN. Finally, the metamorphic rock chert had an average compressive strength of 80.1 MPa, with an average load of 251.7 kN, reflecting moderate strength compared to igneous rocks.

In this case, igneous rocks, especially basalt and diorite/granite, are suitable for structural applications in hydropower projects. At the same time, andesite and chert exhibit lower strengths, suggesting the need to consider their behaviour in the design of geotechnical infrastructures, thereby ensuring the stability and viability of projects in the areas above.

Figure 8 shows the variation in RCS values (in MPa) per sample, according to the rock type and its lithological subgroup. The purple line represents the individual values obtained for each sample. Additionally, three reference lines are indicated: the overall average RCS (75.25 MPa), the maximum limit (110.46 MPa), and the minimum limit (40.03 MPa).

The results show a wide dispersion of values, with some significantly exceeding the maximum limit (notably in the diorite/granite and basalt samples). In contrast, others fall below the minimum limit, particularly in the andesite samples at greater depths. These variations reflect the rock mass’s heterogeneity and the rock type’s influence on mechanical strength.

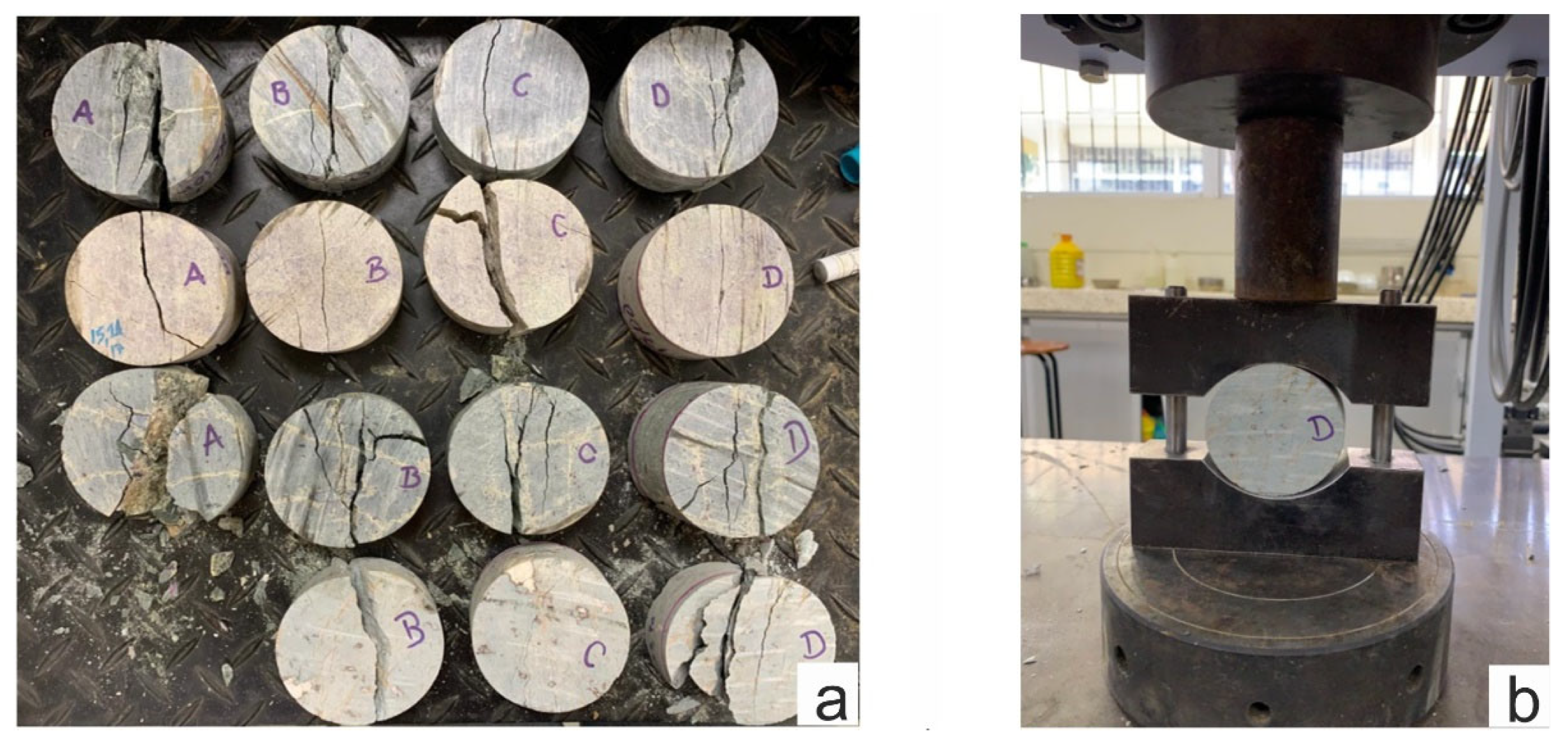

3.4. Brazilian Indirect Traction

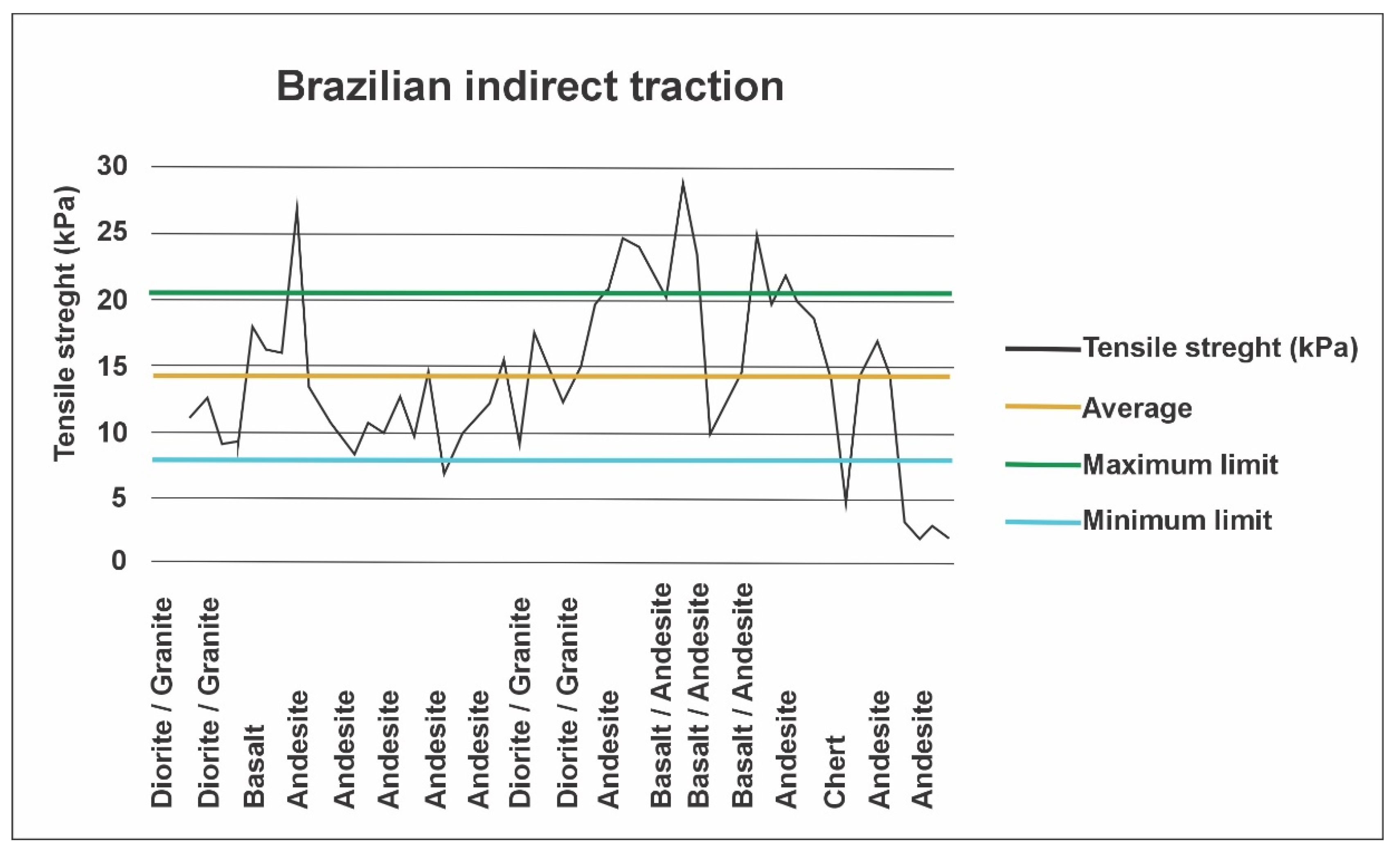

The indirect tensile test, known as the Brazilian test, was conducted to assess the tensile strength of various lithologies in the study areas “El Rosario” and “Santa Rosa”. The results obtained are described below (

Table 6). For diorite/granite, which is an intrusive igneous rock, an average load of 30.5 kN was recorded, with a standard deviation of 4.3 kN. The average stress obtained was 10.9 kPa, with a standard deviation of 1.2 kPa, indicating an average tensile strength. In the case of basalt, a volcanic igneous rock, a significantly higher average load was observed, reaching 57.3 kN, with a standard deviation of 13.9 kN. The average stress was 21.7 kPa, with a standard deviation of 4.8 kPa, suggesting a high tensile strength. Andesite, also a volcanic igneous rock, exhibited an average load of 31.3 kN, with a standard deviation of 6.2 kN. Its average stress was 10.5 kPa, with a standard deviation of 2.02 kPa, reflecting a lower tensile strength than basalt. Chert, a metamorphic rock, recorded an average load of 34.8 kN, with a standard deviation of 12.3 kN. Its average stress was 11.8 kPa, with a standard deviation of 4.91 kPa, indicating a moderate tensile strength. The results of the Brazilian test show that basalt had the highest tensile strength, followed by chert, diorite/granite, and, finally, andesite, which had the lowest stress values.

Figure 9 shows the indirect tensile strength of different lithologies, highlighting the considerable variability between samples. Basalt exhibited the highest values, in several cases exceeding the upper limit of 20.50 kPa, indicating its strong mechanical capacity. In contrast, chert showed the lowest values, falling below the minimum limit of 7.84 kPa, reflecting its brittleness. Andesite and diorite/granite displayed intermediate behaviour, with results mostly falling within the acceptable range. Overall, lithology significantly influences strength, making it a key factor in geotechnical analysis.

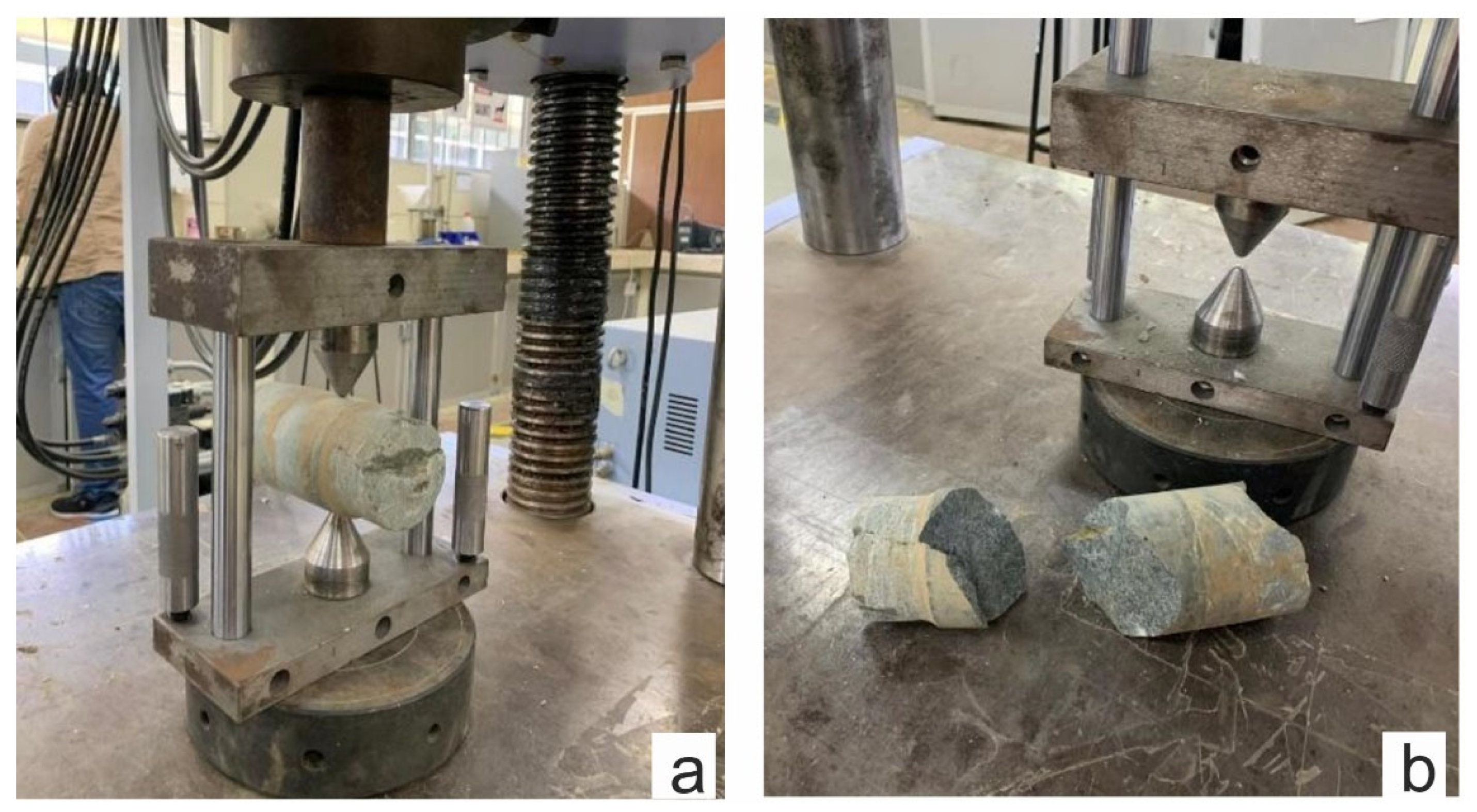

3.5. Point Load Test (PLT)

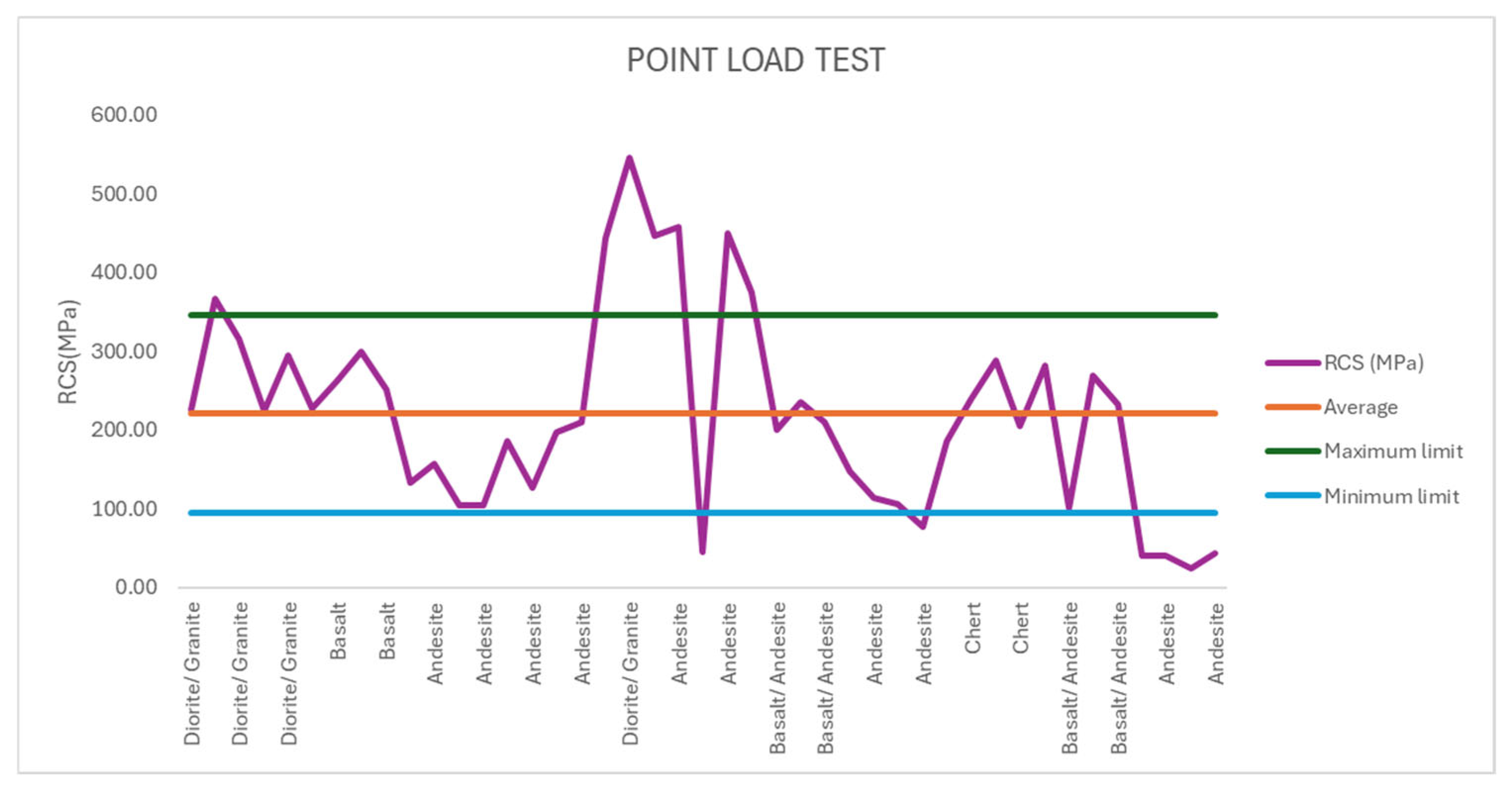

The point load test was conducted on various rock samples to determine their compressive strength. The results (

Table 7) are expressed in terms of Is (point load strength) in megapascals (MPa) and the corrected strength Is(50) at a standard load of 50 mm. For the diorite/granite samples, two depths were recorded in borehole S-SE-01. At a depth of 5.30 m, the Is value was 9.2 MPa, with a correction factor of 1.11, resulting in a corrected strength Is(50) of 225.2 MPa. At 6.20 m, an increase in strength was observed, with Is reaching 18.1 MPa and Is(50) attaining 443.3 MPa. For basalt, also in borehole S-SE-01, two depths were recorded. At 7.60 m, the Is value was 10.75 MPa, which, with the same correction factor of 1.1, resulted in an Is(50) of 263.3 MPa. At 8.00 m, the Is value increased to 11.0 MPa, yielding an Is(50) of 300.1 MPa. Regarding andesite, in borehole S-SE-02, at a depth of 5.30 m, the Is value was 4.2 MPa, with a corresponding Is(50) of 103.64 MPa, using the same correction factor. At 10.50 m, the Is value increased to 11.52 MPa, resulting in an Is(50) of 285.2 MPa. For chert, in borehole S-SE-02, at a depth of 15.20 m, an Is value of 9.7 MPa was recorded, which, with the correction factor of 1.11, resulted in an Is(50) of 238.4 MPa. The diorite/granite samples exhibited high compressive strength, with Is values ranging between 9.19 MPa and 18.10 MPa, and corrected strengths reaching up to 443.3 MPa. Basalt also demonstrated a good load-bearing capacity, with Is values of between 10.7 MPa and 11.0 MPa. Andesite showed Is values of 4.2 MPa to 11.5 MPa, indicating moderate strength. Chert exhibited relatively lower strength than the igneous rocks, with an Is of 9.7 MPa.

These results highlight variations in the compressive strength of the different lithologies analysed, providing valuable information for the geotechnical assessment of the rocks in the study areas.

Figure 10 shows values for various rock samples, compared with the maximum (346.25 MPa), minimum (94.98 MPa), and average (220.62 MPa) limits. Some samples, especially diorite/granite and andesite, exceeded the maximum limit, while others, mostly andesite, were below the minimum.

3.6. Tilt Test

The tilt test results table (

Table 8) presents the basic friction angle (

φb°) obtained for various rock samples, with measurements taken at six different inclinations for each sample (1 to 6) and the final average for each case.

Intrusive Igneous (Diorite/Granite):

The friction angles ranged between 32° and 36°, with an average of 33.4°.

This rock exhibited a relatively high basic friction, indicating good stability under inclined conditions.

Volcanic Igneous (Basalt):

The friction angles ranged from 30° to 33°, with an average of 31.7°.

Although the friction was slightly lower than that of diorite/granite, it remained stable for structural applications.

Andesite:

In the first sample (26.90–28.50 m), the friction values ranged from 26° to 32°, with an average of 30.4°.

In the second sample (24.00–26.00 m), the friction angle remained constant at 35°, indicating good stability.

In the third sample (28.00–30.00 m), friction was also constant at 35°.

Metamorphic Rock (Chert):

Friction values ranged from 29° to 34°, with an average of 31.1°.

This rock exhibited moderate friction, suggesting reasonable but not exceptional stability.

The most critical value corresponds to the diorite/granite sample (S-SR-01, 5.00–6.20 m), where the friction angle dropped to 13–21°, with an average of 18.6°, and a minimum value of as low as 13°. This result suggests that the rock has low frictional resistance, which could lead to potential stability issues.