Mathematical Modeling of the Rail Track Superstructure–Subgrade System

Abstract

1. Introduction

- Quasi-static analytical calculations, which provide compact analytical expressions for evaluating stresses and deflections;

- Multi-body dynamics models based on the Lagrange–D’Alembert equations, describing the interaction between rolling stock and infrastructure;

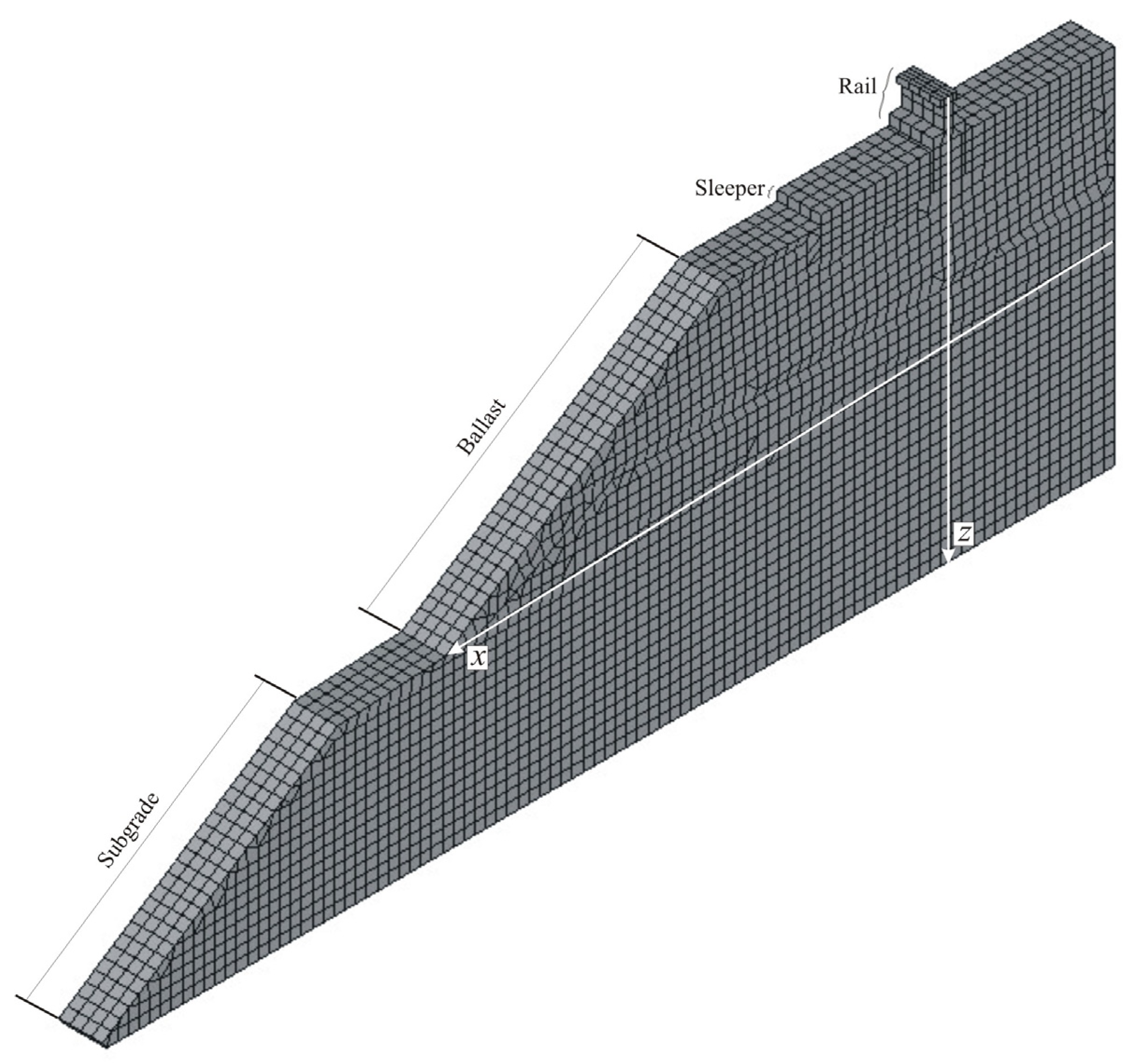

- The finite element method (FEM) in a static form, used for analyzing the stress–strain state of structures under given static loads;

- FEM in a dynamic form, which accounts for inertial effects, damping, and the cyclic nature of loads;

- Wave propagation-based models (wave theory), applied to the analysis of vibration processes, wave propagation in ballast and subgrade, and resonance effects.

2. Main Classes of Mathematical Models and Their Methods

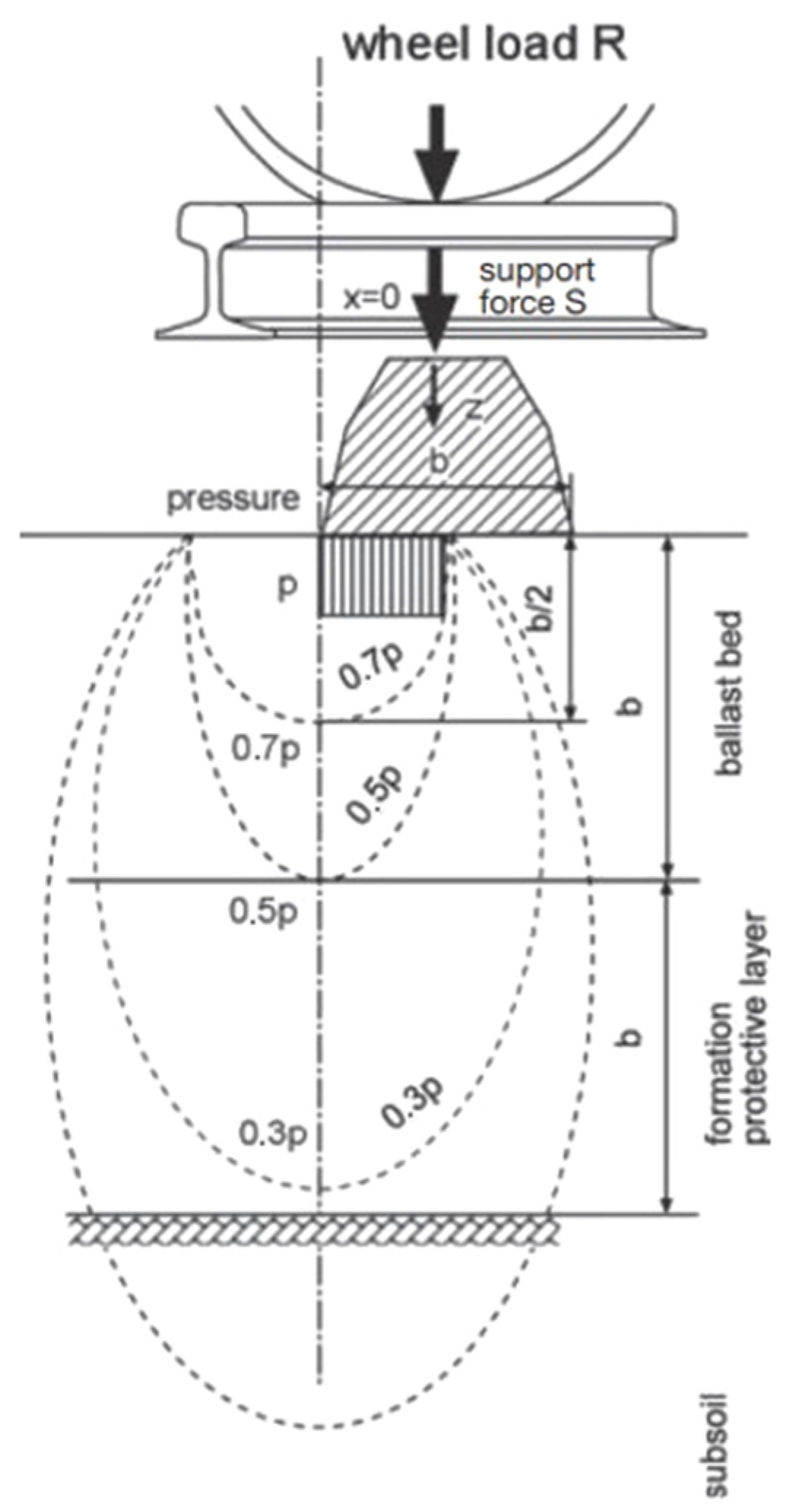

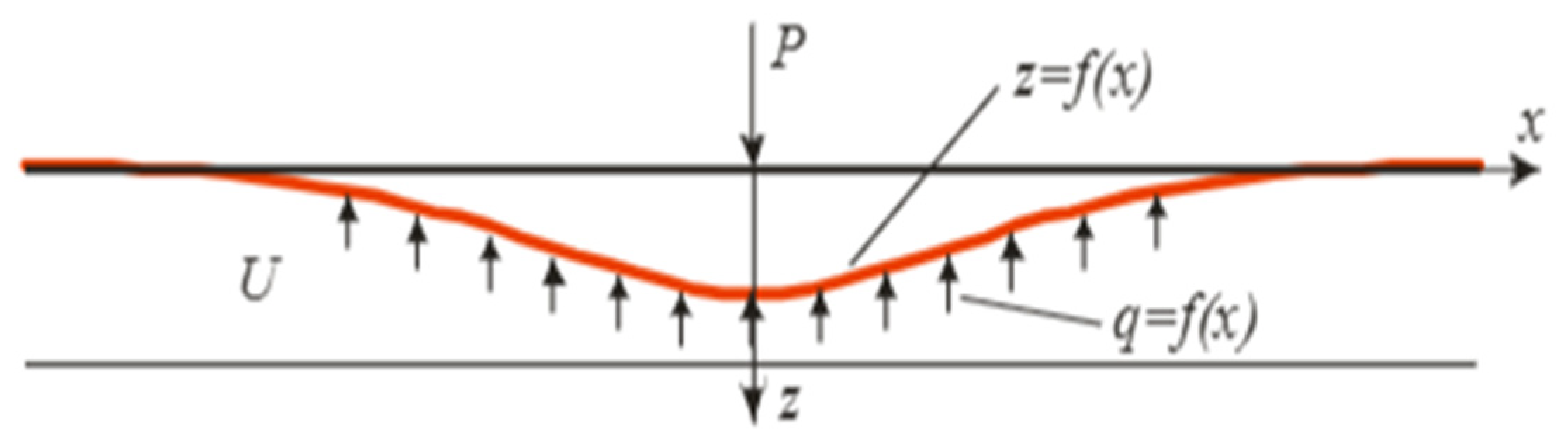

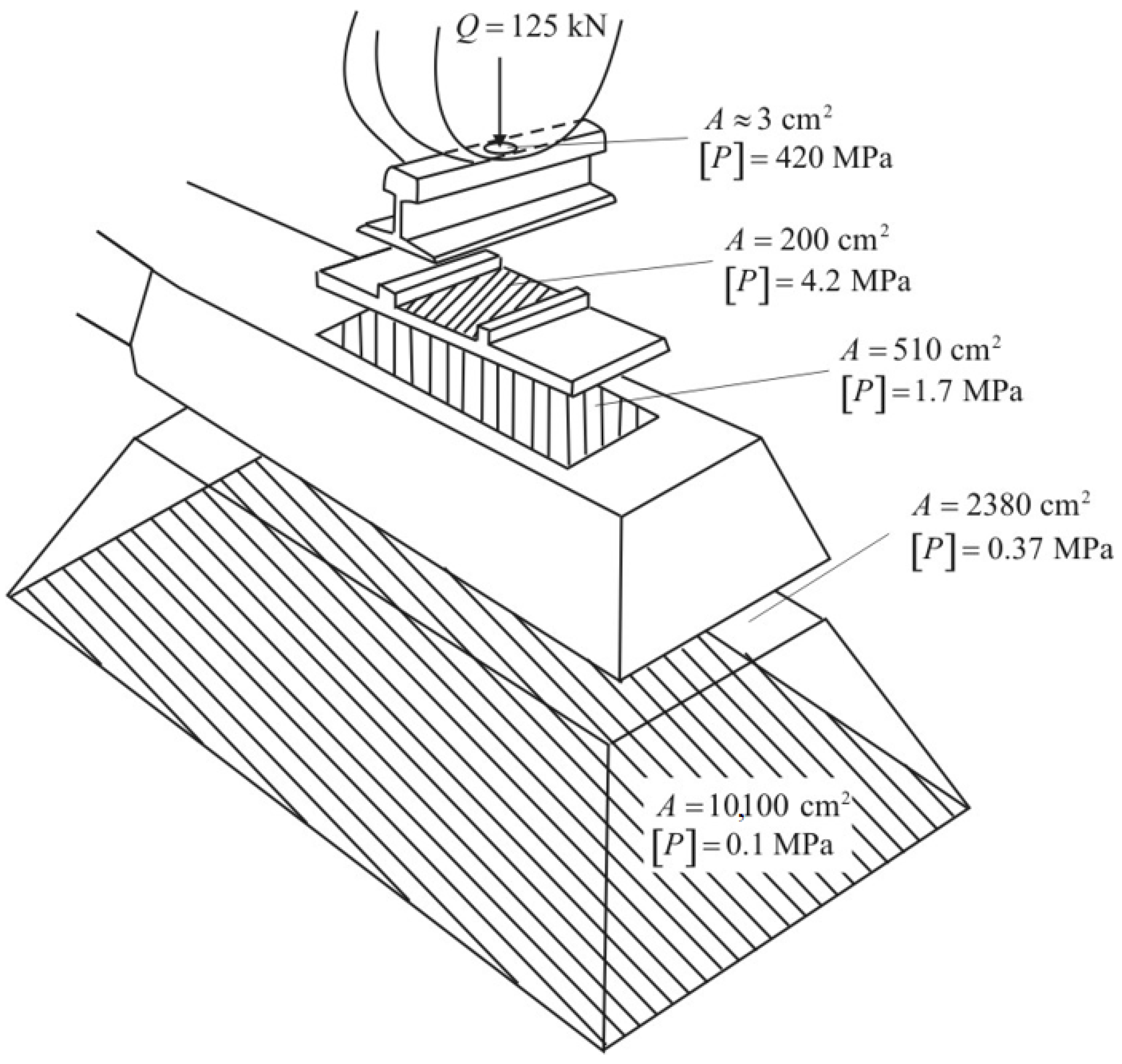

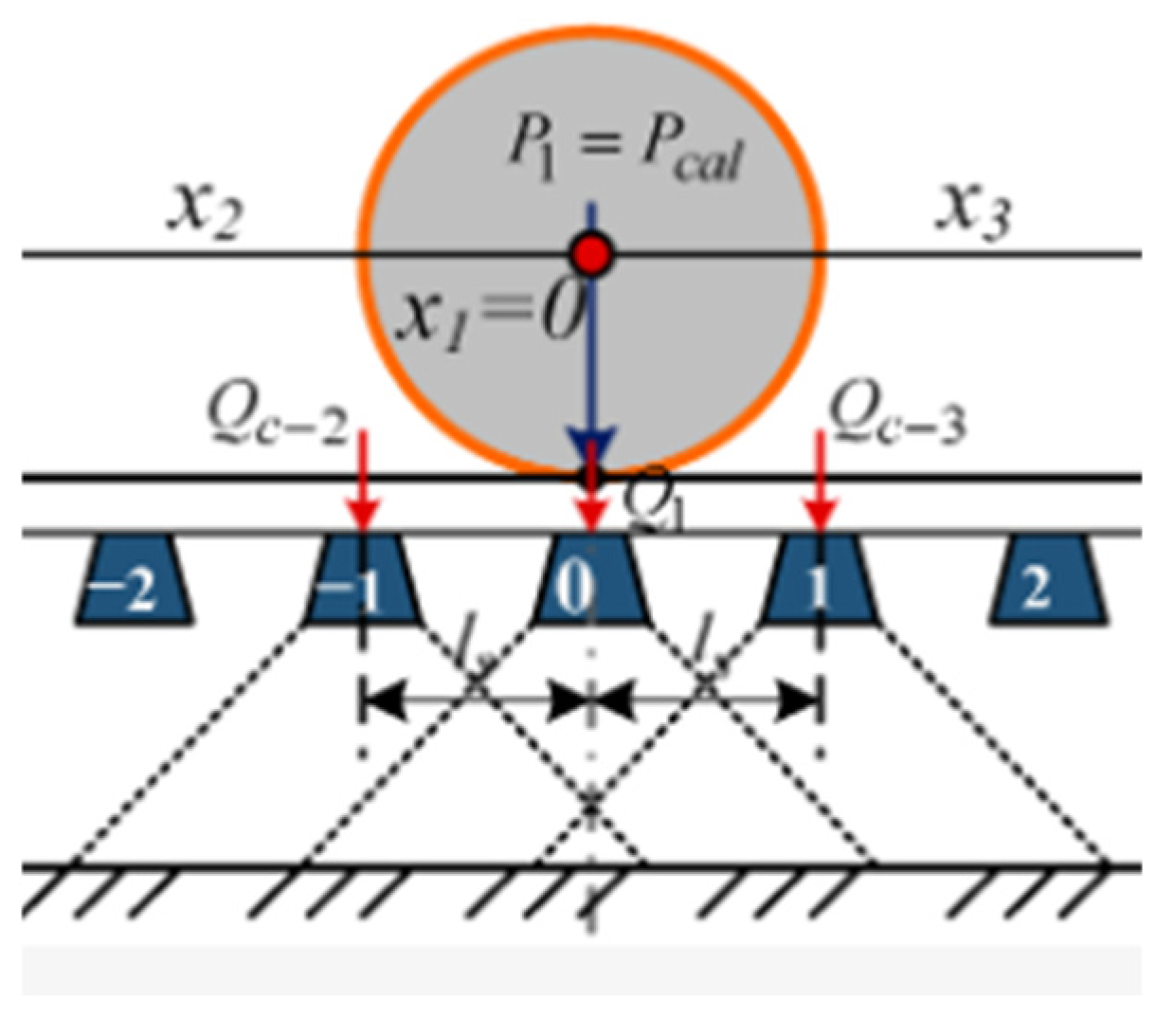

2.1. Quasi-Static Design Method

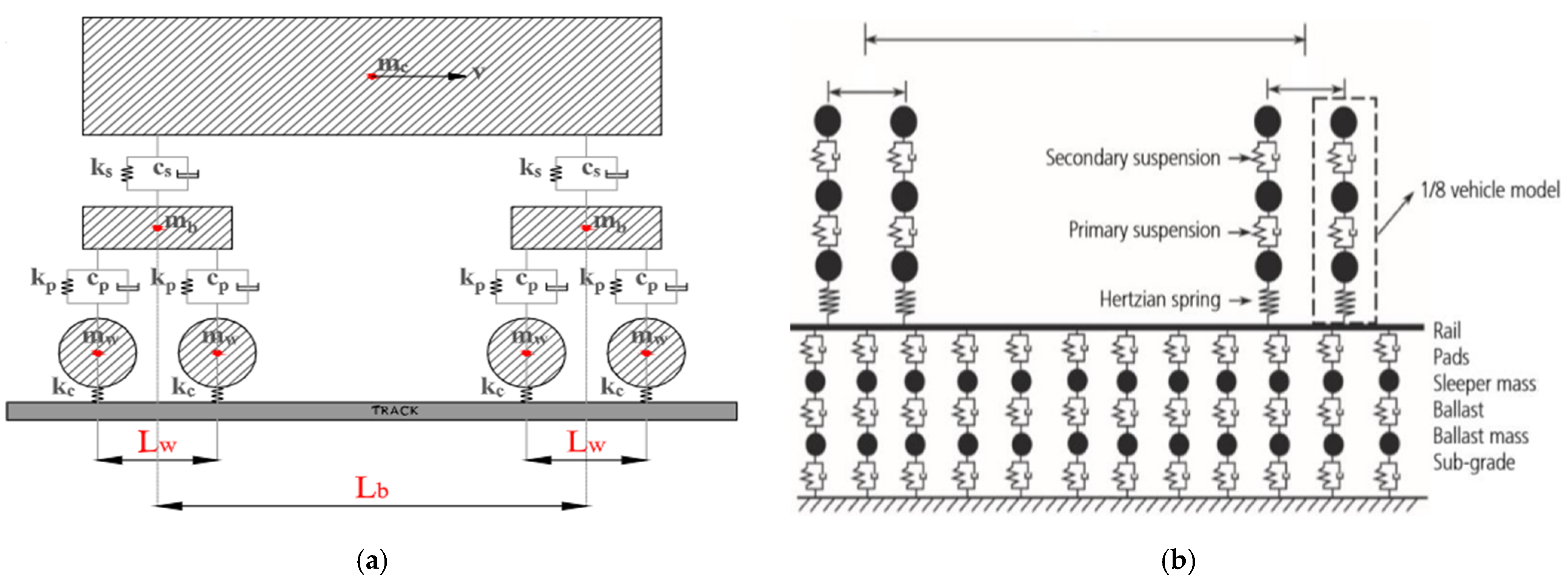

2.2. Mathematical Models of Multibody Dynamics (MBD)

2.3. Finite Element Method (FEM) in Static Analysis of Railway Track

2.4. Finite Element Method (FEM) in Dynamic Analysis of Railway Track

2.5. Wave Propagation-Based Models in Railway Track Analysis

3. Implementation of External Loading in the Models

- Static loading is used when the force changes slowly over time, allowing the inertial effects to be neglected. This approach is often applied to assess the load-bearing capacity of the subgrade and ballast layer under rolling stock loads.

- Quasi-static methods are employed when train speed or other factors lead to variations in the actual wheel–rail load compared to the static case. In this case, the force is represented as a combination of static and dynamic components. The dynamic component is typically introduced using the root mean square (RMS) deviation of real load fluctuations, with a specified probability threshold for the upper limit.

4. Implementation of Granular Material Behavior (Ballast and Subgrade) in the Models

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aela, P.; Powrie, W.; Harkness, J.; Jing, G. Discrete Element Modelling of Railway Ballast Problems: An Overview. Arch Comput. Methods Eng 2024. [Google Scholar] [CrossRef]

- Bosso, N.; Magelli, M.; Zampieri, N. Simulation of wheel and rail profile wear: A review of numerical models. Rail. Eng. Sci. 2022, 30, 403–436. [Google Scholar] [CrossRef]

- Ehrhart, U.; Knabl, D.; Marschnig, S. Track Deterioration Model—State of the Art and Research Potentials. Infrastructures 2024, 9, 86. [Google Scholar] [CrossRef]

- Rempelos, G.; Ognibene, G.; Le Pen, L.; Blainey, S.; Preston, j.; Powrie, W. Railway Track Deterioration Models: A Review of the State of the Art. Transp. Geotech. 2024, 49, 101377. [Google Scholar] [CrossRef]

- Feng, Y.T. Thirty years of developments in contact modelling of non-spherical particles in DEM: A selective review. Acta Mech. Sin. 2023, 39, 722343. [Google Scholar] [CrossRef]

- Kildashti, K.; Dong, K.; Yu, A. Contact force models for non-spherical particles with different surface properties: A review. Powder Technol. 2023, 418, 118323. [Google Scholar] [CrossRef]

- Indraratna, B.; Sajjad, M.B.; Ngo, T.; Correia, A.G.; Kelly, R. Improved performance of ballasted tracks at transition zones: A review of experimental and modelling approaches. Transp. Geotech. 2019, 21, 100260. [Google Scholar] [CrossRef]

- Major, Z.; Németh, A.; Jóvér, V.; Liegner, N.; Fischer, S. Dynamic Modeling Possibilities of Embedded Rail Structures. Acta Polytech. Hung. 2025, 22, 29–43. [Google Scholar] [CrossRef]

- Kurhan, D.; Kurhan, M.; Horváth, B.; Fischer, S. Determining the Deformation Characteristics of Railway Ballast by Mathematical Modeling of Elastic Wave Propagation. Appl. Mech. 2023, 4, 803–815. [Google Scholar] [CrossRef]

- Tran, L.-H.; Hoang, T.; Duhamel, D.; Foret, G.; Messad, S.; Loaec, A. A Fast Analytic Method to Calculate the Dynamic Response of Railways Sleepers. J. Vib. Acoust. 2019, 141, 11005. [Google Scholar] [CrossRef]

- Bettaieb, H. Analytical dynamic and quasi-static model of railway vehicle transit to curved track. Mécanique Ind. 2012, 13, 231–244. [Google Scholar] [CrossRef]

- Ciotlaus, M.; Kollo, G.; Fenesan, C.; Danciu, A.D.; Dragomir, M.L.; Marusceac, V. Rail Wear Evolution on Small-Radius Curves under Mixed Traffic Conditions, In-Field Investigations. Appl. Sci. 2024, 14, 29. [Google Scholar] [CrossRef]

- Gia, K.N.; Ruigómez, J.M.G.; Castillo, F.G. Influence of rail track properties on vehicle–track responses. Proc. Inst. Civ. Eng.-Transp. 2015, 168, 499–509. [Google Scholar] [CrossRef]

- de Melo, A.L.O.; Kaewunruen, S.; Papaelias, M. Parameters and Boundary Conditions in Modelling the Track Deterioration in a Railway System. IOP Conf. Ser. Mater. Sci. Eng. 2019, 603, 032084. [Google Scholar] [CrossRef]

- Kurhan, D.; Leibuk, Y. Research of the Reduced Mass of the Railway Track. Acta Tech. Jaurinensis 2020, 13, 341. [Google Scholar] [CrossRef]

- Jain, A.; Metrikine, A.V.; Steenbergen, M.J.M.M.; van Dalen, K.N. Design of railway transition zones: A novel energy-based criterion. Transp. Geotech. 2024, 46, 101223. [Google Scholar] [CrossRef]

- Jain, A.; Metrikine, A.V.; Steenbergen, M.J.M.M.; van Dalen, K.N. Railway Transition Zones: Energy Evaluation of a Novel Transition Structure for Critical Loading Conditions. Vib. Eng. Technol. 2025, 13, 15. [Google Scholar] [CrossRef]

- Muradian, L.; Shvets, A.; Shvets, A. Influence of wagon body flexural deformation on the indicators of interaction with the railroad track. Arch. Appl. Mech. 2024, 94, 2201–2216. [Google Scholar] [CrossRef]

- Muradian, L.; Shvets, A.; Shvets, A. Some dynamic processes at longitudinally-transverse shift of the cargo. Sci. J. Silesian Univ. Technol. Ser. Transp. 2023, 120, 187–204. [Google Scholar] [CrossRef]

- Fologea, D.; Mazilu, T.; Gheți, M.-A.; Apostol, I.-I. Parametric Study on the Effect of Rail Dampers on Track Decay Rate. Appl. Sci. 2024, 14, 9541. [Google Scholar] [CrossRef]

- Mazilu, T.; Dumitriu, M.; Răcănel, I.-R. Parametric Study of the Influence of Nonlinear Elastic Characteristics of Rail Pads on Wheel–Rail Vibrations. Materials 2023, 16, 1531. [Google Scholar] [CrossRef]

- Tiutkin, O.; Kurhan, M.; Kurhan, M.; Miroshnyk, V. Numerical Analysis of Stabilization Schemes for the Deformed State of Railway Embankment Using Piles. Acta Polytech. Hung. 2025, 22, 213–226. [Google Scholar] [CrossRef]

- Alkhdour, A.; Tiutkin, O.; Fischer, S.; Kurhan, D. An Analytical Method for Determining the Stress–Strain State of a Subgrade with Combined Reinforcement. Infrastructures 2024, 9, 240. [Google Scholar] [CrossRef]

- Andrieiev, V.; Tiutkin, O.; Hubar, O.; Mukhina, N. Results of the Analysis of Reinforcing Structures Performance When Strengthening Subgrade Slopes. Transp. Means 2024, 2024, 678–684. [Google Scholar] [CrossRef]

- Guo, Q.; Li, B.; Ye, Z.; Xu, J. Finite Element Analysis on the Behavior of Solidified Soil Embankments on Piled Foundations under Dynamic Traffic Loads. Appl. Sci. 2024, 14, 4464. [Google Scholar] [CrossRef]

- Alsirawan, R.; Koch, E.; Alnmr, A. Proposed Method for the Design of Geosynthetic-Reinforced Pile-Supported (GRPS) Embankments. Sustainability 2023, 15, 6196. [Google Scholar] [CrossRef]

- Petrenko, V.; Bannikov, D.; Kharchenko, V.; Tkach, T. Regularities of the deformed state of the geotechnical system “soil base—Micropile”. IOP Conf. Ser. Earth Environ. Sci. 2022, 970, 12028. [Google Scholar] [CrossRef]

- Alsirawan, R.; Koch, E. Dynamic analysis of geosynthetic-reinforced pile-supported embankment for a high-speed rail. Acta Polytech. Hung. 2023, 21, 31–50. [Google Scholar] [CrossRef]

- Eller, B.; Fischer, S. Application of concrete canvas for enhancing railway substructure performance under static and dynamic loads. Facta Univ. Ser. Mech. Eng. 2025, 23, 13326. [Google Scholar] [CrossRef]

- Farooq, M.A.; Meena, N.K.; Punetha, P.; Nimbalkar, S.; Lam, N. Experimental and computational analyses of sustainable approaches in railways. Infrastructures 2024, 9, 53. [Google Scholar] [CrossRef]

- Desbrousses, R.L.E.; Meguid, M.A. Effect of Subgrade Compressibility on the Reinforcing Performance of Railroad Geogrids: Insights from Finite Element Analysis. The Canadian Geotechnical Society. 2022. Available online: https://www.researchgate.net/publication/364242857 (accessed on 14 February 2025).

- Ngo, T.; Hasan, M. Finite element modelling of geogrids reinforced ballasted tracks. Transp. Infrastruct. Geotech. 2024, 11, 2425–2447. [Google Scholar] [CrossRef]

- Alsirawan, R.; Koch, E. The finite element modeling of rigid inclusion-supported embankment. Pollack Period. 2022, 17, 86–91. [Google Scholar] [CrossRef]

- Jankowski, W.; Sołkowski, J. The modelling of railway subgrade strengthening foundation on weak soils. Open Eng. 2022, 12, 539–554. [Google Scholar] [CrossRef]

- Xu, F.; Yang, Q.; Liu, W.; Leng, W.; Nie, R.; Mei, H. Dynamic stress of subgrade bed layers subjected to train vehicles with large axle loads. Shock Vib. 2018, 2018, 2916096. [Google Scholar] [CrossRef]

- Auersch, L. Reduction of train-induced vibrations—Calculations of different railway lines and mitigation measures in the transmission path. Appl. Sci. 2023, 13, 6706. [Google Scholar] [CrossRef]

- Hou, B.; Wang, D.; Wang, B.; Chen, X.; Pombo, J. Vibration reduction in ballasted track using ballast mat: Numerical and experimental evaluation by wheelset drop test. Appl. Sci. 2022, 12, 1844. [Google Scholar] [CrossRef]

- Zulkifli, M.A.; Basaruddin, K.S.; Abdul Rahim, Y.; Afendi, M.; Gurubaran, P.; Ibrahim, I. Three-dimensional finite element analysis on railway rail. IOP Conf. Ser. Mater. Sci. Eng. 2018, 429, 012010. [Google Scholar] [CrossRef]

- Kukulski, J.; Jacyna, M.; Gołębiowski, P. Finite element method in assessing strength properties of a railway surface and its elements. Symmetry 2019, 11, 1014. [Google Scholar] [CrossRef]

- Punetha, P.; Maharjan, K.; Nimbalkar, S. Finite element modeling of the dynamic response of critical zones in a ballasted railway track. Front. Built Environ. 2021, 7, 660292. [Google Scholar] [CrossRef]

- Bouhlal, L.; Kassou, F.; Lamdouar, N.; Bouyahyaoui, A. Assembly procedure for elementary matrices of train-track-bridge railway system. arXiv 2024. [Google Scholar] [CrossRef]

- Deng, Y.; Zhao, H.; Li, L.; Yao, Z.; Li, L. Research on static and dynamic loading performance of geosynthetic reinforced and pile-supported embankment. Appl. Sci. 2023, 13, 13152. [Google Scholar] [CrossRef]

- Fesharakifard, R.; Dequidt, A.; Tison, T.; Coste, O. Dynamics of railway track subjected to distributed and local out-of-round wheels. Mech. Ind. 2013, 14, 347–359. [Google Scholar] [CrossRef]

- Chango, I.V.L.; Yan, M.; Ling, X.; Liang, T.; Assogba, O.C. Dynamic response analysis of geogrid reinforced embankment supported by CFG pile structure during a high-speed train operation. Lat. Am. J. Solids Struct. 2019, 16, 1–20. [Google Scholar] [CrossRef]

- Liu, X.; Xiao, J.; Cai, D.; Su, Q.; Yang, G.; Yuan, S.; Jiang, G. Recent advances in subgrade engineering for high-speed railway. Intell. Transp. Infrastruct. (Oxf. Univ. Press) 2023, 2, liad001. [Google Scholar] [CrossRef]

- Moreno, A.G.; López, A.A.; Carrasco García, M.G.; Turias, I.J.; Ruiz Aguilar, J.J. A novel application of computational contact tools on nonlinear finite element analysis to predict ground-borne vibrations generated by trains in ballasted tracks. Modelling 2024, 5, 1454–1468. [Google Scholar] [CrossRef]

- Kuchak, A.J.T.; Marinkovic, D.; Zehn, M. Parametric investigation of a rail damper design based on a lab-scaled model. J. Vib. Eng. Technol. 2021, 9, 51–60. [Google Scholar] [CrossRef]

- Darenskiy, A.N.; Malishevskaya, A.S. Using mathematical models of dynamic systems “crew-track” powers to study the interaction of rolling stock and tracks underground. Inf. Control Syst. Rail Transp. 2017, 1, 43–51. [Google Scholar] [CrossRef][Green Version]

- Giner, I.G.; Alvarez, A.R.; Sánchez-Cambronero García-Moreno, S.; Camacho, J.L. Dynamic modelling of high-speed ballasted railway tracks: Analysis of the behaviour. Transp. Res. Procedia 2016, 18, 357–365. [Google Scholar] [CrossRef]

- Yahia Alabbasi, M.H. Geomechanical Modelling of Railroad Ballast: A Review. Arch. Comput. Methods Eng. 2019, 26, 327–365. [Google Scholar] [CrossRef]

- Hua, X.; Zatar, W.; Cheng, X.; Chen, G.S.; She, Y.; Xu, X.; Liao, Z. Modeling and Characterization of Complex Dynamical Properties of Railway Ballast. Appl. Sci. 2024, 14, 11224. [Google Scholar] [CrossRef]

- Hawksbee, S.; Grossoni, I.; Bezin, Y.; Lee, B.; Watson, G.; Milne, D.; Le Pen, L.; Abadi, T.; Jorge, P. Modelling the Improved Behaviour of a Switch Installed on Ballast-Asphalt Track. In Proceedings of the Fifth International Conference on Railway Technology: Research, Development and Maintenance, Montpellier, France, 22–25 August 2022; Volume 1. 8p. [Google Scholar] [CrossRef]

- Mosleh, A.; Aires Montenegro, P.; Alves Costa, P.; Calçada, R. Railway Vehicle Wheel Flat Detection with Multiple Records Using Spectral Kurtosis Analysis. Appl. Sci. 2021, 11, 4002. [Google Scholar] [CrossRef]

- Sayeed, M.A.; Shahin, M.A. Dynamic Response Analysis of Ballasted Railway Track–Ground System under Train Moving Loads Using 3D Finite Element Numerical Modelling. Transp. Infrastruct. Geotech. 2023, 10, 639–659. [Google Scholar] [CrossRef]

- Kurhan, D.; Kurhan, M. Modeling the Dynamic Response of Railway Track. IOP Conf. Ser. Mater. Sci. Eng. 2019, 708, 12013. [Google Scholar] [CrossRef]

- Kurhan, D.; Fischer, S. Modeling of the Dynamic Rail Deflection using Elastic Wave Propagation. J. Appl. Comput. Mech. 2022, 8, 379–387. [Google Scholar] [CrossRef]

- Feng, G.; Luo, Q.; Lyu, P.; Connolly, D.P.; Wang, T. An Analysis of Dynamics of Retaining Wall Supported Embankments: Towards More Sustainable Railway Designs. Sustainability 2023, 15, 7984. [Google Scholar] [CrossRef]

- Xie, H.; Luo, Q.; Wang, T.; Jiang, L.; Connolly, D.P. Stochastic analysis of dynamic stress amplification factors for slab track foundations. Int. J. Rail Transp. 2024, 12, 281–303. [Google Scholar] [CrossRef]

- Nielsen, J.C.O.; Pieringer, A.; Thompson, D.J.; Torstensson, P.T. Wheel–Rail Impact Loads, Noise and Vibration: A Review of Excitation Mechanisms, Prediction Methods and Mitigation Measures. Notes Numer. Fluid Mech. Multidiscip. Des. 2021, 150, 3–40. [Google Scholar] [CrossRef]

- Charoenwong, C.; Connolly, D.P.; Odolinski, K.; Alves Costa, P.; Galvín, P.; Smith, A. The Effect of Rolling Stock Characteristics on Differential Railway Track Settlement: An Engineering-Economic Model. Transp. Geotech. 2022, 37, 100845. [Google Scholar] [CrossRef]

- Charoenwong, C.; Connolly, D.P.; Colaço, A.; Alves Costa, P.; Woodward, P.K.; Romero, A.; Galvín, P. Railway slab vs ballasted track: A comparison of track geometry degradation. Constr. Build. Mater. 2023, 378, 131121. [Google Scholar] [CrossRef]

- Lichtberger, B. Thack Compendium; Eurailpress Tetzlaff–Hestra GmbH Co. KG.: Hamburg, Germany, 2005; Volume 634. [Google Scholar]

- Fisher, S.; Eller, B.; Kada, Z.; Németh, A. Railway Construction; Univ. –Győr Nonprofit Kft Győr: Győr, Hungary, 2015; Volume 334. [Google Scholar]

- Kovalchuk, V.; Sysyn, M.; Movahedi Rad, M.; Fischer, S. Investigation of the Bearing Capacity of Transport Constructions Made of Corrugated Metal Structures Reinforced with Transversal Stiffening Ribs. Infrastructures 2023, 8, 131. [Google Scholar] [CrossRef]

- Nabochenko, O.; Sysyn, M.; Gerber, U.; Krumnow, N. Analysis of Track Bending Stiffness and Loading Distribution Effect in Rail Support by Application of Bending Reinforcement Methods. Urban Rail Transit 2023, 9, 73–91. [Google Scholar] [CrossRef]

- Kurhan, D. Determination of Load for Quasi-static Calculations of Railway Track Stress-strain State. Acta Tech. Jaurinensis 2016, 9, 83–96. [Google Scholar] [CrossRef]

- Langcuyan, C.P.; Sadiq, S.; Park, T.W.; Won, M.S. Dynamic analysis of MSE wall subjected to surface vibration loading. Open Geosci. 2023, 15, 20220592. [Google Scholar] [CrossRef]

- Moretti, L.; Loprencipe, G.; Di Mascio, P. Competition in rail transport: Methodology to evaluate economic impact of new trains on track. In Proceedings of the Sustainability, Eco-Efficiency and Conservation in Transportation Infrastructure Asset Managementm, Pisa, Italy, 28 April 2014; pp. 669–675. [Google Scholar] [CrossRef]

- Petrenko, V.D.; Yampolskiy, D.O.; Sviatko, I.O. Comparative analysis of calculation models of railway subgrade. Sci. Transp. Prog. 2013, 4, 56–62. [Google Scholar] [CrossRef]

- Cao, X.; Li, Y.; Li, P.; Xu, J.; Zhang, X. Influence of Fastener Stiffness and Damping on Vibration Transfer Characteristics of Urban Railway Bridge Lines Using Vibration Power Flow Method. Appl. Sci. 2023, 13, 12543. [Google Scholar] [CrossRef]

- Choi, J.; Ahn, D.; Kim, S. Behavior Characteristics of a Booted Sleeper Track System According to Substructure Deformation. Appl. Sci. 2021, 11, 4507. [Google Scholar] [CrossRef]

- Cui, X.; Zhou, R.; Guo, G.; Du, B.; Liu, H. Effects of Differential Subgrade Settlement on Slab Track Deformation Based on a DEM-FDM Coupled Approach. Appl. Sci. 2021, 11, 1384. [Google Scholar] [CrossRef]

- Fattah, M.; Majeed, Q.; Joni, H. Effect of Degree of Saturation on Stresses and Pore Water Pressure in the Subgrade Layer Caused by Railway Track Loading. Railw. Sci. 2024, 3, 413–436. [Google Scholar] [CrossRef]

- Groll, W.; Sowiński, B.; Konowrocki, R. Study of Transitional Phenomena in Rail Vehicle Dynamics in Relation to the Reliability and Operational State of the Continuous Welded Rail Track in Terms of Rail Joints. Eksploat. Niezawodn.—Maint. Reliab. 2023, 25, 7. [Google Scholar] [CrossRef]

- Hasnayn, M.; McCarter, W.; Woodward, P.; Connolly, D. Railway Subgrade Performance after Repeated Flooding—Large-Scale Laboratory Testing. Transp. Geotech. 2020, 23, 100329. [Google Scholar] [CrossRef]

- Kuchak, A.T.J.; Marinkovic, D.; Zehn, M. Parametric Investigation of a Rail Damper Design Based on a Lab-Scaled Model. J. Vib. Eng. Technol. 2021, 9, 51–60, Correction to J. Vib. Eng. Technol. 2021, 9, 1805. [Google Scholar] [CrossRef]

- Kuchak, A.T.J.; Marinkovic, D.; Zehn, M. Finite Element Model Updating—Case Study of a Rail Damper. Struct. Eng. Mech. 2020, 73, 27–35. [Google Scholar] [CrossRef]

- Ézsiás, L.; Tompa, R.; Fischer, S. Investigation of the Possible Correlations between Specific Characteristics of Crushed Stone Aggregates. Spectr. Mech. Eng. Oper. Res. 2024, 1, 10–26. [Google Scholar] [CrossRef]

- Abbasi, A.; Zakeri, J.; Norouzi, E.; Mosayebi, S. Field Investigation on the Effect of the Tamping Machine and Dynamic Track Stabilizer on Changing the Rail Support Modulus. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2024, 238, 1072–1083. [Google Scholar] [CrossRef]

- Choi, J.; Kim, S. Qualitative Prediction Model for Dynamic Behavior of Ballasted Tracks. Appl. Sci. 2020, 10, 6258. [Google Scholar] [CrossRef]

- Fattah, M.; Majeed, Q.; Joni, H. Stresses in Saturated and Unsaturated Subgrade Layer Induced by Railway Track Vibration. Infrastructures 2024, 9, 64. [Google Scholar] [CrossRef]

- Gao, X.; Wang, L.; Zhao, C.; Wang, P.; Yi, Q. Experimental and Simulation Study on Rail Admittance Characteristics in Turnout Area of Urban Rail Transit. J. Vib. Control 2023, 30, 3806–3820. [Google Scholar] [CrossRef]

- Jumabekov, B.; Ro’zmetov, Y.; Sultonov, S. Assessment of the Impact on the Railway Track of a Special Purpose Passenger Car Model 61-934. E3S Web Conf. 2021, 264, 02050. [Google Scholar] [CrossRef]

- Naeini, M.; Mohammadinia, A.; Arulrajah, A.; Horpibulsuk, S. Recycled Glass Blends with Recycled Concrete Aggregates in Sustainable Railway Geotechnics. Sustainability 2021, 13, 2463. [Google Scholar] [CrossRef]

- Park, S.; Kim, J.; Kim, J.; Lee, S.; Cho, K. Analysis of Dynamic Characteristics of Deformed Concrete Slab Track on Transition Zone in High-Speed Train Line According to Train Speeds. Appl. Sci. 2020, 10, 7174. [Google Scholar] [CrossRef]

- Sadeghi, J.; Rabiee, S.; Khajehdezfuly, A. Development of Train Ride Comfort Prediction Model for Railway Slab Track System. Lat. Am. J. Solids Struct. 2020, 17, e236. [Google Scholar] [CrossRef]

- Sysyn, M.; Nabochenko, O.; Kovalchuk, V. Experimental Investigation of the Dynamic Behavior of Railway Track with Sleeper Voids. Railw. Eng. Sci. 2020, 28, 290–304. [Google Scholar] [CrossRef]

- Xiao, Y.; Chang, Z.; Mao, J.; Zhou, S.; Wang, X.; Wang, W.; Long, Y. Evaluating the Effect of Rail Fastener Failure on Dynamic Responses of Train-Ballasted Track-Subgrade Coupling System for Smart Track Condition Assessment. Materials 2022, 15, 2675. [Google Scholar] [CrossRef] [PubMed]

- Fischer, S. Investigation of the Settlement Behavior of Ballasted Railway Tracks Due to Dynamic Loading. Spectr. Mech. Eng. Oper. Res. 2025, 2, 24–46. [Google Scholar] [CrossRef]

- Kuang, M.; Safa, R.; Edalatpanah, S.A.; Keyser, R.S. A Hybrid Deep Learning Approach for Sentiment Analysis in Product Reviews. Facta Univ. Ser. Mech. Eng. 2023, 21, 479–500. [Google Scholar] [CrossRef]

- Mzili, T.; Mzili, I.; Riffi, M.E.; Pamucar, D.; Simic, V.; Kurdi, M. A Novel Discrete Rat Swarm Optimization Algorithm for the Quadratic Assignment Problem. Facta Univ. Ser. Mech. Eng. 2023, 21, 529–552. [Google Scholar] [CrossRef]

- Zamfirache, I.A.; Precup, R.E.; Petriu, E.M. Q-Learning, Policy Iteration and Actor-Critic Reinforcement Learning Combined with Metaheuristic Algorithms in Servo System Control. Facta Univ. Ser. Mech. Eng. 2023, 21, 615–630. [Google Scholar] [CrossRef]

- Nosonovsky, M.; Aglikov, A.S. Triboinformatics: Machine Learning Methods for Frictional Instabilities. Facta Univ. Ser. Mech. Eng. 2024, 22, 423–433. [Google Scholar] [CrossRef]

| Model Type | Primary Method for Describing Granular Materials | Main Limitations | Advantages |

|---|---|---|---|

| 1. Quasi-static analytical calculations | Ballast and subgrade are modeled as a uniformly distributed stiffness (Winkler model) | Nonlinearity, plasticity, and rheological properties are not considered | Simplicity, fast calculations, possibility of analytical expressions |

| 2. Multi-body dynamics models (Lagrange–D’Alembert) | Ballast can be represented as discrete masses with elastic and damping connections | Difficult in accurately modeling the granular nature of the material and its redistribution under load | Allows for consideration of the dynamic response of ballast and its interaction with other elements |

| 3. FEM in a static form | Ballast and subgrade are treated as a continuous medium with defined mechanical parameters (elastic modulus, Poisson’s ratio) | Unable to account for structural changes in ballast under loading | Enables modeling of subgrade heterogeneity and localized deformations |

| 4. FEM in a dynamic form | Nonlinear material models (e.g., hypoplastic or elastoplastic) are used, and damping is considered | High computational cost, requires experimental data for accurate calibration | Realistic modeling of ballast nonlinear behavior and cyclic loading effects |

| 5. Elastic wave propagation models (wave theory) | Subgrade and ballast are treated as a wave-propagating medium where elastic waves travel | Difficult to account for plastic and rheological effects, which are important for long-term settlement processes | Effectively describes dynamic load transmission and the wave response of the subgrade to moving loads |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurhan, D.; Fischer, S.; Khmelevskyi, V. Mathematical Modeling of the Rail Track Superstructure–Subgrade System. Geotechnics 2025, 5, 20. https://doi.org/10.3390/geotechnics5010020

Kurhan D, Fischer S, Khmelevskyi V. Mathematical Modeling of the Rail Track Superstructure–Subgrade System. Geotechnics. 2025; 5(1):20. https://doi.org/10.3390/geotechnics5010020

Chicago/Turabian StyleKurhan, Dmytro, Szabolcs Fischer, and Vladyslav Khmelevskyi. 2025. "Mathematical Modeling of the Rail Track Superstructure–Subgrade System" Geotechnics 5, no. 1: 20. https://doi.org/10.3390/geotechnics5010020

APA StyleKurhan, D., Fischer, S., & Khmelevskyi, V. (2025). Mathematical Modeling of the Rail Track Superstructure–Subgrade System. Geotechnics, 5(1), 20. https://doi.org/10.3390/geotechnics5010020