1. Introduction

Coal is a concentrated non-renewable energy source and the leading contributor to the power sector of India. Efficient coal extraction with safety is important for the development of the country and from a conservation point of view. Coal seams are deposited under sedimentary rock formations and possess a number of geological discontinuities [

1], which create strata control problems during mining. An igneous intrusion in the form of a dyke is one of the geological discontinuities, which converts the surrounding coal mass into jhama and pulverized zones during its formation [

2]. A dyke intrudes into a weak zone of the rock mass where a well-developed fracture network exists [

3] and is mostly widespread during the cooling and decompression of the host rocks [

4]. It can be easily disturbed and may contribute to the weakening of the discontinuity system during coal extraction [

5], leading to ground control and mining issues. The strength of the coal/rock is one of the important parameters for designing the support system during mining. Collection of samples from the influenced area of a dyke for strength determination in the laboratory is a difficult task. A number of researchers [

6,

7,

8,

9,

10,

11] reported a non-destructive approach using a Schmidt Hammer (SH) for in situ evaluation of uniaxial compressive strength (UCS) of different types of rock, including dyke, and coal, which is informative for designing purposes. The strength characteristic of the influenced zone, including the dyke, varies considerably and needs to be addressed accordingly for safe mining. UCS of rock/coal is an important parameter in the design of underground natural support [

11] and applied support [

12] in openings. Direct assessment of UCS is obtained by testing samples collected from sites, as per the International Society for Rock Mechanics (ISRM) and American Society for Testing and Materials (ASTM). However, in order to carry out such standard tests, special samples such as cylindrical cores or cubical specimens are to be prepared. Preparation of core specimens has several drawbacks since it is difficult, expensive, and time-consuming. Further, the preparation of irregular-shaped samples from weak or fractured rock mass is also difficult. Under the circumstances, indirect strength indices are becoming popular due to their simple approach for estimating UCS, as suggested by various researchers. The Schmidt Hammer (SH) test is one of the non-destructive approaches [

13] for in situ UCS estimation of rock/coal mass. The SH tests are increasingly being used by rock engineers, since they are simpler, need less preparatory work, are portable, and provide quick results during field and laboratory investigations. A number of researchers [

14,

15,

16,

17,

18] developed formulations for the in situ estimation of UCS of rock/coal free from the influence of geological discontinuities like dyke. The nature of sedimentary structures and imbrication fabric influences the strength of the mass [

19]. Assessment of the in situ strength characteristics in and around the dyke is required for coal extraction and ground control point of view. A number of coal seams in the Jharia coalfield are disturbed due to encountering igneous intrusions, especially dykes [

2,

20]. Dykes alter the mechanical properties of the surrounding rock/coal mass and, therefore, the in situ testing of UCS using SH may provide significant technical data for the design of underground structures in the influenced area. The primary objectives of this study are to investigate the geotechnical impact of dyke intrusions on adjacent coal seams and to quantify the in situ uniaxial compressive strength of coal altered by such intrusions. These insights are critical for the development of optimized support and excavation designs for safe and efficient underground mining in dyke-influenced environments.

Ideally, non-destructive testing by SH is performed without damaging the rock mass. SH models are designed with different levels of impact energy. There are two types of SH: first, the L-type with 0.735 Nm impact energy, and second, the N-type with an impact energy level of 2.207 Nm. Both types are commonly used to determine rock properties [

21]. The N-type hammer is less sensitive to surface irregularities and is suitable for in situ testing, while the L-type hammer has greater sensitivity in the lower range and gives better results when testing weak, porous, and weathered rocks [

22]. Considering the higher value of UCS of the dyke and jhama [

2], a digital SH with an impact energy of 2.207 Nm was used for this study. The hammer provides quick, easy, and accurate test results during in situ measurement of UCS in the field. The observed rebound number/UCS is saved in the hammer during testing and later transferred to a computer for analysis and interpretation.

Several NDT techniques, such as ultrasonic pulse velocity (UPV) measurements and acoustic emission or microseismic monitoring, can be used to estimate the mechanical properties of rock masses, including UCS. However, in the present study, the Schmidt hammer was employed due to its simplicity, portability, cost-effectiveness, and availability within the institutional resources. It also allows for rapid, in situ assessments of surface hardness, which can be empirically correlated to UCS. While the authors acknowledge the advantages of ultrasonic and microseismic methods in capturing more detailed internal structural and dynamic response characteristics, these methods require specialized equipment, controlled test conditions, and extensive calibration datasets, which were beyond the logistical scope of the current field-based study.

The working principle [

23] of the SH is based on the absorption of part of the spring-released energy through plastic deformation of the rock surface, while the remaining elastic energy causes the actual rebound of the hammer. The distance traveled by the mass, expressed as a percentage of the initial extension of the spring, is called the rebound number. The test makes it possible to estimate the compressive strength of a material by measuring the energy absorption from the impact energy delivered by the hammer. The energy absorption depends on the strength and stiffness of the material. From the impact and using the rebound number, the compressive strength of the material can be estimated using a correlation curve (

Figure 1). The SH consists of a spring-loaded piston which is released when the plunger is pressed against a surface. The impact of the piston on the plunger transfers the energy to the material. The extent to which this energy is recovered depends on the hardness (or impact penetration/damage resistance) of the material, which is expressed as a percentage of the maximum stretched length of the key spring before the release of the piston compared to its length after the rebound [

24].

This non-destructive testing method must be performed with the hammer oriented perpendicular to the testing surface to ensure accuracy. Deviation from perpendicular impact can lead to erroneous results; therefore, careful attention is required during testing to maintain proper alignment. Additionally, the testing surface should be flat and smooth, as the Schmidt hammer yields unreliable readings on irregular or uneven surfaces.

An effort has been made to study the effect of a dyke on the strength of coal using a digital SH. In situ UCS testing was conducted in the Jharia coalfields at the Jitpur colliery of Steel Authority of India Limited (SAIL), and secondly at the Bhaura mine (N) of Bharat Coking Coal Limited (BCCL) in India. This study focuses on two distinct mine sites within an Indian coalfield and presents a novel assessment of dyke intrusion influence zones through in situ uniaxial compressive strength (UCS) testing.

2. Experimental Work

Estimation of uniaxial compressive strength was conducted at two different underground coal mines in the Jharia coalfields, in and around the dyke. The dyke was formed due to magma intrusion along pre-existing fractures and fissures within the coal seams and adjacent rock strata. Its orientation is along the NW–SE direction. Firstly, the test was conducted around a 15 m thick dyke intersecting the IX seam at the Jitpur colliery of SAIL. The seam is 9 m thick and developed along the floor to be extracted by the incline slicing longwall method with hydraulic sand stowing. Secondly, the study was carried out in the VI seam at the Bhaura (North) underground mine of BCCL. The seam is around 4 m in thickness and developed along the floor, keeping a 1 m (approx.) coal band in the immediate roof. A number of dykes intersect the VI seam, and the tests were conducted around a 1 m thick dyke at two different locations within a selected panel. Both seams in the selected underground mines were developed along the floor, keeping the coal band in the immediate roof. The development was carried out long ago using conventional drilling and blasting techniques. Under these conditions, spalling, cracks, and weathering were observed in the periphery of the coal pillars, which might influence the in situ test results. Relatively, the surrounding roof near the dyke was smooth/intact, and it was found to be a good choice for the in situ testing. A testing area of around 15 cm in diameter was prepared at every measuring point using a grinding stone in order to make it flat and smooth. To ensure data reliability, multiple Schmidt hammer strikes were conducted at each designated measurement location, confined within a test area of 15 cm in diameter (approx. 225 cm2). At each location, a minimum of 10 valid rebound readings were recorded, discarding any anomalous values caused by surface irregularities or misalignment. The average of the valid readings was then used for further analysis. After pressing the enter key, the instrument was ready for the next strike. The test was conducted in a similar manner for all measuring points at both sites. As per the manual of the digital Schmidt hammer, a rebound number of 7 should be discarded. In cases where the rebound value ≤ 7, it indicates a measurement error. Around 10% error was reported during the testing. A detailed investigation using the digital SH for UCS estimation of coal mass surrounding dykes of different thicknesses is given below.

2.1. Jitpur Colliery

The SH was used to estimate the rebound number and UCS of coal mass around a 15 m thick dolerite dyke intersecting the IX seam. The seam dips towards the southeast direction. The orientation of the dyke aligns closely with the strike direction of the seam but dips at approximately 55° towards the dip side of the working seam. Near the dyke, the side of the coal pillar was loosened, and although the gallery was partially filled with incombustible material, it was not suitable for testing. Therefore, the test was conducted at location 4E/R-L along the roof of the gallery to evaluate the physical effects and changes in the strength properties of the coal mass due to igneous intrusion. The test was conducted right from the edge of the dyke along the roof of the gallery, extending up to a distance of 16.5 m (

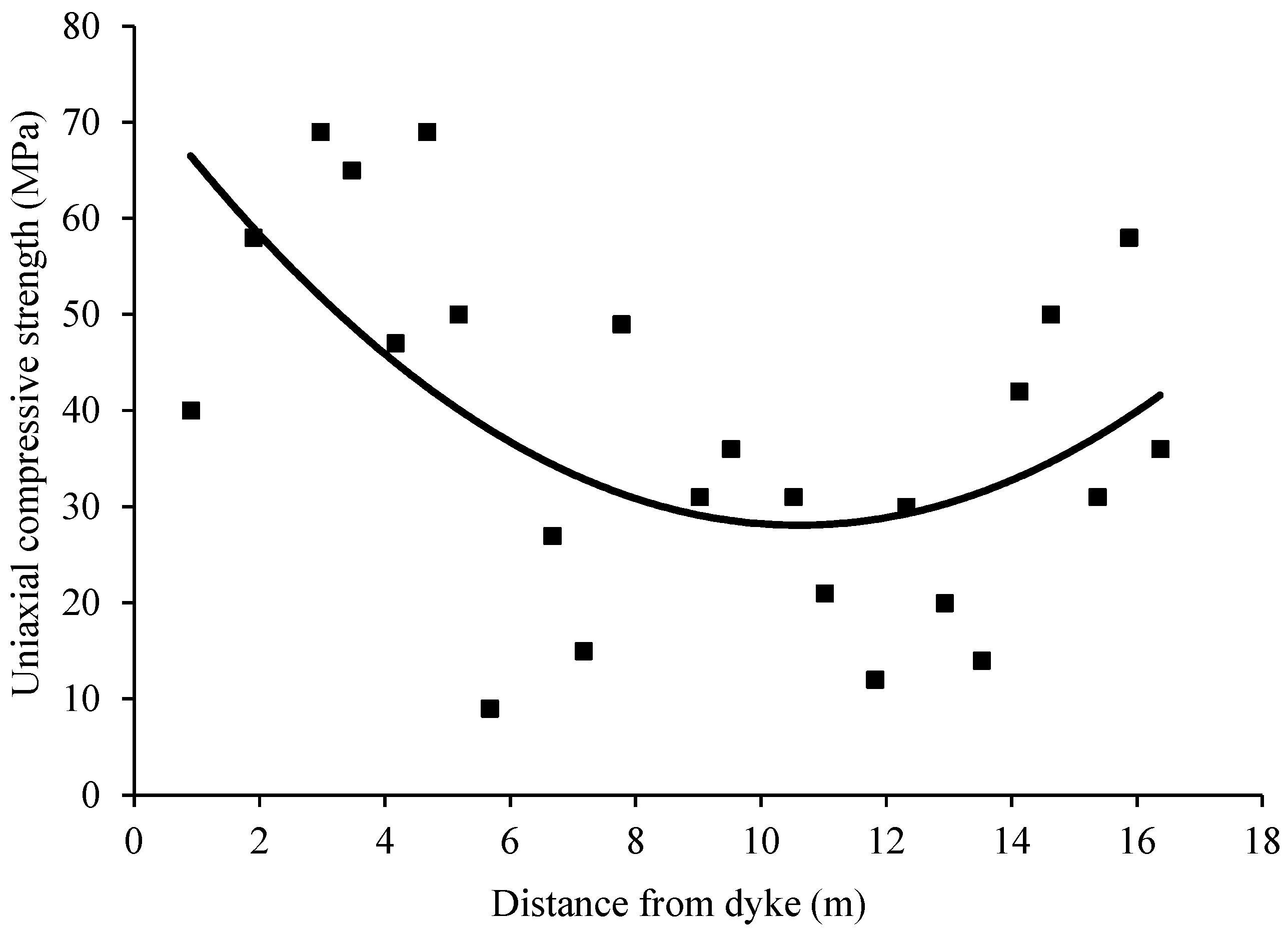

Figure 2), and 25 measuring points were selected. The distance interval between two measuring points was kept between 0.6 and 1 m, depending on the suitability of the testing site.

Analysis of Data Observed at Jitpur Colliery

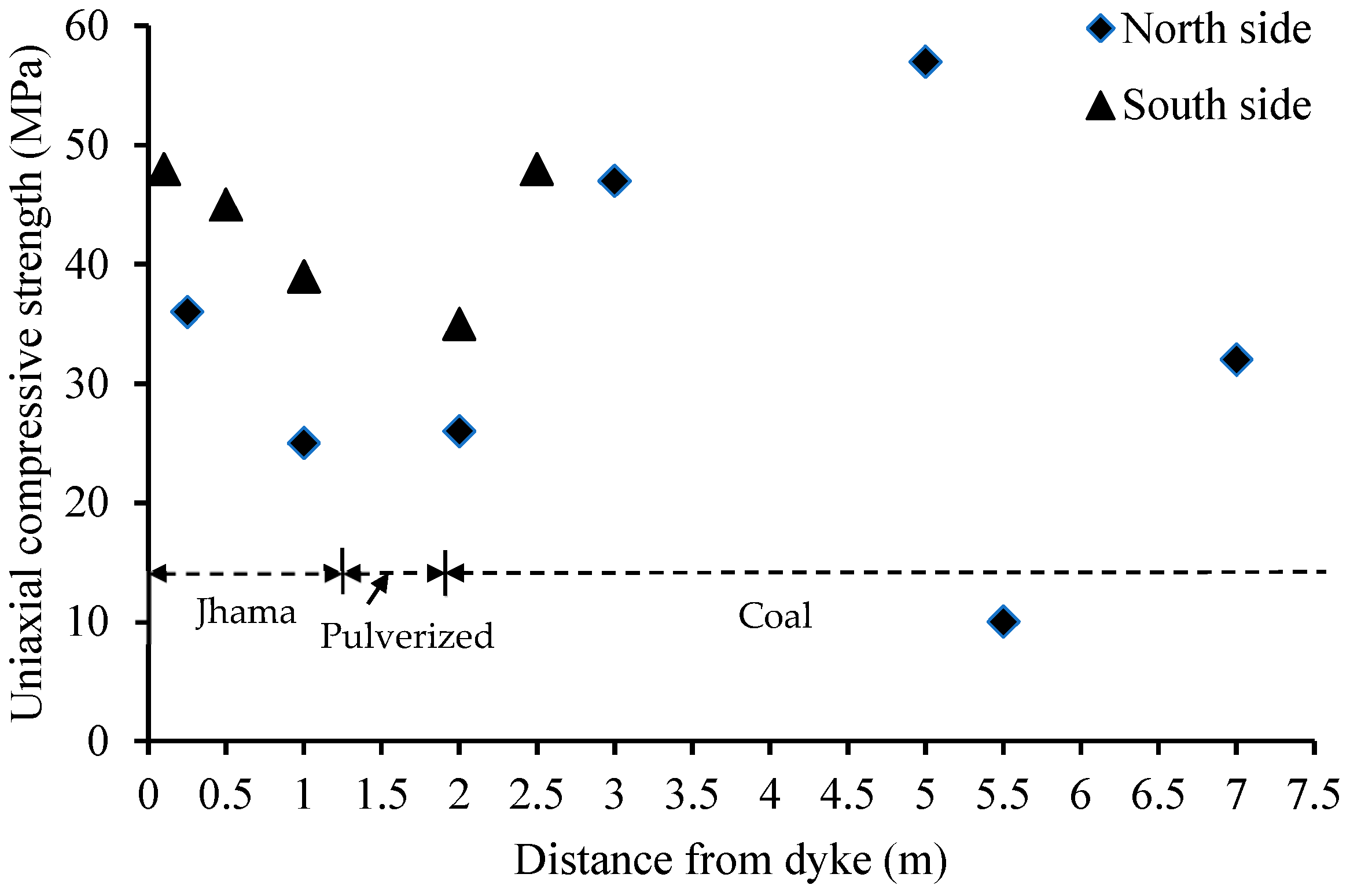

The recorded data, vis-à-vis visual inspection, revealed that the formation of the dyke altered the coal seam into a jhama zone extending up to 10.5 m and a pulverized zone (3 m), with changes in strength characteristics. In the jhama zone, from 3 m to 10.5 m from the edge of the dyke, 31–69 MPa uniaxial compressive strength was recorded. It was found that the strength of jhama gradually decreases with respect to distance from the dyke. Adjacent to the jhama zone, a pulverized zone of around 3 m, which was a mixture of jhama and burnt coal, was observed. Within this zone, the strength was relatively lower than that of jhama and coal. In this zone, 12–30 MPa UCS was recorded by the SH. In the coal mass adjacent to the pulverized zone, which was free from the effect of the dyke, 31–58 MPa UCS was recorded. UCS values observed in the three zones, i.e., jhama, pulverized, and coal mass, with respect to the distance from the dyke, are shown in

Figure 3. The average values of UCS observed in the jhama, pulverized, and coal zones were 45.2 MPa, 20.8 MPa, and 38.5 MPa, respectively. An attempt was made to develop a relationship (Equation (1)) between UCS in the jhama zone and the distance from the edge of the dyke. The purpose of

Figure 3 is not to establish a statistical correlation but rather to visually represent the trend of UCS variation across different zones influenced by the presence of a thicker dyke. The UCS values were obtained through systematic testing within each zone, and the observed trend, particularly the gradual decrease in UCS in the jhama zone with increasing distance from the dyke, is consistent with the expected influence of thermal and structural alteration. The relationship presented in

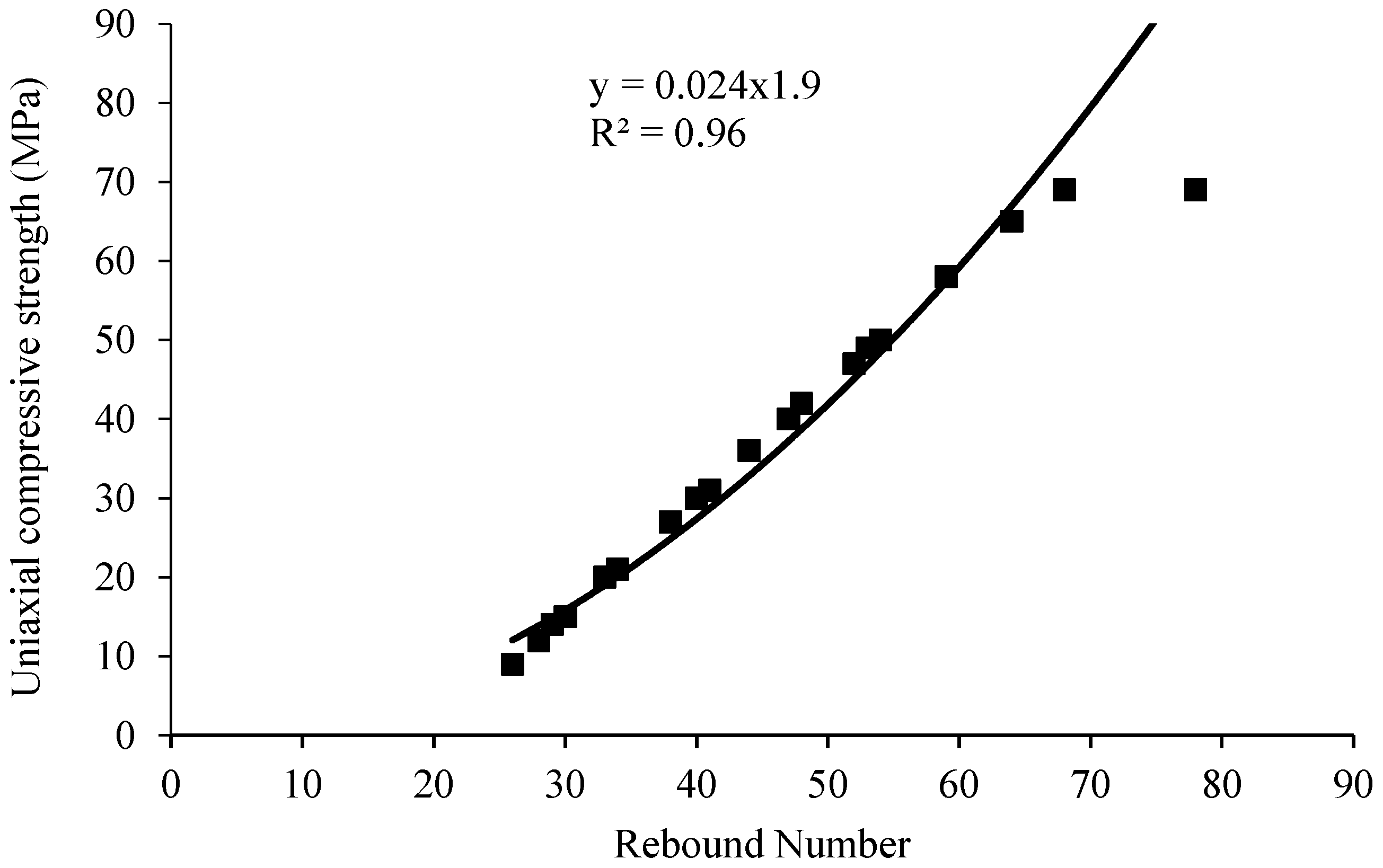

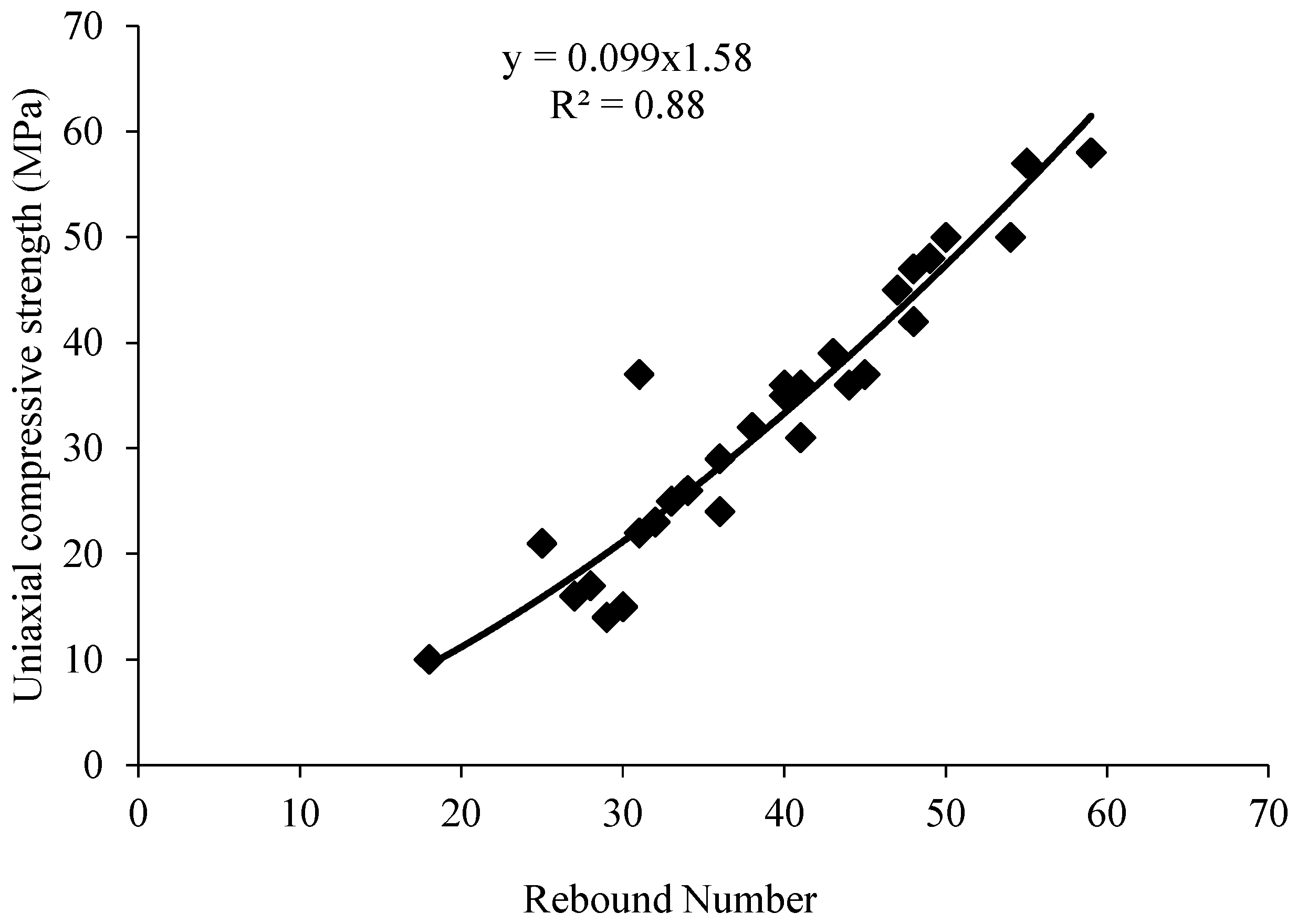

Figure 4 between the observed rebound number and UCS for the considered zones aligns well with the correlation curve provided in the Schmidt Hammer manual. Furthermore, the relationship shown in

Figure 5, developed using the rebound number and UCS values of unaltered coal from both mines, also demonstrates good agreement with the standard guidelines.

where σ

cj is the uniaxial compressive strength of jhama in MPa, and D is the distance from the edge of the dyke in meters. This equation is valid for the given site conditions described in this study.

2.2. Bhaura (North) Underground Mine

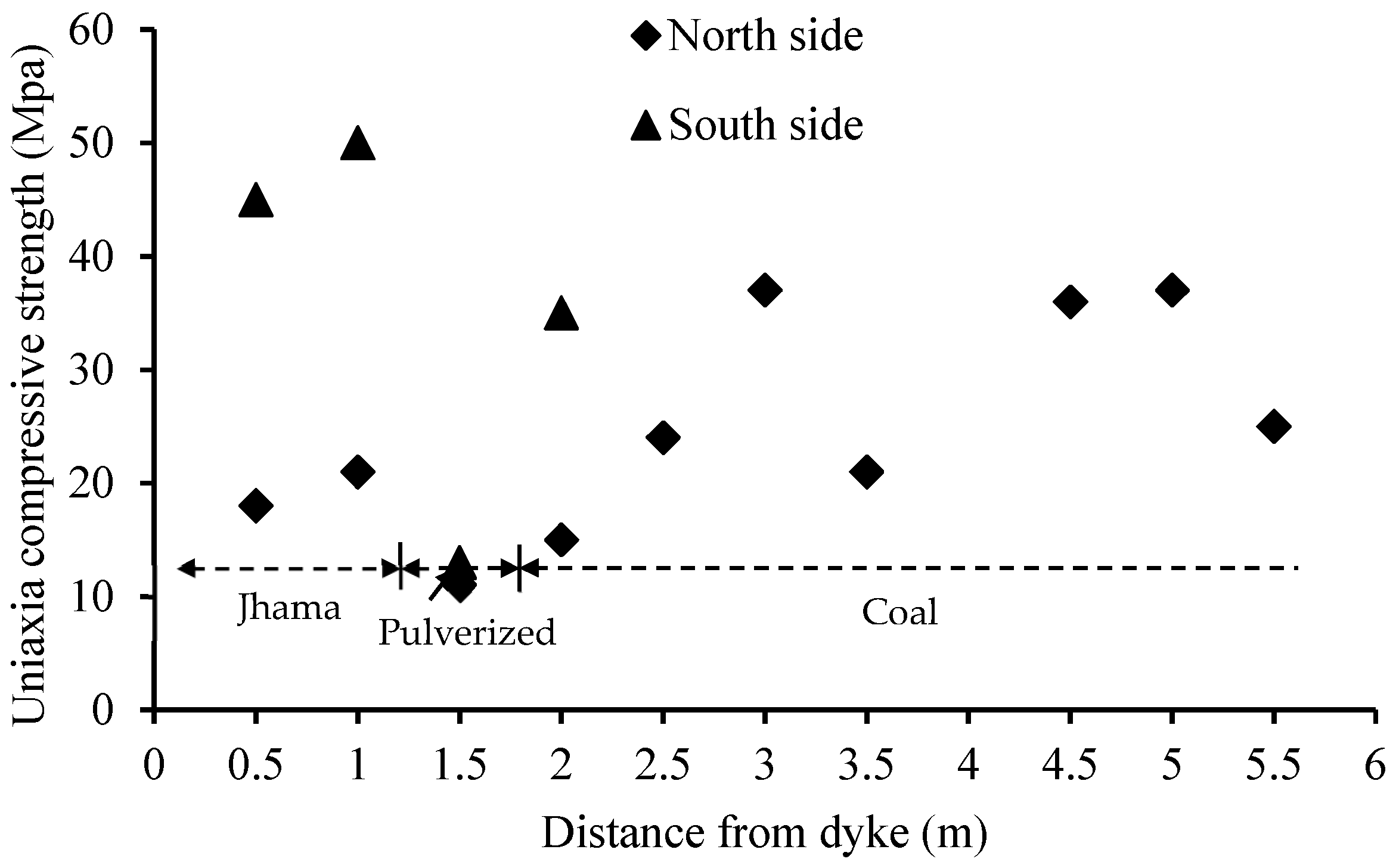

The VI seam of this mine was developed using the bord and pillar method along the floor. A dyke of around 1 m thick was present at location 37R/8L, and water seepage was observed around it. The seam dips towards the southeast direction. The dyke orientation is nearly parallel to the seam’s strike, but it was observed to be nearly perpendicular to the working seam. The test was conducted along the roof on both sides of the dyke. Eleven measuring points were selected up to 5.5 m on the north side of the dyke, and five points were selected up to 3 m on the south side of the dyke (

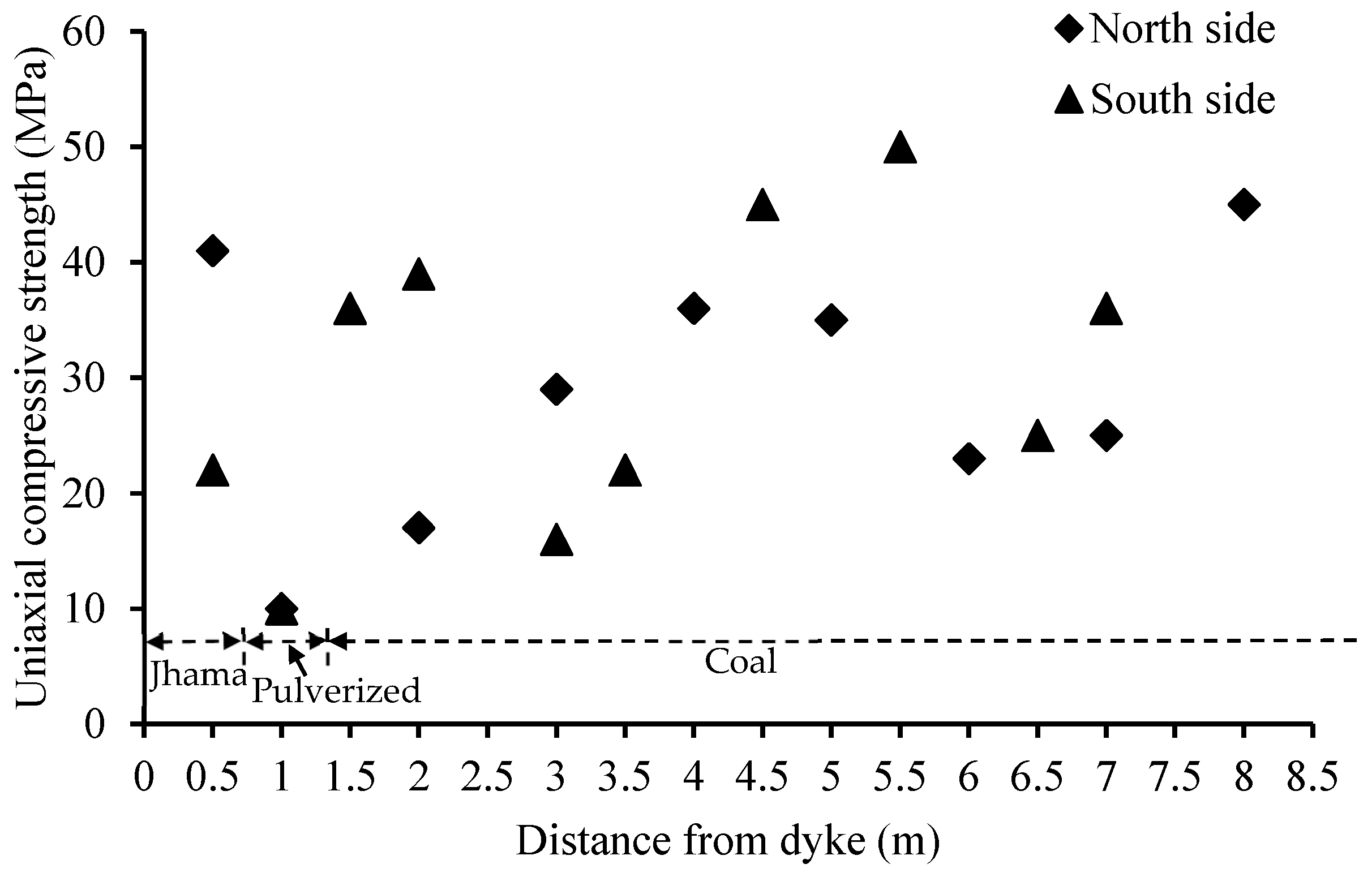

Figure 6). Also, the test was carried out in the coal pillar on both sides of the dyke, up to 2.5 m (six measuring points) and 7 m (eight measuring points) in the south and north directions, respectively. A second test was conducted around the same dyke at location 36R/8L. This test was conducted along the side of the pillar, on both sides of the dyke, up to 8 m and 7 m in the north and south directions, respectively.

Analysis of Data Observed at Bhaura (North) Underground Mine

The test was conducted around the same dyke at two different locations, both exhibiting almost similar characteristics. Due to watery conditions, lower values of UCS were recorded by the SH for the dyke and some affected portions of the jhama. The recorded data, vis-à-vis visual inspection, revealed that the coal altered into jhama that was 0.8–1.3 m in length due to the formation of the dyke. Within the dyke surface, 10–22 MPa UCS was observed at different locations. At different positions in the jhama zone, the observed UCS was 17–54 MPa. Similar to the first site, the strength of jhama gradually decreased with increasing distance from the dyke. Adjacent to the jhama, a pulverized zone around 0.6 m thick was observed in the coal mass. As usual, within this zone, the strength was relatively lower than that of jhama and coal. In the pulverized zone, 10–25 MPa UCS was observed. Beyond the pulverized zone, 25–58 MPa UCS was recorded for coal that was not affected by the dyke. The average values of UCS observed for jhama, pulverized, and coal mass were 36.5 MPa, 13.8 MPa, and 31.7 MPa, respectively. It was observed that the average UCS of the dyke was only 14 MPa due to water seepage. During in situ testing, a noticeable difference in UCS was recorded between the northern and southern sides of the dyke. In the case of location 37R/8L, the northern side of the dyke lies on the rising side of the seam, where water seepage was observed. The presence of moisture could have contributed to a reduction in the UCS of jhama on that side. At location 36R/8L, the variation in UCS between the north and south sides was less distinct. The slightly lower UCS observed on the southern side in this case may be attributed to surface irregularities or localized measurement inconsistencies during testing. Nevertheless, in both cases, the average UCS of the jhama zone remained consistently higher than that of the unaffected coal and the pulverized zone. This observation supports the overall strength-enhancing effect of thermal alteration near the dyke, despite local directional variations. The UCS of the surrounding coal mass along the roof and side of the gallery, as observed by SH at the two locations at the Bhaura (N) mine, is shown in

Figure 7,

Figure 8 and

Figure 9.