1. Introduction

In recent years, there has been a notable increase in energy consumption, which has had a significant impact on climate change. Significant efforts have been dedicated to developing improved steel grades that reduce energy losses in electrical equipment. Grain non-oriented electrical steels (GNOES) are widely used for the manufacture of cores of electric devices and thus, by improving the magnetic properties of these materials, they will have a significant impact on energy consumption [

1,

2]. This improvement can be achieved by increasing magnetic induction and magnetic permeability and reducing core loss, which are affected by the steel composition, thickness, grain size and crystallographic texture [

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13]. Since the processing conditions affect microstructural characteristics and therefore, the magnetic properties [

4,

6,

7,

8,

9,

10,

11], attempts have been made to develop effective methods that reduce energy losses. Unconventional processing methods have been proposed to enhance the magnetic behavior of these steels, such as thermal treatments (in inert or oxidizing atmospheres) before cold rolling [

4,

7,

8,

9,

10,

11], rotation of the hot-rolled steel (90° or 45° with respect to the rolling direction) to conduct the cold rolling process [

6,

7] and two-step cold rolling with intermediate annealing treatment [

8,

14]. The effect of the hot rolling and subsequent annealing (in argon atmosphere) on the modification of hot-rolled bands have been investigated for different steel grades, such as those containing silicon amounts greater than 1% [

15,

16,

17], 0.5% Mn [

18], different Al contents [

5] or low-Si, ultra-low carbon contents [

19]. More recently, it has been reported that processing hot-rolled low and ultralow-carbon Si + Sb non-oriented electrical steels from annealing before cold rolling can also improve the magnetic behavior of the final products [

9,

20]. In all cases, the changes caused by annealing before cold rolling on the final microstructure and magnetic properties were found to be highly dependent on the steel composition and microstructural characteristics of the as-received hot-rolled materials, as well as the conditions used during steel processing [

5,

15,

16,

17,

18,

19]. For instance, F. Hernández Navarro [

20] reported the magnetic behavior of ultra-low carbon (0.006%) steels containing 0.607% Si obtaining core loss to 1.5 T at 50 Hz (W

1.5/50) and magnetic permeability (µ

r) values of about 6.7 W/kg and 2250.0, respectively, after processing hot-rolled electrical steels (deformed at 1200 °C) by annealing before cold rolling (ABCR = 880 °C, 180 min), cold rolling (0.25 mm thickness), and annealing (850 °C, 60 min). In other work, for similar steel composition and processing conditions, but with a hot rolling temperature of 800 °C, energy losses were reduced by up to 5.7 W/kg (W

1.5/50). The reduction in core losses was related to the microstructural and texture changes produced by the reduction in temperature, where the lower volume fraction of <111>//ND components in the steel allowed for the reduction in core losses [

21]. The effects of ABCR were also investigated by the same author in steels with different composition (0.071%C, 0.575%Si and 0.1%Sb) and processing parameters (hot rolling (1100 °C), ABCR (850 °C, 720 min), cold rolling (0.25 mm thickness) and annealing (950 °C, 8 min) [

9]), reaching lower core loss values of about 4.3 W/kg and magnetic permeability (µ

r) of about 2850. H. Ortiz Rangel [

19] reported core loss values of about 3.0 W/kg in electrical steels (0.008%C, 0.328%Si) processed by a similar route, consisting of ABCR, cold rolling and annealing. However, although lower core loss values were obtained, processing conditions were very different; for example, ABCR was conducted at 710 °C for 72 h (4320 min), cold rolling reduction was conducted to obtain a thickness of 0.19 mm and annealing was performed at 700 °C for 3 min. These works show that the magnetic properties of electrical steel depend strongly on steel composition and processing parameters used for their fabrication. In the present investigation, hot-rolled steel samples were processed at different temperatures, subjected to an annealing before cold rolling, similar to other works, at 1200 °C and 800 °C, providing differences to the steel in terms of microstructure and texture obtained before cold rolling [

20,

21], and then subjected to different cold rolling and annealing schedules to evaluate the effect of processing history on the microstructure and magnetic properties of low-carbon Si-Sb grain non-oriented electrical steels.

2. Materials and Methods

An ingot of 16 × 10 × 4 cm was manufactured by fusion and casting in metallic ingot molds, homogenized at 1200 °C (30 min) and hot-rolled up to 1 cm thickness. Smaller ingots with dimensions of 17 × 10 × 1 cm were then obtained and processed by hot rolling. To this end, one ingot was reheated at 1200 °C (15 min) and the other at 800 °C (15 min).

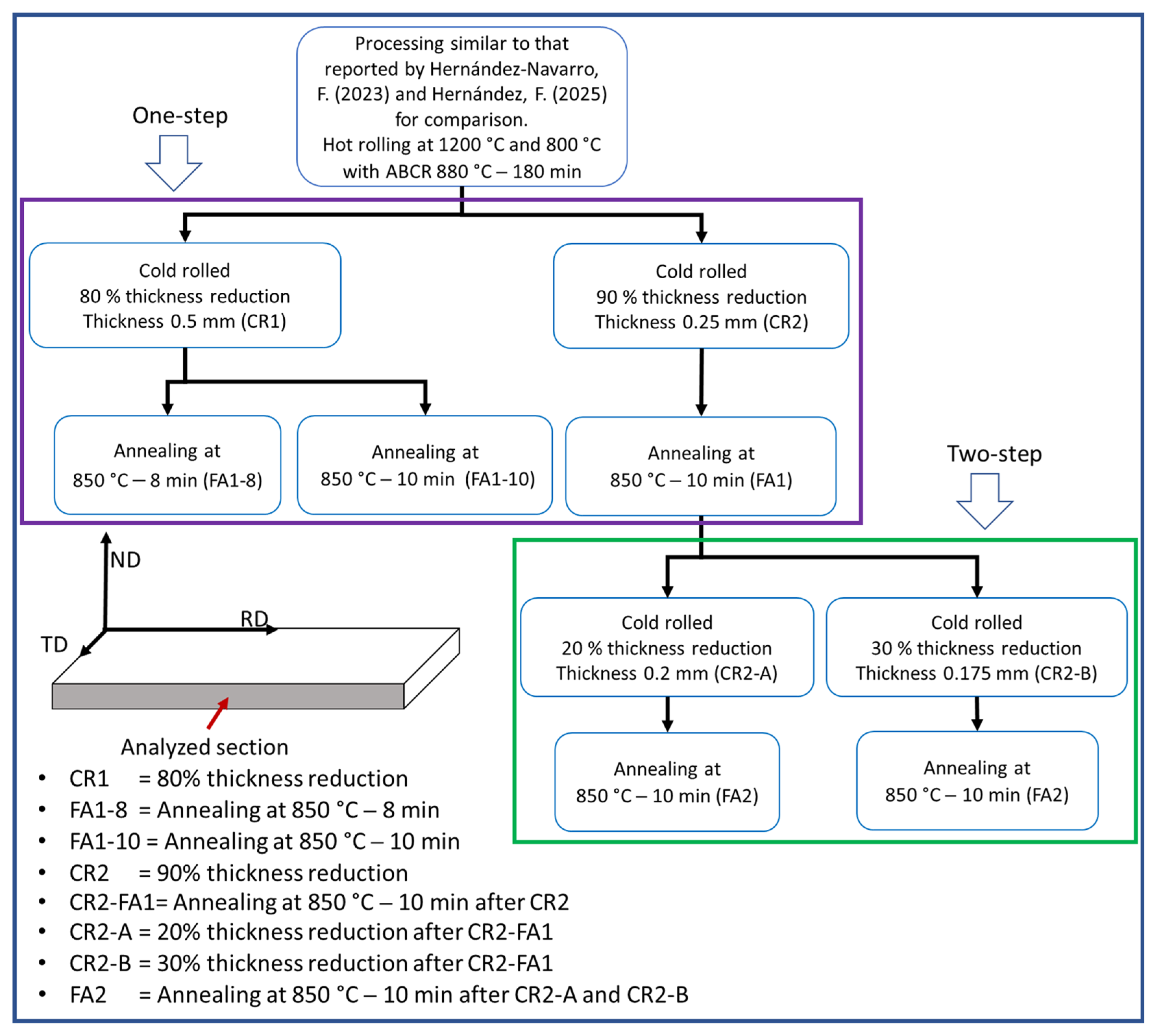

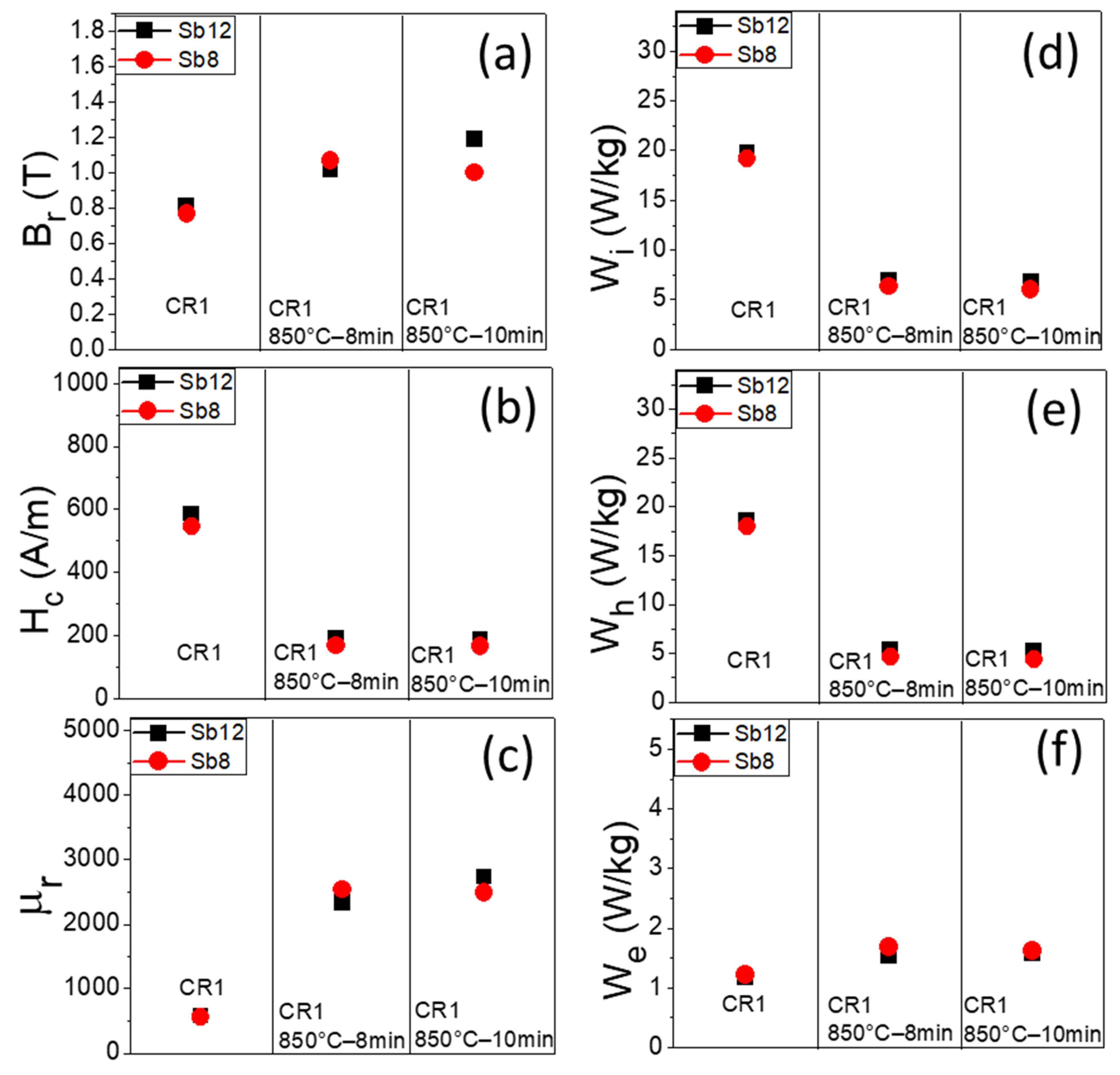

Figure 1 illustrates a flow chart to show the processing steps used for both steels. Both ingots were hot-rolled up to 3 mm thick, reheated (15 min) at 1200 °C and 800 °C, respectively, and hot-rolled to a thickness of 2.5 mm. Steel samples 1200 °C and 800 °C are hereinafter referred to as Sb12 and Sb8, respectively. These temperatures were selected based on the results of previous works [

20,

21], which demonstrate that hot rolling at temperatures either below (800 °C) or above (1200 °C) the upper critical transformation temperature (A

C3) can affect the microstructural characteristics (grain size, texture) of hot-rolled electrical steel bands, having a significant effect on the core losses of final products. However, it is important to mention that the effects of such temperatures have not been reported for steels modified by a two-stage cold rolling and annealing schedule, which is one of the processing routes used in the present work. Steel samples were pickled with a 20% HCl solution and subjected to annealing before cold rolling (ABCR) at 880 °C for 180 min and subjected to one- and two-step cold rolling and annealing schedules. In the first stage, ABCR samples were cold-rolled to a thickness of 0.5 mm (CR1 = 80% thickness reduction) and annealed at 850 °C at 8 and 10 min (FA1-8 and FA1-10). Other ABCR samples were cold-rolled to a thickness of 0.25 mm (CR2 = 90% thickness reduction) and annealed at 850 °C, 10 min (FA1), one-step cold rolling and annealing schedule (purple rectangle in

Figure 1). In the second stage, samples of 0.25 mm thickness were cold-rolled to achieve an additional thickness reduction of 20% (CR2-A = 0.20 mm thickness) and 30% (CR2-B = 0.175 mm thickness), followed by a second annealing conducted at 850 °C for 10 min (FA2), two-step cold rolling and annealing schedule (green rectangle in

Figure 1).

Chemical compositions of experimental steels, determined by optical emission spectrometry (ASTM E-403) and infrared absorption spectrometry (IR-AS, ASTM E-1019), were C: 0.014%, Si: 0.607%, Al: 0.071%, Mn: 0.819%, Cu: 0.173%, Fe: balance for the steel reheated at 1200 °C (Sb12) and C: 0.016%, Si: 0.608%, Al: 0.071%, Mn: 0.812%, Cu: 0.173%, Fe: balance for the steel reheated at 800 °C (Sb8). The Sb content was 0.38% and 0.34% for steels hot-rolled at 1200 °C and 800 °C, respectively. The latter was analyzed by atomic absorption spectrometry using a Varian-spectrAA220 spectrometer (Agilent Technologies, California, United States). All the concentrations mentioned above are expressed in weight percent (wt.%). Dilatometric analyses were performed to determine the A

C1 (start temperature for the austenite transformation) and A

C3 (finish temperature for the austenite transformation). Samples of 10.0 mm × 4.0 mm × 2.3 mm were heated at 20 °C/s from room temperature to 1000 °C. Experiments were conducted in a LINSEIS L78 dilatometer (Linseis Thermal Analysis, Selb, Germany). A

C1 was 910 °C and 861 °C for steels reheated at 1200 °C and 800 °C, respectively. A

C3 temperature could not be determined in any steel, indicating that it is greater than 1000 °C. Microstructure was analyzed by optical microscopy (OM) and scanning electron microscopy (SEM) using OLYMPUS-GX51 (Olympus Corporation, Tokio, Japan) and JEOL-6610l microscopes (JEOL, Ltd., Tokio, Japan), respectively. Grain size was determined by the intercept method as recommended in ASTM E-112. The section analyzed on steel samples to observe the microstructure is also shown schematically in

Figure 1.

Magnetic properties were evaluated in a direction parallel to the rolling direction after cold rolling and annealing conditions. Experiments were conducted in a Single Electrical Steel Sheet Tester DAC-BHW-6 (Soken Electric Co., Ltd., Tokio, Japan). Hysteresis loops were obtained at a magnetic induction of 1.5 T, and at frequencies of 50, 60 and 100 Hz. Remanent magnetic induction (B

r), coercive field (H

c), and relative magnetic permeability (µ

r) were obtained from hysteresis loops. The contribution of hysteresis loss (W

h) and eddy current loss (W

e) to core loss or iron loss (W or W

i) was also determined at 1, 10, 50, 60 and 100 Hz. The magnetometer program provides discrimination by simultaneous Equations (1) and (2) in the multi-frequency method.

where W

c1 and W

c2 are core loss of frequency 1 (f

1) and frequency 2 (f

2), respectively, A is hysteresis loss coefficient, and B is eddy current loss coefficient.

4. Discussion

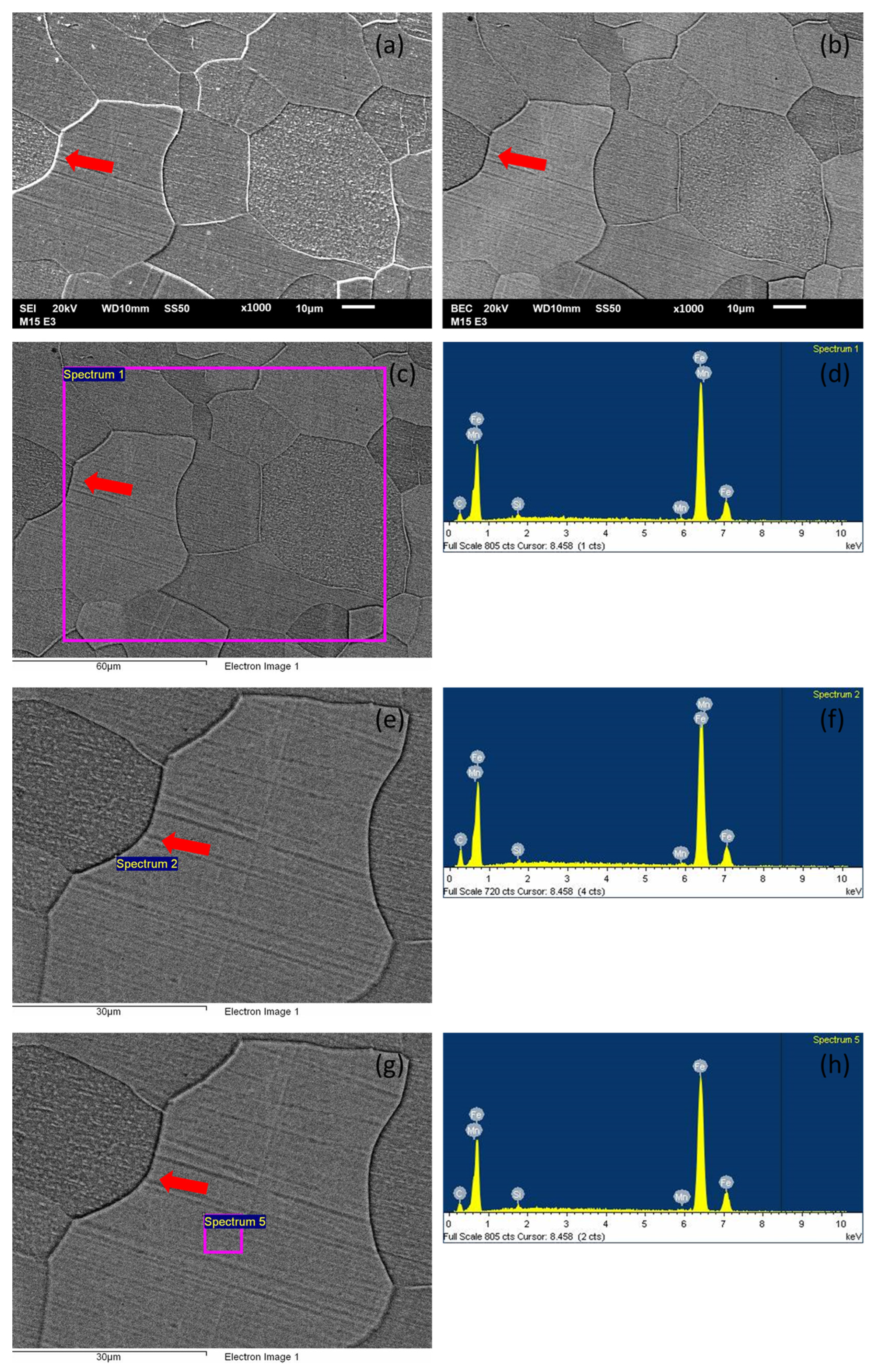

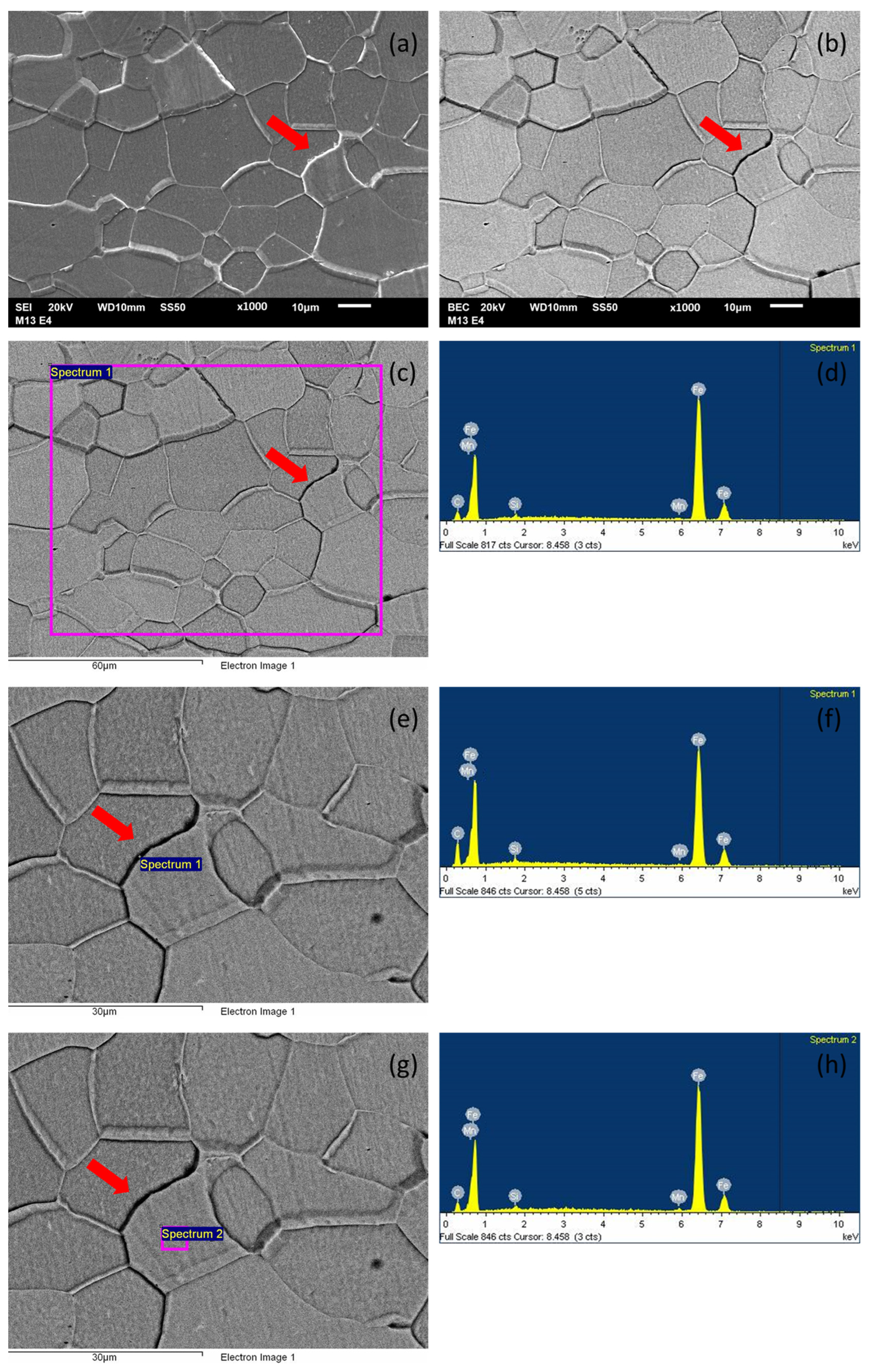

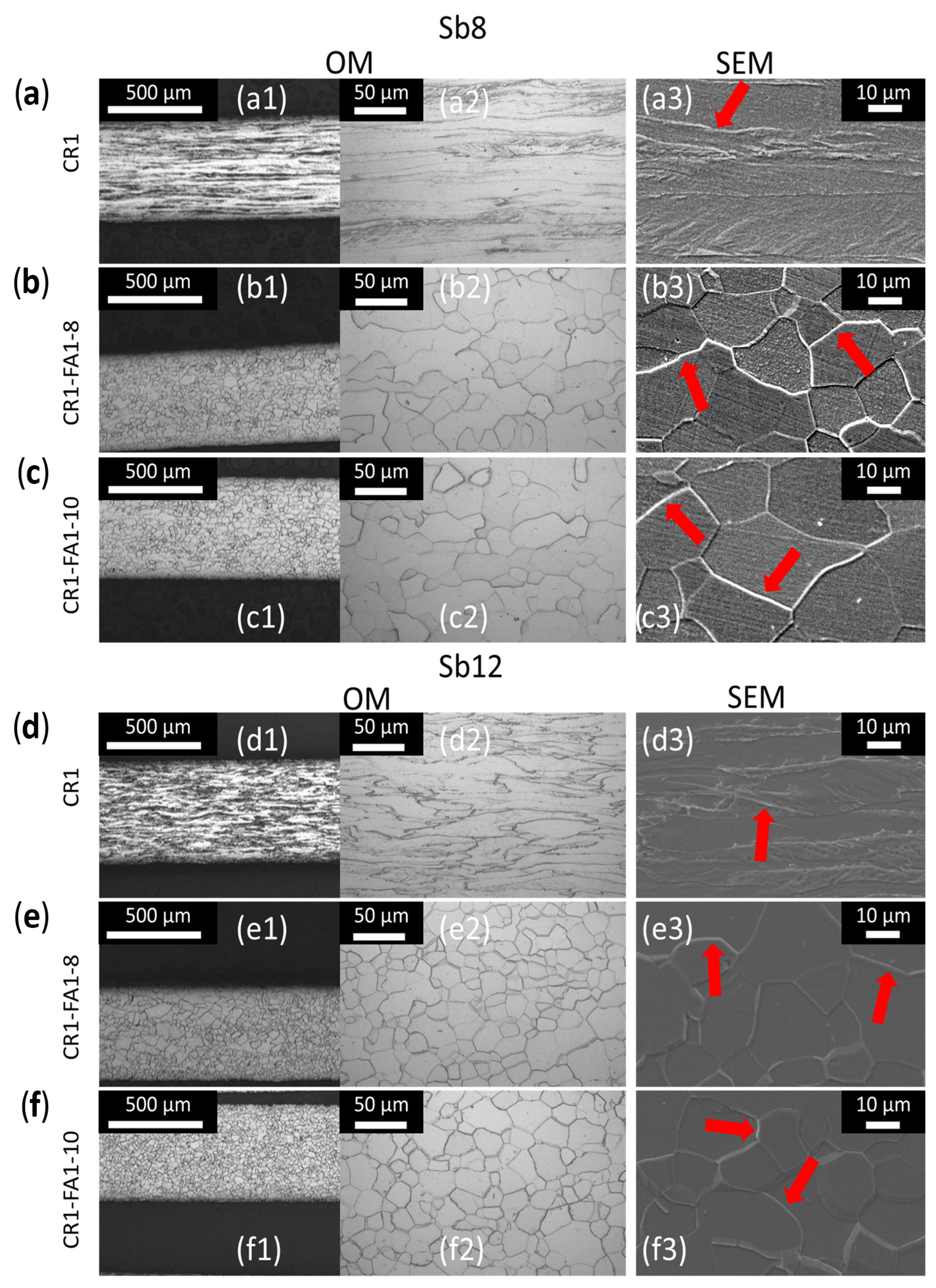

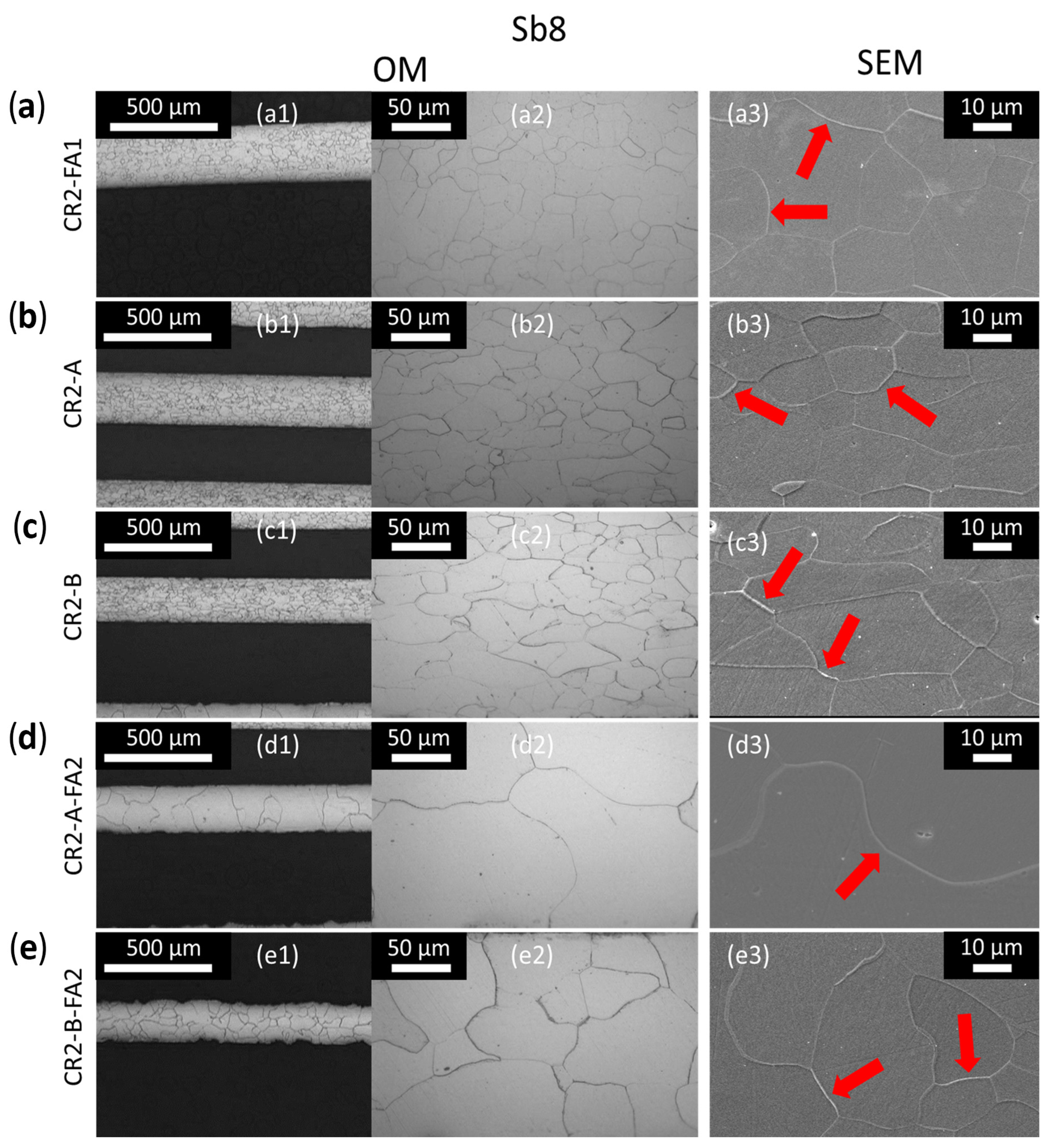

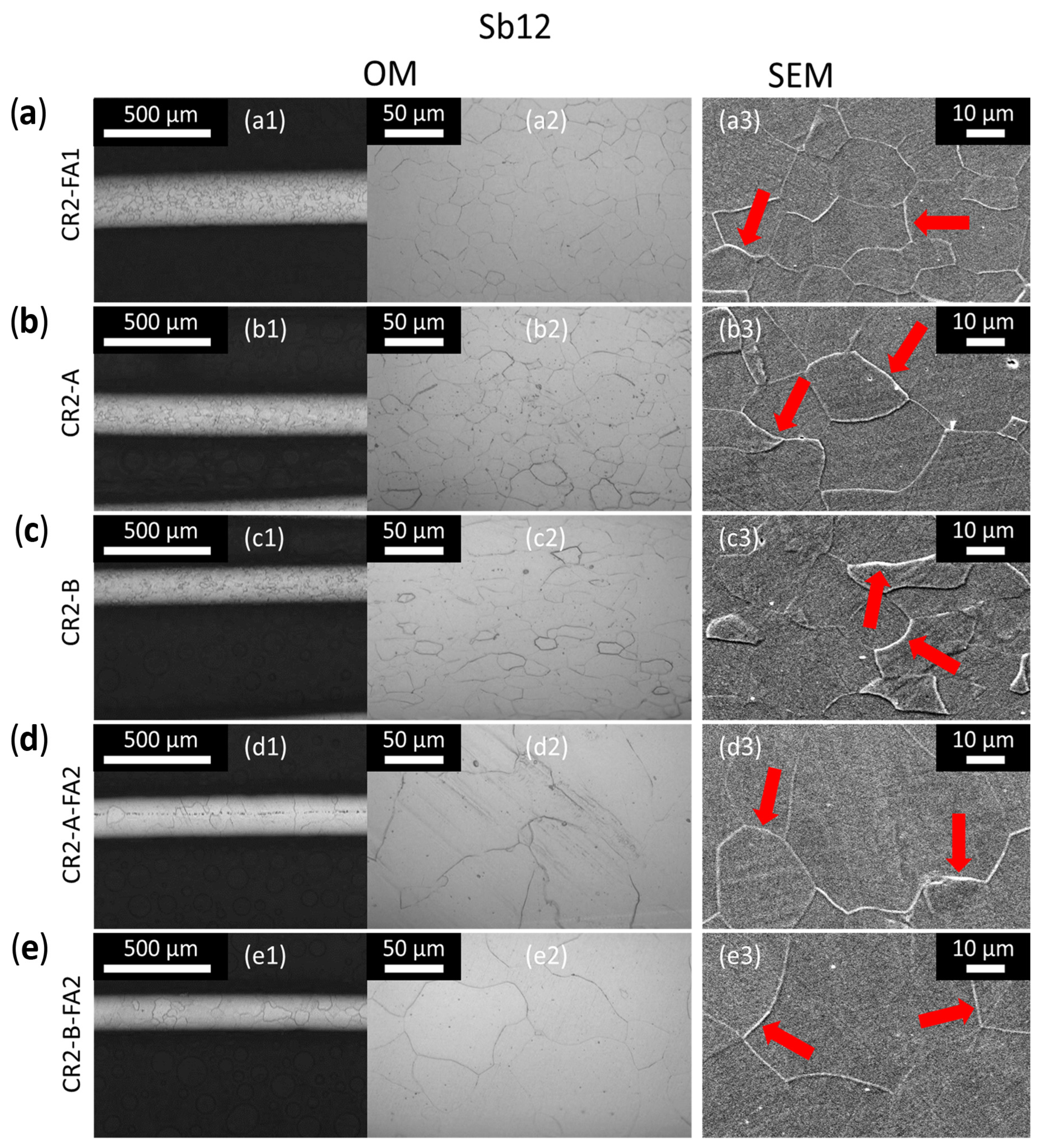

As shown in

Figure 2, after cold rolling, both steels (Sb8 and Sb12) show a microstructure constituting deformed grains, which are elongated in a direction parallel to the rolling direction (

Figure 2). For a thickness reduction of 80% (0.5 mm), the Sb8 steel shows the presence of grains more elongated than in the Sb12 steel. In other works, it has been reported that the size of the deformed bands is affected by the size and shape of the grains before cold rolling at 0.5 mm [

5,

6,

7,

8,

9,

10,

11,

15,

16]. After annealing at 850 °C (8 and 10 min), both steels show a microstructure of equiaxed grains, which is similar to the findings reported in other works [

5,

6,

7,

8,

9,

10,

15,

16]. When steels were cold-rolled to 0.25 mm and annealed at 850 °C for 10 min, the microstructure was very similar in both steels (Sb8 and Sb12), and it was also characterized by the presence of recrystallized grains (

Figure 3 and

Figure 4, respectively).

When Sb8 and Sb12 steels are subjected to a second deformation (20% and 30%) and annealing at 850 °C for 10 min, the microstructure is characterized by the presence of elongated grains in the rolling direction, which is more noticeable for a higher deformation. Similar behavior has been reported in other works [

8,

10,

11,

23].

After the two-step cold rolling and annealing schedule for both steels (Sb8 and Sb12), grain size is larger than the one obtained by the one-step cold rolling and annealing schedule. The grain size of samples subjected to 20% deformation is larger than that of samples with 30% (

Table 1). Similar behavior was reported in other work, where samples subjected to 20% deformation and annealing (850 °C) resulted in larger grain size than samples with higher deformations near 20% [

23]. These works reported the grain growth by the mechanism of strain-induced boundary migration (SIBM), where grains with low internal strain growth by the mobility of the grain boundaries reducing the stored energy. Some authors reported the effect of temperature of first annealing (900 °C, 1000 °C and 1100 °C for 6 min), second deformation (about 60%) and second annealing (1000 °C for 6 min) [

14]. They found that the high deformation degree applied before thermal treatment (60%), making it difficult for the occurrence of grain growth during final annealing. It was explained that the amount of dislocation cells, dislocation walls, or microbands, which represent nucleation sites for recrystallization, depends on the degree of deformation. Therefore, higher deformation levels produce a larger number of defects and result in higher stored energy. The higher the stored energy, the faster the recrystallization process and the smaller the recrystallized grain size. In the present work, it is observed that the grain size of final products is strongly affected by the deformation degree, being larger for the lower deformation (20%). It suggests that for larger deformation levels, the amount of lattice defects is more significant, favoring the nucleation process and thus affecting grain growth for a deformation of 30%. This behavior is similar to one reported in other works, where reductions higher than 30% promoted a fast recrystallization [

8]. Variations in grain size after one-step or two-step cold rolling and annealing schedules (

Table 1), are attributed due to the combined effects of the hot rolling temperature and cold rolling reduction, which affect both nucleation and grain growth during annealing [

14,

20,

21,

24].

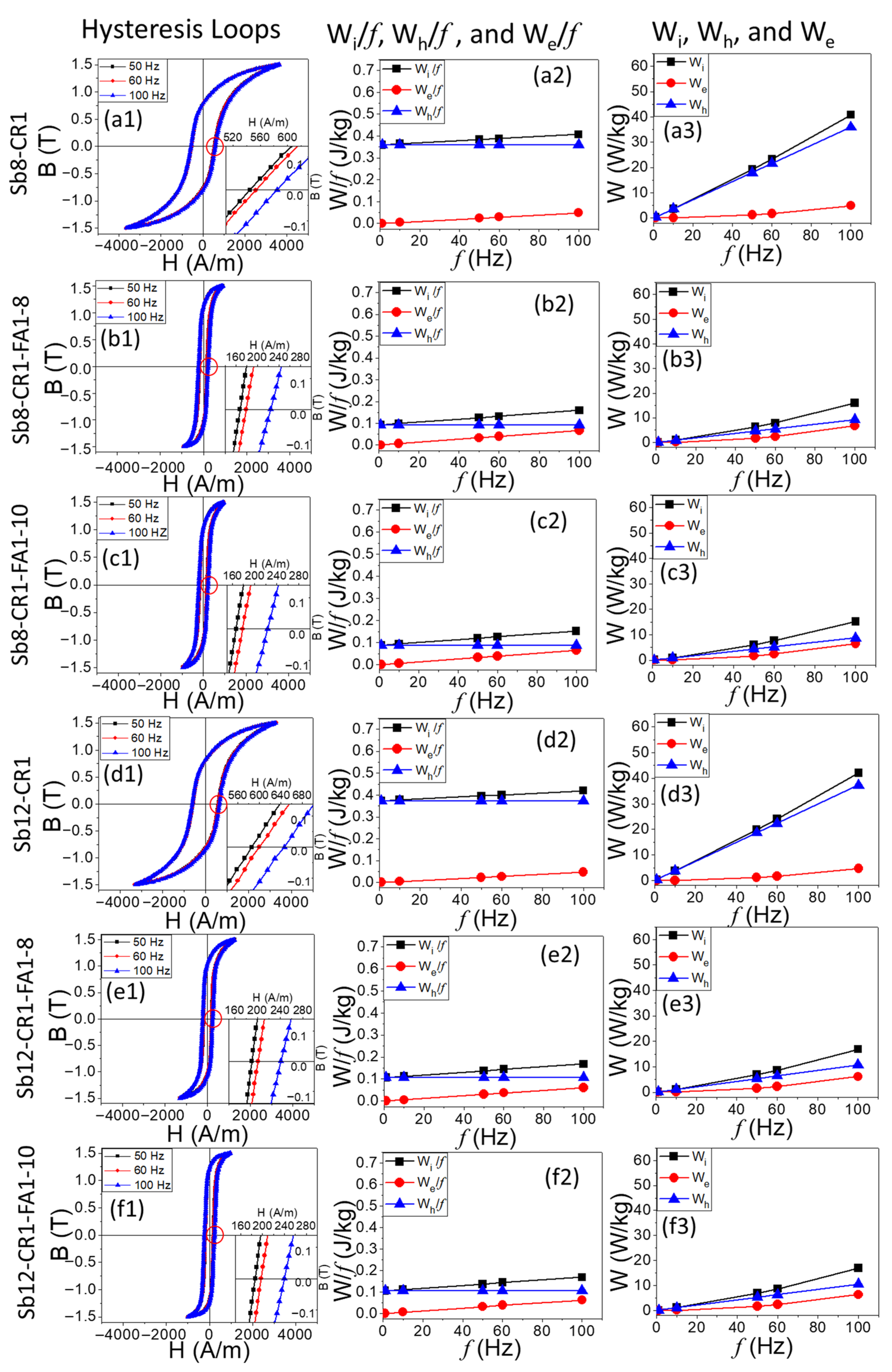

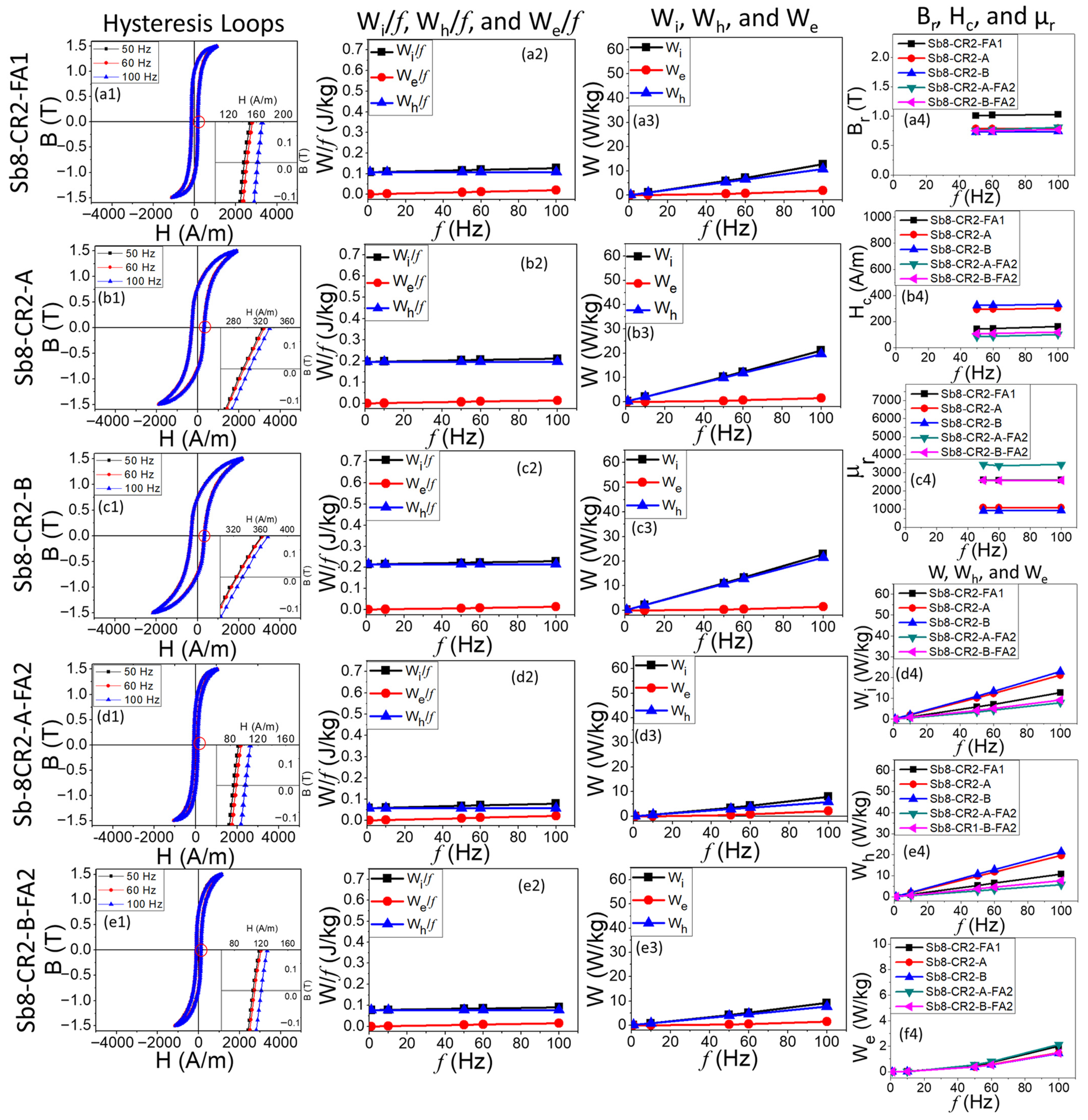

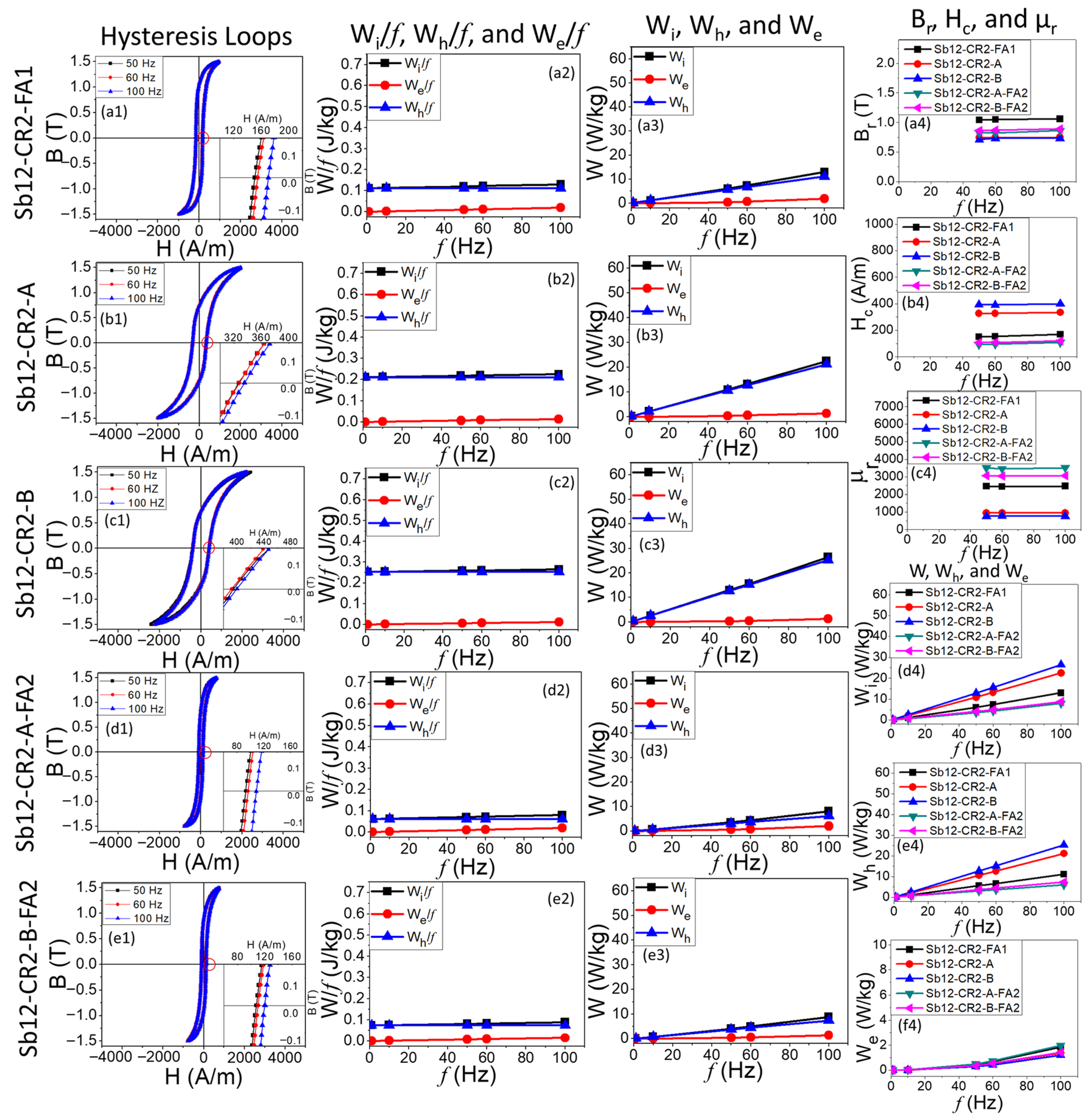

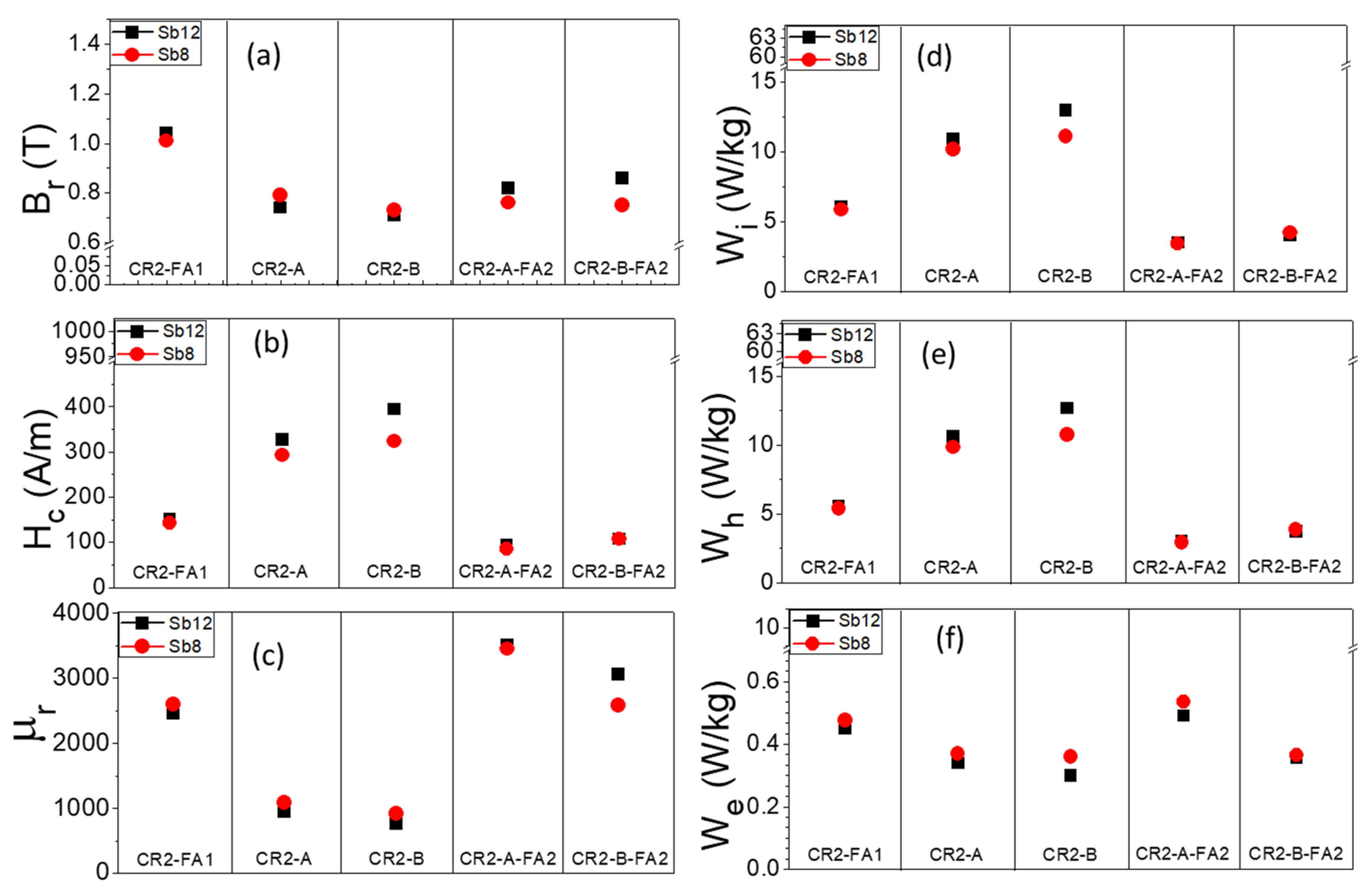

Magnetic properties of both steels (Sb8 and Sb12) after cold rolling (0.25 mm thickness), annealing (850 °C–10 min), second deformation (20% and 30%) and second annealing (850 °C–10 min) are presented in

Figure 8 and

Figure 9. As can be seen, hysteresis cycles of deformed samples (20% and 30%) are wider than those of annealed samples. The larger area observed in cold-rolled samples is also related to the dislocation density, which makes the magnetization process difficult [

9,

11,

20,

25]. In both steels (Sb8 and Sb12) and for the two thicknesses (0.5 mm and 0.25 mm), similar behavior in the losses and coefficient losses (W/f) curves is observed, and core loss (W

i) is greater after deformation and is reduced after annealing; the main contribution comes from hysteresis losses (

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9 and

Figure 10). The contribution of eddy current losses is less significant in all cases, regardless of processing condition (less than 0.6 W/kg at 50 Hz when the thickness is less than 0.25 mm), as observed in

Figure 8,

Figure 9 and

Figure 10.

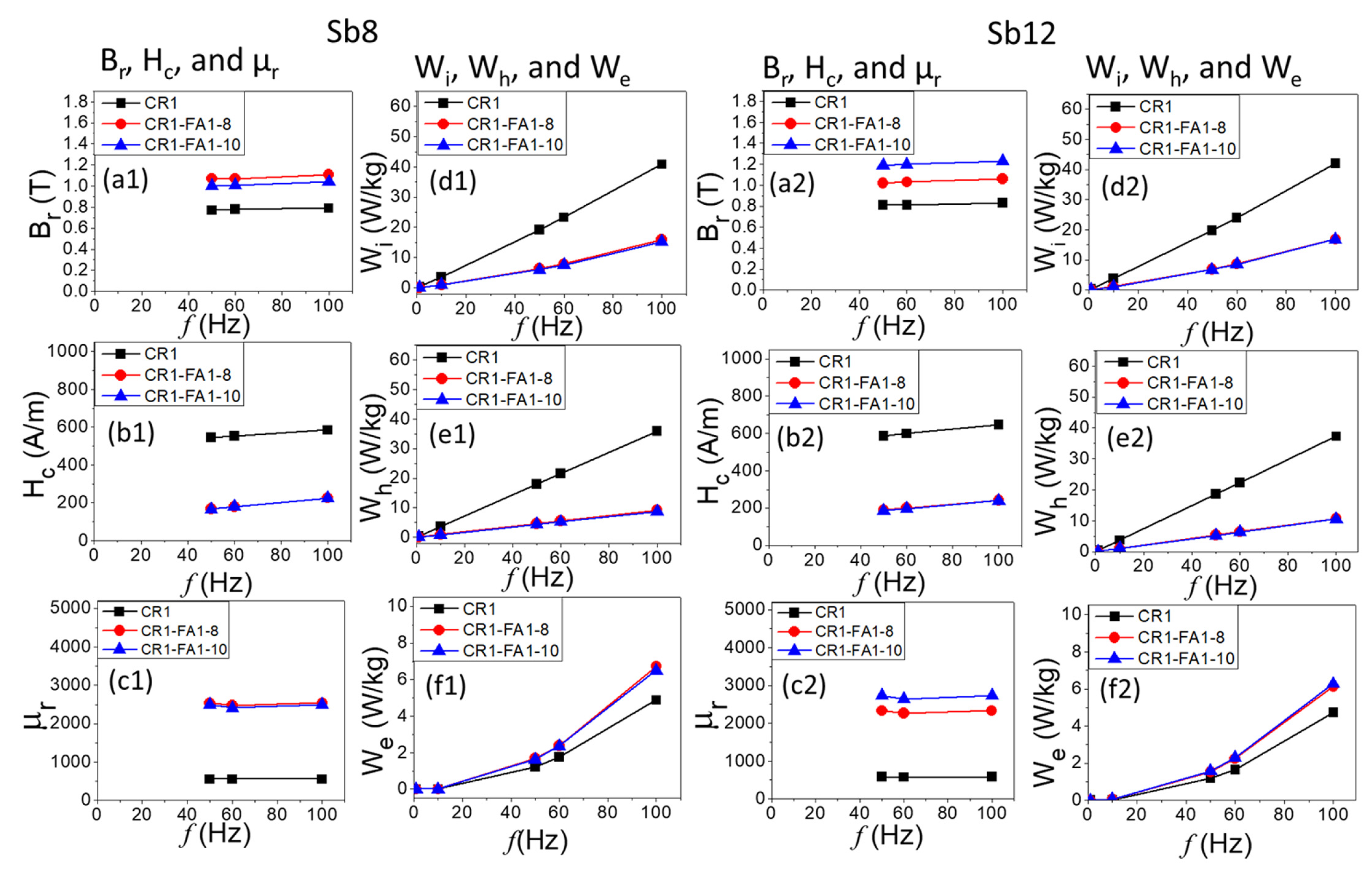

Table 2 shows a comparison between the lowest core loss values obtained in the present work and the ones reported in the literature for other electrical steel grades with similar thicknesses. After cold rolling (0.5 mm and 0.25 mm thickness) and annealing (850 °C for 10 min), core losses of Sb8 steel are 6.0 W/kg and 5.85 W /kg, respectively. In Sb12 steel, core loss values are 6.8 W/kg and 6.0 W/kg, respectively. In both steels, a lower core loss was obtained for a thickness of 0.25 mm. Therefore, regardless of the hot rolling temperature, steel processing by annealing at 880 °C for 180 min, a total thickness reduction of 80% or 90%, and final annealing at 850 °C for 10 min produces lower loss core values for a smaller thickness. In both steels, the lowest core loss values are observed after a total thickness reduction of 90%, annealing at 850 °C for 10 min, 20% deformation and second annealing at 850 °C for 10 min. Core loss values obtained as a function of hot rolling temperature are 3.44 W/kg and 3.52 W/kg for steel Sb8 (800 °C) and Sb12 (1200 °C), respectively (

Figure 10). Such difference is mainly attributed to variations in grain size, which is consistent with those reported in other works, where a larger grain size reduces core loss [

9]. In this work, the thickness with the best magnetic properties was 0.20 mm. The smaller thickness contributed to reducing eddy current losses and the larger grain size contributed to reducing hysteresis losses, leading to lower energy losses for this thickness. Some works have reported core loss values (near 3.0 W/kg [

14,

19]) slightly lower than the ones obtained in the Sb8 and Sb12 steels (3.44 W/kg and 3.52 W/kg). However, in one case, this has been reported in steels with higher silicon content, in which a reduction in thickness was also applied in two stages, although the thickness was greater with respect to the steel of this work. The influence of the Si content allowed for obtaining lower energy losses [

14]. In another case, the steel underwent a long annealing period before cold rolling (ABCR = 710 °C, 72 h) [

19], and although the thickness reduction occurred in one stage, the final thickness was similar to the one used in this work. Therefore, steel processing by the two-step cold rolling and annealing schedule allows for a reduction in annealing time before cold rolling, but also to produce similar core losses. Another advantage of the two-step cold rolling and annealing schedule is observed when the results are compared with other work, where steel processing is performed in a one-step cold rolling and annealing schedule with an annealing conduced at a temperature of 850 °C for 60 min [

23]. Although the time used in that work was larger than the one of this work (60 vs. 10 min), grains size was larger, and core losses were lower in the two-step cold rolling and annealing process. It seems that the combined effects of plastic deformation and annealing are more important than the increase in the annealing time.

Other authors have reported lower core loss values (2.02-2.92 W/kg) than the ones obtained in the present work (3.44 W/kg), but they were obtained in electrical steels containing higher Si contents (1.6–3.45%) [

26,

27]. However, cold rolling in such works was conducted in one stage, and heat treatments were conducted at higher temperatures. Despite the beneficial effects on increasing grain size and lowering core losses, the higher silicon contents and higher annealing temperatures represent a higher processing cost. In addition, increasing the Si content did not always result in lower energy losses, as we can see for the steel with Si content of 3% (

Table 2) [

28]. The higher core loss values compared to the ones obtained in this work are related to a larger thickness and a smaller grain size in the steel with 3%Si. Worthy of mention is that the lowest core loss values obtained in the present investigation (3.44 W/kg) are lower than those (4.4 W/kg) reported for other low Si-Sb steels that used longer ABCR times (850 °C-720 min) [

9] or than those obtained (3.95 W/kg) in high-silicon (3.0%) steels [

28]. These results suggest that the two-step cold rolling and annealing schedule enhances the magnetic properties of these materials with a significant reduction in processing time (

Table 2).

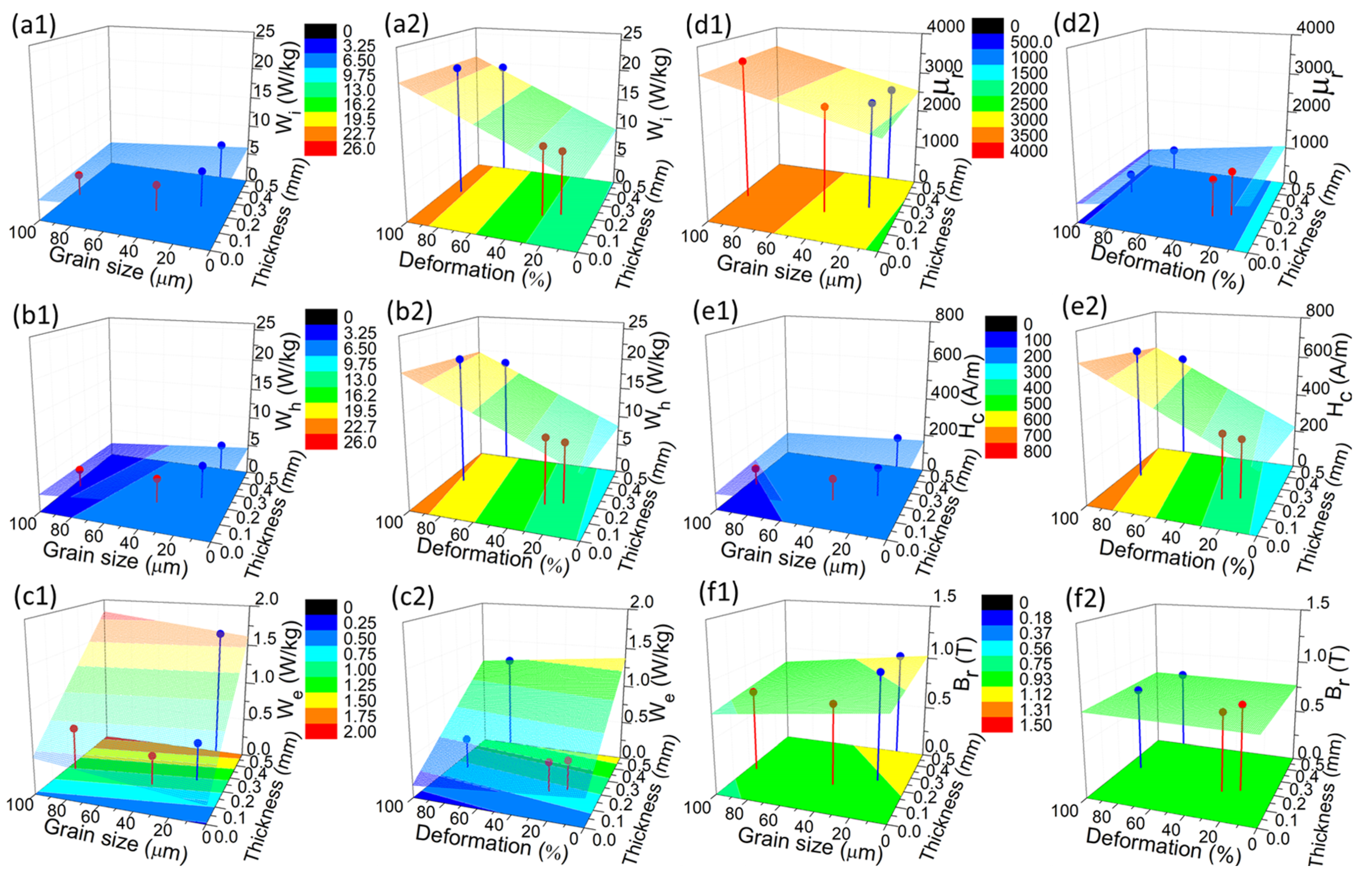

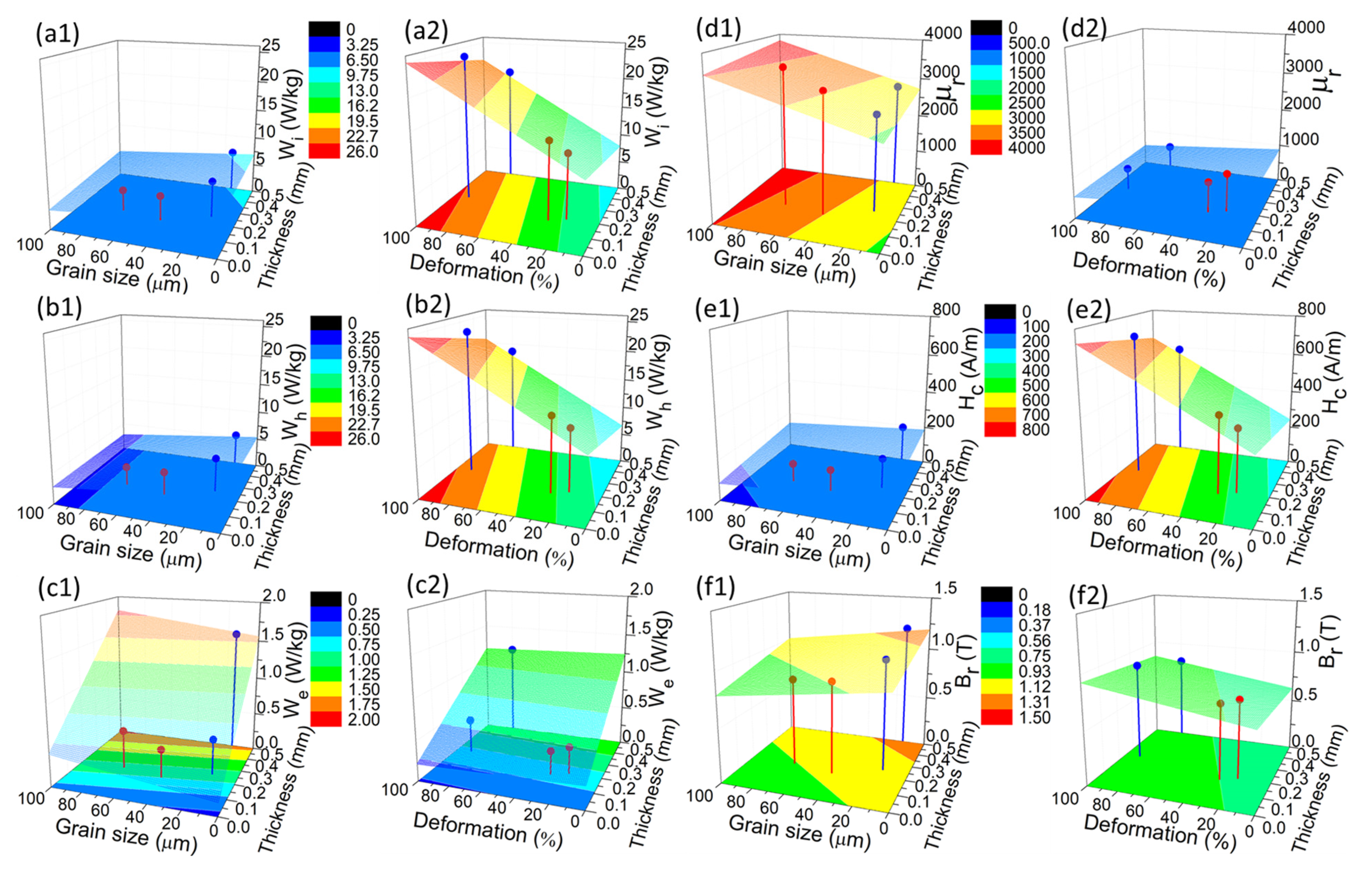

The surface plots shown in

Figure 11 and

Figure 12 present the magnetic properties obtained in Sb8 and Sb12 steels as a function of grain size and deformation. The effect of dislocation density is indirectly observed in these figures since it is well-known that the dislocation density in deformed steels is greater than that in annealed steels [

13,

15,

16,

17,

20,

21]. As mentioned above, the main objective of the present work is to evaluate the effect of processing history on the magnetic properties of ultra-low-carbon Si-Sb electrical steels. In general, it is observed that lower core loss values are obtained for a larger grain size and a smaller thickness (

Figure 11 and

Figure 12 and

Table 2). The two-step cold rolling and annealing schedule allows for obtaining a larger grain size in the final product than the one-step cold rolling and annealing route, and it is affected by the temperature used for the hot rolling process. In most cases, samples processed from hot rolling at 800 °C (Sb8) exhibit a larger grain size after final annealing at 850 °C (

Figure 11 and

Figure 12). It has been reported in another work that, for a 0.6 mm thick steel with additional deformations of 5, 10 and 20% and subsequent annealing at 850 °C for 60 min, a larger grain size is obtained as the deformation is increased [

23]. In the present work, the steel with 0.25 mm thickness with additional deformation of 20% and subsequent annealing at 850 °C for 10 min shows the largest grain size. Larger deformation levels (30%) result in smaller grain size (

Table 1,

Figure 3 and

Figure 4) with a detrimental effect on the magnetic properties of final products (

Figure 11 and

Figure 12). In both steels (Sb8 and Sb12), processing by the two-step cold rolling and annealing schedule allows a core loss reduction of approximately 41%, compared to steel processed by the one-step cold rolling and annealing schedule; this is for samples with a second deformation of 20%. In the case of samples with 30% deformation prior to the second annealing, reductions in core loss were about 32.7% and 27.7% for Sb12 and Sb8 steels, respectively.

These results show that, for the experimental steels, the use of a second cold deformation of 20% plus a second annealing stage (850 °C–10 min) favors grain growth and leads to a more significant reduction in core losses. This is compared to samples subjected to a second deformation of 30%, or with samples processed by one-step cold rolling and annealing schedule.

In general,

Figure 11 and

Figure 12 show that steel thickness will affect the magnetic properties (W

i, W

h, W

e, µ

r, H

c, B

r) differently when you have either a deformed steel or annealed steel, but even with these differences, the magnetic properties are better in annealed steel compared to deformed steel. However, in samples annealed at 850 °C for 10 min, which resulted in equiaxed microstructures, there is a combined effect of thickness and grain size on the magnetic properties. First, the increase in grain size improves some magnetic properties by reducing W

i, W

h, B

r, H

c and increasing µ

r, but this increase in grain size has a detrimental effect on W

e, which increases. Second, the reduction in thickness improves some magnetic properties by reducing W

i, W

e, and H

c, but has a detrimental effect by reducing µr and increasing W

h and B

r.

Changes in magnetic properties can be explained in terms of the movement of the magnetic domain walls after applying a magnetic field [

28]. Other authors mention that an increase in grain size and decrease in the area of the domain wall make the magnetization process easier [

8,

10,

14,

16,

19,

28]. Moreover, the pining effect of the domain wall is present in dislocations, second phases or grain boundaries; in this sense, in this work, the magnetic domain wall motion is mainly affected by grain boundaries [

29]. However, this effect in

Figure 11 and

Figure 12 is only observed for the coercive field and relative magnetic permeability properties, where increasing grain size reduces the amount of grain boundaries, which reduces the coercive field, increases the magnetic permeability, and reduces the hysteresis loss, allowing easy movement of the domain walls after applying the magnetic field. Other authors mention that increasing grain size decreases the magnetic domain wall area but increases the magnetic domain size. In relation to this, hysteresis losses decrease with the reduction in magnetic domain wall area, and eddy current losses decrease with the reduction in magnetic domain size [

28]. This is consistent with what is observed in

Figure 11 and

Figure 12, where hysteresis losses decrease and eddy current losses increase with increasing grain size.

Moreover, W

e can be explained by the classical eddy current theory. For this purpose, other authors use an equation where these losses are directly proportional to the square of pi, the thickness of the sheet, the frequency and the maximum peak of the magnetic induction, and inversely proportional to six times the resistivity [

1,

19], and in some cases, also inversely proportional to the density [

3]. Other authors have reported that an increase in grain size will increase local eddy currents [

1,

3,

10,

19,

23,

24,

28], contributing to the increase in total core losses. This information is consistent with the results of this work, where an increase in frequency increases energy losses due to eddy currents as observed in

Figure 5,

Figure 6,

Figure 8 and

Figure 9, for the different microstructural characteristics obtained through the processing routes.

The reduction in thickness reduces eddy currents contributing to the reduction in energy losses. This can be observed when comparing the results of the different thicknesses in the deformed condition (

Figure 11 and

Figure 12). However, subsequent annealing produces an increase in eddy current losses. In annealed samples, the lowest eddy current losses were obtained for the smallest thickness and the smallest grain size. In deformed samples, the greatest reduction was obtained for the lowest thickness with greater deformation (compare

Figure 11 and

Figure 12(c1) with

Figure 11 and

Figure 12(c2)).

These results suggest that final products must have an optimal grain size-to-thickness ratio to obtain high-efficiency electrical steels with enhanced magnetic properties. Finally, the hot rolling temperature has a significant effect on the characteristics and properties of final products obtained through the processing routes investigated. As shown in

Figure 7 and

Figure 10, samples hot-rolled at a temperature of 800 °C show, in general, lower core losses than samples hot-rolled at 1200 °C; this is after deformation and after annealing of the one- or two-step cold rolling and annealing schedules. The reduction in core losses is consistent with the larger grain size observed in these samples (

Table 1). The only processing condition where samples hot-rolled at 1200 °C exhibited lower core losses (

Figure 10) compared to samples hot-rolled at 800 °C, is after the second annealing of the two-step processing (CR2-B-FA2), which was also consistent with the larger grain size observed in such samples (

Table 1).

The effects of hot rolling temperature (800 °C and 1200 °C) on the crystallographic texture of samples processed by a one-step cold rolling (0.25 mm) and annealing (850 °C, 60 min) schedule was recently reported. It was found that the recrystallization texture of samples hot-rolled at 800 °C, exhibited a higher

ratio than samples hot-rolled at 1200 °C, which improved the magnetic performance of the former. In the present work, samples hot-rolled at 800 °C, exhibited, in general, a better magnetic performance than samples hot-rolled at 1200 °C. Therefore, the enhancement in the magnetic properties could be associated, apart from thickness and grain size, with possible variations in texture. In the present work, the samples hot-rolled at 800 °C, subjected to annealing before cold rolling, and further processed by the two-step cold rolling and annealing route, exhibited the lowest core losses for a thickness reduction of 20% (after second annealing). Other works regarding the effects of a two-step cold rolling and annealing schedule, but without annealing prior to cold rolling, have reported that thickness reductions of 15% (first stage) produce a weak γ-fiber; however, increasing the thickness reduction to 30% leads to a significant increase in the γ-fiber [

8]. Therefore, there exists the possibility that increasing the thickness reduction from 20 to 30%, could increase the volume fraction of γ-fiber, as reported elsewhere [

8]. The possible increase in the γ-fiber, along with the effects of thickness and grain size mentioned above, could explain the detrimental effect in samples with 30% thickness reduction compared to those with 30% thickness reduction. The evolution of crystallographic texture in electrical steels processed by the two-step cold rolling and annealing schedule, and its effect on the magnetic properties of the final products, has not yet been reported. However, this could be considered in future work.