Abstract

Governments worldwide are actively committed to achieving their carbon emission reduction targets, and one avenue under exploration is harnessing the potential of hydrogen. Blending hydrogen with natural gas is emerging as a promising strategy to reduce carbon emissions, as it burns cleanly without emitting carbon dioxide. This blending could significantly contribute to emissions reduction in both residential and commercial settings. However, a critical challenge associated with this approach is the potential for Hydrogen Embrittlement (HE), a phenomenon wherein the mechanical properties of pipe steels degrade due to the infiltration of hydrogen atoms into the metal lattice structure. This can result in sudden and sever failures when the steel is subjected to mechanical stress. To effectively implement hydrogen-natural gas blending, it is imperative to gain a comprehensive understanding of how hydrogen affects the integrity of pipe steel. This necessitates the development of robust experimental methodologies capable of monitoring the presence and impact of hydrogen within the microstructures of steel. Key techniques employed for this assessment include microscopic observation, hydrogen permeation tests, and tensile and fatigue testing. In this study, samples from two distinct types of pipeline steels used in the natural gas distribution network underwent rigorous examination. The findings from this research indicate that charged samples exhibit a discernible decline in fatigue and tensile properties. This deterioration is attributed to embrittlement and reduced ductility stemming from the infiltration of hydrogen into the steel matrix. The extent of degradation in fatigue properties is correlated not only to the hydrogen content but also to the hydrogen permeability and diffusion rate influenced by steel’s microstructural features, with higher charging current densities indicating a more significant presence of hydrogen in the natural gas pipeline blend.

1. Introduction

The progressive depletion of fossil fuel reserves, coupled with the environmental issues stemming from their combustion—which has exacerbated global warming [1,2]—has driven the pursuit of alternative energy sources. Significantly, natural gas by itself is responsible for about 21% of emissions from the fossil fuels [3]. To develop a less carbon-intensive alternative to pure natural gas, one potential approach that has gained significant attention recently is to blend hydrogen into existing natural gas streams [4,5,6,7,8,9]. Since hydrogen combustion does not produce carbon dioxide, this method could substantially reduce carbon emissions. Consequently, household and business emissions will decrease with the integration of hydrogen into the natural gas system. Various projects have assessed the economic aspects of integrating hydrogen into natural gas pipelines, focusing on both the benefits for renewable integration and emission reduction, as well as the costs of upgrading infrastructure [10], with numerous trials in Europe and fewer in the United States, and ongoing efforts in countries like Australia, Canada, and Germany.

A critical challenge associated with the utilization of natural gas/hydrogen mixtures is Hydrogen Embrittlement (HE), which refers to the degradation of the mechanical properties of materials when exposed to hydrogen [11]. When hydrogen-blended transmission is implemented in natural gas pipelines, the pipes will be continuously exposed to varying hydrogen concentrations over extended periods. Under pressure and flow, hydrogen molecules will dissociate into H atoms, which will penetrate the steel through adsorption, reacting with the metal’s atomic structure and likely causing microcrack propagation. This process deteriorates the macromechanical properties of the pipe steels [12]. The interaction between hydrogen and the metal microstructure has been extensively studied, leading to the proposal of several mechanisms to explain the phenomenon of HE including hydrogen pressure theory (HPT) [13], hydrogen-enhanced decohesion mechanism (HEDE) [14,15], hydrogen-enhanced localized plasticity (HELP) [16], adsorption-induced dislocation emission (AIDE) [17], hydrogen-enhanced strain-induced vacancy formation (HESIVM) [18], hydrogen-enhanced macroscopic plasticity (HEMP) [19], hydride formation [20], hydrogen-induced reduction in surface energy [21], and hydrogen assisted micro-void coalescence [22,23]. No single theory can fully and accurately explain the effects of hydrogen. Often, multiple mechanisms may be at play simultaneously. Hydrogen-enhanced decohesion (HEDE) is predominant in brittle intergranular fractures, hydrogen-enhanced localized plasticity (HELP) in slip-band fractures, and adsorption-induced dislocation emission (AIDE) in cleavage-like and dimpled intergranular fractures [24].

To understand the impact of hydrogen on pipeline steels, experimental techniques like hydrogen permeation, hydrogen charging, and mechanical testing are essential. These methods determine hydrogen content, and its influence on mechanical properties. Hydrogen permeation tests can be carried out in either aqueous or gaseous environment [25]. Hydrogen charging (H-charging) can be accomplished through electrochemical, chemical, or gaseous methods. Among these, gaseous H-charging, achieved using high-pressure gas, is more effective in simulating the actual transportation conditions of pipeline steels [26]. However, this method requires more equipment and poses significant safety risks. Tensile testing of hydrogen-charged specimens helps determine parameters like reduction in area and elongation, indicating the extent of hydrogen-induced damage [27,28,29]. These tests can be conducted either in-situ, where samples are charged with hydrogen simultaneously as testing is performed, or ex-situ, where pre-charged samples are subsequently tested in the air, with the former more accurately simulating real service conditions. However, the facilities required for in-situ testing are expensive and often not readily available. Conventional Strain Rate Test (CSRT) and Slow Strain Rate Test (SSRT) are commonly used for assessing HE susceptibility. While SSRT, with its controlled and gradual deformation rate, is recognized for closely simulating the actual stress conditions encountered by materials in practical applications and is extensively employed in experiments involving hydrogen-induced phenomena [30], there are reports [31,32] indicating that both SSRT and CSRT have produced nearly identical results when evaluating localized conditions, such as local stress and local hydrogen distribution at the fracture initiation point. Studies indicate that the ductility of pipeline steel, typically measured by reduction in area at fracture (RA) or elongation to fracture, is often significantly diminished in the presence of hydrogen. For smooth specimens, the reduction in RA when exposed to hydrogen gas can range from 20% to as much as 50% compared to tensile test results conducted in air [32,33,34].

Additionally, pipelines endure cyclic loading due to daily pressure fluctuations during regular operation and upset conditions, such as shutdowns, which cause the pipeline to transition from near-atmospheric pressure back up to full operating pressure. So, understanding the fatigue characteristics of steel pipelines within a hydrogen environment is essential for assessing the structural integrity of pipeline infrastructure during the transportation of hydrogen/natural gas blends [35]. fatigue testing reveals how hydrogen reduces the fatigue life of steels by accelerating crack initiation and propagation, using cyclic loading techniques such as rotating beam or axial fatigue tests to assess hydrogen’s influence on fatigue behavior [25].

Fatigue testing of hydrogen-impacted steels can be categorized into two main approaches: fatigue crack growth rate (FCGR) tests and fatigue life tests. Similar to tensile tests, these tests can also be conducted either in-situ [36,37] or ex-situ [38,39]. FCGR tests focus on the rate at which existing cracks propagate under cyclic loading in the presence of hydrogen. FCGR testing is typically performed on compact tension (CT) specimens. The recommended dimensions for CT specimens are outlined in the ASTM E647 standard [40]. Numerous studies have shown that hydrogen significantly accelerates crack growth rates, particularly in high-strength steels [41,42,43,44]. However, other reports indicate that multiple parameters and conditions can influence this trend. Dmytrakh et al. [45] studied the impact of hydrogen concentration on FCGR in ferrite-pearlitic low-alloyed steel, identifying a threshold hydrogen concentration below which FCGR decreases with increasing hydrogen concentration, suggesting an increase in crack growth resistance, and above which FCGR increases due to hydrogen-dislocation interactions, involving dislocation pinning or dragging and enhanced plasticity. Yamabe et al. [46] examined the effects of hydrogen pressure, test frequency, and temperature on the FCGR of annealed low-carbon steel with a ferrite-pearlite microstructure. Their results showed that hydrogen-enhanced FCGR acceleration is accompanied by localized plastic deformations near the crack tip, likely caused by steep hydrogen concentration gradients. An et al. [47] investigated the effects of hydrogen pressure on the fatigue properties of X80 pipeline steel with a ferrite and bainite microstructure, specifically focusing on the fatigue crack growth rate (FCGR). They concluded that hydrogen-accelerated crack initiation is more significant than crack growth in reducing fatigue life as hydrogen pressure increases.

Fatigue life tests assess the overall lifespan of a material until failure under cyclic loading The literature predominantly focuses on FCGR tests, with relatively few studies performing fatigue life tests and addressing S-N curves. However, predictive models based on fracture mechanics for FCGR in hydrogen environments can be used to estimate the remaining lifespan of pipelines [48,49]. Meng et al. [50] demonstrated that the fatigue properties of X80 pipeline steel are significantly compromised by hydrogen in natural gas/hydrogen mixtures. Using the mentioned method for predicting the fatigue life, their findings indicated a severe reduction in fatigue life, from 24,431 cycles in nitrogen gas to 2130 cycles in a 5 vol% hydrogen blend at 12 MPa. Among the few studies on hydrogen embrittlement (HE) of pipeline steels that perform fatigue life tests, Faucon et al. [51] developed an in situ gaseous hydrogen charging fatigue setup to investigate the hydrogen-accelerated fatigue life of API X60 pipeline steel. They tested specimens at hydrogen pressures of 70 and 150 barg. The presence of hydrogen reduced the fatigue life of the by 37%. Additionally, no significant difference in fatigue behavior was observed between the two hydrogen pressures, suggesting that maximum hydrogen saturation in the crack process zone was reached at 70 barg. In contrast, Nahm et al. [52] investigated the high cycle fatigue behavior of hydrogen-embrittled AISI 304 stainless steel and found that the material exhibited similar S-N curve tendencies and fatigue strength as untreated specimens, despite containing approximately 8.1 times more hydrogen. This indicates a relatively low sensitivity of AISI 304 stainless steel to hydrogen gas. The specimens were precharged in an ultra-high-pressure hydrogen exposure vessel at 10 MPa and 300 °C for 120 h, then stored in liquid nitrogen before being subjected to fatigue testing at room temperature.

While literature generally indicates a reduction in plastic deformation ability and deterioration in fracture and fatigue resistances of pipe steels in hydrogen-containing environments [53], the susceptibility and behavior of HE in pipeline steels can vary based on material characteristics (microstructure, grain boundaries, dislocations, and inclusions) and hydrogen exposure conditions. To assess the feasibility of blending hydrogen with natural gas within the current distribution network, a comprehensive examination and testing of pipeline steels appear crucial. This is particularly important considering the potential degradation of fatigue properties in the existing pipeline steels due to prolonged service. This study investigated the mechanical behavior of two distinct pipe steels from the natural gas distribution network using tensile and fatigue tests. To induce hydrogen absorption, an electrochemical charging process is employed in a solution rich in H+ ions. This charging process, accomplished by a potentiostat applying a constant current, prompts the hydrogen evolution reaction at the steel specimen, acting as the cathode of the charging cell. Immediate tensile and fatigue testing following the charging process enables the evaluation of mechanical properties in comparison to non-charged samples. Different charging current densities are employed to simulate various hydrogen blend scenarios. Also, a unique method, involving electrochemical hydrogen permeation and charging experiments, was applied to simulate real hydrogen exposure conditions for pipeline steels. It is important to note that while this study strives to replicate real operating conditions as closely as possible, it might not fully capture the exact complexities and variables present in actual field conditions.

2. Materials

This study examines two different pipeline steels extracted from circumferential sections of pipes within the existing natural gas distribution network. The first sample, designated as AO-C1, is a 26-inch pipe of grade 359 (equivalent to API X52) with a thickness of 7.14 mm. The second sample, referred to as N-C1, is a 24-inch pipe of grade 448 (equivalent to API X65) with a thickness of 12.7 mm. N-C1 pipe is new and has not been in service, however, the AO-C1 pipe had been in service since 1954. The detailed chemical compositions of both steels are given in Table 1. The mean hardness values for AO-C1 and N-C1 were measured as HV1 162 and HV1 222, respectively.

Table 1.

Chemical composition of AO-C1 and N-C1 pipeline steels (wt%).

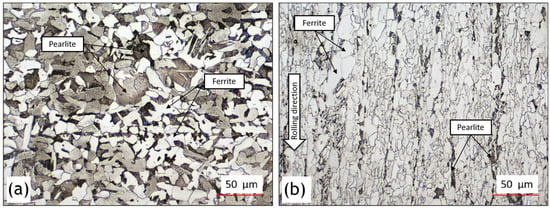

Figure 1 presents confocal images of the microstructures of the steels. As shown in Figure 1a, the AO-C1 steel exhibits a ferritic-pearlitic microstructure with relatively coarse equiaxed grains, where the white phase represents ferrite and the darker phase indicates pearlite. In contrast, Figure 1b illustrates the microstructure of the N-C1 steel, which displays polygonal ferrite (white) and elongated colonies of pearlite (dark) extending along the rolling direction (indicated by the white arrow).

Figure 1.

Microstructure of (a) AO-C1 steel; (b) N-C1 steel. Etchant: nital (5%).

3. Experimental

3.1. Test Specimens

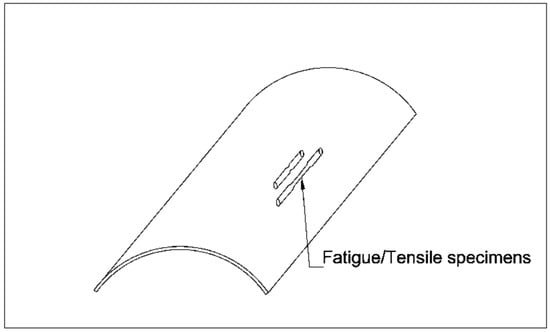

Both tensile and fatigue specimens were machined from the longitudinal direction of the pipe sections, as illustrated in Figure 2. The selection of the longitudinal direction was mainly due to the low thickness of the AO-C1 pipe section, which made it impossible to cut samples in the circumferential direction given the sections’ curvature. However, as the primary intention of this research is to investigate the impact of hydrogen diffusion on the mechanical properties of the steel, not the mechanical behavior of the pipes, we assume that the hydrogen impact observed in longitudinal samples can be extended to circumferential samples as well.

Figure 2.

Specimen orientation.

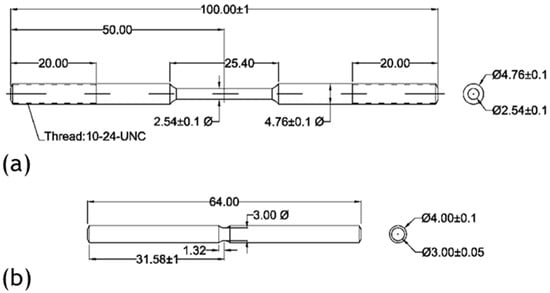

The geometries of the tensile and fatigue specimens are illustrated in Figure 3a,b respectively. These designs were influenced by limitations related to pipe thickness, as well as the capabilities of the machining and testing equipment.

Figure 3.

Specimen geometries of (a) Tensile specimen; (b) Fatigue specimen; All dimensions are in mm.

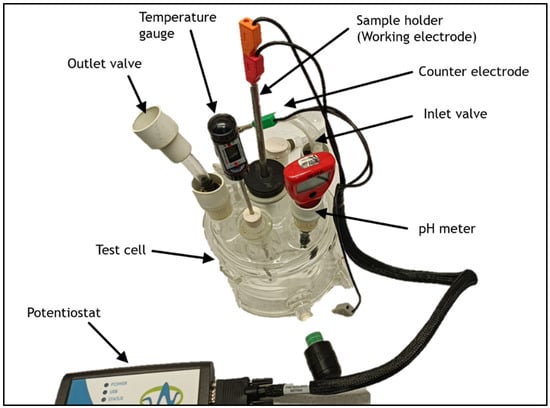

3.2. Electrochemical Hydrogen Charging

To induce hydrogen absorption, an electrochemical charging process was employed using the test set up shown in Figure 4. The test cell was filled with a 0.1 M NaOH electrolyte containing 3.3 g/L Ammonium Thiocyanate (NH4SCN) as a poison to prevent the recombination of hydrogen atoms into H2 [25]. The test cell was equipped with two one-sided valves for purging, as well as openings for pH and temperature meters, and it was fully sealed. Specimens were cleaned with acetone before insertion into the cell, and all areas except the gauge area were covered with insulating tape to ensure that only the calculated surface area was exposed to the electrolyte and electrochemically charged. Before the start of the charging process, the test cell was purged with argon gas to remove all oxygen. The charging process was carried out by a potentiostat applying a constant current to promote the hydrogen evolution reaction at the steel surface. The specimen served as the working electrode, while platinum was used as the counter electrode. The selection of electrolyte, charging current density, and charging time was based on permeation method outlined in the authors previous work [25] on the same materials using a double electrolyte cell based on the Devanathan-Stachursky method [54], in accordance with ISO 17081 [55]. The permeation tests provided effective diffusivity (Deff), hydrogen concentration in interstitial lattice and reversible trap sites (C0R), and time to steady state (tss) for both steels, as shown in Table 2. The charging current density for both steels was 10 mA/cm2.

Figure 4.

Experimental setup for electrochemical hydrogen charging.

Table 2.

Output of permeation tests.

Several researchers [56,57,58] have noted a correlation between hydrogen concentration in electrochemical charging and the square root of the charging current density, described by the equation:

Using the values of charging current density and hydrogen concentration from the permeation tests, the constant factor K was calculated for each steel. This constant was then used to correlate different hydrogen concentrations with charging current densities. Table 3 summarizes the relationships between hydrogen content, charging current densities, and charging times for the electrochemical hydrogen charging experiments. To ensure maximum hydrogen saturation, the charging time was set to 1.5 times the steady state time (tss) determined from the permeation tests.

Table 3.

Electrochemical hydrogen charging parameters.

3.3. Tensile and Fatigue Tests

Tensile testing is the most common method for measuring material properties and is widely used to characterize hydrogen embrittlement (HE). In this study, conventional strain rate tests (CSRT) were conducted on precharged specimens using a PASCO tensile testing machine (ME-8236) immediately after removal from the charging cell. The tests aimed to determine mechanical properties such as ultimate tensile strength (UTS), yield strength (YS), and elongation after rupture (EL). The strain rates were set at 0.2 min−1 and displacement was recorded using an extensometer.

The fatigue life and mechanisms of precharged specimens from both steels at room temperature were evaluated using a cantilevered rotary bending fatigue tester (SM1090V, TECQUIPMENT, Nottingham, UK). The tests were conducted at a frequency of 60 Hz and a stress ratio of R = −1 by rotating bending cyclic loading (sine wave). AO-C1 samples were subjected to a bending stress of 278 MPa at the specimen’s neck center, representing approximately 80% of the yield strength. For the N-C1 steel, which has a higher yield strength, samples were tested at two stress levels: 444 MPa and 278 MPa, corresponding to approximately 80% and 50% of the yield strength, respectively. The tests continued until fracture occurred, and the total number of cycles to fracture was recorded. To ensure repeatability and consistency of the results, each test was conducted twice, resulting in an overall variation of approximately 10%.

4. Results and Discussion

4.1. Tensile Behavior

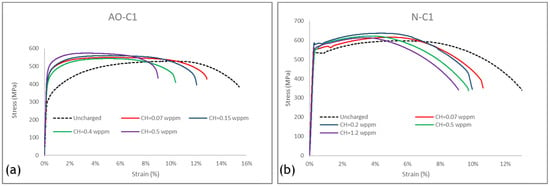

The stress-strain curves for the uncharged and charged tensile specimens from AO-C1 and N-C1 pipeline steels are illustrated in Figure 5a,b, with corresponding tensile data presented in Figure 6a–d. The results from tensile tests on uncharged samples show that AO-C1 exhibits higher ductility, whereas N-C1 demonstrates greater yield strength (YS) and ultimate tensile strength (UTS). Additionally, it is notable that the difference between YS and UTS is relatively small in N-C1, suggesting that this steel will reach final fracture more quickly when subjected to tensile loads beyond the elastic region, compared to AO-C1. This implies a more abrupt transition to failure under plastic deformation for N-C1.

Figure 5.

CSRT results for Uncharged and charged with varying hydrogen contents for (a) AO-C1 steel; (b) N-C1 steel.

Figure 6.

Effect of hydrogen content on tensile properies of specimens: (a,b) AO-C1 steel; (c,d) N-C1 steel.

Figure 6a,c illustrate the yield strength (YS) and ultimate tensile strength (UTS) for both uncharged and hydrogen-charged samples with varying hydrogen content. It is evident from the figures that the YS of both materials increases after hydrogen charging compared to their uncharged state. This observation is consistent with findings from previous studies [59,60]. The increase in YS is typically attributed to the solid solution strengthening effect of interstitial hydrogen. When hydrogen atoms occupy interstitial sites within the metal lattice, they hinder dislocation movement, thereby enhancing the material’s resistance to deformation and increasing its yield strength [61]. Within the range of hydrogen contents tested in this study, the maximum difference between the tensile strength of precharged and uncharged AO-C1 samples is 36%, and for N-C1 samples, it is 16%. The more substantial increase for AO-C1 steel may be due to degradation over its extended service period, as the yield strength of the uncharged samples (290 MPa) is below the expected grade standard of 359 MPa. The maximum difference in UTS between uncharged and charged samples is 9% for AO-C1 and 6% for N-C1. Thus, while hydrogen charging significantly impacts the yield strength, its effect on the ultimate tensile strength is relatively minor, aligning with findings from aforementioned studies.

The elongation and toughness at fracture of the steels are shown in Figure 6b,d. For the AO-C1 sample, the total elongation decreased from 15.5% for the uncharged sample to 9% for the charged sample with 0.5 wppm hydrogen content. In the case of N-C1 steel, the elongation for the uncharged sample and the samples with 0.5 and 1.4 wppm hydrogen content were 13%, 9.7%, and 8.7%, respectively. These findings demonstrate that the total elongation at fracture for both steels is significantly reduced in hydrogen-charged samples compared to those without hydrogen charging, consistent with the phenomenon of HE, where the presence of hydrogen reduces ductility and toughness in steels and is well-documented in previous studies [29,31,34,61,62,63]. A similar trend is observed in the toughness values. For samples charged with 0.5 wppm hydrogen content, the toughness values decreased by 33% for AO-C1 steel and 25% for N-C1 steel.

To summarize the tensile test results, it is evident that both steels experience a significant loss of ductility and toughness due to hydrogen HE. However, at the same hydrogen content (i.e., 0.5 wppm), AO-C1 steel exhibits a more pronounced impact. It is also important to note that similar hydrogen content values are not achieved with similar charging current densities. As shown in Table 3, the equivalent charging current density for achieving 0.5 wppm hydrogen content was 627.8 mA/cm2 for AO-C1 steel, compared to 15.6 mA/cm2 for N-C1 steel. This is also why AO-C1 steel was tested within a lower range of hydrogen contents due to the potentiostat’s maximum current capacity constraints. The difference in charging current densities and the corresponding hydrogen content can be attributed to the deformation states of the steels. N-C1 steel, being heavily deformed (cold rolled), has more defects, allowing for more hydrogen trapping which leads to lower diffusivity and higher hydrogen concentration [64,65,66] as reflected in Table 2. However, reversible traps do not contribute to the HE phenomenon, which justifies the lower loss of ductility in N-C1 steel compared to AO-C1 steel at the same hydrogen content. Further explanation on this issue is provided in the next section on the results for fatigue tests.

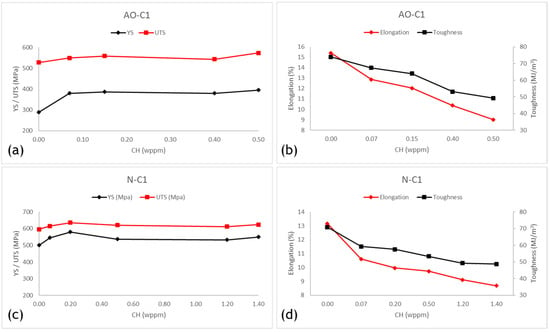

4.2. Fractography of Tensile Samples

The detailed examination of fracture surfaces provides essential insights into the failure mechanisms of tested materials. Fracture surfaces of tensile specimens, both uncharged and hydrogen-charged, were analyzed using scanning electron microscopy (SEM). Figure 7a,d show the fracture surfaces of uncharged and hydrogen-charged (1.2 wppm hydrogen content) N-C1 steel, respectively. Side views of the samples are presented Figure 7b,e.

Figure 7.

SEM fracture surfaces of N-C1 tensile samples; (a) CH = 0 (Uncharged); (b) Side view of “a”; (c) Magnification of green area in “a”; (d) CH = 1.2 wppm; (e) Side view of “d”; (f) Magnification of green area in “d”.

The ductile fracture of the uncharged sample is effortlessly characterized by a reduced fracture area and a distinctive cup-and-cone appearance, as seen in Figure 7a,b. Ductile fracture typically occurs in two stages: initial necking and void formation, followed by void coalescence and eventual shear lip formation. The cup-and-cone morphology features a central fibrous region surrounded by a shear lip at an angle, indicative of significant plastic deformation and energy absorption prior to fracture. In the central regions, the fracture surface is characterized by dimple fracture features (Figure 7c). These dimples result from the nucleation, growth, and coalescence of micro-voids, reflecting the material’s ability to undergo substantial plastic strain before failure. The morphology of the shear lip region in the uncharged sample is dominated by shear dimples that are elongated and oriented along the direction of shear (Figure 8a). Compared to the central fibrous region, the shear lip region tends to have a smoother and more streamlined appearance.

In contrast, the fracture surface of the sample charged with 1.2 wppm hydrogen content shows two distinctive regions: the central and marginal (or edge) zones, with remarkably different characteristics. The cup-and-cone appearance with a shear lip is not observed; instead, the edges of the fracture surface are sharp (Figure 7e), highlighting the complexity of the fracture process. The central region (Figure 7f) is characterized by dimple fracture features similar to those of the uncharged sample, but the dimples are shallower and some microcracks are present, indicating brittleness imposed by hydrogen diffusion. Additionally, the size of the central zone is considerably smaller compared to the uncharged sample. The most apparent difference in the fracture surface of the hydrogen embrittled sample can be observed in the marginal or edge zone. During charging, hydrogen forms on the surface of the material and gradually permeates from the exterior to the interior, resulting in higher hydrogen concentrations at the exterior zones. In the marginal zones, brittle fracture characteristics are distinctly observed, including cleavage facets (Figure 8b), quasi-cleavage facets, and intergranular fracture (Figure 8c,d).

Cleavage facets form in steel due to hydrogen embrittlement from the highly localized and rapid propagation of cracks along specific crystallographic planes. Hydrogen atoms diffuse into the steel lattice, weakening atomic bonds and causing embrittlement. When stressed, these weakened regions are more prone to fracture, and cracks propagate along crystallographic planes, creating cleavage facets. Stress concentrations or material defects can initiate cracks along these preferred planes, which then propagate rapidly through the material along the path of least resistance. Consequently, the fracture surface exhibits flat, shiny facets perpendicular to the applied stress direction. Quasi-cleavage facets resemble cleavage facets but are less well-defined and may appear slightly curved. Intergranular fracture occurs along grain boundaries, indicating a failure mode where hydrogen-induced embrittlement weakens these boundaries, making them preferential paths for fracture propagation.

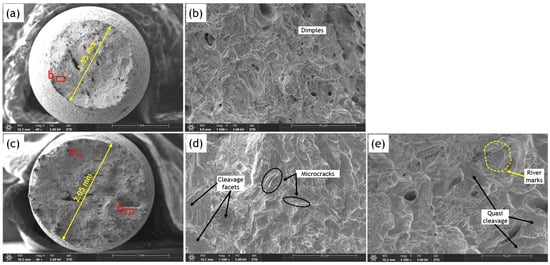

Figure 9a–e show the fracture surfaces of an uncharged sample and a sample charged with 0.5 wppm hydrogen content of AO-C1 steel. The reduced fracture area can be observed by comparing Figure 9a and Figure 9e. While the reduction in area for the uncharged sample is approximately 63%, it is only 35% for the charged sample. Furthermore, the fracture surface of the uncharged sample exhibits ductile dimple features, as shown in Figure 9b. In contrast, the fracture surface of the hydrogen-charged sample displays features indicative of brittle fracture induced by HE, such as cleavage facets, microcracks (Figure 9d), quasi-cleavage facets, and river marks (Figure 9e).

Figure 9.

SEM fracture surfaces of AO-C1 tensile samples; (a) CH = 0 (Uncharged); (b) Magnification of red area marked by “b”; (c) CH = 1.2 wppm; (d) Magnification of red area marked by “d”; (e) Magnification of red area marked by “e”.

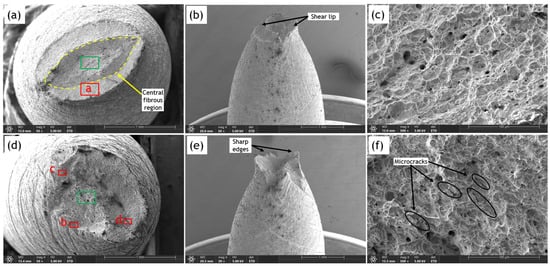

4.3. Fatigue Behavior

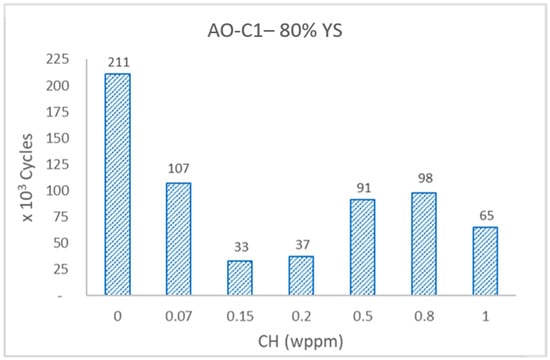

Figure 10 shows the fatigue results of AO-C1 samples in bar graph format. It is important to note that the specimens were machined from a section of pipe with a prolonged service history. Thus, the relatively low number of fatigue cycles reflects the remaining fatigue life of the specimens and cannot be directly compared to steels of a similar grade with no service history. Despite the inherent scatter typically seen in fatigue test results, it is evident that specimens have experienced a substantial decrease in fatigue life with increasing hydrogen content. Specifically, the specimen exhibited approximately a 70% reduction in fatigue life at 1 wppm hydrogen content. This significant decline in fatigue life due to HE aligns with the findings of Meng et al. [50] and Faucon et al. [51], however they employed different methodologies. Both studies utilized in-situ gaseous hydrogen charging, contrasting with the electrochemical hydrogen charging method employed in this study, and while Meng estimated fatigue life using fatigue crack growth rate models, Faucon conducted actual fatigue life tests.

Figure 10.

Effect of hydrogen content on fatigue life of AO-C1 specimens tested at 80% YS.

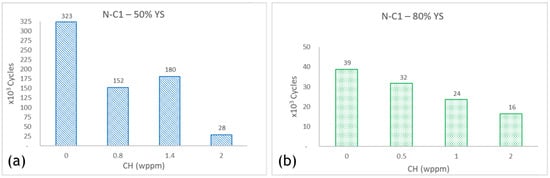

Fatigue test results for N-C1 specimens are shown in Figure 11a,b. Figure 11a presents the results for specimens tested at 80% of YS of the material, while Figure 11b shows the results for specimens tested at 50% of YS. At 50% YS, the maximum stress at the specimen’s neck center is equivalent to the imposed stress on AO-C1 specimens (278 MPa). This means that when tested at the same stress levels, N-C1 specimens demonstrated a higher fatigue life compared to AO-C1 samples, with uncharged N-C1 samples showing approximately 1.5 times more fatigue cycles. However, it should be noted that AO-C1 specimens have a considerably prolonged service history.

Figure 11.

Effect of hydrogen content on fatigue life of N-C1 specimens tested at; (a) 50% YS; (b) 80% YS.

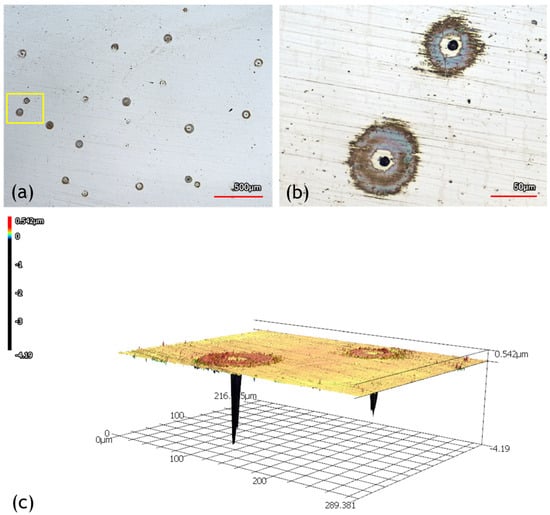

When tested at 80% YS, N-C1 specimens exhibited significantly fewer fatigue cycles compared to AO-C1 samples tested at 80% YS. Based on tensile tests, the ductility of AO-C1 is higher than N-C1, and it is generally believed that ductile materials exhibit better fatigue resistance, though fracture toughness is a more accurate indicator of this property [67]. Moreover, the poor fatigue resistance of N-C1 steels at higher values of stresses can be attributed to their microstructure, which includes numerous pores as shown in Figure 12. In uncharged samples, these pores can act as stress concentration points, reducing the fatigue life of the specimens.

Figure 12.

Observed porosities in N-C1 microstructure; (a) As polished (not etched) specimen to avoid impact from etchant; (b) Magnification of the yellow square in (a); (c) 3d profile of the pores in (b).

Similar to AO-C1 samples, the fatigue life of N-C1 samples decreased after hydrogen charging. However, the impact of hydrogen content on fatigue life reduction is not as severe in N-C1 samples. For instance, at 1 wppm hydrogen content, the fatigue life decreased by approximately 23%, significantly lower than the 70% reduction observed in AO-C1 samples at the same hydrogen content when both were tested at 80% of their respective yield strengths. This difference can be attributed to the presence of pores in the microstructure of N-C1 steel. Generally, pores can act as either reversible or irreversible trapping sites for hydrogen, depending on their specific characteristics. Yaktiti et al. [68] investigated the role of porosities in hydrogen diffusion in steel, demonstrating that pores act as reversible trap sites. These pores delay hydrogen diffusion, and the trapped hydrogen can be desorbed from these sites at room temperature. Therefore, the higher hydrogen content in N-C1 steel can be attributed to reversible hydrogen trapped in porosities that desorb during testing, not contributing to the hydrogen embrittlement of the specimens.

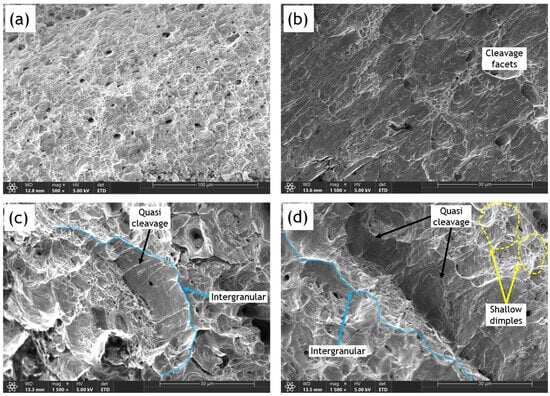

4.4. Fractography of Fatigue Samples

Fracture surfaces of fatigue specimens, both uncharged and hydrogen-charged with varying hydrogen content, were analyzed using SEM. In the study of fatigue failure surfaces, three primary features are consistently observed: the origin, the fatigue zone, and the overload zone. The origin is the point where the crack initiates. A single crack origin typically suggests a failure under low overstress conditions, whereas multiple origins might indicate high stress or significant stress concentrations. The crack then propagates slowly through the fatigue zone, where progression marks (or beach marks) are usually observed. Eventually, the crack reaches a critical size, and the remaining material can no longer sustain the applied stress, leading to the overload zone. In this zone, most cracks exhibit macroscopically brittle fracture characteristics.

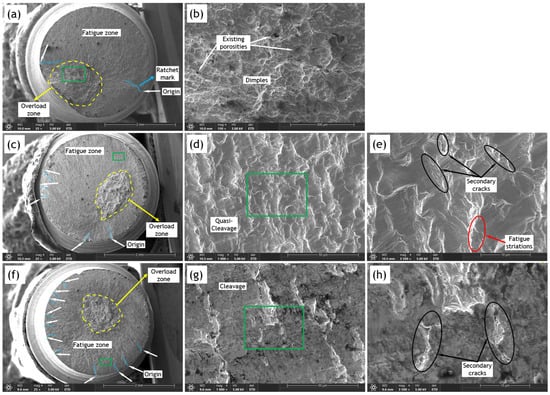

The fractography of N-C1 fatigue samples tested at 50% of YS is provided in Figure 13a–h. In these figures, the overload zone is marked with a dashed yellow line, crack origins are marked with white arrows, and ratchet marks are highlighted with transparent blue lines. The green square indicates the area for which the magnified image is provided in the adjacent figure.

Figure 13.

SEM fracture surfaces of N-C1 fatigue samples tested at 50% of YS; (a) CH = 0 (Uncharged); (b) Magnification of green area in (a); (c) CH = 0.8 wppm; (d) Magnification of green area in (c); (e) Magnification of green area in (d); (f) CH = 2.0 wppm; (g) Magnification of green area in (f); (h) Magnification of green area in (g).

Figure 13b shows the overload zone for the uncharged (CH = 0) sample, featuring dimples characteristic of ductile fracture. The morphology of this zone is similar in the two hydrogen-charged samples. However, its location shifts to the center of the fracture surface in charged samples, indicative of higher stresses [68]. As similar bending stress is applied to all samples during the test, this increase in stress can be explained by the HELP mechanism. According to this theory, hydrogen presence around dislocations leads to a local decrease in yield stress, facilitating local dislocation movement [25]. This effectively increases the ratio of imposed stress to local yield stress.

Additionally, Figure 13c,f show an increase in the number of crack origins and ratchet marks with higher hydrogen content. The sample with 2 wppm hydrogen content exhibits a significantly higher number of origins. This increase in crack initiation sites is attributed to hydrogen-induced defects and microcracks, indicative of HE.

The fatigue zone also shows a quasi-cleavage surface in the sample with 0.8 wppm hydrogen content, which transitions to a cleavage surface in the sample with 2 wppm hydrogen content, reflecting the reduced ductility caused by HE, as illustrated in Figure 13d,g. Moreover, there is an increase in the number and density of secondary cracks, as hydrogen promotes crack branching and secondary crack formation. This is evident from Figure 13e,h, where higher hydrogen content correlates with larger secondary cracks.

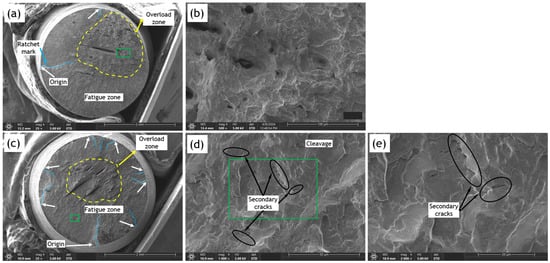

Similar features were observed in the fracture surfaces of AO-C1 fatigue samples and N-C1 fatigue samples tested at 80% YS. Figure 14a–e shows the SEM images for uncharged and charged samples (with 1.0 wppm hydrogen content) from AO-C1 steel. The primary difference between these images with those of N-C1 steel lies in the morphology of the overload zone, which exhibits more ductile features in AO-C1 samples. This is attributed to the fact that AO-C1 steel is inherently more ductile than N-C1 steel.

Figure 14.

SEM fracture surfaces of AO-C1 fatigue samples (base metal) tested at 80% of YS; (a) CH = 0 (Uncharged); (b) Magnification of green area in (a); (c) CH = 1.0 wppm; (d) Magnification of green area in (c); (e) Magnification of green area in (d).

5. Conclusions

In this study, a comprehensive analysis of the microstructural and mechanical properties of two pipeline steels, AO-C1 and N-C1, was conducted to understand their behavior under HE. Both steels had a service history in the natural gas distribution network, making the study particularly intriguing and complex, especially in terms of fatigue assessment. Electrochemical hydrogen charging was employed to facilitate hydrogen absorption, with charging parameters determined from permeation tests conducted on the same steels. Conventional strain rate tensile tests and fatigue tests were performed to assess the impact of hydrogen on these steels. The major results are as follows:

- Hydrogen charging increases YS for both steels due to the solid solution strengthening effect of interstitial hydrogen. Specifically, the maximum difference between the tensile strength of precharged AO-C1 and N-C1 samples compared to uncharged samples was 36% and 16%, respectively.

- The elongation and toughness at fracture decreased for both steels upon hydrogen charging. For instance, AO-C1’s total elongation decreased from 15.5% (uncharged) to 9% (charged with 0.5 wppm hydrogen content), while N-C1’s elongation decreased from 13% (uncharged) to 8.7% (charged with 1.4 wppm hydrogen content).

- AO-C1 samples exhibited a 70% reduction in fatigue life at 1 wppm hydrogen content. The fatigue test results for N-C1 samples showed higher fatigue life compared to AO-C1 when tested at the same stress levels, but lower fatigue life at 80% of YS compared to AO-C1 samples tested at 80% YS.

- The fractography analysis revealed that uncharged tensile samples exhibit a ductile fracture characterized by reduced fracture area, distinct cup-and-cone morphology and dimple features, while hydrogen-charged samples show a transition to brittle fracture with sharp edges, cleavage facets, and microcracks indicative of HE. Also, the fractography of fatigue samples revealed an overload zone characterized by brittle fracture features, which shifted to the center of the fracture surface in hydrogen-charged samples. Increased numbers of crack origins and ratchet marks were observed with higher hydrogen content, indicating hydrogen-induced defects and microcracks.

To further advance the understanding of HE in these two pipeline steels, the following future works are proposed:

- Conduct in-situ mechanical tests to investigate the impact of applied stresses on hydrogen embrittlement in real-time. This will help in understanding the dynamic interaction between mechanical stress and hydrogen diffusion within the steel matrix.

- Perform fatigue crack growth rate tests to validate the predictive models for fatigue life. This will aid in developing more accurate life prediction models for pipeline steels exposed to hydrogen environments.

- Conduct experiments to determine hydrogen fugacity and solubility (Sieverts’ constant) for both steels from desorption spectrometry data. Correlating electrochemical charging current density to the pressure of hydrogen in pipelines will provide a more comprehensive understanding of hydrogen behavior in pipeline steels.

These future directions will enhance the predictive maintenance and safe operation of hydrogen-natural gas blended pipelines, contributing to the reliability and efficiency of the existing distribution network.

Author Contributions

H.G.: experimental work, analysis, writing initial draft, Z.F.: conceptualization of work, review, analysis, supervision, T.A.: feedback, analysis, M.A.I.: feedback, analysis. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by Natural Sciences and Engineering Research Council of Canada (NSERC), grant # ALLRP 570445-2021.

Data Availability Statement

The information contained in this report represents the opinions expressed by the authors and do not reflect the opinions of Enbridge Inc., Enbridge Gas Inc., or any other affiliate companies or other corporate entities with which the authors are affiliated with. The authors’ opinions are based upon information they consider reliable, but neither Enbridge, nor its affiliates, nor the companies with which the authors are affiliated, warrant their fitness for use, completeness, or accuracy, and they should not be relied upon as such.

Conflicts of Interest

Author Tahrim Alam was employed by the company Enbridge Gas Inc. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Leung, D.Y.; Caramanna, G.; Maroto-Valer, M.M. An overview of current status of carbon dioxide capture and storage technologies. Renew. Sustain. Energy Rev. 2014, 39, 426–443. [Google Scholar] [CrossRef]

- Shindell, D.; Smith, C. Climate and air-quality benefits of a realistic phase-out of fossil fuels. Nature 2019, 573, 408–411. [Google Scholar] [CrossRef] [PubMed]

- Sofian, M.; Haq, M.B.; Al Shehri, D.; Rahman, M.M.; Muhammed, N.S. A review on hydrogen blending in gas network: Insight into safety, corrosion, embrittlement, coatings and liners, and bibliometric analysis. Int. J. Hydrogen Energy 2024, 60, 867–889. [Google Scholar] [CrossRef]

- Haeseldonckx, D.; D’haeseleer, W. The use of the natural-gas pipeline infrastructure for hydrogen transport in a changing market structure. Int. J. Hydrogen Energy 2007, 32, 1381–1386. [Google Scholar] [CrossRef]

- Tabkhi, F.; Azzaro-Pantel, C.; Pibouleau, L.; Domenech, S. A mathematical framework for modelling and evaluating natural gas pipeline networks under hydrogen injection. Int. J. Hydrogen Energy 2008, 33, 6222–6231. [Google Scholar] [CrossRef]

- Öney, F.; Veziro⋗lu, T.N.; Dülger, Z. Evaluation of pipeline transportation of hydrogen and natural gas mixtures. Int. J. Hydrogen Energy 1994, 19, 813–822. [Google Scholar] [CrossRef]

- Liu, B.; Liu, S.; Guo, S.; Zhang, S. Economic study of a large-scale renewable hydrogen application utilizing surplus renewable energy and natural gas pipeline transportation in China. Int. J. Hydrogen Energy 2019, 45, 1385–1398. [Google Scholar] [CrossRef]

- Cerniauskas, S.; Jose Chavez Junco, A.; Grube, T.; Robinius, M.; Stolten, D. Options of natural gas pipeline reassignment for hydrogen: Cost assessment for a Germany case study. Int. J. Hydrogen Energy 2020, 45, 12095–12107. [Google Scholar] [CrossRef]

- Zhu, Y.-Q.; Song, W.; Wang, H.-B.; Qi, J.-T.; Zeng, R.-C.; Ren, H.; Jiang, W.-C.; Meng, H.-B.; Li, Y.-X. Advances in reducing hydrogen effect of pipeline steels on hydrogen-blended natural gas transportation: A systematic review of mitigation strategies. Renew. Sustain. Energy Rev. 2024, 189, 113950. [Google Scholar] [CrossRef]

- Topolski, K.; Reznicek, E.P.; Erdener, B.C.; San Marchi, C.W.; Ronevich, J.A.; Fring, L.; Simmons, K.; Fernandez, O.J.G.; Hodge, B.-M.; Chung, M. Hydrogen Blending into Natural Gas Pipeline Infrastructure: Review of the State of Technology; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2022. [Google Scholar]

- Johnson, W.H. On Some Remarkable Changes Produced in Iron and Steel by the Action of Hydrogen and Acids. Nature 1875, 11, 393. [Google Scholar] [CrossRef]

- Nagumo, M. Fundamentals of Hydrogen Embrittlement; Springer: Berlin/Heidelberg, Germany, 2016; Volume 921. [Google Scholar]

- Zapffe, C.; Sims, C. Hydrogen embrittlement, internal stress and defects in steel. Trans. Aime 1941, 145, 225–271. [Google Scholar]

- Pfeil, L.B. The effect of occluded hydrogen on the tensile strength of iron. Proc. R. Soc. Lond. A 1926, 112, 182–195. [Google Scholar]

- Gerberich, W.W.; Oriani, R.A.; Lji, M.J.; Chen, X.; Foecke, T. The necessity of both plasticity and brittleness in the fracture thresholds of iron. Philos. Mag. A 1991, 63, 363–376. [Google Scholar] [CrossRef]

- Beachem, C.D. A new model for hydrogen-assisted cracking (hydrogen “embrittlement”). Metall. Mater. Trans. B 1972, 3, 441–455. [Google Scholar] [CrossRef]

- Lynch, S. Hydrogen embrittlement and liquid-metal embrittlement in nickel single crystals. Scr. Metall. 1979, 13, 1051–1056. [Google Scholar] [CrossRef]

- Nagumo, M. Hydrogen related failure of steels—A new aspect. Mater. Sci. Technol. 2004, 20, 940–950. [Google Scholar] [CrossRef]

- Liu, Q.; Zhou, Q.; Venezuela, J.; Zhang, M.; Atrens, A. Evaluation of the influence of hydrogen on some commercial DP, Q&P and TWIP advanced high-strength steels during automobile service. Eng. Fail. Anal. 2018, 94, 249–273. [Google Scholar]

- Westlake, D. Generalized Model for Hydrogen Embrittlement; Argonne National Lab., Ill.: Lemont, IL, USA, 1969. [Google Scholar]

- Uhlig, H. Stress-Corrosion Cracking. In Engineering Fundamentals and Environmental Effects; Staehle, R.W., Forty, A.J., Van Ruoyan, D., Eds.; NACE: Houston, TX, USA, 1969. [Google Scholar]

- Dwivedi, S.K.; Vishwakarma, M. Hydrogen embrittlement in different materials: A review. Int. J. Hydrogen Energy 2018, 43, 21603–21616. [Google Scholar] [CrossRef]

- Dwivedi, S.K.; Vishwakarma, M. Effect of hydrogen in advanced high strength steel materials. Int. J. Hydrogen Energy 2019, 44, 28007–28030. [Google Scholar] [CrossRef]

- Lynch, S. Discussion of some recent literature on hydrogen-embrittlement mechanisms: Addressing common misunderstandings. Corros. Rev. 2019, 37, 377–395. [Google Scholar] [CrossRef]

- Li, Q.; Ghadiani, H.; Jalilvand, V.; Alam, T.; Farhat, Z.; Islam, M.A. Hydrogen Impact: A Review on Diffusibility, Embrittlement Mechanisms, and Characterization. Materials 2024, 17, 965. [Google Scholar] [CrossRef]

- Koren, E.; Hagen, C.M.; Wang, D.; Lu, X.; Johnsen, R.; Yamabe, J. Experimental comparison of gaseous and electrochemical hydrogen charging in X65 pipeline steel using the permeation technique. Corros. Sci. 2023, 215, 111025. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, M.; Liu, G. Effect of hydrogen on ductility of high strength 3Ni–Cr–Mo–V steels. Mater. Sci. Eng. A 2014, 594, 40–47. [Google Scholar] [CrossRef]

- Elhoud, A.M.; Renton, N.C.; Deans, W.F. Hydrogen embrittlement of super duplex stainless steel in acid solution. Int. J. Hydrogen Energy 2010, 35, 6455–6464. [Google Scholar] [CrossRef]

- Dong, C.-F.; Xiao, K.; Liu, Z.-Y.; Yang, W.-J.; Li, X.-G. Hydrogen induced cracking of X80 pipeline steel. Int. J. Miner. Metall. Mater. 2010, 17, 579–586. [Google Scholar] [CrossRef]

- Parkins, R. Development of Strain-Rate Testing and Its Implications; ASTM International: Conshohocken, PA, USA, 1979. [Google Scholar]

- Hagihara, Y.; Ito, C.; Hisamori, N.; Suzuki, H.; Takai, K.; Akiyama, E. Evaluation of delayed fracture characteristics of high strength steel based on CSRT method. Tetsu Hagane/J. Iron Steel Inst. Jpn. 2008, 94, 215–221. [Google Scholar] [CrossRef]

- Hagihara, Y. Evaluation of delayed fracture characteristics of high-strength bolt steels by CSRT. ISIJ Int. 2012, 52, 292–297. [Google Scholar] [CrossRef]

- San Marchi, C.W.; Somerday, B.P. Technical Reference for Hydrogen Compatibility of Materials; Sandia National Laboratories (SNL): Albuquerque, NM, USA; Livermore, CA, USA, 2012.

- Xu, K.; Rana, M. Tensile and fracture properties of carbon and low alloy steels in high pressure hydrogen. Eff. Hydrog. Mater. 2009, 357–364. [Google Scholar]

- Laureys, A.; Depraetere, R.; Cauwels, M.; Depover, T.; Hertelé, S.; Verbeken, K. Use of existing steel pipeline infrastructure for gaseous hydrogen storage and transport: A review of factors affecting hydrogen induced degradation. J. Nat. Gas Sci. Eng. 2022, 101, 104534. [Google Scholar] [CrossRef]

- Sun, Z.; Benoit, G.; Moriconi, C.; Hamon, F.; Halm, D.; Hamon, F.; Hénaff, G. Fatigue crack propagation under gaseous hydrogen in a precipitation-hardened martensitic stainless steel. Int. J. Hydrogen Energy 2011, 36, 8641–8644. [Google Scholar] [CrossRef]

- Alvaro, A.; Wan, D.; Olden, V.; Barnoush, A. Hydrogen enhanced fatigue crack growth rates in a ferritic Fe-3 wt% Si alloy and a X70 pipeline steel. Eng. Fract. Mech. 2019, 219, 106641. [Google Scholar] [CrossRef]

- Lee, S.G.; Kim, I.S. Effect of pre-charged hydrogen on fatigue crack growth of low alloy steel at 288 °C. Mater. Sci. Eng. A 2006, 420, 279–285. [Google Scholar] [CrossRef]

- Colombo, C.; Fumagalli, G.; Bolzoni, F.; Gobbi, G.; Vergani, L. Fatigue behavior of hydrogen pre-charged low alloy Cr–Mo steel. Int. J. Fatigue 2016, 83, 2–9. [Google Scholar] [CrossRef]

- ASTM E 647; Standard Test Method for Measurement of Fatigue Crack Growth Rates. American Society of Testing and Materials: Philadelphia, PA, USA, 2001.

- Tsay, L.; Yu, S.; Huang, R.-T. Effect of austenite instability on the hydrogen-enhanced crack growth of austenitic stainless steels. Corros. Sci. 2007, 49, 2973–2984. [Google Scholar] [CrossRef]

- Álvarez, G.; Zafra, A.; Belzunce, F.J.; Rodríguez, C. Effect of Internal Hydrogen on the Fatigue Crack Growth Rate in the Coarse-Grain Heat-Affected Zone of a CrMo Steel. Metals 2022, 12, 673. [Google Scholar] [CrossRef]

- Stewart, A.T. The influence of environment and stress ratio on fatigue crack growth at near threshold stress intensities in low-alloy steels. Eng. Fract. Mech. 1980, 13, 463–478. [Google Scholar] [CrossRef]

- Toplosky, J.; Ritchie, R. On the influence of gaseous hydrogen in decelerating fatigue crack growth rates in ultrahigh strength steels. Scr. Metall. 1981, 15, 905–908. [Google Scholar] [CrossRef]

- Dmytrakh, I.; Leshchak, R.; Syrotyuk, A.; Barna, R. Effect of hydrogen concentration on fatigue crack growth behaviour in pipeline steel. Int. J. Hydrogen Energy 2017, 42, 6401–6408. [Google Scholar] [CrossRef]

- Yamabe, J.; Yoshikawa, M.; Matsunaga, H.; Matsuoka, S. Hydrogen trapping and fatigue crack growth property of low-carbon steel in hydrogen-gas environment. Int. J. Fatigue 2017, 102, 202–213. [Google Scholar] [CrossRef]

- An, T.; Peng, H.; Bai, P.; Zheng, S.; Wen, X.; Zhang, L. Influence of hydrogen pressure on fatigue properties of X80 pipeline steel. Int. J. Hydrogen Energy 2017, 42, 15669–15678. [Google Scholar] [CrossRef]

- Cheng, A.; Chen, N.-Z. Fatigue crack growth modelling for pipeline carbon steels under gaseous hydrogen conditions. Int. J. Fatigue 2017, 96, 152–161. [Google Scholar] [CrossRef]

- Anderson, T.L.; Anderson, T.L. Fracture Mechanics: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Meng, B.; Gu, C.; Zhang, L.; Zhou, C.; Li, X.; Zhao, Y.; Zheng, J.; Chen, X.; Han, Y. Hydrogen effects on X80 pipeline steel in high-pressure natural gas/hydrogen mixtures. Int. J. Hydrogen Energy 2017, 42, 7404–7412. [Google Scholar] [CrossRef]

- Faucon, L.E.; Boot, T.; Riemslag, T.; Scott, S.P.; Liu, P.; Popovich, V. Hydrogen-Accelerated Fatigue of API X60 Pipeline Steel and Its Weld. Metals 2023, 13, 563. [Google Scholar] [CrossRef]

- Nahm, S.-H.; Shim, H.-B.; Baek, U.; Suh, C.-M. Very High Cycle Fatigue Behaviors and Surface Crack Growth Mechanism of Hydrogen-Embrittled AISI 304 Stainless Steels. Mater. Sci. Appl. 2018, 09, 393–411. [Google Scholar] [CrossRef][Green Version]

- Zhang, P.; Laleh, M.; Hughes, A.E.; Marceau, R.; Hilditch, T.; Tan, M. A systematic study on the influence of electrochemical charging conditions on the hydrogen embrittlement behaviour of a pipeline steel. Int. J. Hydrogen Energy 2023, 48, 16501–16516. [Google Scholar] [CrossRef]

- Devanathan, M.; Stachurski, Z. The adsorption and diffusion of electrolytic hydrogen in palladium. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1962, 270, 90–102. [Google Scholar]

- ISO 17081; Method of Measurement of Hydrogen Permeation and Determination of Hydrogen Uptake and Transport in Metals by an Electrochemical Technique. International Organization for Standardization: Geneva, Switzerland, 2014.

- Iyer, R.N.; Pickering, H.W.; Zamanzadeh, M. Analysis of hydrogen evolution and entry into metals for the discharge-recombination process. J. Electrochem. Soc. 1989, 136, 2463. [Google Scholar] [CrossRef]

- Perng, T.; Wu, J. A brief review note on mechanisms of hydrogen entry into metals. Mater. Lett. 2003, 57, 3437–3438. [Google Scholar] [CrossRef]

- Devanathan, M.; Stachurski, Z. The mechanism of hydrogen evolution on iron in acid solutions by determination of permeation rates. J. Electrochem. Soc. 1964, 111, 619. [Google Scholar] [CrossRef]

- Duprez, L.; Verbeken, K.; Verhaege, M. Effect of hydrogen on the mechanical properties of multiphase high strength steels. Eff. Hydrogen Mater. 2009, 39, 62–69. [Google Scholar]

- Depover, T.; Wallaert, E.; Verbeken, K. On the synergy of diffusible hydrogen content and hydrogen diffusivity in the mechanical degradation of laboratory cast Fe-C alloys. Mater. Sci. Eng. A 2016, 664, 195–205. [Google Scholar] [CrossRef]

- Cottrell, A.H.; Bilby, B.A. Dislocation Theory of Yielding and Strain Ageing of Iron. Proc. Phys. Society. Sect. A 1949, 62, 49. [Google Scholar] [CrossRef]

- Michler, T.; Ebling, F.; Oesterlin, H.; Fischer, C.; Wackermann, K. Comparison of tensile properties of X60 pipeline steel tested in high pressure gaseous hydrogen using tubular and conventional specimen. Int. J. Hydrogen Energy 2022, 47, 34676–34688. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Park, J.; Kim, W.S.; Nahm, S.H.; Beak, U.B. Effect of low partial hydrogen in a mixture with methane on the mechanical properties of X70 pipeline steel. Int. J. Hydrogen Energy 2020, 45, 2368–2381. [Google Scholar] [CrossRef]

- Banerjee, K.; Chatterjee, U.K. Hydrogen permeation and hydrogen content under cathodic charging in HSLA 80 and HSLA 100 steels. Scr. Mater. 2001, 44, 213–216. [Google Scholar] [CrossRef]

- Matsumoto, K.; Kobayashi, Y.; Ume, K.; Murakami, K.; Taira, K.; Arikata, K. Hydrogen induced cracking susceptibility of high-strength line pipe steels. Corrosion 1986, 42, 337–345. [Google Scholar] [CrossRef]

- Park, G.T.; Koh, S.U.; Jung, H.G.; Kim, K.Y. Effect of microstructure on the hydrogen trapping efficiency and hydrogen induced cracking of linepipe steel. Corros. Sci. 2008, 50, 1865–1871. [Google Scholar] [CrossRef]

- Manson, S.; Hirschberg, M. The role of ductility, tensile strength and fracture toughness in fatigue. J. Frankl. Inst. 1970, 290, 539–548. [Google Scholar] [CrossRef]

- Sachs, N.W. Understanding the surface features of fatigue fractures: How they describe the failure cause and the failure history. J. Fail. Anal. Prev. 2005, 5, 11–15. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).