Probabilistic Failure Estimation of an Oblique Loaded Footing Settlement on Cohesive Geomaterials with a Modified Cam Clay Material Yield Function

Abstract

:1. Introduction

2. Dynamic Soil–Pore–Fluid Interaction: The System of Equations and Its Numerical Solution

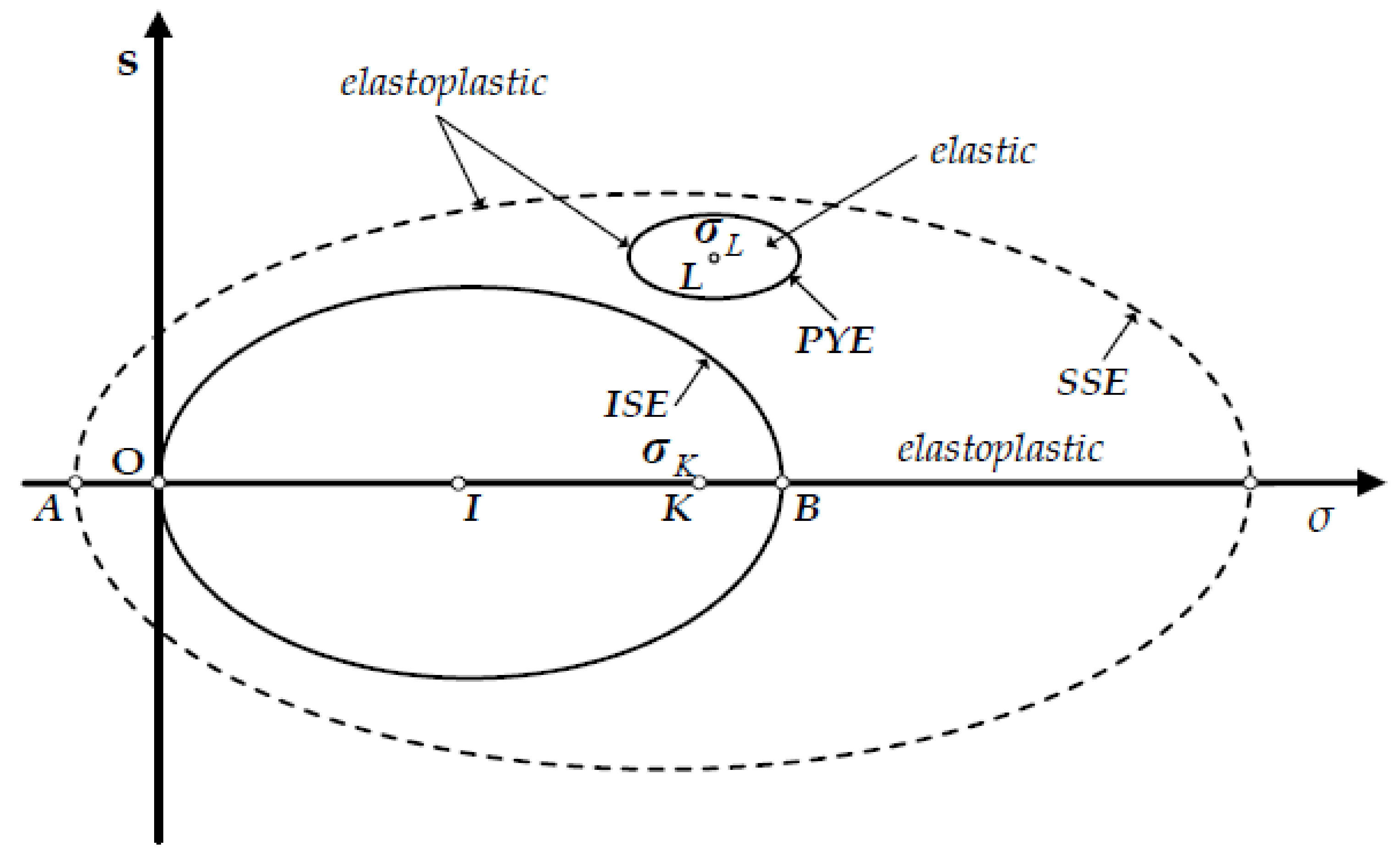

3. The Constitutive Material Yield Function

3.1. Plastic Yield Envelope and Bond Strength Envelope Mathematical Representation

4. Stochastic Processes, the Truncated Normal Distribution and Latin Hypercube Sampling

4.1. The Karhunen–Loeve Series and the Truncated Normal Variables

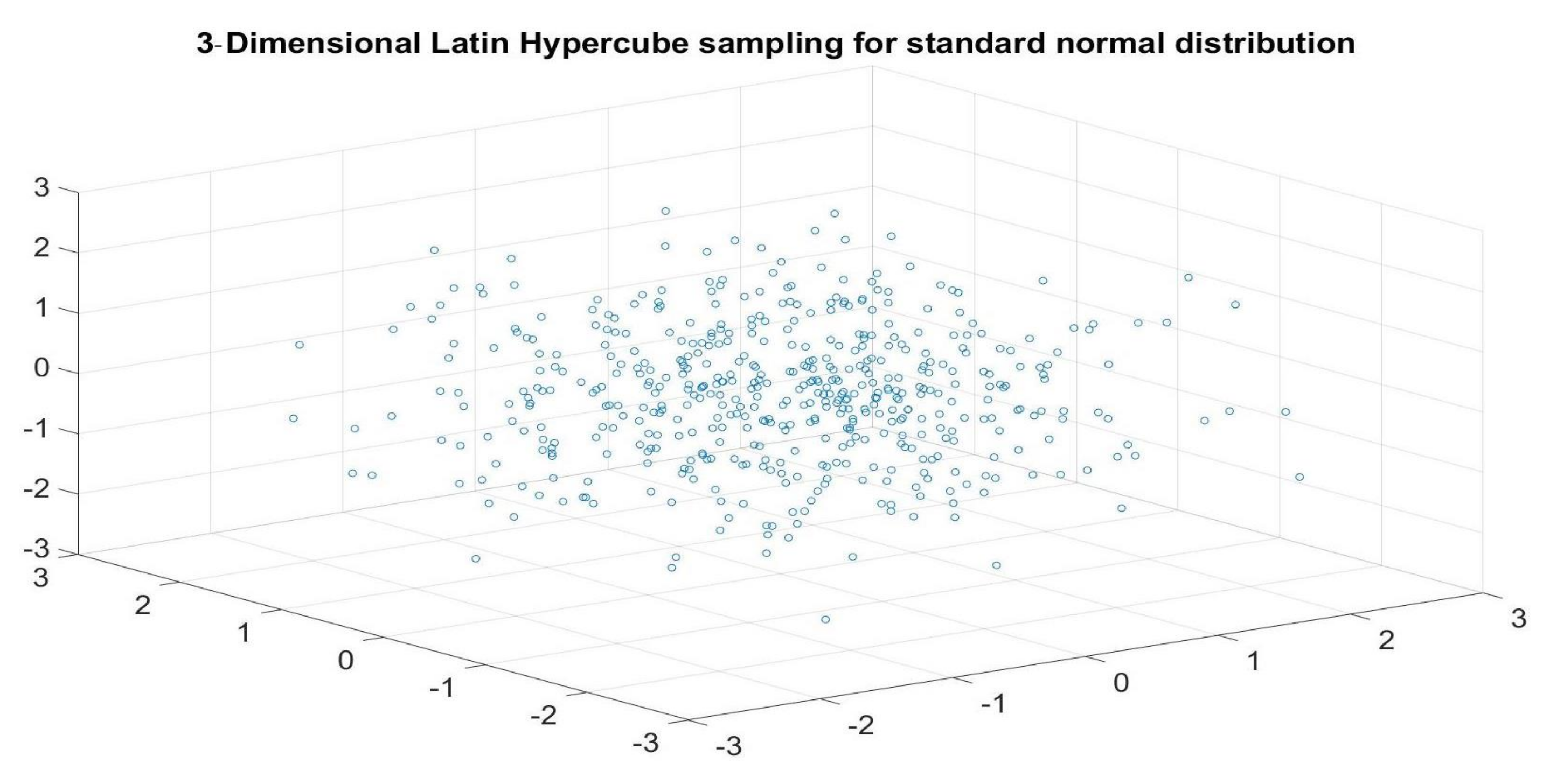

4.2. Latin Hypercube Sampling

- The interval [0,1] of the cumulative distribution function (CDF) is subdivided into equal subspaces

- A random number is chosen and through the inverse CDF a sample is acquired

- All the vectors are permuted in a random way and thus the vector realization X is composed

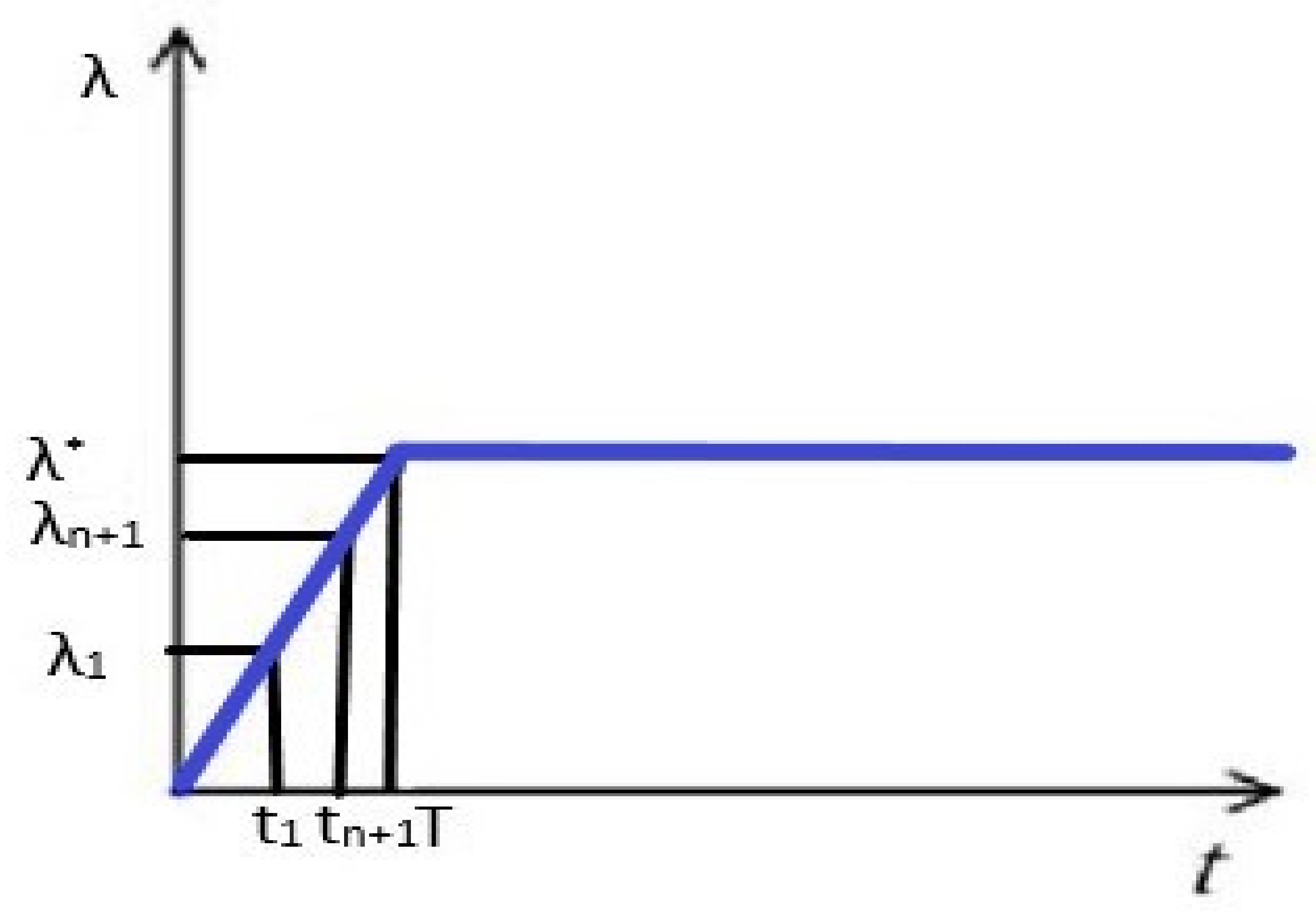

5. An Improvement of a Proposed Algorithm for the Determination of Failure Load in Ramp Dynamic Load Function

6. Numerical Tests on Stochastic Failure of Shallow Foundations with Random Linear and Non-Linear Material Properties

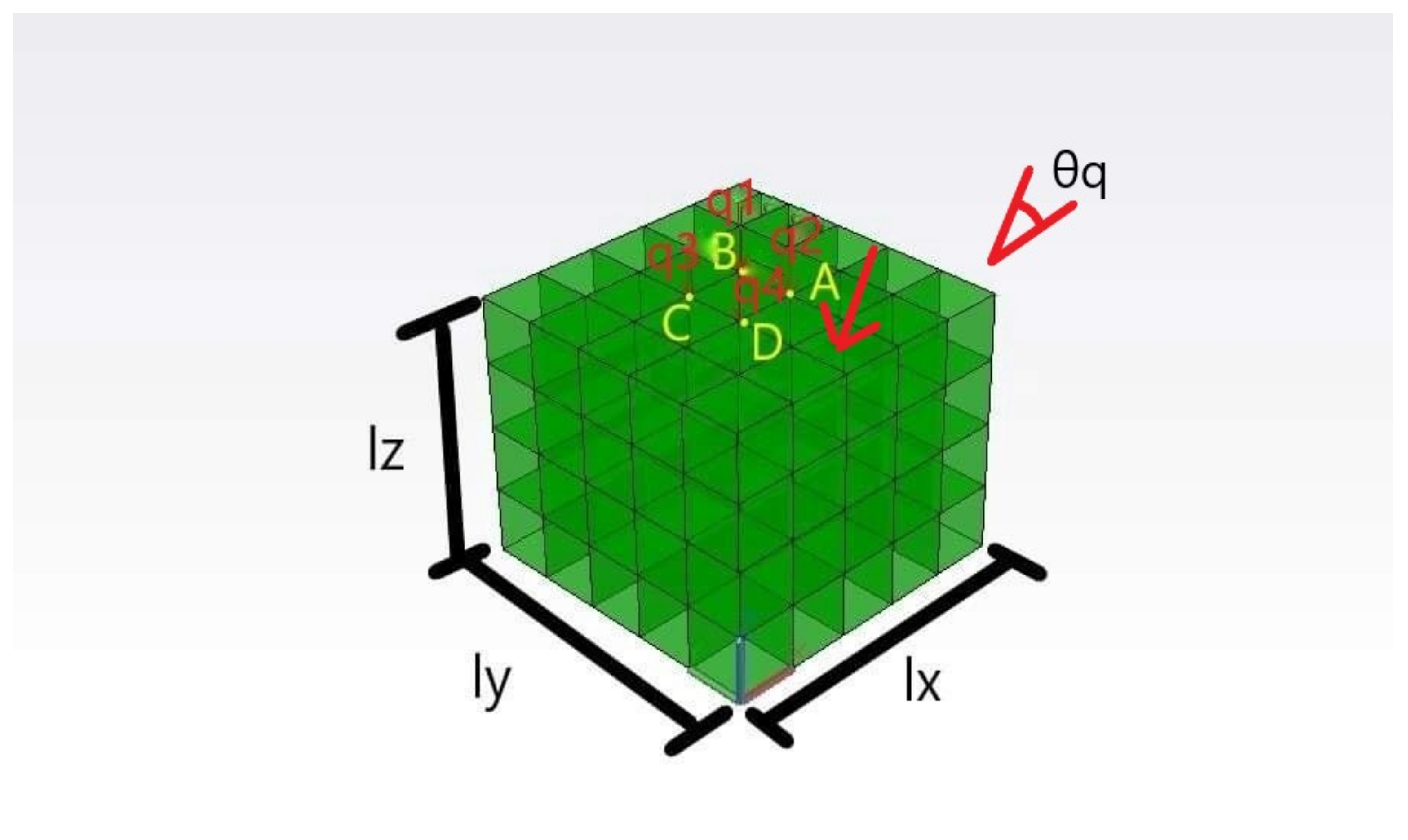

6.1. Description of the Problem

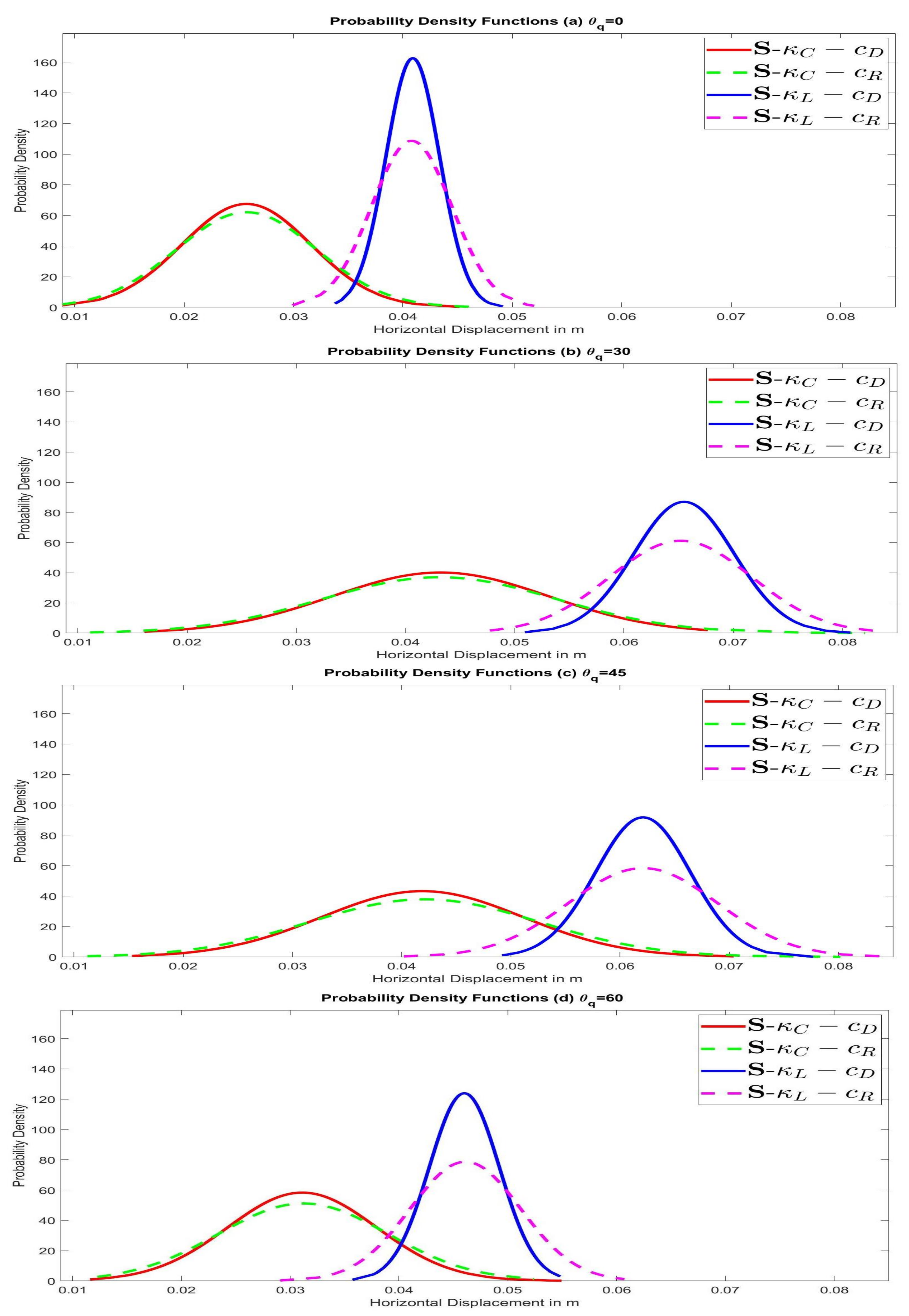

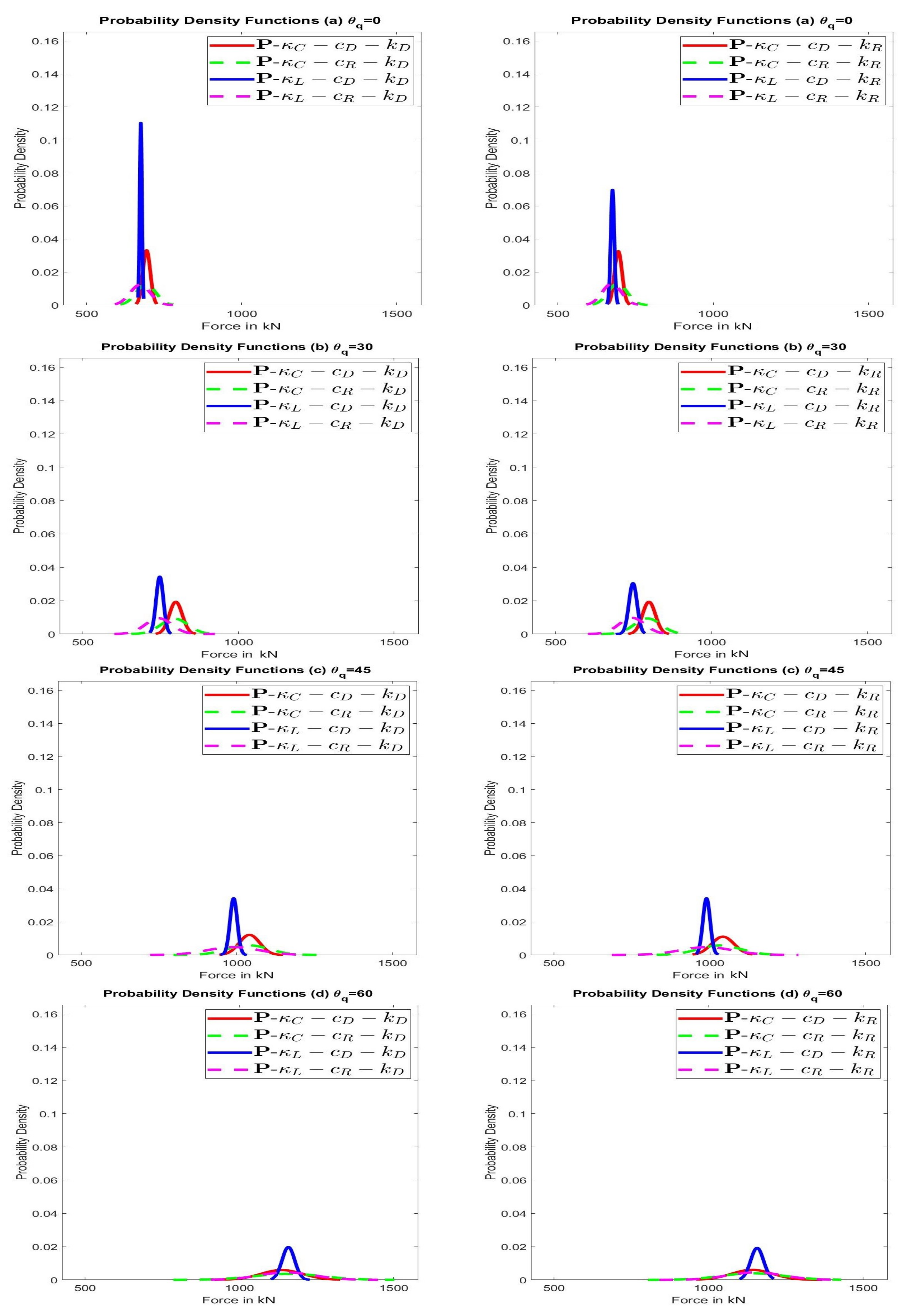

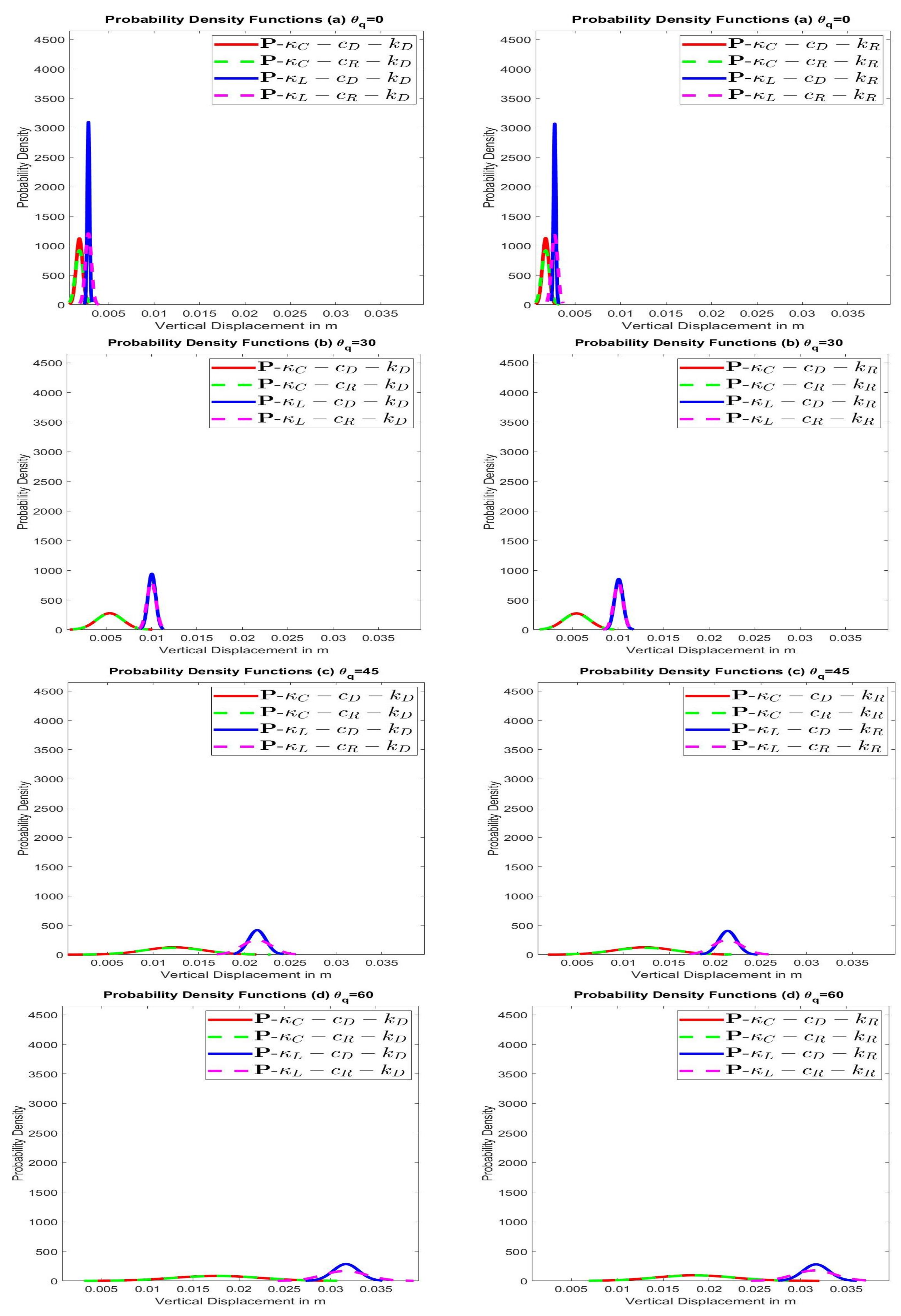

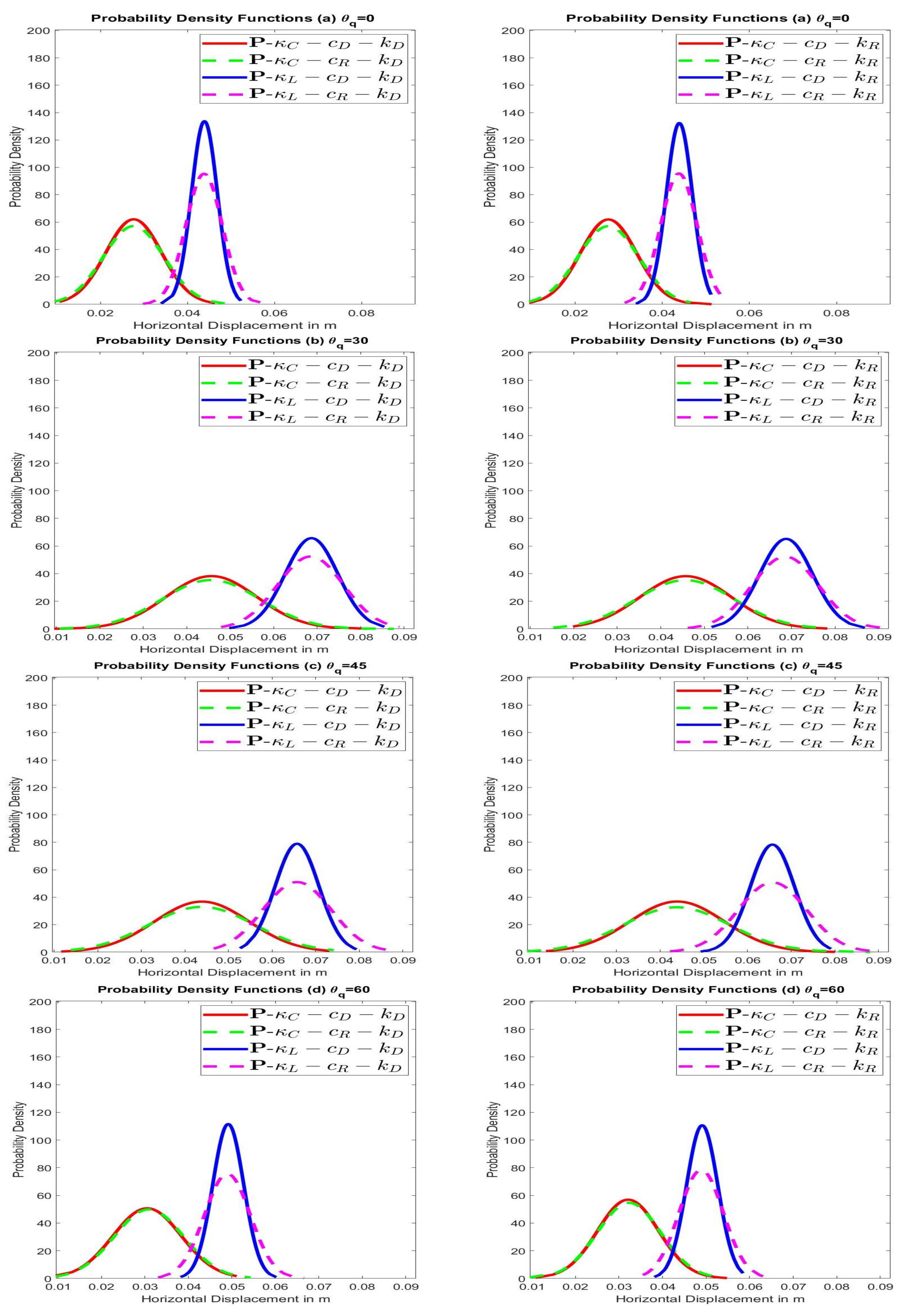

6.2. Presentation of the Results

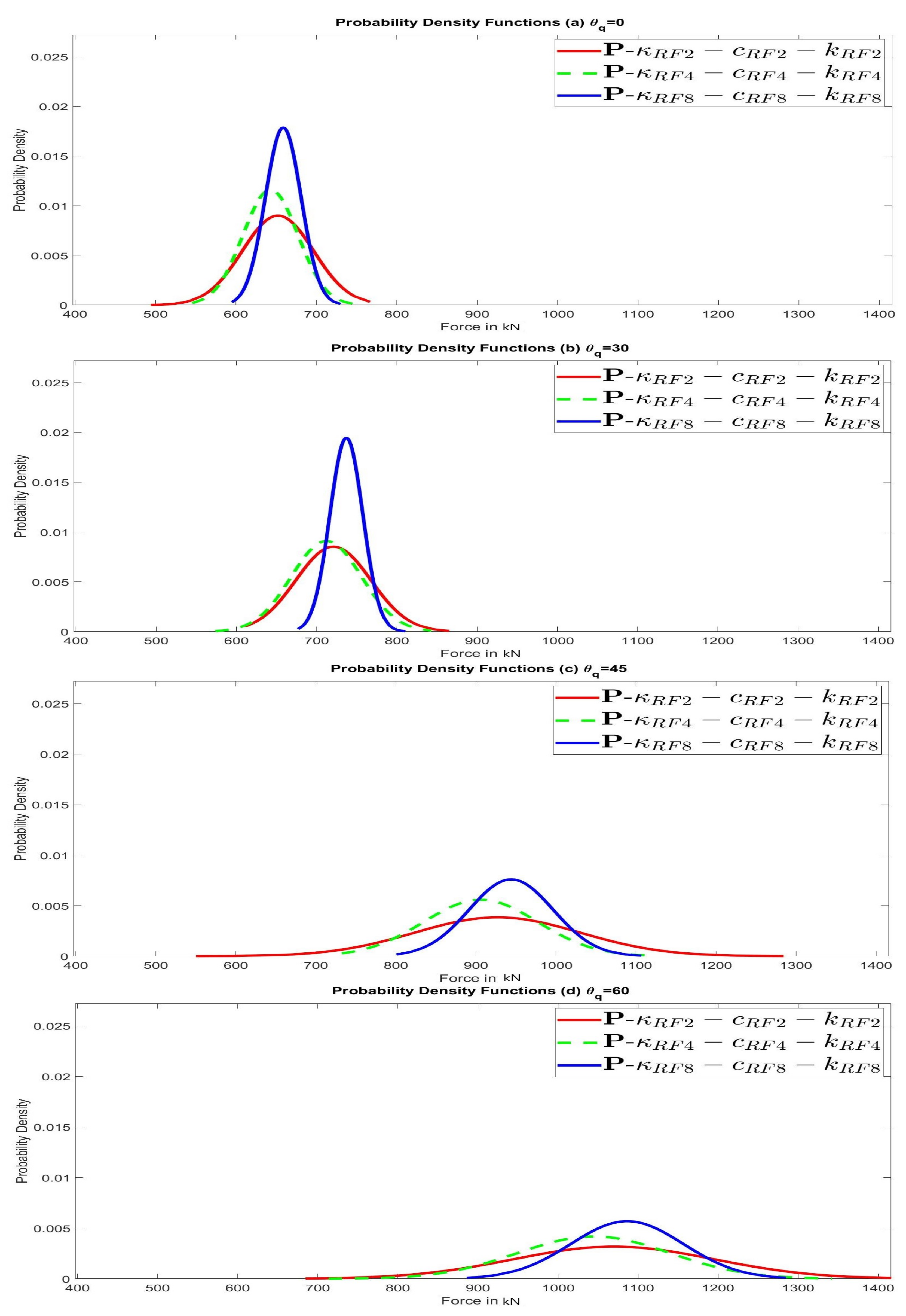

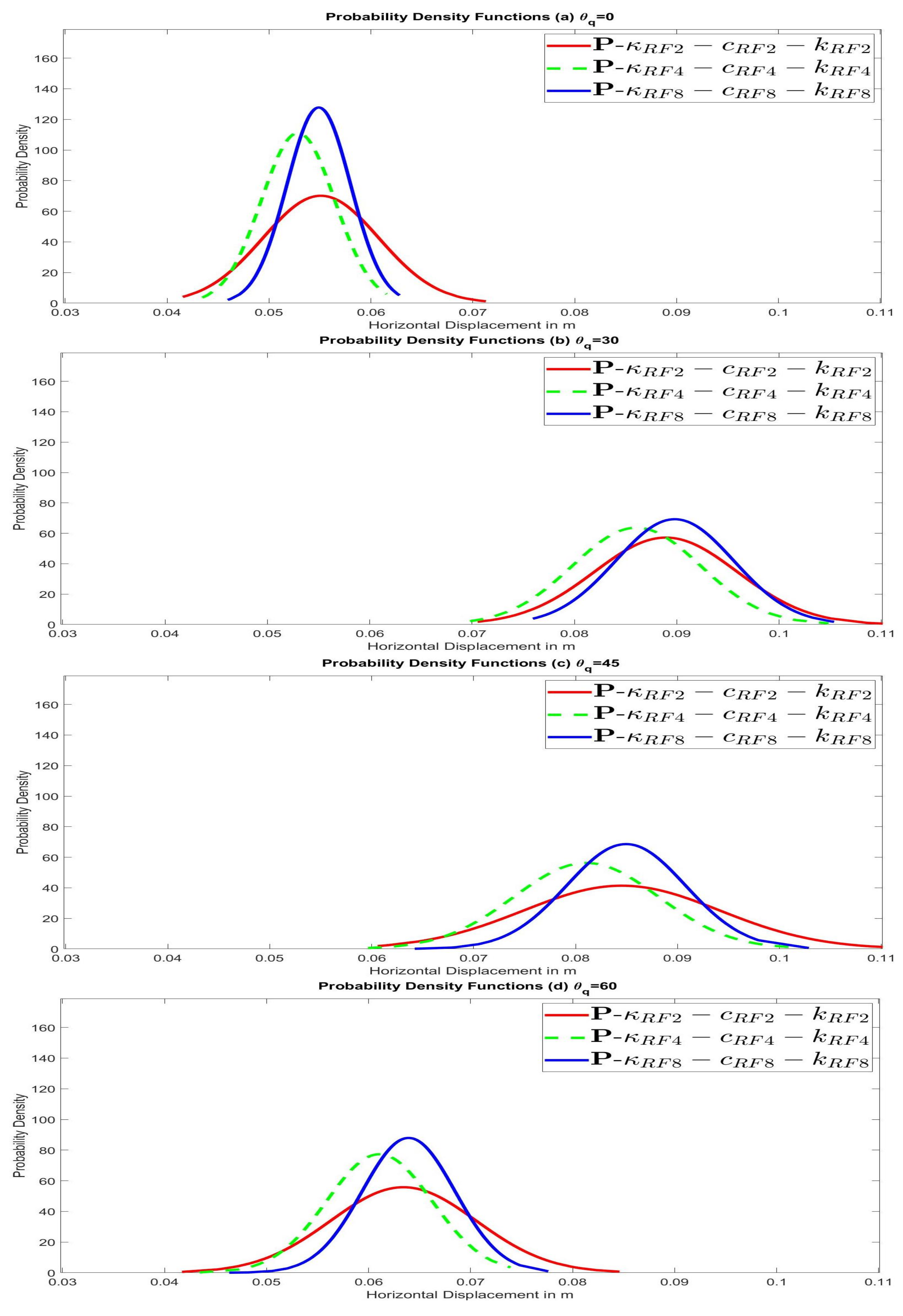

6.2.1. Limit Failure Force and Displacement

6.2.2. Limit Stresses–Strains and Failure Spline

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Friction variables | |

| Friction variable indicating the influence of possible vertical load in the lateral of | |

| the foundation | |

| Friction variable indicating the influence of the cohesion of the soil | |

| Friction variable indicating the influence of the settlement dimensions | |

| alongside with the total weight of the soil | |

| Shape variables | |

| Shape variable indicating the influence of possible vertical load in the lateral of | |

| the foundation | |

| Shape variable indicating the influence of the cohesion of the soil | |

| Shape variable indicating the influence of the settlement dimensions | |

| alongside with the total weight of the soil | |

| Compressibility factor | |

| c | Critical state line inclination |

| k | Permeability in units |

| Friction angle | |

| Total mass matrix | |

| Total damping matrix | |

| Total stiffness matrix | |

| Solid skeleton mass matrix | |

| Density of the soil | |

| Deformation matrix | |

| Elasticity matrix | |

| Solid skeleton damping matrix | |

| Solid skeleton stiffness matrix | |

| Unity matrix | |

| Loading vector | |

| Matrix of permeability in units | |

| Shape functions for pore pressure | |

| Shape functions for displacements | |

| Saturation matrix | |

| Coupling matrix | |

| Permeability matrix | |

| Equivalent forces due to external loading | |

| Q | Variable for combining the influence of bulk moduli of fluid and solid skeleton in |

| porous problems | |

| Total stress tensor | |

| Deviatoric component of the stress tensor | |

| Hydrostatic component of the stress tensor | |

| a | Halfsize of the bond strength envelope |

| Deviatoric component of the stress point of the centre of the plastic yield envelope | |

| Hydrostatic component of the stress point of the centre of the plastic yield envelope | |

| Similarity factor between the plastic yield envelope and bond strength envelope | |

| Generalized elliptic envelope | |

| Plastic yield envelope (PYE) | |

| F | Bond strength envelope (BSE) |

| Specific volume of the soil | |

| q | Von Mises stress |

| e | Deviatoric strain measure |

| Deviatoric component of the strain tensor | |

| f | Random function |

| Value of the random function at nodal points | |

| Shape functions | |

| Total number of shape functions | |

| Truncated normal PDF | |

| Standard normal PDF | |

| Standard normal CDF | |

| Standard deviation of the random variable before truncation | |

| A, B, | Normalized coordinates of the subspace of the truncated PDF |

| limits and x respectively | |

| Karhunen–Loeve random field | |

| Number of subintervals in the Latin hypercube Sampling | |

| Mean value of the random field | |

| Random vector created by the Latin hypercube sampling | |

| , , | Total number of eigenvalues and eigenfunctions |

| respectively | |

| b | Correlation length |

| Covariance function | |

| Load factor causing failure of the body at exactly the time which ends | |

| the rampload function | |

| T | Time which the rampload function ends |

| Symmetrization factor of the stochastic process | |

| Trial load factor of step n causing failure | |

| Time of failure at the generalized load factor | |

| Maximum trial load factor which causes safety | |

| Initial trial load factor causing failure | |

| Initial trial load factor which causes safety | |

| Equivalent forces of the shallow foundation | |

| Obliquity angle | |

| Dimensions of the total finite element mesh | |

| Geostatic stresses in vertical direction and directions x and y respectively | |

| Inclination of isotropic compression line for the respective normally | |

| consolidated clay | |

| Initial halfisize of the ellipse | |

| Residual halfisize of the ellipse | |

| OCR | Overconsolidation ratio |

| G | Shear modulus |

| Bulk modulus | |

| Specific weight | |

| Initial specific volume of the soil | |

| Displacement vector in direction x | |

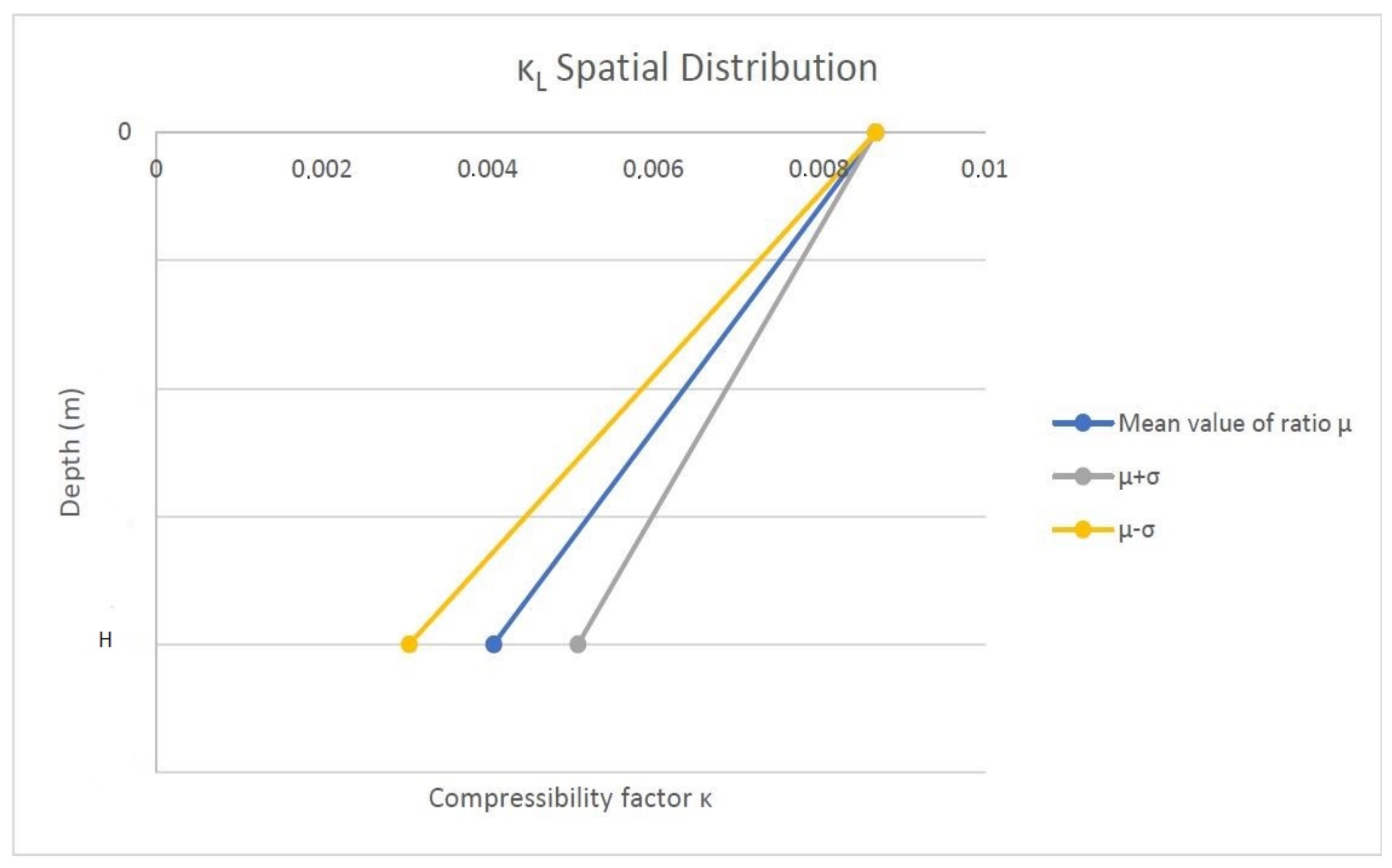

| Compressibilty factor at depth = 0 | |

| Compressibilty factor at maximum depth | |

| Ratio of the compressibility factors measured at depth = 0 and at | |

| maximum depth | |

| Mean value of ratio R | |

| Compressibilty factor at maximum depth when the ratio R has its | |

| mean value | |

| Linear distribution over depth for the compressibility factor | |

| Constant distribution over depth for the compressibility factor | |

| Mean value of | |

| Random variable case for the critical state line inclination | |

| Deterministic case for the critical state line inclination | |

| Mean value of the friction angle | |

| Standard deviation of the friction angle | |

| Mean value of the permeability | |

| Coefficient of variation of the friction angle | |

| Mean value of the compressibility factor in the random field representation | |

| Mean value of the critical state line inclination in the random | |

| field representation | |

| Mean value of the permeability in the random field representation | |

| Standard deviation of the compressibility factor in the random field | |

| representation | |

| Standard deviation of the critical state line inclination in the random field | |

| representation | |

| Standard deviation of the permeability in the random field representation | |

| Mean values of the results | |

| Coefficient of variation of the results | |

| M | Maximum values of the results |

| Minimum values of the results | |

| N | Total settlement force |

| Horizontal displacement at failure | |

| Vertical displacement at failure | |

| Volumetric stress at failure | |

| Von Mises stress at failure | |

| Volumetric strain at failure | |

| Deviatoric strain at failure | |

| Percentage plastic volumetric strains at failure | |

| Percentage plastic deviatoric strains at failure |

Appendix A

| N | ||||||||||

| - | - | - | - | - | - | - | - | |||

| 668.94 | 667.19 | 645.75 | 643.56 | 809.81 | 805.00 | 759.06 | 755.13 | |||

| 0.02 | 0.04 | 0.01 | 0.04 | 0.03 | 0.06 | 0.01 | 0.06 | |||

| M | 700.00 | 721.00 | 658.00 | 700.00 | 861.00 | 882.00 | 770.00 | 833.00 | ||

| 651.00 | 609.00 | 637.00 | 588.00 | 777.00 | 714.00 | 756.00 | 665.00 | |||

| 1.08 | 1.18 | 1.03 | 1.19 | 1.11 | 1.24 | 1.02 | 1.25 | |||

| N | ||||||||||

| - | - | - | - | - | - | - | - | |||

| 1120.90 | 1121.30 | 1030.30 | 1029.90 | 1330.40 | 1331.80 | 1225.40 | 1226.80 | |||

| 0.04 | 0.10 | 0.01 | 0.09 | 0.05 | 0.10 | 0.02 | 0.09 | |||

| M | 1239.00 | 1358.00 | 1057.00 | 1218.00 | 1491.00 | 1624.00 | 1274.00 | 1456.00 | ||

| 1043.00 | 931.00 | 1008.00 | 861.00 | 1232.00 | 1106.00 | 1190.00 | 1022.00 | |||

| 1.19 | 1.46 | 1.05 | 1.41 | 1.21 | 1.47 | 1.07 | 1.42 | |||

| - | - | - | - | - | - | - | - | |||

| 0.0018 | 0.0019 | 0.0029 | 0.0029 | 0.0051 | 0.0051 | 0.0094 | 0.0094 | |||

| 0.21 | 0.25 | 0.04 | 0.11 | 0.25 | 0.26 | 0.03 | 0.04 | |||

| M | 0.0026 | 0.0028 | 0.0031 | 0.0035 | 0.0075 | 0.0076 | 0.0101 | 0.0102 | ||

| 0.0010 | 0.0010 | 0.0027 | 0.0024 | 0.0024 | 0.0024 | 0.0087 | 0.0088 | |||

| 2.67 | 2.73 | 1.16 | 1.44 | 3.16 | 3.18 | 1.15 | 1.16 | |||

| - | - | - | - | - | - | - | - | |||

| 0.0121 | 0.0122 | 0.0207 | 0.0207 | 0.0186 | 0.0187 | 0.0307 | 0.0307 | |||

| 0.23 | 0.25 | 0.04 | 0.07 | 0.22 | 0.25 | 0.04 | 0.08 | |||

| M | 0.0173 | 0.0182 | 0.0222 | 0.0233 | 0.0263 | 0.0278 | 0.0332 | 0.0352 | ||

| 0.0060 | 0.0062 | 0.0188 | 0.0185 | 0.0095 | 0.0098 | 0.0278 | 0.0271 | |||

| 2.87 | 2.95 | 1.18 | 1.26 | 2.76 | 2.84 | 1.19 | 1.30 | |||

| - | - | - | - | - | - | - | - | |||

| 0.0257 | 0.0257 | 0.0409 | 0.0408 | 0.0432 | 0.0431 | 0.0655 | 0.0652 | |||

| 0.23 | 0.25 | 0.06 | 0.09 | 0.23 | 0.25 | 0.07 | 0.10 | |||

| M | 0.0370 | 0.0382 | 0.0454 | 0.0475 | 0.0617 | 0.0645 | 0.0745 | 0.0773 | ||

| 0.0127 | 0.0130 | 0.0358 | 0.0362 | 0.0216 | 0.0220 | 0.0555 | 0.0563 | |||

| 2.91 | 2.94 | 1.27 | 1.31 | 2.86 | 2.93 | 1.34 | 1.37 | |||

| - | - | - | - | - | - | - | - | |||

| 0.0419 | 0.0421 | 0.0621 | 0.0621 | 0.0311 | 0.0312 | 0.0460 | 0.0461 | |||

| 0.22 | 0.25 | 0.07 | 0.11 | 0.22 | 0.25 | 0.07 | 0.11 | |||

| M | 0.0586 | 0.0632 | 0.0701 | 0.0749 | 0.0435 | 0.0465 | 0.0520 | 0.0554 | ||

| 0.0216 | 0.0224 | 0.0525 | 0.0533 | 0.0161 | 0.0166 | 0.0390 | 0.0399 | |||

| 2.71 | 2.82 | 1.33 | 1.41 | 2.71 | 2.80 | 1.33 | 1.39 | |||

| N | , | , | ||||||||

| - | - | - | - | - | - | - | - | |||

| 693.47 | 691.40 | 674.89 | 672.91 | 694.26 | 692.14 | 675.75 | 673.60 | |||

| 0.02 | 0.05 | 0.01 | 0.05 | 0.02 | 0.04 | 0.01 | 0.05 | |||

| M | 724.10 | 751.64 | 683.38 | 733.44 | 722.97 | 751.66 | 688.53 | 733.60 | ||

| 674.89 | 629.52 | 668.17 | 607.46 | 675.09 | 636.80 | 665.44 | 617.92 | |||

| 1.07 | 1.19 | 1.02 | 1.21 | 1.07 | 1.18 | 1.03 | 1.19 | |||

| N | , | , | ||||||||

| - | - | - | - | - | - | - | - | |||

| 798.42 | 794.09 | 746.87 | 743.03 | 798.99 | 794.52 | 747.81 | 744.16 | |||

| 0.03 | 0.05 | 0.02 | 0.06 | 0.03 | 0.05 | 0.02 | 0.06 | |||

| M | 850.39 | 868.48 | 751.43 | 816.38 | 850.59 | 868.20 | 760.42 | 816.63 | ||

| 769.53 | 710.21 | 702.08 | 659.51 | 773.25 | 714.13 | 699.54 | 669.53 | |||

| 1.11 | 1.22 | 1.07 | 1.24 | 1.10 | 1.22 | 1.09 | 1.22 | |||

| N | , | , | ||||||||

| - | - | - | - | - | - | - | - | |||

| 1040.50 | 1035.90 | 989.56 | 988.71 | 1041.30 | 1031.20 | 989.05 | 988.57 | |||

| 0.03 | 0.07 | 0.01 | 0.08 | 0.03 | 0.07 | 0.01 | 0.09 | |||

| M | 1079.10 | 1163.90 | 1005.90 | 1175.60 | 1099.20 | 1163.90 | 1007.10 | 1175.60 | ||

| 937.26 | 896.72 | 964.87 | 832.49 | 932.40 | 894.52 | 963.24 | 830.55 | |||

| 1.15 | 1.30 | 1.04 | 1.41 | 1.18 | 1.30 | 1.05 | 1.42 | |||

| N | , | , | ||||||||

| - | - | - | - | - | - | - | - | |||

| 1137.00 | 1158.50 | 1158.50 | 1152.90 | 1140.30 | 1143.60 | 1156.60 | 1150.90 | |||

| 0.06 | 0.10 | 0.02 | 0.08 | 0.06 | 0.09 | 0.02 | 0.08 | |||

| M | 1262.50 | 1435.60 | 1204.30 | 1308.60 | 1265.40 | 1434.10 | 1205.60 | 1302.20 | ||

| 1039.70 | 1037.50 | 1120.40 | 974.57 | 1016.70 | 1001.00 | 1115.90 | 973.22 | |||

| 1.21 | 1.38 | 1.07 | 1.34 | 1.24 | 1.43 | 1.08 | 1.34 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 0.0018 | 0.0018 | 0.0028 | 0.0028 | 0.0018 | 0.0018 | 0.0028 | 0.0028 | |||

| 0.20 | 0.24 | 0.05 | 0.12 | 0.20 | 0.24 | 0.05 | 0.12 | |||

| M | 0.0024 | 0.0026 | 0.0030 | 0.0034 | 0.0024 | 0.0026 | 0.0030 | 0.0034 | ||

| 0.0010 | 0.0010 | 0.0026 | 0.0022 | 0.0010 | 0.0010 | 0.0026 | 0.0021 | |||

| 2.54 | 2.67 | 1.18 | 1.53 | 2.49 | 2.61 | 1.16 | 1.59 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 0.0054 | 0.0054 | 0.0100 | 0.0100 | 0.0054 | 0.0054 | 0.0101 | 0.0100 | |||

| 0.27 | 0.27 | 0.04 | 0.05 | 0.27 | 0.27 | 0.05 | 0.05 | |||

| M | 0.0081 | 0.0082 | 0.0106 | 0.0108 | 0.0083 | 0.0084 | 0.0109 | 0.0111 | ||

| 0.0024 | 0.0025 | 0.0088 | 0.0089 | 0.0024 | 0.0024 | 0.0088 | 0.0089 | |||

| 3.30 | 3.34 | 1.20 | 1.21 | 3.41 | 3.45 | 1.24 | 1.25 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 0.0123 | 0.0123 | 0.0214 | 0.0213 | 0.0123 | 0.0123 | 0.0214 | 0.0213 | |||

| 0.26 | 0.28 | 0.04 | 0.07 | 0.26 | 0.28 | 0.05 | 0.07 | |||

| M | 0.0180 | 0.0189 | 0.0228 | 0.0241 | 0.0182 | 0.0191 | 0.0230 | 0.0242 | ||

| 0.0051 | 0.0051 | 0.0189 | 0.0191 | 0.0051 | 0.0051 | 0.0188 | 0.0190 | |||

| 3.56 | 3.70 | 1.21 | 1.26 | 3.58 | 3.75 | 1.22 | 1.27 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 0.0175 | 0.0177 | 0.0317 | 0.0316 | 0.0184 | 0.0186 | 0.0317 | 0.0315 | |||

| 0.27 | 0.27 | 0.04 | 0.08 | 0.23 | 0.23 | 0.05 | 0.07 | |||

| M | 0.0267 | 0.0271 | 0.0341 | 0.0361 | 0.0263 | 0.0269 | 0.0342 | 0.0358 | ||

| 0.0089 | 0.0090 | 0.0286 | 0.0280 | 0.0112 | 0.0113 | 0.0286 | 0.0282 | |||

| 3.02 | 2.99 | 1.19 | 1.29 | 2.35 | 2.38 | 1.20 | 1.27 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 0.0276 | 0.0276 | 0.0439 | 0.0438 | 0.0277 | 0.0276 | 0.0439 | 0.0438 | |||

| 0.23 | 0.25 | 0.07 | 0.10 | 0.23 | 0.25 | 0.07 | 0.10 | |||

| M | 0.0398 | 0.0416 | 0.0496 | 0.0520 | 0.0400 | 0.0418 | 0.0499 | 0.0523 | ||

| 0.0136 | 0.0139 | 0.0382 | 0.0386 | 0.0136 | 0.0139 | 0.0380 | 0.0388 | |||

| 2.93 | 3.00 | 1.30 | 1.35 | 2.94 | 3.02 | 1.31 | 1.35 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 0.0457 | 0.0456 | 0.0687 | 0.0685 | 0.0457 | 0.0456 | 0.0688 | 0.0686 | |||

| 0.23 | 0.25 | 0.09 | 0.11 | 0.23 | 0.25 | 0.09 | 0.11 | |||

| M | 0.0655 | 0.0683 | 0.0799 | 0.0835 | 0.0656 | 0.0684 | 0.0803 | 0.0839 | ||

| 0.0228 | 0.0232 | 0.0546 | 0.0558 | 0.0228 | 0.0232 | 0.0544 | 0.0556 | |||

| 2.87 | 2.94 | 1.46 | 1.50 | 2.88 | 2.95 | 1.48 | 1.51 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 0.0439 | 0.0439 | 0.0657 | 0.0657 | 0.0439 | 0.0438 | 0.0657 | 0.0657 | |||

| 0.25 | 0.28 | 0.08 | 0.12 | 0.25 | 0.28 | 0.08 | 0.12 | |||

| M | 0.0628 | 0.0675 | 0.0754 | 0.0807 | 0.0626 | 0.0672 | 0.0752 | 0.0806 | ||

| 0.0186 | 0.0189 | 0.0547 | 0.0558 | 0.0186 | 0.0187 | 0.0544 | 0.0555 | |||

| 3.37 | 3.57 | 1.38 | 1.45 | 3.36 | 3.60 | 1.38 | 1.45 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 0.0305 | 0.0309 | 0.0492 | 0.0490 | 0.0321 | 0.0323 | 0.0491 | 0.0489 | |||

| 0.26 | 0.26 | 0.07 | 0.11 | 0.22 | 0.23 | 0.07 | 0.10 | |||

| M | 0.0459 | 0.0468 | 0.0564 | 0.0601 | 0.0448 | 0.0461 | 0.0564 | 0.0589 | ||

| 0.0155 | 0.0159 | 0.0420 | 0.0422 | 0.0194 | 0.0196 | 0.0420 | 0.0423 | |||

| 2.95 | 2.95 | 1.34 | 1.42 | 2.31 | 2.35 | 1.34 | 1.39 | |||

| N | ||||||||

| b = 2 m | b = 4 m | b = 8 m | b = 2 m | b = 4 m | b = 8 m | |||

| 652.06 | 642.80 | 658.60 | 720.63 | 711.95 | 736.82 | |||

| 0.07 | 0.05 | 0.03 | 0.06 | 0.06 | 0.03 | |||

| M | 714.77 | 700.04 | 699.92 | 795.46 | 788.87 | 764.27 | ||

| 566.54 | 569.01 | 610.76 | 617.93 | 625.67 | 683.02 | |||

| 1.26 | 1.23 | 1.15 | 1.29 | 1.26 | 1.12 | |||

| N | ||||||||

| b = 2 m | b = 4 m | b = 8 m | b = 2 m | b = 4 m | b = 8 m | |||

| 926.81 | 905.85 | 943.85 | 1069.60 | 1044.70 | 1086.30 | |||

| 0.11 | 0.08 | 0.06 | 0.12 | 0.09 | 0.06 | |||

| M | 1104.00 | 1031.60 | 1056.80 | 1287.50 | 1213.10 | 1231.30 | ||

| 727.98 | 745.38 | 823.83 | 840.41 | 855.21 | 945.59 | |||

| 1.52 | 1.38 | 1.28 | 1.53 | 1.42 | 1.30 | |||

| b = 2 m | b = 4 m | b = 8 m | b = 2 m | b = 4 m | b = 8 m | |||

| 0.0031 | 0.0030 | 0.0031 | 0.0121 | 0.0114 | 0.0118 | |||

| 0.15 | 0.12 | 0.05 | 0.10 | 0.08 | 0.06 | |||

| M | 0.0040 | 0.0038 | 0.0034 | 0.0139 | 0.0127 | 0.0135 | ||

| 0.0022 | 0.0023 | 0.0027 | 0.0093 | 0.0098 | 0.0104 | |||

| 1.79 | 1.62 | 1.24 | 1.50 | 1.29 | 1.29 | |||

| b = 2 m | b = 4 m | b = 8 m | b = 2 m | b = 4 m | b = 8 m | |||

| 0.0254 | 0.0240 | 0.0250 | 0.0374 | 0.0355 | 0.0370 | |||

| 0.11 | 0.08 | 0.05 | 0.12 | 0.10 | 0.05 | |||

| M | 0.0301 | 0.0278 | 0.0283 | 0.0447 | 0.0423 | 0.0417 | ||

| 0.0191 | 0.0203 | 0.0228 | 0.0273 | 0.0299 | 0.0346 | |||

| 1.58 | 1.37 | 1.24 | 1.64 | 1.42 | 1.20 | |||

| b = 2 m | b = 4 m | b = 8 m | b = 2 m | b = 4 m | b = 8 m | |||

| 0.0551 | 0.0528 | 0.0549 | 0.0889 | 0.0861 | 0.0898 | |||

| 0.10 | 0.07 | 0.06 | 0.08 | 0.07 | 0.06 | |||

| M | 0.0647 | 0.0595 | 0.0609 | 0.0987 | 0.0955 | 0.1001 | ||

| 0.0426 | 0.0457 | 0.0484 | 0.0750 | 0.0730 | 0.0751 | |||

| 1.52 | 1.30 | 1.26 | 1.32 | 1.31 | 1.33 | |||

| b = 2 m | b = 4 m | b = 8 m | b = 2 m | b = 4 m | b = 8 m | |||

| 0.0845 | 0.0810 | 0.0850 | 0.0634 | 0.0611 | 0.0639 | |||

| 0.11 | 0.09 | 0.07 | 0.11 | 0.08 | 0.07 | |||

| M | 0.1000 | 0.0931 | 0.0946 | 0.0756 | 0.0704 | 0.0712 | ||

| 0.0670 | 0.0680 | 0.0720 | 0.0493 | 0.0516 | 0.0533 | |||

| 1.49 | 1.37 | 1.31 | 1.53 | 1.36 | 1.34 | |||

| - | - | - | - | - | - | - | - | |||

| 59.81 | 59.66 | 59.71 | 59.55 | 62.71 | 62.59 | 62.80 | 62.68 | |||

| 1.14 × 10−3 | 0.03 | 6.08 × 10−4 | 0.03 | 8.38 × 10−4 | 0.02 | 1.10 × 10−3 | 0.02 | |||

| 59.21 | 58.36 | 59.41 | 57.96 | 62.43 | 61.51 | 62.30 | 61.23 | |||

| - | - | - | - | - | - | - | - | |||

| 727.14 | 727.03 | 628.98 | 628.49 | 831.76 | 831.56 | 712.12 | 712.67 | |||

| 0.05 | 0.11 | 0.01 | 0.10 | 0.06 | 0.11 | 0.01 | 0.09 | |||

| 663.98 | 595.68 | 623.40 | 516.65 | 758.50 | 686.22 | 706.17 | 585.51 | |||

| - | - | - | - | - | - | - | - | |||

| 102.67 | 102.51 | 99.19 | 98.97 | 86.15 | 86.04 | 82.39 | 82.27 | |||

| 0.01 | 0.01 | 2.17 × 10−3 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | |||

| 101.49 | 100.96 | 98.88 | 96.99 | 85.32 | 85.38 | 81.32 | 81.22 | |||

| - | - | - | - | - | - | - | - | |||

| 1054.80 | 1054.90 | 947.37 | 947.81 | 1104.70 | 1104.30 | 991.54 | 991.90 | |||

| 0.03 | 0.11 | 2.41 × 10−3 | 0.11 | 0.03 | 0.11 | 2.30 × 10−3 | 0.11 | |||

| 994.62 | 839.67 | 943.22 | 754.34 | 1042.10 | 888.32 | 987.30 | 796.09 | |||

| - | - | - | - | - | - | - | - | |||

| 7.68 | 7.68 | 14.42 | 14.36 | 8.76 | 8.74 | 16.60 | 16.52 | |||

| 0.22 | 0.25 | 0.01 | 0.07 | 0.22 | 0.24 | 0.01 | 0.06 | |||

| - | - | - | - | - | - | - | - | |||

| 5.50 | 5.51 | 11.20 | 11.19 | 5.90 | 5.91 | 11.93 | 11.92 | |||

| 0.24 | 0.26 | 4.02 × 10−3 | 0.05 | 0.24 | 0.26 | 4.26 × 10−3 | 0.04 | |||

| - | - | - | - | - | - | - | - | |||

| 8.86 | 8.86 | 16.90 | 16.85 | 8.38 | 8.36 | 15.92 | 15.84 | |||

| 0.23 | 0.25 | 0.01 | 0.06 | 0.23 | 0.25 | 0.01 | 0.05 | |||

| - | - | - | - | - | - | - | - | |||

| 10.34 | 10.36 | 19.45 | 19.42 | 10.29 | 10.32 | 19.21 | 19.21 | |||

| 0.22 | 0.24 | 0.01 | 0.05 | 0.22 | 0.24 | 0.01 | 0.05 | |||

| - | - | - | - | - | - | - | - | |||

| 0.32 | 0.32 | 0.25 | 0.25 | 0.28 | 0.28 | 0.21 | 0.20 | |||

| 0.06 | 0.10 | 0.02 | 0.07 | 0.08 | 0.13 | 0.02 | 0.12 | |||

| - | - | - | - | - | - | - | - | |||

| 0.12 | 0.12 | 0.08 | 0.08 | 0.10 | 0.10 | 0.07 | 0.07 | |||

| 0.12 | 0.15 | 0.01 | 0.08 | 0.11 | 0.17 | 0.01 | 0.12 | |||

| - | - | - | - | - | - | - | - | |||

| 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.02 | 0.02 | |||

| 0.06 | 0.25 | 0.03 | 0.25 | 0.08 | 0.30 | 0.02 | 0.31 | |||

| - | - | - | - | - | - | - | - | |||

| 0.17 | 0.18 | 0.13 | 0.13 | 0.19 | 0.19 | 0.14 | 0.14 | |||

| 0.11 | 0.11 | 0.01 | 0.01 | 0.11 | 0.11 | 0.01 | 0.02 | |||

| X | Y | Z | Probability | X | Y | Z | Probability | |||

| - | 3.21 | 2.21 | 3.79 | 100.00 | 1.79 | 2.21 | 3.79 | 100.00 | ||

| - | 3.21 | 2.21 | 3.79 | 100.00 | 1.79 | 2.21 | 3.79 | 100.00 | ||

| - | 3.21 | 2.21 | 3.79 | 100.00 | 1.79 | 2.21 | 3.79 | 100.00 | ||

| - | 3.21 | 2.21 | 3.79 | 100.00 | 1.79 | 2.21 | 3.79 | 100.00 | ||

| X | Y | Z | Probability | X | Y | Z | Probability | |||

| - | 1.79 | 2.21 | 3.79 | 100.00 | 1.79 | 2.21 | 3.79 | 100.00 | ||

| - | 1.79 | 2.21 | 3.79 | 100.00 | 1.79 | 2.21 | 3.79 | 100.00 | ||

| - | 1.79 | 2.21 | 3.79 | 100.00 | 1.79 | 2.21 | 3.79 | 100.00 | ||

| - | 1.79 | 2.21 | 3.79 | 100.00 | 1.79 | 2.21 | 3.79 | 100.00 | ||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 58.77 | 58.61 | 58.53 | 58.37 | 58.76 | 58.60 | 58.51 | 58.35 | |||

| 1.88× 10−3 | 0.03 | 9.13× 10−4 | 0.03 | 2.21× 10−3 | 0.03 | 1.88× 10−3 | 0.03 | |||

| 58.55 | 57.80 | 58.29 | 57.68 | 58.35 | 57.95 | 57.98 | 57.55 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 61.97 | 61.85 | 62.46 | 62.35 | 61.96 | 61.85 | 62.45 | 62.35 | |||

| 1.2× 10−3 | 0.02 | 0.03 | 0.04 | 1.38× 10−3 | 0.02 | 0.03 | 0.04 | |||

| 61.55 | 60.80 | 59.33 | 58.85 | 61.46 | 60.03 | 60.15 | 59.96 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 651.89 | 647.68 | 553.58 | 551.63 | 645.94 | 640.38 | 553.13 | 551.47 | |||

| 0.06 | 0.08 | 0.29 | 0.31 | 0.08 | 0.10 | 0.29 | 0.31 | |||

| 506.76 | 524.91 | 7.05 | 7.12 | 487.21 | 452.06 | 7.06 | 7.12 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 585.67 | 631.72 | 660.34 | 654.98 | 554.99 | 598.62 | 658.64 | 652.31 | |||

| 0.13 | 0.13 | 0.01 | 0.08 | 0.30 | 0.31 | 0.01 | 0.08 | |||

| 432.41 | 474.54 | 650.04 | 547.02 | 3.80 | 0.19 | 649.08 | 544.82 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 104.93 | 104.73 | 102.52 | 102.28 | 105.04 | 104.83 | 102.64 | 102.39 | |||

| 4.43× 10−3 | 0.01 | 3.17× 10−3 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | |||

| 104.24 | 102.94 | 101.86 | 99.49 | 103.74 | 103.25 | 101.04 | 100.26 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 85.96 | 85.86 | 83.44 | 83.34 | 86.03 | 85.93 | 83.52 | 83.41 | |||

| 1.71× 10−3 | 2.30× 10−3 | 0.02 | 0.02 | 0.01 | 4.78× 10−3 | 0.02 | 0.02 | |||

| 85.74 | 85.43 | 82.12 | 81.71 | 85.33 | 85.35 | 81.32 | 81.38 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 1023.70 | 1019.40 | 880.24 | 877.83 | 1019.70 | 1015.50 | 880.04 | 877.72 | |||

| 0.02 | 0.09 | 0.23 | 0.26 | 0.03 | 0.09 | 0.23 | 0.26 | |||

| 980.69 | 825.87 | 83.43 | 83.99 | 935.75 | 825.01 | 82.94 | 83.48 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 1001.00 | 1032.30 | 972.18 | 970.95 | 958.26 | 977.07 | 971.70 | 969.90 | |||

| 0.04 | 0.13 | 3.28× 10−3 | 0.10 | 0.20 | 0.24 | 3.26× 10−3 | 0.10 | |||

| 943.32 | 862.25 | 965.64 | 780.05 | 233.89 | 235.83 | 965.46 | 779.38 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 7.45 | 7.45 | 13.92 | 13.87 | 7.45 | 7.45 | 13.91 | 13.87 | |||

| 0.22 | 0.25 | 3.87× 10−3 | 0.07 | 0.22 | 0.25 | 3.90× 10−3 | 0.07 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 8.53 | 8.52 | 15.49 | 15.40 | 8.53 | 8.52 | 15.49 | 15.40 | |||

| 0.22 | 0.24 | 0.19 | 0.20 | 0.22 | 0.24 | 0.19 | 0.20 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 5.32 | 5.31 | 10.02 | 9.99 | 5.29 | 5.32 | 10.02 | 9.99 | |||

| 0.27 | 0.28 | 0.36 | 0.37 | 0.27 | 0.28 | 0.36 | 0.37 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 5.11 | 5.35 | 11.53 | 11.51 | 4.68 | 4.88 | 11.53 | 11.49 | |||

| 0.35 | 0.31 | 3.19× 10−3 | 0.04 | 0.62 | 0.60 | 3.48× 10−3 | 0.04 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 8.97 | 8.97 | 17.20 | 17.15 | 8.98 | 8.97 | 17.21 | 17.16 | |||

| 0.23 | 0.25 | 0.01 | 0.06 | 0.23 | 0.25 | 0.01 | 0.06 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 8.38 | 8.37 | 15.30 | 15.22 | 8.39 | 8.37 | 15.32 | 15.24 | |||

| 0.23 | 0.25 | 0.19 | 0.20 | 0.23 | 0.25 | 0.19 | 0.20 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 10.30 | 10.30 | 18.95 | 18.91 | 10.33 | 10.29 | 18.96 | 18.92 | |||

| 0.25 | 0.27 | 0.21 | 0.21 | 0.24 | 0.27 | 0.21 | 0.21 | |||

| , | , | |||||||||

| - | - | - | - | - | - | - | - | |||

| 9.65 | 9.61 | 19.78 | 19.67 | 9.73 | 9.72 | 19.76 | 0.02 | |||

| 0.24 | 0.25 | 0.01 | 0.04 | 0.23 | 0.23 | 0.01 | 0.04 | |||

| X | Y | Z | Probability | |||||||

| -- | 3.21 | 2.21 | 3.79 | 100.00 | ||||||

| -- | 3.21 | 2.21 | 3.79 | 100.00 | ||||||

| -- | 3.21 | 2.21 | 3.79 | 100.00 | ||||||

| -- | 3.21 | 2.21 | 3.79 | 100.00 | ||||||

| -- | 3.21 | 2.21 | 3.79 | 100.00 | ||||||

| -- | 3.21 | 2.21 | 3.79 | 100.00 | ||||||

| -- | 3.21 | 2.21 | 3.79 | 100.00 | ||||||

| -- | 3.21 | 2.21 | 3.79 | 100.00 | ||||||

| X | Y | Z | Probability | |||||||

| -- | 3.79 | 2.21 | 3.79 | 100.00 | ||||||

| -- | 3.79 | 2.21 | 3.79 | 100.00 | ||||||

| -- | 3.79 | 2.21 | 3.79 | 93.75 | ||||||

| 4.79 | 0.21 | 0.21 | 6.25 | |||||||

| -- | 3.79 | 2.21 | 3.79 | 93.75 | ||||||

| 4.79 | 0.21 | 0.21 | 6.25 | |||||||

| -- | 3.79 | 2.21 | 3.79 | 100.00 | ||||||

| -- | 3.79 | 2.21 | 3.79 | 100.00 | ||||||

| -- | 3.79 | 2.21 | 3.79 | 93.75 | ||||||

| 4.79 | 0.21 | 0.21 | 6.25 | |||||||

| -- | 3.79 | 2.21 | 3.79 | 93.75 | ||||||

| 4.79 | 0.21 | 0.21 | 6.25 | |||||||

| X | Y | Z | Probability | |||||||

| -- | 1.79 | 2.21 | 3.79 | 100.00 | ||||||

| -- | 1.79 | 2.21 | 3.79 | 100.00 | ||||||

| -- | 1.79 | 2.21 | 3.79 | 93.75 | ||||||

| 4.79 | 0.21 | 0.21 | 6.25 | |||||||

| -- | 1.79 | 2.21 | 3.79 | 93.75 | ||||||

| 4.79 | 0.21 | 0.21 | 6.25 | |||||||

| -- | 1.79 | 2.21 | 3.79 | 100.00 | ||||||

| -- | 1.79 | 2.21 | 3.79 | 100.00 | ||||||

| -- | 1.79 | 2.21 | 3.79 | 93.75 | ||||||

| 4.79 | 0.21 | 0.21 | 6.25 | |||||||

| -- | 1.79 | 2.21 | 3.79 | 93.75 | ||||||

| 4.79 | 0.21 | 0.21 | 6.25 | |||||||

| X | Y | Z | Probability | |||||||

| -- | 1.79 | 2.21 | 3.79 | 81.25 | ||||||

| 1.79 | 1.79 | 3.79 | 12.50 | |||||||

| 1.79 | 3.21 | 3.79 | 6.25 | |||||||

| -- | 1.79 | 2.21 | 3.79 | 93.75 | ||||||

| 1.79 | 3.21 | 3.79 | 6.25 | |||||||

| -- | 1.79 | 2.21 | 3.79 | 100.00 | ||||||

| -- | 1.79 | 2.21 | 3.79 | 100.00 | ||||||

| -- | 1.79 | 2.21 | 3.79 | 87.50 | ||||||

| 1.79 | 3.21 | 3.79 | 6.25 | |||||||

| 0.21 | 0.21 | 0.21 | 6.25 | |||||||

| -- | 1.79 | 2.21 | 3.79 | 81.25 | ||||||

| 1.79 | 2.79 | 3.79 | 12.50 | |||||||

| 0.21 | 0.21 | 0.21 | 6.25 | |||||||

| -- | 1.79 | 2.21 | 3.79 | 100.00 | ||||||

| -- | 1.79 | 2.21 | 3.79 | 100.00 | ||||||

| b = 2 m | b = 4 m | b = 8 m | b = 2 m | b = 4 m | b = 8 m | |||||

| 57.92 | 57.68 | 58.29 | 60.38 | 59.67 | 61.37 | |||||

| 0.04 | 0.03 | 0.01 | 0.11 | 0.10 | 0.05 | |||||

| 56.95 | 56.85 | 57.67 | 48.89 | 49.76 | 57.69 | |||||

| b = 2 m | b = 4 m | b = 8 m | b = 2 m | b = 4 m | b = 8 m | |||||

| 512.39 | 497.14 | 573.23 | 621.49 | 607.80 | 634.77 | |||||

| 0.32 | 0.31 | 0.04 | 0.11 | 0.08 | 0.04 | |||||

| 6.84 | 6.92 | 509.42 | 493.61 | 519.47 | 566.88 | |||||

| b = 2 m | b = 4 m | b = 8 m | b = 2 m | b = 4 m | b = 8 m | |||||

| 103.22 | 104.88 | 103.65 | 101.89 | 103.44 | 92.96 | |||||

| 0.03 | 0.03 | 0.02 | 0.29 | 0.28 | 0.22 | |||||

| 98.04 | 96.97 | 99.64 | 80.98 | 78.60 | 81.08 | |||||

| b = 2 m | b = 4 m | b = 8 m | b = 2 m | b = 4 m | b = 8 m | |||||

| 842.46 | 839.72 | 919.65 | 946.08 | 942.54 | 957.25 | |||||

| 0.27 | 0.26 | 0.04 | 0.14 | 0.10 | 0.04 | |||||

| 84.38 | 84.52 | 821.08 | 710.68 | 753.96 | 858.87 | |||||

| b = 2 m | b = 4 m | b = 8 m | b = 2 m | b = 4 m | b = 8 m | |||||

| 14.55 | 13.17 | 14.14 | 14.04 | 12.58 | 15.37 | |||||

| 0.21 | 0.24 | 0.08 | 0.28 | 0.30 | 0.17 | |||||

| b = 2 m | b = 4 m | b = 8 m | b = 2 m | b = 4 m | b = 8 m | |||||

| 9.97 | 8.74 | 11.06 | 12.09 | 10.79 | 11.65 | |||||

| 0.57 | 0.51 | 0.09 | 0.22 | 0.29 | 0.09 | |||||

| b = 2 m | b = 4 m | b = 8 m | b = 2 m | b = 4 m | b = 8 m | |||||

| 18.25 | 16.63 | 17.67 | 15.88 | 14.41 | 16.25 | |||||

| 0.20 | 0.23 | 0.07 | 0.27 | 0.28 | 0.16 | |||||

| b = 2 m | b = 4 m | b = 8 m | b = 2 m | b = 4 m | b = 8 m | |||||

| 19.99 | 17.83 | 20.30 | 20.77 | 18.95 | 20.10 | |||||

| 0.24 | 0.27 | 0.07 | 0.20 | 0.24 | 0.07 | |||||

| X | Y | Z | Probability | |||||||

| b = 2 m | 3.21 | 2.21 | 3.79 | 100.00 | ||||||

| b = 4 m | 3.21 | 2.21 | 3.79 | 100.00 | ||||||

| b = 8 m | 3.21 | 2.21 | 3.79 | 100.00 | ||||||

| X | Y | Z | Probability | |||||||

| b = 2 m | 3.79 | 2.21 | 3.79 | 43.75 | ||||||

| 4.79 | 2.21 | 0.21 | 18.75 | |||||||

| 4.79 | 0.21 | 0.21 | 12.50 | |||||||

| 3.21 | 1.79 | 3.79 | 12.50 | |||||||

| 3.21 | 2.21 | 3.79 | 12.50 | |||||||

| b = 4 m | 3.79 | 2.21 | 3.79 | 56.25 | ||||||

| 4.79 | 0.21 | 0.21 | 18.75 | |||||||

| 3.21 | 1.79 | 3.79 | 12.50 | |||||||

| 3.21 | 2.21 | 3.79 | 12.50 | |||||||

| b = 8 m | 3.79 | 2.21 | 3.79 | 75 | ||||||

| 3.21 | 2.21 | 3.79 | 12.5 | |||||||

| 4.79 | 0.21 | 0.21 | 6.25 | |||||||

| 4.79 | 2.21 | 0.21 | 6.25 | |||||||

| X | Y | Z | Probability | |||||||

| b = 2 m | 1.79 | 2.21 | 3.79 | 87.50 | ||||||

| 1.79 | 1.79 | 3.79 | 6.25 | |||||||

| 4.79 | 0.21 | 0.21 | 6.25 | |||||||

| b = 4 m | 1.79 | 2.21 | 3.79 | 68.75 | ||||||

| 1.79 | 1.79 | 3.79 | 25.00 | |||||||

| 4.79 | 0.21 | 0.21 | 6.25 | |||||||

| b = 8 m | 1.79 | 2.21 | 3.79 | 100.00 | ||||||

| X | Y | Z | Probability | |||||||

| b = 2 m | 1.79 | 2.21 | 3.79 | 100.00 | ||||||

| b = 4 m | 1.79 | 2.21 | 3.79 | 100.00 | ||||||

| b = 8 m | 1.79 | 2.21 | 3.79 | 100.00 | ||||||

References

- Terzaghi, K.V. Theoretical Soil Mechanics; Wiley and Sons: Hoboken, NJ, USA, 1966. [Google Scholar]

- Zhou, H.; Zheng, G.; Yin, X.; Jia, R.; Yang, X. The bearing capacity and failure mechanism of a vertically loaded strip footing placed on the top of slopes. Comput. Geotech. 2018, 94, 12–21. [Google Scholar] [CrossRef]

- Naderi, E.; Asakereh, A.; Dehghani, M. Bearing Capacity of Strip Footing on Clay Slope Reinforced with Stone Columns. Arab. J. Sci. Eng. 2018, 43, 5559–5572. [Google Scholar] [CrossRef]

- Sultana, P.; Dey, A.K. Estimation of Ultimate Bearing Capacity of Footings on Soft Clay from Plate Load Test Data Considering Variability. Indian Geotech. J. 2019, 49, 170–183. [Google Scholar] [CrossRef]

- Fu, D.; Zhang, Y.; Yan, Y. Bearing capacity of a side-rounded suction caisson foundation under general loading in clay. Comput. Geotech. 2020, 123, 103543. [Google Scholar] [CrossRef]

- Li, S.; Yu, J.; Huang, M.; Leung, G. Upper bound analysis of rectangular surface footings on clay with linearly increasing strength. Comput. Geotech. 2021, 129, 103896. [Google Scholar] [CrossRef]

- Michalowski, R.L.; Shi, L. Bearing Capacity of Footings over Two-Layer Foundation Soils. J. Geotech. Eng. 1995, 121. [Google Scholar] [CrossRef]

- Rao, P.; Liu, Y.; Cui, J. Bearing capacity of strip footings on two-layered clay under combined loading. Comput. Geotech. 2015, 69, 210–218. [Google Scholar] [CrossRef]

- Papadopoulou, K.; Gazetas, G. Shape Effects on Bearing Capacity of Footings on Two-Layered Clay. Geotech. Geol. Eng. 2020, 38, 1347–1370. [Google Scholar] [CrossRef]

- Michalowski, R.L. An Estimate of the Influence of Soil Weight on Bearing Capacity Using Limit Analysis. Soils Found. 1997, 37, 57–64. [Google Scholar] [CrossRef] [Green Version]

- Michalowski, R.L. Upper-bound load estimates on square and rectangular footings. Geotechnique 2001, 51, 787–798. [Google Scholar] [CrossRef]

- Martin, C. Exact bearing capacity calculations using the method of characteristics. In Proceedings of the 11th International Conference IACMAG Graz, Turin, Italy, 19–24 June 2005. [Google Scholar]

- Matthies, H.G.; Brenner, C.E.; Butcher, G.; Soares, C.G. Uncertainties in probabilistic numerical analysis of structures and solids- Stochastic finite elements. Struct. Saf. 1997, 19, 283–336. [Google Scholar] [CrossRef]

- Assimaki, D.; Pecker, A.; Popescu, R.; Prevost, J. Effects of spatial variabilty of soil properties on surface ground motion. J. Earthq. Eng. 2003, 7, 1–44. [Google Scholar] [CrossRef]

- Popescu, R.; Deodatis, G.; Nobahar, A. Effects of random heterogeneity of soil properties on bearing capacity. Probabilistic Eng. Mech. 2005, 20, 324–341. [Google Scholar] [CrossRef]

- Meftah, F.; Dal-Pont, S.; Schrefler, B.A. A three-dimensional staggered finite element approach for random parametric modeling of thermo-hygral coupled phenomena in porous media. Int. J. Numer. Anal. Methods Geomech. 2012, 36, 574–596. [Google Scholar] [CrossRef]

- Li, D.Q.; Qi, X.H.; Cao, Z.J.; Tang, X.S.; Zhou, W.; Phoon, K.K.; Zhou, C.B. Reliability analysis of strip footing considering spatially variable undrained shear strength that linearly increases with depth. Soils Found. 2015, 55, 866–880. [Google Scholar] [CrossRef] [Green Version]

- Karhunen, K. Uber lineare Methoden in der Wahrscheinlichkeitsrechnung. In Annales Academiae Scientarium Fenniciae; Series A. 1; Soumalainen Tiedeakatemia: Helsinki, Finland, 1947; Volume 37, pp. 1–79. [Google Scholar]

- Ghanem, R.; Spanos, D. Stochastic Finite Elements: A Spectral Approach; Springer: Cham, Switzerland, 1991; Volume 1, pp. 1–214. [Google Scholar] [CrossRef]

- Papadrakakis, M.; Papadopoulos, V. Robust and efficient methods for the stochastic finite element analysis using Monte Carlo simulation. Comput. Methods Appl. Mech. Eng. 1996, 134, 325–340. [Google Scholar] [CrossRef]

- Sett, K.; Jeremic, B. Probabilistic elasto-plasticity: Solution and verification in 1D. Acta Geotech. 2007, 2, 211–220. [Google Scholar] [CrossRef]

- Liu, W.; Sun, Q.; Miao, H.; Li, J. Nonlinear stochastic seismic analysis of buried pipeline systems. Soil Dyn. Earthq. Eng. 2015, 74, 69–78. [Google Scholar] [CrossRef]

- Ali, A.; Lyamin, A.; Huang, J.; Li, J.; Cassidy, M.; Sloan, S. Probabilistic stability assessment using adaptive limit analysis and random fields. Acta Geotech. 2017, 12, 937–948. [Google Scholar] [CrossRef]

- Brantson, E.T.; Ju, B.; Wu, D.; Gyan, P.S. Stochastic porous media modeling and high-resolution schemes for numerical simulation of subsurface immiscible fluid flow transport. Acta Geophys. 2018, 66, 243–266. [Google Scholar] [CrossRef]

- Chwała, M. Undrained bearing capacity of spatially random soil for rectangular footings. Soils Found. 2019, 59, 1508–1521. [Google Scholar] [CrossRef]

- Olsson, A.; Sandberg, G.; Dahlblom, O. On Latin hypercube sampling for structural reliability analysis. Struct. Saf. 2003, 25, 47–68. [Google Scholar] [CrossRef]

- Simoes, J.; Neves, L.; Antao, A.; Guerra, N. Reliability assessment of shallow foundations on undrained soils considering soil spatial variability. Comput. Geotech. 2020, 119, 103369. [Google Scholar] [CrossRef]

- Kawa, M.; Puła, W. 3D bearing capacity probabilistic analyses of footings on spatially variable c-ϕ soil. Acta Geotech. 2020, 15, 1453–1466. [Google Scholar] [CrossRef] [Green Version]

- Chwała, M. On determining the undrained bearing capacity coefficients of variation for foundations embedded on spatially variable soil. Stud. Geotech. Mech. 2020, 42, 125–136. [Google Scholar] [CrossRef]

- Li, Y.; Fenton, G.A.; Hicks, M.A.; Xu, N. Probabilistic Bearing Capacity Prediction of Square Footings on 3D Spatially Varying Cohesive Soils. Geotech. Geoevironmental Eng. 2021, 147, 04021035. [Google Scholar] [CrossRef]

- Kavvadas, M.; Amorosi, A. A constitutive model for structured soils. Geotechnique 2000, 50, 263–273. [Google Scholar] [CrossRef]

- Vrakas, A. On the computational applicability of the modified Cam-clay model on the ‘dry’ side. Comput. Geotech. 2018, 94, 214–230. [Google Scholar] [CrossRef]

- Stavroulakis, G.; Giovanis, D.; Papadopoulos, V.; Papadrakakis, M. A GPU domain decomposition solution for spectral stochastic finite element method. Comput. Methods Appl. Mech. Eng. 2014, 327, 392–410. [Google Scholar] [CrossRef]

- Stavroulakis, G.; Giovanis, D.; Papadopoulos, V.; Papadrakakis, M. A new perspective on the solution of uncertainty quantification and reliability analysis of large-scale problems. Comput. Methods Appl. Mech. Eng. 2014, 276, 627–658. [Google Scholar] [CrossRef]

- Savvides, A.; Papadrakakis, M. A computational study on the uncertainty quantification of failure of clays with a modified Cam-Clay yield criterion. SN Appl. Sci. 2021, 3, 659. [Google Scholar] [CrossRef]

- Huysmans, M.; Dassargues, A. Stochastic analysis of the effect of spatial variability of diffusion parameters on radionuclide transport in a low permeability clay layer. Hydrogeol. J. 2006, 14, 1094–1106. [Google Scholar] [CrossRef] [Green Version]

- Zhang, P.; Yin, Z.Y.; Jin, Y.F.; Chan, T.H.T.; Gao, F.P. Intelligent modelling of clay compressibility using hybrid meta-heuristic and machine learning algorithms. Geotech. Geoevironmental Eng. 2021, 12, 441–452. [Google Scholar] [CrossRef]

- Wang, Y.; Akeju, O.V. Quantifying the cross-correlation between effective cohesion and friction angle of soil from limited site-specific data. Soils Found. 2021, 56, 1055–1070. [Google Scholar] [CrossRef]

- Robert, C.P. Simulation of truncated normal variables. Stat. Comput. 1995, 5, 121–125. [Google Scholar] [CrossRef] [Green Version]

- Barr, D.R.; Sherrill, E.T. Mean and variance of truncated normal distributions. Am. Stat. 1999, 53, 357–361. [Google Scholar] [CrossRef]

- Zienkiewicz, O.C.; Chan, A.H.C.; Pastor, M.; Schrefler, B.A.; Shiomi, T. Computational Geomechanics with Special Reference to Earthquake Engineering; Wiley: Chichester, UK, 1999; Volume 1, pp. 17–49. [Google Scholar]

- Biot, M.A. General theory of three dimensional consolidation. J. Appl. Phys. 1941, 12, 155–164. [Google Scholar] [CrossRef]

- Lewis, R.W.; Schrefler, B.A. The Finite Element Method in the Deformation and Consolidation of Porous Media; Wiley Sons: Hoboken, NJ, USA, 1988; Volume 1, pp. 1–508. [Google Scholar] [CrossRef]

- Borja, R.; Lee, S. Cam-Clay plasticity, Part 1: Implicit integration of elasto-plastic constitutive relations. Comput. Methods Appl. Mech. Eng. 1990, 78, 49–72. [Google Scholar] [CrossRef]

- Borja, R. Cam-Clay plasticity, Part 2: Implicit integration of constitutive equation based on a nonlinear elastic stress predictor. Comput. Methods Appl. Mech. Eng. 1991, 88, 225–240. [Google Scholar] [CrossRef]

- Kalos, A. Investigation of the Nonlinear Time-Dependent Soil Behavior. Ph.D. Dissertation, National Technical Univerisity of Athens, Athens, Greece, 2014; pp. 193–236. [Google Scholar]

- Liu, W.; Belytschko, T.; Mani, A. Random fields finite element. Int. J. Numer. Methods Eng. 1986, 23, 1831–1845. [Google Scholar] [CrossRef]

- Li, C.; Kiureghian, A.D. Optimal discretization of random fields. J. Eng. Mech. 1993, 119, 1136–1154. [Google Scholar] [CrossRef]

- Fenton, G.; Griffiths, D. Bearing Capacity Prediction of Spatially Random c-ϕ Soils. Can. Geotech. J. 2003, 40, 54–65. [Google Scholar] [CrossRef]

- Pryse, S.; Adhikari, S. Stochastic finite element response analysis using random eigenfunction expansion. Comput. Struct. 2017, 192, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Peng, X.; Zhang, L.; Jeng, D.; Chenc, L.; Liao, C.; Yang, H. Effects of cross-correlated multiple spatially random soil properties on wave-induced oscillatory seabed response. Appl. Ocean Res. 2017, 62, 57–69. [Google Scholar] [CrossRef]

- Yue, Q.; Yao, J.; Alfredo, H.; Spanos, P.D. Efficient random field modeling of soil deposits properties. Soil Dyn. Earthq. Eng. 2018, 108, 1–12. [Google Scholar] [CrossRef]

- Papadopoulos, V.; Giovanis, D. Stochastic Finite Element Methods. An Introduction; Springer: Cham, Switzerland, 2018; Volmue 1, pp. 30–35. [Google Scholar] [CrossRef]

- Ang, A.S.; Tang, W. Probability Concepts in Engineering Planning and Design; Wiley and Sons: Hoboken, NJ, USA, 1975; Volume 1. [Google Scholar]

- Baecher, G.; Christian, J. Reliability and Statistics in Geotechnical Engineering; Wiley and Sons: Hoboken, NJ, USA, 2003; pp. 177–203. [Google Scholar]

- Bouhari, A. Adaptative Monte Carlo Method, A Variance Reduction Technique. Monte Carlo Methods Appl. 2004, 10, 1–24. [Google Scholar] [CrossRef]

- Melenk, J.M.; Babuska, I. The partition of unity finite element method: Basic theory and applications. Comput. Methods Appl. Mech. Eng. 1996, 139, 289–314. [Google Scholar] [CrossRef] [Green Version]

- Szabo, B.; Babuska, I. Intoduction to finite element analysis. Formulation, verification and validation. Wiley Ser. Comput. Mech. 2011, 1, 1–382. [Google Scholar] [CrossRef]

- Stickle, M.M.; Yague, A.; Pastor, M. Free Finite Element Approach for Saturated Porous Media: Consolidation. Math. Probl. Eng. 2016, 2016, 4256079. [Google Scholar] [CrossRef] [Green Version]

| Bisection Algorithm | Bisection Algorithm | Bisection Algorithm | Proposed Algorithm | Absolute Percentage Difference | |

|---|---|---|---|---|---|

| Initial value of failure stress (kPa) | 5000 | 5000 | 5000 | 5000 | |

| Initial value of safety stress (kPa) | 1000 | 2000 | 3000 | - | |

| Convergence tolerance | 0.01 | 0.01 | 0.01 | 0.01 | |

| Number of trials for convergence | 6 | 5 | 5 | 3 | |

| Displacement of failure at convergence (m) | 0.03054 | 0.03072 | 0.03054 | 0.03072 | 0.58 |

| Load of failure at convergence (kPa) | 4484.38 | 4478.52 | 4484.38 | 4477.50 | 0.15 |

| Computational time (mins) | 750 | 833 | 663 | 302 | 54.45 |

| Kpa | Kpa | OCR | |||||

|---|---|---|---|---|---|---|---|

| 10 | 1600 | 400 | 4 | 1.627 | 0.75 | 0.05 | 20 |

| c | Abbreviation | |

|---|---|---|

| Constant | Deterministic | -- |

| Constant | Random | -- |

| Linear | Deterministic | -- |

| Linear | Random | -- |

| c | k | Abbreviation | |

|---|---|---|---|

| Constant | Deterministic | Deterministic | --- |

| Constant | Random | Deterministic | --- |

| Linear | Deterministic | Deterministic | --- |

| Linear | Random | Deterministic | --- |

| Constant | Deterministic | Random | --- |

| Constant | Random | Random | --- |

| Linear | Deterministic | Random | --- |

| Linear | Random | Random | --- |

| Random Field, b = 2 | Random Field, b = 2 | Random Field, b = 2 | --- |

| Random Field, b = 4 | Random Field, b = 4 | Random Field, b = 4 | --- |

| Random Field, b = 8 | Random Field, b = 8 | Random Field, b = 8 | --- |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Savvides, A.-A.; Papadrakakis, M. Probabilistic Failure Estimation of an Oblique Loaded Footing Settlement on Cohesive Geomaterials with a Modified Cam Clay Material Yield Function. Geotechnics 2021, 1, 347-384. https://doi.org/10.3390/geotechnics1020017

Savvides A-A, Papadrakakis M. Probabilistic Failure Estimation of an Oblique Loaded Footing Settlement on Cohesive Geomaterials with a Modified Cam Clay Material Yield Function. Geotechnics. 2021; 1(2):347-384. https://doi.org/10.3390/geotechnics1020017

Chicago/Turabian StyleSavvides, Ambrosios-Antonios, and Manolis Papadrakakis. 2021. "Probabilistic Failure Estimation of an Oblique Loaded Footing Settlement on Cohesive Geomaterials with a Modified Cam Clay Material Yield Function" Geotechnics 1, no. 2: 347-384. https://doi.org/10.3390/geotechnics1020017

APA StyleSavvides, A.-A., & Papadrakakis, M. (2021). Probabilistic Failure Estimation of an Oblique Loaded Footing Settlement on Cohesive Geomaterials with a Modified Cam Clay Material Yield Function. Geotechnics, 1(2), 347-384. https://doi.org/10.3390/geotechnics1020017