The Mechanical Response of a Silty Sand Stabilized with Colloidal Silica

Abstract

:1. Introduction

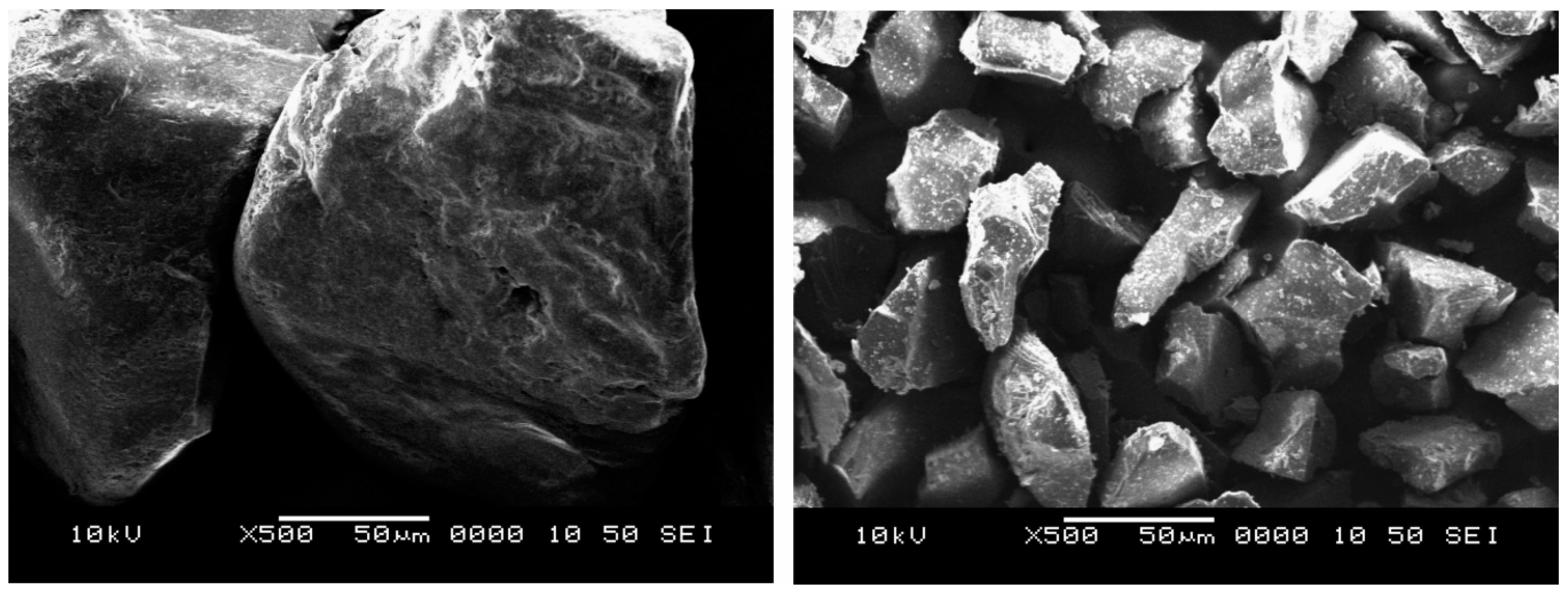

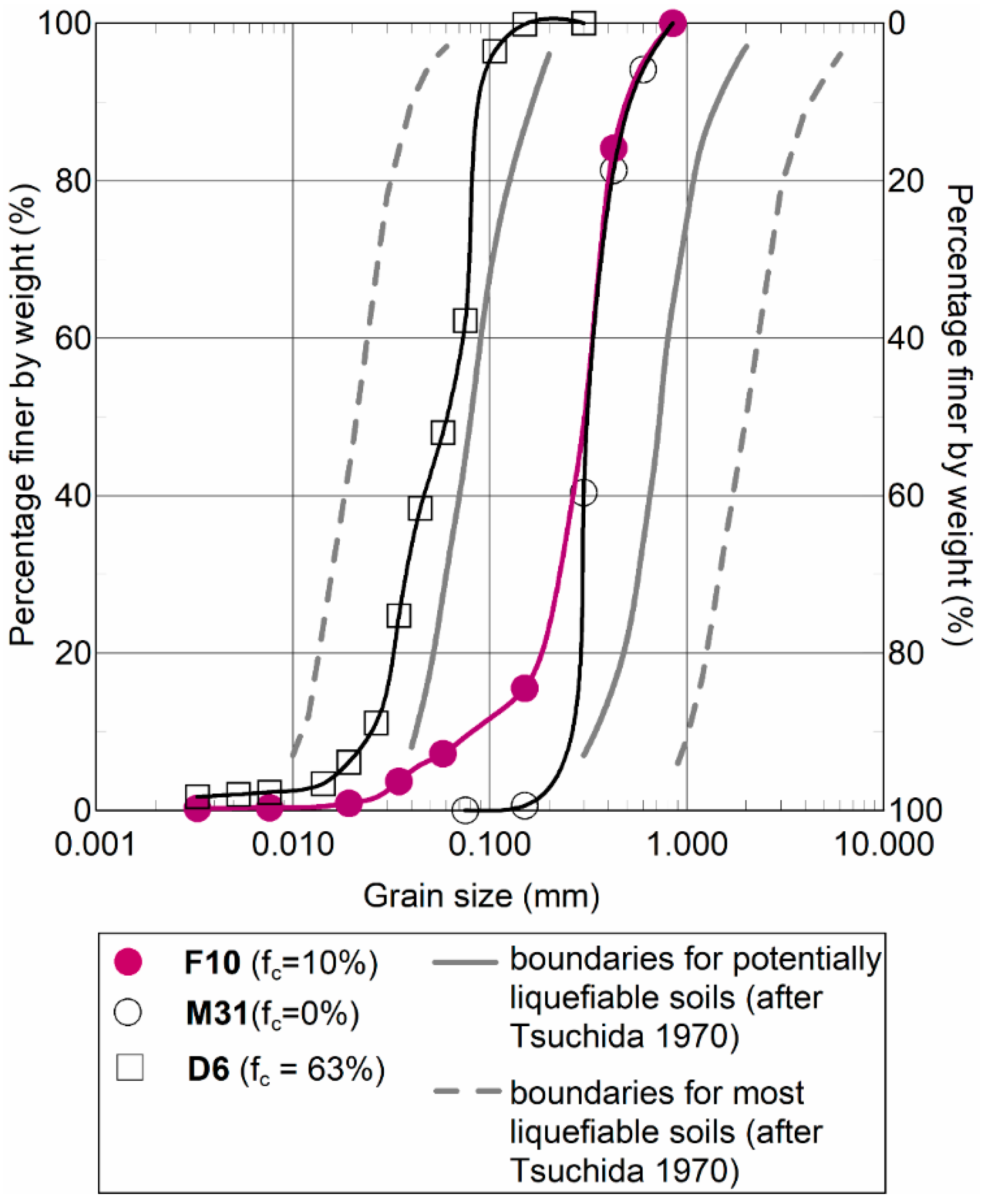

2. Tested Materials

2.1. Soil Properties

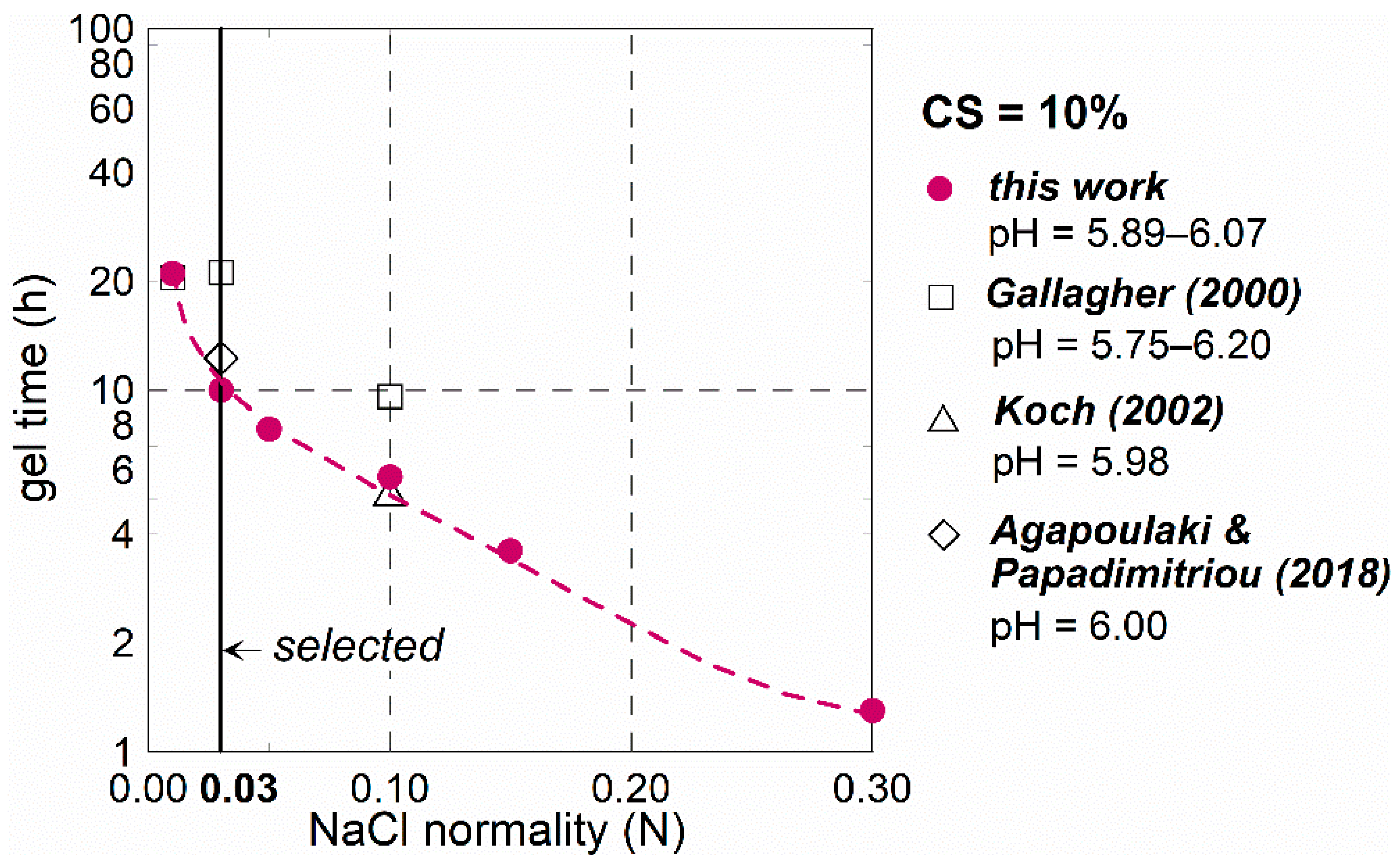

2.2. CS Solution Properties

3. Experimental Procedure

3.1. Specimen Preparation

3.2. Testing

4. Test Results and Discussion

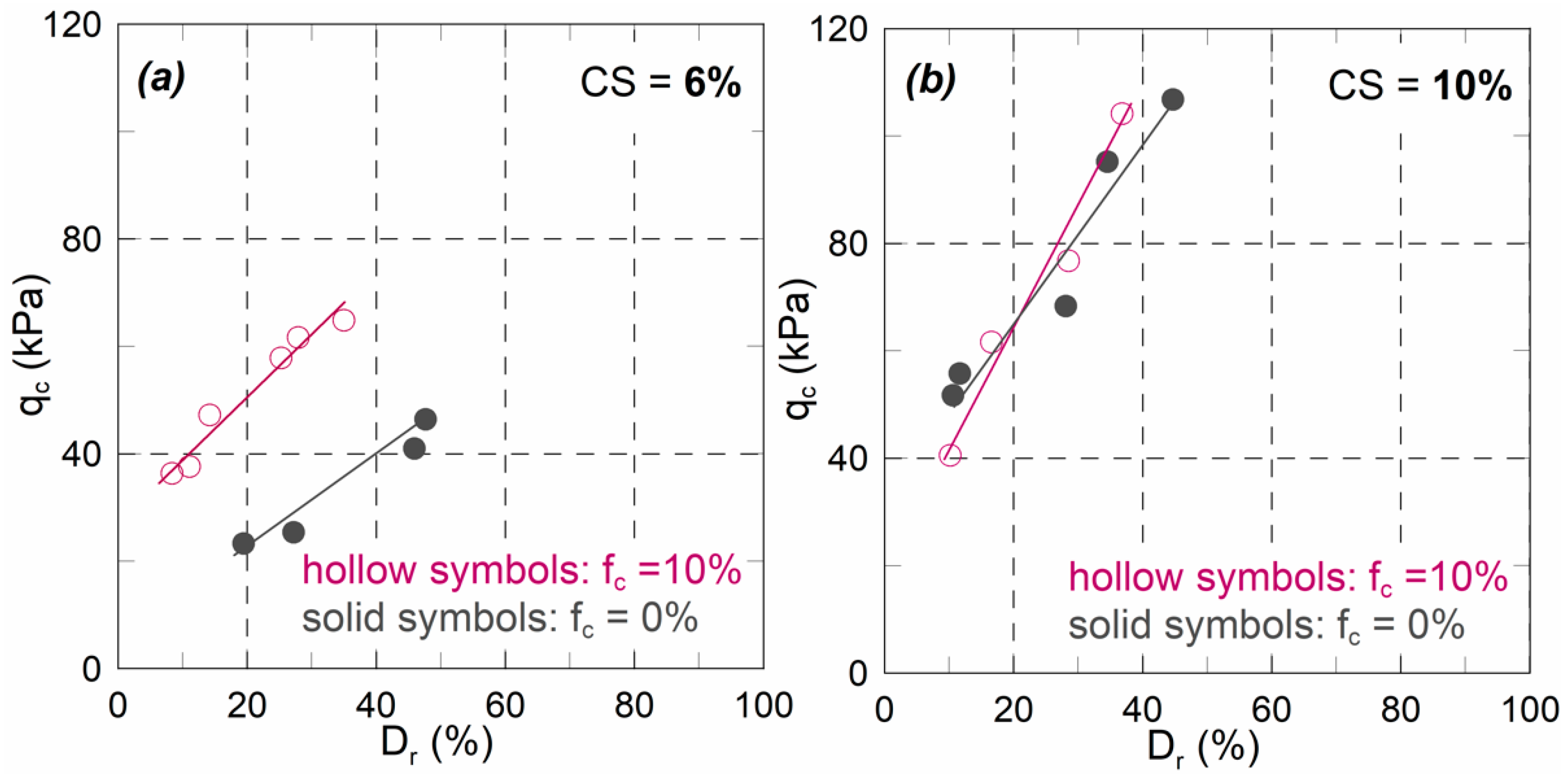

4.1. Unconfined Compression Tests

4.2. Monotonic Triaxial Tests

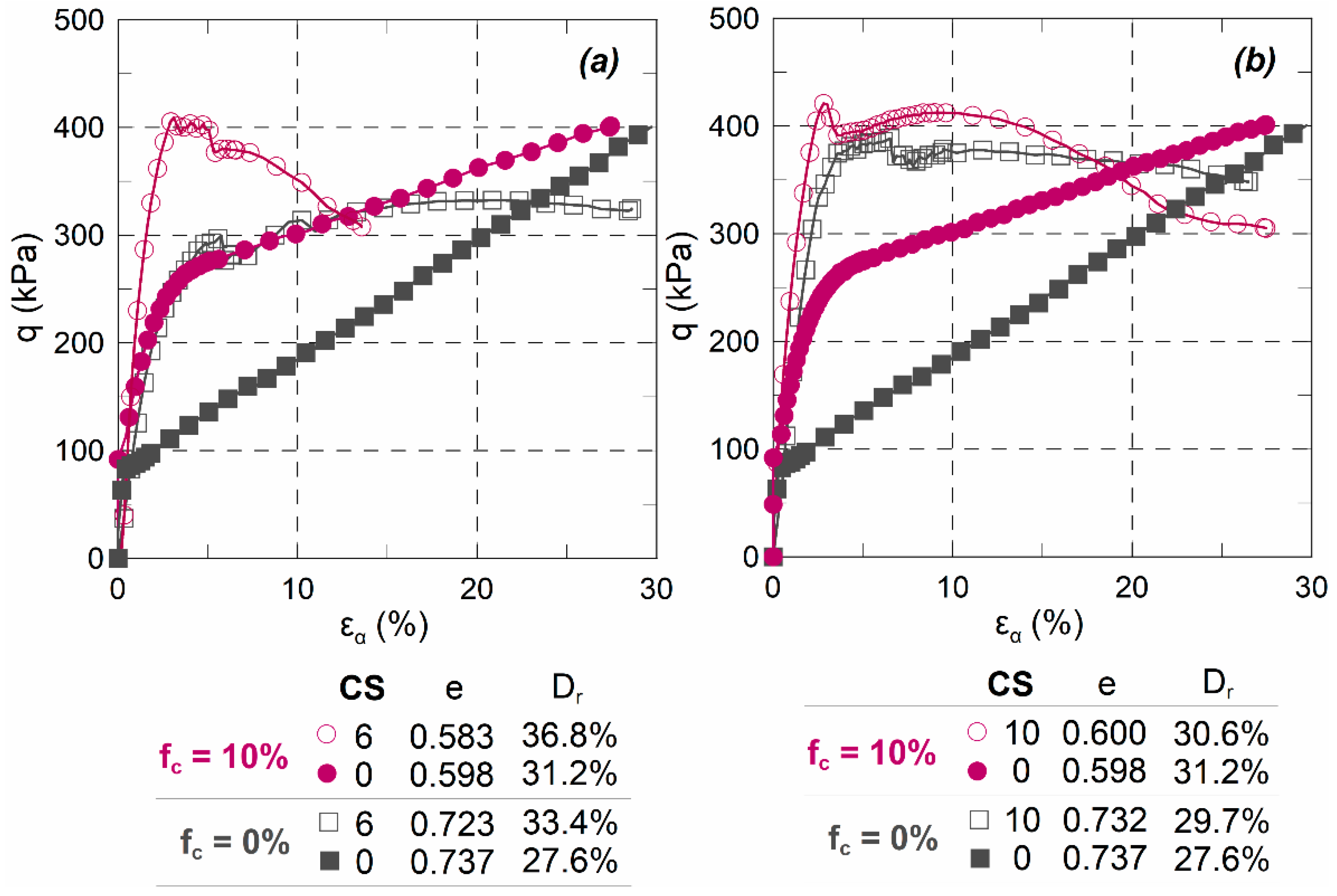

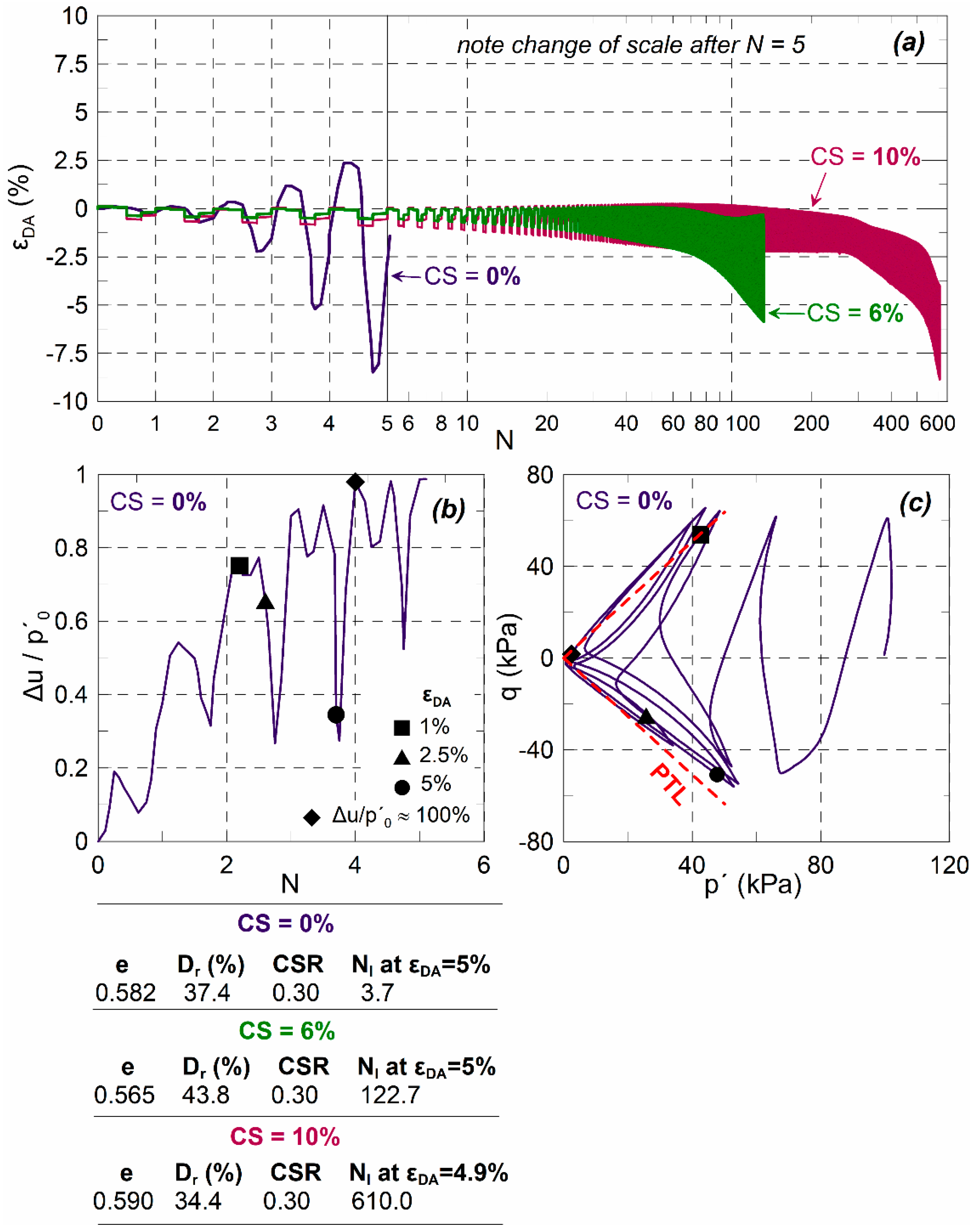

4.3. Cyclic Triaxial Tests

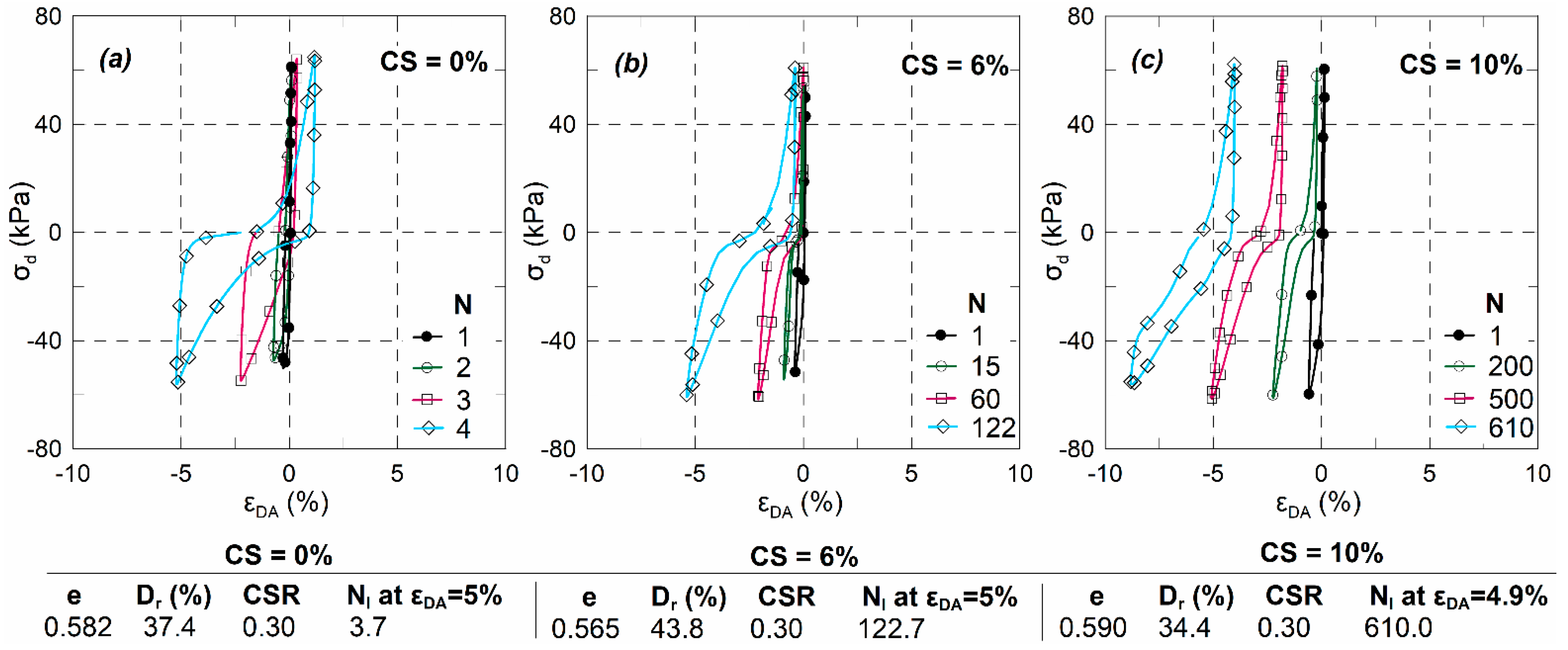

4.4. Post-Cyclic Monotonic Triaxial Tests

5. Discussion and Conclusions

- (a)

- CS stabilized silty sand exhibits an unconfined compressive strength, which depends on both CS concentration and density;

- (b)

- Under undrained monotonic loading, the CS-stabilized silty sand exhibits brittle behaviour and increased maximum strength as compared to the strain-hardening behaviour of the untreated silty sand. Furthermore, for the studied range of densities, the su of the stabilized specimens is significantly higher, up to 6.7 times the corresponding su of the untreated silty sand, under the same p′0;

- (c)

- The undrained shear strength, su, of the stabilized silty sand is not considerably influenced by soil density variations, but it is significantly increased with increasing p′0;

- (d)

- CS stabilization of silty sand results in significantly increased liquefaction resistance as compared to the corresponding of the untreated silty sand. An increase in CS from 6% to 10% results in further improved CRR15 values only at Dr < 40%. At higher densities, the liquefaction resistance for both CS concentrations practically coincides;

- (e)

- CS-stabilized specimens exhibit increased deformation resistance to cyclic loading as compared to the untreated, which experience much larger εDA in fewer cycles; and

- (f)

- Post-cycling undrained monotonic shear strength of stabilized specimens is not affected by the accumulated strains (at least εDA = 5%) during the preceding cyclic loading, indicating that no deterioration of soil improvement occurs during cyclic loading.

Author Contributions

Funding

Conflicts of Interest

References

- Gallagher, P.M.; Mitchell, J.K. Influence of colloidal silica grout on liquefaction potential and cyclic undrained behavior of loose sand. Soil Dyn. Earthq. Eng. 2002, 22, 1017–1026. [Google Scholar] [CrossRef]

- Gallagher, P.M. Passive Site Remediation for Mitigation of Liquefaction Risk. Ph.D. Dissertation, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2000. [Google Scholar]

- Agapoulaki, G.; Papadimitriou, A.G. Rheological properties of colloidal silica grout for passive stabilization against liquefaction. J. Mater. Civ. Eng. 2018, 30, 04018251. [Google Scholar] [CrossRef]

- Wong, C.; Pedrotti, M.; El Mountassir, G.; Lunn, R.J. A study on the mechanical interaction between soil and colloidal silica gel for ground improvement. Eng. Geol. 2018, 243, 84–100. [Google Scholar] [CrossRef] [Green Version]

- Batilas, A.; Pantazopoulos, I.; Athanasopoulos, G. Effects of colloidal silica grouting on the dynamic properties of sandy soils. In Proceedings of the 16th European Conference Earthquake Engineering, Thessaloniki, Greece, 18–21 June 2018. [Google Scholar]

- Ciardi, G.; Bardotti, R.; Vannucchi, G.; Madiai, C. Effects of high-diluted colloidal silica grouting on the behaviour of a liquefiable sand. Geotech. Res. ICE 2020, 7, 193–208. [Google Scholar] [CrossRef]

- Ata, A.; Vipulanandan, C. Factors affecting mechanical and creep properties of silicate-grouted sands. J. Geot. Geoenviron. Eng. 1999, 125, 868–876. [Google Scholar] [CrossRef]

- Ochoa-Cornejo, F.; Bobet, A.; Johnston, C.; Santagata, M.; Sinfield, J.V. Dynamic properties of a sand-nanoclay composite. Géotechnique 2020, 70, 210–225. [Google Scholar] [CrossRef]

- Terzis, D.; Laloui, L. A decade of progress and turning points in the understanding of bio-improved soils: A review. Geomech. Energy Environ. 2019, 19, 100116. [Google Scholar] [CrossRef]

- Iler, R.K. The Chemistry of Silica: Solubility, Polymerization, Colloid and Surface Properties and Biochemistry; John Wiley & Sons: New York, NY, USA, 1979. [Google Scholar]

- Huang, Y.; Wang, L. Laboratory investigation of liquefaction mitigation in silty sand using nanoparticles. Eng. Geol. 2016, 204, 23–32. [Google Scholar] [CrossRef]

- Whang, J.M. Chemical-based barrier materials. In Assessment of Barrier Containment Technologies for Environmental Remediation Applications; Rumer, R.R., Mitchell, J.K., Eds.; National Technical Information Service: Springfield, VA, USA, 1995; Section 9. [Google Scholar]

- Gallagher, P.M.; Lin, Y. Colloidal silica transport through liquefiable porous media. J. Geotech. Geoenv. Eng. 2009, 135, 1702–1712. [Google Scholar] [CrossRef]

- Persoff, P.; Moridis, J.; Apps, J.A.; Pruess, K. Evaluation tests for colloidal silica for use in grouting applications. Geotech. Test. J. 1998, 21, 264–269. [Google Scholar] [CrossRef] [Green Version]

- Persoff, P.; Apps, J.; Moridis, J.; Whang, J.M. Effect of dilution and contaminants on sand grouted with colloidal silica. J. Geotech. Geoenviron. Eng. 1999, 125, 16545. [Google Scholar] [CrossRef] [Green Version]

- Hench, L.L.; West, J.K. The sol-gel process. Chem. Rev. J. 1990, 90, 33–72. [Google Scholar] [CrossRef]

- Jurinak, J.J.; Summers, L.E. Oilfield applications of colloidal silica gel. J. SPE Prod. Eng. 1991, 6, 406–412. [Google Scholar] [CrossRef]

- Noll, M.R.; Bartlett, C.; Dochat, T.M. In situ permeability reduction and chemical fixation using colloidal silica. In Proceedings of the 6th National Outdoor Conference Aquifer Restoration, Las Vegas, NV, USA, 11–13 May 1992. [Google Scholar]

- Yonekura, R.; Kaga, M. Current chemical grout engineering in Japan. In Grouting, Soil Improvement and Geosynthetics; Borden, R.H., Holtz, R.O., Juran, I., Eds.; American Society of Civil Engineers: New York, NY, USA, 1992; GSP 30; pp. 725–736. [Google Scholar]

- Bolisetti, T.; Reitsma, S.; Balachandar, R. Experimental Investigations of Colloidal Silica Grouting in Porous Media. J. Geotech. Geoenviron. Eng. 2009, 135, 697–700. [Google Scholar] [CrossRef]

- Butrón, C.; Axelsson, M.; Gustafson, G. Silica sol for rock grouting: Laboratory testing of strength, fracture behaviour and hydraulic conductivity. Tunn. Undergr. Space Technol. 2009, 24, 603–607. [Google Scholar] [CrossRef]

- Butrón, C.; Gustafson, G.; Fransson, Å.; Funehag, J. Drip sealing of tunnels in hard rock: A new concept for the design and evaluation of permeation grouting. Tunn. Undergr. Space Technol. 2010, 25, 114–121. [Google Scholar] [CrossRef]

- Georgiannou, V.N.; Pavlopoulou, E.M.; Bikos, Z. Mechanical behaviour of sand stabilised with colloidal silica. Proc. Inst. Civil. Eng. Geotech. Res. ICE 2017, 4, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Vranna, A.; Tika, T.; Papadimitriou, A. Laboratory investigation into the monotonic and cyclic behaviour of a clean sand stabilised with colloidal silica. Géotechnique 2020, 1–14. [Google Scholar] [CrossRef]

- Spagnoli, G. A review of soil improvement with nonconventional grouts. Int. J. Geotech. Eng. 2020, 15, 273–287. [Google Scholar] [CrossRef]

- Jefferies, M.; Been, K. Soil Liquefaction-A Critical State Approach; Taylor and Francis: London, UK, 2006. [Google Scholar]

- Díaz-Rodríguez, J.A.; Izarraras, A.V.M.; Bandini, P.; Lopez-Molina, J.A. Cyclic strength of a natural liquefiable sand stabilized with colloidal silica grout. Can. Geot. J. 2008, 45, 1345–1355. [Google Scholar] [CrossRef]

- Moradi, G.; Seyedi, S. Evaluation of uniform delivery of colloidal nano-Silica stabilizer to liquefiable silty sands. Int. J. Nano Dimens. 2015, 6, 501–508, (Special Issue for NCNC, December 2014, Iran). [Google Scholar] [CrossRef]

- Bao, X.; Jin, Z.; Cui, H.; Chen, X.; Xie, X. Soil liquefaction mitigation in geotechnical engineering: An overview of recently developed methods. Soil Dyn. Earthq. Eng. 2019, 120, 273–291. [Google Scholar] [CrossRef]

- Zhao, M.; Liu, G.; Zhang, C.; Guo, W.; Luo, Q. State-of-the-art of colloidal silica-based soil liquefaction mitigation: An emerging technique for ground improvement. Appl. Sci. 2020, 10, 15. [Google Scholar] [CrossRef] [Green Version]

- Mollamahmutoglu, M.; Yilmaz, Y. Pre- and post-cyclic loading strength of silica grouted sand. J. Geot. Eng. 2010, 163, 343–348. [Google Scholar] [CrossRef]

- Triantafyllos, P.; Georgiannou, V.; Pavlopoulou, E.-M.; Dafalias, Y. Strength and dilatancy of sand before and after stabilization with colloidal-silica gel. Géotechnique 2021, 1–15. [Google Scholar] [CrossRef]

- Spencer, L.M.; Rix, G.J.; Gallagher, P. Colloidal silica gel and sand mixture dynamic properties. In Geotechnical Earthquake Engineering and Soil Dynamics IV(GSP 181); American Society of Civil Engineers: Sacramento, CA, USA, 2008. [Google Scholar] [CrossRef]

- Towhata, Y. Developments of soil improvement technologies for mitigation of liquefaction risk. In Earthquake Geotechnical Engineering; Pitilakis, K.D., Ed.; Springer: Dordrecht, The Netherlands, 2007; pp. 355–383. [Google Scholar]

- Gallagher, P.M.; Finsterle, S. Physical and numerical model of colloidal silica injection for passive site stabilization. Vadose Zone J. 2004, 3, 917–925. [Google Scholar] [CrossRef]

- Silverbond. Dedusted Crystalline Silica Flour Technical Data, CAS-Nr.: 14808-60-7. 2013. Available online: http://www.sibelco.be (accessed on 16 July 2021).

- British Standards Institution. Determination of permeability by the constant-head method. In Methods of Test for Soils for Civil Engineering Purposes; British Standards Institution: London, UK, 1990; Volume 1377, Part 5; pp. 11–15. [Google Scholar]

- Vranna, A.; Tika, T. Laboratory improvement of liquefiable sand by colloidal silica and weak cementation. Ground Improv. 2019. [Google Scholar] [CrossRef]

- Sydansk, A.D. A newly developed chromium (III) technology. SPE Reserv. Engng 1990, 5, 346–352. [Google Scholar] [CrossRef]

- Koch, A.J. Model testing of passive site stabilization. Master’s Dissertation, Civil Engineering Department, Drexel University, Philadelphia, PA, USA, 2002. [Google Scholar]

- Vranna, A.D. Laboratory Investigation into the Behaviour of Improved Liquefiable Soils under Monotonic and Cyclic Loading. Ph.D. Dissertation, Aristotle University of Thessaloniki, Thessaloniki, Greece, 2016. (In Greek). [Google Scholar]

- Ladd, R.S. Preparing test specimens using undercompaction. Geot. Test. J. 1978, 1, 16–23. [Google Scholar]

- British Standards Institution. Test 12, Shear strength tests. In Methods of Test for Soils for Civil Engineering Purposes; British Standards Institution: London, UK, 1990; Volume 1377, Part 7; pp. 1–48. [Google Scholar]

- Ishihara, K. Liquefaction and flow failure during earthquakes. Géotechnique 1993, 43, 351–415. [Google Scholar] [CrossRef]

| Soil | fc (%) | emin | emax | γdmin (kΝ/m3) | γdmax (kΝ/m3) | Gs | Cu | d50 (mm) | PI | k (m/s) |

|---|---|---|---|---|---|---|---|---|---|---|

| SF10 | 10 | 0.414 | 0.682 | 15.47 | 18.40 | 2.653 | 4.13 | 0.30 | 0 | 1.33∙10−4 |

| M31 | 0 | 0.558 | 0.805 | 14.43 | 16.71 | 2.655 | 1.50 | 0.31 | 0 | 5.16∙10−4 |

| D6 | 63 | - | - | - | - | 2.639 | 2.73 | 0.06 | 0 | - |

| Test | CS (%) | e | Dr (%) | su-max (kPa) | su-ult (kPa) | εα (%) at su-max | εα (%) at su-ult |

|---|---|---|---|---|---|---|---|

| MT-S6-1 | 6 | 0.638 | 16.3 | 165.7 | 153.1 | 4.2 | 6.4 |

| MT-S6-2 | 6 | 0.634 | 17.8 | 177.7 | 167.4 | 5.9 | 10.8 |

| MT-S6-3 | 6 | 0.583 | 36.8 | 204.6 | 189.9 | 3.1 | 6.1 |

| MT-S10-1 | 10 | 0.655 | 9.9 | 151.4 | 151.4 | 7.7 | 7.7 |

| MT-S10-2 | 10 | 0.600 | 30.6 | 210.5 | 206.2 | 3.8 | 9.0 |

| MT-S10-3 | 10 | 0.551 | 49.1 | 231.0 | 230.5 | 5.0 | 6.0 |

| Test | e | Dr (%) | qcs (kPa) | p′cs (kPa) | qpt (kPa) | p′pt (kPa) | εα (%) at qpt |

|---|---|---|---|---|---|---|---|

| MT-1 | 0.530 | 56.6 | 1291.2 | 992.4 | - | - | - |

| MT-2 | 0.596 | 32.1 | 763.6 | 584.5 | - | - | - |

| MT-3 | 0.597 | 31.9 | 422.4 | 332.8 | - | - | - |

| MT-4 | 0.598 | 31.2 | 394.5 | 305.0 | - | - | - |

| MT-5 | 0.610 | 26.7 | 161.6 | 124.4 | - | - | - |

| MT-6 | 0.630 | 19.2 | 112.3 | 89.4 | 75.9 | 58.3 | 7 |

| MT-7 | 0.640 | 15.6 | 69.2 | 54.1 | 54.2 | 42.1 | 10.3 |

| MT-8 | 0.643 | 14.5 | 56.4 | 40.3 | 50.1 | 34.2 | 13.1 |

| MT-9 | 0.659 | 8.6 | 34.9 | 27.2 | 35.6 | 27.4 | 9.0 |

| Test | CS (%) | e | Dr (%) | CSR | N1% | N2.5% | Nl | su-max (kPa) |

|---|---|---|---|---|---|---|---|---|

| CT-S6-1 | 6 | 0.636 | 17.2 | 0.40 | 0.7 | 0.8 | 3.8 | 165.1 |

| CT-S6-2 | 6 | 0.624 | 21.8 | 0.32 | 0.8 | 7.8 | 18.3 | 195.9 |

| CT-S6-3 | 6 | 0.616 | 24.6 | 0.27 | 1.7 | 14.8 | 46.7 | - |

| CT-S6-4 | 6 | 0.572 | 41.2 | 0.43 | 0.7 | 15.8 | 51.9 | 164.8 |

| CT-S6-5 | 6 | 0.565 | 43.8 | 0.30 | 18.6 | 80.7 | 122.7 | 224.7 |

| CT-S6-6 | 6 | 0.562 | 44.6 | 0.25 | 10.8 | 54.3 | 132.5 | 202.3 |

| CT-S6-7 | 6 | 0.537 | 54.0 | 0.62 | 0.6 | 1.6 | 1.8 | 233.6 |

| CT-S6-8 | 6 | 0.513 | 63.1 | 0.60 | 0.6 | 0.7 | 0.8 | 272.1 |

| CT-S10-1 | 10 | 0.636 | 17.0 | 0.60 | 0.6 | 0.7 | 1.7 | 219.2 |

| CT-S10-2 | 10 | 0.620 | 23.0 | 0.31 | 0.7 | 7.3 | 49.8 | 193.8 |

| CT-S10-3 | 10 | 0.617 | 24.2 | 0.43 | 0.7 | 1.8 | 9.8 | 140.2 |

| CT-S10-4 | 10 | 0.590 | 34.4 | 0.30 | 6.7 | 384.6 | 640.0 | 177.5 |

| CT-S10-5 | 10 | 0.582 | 37.1 | 0.36 | 0.6 | 1.1 | 10.0 | 142.0 |

| CT-S10-6 | 10 | 0.582 | 37.4 | 0.33 | 9.8 | 105.3 | 222.3 | - |

| Test | e | Dr (%) | CSR | N1% | N2.5% | Nl |

|---|---|---|---|---|---|---|

| CT-1 | 0.650 | 12.1 | 0.14 | 11.2 | 12.2 | - |

| CT-2 | 0.654 | 10.5 | 0.32 | 1.7 | 2.2 | 2.6 |

| CT-3 | 0.614 | 25.3 | 0.21 | 14.2 | 14.7 | 15.1 |

| CT-4 | 0.613 | 25.8 | 0.30 | 2.2 | 2.7 | 3.1 |

| CT-5 | 0.602 | 29.7 | 0.24 | 6.7 | 7.8 | 8.8 |

| CT-6 | 0.600 | 30.5 | 0.21 | 8.7 | 9.3 | 10.1 |

| CT-7 | 0.582 | 37.2 | 0.15 | 120.6 | 122.6 | 124.2 |

| CT-8 | 0.582 | 37.4 | 0.30 | 2.2 | 2.6 | 3.7 |

| CT-9 | 0.567 | 42.9 | 0.38 | 0.8 | 1.5 | 2.1 |

| CT-10 | 0.507 | 65.3 | 0.33 | 5.8 | 7.7 | 9.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vranna, A.; Tika, T. The Mechanical Response of a Silty Sand Stabilized with Colloidal Silica. Geotechnics 2021, 1, 243-259. https://doi.org/10.3390/geotechnics1020013

Vranna A, Tika T. The Mechanical Response of a Silty Sand Stabilized with Colloidal Silica. Geotechnics. 2021; 1(2):243-259. https://doi.org/10.3390/geotechnics1020013

Chicago/Turabian StyleVranna, Antigoni, and Theodora Tika. 2021. "The Mechanical Response of a Silty Sand Stabilized with Colloidal Silica" Geotechnics 1, no. 2: 243-259. https://doi.org/10.3390/geotechnics1020013

APA StyleVranna, A., & Tika, T. (2021). The Mechanical Response of a Silty Sand Stabilized with Colloidal Silica. Geotechnics, 1(2), 243-259. https://doi.org/10.3390/geotechnics1020013