1. Introduction

In the design of mining operations, two critical pillars underpin the success of any project: safety and profitability. One of the key factors influencing the overall productivity of an underground mine is its hoisting capacity. An efficient hoisting system forms a solid foundation for stockpiling, ore blending, and strategic mine planning.

A growing solution in mining system optimization is automation, which refers to the automated control of machinery or equipment with minimal human intervention. In such systems, robotic or mechanical movements are pre-programmed and managed autonomously. The mining industry has shown increasing interest in automation due to its potential to streamline operations, improve efficiency, and reduce human presence in hazardous environments. These systems enhance operational productivity, optimize resource utilization, and promote a safer working environment for personnel.

The mine under study is located approximately 7.3 km northeast of Bulawayo, within the meta-andesites of the Kensington Formation. The mineralized zones align along the axis of a synclinal fold in the Upper Bulawayan Group of the Bulawayo Greenstone Belt and comprise four principal north–south striking mineralized deposits, dipping steeply to both the east and west. The mine is accessed via two shafts: The North 1 Shaft (double drum), used for man hoisting, and the Main Vertical Shaft (single drum), used for both ore and personnel hoisting. The Main Shaft extends to the 12-Level, while the North 1 Shaft reaches the 17-Level.

A key operational challenge faced by the mine is meeting its daily hoisting target of 380 tonnes. While the mining department reports achieving this target, weight meter readings from the shaft ore bins consistently indicate an actual daily hoist of approximately 350 tonnes. The mine’s planned hourly hoisting capacity is 31.6 tonnes, equating to 380 tonnes over 12 effective hoisting hours. However, actual throughput averages only 29 tonnes per hour, resulting in a daily shortfall of 30 tonnes. A detailed investigation revealed that the primary source of this inefficiency lies in the continued use of a manual skip-loading system. This method introduces delays and inaccuracies in hoisted tonnage reporting, often due to human error and, in some cases, deliberate misreporting.

To address this issue, the current study proposes the development and implementation of an advanced automated skip-loading system. By integrating real-time sensors and control algorithms, the system aims to monitor and optimize key hoisting performance indicators. This transition is expected to improve operational efficiency, particularly during the post-primary blasting phase (re-entry), when hoisting operations are typically idle. With gold prices at US$70,000 per kilogram (as of 22 May 2024), the mine’s production shortfall translates into significant revenue losses estimated at US$150,423 per month, or an annualized loss of US$1,805,076. These figures underscore the urgency for technological intervention.

The proposed automation solution will eliminate human involvement in tonnage reporting, enhance the accuracy of ore accountability, and support a more reliable and efficient hoisting operation. Beyond addressing current operational inefficiencies, the project aims to demonstrate how automation can revolutionize underground mine hoisting systems by enabling continuous, uninterrupted operations even during periods that are traditionally dormant.

2. Materials and Methods

2.1. Underground to Surface Transportation

This study employed a mixed-methods approach, incorporating both qualitative and quantitative data to develop a comprehensive understanding of automation in the mining sector. Structured and semi-structured interviews with key industry personnel provided firsthand insights into existing levels of automation, operational challenges, and future prospects. A desk-based investigation, supported by an extensive literature review, was also conducted to evaluate current automation trends in both local and international contexts. This enabled a benchmark comparison between Zimbabwean mining practices and global standards.

However, access to detailed proprietary systems within local mines was limited due to strict confidentiality policies designed to protect competitive advantage. To address this constraint, alternative data sources such as throughput reports, milled tonnage records, and trammed tonnage logs were used to infer automation levels and assess system performance. Complementing this, a field study involving direct observation, time-and-motion analysis, and physical assessment of existing infrastructure provided empirical validation of the collected data.

This holistic methodology ensured a rigorous and well-grounded evaluation of automation within Zimbabwean mining operations, effectively bridging the gap between theoretical frameworks and real-world implementation

2.2. Control Systems and the Components of Industrial Automation Systems

In engineering, control systems are central to automation, playing a critical role in monitoring and managing complex operations across a wide range of applications, including manufacturing, transportation, energy production, and environmental monitoring.

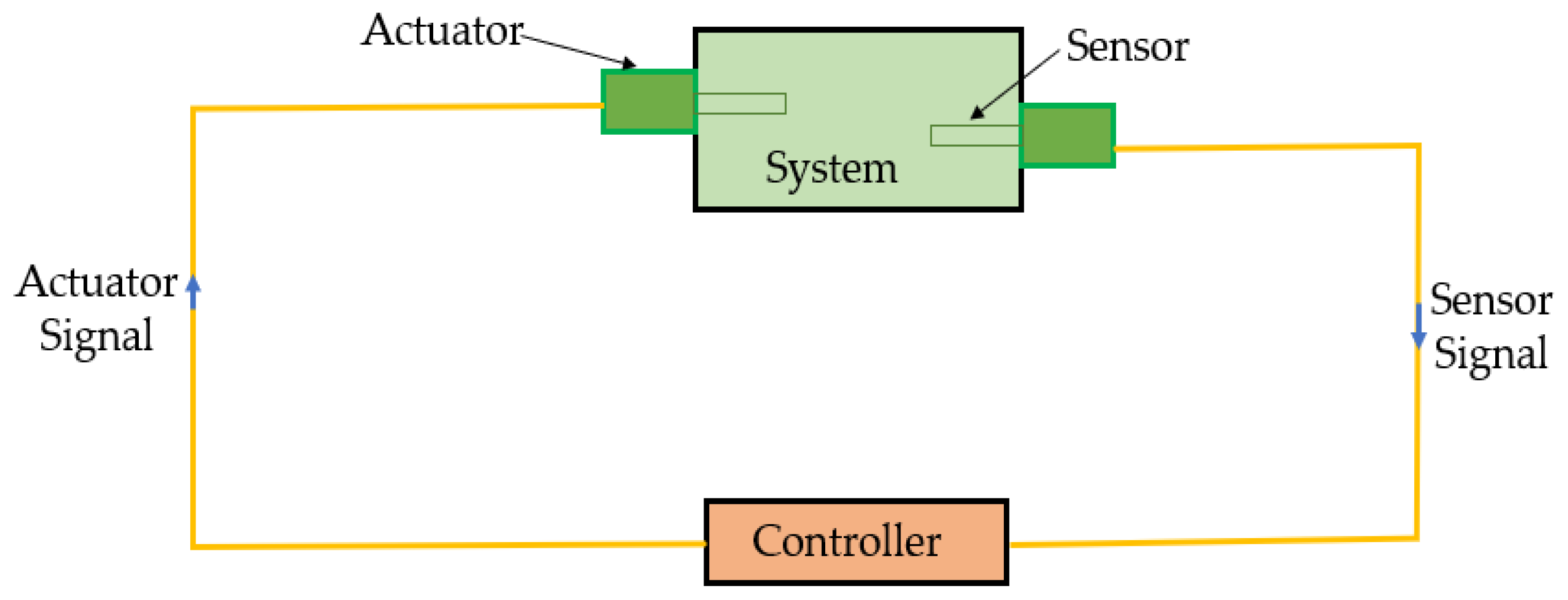

At the core of any automated system lies a well-defined control architecture. This structure typically begins with sensors that collect real-time data from the physical environment. The data is then transmitted to a controller, which processes the information and determines the appropriate response based on predefined algorithms or feedback logic. The controller subsequently sends signals to actuators, which carry out physical actions to influence the process, thereby completing the control loop.

This feedback-driven process ensures that the system maintains desired performance levels, adapts to changing conditions, and minimizes the need for human intervention. By integrating sensing, decision-making, and action, automated systems can operate with high precision and reliability.

A general structure of an automated system is illustrated in

Figure 1, highlighting the key components sensors, controllers, actuators and their interconnections. This foundational model applies across a wide range of industrial applications and forms the basis for more advanced and specialized automation technologies.

Sensors serve as the data-gathering units of automated systems, monitoring critical variables such as motion, temperature, pressure, and proximity [

1]. These measurements enable effective control, predictive maintenance, and improved safety across various industries. Actuators, on the other hand, function as mechanical output devices. When selecting industrial-grade sensors, it is essential to consider the operating environment, as exposure to dust and moisture can affect their calibration and overall reliability. Actuators convert electrical control signals into physical movement using electric motors, hydraulic cylinders, or solenoids allowing automated systems to perform precise and coordinated tasks [

2]. Controllers, including Programmable Logic Controllers (PLCs) and microcontrollers, process sensor inputs to manage operational logic and execute commands in real time. Serving as the decision-making core of automation systems, these devices ensure responsive and efficient process control. For this project, a functional prototype was developed, with industrial-grade automation components selected according to market standards and sourced from Fengwei Automation in Taiwan [

2].

Human–Machine Interfaces (HMIs) provide a graphical and interactive platform for operators to monitor and control automated processes. Systems such as SCADA (Supervisory Control and Data Acquisition) allow for real-time visualization, diagnostics, and remote access to industrial operations [

3]. Communication networks interconnect all components within the automation architecture. These networks include both wired protocols such as Ethernet and Modbus and wireless technologies like Wi-Fi and Zigbee, enabling seamless data exchange and system integration [

2].

Power supply systems ensure consistent and stable delivery of electricity to all components. They incorporate transformers, inverters, and backup systems to protect against power interruptions while maintaining compliance with safety and operational standards. Together, these elements form the backbone of industrial automation, enabling systems to operate with high levels of efficiency, reliability, and adaptability [

4].

2.2.1. Control Algorithms and Programming

At the heart of automation lies the algorithmic logic that translates sensor data into actionable control signals. These range from basic PID (Proportional-Integral-Derivative) controllers to more advanced techniques like model-based predictive control. The choice of control algorithm depends on the complexity and requirements of the application.

Programming these systems requires platforms and languages tailored to the specific hardware:

PLCs are typically programmed using ladder logic, a visual programming language designed for industrial control.

Microcontrollers, such as those found on Arduino boards, use the Arduino IDE with programming in C or C++.

Industrial PCs and embedded computers, commonly used for advanced automation and robotics tasks, are typically programmed in languages such as C, C++, or Python (Python Software Foundation, 2024, version 3.12.4, Wilmington, DE, USA). These systems often operate within real-time operating systems or frameworks like ROS (Robot Operating System).

2.2.2. The Role of IoT in Automation

The Internet of Things (IoT) introduces a transformative dimension to automation by connecting physical devices such as sensors, actuators, and controllers via internet-enabled networks. As described by Sethi and Sarangi [

5], IoT integrates these elements with digital platforms to achieve shared operational goals. By embedding sensors into industrial equipment, engineers can collect real-time data on performance, efficiency, and maintenance needs. This data can then be analyzed to optimize operations, reduce downtime, and enhance overall productivity.

Moreover, IoT enables remote monitoring and control, allowing engineers to supervise operations from virtually any location with internet access. Overall, IoT enhances the intelligence, connectivity, and flexibility of engineering systems, offering the disruptive potential to reshape modern industrial processes and usher in a new era of smart, data-driven automation.

2.3. Automation and Artificial Intelligence in the Mining Industry

Automation in mining refers to the deployment of systems that leverage sensors and real-time data connectivity to enhance operational efficiency, safety, and reliability. Typical applications include sensor-integrated machinery and automated haulage systems, which reduce human intervention in hazardous environments and streamline production processes [

6]. In contrast, Artificial Intelligence (AI) involves the use of cognitive technologies capable of learning, reasoning, and making autonomous decisions. In the mining sector, AI applications include predictive maintenance analytics—which anticipate equipment failures—and autonomous drilling rigs that operate using real-time geological data and adaptive control logic.

Understanding the distinction between automation and AI allows engineers to strategically integrate both paradigms: automation for physical execution and AI for intelligent decision-making. Together, these technologies significantly boost productivity while reducing operational risks. One of the key advantages of automation in mining is the reduction in manual labor in high-risk areas, thereby improving personnel safety and optimizing resource utilization. This aligns with the broader objective of fostering safer, more efficient mining environments.

Several mining operations have adopted autonomous hoisting systems to address inefficiencies and improve productivity. For example, the integration of advanced control algorithms and real-time sensor feedback has led to more efficient ore transportation cycles, minimized delays, and increased effective hoisting hours—an essential factor in meeting daily production targets [

7]. In deep underground mines, vertical shaft system automation frameworks utilize pre-existing electrical circuitry along the shaft to interconnect all components of the automated system, including sensors, actuators, and the Human–Machine Interface (HMI). In the area of autonomous ore loading, two primary measurement approaches are employed: volumetric and load-based systems.

Volumetric systems are generally used when the ore has a consistent density or when the density of waste rock is significantly lower than that of the ore. These systems often use cartridge or pocket mechanisms with gate or switching controls to regulate material flow based on volume.

Load-based systems, on the other hand, are preferred when ore density varies, as this can affect hoist capacity. These systems utilize load cells that support both the ore pocket and its contents, ensuring consistent loads and preventing overfilling regardless of material density. This method enhances both operational efficiency and safety.

Collectively, these automated and AI-enhanced systems are transforming the mining sector by optimizing workflow, reducing waste, and ensuring more predictable and safer operations.

Table 1 presents a summary of real-world case studies in which mining companies have successfully implemented automation and AI technologies.

Table 1 highlights the specific technologies adopted, operational improvements achieved, and measurable outcomes in terms of productivity, safety, and efficiency.

Case studies from Caledonia Corporation’s Blanket Mine, Sweden’s Kiruna Mine, and Agnico Eagle’s Goldex Mine illustrate significant advancements in automation and operational efficiency within the mining industry. At Blanket Mine, Caledonia’s investment in the Number 4 Shaft expansion increased hoisting capacity from 500 tonnes per day (t/d) to 3000 t/d through the implementation of an automated loading system. This upgrade reduced labor costs, spillage, and loading times while significantly improving safety and operational efficiency [

15].

The Kiruna Mine in Sweden, operated by LKAB, features an advanced automated hoisting system managed by ABB’s mine hoist solutions. The system includes real-time monitoring and diagnostics via ABB’s System 800xA and Argus data logging tools, ensuring optimized ore handling and long-term sustainability [

9].

Similarly, Agnico Eagle’s Goldex Mine has implemented the Railveyor™ Truly Autonomous system for ore haulage. Since 2018, this system has exceeded its initial capacity by transporting over 10 million tonnes of ore. It enhances productivity while reducing environmental impact by minimizing reliance on diesel truck haulage, thereby contributing to increased gold production and notable safety improvements [

10].

These examples collectively demonstrate the transformative impact of automation in enhancing operational efficiency, safety, and sustainability in modern mining operations. Anglo American has also made strides in automation at its Los Bronces copper mine in Chile by deploying its first two autonomous Komatsu 930 × 10

−4 trucks as part of a broader modernization initiative [

14]. This initiative includes the use of autonomous drilling rigs and the establishment of an Integrated Remote Operation Centre (IROC) to improve both safety and efficiency. In alignment with its FutureSmart Mining strategy, Anglo plans to expand the fleet to 62 autonomous electric-drive trucks by 2024 and explore the integration of hybrid hydrogen fuel cell-lithium battery technology to support sustainable mining practices.

Additionally, as DeLorenzo [

11] notes, Rio Tinto’s Gudai-Darri Mine in Australia features a fully automated iron ore sampling laboratory, which plays a key role in the mining process. The lab rapidly analyses both lump and fine ore samples, delivering accurate ore grade data within minutes. Samples are transported via conveyor from the collection station and handled by robotic systems that move them into the automated production cell. This setup enables real-time monitoring and precise assessment of on-site stockpiled iron ore, further improving quality control and operational efficiency.

3. Results and Discussions

3.1. Current Loading System Results

The current manual loading system cycle begins with the bellman and his assistant opening the box and loading a cocopan. Once the cocopan is full, it is loaded onto the skip. After signaling the hoist driver that the skip is loaded, the skip is hoisted to the surface and unloaded by the surface bellman and his assistant upon arrival. While the loaded skip is being hoisted to the surface, an empty cocopan is loaded underground to ensure quick and continuous loading

3.1.1. Hoisting Time Parameters

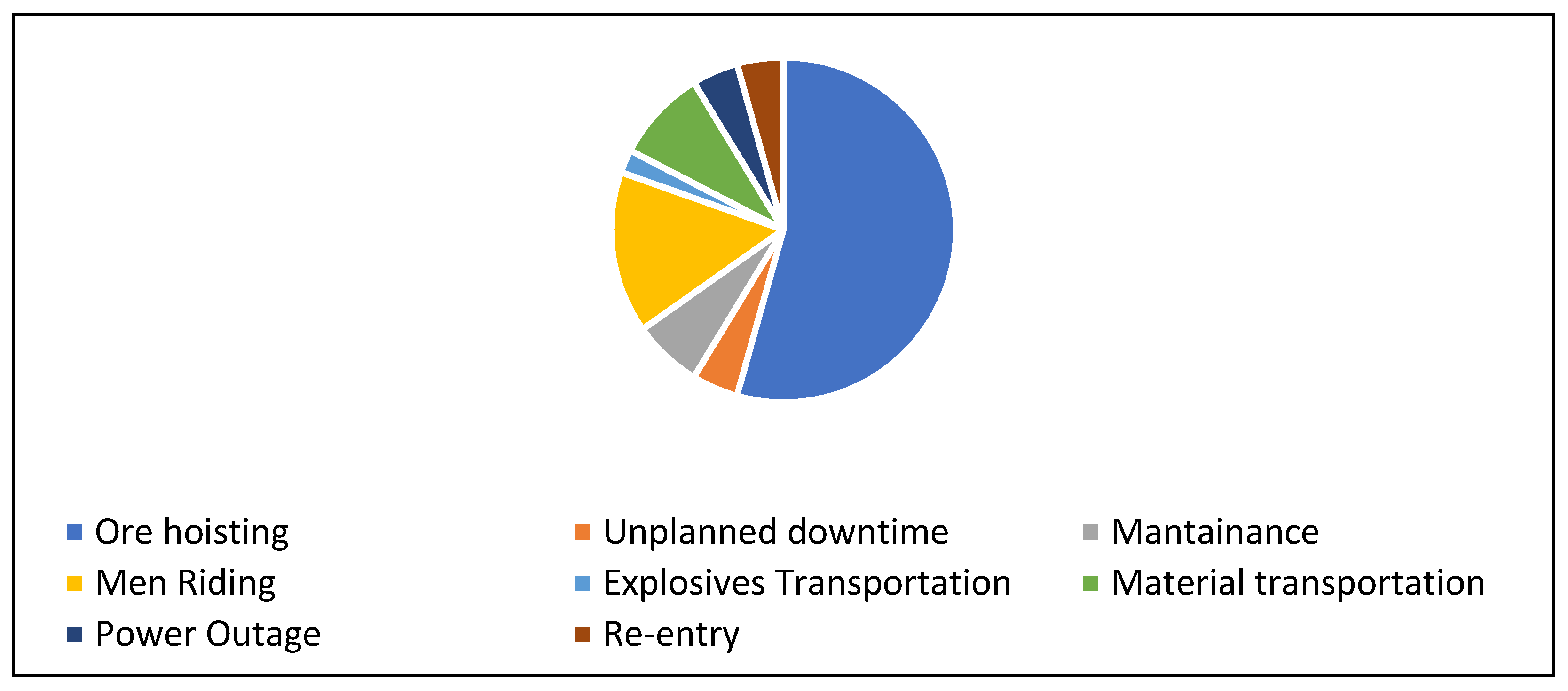

Figure 2 illustrates the daily utilization of the mine’s hoisting system. The planned effective ore hoisting time is set at 12 h. Additionally, specific time allocations are made for various activities: 2.5 h for personnel transportation, 2 h for material transportation, 1 h daily for breakdown allowance, 1 h daily for power outage allowance, 2 h for hoisting station re-entry, 0.5 h for explosives transportation, and 1.5 h for scheduled maintenance.

Time and motion studies were conducted to determine the average cycle times for the two shafts the Main Vertical Shaft and the North 1 Shaft while monitoring the hoisting personnel. The results indicated that the mine’s hoisting system is capable of achieving the throughput target of 380 tons. This suggests that the current shortfall in meeting the target is due to reliance on manual loading systems and human tonnage reporting.

Table 2 presents the time and motion study results for hoisting cycle times.

3.1.2. Task Completion Rate Calculation

The task completion rate (Equation (1)) quantifies the progress of tasks in an operation. It indicates the proportion of work that has been completed successfully relative to the planned total work. In this project, this metric was used to calculate the task completion rate of the current hoisting system as below:

Cycle time = 7 min 12 s

Expected hourly tonnage (2 ton per cycle) = = 16.6 tons/h

Expected daily tonnage (12 h) = 200 tons

Actual tonnage hoisted = 160 tons

Cycle time = 4 min

Expected hourly tonnage (1 ton per cycle) = = 15 tons/h

Expected daily tonnage (12 h) = 180 tons

Actual tonnage hoisted = 140 tons

Task completion rate = () × 100% = × 100%= 92.1% completion rate

3.2. Design Phase Results

Structural Design Results

Figure 3 illustrates the longitudinal section of the loading area layout, highlighting the integration of the newly developed system. This system comprises an ore bin and vibro-feeder setup, which loads a conveyor belt to facilitate ore transportation from the draw point of the ore pass. The vibrating feeder is mounted beneath the ore bin at the draw point and is responsible for transferring ore onto the conveyor belt. It operates using a vibratory tray, drive unit, spring system, controller, and mounting frame. When activated, the drive unit generates vibrations that are transferred by the spring system to the tray, producing controlled oscillations. Ore from the bin is deposited onto the tray, which propels it forward through rapid, angled vibrations. This process ensures consistent and controlled feeding onto the conveyor belt.

The bin and vibro-feeder arrangement also include a dust isolation hood to minimize particulate emissions. The conveyor then channels the ore into the loading flask, which is designed to accommodate a payload of up to one ton. To prevent collisions during loading, the chute is precisely aligned with the shaft to maintain a flush orientation. It is set at an angle of 70 degrees relative to the horizontal plane, promoting gravity-assisted flow. The loading flask is equipped with a hydraulic door to enable efficient ore discharge. During loading operations, the skip is positioned directly beneath the hoisting level.

3.3. Control System Design Results

In this study, several assumptions were made: ore fragmentation was considered relatively consistent; sensors were assumed to function within their rated accuracy under calibrated conditions; and the average operator response time in the manual system was estimated at 2 to 3 s.

The system functionality requirements for designing the automated skip-loading system were defined through functional decomposition—breaking down the system into manageable and interrelated components. This included defining the process flow from the initiation to the termination of the control system algorithm. Key components of the system include:

A belt scale sensor module to measure the weight of ore on the conveyor belt.

A volume sensor module in the loading flask to prevent overfilling, especially in cases where ore density varies.

A control algorithm module to manage logic execution.

An actuator module to perform mechanical actions.

A user interface module for operator interaction.

Each module was designed to execute its specific function accurately, contributing to the overall objective of autonomously and efficiently loading ore into the skip. The automated loading system incorporates a compact Programmable Logic Controller (PLC), a stepper motor to drive the conveyor belt, and a hydraulic cylinder to control the loading flask gate. A limit switch ensures proper skip alignment. Ore weight is measured by a belt scale, while an ultrasonic sensor monitors ore volume in the flask.

The operation begins when the conveyor receives ore from the vibro-feeder, continuing until the belt scale registers a one-ton payload. As a backup, the ultrasonic sensor detects whether the flask has reached its maximum capacity, providing redundancy in case of belt scale failure. If the flask sensor is not triggered within 5 min, the conveyor stops automatically signaling ore depletion. Upon detecting full capacity, the system checks skip alignment. If confirmed, it opens the flask gate. After a 10 s delay, the gate closes, and a signal is sent to the hoist driver to initiate hoisting. If hoisting is not confirmed within 5 min, the system shuts down for safety. When hoisting is verified via the underground proximity sensor (limit switch), the system resets and prepares for the next cycle. Additionally, the system features a remote monitoring interface hosted on an online database. This platform collects real-time data on hoisted tonnage, enabling surface-level management to track key hoisting performance indicators (KPIs).

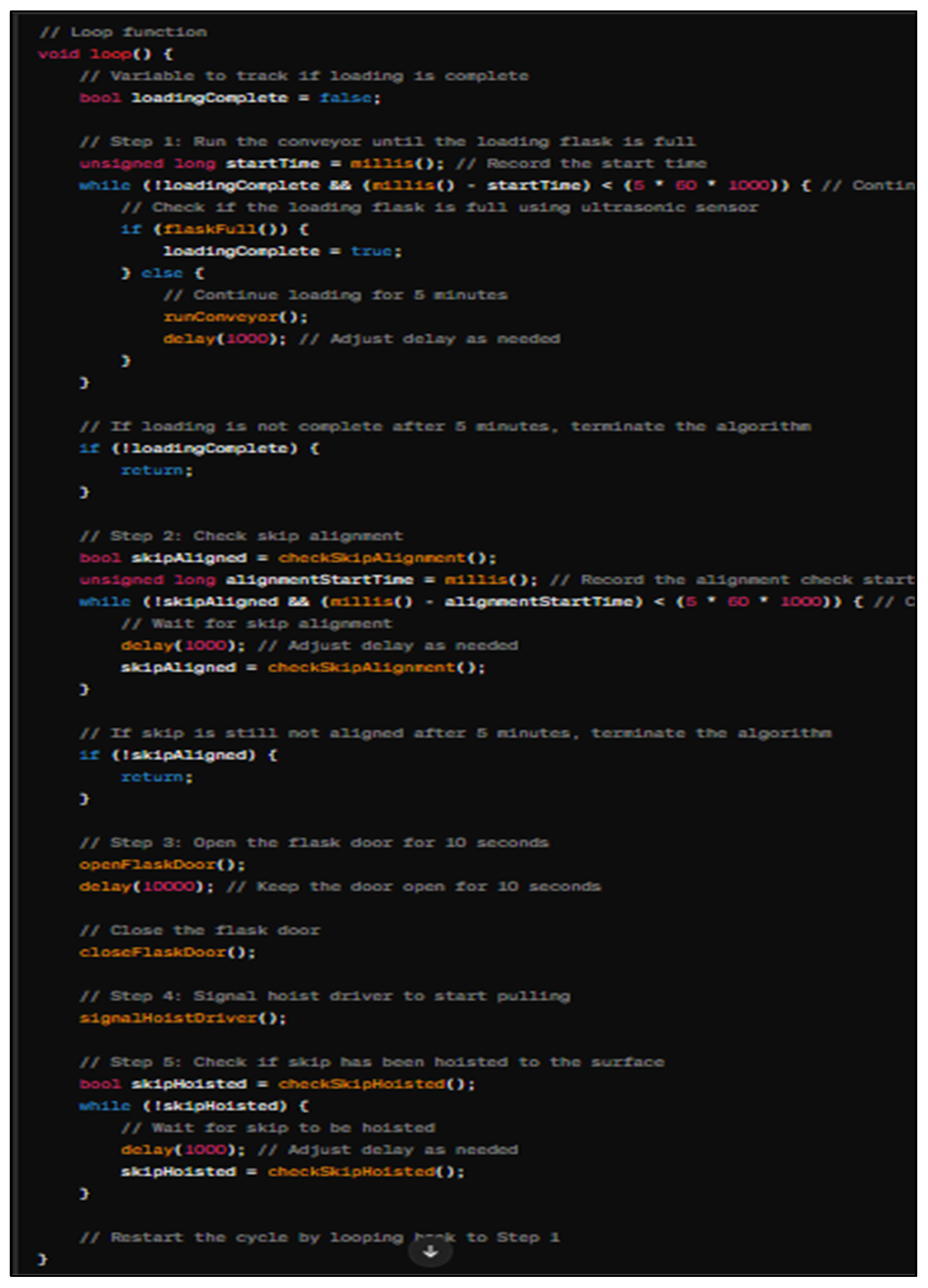

Controller Programming Results

The controller was programmed using the C++ programming language. The algorithm executes the following processes: ore handling and loading flask control, skip loading and positioning, conveyor and flask door control, ore loading and hoisting initiation, hoisting and unloading, skip lowering for repositioning, and iteration until no more ore is detected. The control algorithm follows the sequence outlined in the flowchart presented in

Figure 4.

Figure 5 presents the code structure in the C++ language, which was programmed into the system. The code below consists of backup functions that can be tailored to specific sensors and actuators.

3.4. Design Validation Results

In this study, design validation was conducted through digital simulations, with a primary emphasis on physical prototyping to assess the performance of the automated skip-loading system. For the prototype, an Arduino Mega 2560 microcontroller, a 3D-printed circuit board, weight and volume sensors, and stepper motors were used to establish a reliable platform for testing the system’s efficiency and functionality. Upon completion of the prototype, rigorous testing was carried out under various operating conditions to evaluate its performance and operational parameters.

The newly designed system is expected to reduce loading time by 12%, primarily by replacing the traditional bell signal exchanges between the bottom bellman and the hoist driver with direct communication via sensors. As the study focused on prototyping rather than full-scale industrial implementation, a conservative approach was adopted in the calculations, using current operational metrics to account for potential inefficiencies.

It is important to note that the automated loading system ensures more accurate ore reporting and tonnage measurement, thereby supporting precise achievement of daily targets. Additionally, the system is projected to improve hoisting system utilization by 16.6%, owing to its ability to operate during the 2 h re-entry period effectively minimizing skip idle time compared to the existing manual system.

Figure 6 presents a comparison of ore hoisting hours between the current system and the proposed automated system, while

Table 3 outlines the expected hoisting parameters for the automated skip-loading system.

3.5. Prototyping Results

In prototyping the automated system, an Arduino Mega 2560 microcontroller was used as the central controller, while a 3D-printed circuit board facilitated custom connectivity and component layout. Key components included weight sensors to measure the ore load, volume sensors to detect the capacity of the loading flask, and stepper motors to enable precise mechanical movements. This combination provided a robust foundation for evaluating the system’s efficiency and functionality.

Following the assembly of the prototype, rigorous testing was carried out to verify the system’s reliability, accuracy, and overall effectiveness under conditions simulating real-world operation. The developed system prototype is illustrated in

Figure 7.

3.6. Cost–Benefit Results

The automated ore loading system required a total capital investment of $2,353,135. This includes the purchase and installation of key equipment such as conveyor belts, belt scales, vibro-feeders, motors, load and volume sensors, programmable logic controllers (PLCs), and associated wiring components. Structural modifications—such as flask replacements, ore bin upgrades, and the conversion of the headgear system to self-tipping unloading were also accounted for. Labor costs for engineers, technicians, and assistants, along with logistics expenses for shipping and local transportation, were included in the investment. It is important to note that the automated system is not intended to replace human labor; rather, existing operators will be trained to supervise and monitor the system from the control room.

During the installation phase, the mine is expected to incur a revenue loss of approximately $1,439,935 due to operational downtime. However, the system is projected to increase hoisting capacity by 50 tonnes per day, resulting in an estimated annual revenue gain of $3,008,460—based on a gold price of $70,000/kg (as of 22 May 2024), a head grade of 2.9 g/t, and a processing plant efficiency of 95%.

A detailed breakdown of the costs and projected revenue associated with the automated loading system is provided in

Table 4.

To evaluate the long-term financial viability of the Modernization of Hoisting Operations Through the Design of an Automated Skip Loading System—Enhancing Efficiency and Sustainability, a Net Present Value (NPV) analysis was conducted. This analysis quantifies the expected return on investment by comparing projected cost savings and efficiency gains against the initial capital and installation costs over the system’s operational lifespan.

The Net Present Value (NPV) is calculated using Equation (2):

An interest rate (i) of 10% was applied, with a project lifespan of n = 4 years, based on the current life-of-mine as determined from the proven reserves. The detailed NPV calculation is presented as follows:

These results yield a final Net Present Value (NPV) of US

$1,019,701. The analysis confirms the project’s financial viability, as it produces a positive NPV over the 4-year operational period based on the current Life of Mine (LOM).

Table 5 presents the corresponding payback period analysis.

As shown in

Table 5, the project achieves a positive cash flow within 2 years and 11 months from the initial investment date, with a Return on Investment (ROI) of 69.7% over 4 years.

3.7. Sensitivity Analysis

The sensitivity analysis in

Table 6 revealed the project’s exposure to key variables affecting its economic performance. Gold price variation emerged as the most critical factor: a 20% increase in price resulted in a best-case NPV of US

$3.53 million, while a 20% decrease drove the project into negative returns with an NPV of US

$1.49 million.

Ore grade variation was modeled at ±10%, based on internal mine planning prediction metrics derived from geological data, which account for uncertainties in grade control and orebody characteristics. Within this range, a 10% increase in grade yielded an NPV of US$1.97 million, while a 10% decrease reduced the NPV to just US$66,061 highlighting the project’s strong dependence on accurate geological forecasting and grade control.

Regarding installation downtime, the best-case scenario assumes zero downtime, which is achievable if the mine builds sufficient surface stockpiles prior to the installation process to ensure uninterrupted ore feed to the processing plant. Under these conditions, the project achieves an NPV of US$2.46 million. Conversely, the worst-case scenario two months of installation delay without mitigation results in an NPV of US$420,232, emphasizing the importance of proactive planning to minimize operational disruptions.

4. Conclusions

The study found that, due to loading delays, ore miscounting, and human error, the current system, limited by manual processes, was only able to utilize 91.6% of its capacity and consistently failed to meet the daily hoisting target of 380 tons. To address these issues and ensure a smooth, efficient loading process, a newly designed automated system was introduced. This system features a bin and conveyor setup, a programmable logic controller (PLC) for precise operational control, and ultrasonic sensors for accurate ore measurement.

Automation has significantly improved ore-handling efficiency, reducing idle time by 12% and increasing system utilization by 16.6%. A cost–benefit analysis confirmed the project’s economic viability, showing a Net Present Value (NPV) of US$1,019,701, a return on investment (ROI) of 69.7%, and positive cash flow achieved within two years and eleven months. Sensitivity analysis indicated that the project’s performance is particularly influenced by variations in gold price, ore grade, and installation downtime.

To further optimize hoisting operations, the study recommended upgrading the headgear to a self-tipping unloading system, adopting Kimberley skips for faster tipping, fully automating the loading process for real-time control and consistency, and installing rock breakers at tramming-level grizzlies to maintain continuous ore flow. Overall, the study’s findings confirm that automating skip loading significantly enhances operational throughput, reduces labor dependency, improves safety, and ensures accurate ore tonnage tracking.

Author Contributions

K.B.S.: Writing—review & editing, Writing—original draft, Visualization, Methodology, Investigation, Formal analysis, Conceptualization. R.M. (Rejoice Moyo): Writing—review & editing, Writing—original draft, Visualization, Supervision, Methodology, Investigation, Formal analysis, Conceptualization. R.M. (Richard Masethe): Writing—review & editing, Supervision, Methodology, Investigation, Formal analysis. T.Z.: Writing—review & editing, Supervision, Methodology, Investigation, Formal analysis. M.O.: Writing—review & editing, Supervision, Methodology. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding, and the APC was funded by the University of KwaZulu-Natal.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Acknowledgments

The authors extend their gratitude to the Mining and Electrical Engineering Department at Midlands State University, for their valuable technical contributions to this project. Special thanks are also given to the mining practitioners whose direct and indirect support played a vital role in the success of this research.

Conflicts of Interest

The authors declare no conflicts of interest, and the funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Fernandez, N.; Brambley, M.R.; Katipamula, S.; Cho, H.; Goddard, J.; Dinh, L. Self-Correcting HVAC Controls Project Final Report; Pacific West National Laboratories, US Department of Energy: Richland, WA, USA, 2009; pp. 35–36.

- Peters, B. Automated Systems. In CIE IGCSE Computer Science Revision Notes; Save My Exams: London, UK, 2023. [Google Scholar]

- Automation Community. What is a Human Machine Interface (HMI)? Types, Advantages. Automation Community, 30 December 2023. Available online: https://automationcommunity.com/human-machine-interface/ (accessed on 22 March 2024).

- Dong, L.; Nguang, S. Consensus Tracking of Multi-Agent Systems with Switching Topologies; Elsevier: Amsterdam, The Netherlands, 2020; pp. 29–35. [Google Scholar]

- Sethi, P.; Sarangi, S.R. Internet of Things: Architectures, Protocols, and Applications. J. Electr. Comput. Eng. 2017, 2017, 9324035. [Google Scholar] [CrossRef]

- Hyder, Z.; Siau, K.; Nah, F. Artificial Intelligence, Machine Learning, and Autonomous Technologies in Mining Industry. J. Database Manag. 2019, 30, 67–79. [Google Scholar] [CrossRef]

- Sanchez, F.; Hartlieb, P. Innovation in the Mining Industry: Technological Trends and a Case Study of the Challenges of Disruptive Innovation. Min. Metall. Explor. 2020, 37, 1385–1399. [Google Scholar] [CrossRef]

- Caledonia Mining Corporation PLC. 2025 Operations. Available online: https://www.caledoniamining.com/operations/blanket-gold-mine/ (accessed on 21 May 2024).

- Mining Technology, Sweden. Mining Technology. Mining-Technology.com. 20 August 2020. Available online: https://www.mining-technology.com/projects/kiruna/?cf-view (accessed on 1 March 2024).

- Rail-Veyor. RailVeyor™ Material Haulage System Hauls Over 10 Million Tonnes at Agnico Eagle’s Goldex Mine. RailVeyor, 3 December 2022. Available online: https://www.railveyor.com/news/railveyor-material-haulage-system-hauls-over-10-million-tonnes-at-agnico-eagles-goldex-mine/ (accessed on 25 April 2024).

- DeLorenzo, L. The Transformational Technology behind Rio Tinto’s Most Advanced Mine. Mining Magazine, 18 December 2022. Available online: https://miningmagazine.com.au/the-transformational-technology-behind-rio-tintos-most-advanced-mine/ (accessed on 23 March 2024).

- Rio Tinto. Annual Report 2020: Strategic Report; Rio Tinto: London, UK, 2021; Available online: https://www.riotinto.com/invest/reports (accessed on 8 June 2025).

- BHP. BHP and Microsoft Use AI to Lift Escondida Copper Recovery. BHP.com 2023. Available online: https://www.bhp.com/news/media-centre/releases/2023/05/bhp-and-microsoft-use-ai-to-lift-escondida-copper-recovery (accessed on 22 March 2024).

- Moore, P. Anglo American Starts Autonomous Haulage at Los Bronces Copper Mine in Chile. International Mining, 19 May 2022. Available online: https://im-mining.com/2022/05/19/anglo-american-starts-autonomous-haulage-at-los-bronces-copper-mine-in-chile/ (accessed on 2 April 2024).

- Slater, D. Zim Mine Sets Production Record. Mining Weekly, 15 December 2023. Available online: https://www.miningweekly.com/article/zim-mine-sets-production-record-2023-12-15 (accessed on 25 April 2024).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).