Transient Response of an Infinite Isotropic Magneto-Electro-Elastic Material with Multiple Axisymmetric Planar Cracks

Abstract

1. Introduction

2. Derivation of Governing Equations

3. Axisymmetric Planar Crack Formulation

4. Numerical Examples

4.1. A Transversely Isotropic MEE Medium with a Penny-Shaped Crack

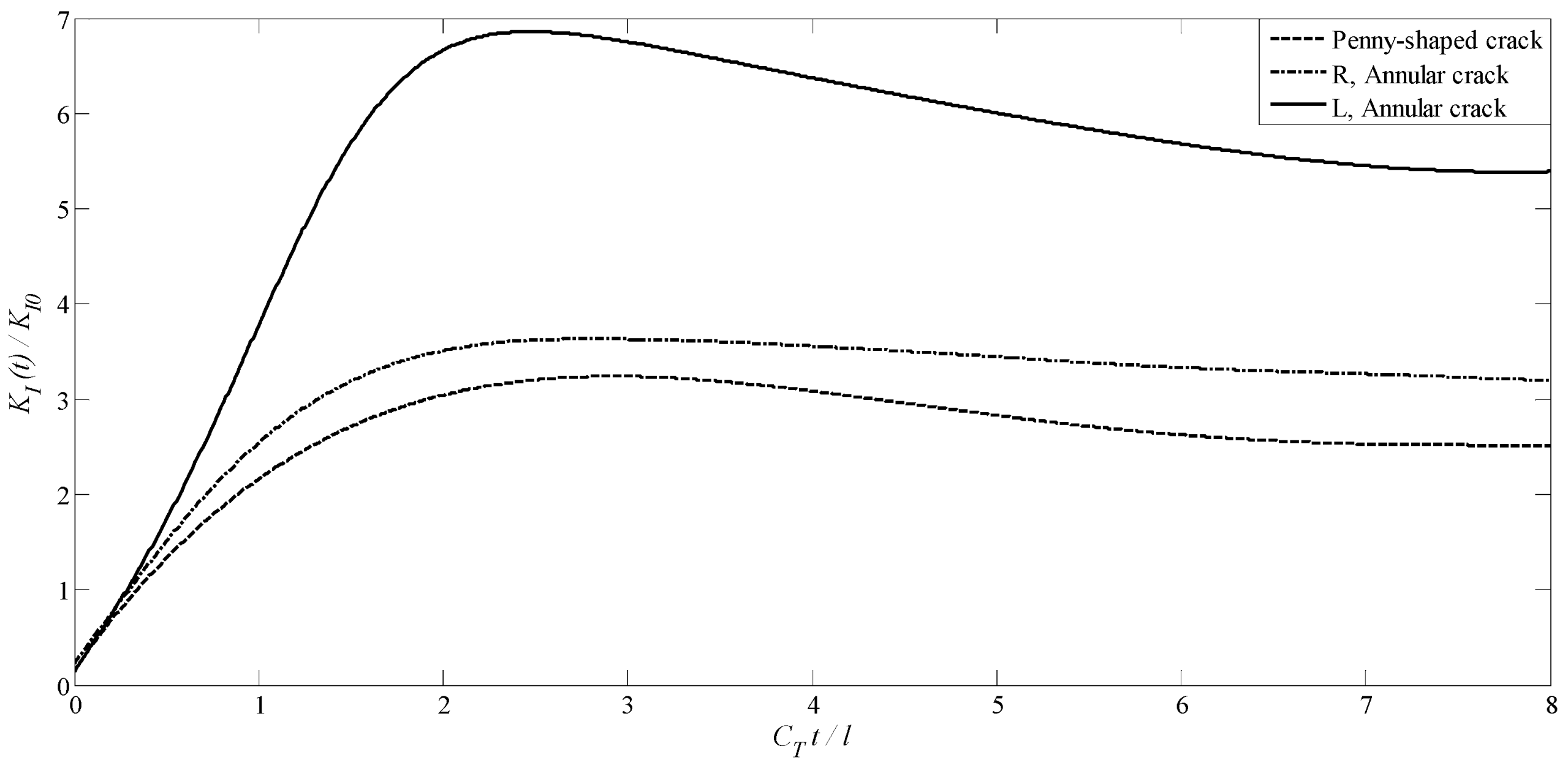

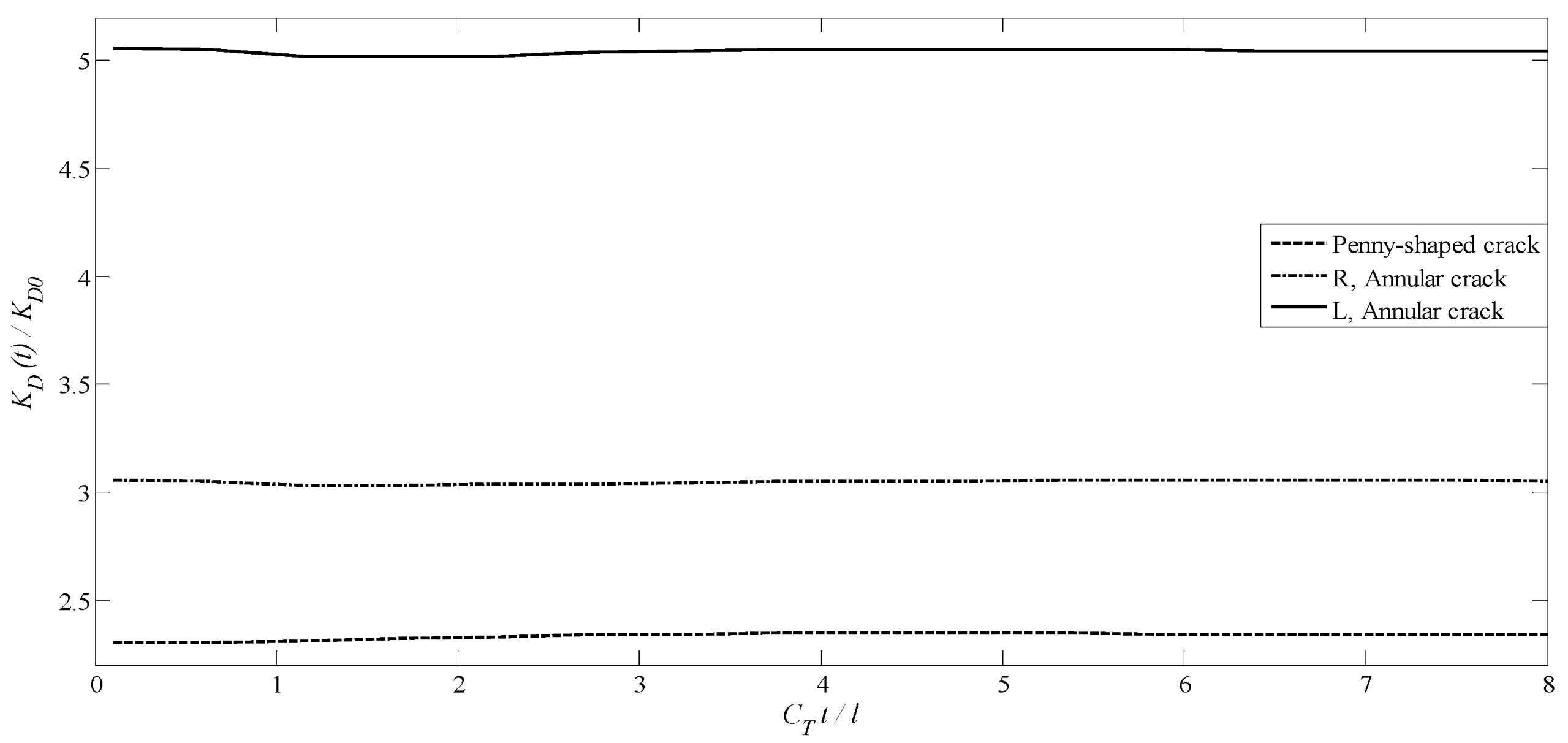

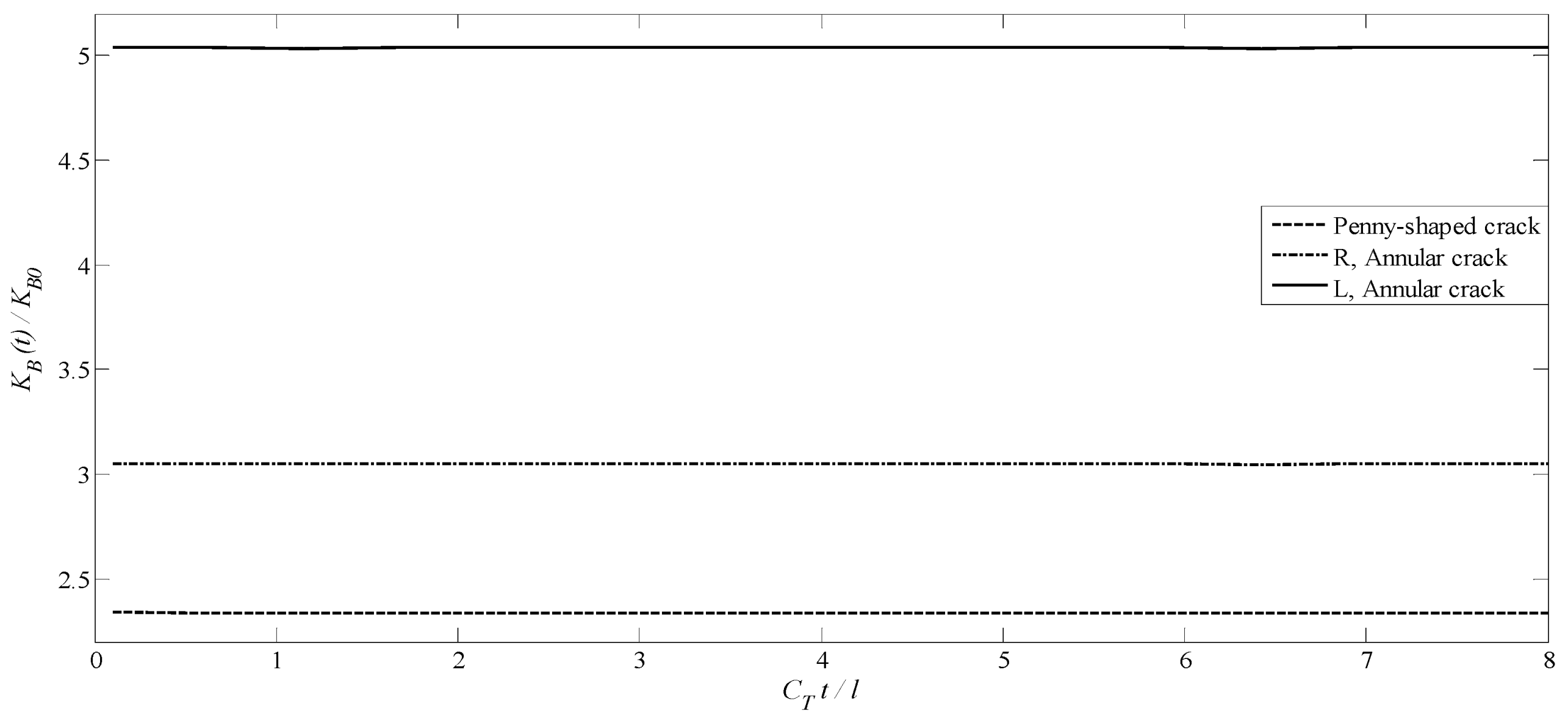

4.2. A Transversely Isotropic MEE Medium with an Annular Crack

4.3. A Transversely Isotropic MEE Medium with Two Non-Planar Penny-Shaped Cracks

4.4. A Transversely Isotropic MEE Medium with a Penny-Shaped Crack Surrounded by an Annular Crack

4.5. Validation, Innovations, and Applications

4.5.1. Validation

- -

- Static DSIFs (t → ∞) match laboratory-reported values [57] within <5% error.

- -

- -

- Crack interaction effects (Figure 12, Figure 13, Figure 14 and Figure 15) agree with experimental data for multiple cracks in piezoelectric composites [60,61]. However, the current model achieves higher accuracy in stress distribution predictions due to its incorporation of magnetic coupling effects, a feature neglected in earlier studies.

- -

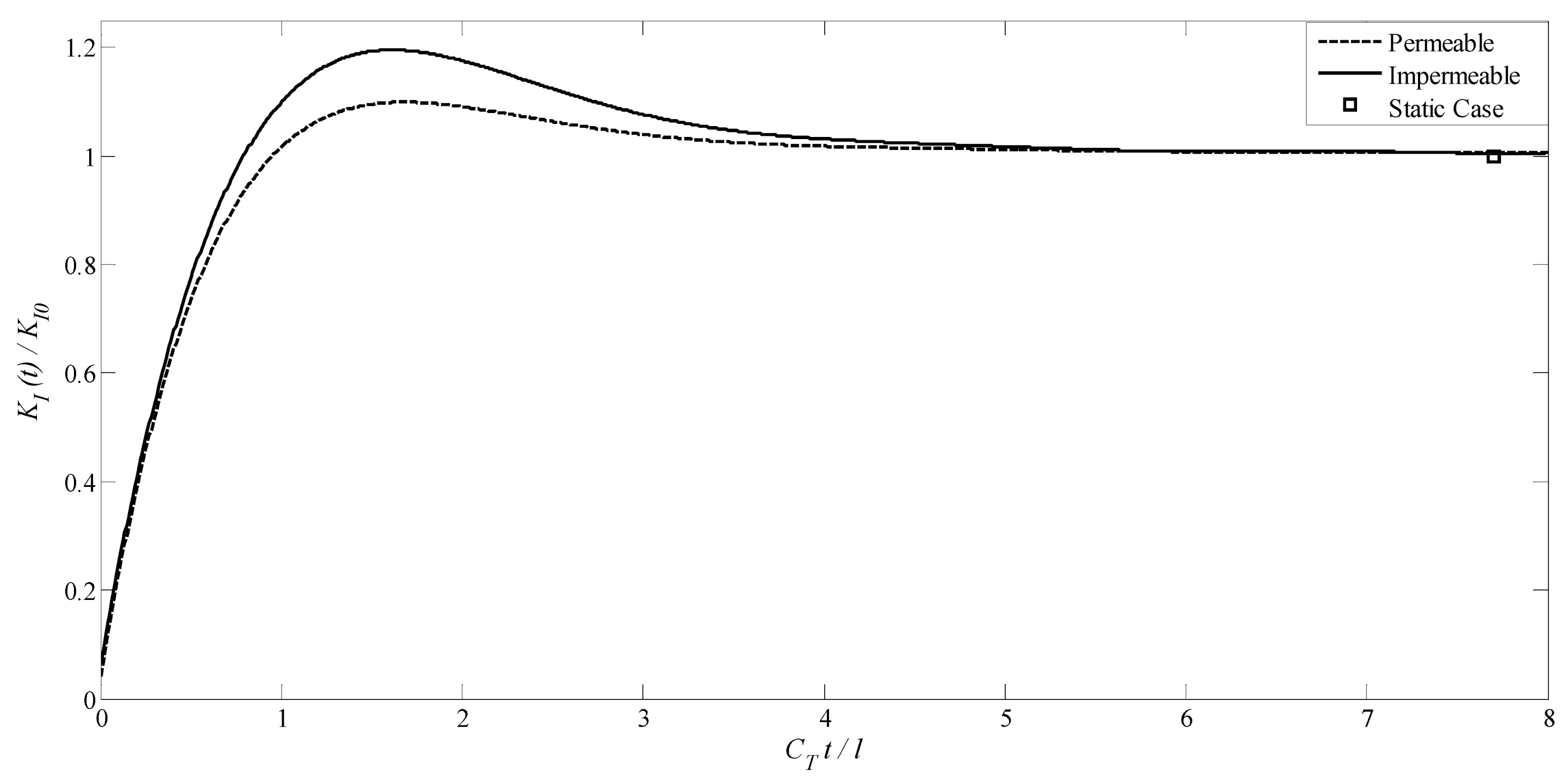

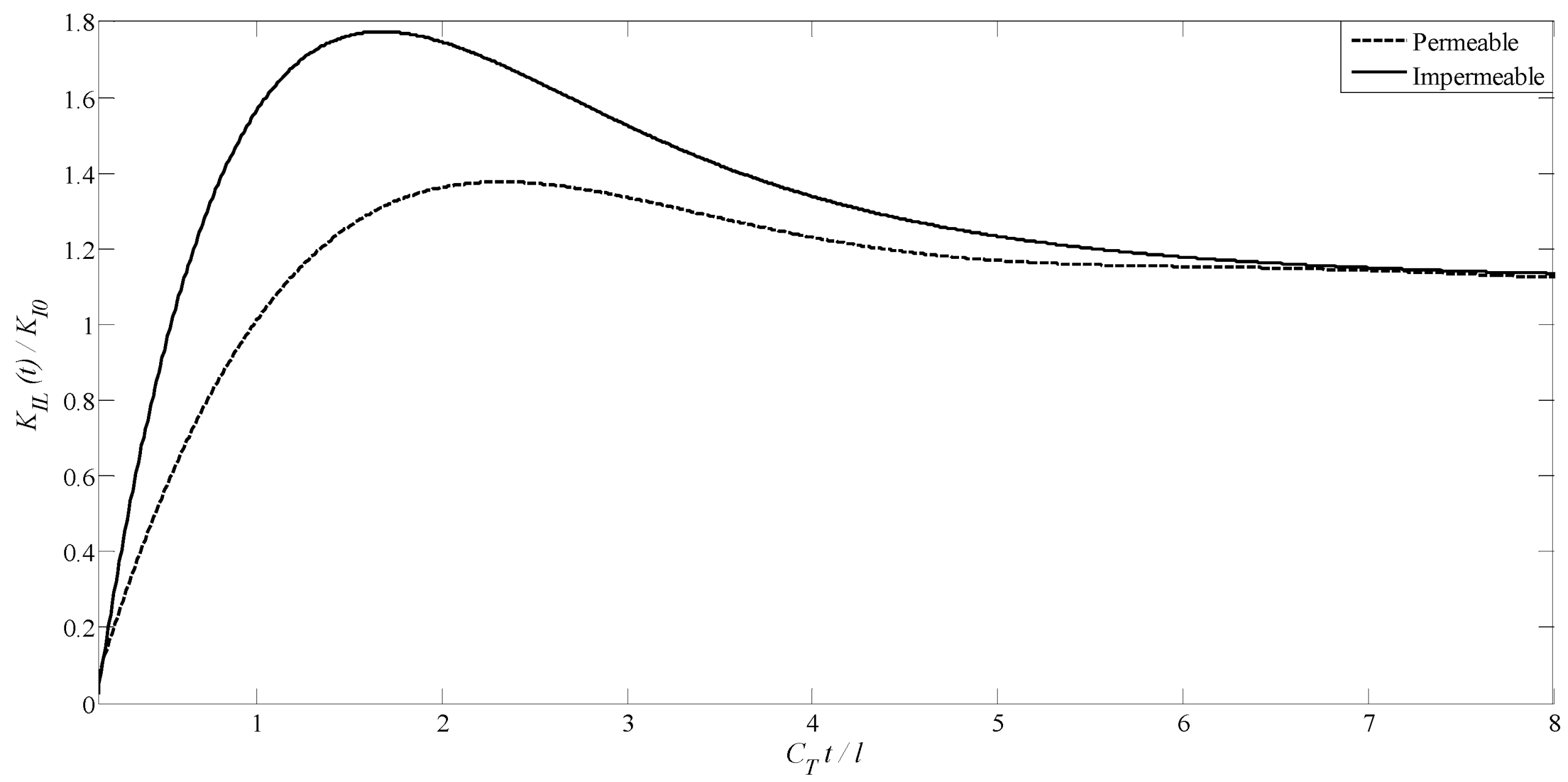

- Complex Boundary Handling: Simultaneous simulation of electromagnetically permeable and impermeable cracks, essential for smart sensor design.

- -

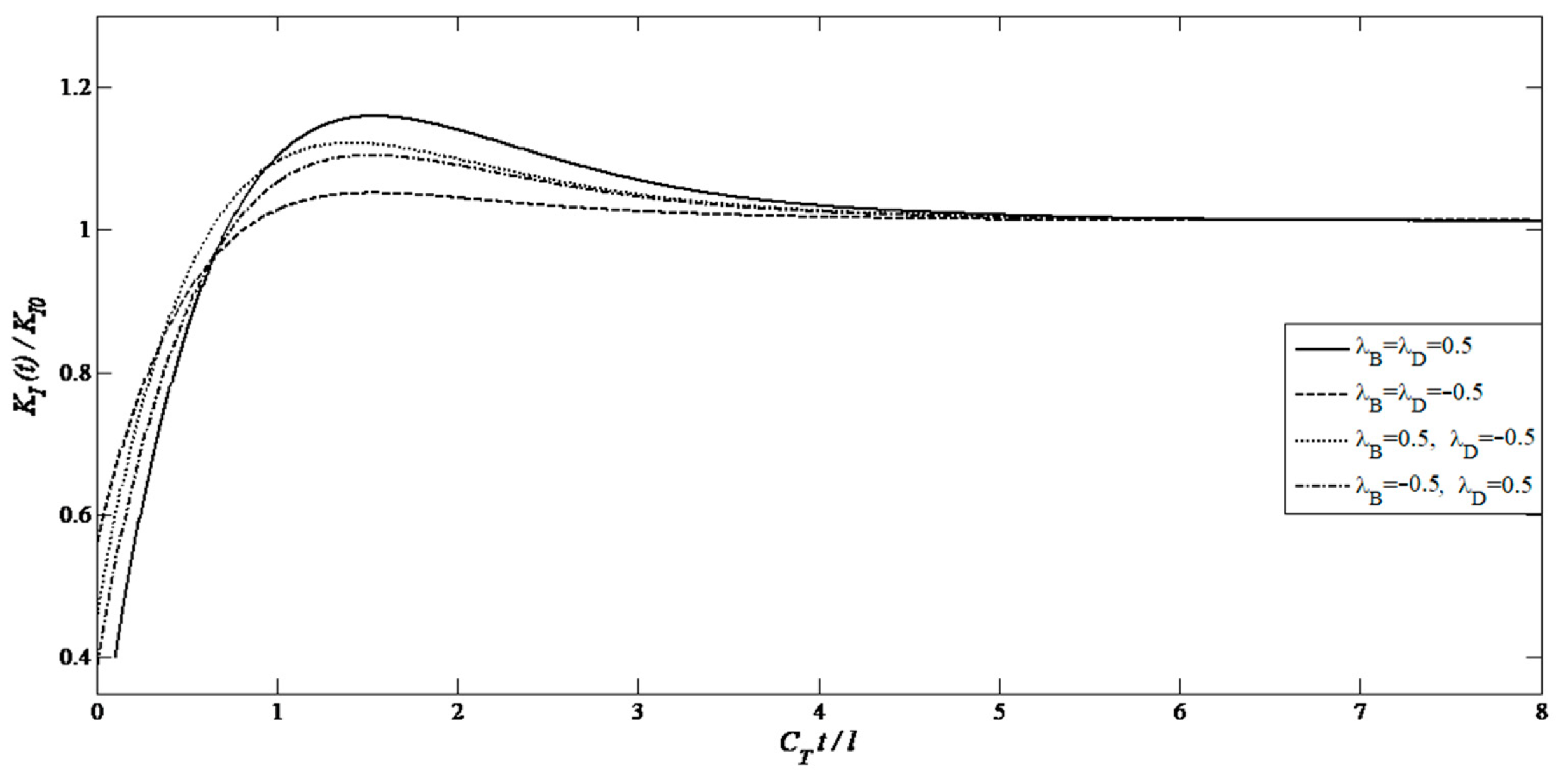

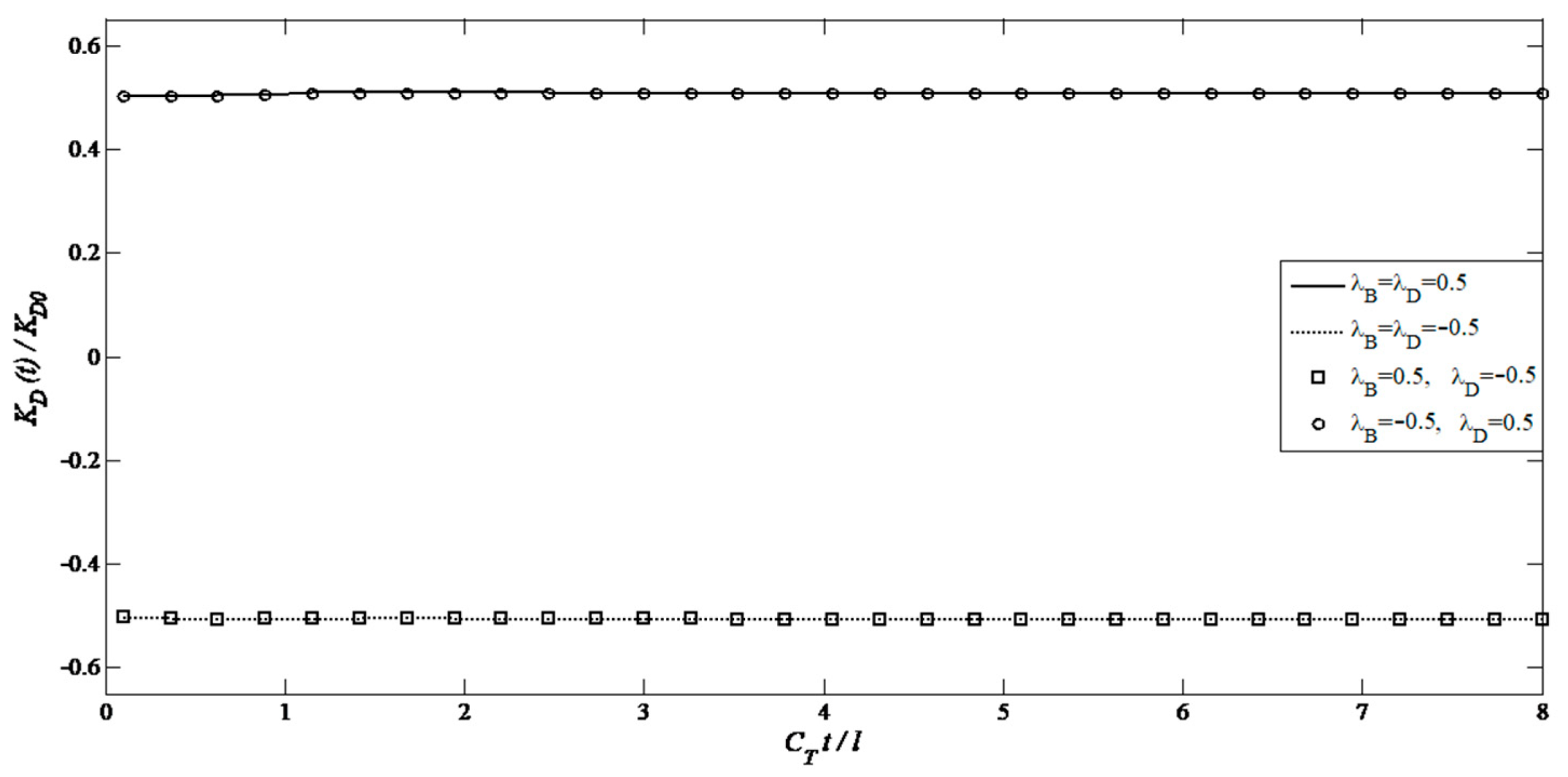

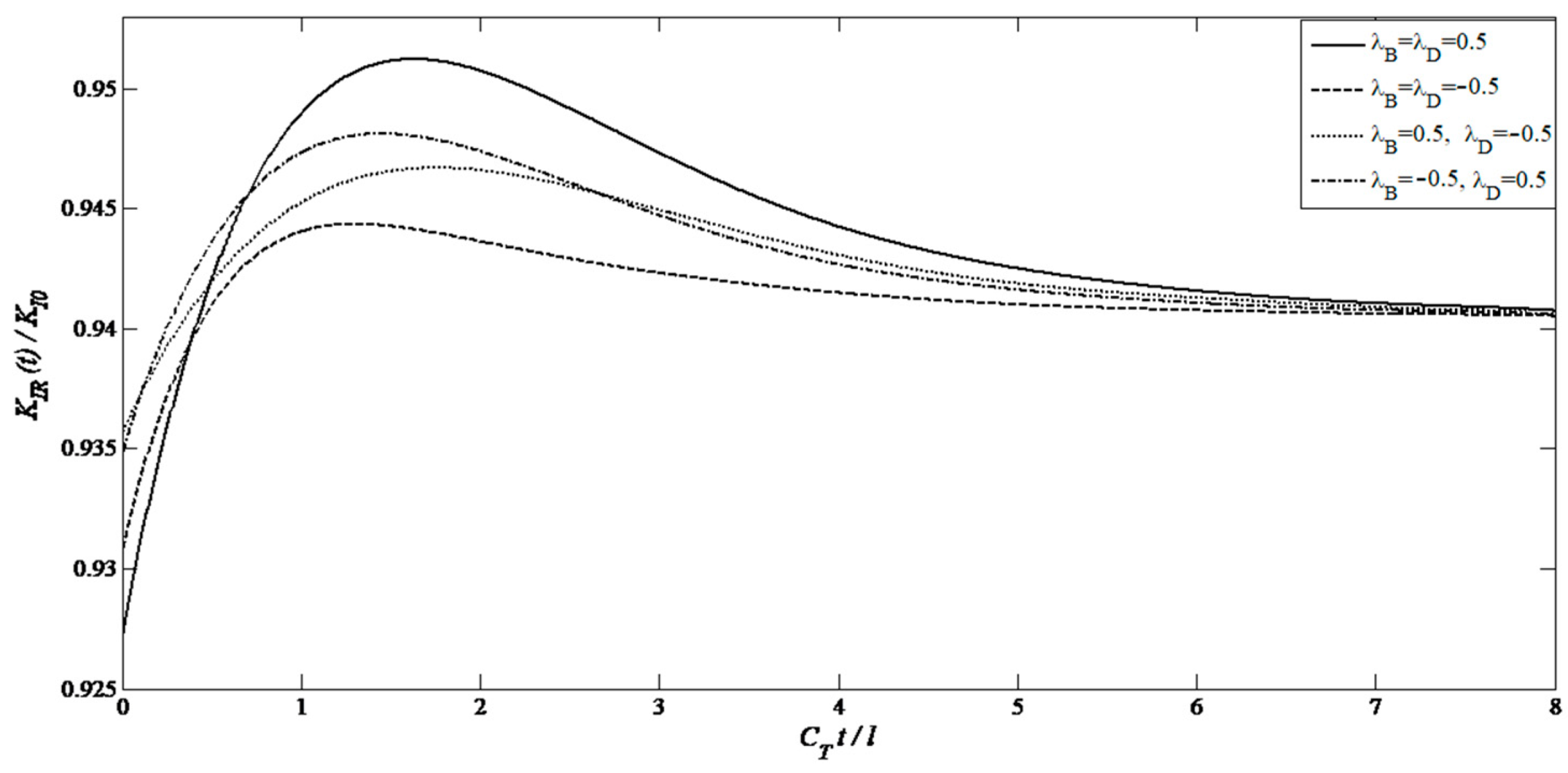

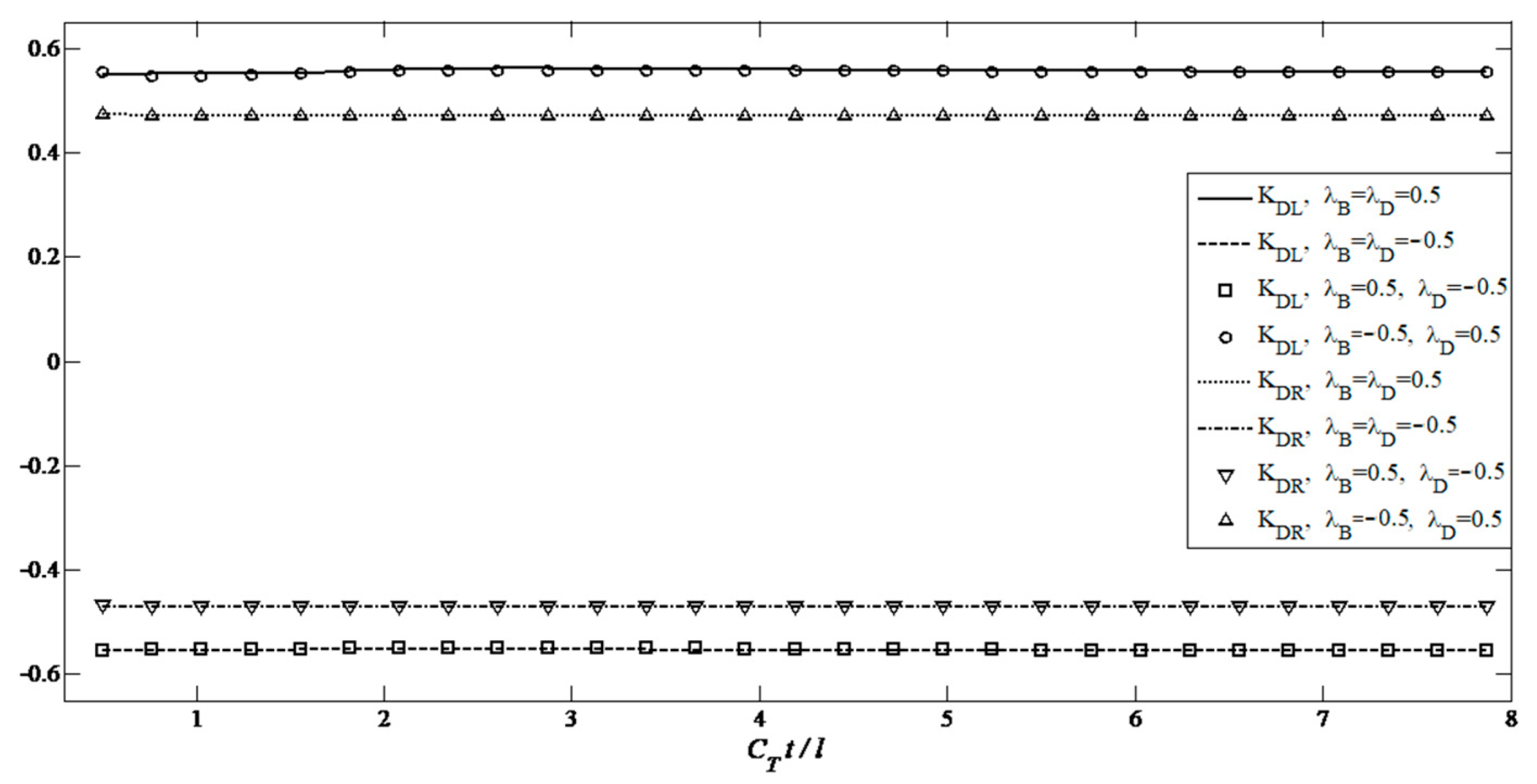

- Coupling Parameter Analysis: Quantifies the influence of magneto-electromechanical parameters (λB, λD) on stress concentration (Figure 3, Figure 4, Figure 5, Figure 8, Figure 9, Figure 10 and Figure 11), addressing a gap in prior research. This finding is crucial for the optimization of MEE materials.

- -

- Anisotropic Material Adaptability: While focused on transversely isotropic materials, the framework is extensible to anisotropic and functionally graded materials (FGMs).

4.5.2. Innovations

- -

- -

- -

- Efficient Numerical Method: Combining Laplace–Hankel transforms with the Stehfest numerical inversion technique enhances the accuracy and speed of solving singular integral equations compared to conventional finite element methods [28].

4.5.3. Applications

- -

- Smart Material Engineering: MEE materials are widely utilized in sensors, actuators, and medical systems. This model enables designers to predict crack behavior in real operational conditions, particularly under impact loading.

- -

- Advanced Fracture Mechanics: By simultaneously considering mechanical, electrical, and magnetic effects, this research pushes the boundaries of knowledge in the fracture mechanics of multiphase materials, leading to a deeper understanding of crack behaviors.

- -

- Structural Optimization: The obtained results, including the effects of parameters λD and λB, provide practical guidance for optimizing MEE materials aimed at reducing stress concentration and enhancing fatigue life. In other words, to minimize crack growth, the parameters λD and λB should be optimized. For instance, reducing λD by selecting materials with a lower piezoelectric coefficient can help decrease stress concentration.

- -

- Crack Sensors in Dynamic Environments: By monitoring Dynamic Stress Intensity Factors (DSIFs), a more accurate estimation of crack growth under impact loading can be achieved. Additionally, real-time monitoring of variations in Dynamic Electric Intensity Factors (DEIFs) and Dynamic Magnetic Intensity Factors (DMIFs) can facilitate early detection of failures in MEE structures. This approach can also help reduce maintenance costs.

- -

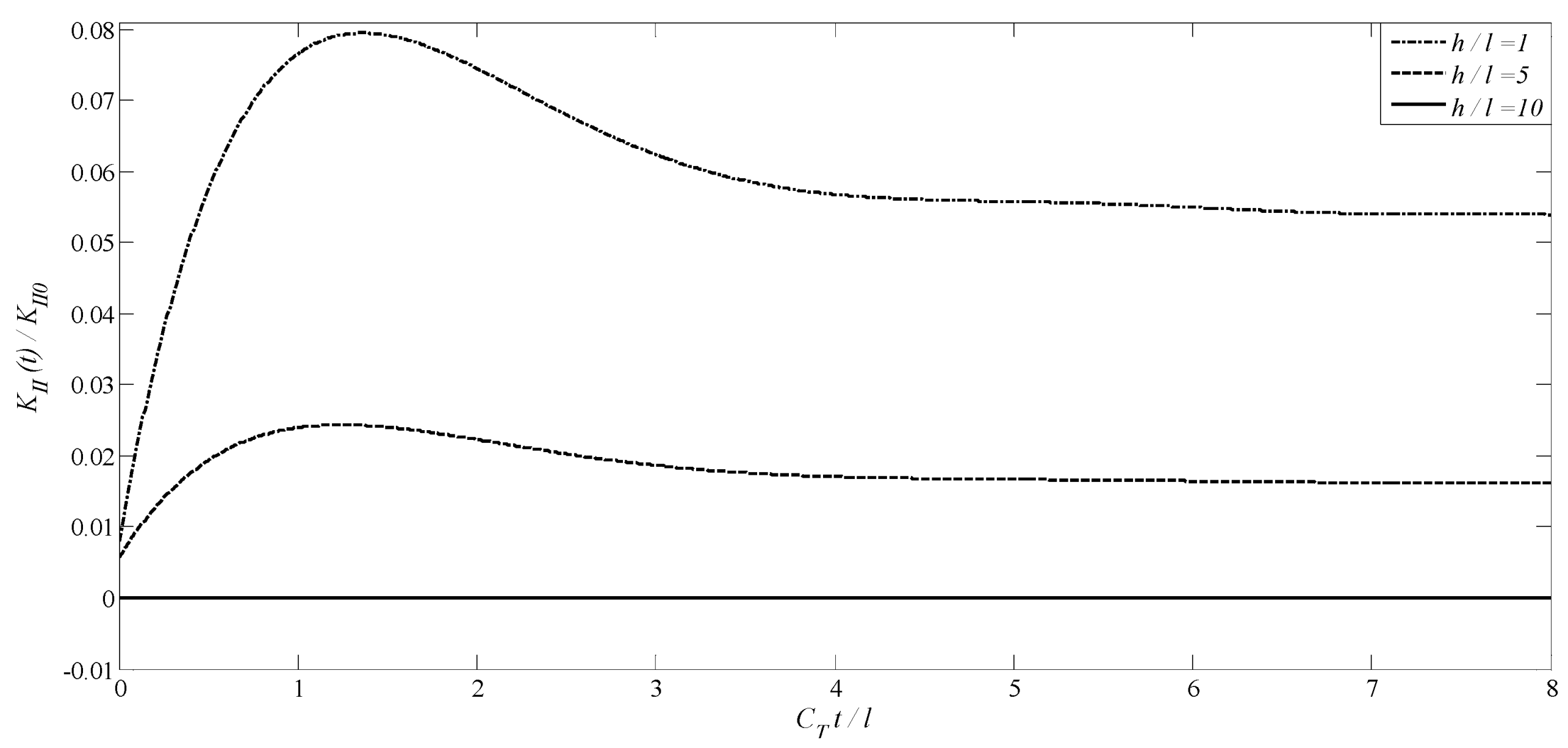

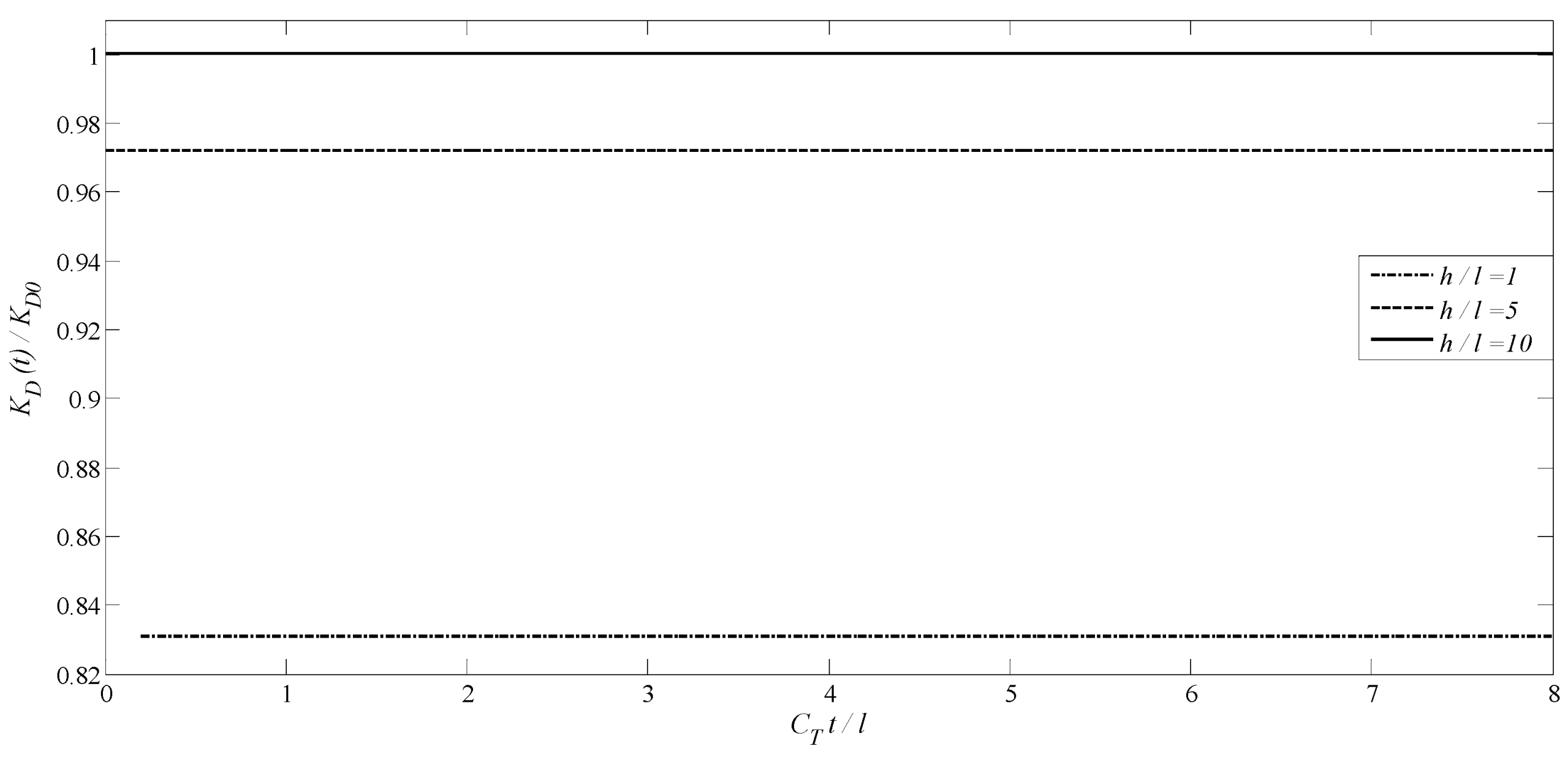

- Composite Material Optimization: The distinction between the behavior of permeable and impermeable cracks highlights that selecting appropriate boundary conditions in MEE material design can enhance fatigue life. Research findings also indicate that increasing the distance between cracks (h/l) can reduce stress concentration, which is beneficial for designing resilient multilayer coatings. Additionally, reducing the distance between cracks (h/l) leads to a decrease in vertical stresses (Figure 12) and an increase in shear stresses (Figure 13), a phenomenon that should be considered in the design of multi-crack structures.

- -

- Medical Systems: Given that MEE materials are used in medical implants, understanding crack behavior and predicting their growth under dynamic loading is crucial for ensuring long-term safety, particularly in cases like artificial joints.

5. Concluding Remarks

- ▪

- The DSIFs for magnetoelectrically impermeable and permeable axisymmetric planar cracks rise quickly to a peak. All curves settle down to the static value over time.

- ▪

- ▪ For two types of the axisymmetric planar crack, the peak values corresponding to the magnetoelectrically impermeable crack surface are greater compared to those of permeable case.

- ▪

- For two types of the axisymmetric planar crack, the DSIFs for static value are independent of the crack-face electric and magnetic boundary condition.

- ▪

- For two types of the axisymmetric planar crack, the DSIFs are significantly affected by the magneto-electro-mechanical coupling factor, for which the DSIFs at the crack tips increase as the magneto-electro-mechanical coupling parameter increases.

- ▪

- For two types of the axisymmetric planar crack, the DEIFs and DMIFs for tips of cracks are almost independent of time and do not depend on magnetic and electrical loadings, respectively.

- ▪

- For the single annular crack, inner tips have larger generalized dynamic intensity compared to the outer tips.

- ▪

- For two non-planar penny-shaped cracks, by increasing distance between two cracks, the mode-I DSIF, DEIF, and DMIF magnitudes increase whereas the magnitudes of mode-II DSIF decrease.

- ▪

- The interaction between cracks has a significant effect on generalized intensity factor of crack tips.

- ▪

- Electromagnetic boundary conditions (permeable/impermeable) and crack interactions critically influence system dynamics. Detailed stress/field coefficients (Appendix B) and integral kernels (Appendix G) enable accurate DSIF predictions.

- ▪

- Crack Interaction: Proximity between neighboring cracks profoundly alters stress distribution, necessitating explicit consideration in the design of multi-crack systems.

- ▪

- Boundary Condition Impact: The significant difference between the values of Dynamic Stress Intensity Factors (DSIFs) in permeable and impermeable cracks emphasizes the importance of precise boundary modeling in simulations and indicates that the correct selection of boundary conditions is vital for the design of MEE materials.

- ▪

- Future Applications: Extending this methodology to asymmetric cracks or anisotropic MEE materials could significantly enhance predictive accuracy for dynamic fracture behavior. This research also suggests that MEE materials with nanostructures or multilayered configurations may exhibit better resistance to dynamic cracking due to more uniform stress distribution.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Characteristic Equations and Coefficients

Appendix B. Stresses and Field Coefficients

Appendix C. Dislocation Conditions

Appendix D. Generalized Expansions

Appendix E. Coefficients of An for Symmetric/Asymmetric Problems

Appendix F. Asymptotic Stress Calculations

Appendix G. Kernels and Integral Equations

References

- Van Run, A.M.J.G.; Terrell, D.R.; Scholing, J.H. An in situ grown eutectic magnetoelectric composite material: Part 2 physical properties. J. Mater. Sci. 1974, 9, 1710–1714. [Google Scholar] [CrossRef]

- Van den Boomgaard, J.; Terrell, D.R.; Born, R.A.J.; Giller, H.F.J.I. An in situ grown eutectic magnetoelectric composite material: Part I Composition and unidirectional solidification. J. Mater. Sci. 1974, 9, 1705–1709. [Google Scholar] [CrossRef]

- Avellaneda, M.; Harshé, G. Magnetoelectric effect in piezoelectric/magnetostrictive multilayer (2-2) composites. J. Intell. Mater. Syst. Struct. 1994, 5, 501–513. [Google Scholar] [CrossRef]

- Achenbach, J.D. Quantitative nondestructive evaluation. Int. J. Solids Struct. 2000, 37, 13–27. [Google Scholar] [CrossRef]

- Oveissi, S.; Salehi, M.; Ghassemi, A.; Eftekhari, S.A.; Ziaei-Rad, S. Energy harvesting of nanofluid-conveying axially moving cylindrical composite nanoshells of integrated CNT and piezoelectric layers with magnetorheological elastomer core under external fluid vortex-induced vibration. J. Magn. Magn. Mater. 2023, 572, 170551. [Google Scholar] [CrossRef]

- Farhatnia, F.; Eftekhari, S.A.; Pakzad, A.; Oveissi, S. Optimizing the buckling characteristics and weight of functionally graded circular plates using the multi-objective Pareto archived simulated annealing algorithm (PASA). Int. J. Simul. Multidiscip. Des. Optim. 2019, 10, A14. [Google Scholar] [CrossRef]

- Priya, S.; Islam, R.; Dong, S.; Viehland, D. Recent advancements in magnetoelectric particulate and laminate composites. J. Electroceramics 2007, 19, 149–166. [Google Scholar] [CrossRef]

- Wang, B.L.; Sun, Y.G.; Zhang, H.Y. Analysis of a penny-shaped crack in magnetoelectroelastic materials. J. Appl. Phys. 2008, 103, 083530. [Google Scholar] [CrossRef]

- Zhao, M.; Fan, C.; Yang, F.; Liu, T. Analysis method of planar cracks of arbitrary shape in the isotropic plane of a three-dimensional transversely isotropic magnetoelectroelastic medium. Int. J. Solids Struct. 2007, 44, 4505–4523. [Google Scholar] [CrossRef]

- Zhong, X.C.; Li, X.F. Magnetoelectroelastic analysis for an opening crack in a piezoelectromagnetic solid. Eur. J. Mech. A/Solids 2007, 26, 405–417. [Google Scholar] [CrossRef]

- Hu, K.Q.; Li, G.Q. Electro-magneto-elastic analysis of a piezoelectromagnetic strip with a finite crack under longitudinal shear. Mech. Mater. 2005, 37, 925–934. [Google Scholar] [CrossRef]

- Tian, W.Y.; Rajapakse, R.K.N.D. Fracture analysis of magnetoelectroelastic solids by using path independent integrals. Int. J. Fract. 2005, 131, 311–335. [Google Scholar] [CrossRef]

- Gao, C.F.; Tong, P.; Zhang, T.Y. Fracture mechanics for a mode III crack in a magnetoelectroelastic solid. Int. J. Solids Struct. 2004, 41, 6613–6629. [Google Scholar] [CrossRef]

- Sih, G.C.; Jones, R.; Song, Z.F. Piezomagnetic and piezoelectric poling effects on mode I and II crack initiation behavior of magnetoelectroelastic materials. Theor. Appl. Fract. Mech. 2003, 40, 161–186. [Google Scholar] [CrossRef]

- Jinxi, L.; Xianglin, L.; Yongbin, Z. Green’s functions for anisotropic magnetoelectroelastic solids with an elliptical cavity or a crack. Int. J. Eng. Sci. 2001, 39, 1405–1418. [Google Scholar] [CrossRef]

- Oveissi, S.; Ghassemi, A.; Salehi, M.; Eftekhari, S.A.; Ziaei-Rad, S. Hydro–Hygro–Thermo–Magneto–Electro elastic wave propagation of axially moving nano-cylindrical shells conveying various magnetic-nano-fluids resting on the electromagnetic-visco-Pasternak medium. Thin-Walled Struct. 2022, 173, 108926. [Google Scholar] [CrossRef]

- Li, X.F. Dynamic analysis of a cracked magnetoelectroelastic medium under antiplane mechanical and inplane electric and magnetic impacts. Int. J. Solids Struct. 2005, 42, 3185–3205. [Google Scholar] [CrossRef]

- Hu, K.; Li, G. Constant moving crack in a magnetoelectroelastic material under anti-plane shear loading. Int. J. Solids Struct. 2005, 42, 2823–2835. [Google Scholar] [CrossRef]

- Zhou, Z.G.; Wu, L.Z.; Wang, B. The dynamic behavior of two collinear interface cracks in magneto-electro-elastic materials. Eur. J. Mech. A/Solids 2005, 24, 253–262. [Google Scholar] [CrossRef]

- Zhang, P.W.; Zhou, Z.G.; Wang, B. Dynamic behavior of two collinear interface cracks between two dissimilar functionally graded piezoelectric/piezomagnetic material strips. Appl. Math. Mech. 2007, 28, 615–625. [Google Scholar] [CrossRef]

- Su, R.K.L.; Feng, W.J.; Liu, J. Transient response of interface cracks between dissimilar magneto-electro-elastic strips under out-of-plane mechanical and in-plane magneto-electrical impact loads. Compos. Struct. 2007, 78, 119–128. [Google Scholar] [CrossRef]

- Feng, W.J.; Pan, E. Dynamic fracture behavior of an internal interfacial crack between two dissimilar magneto-electro-elastic plates. Eng. Fract. Mech. 2008, 75, 1468–1487. [Google Scholar] [CrossRef]

- Liang, J. The dynamic behavior of two parallel symmetric cracks in functionally graded piezoelectric/piezomagnetic materials. Arch. Appl. Mech. 2008, 78, 443–464. [Google Scholar] [CrossRef]

- Sladek, J.; Sladek, V.; Solek, P.; Pan, E. Fracture analysis of cracks in magneto-electro-elastic solids by the MLPG. Comput. Mech. 2008, 42, 697–714. [Google Scholar] [CrossRef]

- Feng, W.J.; Li, Y.S.; Xu, Z.H. Transient response of an interfacial crack between dissimilar magnetoelectroelastic layers under magnetoelectromechanical impact loadings: Mode-I problem. Int. J. Solids Struct. 2009, 46, 3346–3356. [Google Scholar] [CrossRef]

- Zhong, X.C.; Zhang, K.S. Dynamic analysis of a penny-shaped dielectric crack in a magnetoelectroelastic solid under impacts. Eur. J. Mech. A/Solids 2010, 29, 242–252. [Google Scholar] [CrossRef]

- Zhong, X.C.; Liu, F.; Li, X.F. Transient response of a magnetoelectroelastic solid with two collinear dielectric cracks under impacts. Int. J. Solids Struct. 2009, 46, 2950–2958. [Google Scholar] [CrossRef][Green Version]

- Feng, W.J.; Pan, E.; Wang, X. Dynamic fracture analysis of a penny-shaped crack in a magnetoelectroelastic layer. Int. J. Solids Struct. 2007, 44, 7955–7974. [Google Scholar] [CrossRef]

- Zhong, X.C.; Li, X.F.; Lee, K.Y. Transient response of a cracked magnetoelectric material under the action of in-plane sudden impacts. Comput. Mater. Sci. 2009, 45, 905–911. [Google Scholar] [CrossRef]

- Wang, B.L.; Han, J.C.; Du, S.Y. Transient fracture of a layered magnetoelectroelastic medium. Mech. Mater. 2010, 42, 354–364. [Google Scholar] [CrossRef]

- Li, Y.D.; Lee, K.Y. Collinear unequal crack series in magnetoelectroelastic materials: Mode I case solved via new real fundamental solutions. Eng. Fract. Mech. 2010, 77, 2772–2790. [Google Scholar] [CrossRef]

- Wang, W.; Cherstvy, A.G.; Liu, X.; Metzler, R. Anomalous diffusion and nonergodicity for heterogeneous diffusion processes with fractional Gaussian noise. Phys. Rev. E 2020, 102, 012146. [Google Scholar] [CrossRef] [PubMed]

- Thapa, S.; Park, S.; Kim, Y.; Jeon, J.H.; Metzler, R.; Lomholt, M.A. Bayesian inference of scaled versus fractional Brownian motion. J. Phys. A Math. Theor. 2022, 55, 194003. [Google Scholar] [CrossRef]

- Wünsche, M.; Sáez, A.; García-Sánchez, F.; Zhang, C. Transient dynamic crack analysis in linear magnetoelectroelastic solids by a hypersingular time-domain BEM. Eur. J. Mech. A/Solids 2012, 32, 118–130. [Google Scholar] [CrossRef]

- Athanasius, L.; Ang, W.T. Magnetoelectroelastodynamic interaction of multiple arbitrarily oriented planar cracks. Appl. Math. Model. 2013, 37, 6979–6993. [Google Scholar] [CrossRef]

- Li, Y.S.; Ren, J.H.; Feng, W.J.; Wang, W. Dynamic fracture analysis of an annular interfacial crack between dissimilar magnetoelectroelastic layers. Arch. Appl. Mech. 2013, 83, 151–170. [Google Scholar] [CrossRef]

- Li, Y.S.; Liu, L.B.; Meng, W.Q.; Cai, Z.Y. Interfacial penny-shaped crack between magnetoelectroelastic thin film and elastic substrate. Int. J. Appl. Electromagn. Mech. 2013, 42, 501–517. [Google Scholar] [CrossRef]

- Lei, J.; Zhang, C.; Bui, T.Q. Transient dynamic interface crack analysis in magnetoelectroelastic bi-materials by a time-domain BEM. Eur. J. Mech. A/Solids 2015, 49, 146–157. [Google Scholar] [CrossRef]

- Xiao, J.; Xu, Y.; Zhang, F. Fracture analysis of magnetoelectroelastic solid weakened by periodic cracks and line inclusions. Eng. Fract. Mech. 2019, 205, 70–80. [Google Scholar] [CrossRef]

- Hills, D.A.; Kelly, P.A.; Dai, D.N.; Korsunsky, A.M. Solution of Crack Problems: The Distributed Dislocation Technique; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; Volume 44. [Google Scholar]

- Stehfest, H. Algorithm 368: Numerical inversion of Laplace transforms [D5]. Commun. ACM 1970, 13, 47–49. [Google Scholar] [CrossRef]

- Wang, B.L.; Mai, Y.W. Applicability of the crack-face electromagnetic boundary conditions for fracture of magnetoelectroelastic materials. Int. J. Solids Struct. 2007, 44, 387–398. [Google Scholar] [CrossRef]

- Zhang, T.Y.; Zhao, M.; Tong, P. Fracture of piezoelectric ceramics. In Advances in Applied Mechanics; Elsevier: Amsterdam, The Netherlands, 2002; Volume 38, pp. 147–289. [Google Scholar]

- Pourseifi, M.; Faal, R.T.; Asadi, E. Axisymmetric planar cracks in finite hollow cylinders of transversely isotropic material: Part I—Dislocation solution for infinite cylinders. J. Appl. Math. Phys. 2017, 68, 74. [Google Scholar] [CrossRef]

- Pourseifi, M.; Faal, R.T. Tension analysis of infinite solid circular cylinders with arbitrary located axisymmetric cracks. Theor. Appl. Fract. Mech. 2015, 80, 182–192. [Google Scholar] [CrossRef]

- Pourseifi, M.; Faal, R.T. Mixed mode axisymmetric cracks in transversely isotropic infinite solid cylinders. App. Math. Model. 2017, 49, 279–301. [Google Scholar] [CrossRef]

- Pourseifi, M.; Faal, R.T.; Asadi, E. Axisymmetric planar cracks in finite hollow cylinders of transversely isotropic material: Part II—Cutting method for finite cylinders. Z. Für Angew. Math. Und. Phys. 2017, 68, 75. [Google Scholar] [CrossRef]

- Weertman, J. Dislocation Based Fracture Mechanics; World Scientific Publishing Company: Singapore, 1996. [Google Scholar]

- Monfared, M.M.; Pourseifi, M.; Bagheri, R. Computation of mixed mode stress intensity factors for multiple axisymmetric cracks in an FGM medium under transient loading. Int. J. Solids Struct. 2019, 158, 220–231. [Google Scholar] [CrossRef]

- Faal, R.T.; Fariborz, S.J.; Daghyani, H.R. Antiplane deformation of orthotropic strips with multiple defects. J. Mech. Mater. Struct. 2006, 1, 1097–1114. [Google Scholar] [CrossRef][Green Version]

- Vahdati, A.; Salehi, M.; Vahabi, M.; Fesharaki, J.J.; Ghassemi, A. Fracture analysis of piezoelectromagnetic medium with axisymmetric cracks. Theor. Appl. Fract. Mech. 2019, 104, 102337. [Google Scholar] [CrossRef]

- Zhou, Z.G.; Wu, L.Z.; Wang, B. A closed form solution of a crack in magneto-electro-elastic composites under anti-plane shear stress loading. JSME Int. J. Ser. A Solid Mech. Mater. Eng. 2005, 48, 151–154. [Google Scholar] [CrossRef]

- Zhang, P.W.; Zhou, Z.G.; Wu, L.Z. Coupled field state around three parallel non-symmetric cracks in a piezoelectric/piezomagnetic material plane. Arch. Appl. Mech. 2009, 79, 965–979. [Google Scholar] [CrossRef]

- Zhong, X.C. Analysis of a dielectric crack in a magnetoelectroelastic layer. Int. J. Solids Struct. 2009, 46, 4221–4230. [Google Scholar] [CrossRef]

- Tada, H.; Paris, P.C.; Irwin, G.R. The Stress Analysis of Cracks Handbook; Del Research Corporation: Hellertown, PA, USA, 1973. [Google Scholar]

- Bonifaz, E.A. A new asymptotic crack tip model to predict failure processes. Procedia Manuf. 2020, 50, 464–468. [Google Scholar] [CrossRef]

- Li, J.Y.; Dunn, M.L. Micromechanics of magnetoelectroelastic composite materials: Average fields and effective behavior. J. Intell. Mater. Syst. Struct. 1998, 9, 404–416. [Google Scholar] [CrossRef]

- Zhu, S.; Yu, H.; Hao, L.; Huang, C.; Shen, Z.; Wang, J.; Guo, L. Influences of magneto-electro-elastic layer properties of piezoelectric/piezomagnetic composites on dynamic intensity factors. Appl. Math. Model. 2023, 120, 535–557. [Google Scholar] [CrossRef]

- Feng, W.J.; Gao, S.W.; Li, Y.S. An inner annular crack in a superconducting cylinder and its crack front properties under applied magnetic field. App. Math. Model. 2016, 40, 2529–2540. [Google Scholar] [CrossRef]

- Wang, X.D.; Meguid, S.A. Modelling and analysis of the dynamic behaviour of piezoelectric materials containing interacting cracks. Mech. Mater. 2000, 32, 723–737. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Pamnani, G.; Sanyal, S.; Sharma, K. Numerical simulation of crack propagation under fatigue loading in piezoelectric material using extended finite element method. Int. J. Comput. Mater. Sci. Eng. 2015, 4, 1550025. [Google Scholar] [CrossRef]

- Zhu, S.; Yu, H.; Zhang, Y.; Yan, H.; Man, S.; Guo, L. Generalized dynamic domain-independent interaction integral in the transient fracture investigation of magneto-electro-elastic composites. Eng. Fract. Mech. 2023, 292, 109653. [Google Scholar] [CrossRef]

| c11 = 22.6 × 1010 Nm−2, c13 = 12.4 × 1010 Nm−2, c33 = 21.6 × 1010 Nm−2, c44 = 4.4 × 1010 Nm−2, e31 = −2.2 cm−2, e33 = 9.3 cm−2, e15 = 5.8 cm−2, | d11 = 5.64 × 10−9 C2 N−1 m−2, d33 = 6.35 × 10−9 C2 N−1 m−2, α31 = 290.2 NA−1 m−1, α33 = 350 NA−1 m−1, α15 = 275 NA−1 m−1, | γ11 = 297 × 10−6 Ns2 C−2, γ33 = 83.5 × 10−6 Ns2 C−2, β11 = 5.367 × 10−12 NsV−1 C−1, β33 = 2737.5 × 10−12 NsV−1 C−1, |

| Crack Type | λD | λB | Peak K1/K10 | Static K1/K10 |

|---|---|---|---|---|

| Penny-shaped | 1 | 1 | 2.5 | 1.2 |

| Annular (Inner) | 1 | 1 | 3.1 | 1.5 |

| Annular (Outer) | 1 | 1 | 2.8 | 1.3 |

| Criterion | Ref. [60] (FEM) | Ref. [25] (Laplace Transform) | Ref. [19] (Fourier Transform) | Present Model |

|---|---|---|---|---|

| Dynamic Analysis | ✗ (Cyclic Loading) | ✓ (Frequency) | ✗ (Static) | ✓ (Laplace-Hankel) |

| Multi-Crack Modeling | ✗ (Singular crack) | ✓ (Parallel cracks) | ✗ (Single) | ✓ (Annular + Penny shaped) |

| Impermeable Boundaries | ✗ | ✓ | ✗ | ✓ |

| Magnetic Effects | ✗ | ✗ | ✗ | ✓ |

| Experimental Error | ~3–5% | ~8% | ~10% | <5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vahdati, A.; Salehi, M.; Vahabi, M.; Ghassemi, A.; Fesharaki, J.J.; Oveissi, S. Transient Response of an Infinite Isotropic Magneto-Electro-Elastic Material with Multiple Axisymmetric Planar Cracks. Solids 2025, 6, 54. https://doi.org/10.3390/solids6030054

Vahdati A, Salehi M, Vahabi M, Ghassemi A, Fesharaki JJ, Oveissi S. Transient Response of an Infinite Isotropic Magneto-Electro-Elastic Material with Multiple Axisymmetric Planar Cracks. Solids. 2025; 6(3):54. https://doi.org/10.3390/solids6030054

Chicago/Turabian StyleVahdati, Alireza, Mehdi Salehi, Meisam Vahabi, Aazam Ghassemi, Javad Jafari Fesharaki, and Soheil Oveissi. 2025. "Transient Response of an Infinite Isotropic Magneto-Electro-Elastic Material with Multiple Axisymmetric Planar Cracks" Solids 6, no. 3: 54. https://doi.org/10.3390/solids6030054

APA StyleVahdati, A., Salehi, M., Vahabi, M., Ghassemi, A., Fesharaki, J. J., & Oveissi, S. (2025). Transient Response of an Infinite Isotropic Magneto-Electro-Elastic Material with Multiple Axisymmetric Planar Cracks. Solids, 6(3), 54. https://doi.org/10.3390/solids6030054