Abstract

Ag2Se has attracted significant attention as a promising alternative to Bi2Te3 for near-room-temperature thermoelectric (TE) applications. In this study, flexible Ag2Se thin films were fabricated via magnetron sputtering under different sputtering power settings, followed by post-deposition annealing to optimize their TE properties. Structural and compositional analyses confirmed the successful synthesis of Ag2Se films with high crystallinity. Additionally, tuning the sputtering power and annealing temperatures can effectively enhance the electrical conductivity, Seebeck coefficient, and overall power factor. A significant power factor of ~17.4 µW·cm−1·K−2 at 100 °C was achieved in the 30 W sputtering power and 300 °C annealing sample, pointing out the huge potential of Ag2Se thin films as self-powered flexible devices.

1. Introduction

Thermoelectric (TE) materials, as a series of functional materials, can convert temperature differences into electrical potentials, or vice versa [1,2,3]. Thus, devices fabricated from TE materials are widely investigated by researchers to solve the issues like heat recovery, room-temperature power generation, or self-charging power sources [4,5,6]. Typically, the efficiency of the TE devices is determined by the intrinsic properties of the TE materials, which are evaluated by the dimensionless figure of merit, zT (zT = S2σT∕κ, where S, σ, T, and κ are the Seebeck coefficient, electrical conductivity, absolute temperature, and total thermal conductivity, respectively) [7,8]. To fabricate TE devices for the applications of room-temperature power generation or self-charging power sources, forming TE materials into thin films [9] and employing flexible substrates, like polyimide (PI) [10], etc., are two effective strategies for researchers to enhance flexibility, though sometimes leading to a slight reduction in thermoelectric performance [9]. However, considering that the thermal conductivity (κ) values of thin films are difficult to measure accurately, the power factor (PF = S2σ) is commonly used to assess their TE performance potential [11]. The literature reports that intrinsic Ag2Se thin films typically exhibit κ values around 1.20 to 1.35 W·m−1·K−1, located in the range of approximately 1.9 to 2.2 of Ag/Se ratio [12]. In addition, S and σ are coupled with the carrier concentration (n), which shows that the increase in n leads to the increase in σ and the decrease in S [13,14]. Thus, the simultaneous increase in S and σ is also a challenge for researchers to enhance the TE performance of flexible thin films.

Over the past several decades, near-room-temperature TE materials, such as Bi2Te3 and Sb2Te3, have been extensively studied. In recent years, considerable efforts have been devoted to exploring new material systems with high TE performance near room temperature, with particular attention given to silver and silver–copper chalcogenides (Ag2Q and AgCuQ, where Q = S, Se, and Te) [15,16]. Specifically, Ag2Se thin films exhibit comparable n-type TE performance to that of mature Bi2Te3, showing high σ and low κ near room temperature [17]. Moreover, the abundance of Ag2Se in the Earth’s crust and its environmental compatibility make it a promising alternative to Bi2Te3 [18]. Furthermore, Ag2Se possesses a relatively narrow band gap (~0.02 eV to 0.22 eV), demonstrating huge potential for the enhancement of TE performance [15]. Although Ag2Se possesses a relatively stable orthorhombic structure near room temperature, a phase transition occurs when the temperature reaches approximately 130 °C [18]. Thus, Ag2Se thin films are typically measured in the temperature range of room temperature to 100 °C. According to various reports on Ag2Se TE thin films, multiple methods have been developed for the fabrication of high-performance Ag2Se thin films, such as adjusting the Ag/Se ratio (e.g., Ag1.8Se [19] and Ag2.06Se [20]), texturing (e.g., (00l)-oriented [21] and (013)-oriented texturing [22]), and doping (e.g., Te [21], Ga [23], and S [24]).

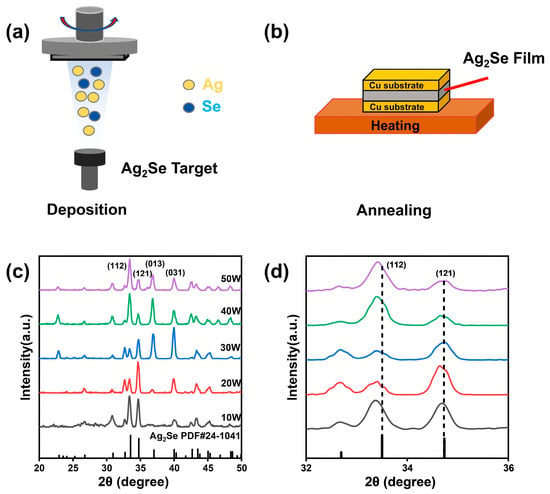

In this work, we synthesized Ag2Se thin film samples by a widely utilized magnetron sputtering method under different sputtering power settings, followed by a post-deposition annealing process at different annealing temperatures. Magnetron sputtering was selected due to its suitability for precise parameter control, high film uniformity, and compatibility with flexible substrates. In addition, post-deposition annealing was performed to enhance the crystallinity and phase purity of the Ag2Se thin films, addressing how sputtering power and annealing temperature affected TE performance. The schematic diagrams of the magnetron sputtering process and the post-deposition annealing process are shown in Figure 1a and 1b, respectively. The aim of this work was to synthesize high-performance flexible Ag2Se thin films by magnetron sputtering followed by post-deposition annealing. Moreover, the influence of sputtering power and annealing temperature on TE performance was systematically investigated based on the crystal structure and microstructural analysis.

Figure 1.

(a) The schematic diagram of the magnetron sputtering method for Ag2Se fabrication; (b) the schematic diagram of the post-deposition annealing method; (c) XRD patterns of the synthesized 10–50 W sputtering power sample from 20° to 50°; (d) enlarged XRD patterns of the synthesized 10–50 W sputtering power sample from 32° to 36°.

2. Materials and Methods

Thin film fabrication: Firstly, the polyimide (PI) substrates were cut into chips with the size of 20 mm × 20 mm × 0.12 mm and ultrasonically and sequentially cleaned in deionized water, ethanol, and acetone, with 20 min for each step. The PI substrates were chosen for their high mechanical and thermal stability, which enabled post-deposition annealing without degradation. Moreover, the flexibility of the PI substrate is outstanding, making it widely used in flexible TE device fabrication [21,22]. Secondly, Ag2Se thin films were deposited on PI substrates using the magnetron sputtering technique. As shown in Figure 1a, the Ag2Se target material (99.99% purity, Zhongnuo Advanced Material Co., Ltd., Beijing, China) was loaded into the vacuum chamber, which was evacuated to a pressure below 3.0 × 10−3 Pa. During the deposition process of Ag2Se thin films, the working pressure was maintained at 0.5 Pa with an argon (Ar) flow rate of 40 sccm. The sputtering power of this process was set to 10 W, 20 W, 30 W, 40 W, and 50 W to further investigate the effect of sputtering power on TE performance.

Post-deposition annealing: The synthesized 30 W sample of Ag2Se thin films were sandwiched between the Cu substrates and placed on the heater, as shown in Figure 1b. The annealing environment is in vacuum with a glove box at the annealing temperature for 30 min, followed by another 30 min to maintain the temperature, and an automatic decrease to room temperature. The annealing temperatures of the thin film samples were set to 150 °C, 200 °C, 250 °C, 300 °C, and 350 °C to investigate the effect of annealing temperature on TE performance.

Characterization: X-ray diffraction (XRD, D/max-2500, Rigaku Corporation, Tokyo, Japan) was used to characterize the crystal structure of the synthesized samples with a scanning range of 2θ = 10° to 50° and a scanning speed of 10°/min. The distribution and analysis of the valence states of elements were detected by an X-ray photoelectron spectroscope (XPS; ESCALAB Xi+, Thermo Fisher, Waltham, MA, USA). The surface and cross-sectional morphology of the synthesized samples were observed by field-emission scanning electron microscopy (SEM, Supra 55 Sapphire, Zeiss, Oberkochen, Germany), and the elemental composition was analyzed by the equipped energy dispersive X-ray spectrometer (EDS, BRUKER QUANTAX 200, Zeiss, Oberkochen, Germany). The high-resolution nanostructure of the synthesized samples was characterized by a spherical aberration-corrected transmission electron microscope (AC-TEM, Titan3 Themis G2, FEI, Hillsboro, CA, USA). The S and σ of the synthesized samples were measured using an SBA apparatus (SBA458, Netzsch, Selb, Germany). The carrier concentration (n) and carrier mobility (μ) at room temperature were measured by a Hall measurement system (HL5500PC, Nanometrics, Milpitas, CA, USA). The thickness of the synthesized thin films was measured by a surface-profile measurement system (Dektak XT, Bruker, Billerica, MA, USA).

3. Results and Discussions

Figure 1d shows the X-ray diffraction (XRD) patterns of Ag2Se TE thin films with different sputtering power settings of 10 W, 20 W, 30 W, 40 W, and 50 W from 2θ = 20° to 50°, respectively. All the diffraction peaks of the samples can be well indexed to the standard PDF card (PDF#24-1041) of the orthorhombic β-Ag2Se phase without impurity peaks detected, confirming the high purity in the phases and crystallinity of all the synthesized samples. Although all the samples exhibit the (013) diffraction peak, its intensity increases significantly at intermediate sputtering powers (particularly at 30 W and 40 W), suggesting a progressive enhancement of preferential orientation along the (013) plane rather than a uniform growth behavior across all conditions [22]. In addition, the 30 W sample shows the strongest (013) characteristic peak, which is associated with the higher crystallinity and μ [18,25]. Figure 1d shows the enlarged XRD patterns of the (112) and (121) characteristic peaks of the synthesized samples from 32° to 36°. Both the (112) and (121) characteristic peaks shift to the lower angle, pointing out the expansion of the lattice in the synthesized samples. The calculated lattice parameters of the synthesized samples are listed in Table S1. According to the lattice parameters and the lattice volume, the expansion of the lattice can be observed, which agrees with the conclusion by the XRD patterns.

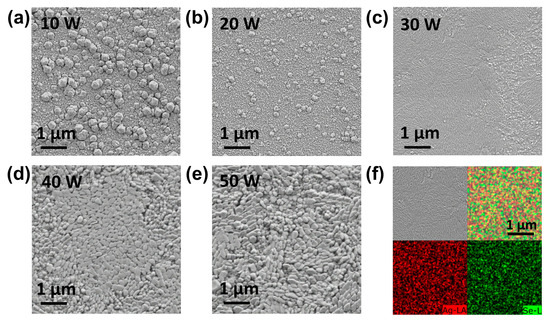

To better understand the surface morphology and crystallinity of the synthesized samples, scanning electron microscopy (SEM) was performed, as shown in Figure 2a–e. The observed SEM images, supported by the EDS results in Figure 2f, indicate the uniformly distributed elemental consistent of the Ag2Se phase. Specifically, the 30 W sample shows a denser and more uniform microstructure than the other samples with high crystallinity. Moreover, the 10 W and 20 W samples show Ag-rich clusters. In contrast, the surfaces of the 40 W and 50 W samples become dense and continuous. These results suggest that the increase in sputtering power initially suppresses the Ag-rich clusters and promotes the formation of a dense Ag2Se phase but leads to surface disorder beyond 30 W. In addition, the increase in sputtering power also strengthens the preferential growth of (013), resulting in a denser Ag2Se phase up to 30 W. Notably, the 30 W sample has the closest Ag/Se atomic ratio to 2.02. Beyond this power, the Ag/Se atomic ratio of all the samples, listed in Table S2, decreased with increasing sputtering power, indicating the consistent tendency with the SEM observations. The cross-sectional SEM morphology of the representative Ag2Se thin film is shown in Figure S1. The average thickness values of the synthesized Ag2Se thin films are listed in Table S3.

Figure 2.

SEM images of the surface morphology in (a) 10 W, (b) 20 W, (c) 30 W, (d) 40 W, and (e) 50 W Ag2Se thin film samples; (f) EDS mapping image of the 30 W sample with Ag, Se, and all the two-element distributions.

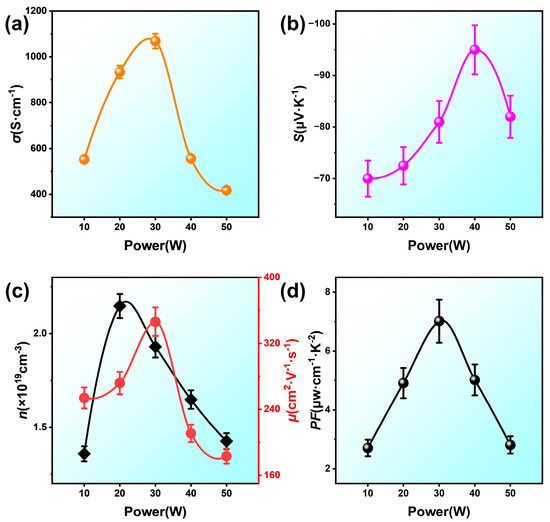

Figure 3 shows the temperature-dependent σ (a), S (b), n and μ (c), PF (d) of all the synthesized Ag2Se thin film samples at room temperature. In Figure 3a, σ first increased with increasing sputtering power, reaching a maximum value of 30 W, and then decreased. In Figure 3b, the absolute value of S first increased with increasing sputtering power up to 40 W, followed by a decrease at 50 W. All the S values shown in the figure are negative, confirming the successful fabrication of n-type Ag2Se thin films. In Figure 3c, the carrier concentration (n) and carrier mobility (μ) correlated well with the tendency of S and σ, which also confirms the XRD results of the better μ in the 30 W sample. Figure 3d demonstrates the PF value with different sputtering power settings. The maximum PF value of 7.0 µW·cm−1·K−2 at room temperature is achieved by the 30 W sample. Thus, the simultaneous enhancement of S and σ can be achieved by tuning the sputtering power up to 30 W, pointing out the successful decoupling of these two parameters. Moreover, TE performance results are also consistent with the SEM observations and Ag/Se ratio results, further confirming the reliable tendency and results in TE performance. However, the PF values are low even compared to our previous work [20,21,22]. Thus, we further conducted post-deposition annealing to enhance the TE performance of Ag2Se thin films.

Figure 3.

The (a) electrical conductivity σ, (b) Seebeck coefficient S, (c) carrier concentration and carrier mobility, and (d) power factor (PF) of 10 W, 20 W, 30 W, 40 W, and 50 W Ag2Se thin film samples at room temperature.

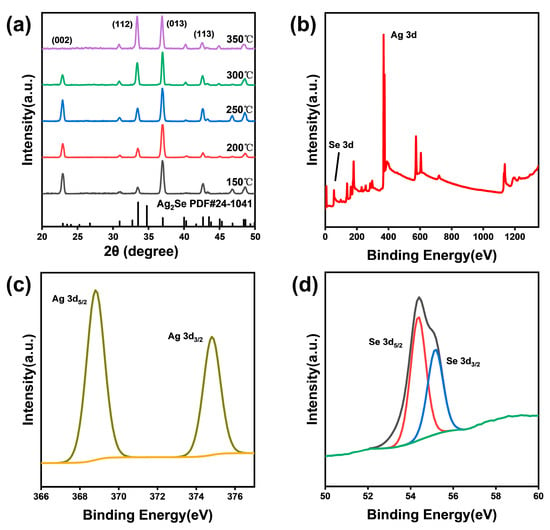

After identifying the thin film sample with the highest PF value of different sputtering power settings, the 30 W sample was then subjected to post-deposition annealing treatment to improve its microstructure and further affect the TE performance [19,21]. The annealing temperatures were set to 150 °C, 200 °C, 250 °C, 300 °C, and 350 °C. Figure 4a shows the XRD patterns of the annealed Ag2Se thin film samples from 2θ = 20° to 50°. All the observed diffraction peaks can be well indexed to the standard PDF card (PDF#24-1041) of Ag2Se without significant impurity peaks, pointing out the relatively pure phase of the orthorhombic β- Ag2Se phase possessed by the annealed samples. Compared to the samples without annealing shown in Figure 1d, (002), (112), and (113) characteristic peaks appeared with significantly high intensity.

Figure 4.

(a) XRD patterns of the synthesized 30 W sample after different annealing temperatures from 20° to 50°; XPS spectra of the (b) survey spectrum, (c) Ag 3d, and (d) Se 3d.

In addition to XRD analysis, X-ray photoelectron spectroscopy (XPS) analysis was employed to further investigate the elemental valence states in the 30 W sample annealed at 300 °C. According to the spectrum in Figure 4c, the Ag 3d spectrum exhibits two distinct peaks of Ag 3d3/2 and Ag 3d5/2 located at approximately ~374.8 eV and ~368.8 eV, respectively, indicating the presence of the Ag+ oxidation state without the detectable metallic Ag state. In Figure 4d, the Se 3d spectrum reveals two peaks of Se 3d3/2 and Se 3d5/2 located at ~55.2 eV and ~54.4 eV, respectively, pointing out the existence of Se2- species. These results confirm the formation of Ag2Se with high purity and stable elemental valence states.

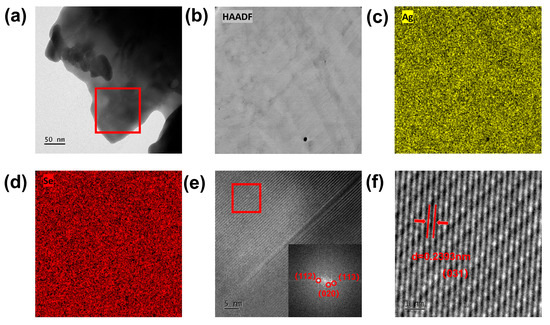

To further investigate the nanostructure of Ag2Se thin films, the 30 W sample annealed at 300 °C was then studied by a transmission electron microscope (TEM). Figure 5a shows a low-resolution TEM image of the 30 W sample annealed at 300 °C, with a well-crystallized structure. Figure 5b is the high-resolution, high-angle annular dark field (HR-HAADF) image of the red circled area in Figure 5a. Figure 5c,d present the EDS mapping of the observed area in Figure 5b with Ag and Se elemental analyses, respectively. As the figures show, the annealed sample exhibits a highly ordered Ag2Se phase without any impurity phases or clusters. Figure 5e shows the atomic-scale HR-TEM image of the rectangular area in Figure 5b with the inset of the fast Fourier transform (FFT) image. Figure 5f presents the observed image of the red rectangle area in Figure 5e. As the figure shows, the atomic distributions are uniform and neatly organized. The d-spacing of the observed area was calculated as 0.2393 nm, which corresponds to the (031) plane in standard Ag2Se. Post-deposition annealing can increase the crystallinity by suppressing the formation of Ag-rich clusters and re-organizing the nanostructure to the dense and pure Ag2Se phase. In summary, these results demonstrate the successful synthesis of high-quality Ag2Se thin films by magnetron sputtering and post-deposition annealing, with a well-ordered nanostructure and high crystallinity at the atomic scale.

Figure 5.

(a) A low-resolution TEM image of the 30 W sample annealed at 300 °C; (b) the HR-HAADF image of the red circled area in (a); EDS mapping of Ag (c) and Se (d) in the (b) area; (e) an atomic-scale HR-TEM image of the rectangular area in (b) with the inset of the FFT image; (f) the enlarged red rectangle area in (e) with an atomic distribution.

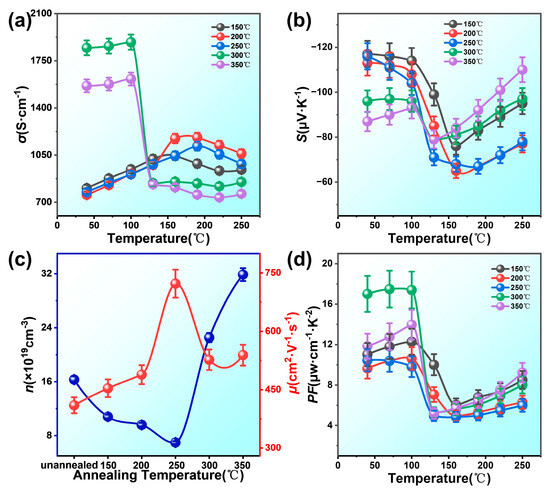

Finally, the annealed Ag2Se thin film samples were measured by the ZEM-3 and LFA instruments to analyze TE properties. Figure 6 shows the temperature-dependent σ (a), S (b), n, and μ (c), and PF (d) at different annealing temperatures. Since the phase transition happened at around 130 °C, the diagrams can be divided into two temperature regions: from room temperature to 100 °C (orthorhombic Ag2Se) and from 150 °C to 250 °C (cubic Ag2Se). Most of the reports only consider the orthorhombic temperature region since TE performance decreases sharply after the phase transition [21,22]. In the orthorhombic Ag2Se temperature area in Figure 6a, σ increases with the increasing temperature. The 30 W sample annealed at 300 °C exhibits the highest σ at 100 °C among all the annealed samples. The samples annealed at 300 °C and 350 °C exhibit relatively high σ in the orthorhombic Ag2Se temperature area but decreased sharply in the cubic Ag2Se temperature region. In Figure 6b, the absolute value of S in most of the annealed samples decreased during the phase transition and then increased with further temperature rises. In addition, the negative S values also indicate n-type Ag2Se after post-deposition annealing. Figure 6c shows the n and μ of the annealed samples at room temperature. These trends are consistent with the variations in σ and S observed in Figure 6a and 6b, respectively. Figure 6d illustrates that the PF values of the annealed samples are temperature-dependent. All the PF values also decreased sharply after the phase transition temperature, showing that the PF values in orthorhombic Ag2Se consistently exhibit higher TE performance than cubic Ag2Se. The 30 W sample annealed at 300 °C possesses the highest PF values of around ~17.4 µW·cm−1·K−2 at 100 °C. Finally, the 30 W sample annealed at 300 °C was served as n-leg, with p-leg Sb2Te3 used to fabricate a flexible TE generator. The measured output voltage (U) and output power (P) of this device as a function of current (I) with the temperature difference ΔT (set as 5, 15, 25, 35, 45, and 55 K) are shown in Figure S2. The maximum U and P are ~140.3 mV and ~6530.0 nW under the ΔT of 55 K. Moreover, the calculated power density is around 181.4 W·m−2 in the fabricated f-TEG.

Figure 6.

The temperature-dependent (a) electrical conductivity σ, (b) Seebeck coefficient S, and (d) power factor (PF) of the 150–250 °C-annealed Ag2Se thin film samples; (c) the carrier concentration (n) and carrier mobility (μ) of the 150–250 °C-annealed Ag2Se thin film samples at room temperature.

4. Conclusions

In summary, flexible Ag2Se thin films were successfully synthesized by magnetron sputtering under various sputtering powers, followed by post-deposition annealing at various temperatures to further optimize their TE performance. XRD, SEM, XPS, and TEM analyses confirmed the formation of phase-pure, highly crystalline Ag2Se thin films. The sputtering power significantly influenced the film’s morphology, carrier concentration, and mobility, with the 30 W sample exhibiting the optimal thermoelectric properties. Further annealing treatment, particularly at 300 °C, enhanced its crystallinity and carrier mobility, leading to a peak power factor of ~17.4 μW·cm−1·K−2 at 100 °C. These findings demonstrate the effectiveness of tuning the sputtering and annealing parameters in enhancing the thermoelectric performance of flexible Ag2Se films, providing valuable guidance for the design of high-performance flexible thermoelectric devices.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/solids6030042/s1, Figure S1. (a) SEM images of the cross-sectional morphology in the 30 W Ag2Se thin film sample; (b) EDS mapping of the cross-sectional image of the 30 W sample with the Ag and Se elemental distribution; Figure S2. The output voltage (U) and output power (P) of the fabricated f-TEGs with the increase in current (I) at temperature differences (ΔT) of 5, 15, 25, 35, 45, and 55 K. The inset photograph is the fabricated f-TEGs; Table S1. Lattice parameters and volume of Ag2Se samples under different sputtering power settings; Table S2. Ag/Se atomic ratios of Ag2Se samples under different sputtering power settings; Table S3. Average thickness of Ag2Se samples under different sputtering power.

Author Contributions

Z.Z. (Zinan Zhong): writing—original draft, formal analysis, and conceptualization. Z.Z. (Zilong Zhang): writing—original draft, data curation, and conceptualization. F.L.: formal analysis and data curation. Y.C.: methodology and formal analysis. J.L.: funding acquisition and supervision. Z.Z. (Zhuanghao Zheng): writing—review and editing and supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (62274112), the National Natural Science Foundation of Guangdong province of China (2024B1515020119), and the Science and Technology Plan Project of Shenzhen (JCYJ20220531103601003).

Data Availability Statement

The original contributions presented in this study are included in the article/Supplementary Materials. Further inquiries can be directed to the corresponding author(s).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bell, L.E. Cooling, Heating, Generating Power, and Recovering Waste Heat with Thermoelectric Systems. Science 2008, 321, 1457–1461. [Google Scholar] [CrossRef]

- Rowe, D.M. Thermoelectrics Handbook: Macro to Nano; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef]

- Zhang, L.; Shi, X.-L.; Yang, Y.-L.; Chen, Z.-G. Flexible thermoelectric materials and devices: From materials to applications. Mater. Today 2021, 46, 62–108. [Google Scholar] [CrossRef]

- Liu, R.; Wang, Z.L.; Fukuda, K.; Someya, T. Flexible self-charging power sources. Nat. Rev. Mater. 2022, 7, 870–886. [Google Scholar] [CrossRef]

- Yang, Q.; Yang, S.; Qiu, P.; Peng, L.; Wei, T.-R.; Zhang, Z.; Shi, X.; Chen, L. Flexible thermoelectrics based on ductile semiconductors. Science 2022, 377, 854–858. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhao, L.-D. Seeking new, highly effective thermoelectrics. Science 2020, 367, 1196–1197. [Google Scholar] [CrossRef] [PubMed]

- Kennedy, J.; Murmu, P.P.; Kumar, P.; Ramanath, G. Multifold enhancements in thermoelectric power factor in isovalent sulfur doped bismuth antimony telluride films. Mater. Res. Bull. 2021, 142, 111426. [Google Scholar] [CrossRef]

- Jia, Y.; Jiang, Q.; Sun, H.; Liu, P.; Hu, D.; Pei, Y.; Liu, W.; Crispin, X.; Fabiano, S.; Ma, Y. Wearable thermoelectric materials and devices for self-powered electronic systems. Adv. Mater. 2021, 33, 2102990. [Google Scholar] [CrossRef]

- Zheng, Z.-H.; Shi, X.-L.; Ao, D.-W.; Liu, W.-D.; Li, M.; Kou, L.-Z.; Chen, Y.-X.; Li, F.; Wei, M.; Liang, G.-X. Harvesting waste heat with flexible Bi2Te3 thermoelectric thin film. Nat. Sustain. 2023, 6, 180–191. [Google Scholar] [CrossRef]

- Tang, X.; Li, Z.; Liu, W.; Zhang, Q.; Uher, C. A comprehensive review on Bi2Te3-based thin films: Thermoelectrics and beyond. Interdiscip. Mater. 2022, 1, 88–115. [Google Scholar] [CrossRef]

- Zhang, L.; Song, G.; Luo, D.; Chen, Y.; Wu, Y.; You, J. Thermoelectric Property of Flexible Ag2Se Films and Output Power of Its Generator. Mater. Sci. Eng. B 2025, 320, 118445. [Google Scholar] [CrossRef]

- Shi, X.-L.; Zou, J.; Chen, Z.-G. Advanced thermoelectric design: From materials and structures to devices. Chem. Rev. 2020, 120, 7399–7515. [Google Scholar] [CrossRef] [PubMed]

- Kuang, N.; Zuo, Z.; Wang, W.; Liu, R.; Zhao, Z. Optimized thermoelectric properties and geometry parameters of annular thin-film thermoelectric generators using n-type Bi2Te2.7Se0.3 and p-type Bi0.5Sb1.5Te3 thin films for energy harvesting. Sens. Actuators A Phys. 2021, 332, 113030. [Google Scholar] [CrossRef]

- Wei, T.R.; Qiu, P.; Zhao, K.; Shi, X.; Chen, L. Ag2Q-based (Q = S, Se, Te) silver chalcogenide thermoelectric materials. Adv. Mater. 2023, 35, 2110236. [Google Scholar] [CrossRef] [PubMed]

- Li, N.H.; Zhang, Q.; Shi, X.L.; Jiang, J.; Chen, Z.G. Silver copper chalcogenide thermoelectrics: Advance, controversy, and perspective. Adv. Mater. 2024, 36, 2313146. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Shi, X.-L.; Duan, J.; Liu, Q.; Chen, Z.-G. Advances in Ag2 Se-based thermoelectrics from materials to applications. Energy Environ. Sci. 2023, 16, 1870–1906. [Google Scholar] [CrossRef]

- Zhu, M.; Shi, X.-L.; Wu, H.; Liu, Q.; Chen, Z.-G. Advances in Ag2S-based thermoelectrics for wearable electronics: Progress and perspective. Chem. Eng. J. 2023, 473, 145236. [Google Scholar] [CrossRef]

- Hou, S.; Liu, Y.; Yin, L.; Chen, C.; Wu, Z.; Wang, J.; Luo, Y.; Xue, W.; Liu, X.; Zhang, Q. High performance wearable thermoelectric generators using Ag2Se films with large carrier mobility. Nano Energy 2021, 87, 106223. [Google Scholar] [CrossRef]

- Zheng, Z.-H.; Zhang, D.-L.; Niu, J.-Y.; Shi, X.-L.; Chen, T.-B.; Chen, Y.-F.; Li, F.; Liang, G.-X.; Chen, Y.-X.; Fan, P. Achieving ultrahigh power factor in n-type Ag2Se thin films by carrier engineering. Mater. Today Energy 2022, 24, 100933. [Google Scholar] [CrossRef]

- Yang, D.; Shi, X.-L.; Li, M.; Nisar, M.; Mansoor, A.; Chen, S.; Chen, Y.; Li, F.; Ma, H.; Liang, G.X. Flexible power generators by Ag2Se thin films with record-high thermoelectric performance. Nat. Commun. 2024, 15, 923. [Google Scholar] [CrossRef]

- Chen, Y.-X.; Shi, X.-L.; Zhang, J.-Z.; Nisar, M.; Zha, Z.-Z.; Zhong, Z.-N.; Li, F.; Liang, G.-X.; Luo, J.-T.; Li, M.; et al. Deviceization of high-performance and flexible Ag2Se films for electronic skin and servo rotation angle control. Nat. Commun. 2024, 15, 8356. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Liu, Y.; Li, Y.; Cai, K. The influence of Ga doping on preparation and thermoelectric properties of flexible Ag2Se films. Compos. Commun. 2021, 27, 100895. [Google Scholar] [CrossRef]

- Wu, M.; Cai, K.; Li, X.; Li, Y.; Liu, Y.; Lu, Y.; Wang, Z.; Zhao, W.; Wei, P. Ultraflexible and high-thermoelectric-performance sulfur-doped Ag2Se film on nylon for power generators. ACS Appl. Mater. Interfaces 2022, 14, 4307–4315. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Qiu, Y.; Cai, K.; Yao, Q.; Chen, S.; Chen, L.; He, J. High Performance N-Type Ag2Se Film on Nylon Membrane for Flexible Thermoelectric Power Generator. Nat. Commun. 2019, 10, 841. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).