Electricity Cost Forecasting in the South African Mining Industry: A Gap Analysis

Abstract

1. Introduction

1.1. Background

1.2. Problem Statement

1.3. Aim & Scope

2. Literature on Mine Electricity Cost Forecasting

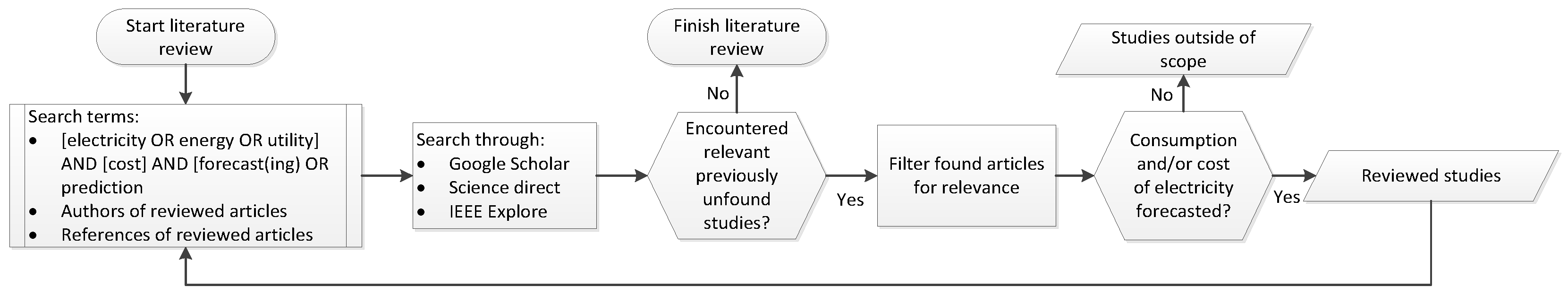

2.1. Search Strategy

2.2. Existing Electricity Cost Budgets

2.2.1. Step 1: Inform

2.2.2. Step 2: Data

2.2.3. Step 3: Evaluate

2.2.4. Step 4: Develop

2.2.5. Step 5: Convert

2.2.6. Step 6: Report and Approve

2.3. Summary of Literature

- Adjustments to the baseline electricity usage data should be made using knowledge of planned increases in electricity consumption by each energy-intensive system. Adjustments should also be made to account for changes between the TOU of the baseline period and the future period being budgeted for. All this should be overseen by a person with in-depth knowledge of the electricity usage patterns of the mine. This method should ultimately be easily scalable. Costs should then be assigned to the electricity budget using the relevant utility costing structure.

- The developed budget should be validated using past data and knowledge about planned future changes to ensure its accuracy. Changes made to the input data should be well documented. The validated budgets and supporting documents should thereafter be approved by a responsible entity. The budget should be reported in an easily accessible manner using visual mediums.

- Input: The collection and evaluation of all data and information required for the budgeting process.

- Method: The processing of the data collected in the “Input” into electricity profiles and costs.

- Output: The presentation of the results of the “Method” to relevant parties.

3. Methods

3.1. Determining Best Practices for Electricity Cost Budgets on Mines

3.1.1. Input

- (a)

- Budgets should be developed per energy intensive system.

- (b)

- Input data should be in a half-hourly resolution.

- (c)

- Input data should be of verifiable quality.

- (d)

- Electricity usage data should be used for most systems. Production data can be used for systems directly related to processing or hoisting.

- (e)

- Relevant data should be used to adjust the historic electricity usage baseline.

3.1.2. Method

- (a)

- Budgets should be developed by a person with established knowledge of the energy management systems of the mining operation.

- (b)

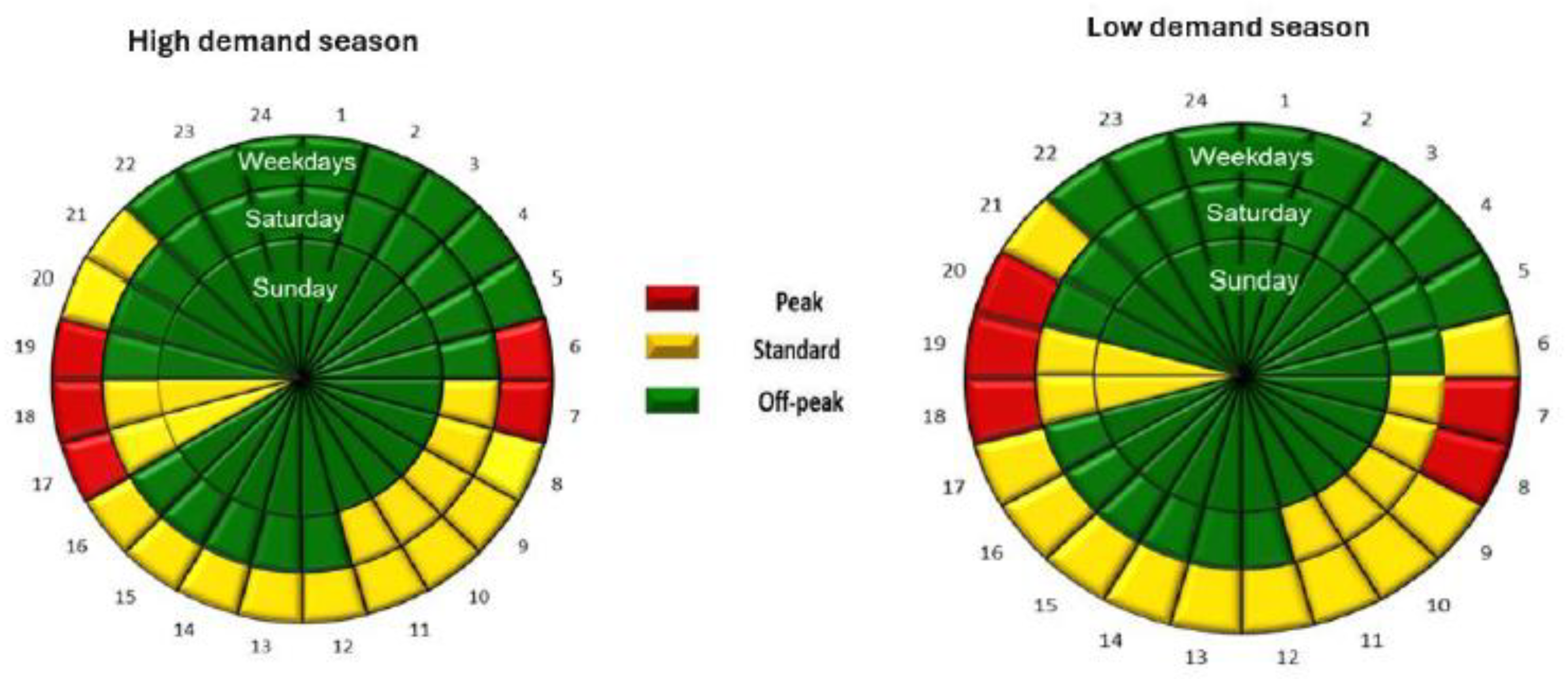

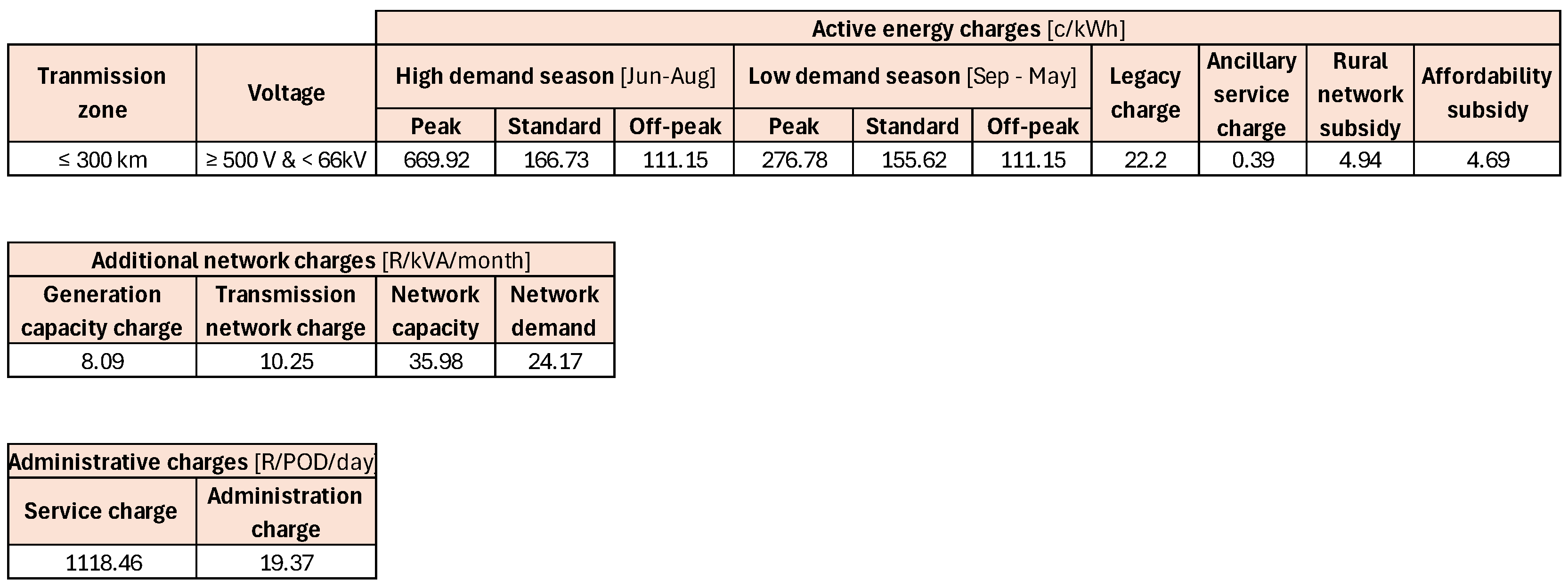

- Time-of-use should be accounted for in the development of the electricity budget.

- (c)

- Tariff structures from the relevant utility company should be used to assign costs to electricity forecasts. In the case of most South African mines this is the Eskom Megaflex tariff structure.

- (d)

- The budgeting method should be scalable and adaptable.

- (e)

- Developed budgets (electricity and cost) should be validated before being presented for use.

3.1.3. Output

- (a)

- The developed budget should be available per energy intensive system.

- (b)

- The developed budget should be available in at least an hourly resolution.

- (c)

- Costs and effective tariffs should be available per energy intensive system and should have different tariffs according to their operation.

- (d)

- Planned deviations from historic electricity usage patterns should be well documented for traceability.

- (e)

- Developed budgets should be presented in a concise manner and visualized in an appropriate way for the intended audience.

3.2. Survey Development

- At least two years of experience with mine budget cycles.

- Have some knowledge of the entire budget development process.

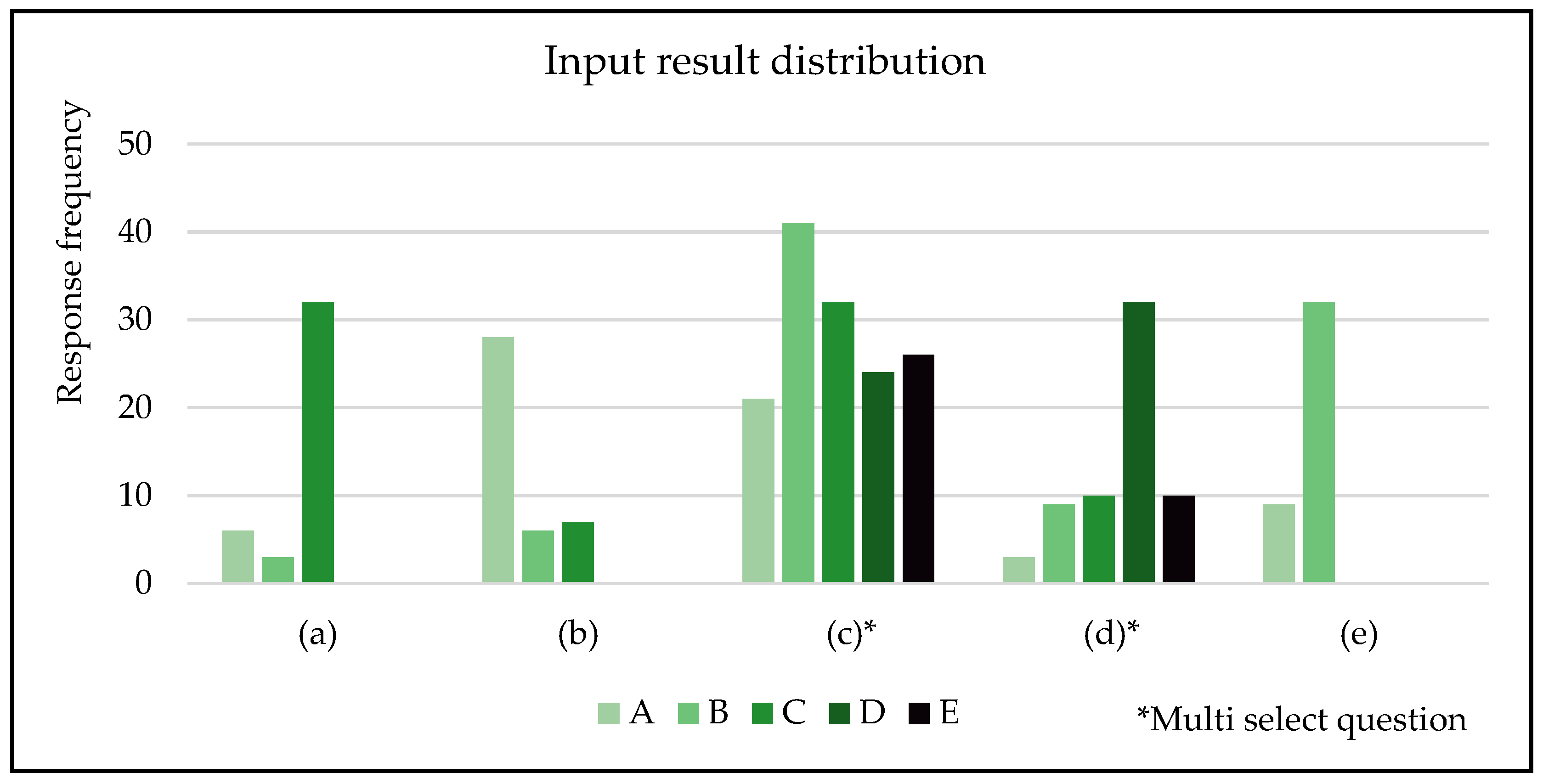

4. Industry Performance vs. Best Practice Results

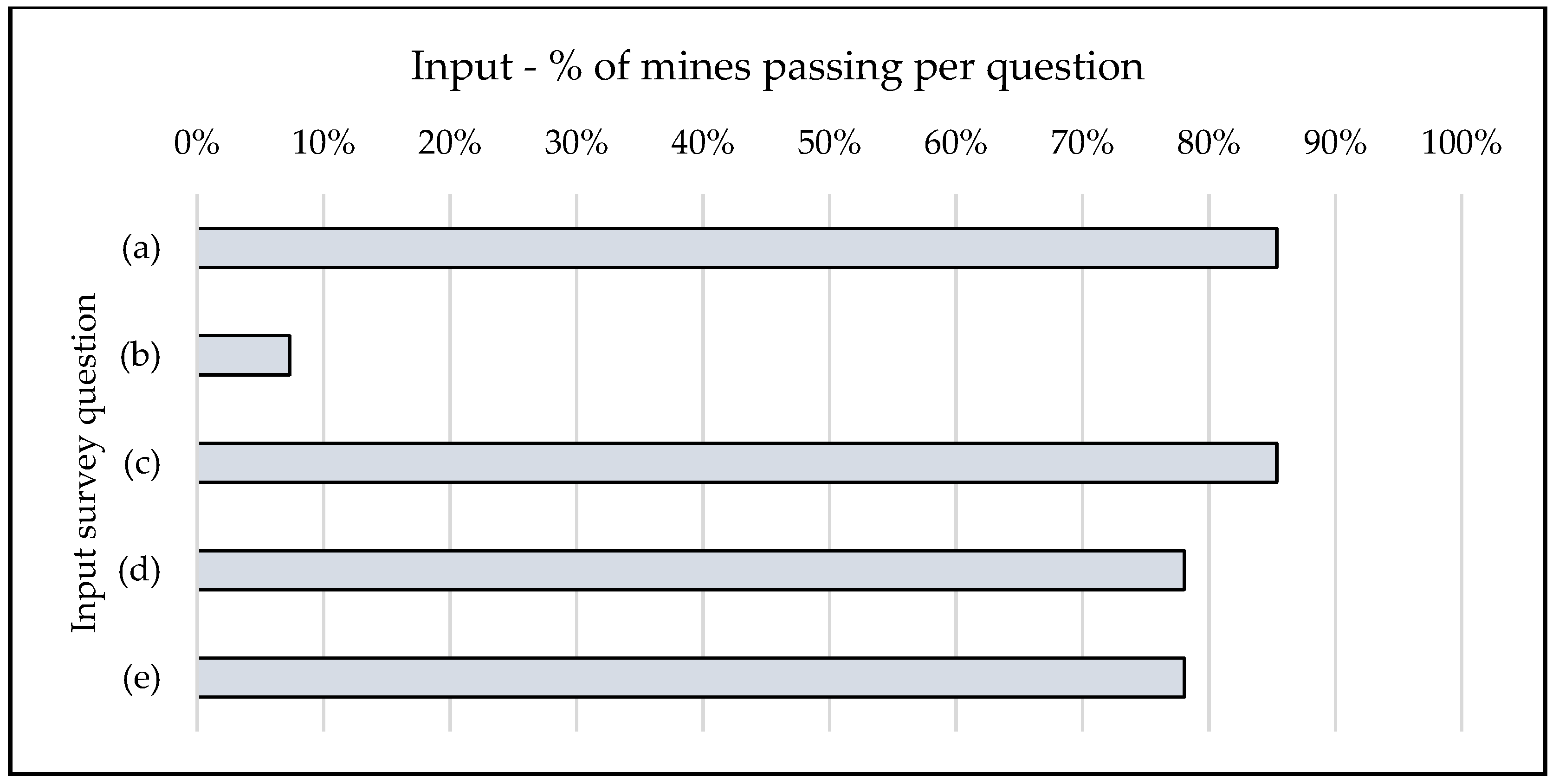

4.1. Input

- (a)

- Most of the mines surveyed (78%) develop budgets per energy intensive system. The remaining sites develop them per feeder or for the whole POD. To pass, the input data should be split at least per feeder, as 85% of the mines have done.

- (b)

- The utilization of monthly input data during the budgeting processes was most prominent. Only seven mines used half-hourly data as input for their budgeting process. Input data needs to be half-hourly to align with best practices.

- (c)

- The surveys found that the input data used to develop electricity cost budgets on mines is generally of high quality. All the mines surveyed contract third party metering companies where data quality is a contractual obligation. For half of the business units, data is from calibrated meters. For best practices, at least two data quality checks should be present in the process.

- (d)

- The majority of sites (78%) used electricity usage data to account for planned changes. Some of the surveyed sites (9/41) uses production data as the only input for their budget development and did not align with best practices.

- (e)

- 78% of the surveyed sites utilized planned electricity usage increases to plan for future changes, while 9 of the 41 sites relied on production scaling. Production scaling for systems other than hoisting and processing is not in line with best practices.

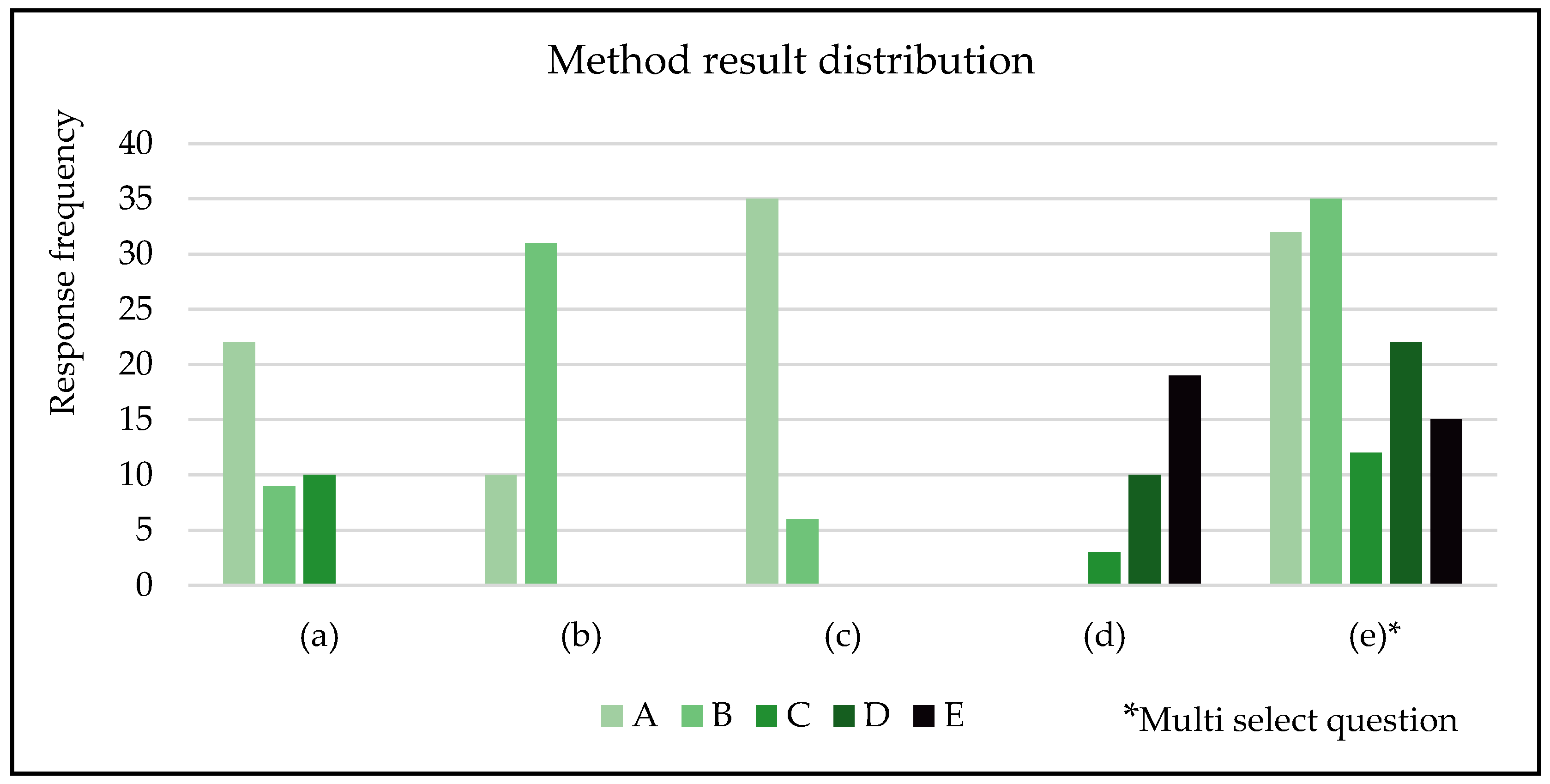

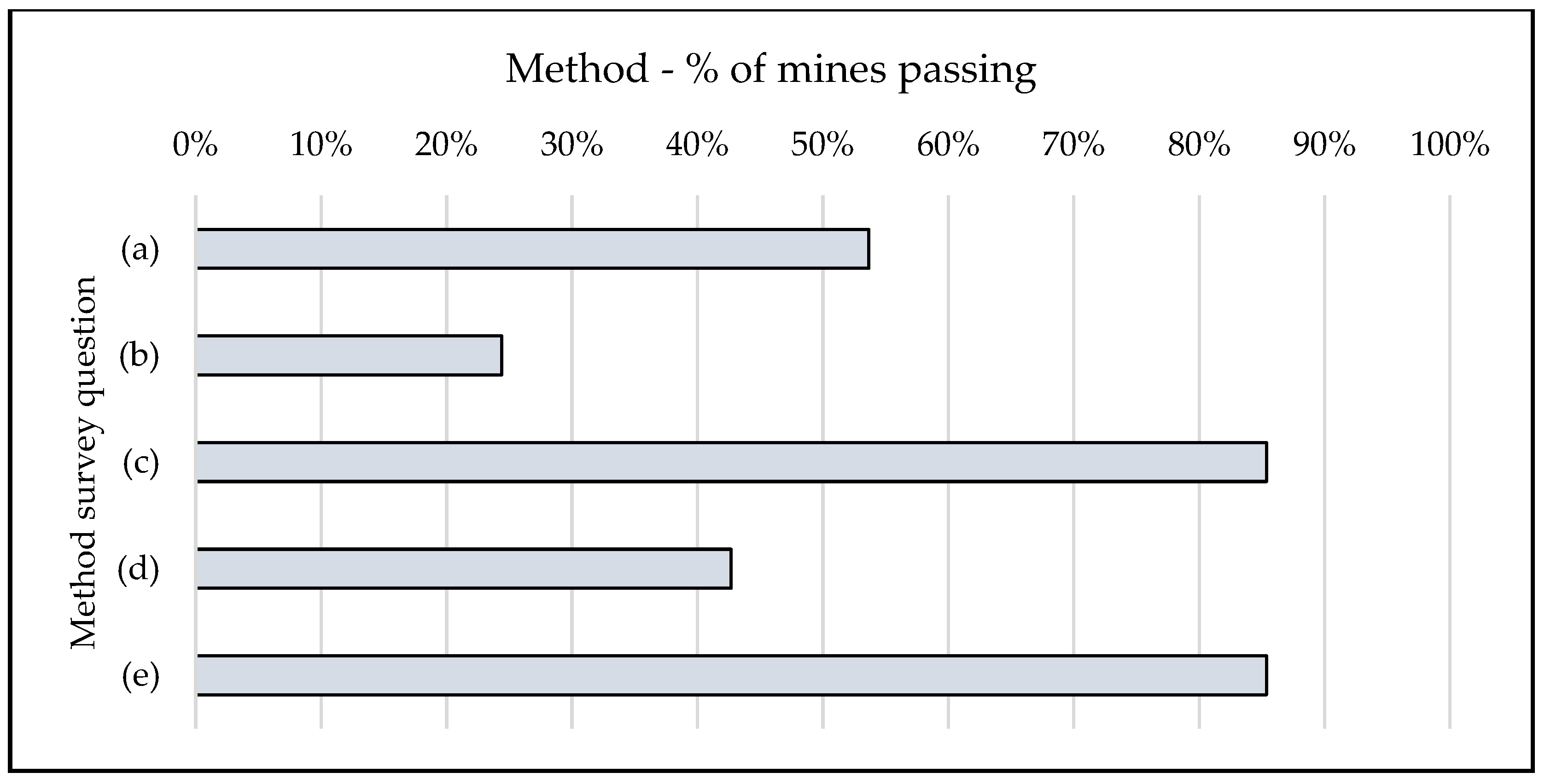

4.2. Method

- (a)

- For most mines, electricity cost budget development is done by the engineering department. The remaining mines had budgets developed by their respective financial departments, or by third party companies involved in the energy management of the mines. For best practices, the mine’s engineering department should be either fully responsible for, or at least heavily involved in, the development of the budget.

- (b)

- As 68% of mines only used monthly data as their input, they could not account for TOU in detail using Megaflex tariffs to determine the cost of their budgets.

- (c)

- The mines interviewed all use similar methods to cost their developed electricity budgets. This involves using historical percentage splits for the TOU of active energy charges. The charges are then combined with historical fixed charges and multiplied with the expected tariff increase for the year. Only 6 of the 41 sites did account for TOU in the costing of their budgets using the official Eskom tariff structure. This could only be done because they started the budget process with at least hourly data.

- (d)

- On average, those surveyed rated their budgeting process as 9/10 in terms of how time consuming and tedious the process is. This is an indication that the methods are not scalable and would not easily adapt to a larger scale or other systems. There is a positive correlation between the sites who find the process less time-consuming and the sites that outsource the development of budgets.

- (e)

- Most budgets are validated before they are used. The majority of sites (85%) used at least two forms of validation. The most applied method was to compare the developed budget to past actual data and past budgets. Both internal and third-party validation is used. It is important to note that despite validation and checks being in place, errors in budgets do still occur. This is largely due to human error, amplified by the large volumes of budgets that often need to be developed in a short period of time, and due to the bulk of budget development being done in Excel, thus there are no built-in checking mechanisms.

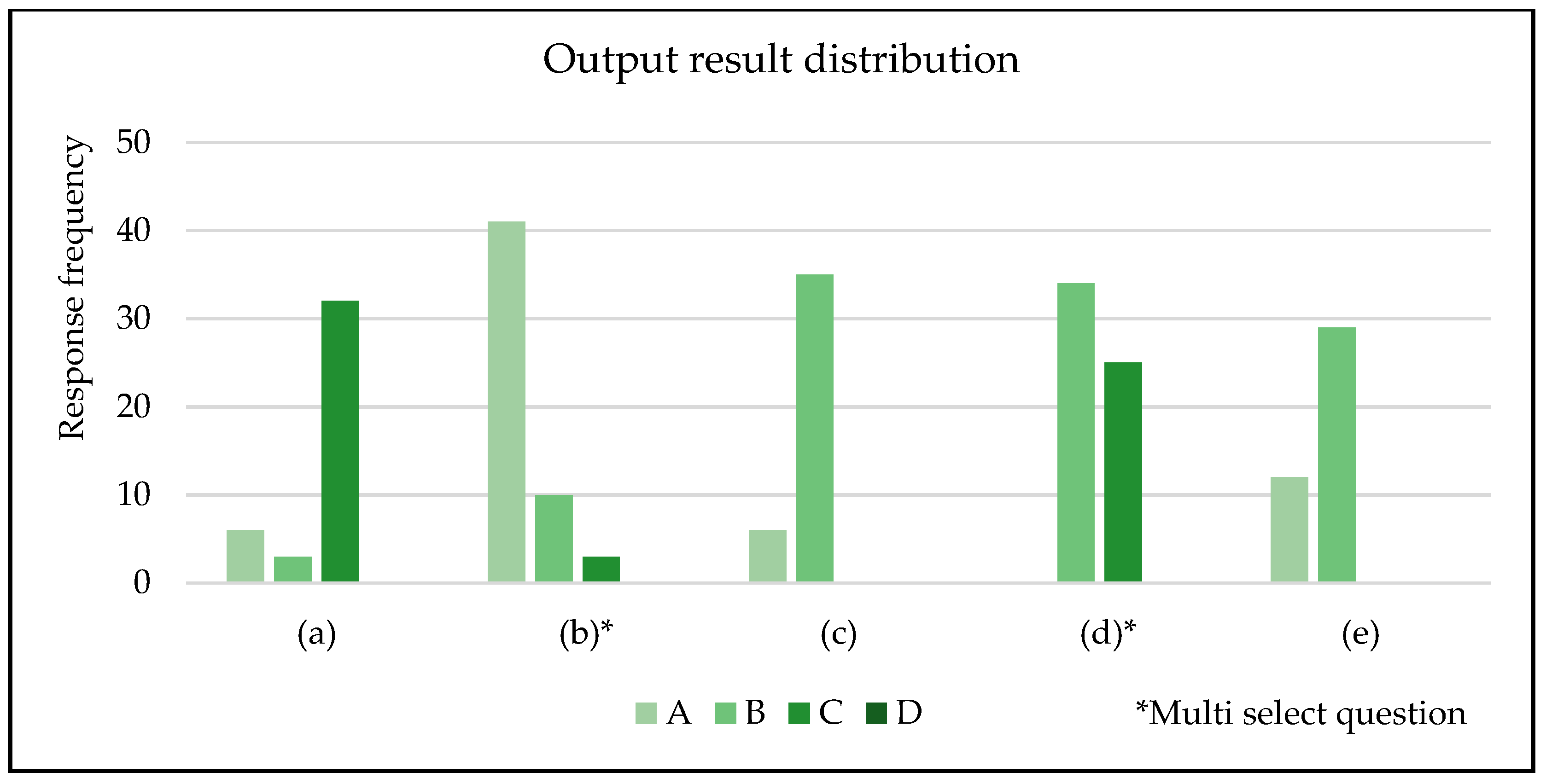

4.3. Output

- (a)

- In line with the inputs, most budgets were developed per energy intensive system or feeder (85%).

- (b)

- The budgets developed by the mines surveyed were mostly available in a monthly resolution due to the monthly inputs used. All mines presented their budgets in a monthly format, even if it was also available in higher resolutions. Some sites used daily data only for data cleaning, and still developed a monthly budget. Ten sites developed daily budgets, and three sites developed half-hourly budgets.

- (c)

- Most sites split their budget cost beyond the POD level. Unfortunately, most do this by just splitting the cost by percentage, not using TOU. 6/41 sites used TOU and have individual tariffs per energy intensive system.

- (d)

- Only 29% of mines surveyed formally reported on specific changes made to baseline input data. There is a correlation between mines who formally document the budgeting process and mines using third party companies to develop their budgets.

- (e)

- All surveyed mines used visualization to present developed budgets, and most had various types of formats used to present the budgets, depending on who it is presented to. Effective reporting requires a combination of values and visuals, as done by 82% of participants.

5. Discussion

5.1. Results Summary

5.2. Next Steps

5.3. Alignment with Sustainable Development Goals (SDGs)

- Affordable and Clean Energy (SDG 7): The focus on improving electricity cost forecasting and energy management supports the goal of ensuring access to affordable, reliable, sustainable, and modern energy for all.

- Industry, Innovation, and Infrastructure (SDG 9): Enhancing the budgeting processes and adopting best practices in electricity management contributes to resilient infrastructure, promoting inclusive and sustainable industrialization and innovation.

- Responsible Consumption and Production (SDG 12): By improving energy management and reducing inefficiencies, the study supports sustainable consumption and production.

6. Conclusions

- Input data resolution.

- Improvement will allow improved costing by allowing TOU costing. This will improve the cost results as well.

- Improvement will result in a high-resolution result.

- Budget method scalability.

- Currently, manual methods are relied on.

- Investigations into advanced forecasting methods, their applicability and scalability are recommended to identify suitable solutions.

- Process and result documentation.

- Improvement of documentation practices throughout the process will improve the quality and traceability of the budgets and allow for repeatability of methods.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| GDP | Gross Domestic Product |

| M&V | Measurement and Verification |

| NMD | Notified Maximum Demand |

| POD | Point of Delivery |

| SDG | Sustainable Development Goal |

| TOU | Time-of-Use |

| UN | United Nations |

Appendix A

Appendix A.1. Budgeting Process Questionnaire

Appendix A.1.1. Input

- (a)

- To what level of the operation is the input data separated? (s)

- A.

- Incomer/POD

- B.

- Feeders

- C.

- Systems

- D.

- Components

- (b)

- What is the resolution of the input data? (s)

- A.

- Monthly

- B.

- Daily

- C.

- Half-hourly

- D.

- Other

- (c)

- How is the quality of the input data ensured? (q, m)

- A.

- Calibrated meters

- B.

- Independent checks

- C.

- Incident tracking

- D.

- Outlier elimination

- E.

- External validation—data used for reporting etc.

- (d)

- What input data is used in the budget creation process? (m)

- A.

- Historic tonnes with fixed kWh/t

- B.

- Planned tonnes with fixed kWh/t

- C.

- Historic energy budgets

- D.

- Historic actual energy data

- E.

- Combination of tonnes and energy data

- (e)

- How are planned changes budgeted for? (q, s)

- A.

- Using increased tonnes (rate kWh/t)

- B.

- Using increased energy

- C.

- Not budgeted for

- D.

- Other

Appendix A.1.2. Method

- (a)

- Who is responsible for budget development? (q, s)

- A.

- Engineering department

- B.

- Financial department

- C.

- Third party company

- (b)

- Are adjustments made to the input data to account for changes in TOU between the baseline period and future budget period (for example when the baseline month has more weekdays than the future budget month)? (s)

- A.

- Yes

- B.

- No

- (c)

- Is costing split into systems? (s)

- A.

- Yes

- B.

- No

- (d)

- On a scale of 1–10, where 1 is very quick and 10 is very time consuming, how time-consuming is the current budgeting process? (q, s)

- A.

- 0–2

- B.

- 3–4

- C.

- 5–6

- D.

- 7–8

- E.

- 9–10

- (e)

- How is the budget output validated? (q, m)

- A.

- Compare to past actual data

- B.

- Compare to past budget data

- C.

- Internal validation process

- D.

- Third party validation process

- E.

- Validated in use

Appendix A.1.3. Output

- (a)

- To what level of the operation is the budget separated? (s)

- A.

- Incomer/POD

- B.

- Feeders

- C.

- Systems

- D.

- Components

- (b)

- What is the resolution of the created budget? (m)

- A.

- Monthly

- B.

- Daily

- C.

- Hourly

- D.

- Half hourly

- E.

- Other

- (c)

- Are the final costs split into systems according to TOU? (q, s)

- A.

- Yes

- B.

- No

- (d)

- How is the budget presented? (q, m)

- A.

- Values only

- B.

- Values and visual medium

- C.

- Values, visuals and summary of changes

- D.

- Other

- (e)

- Is the budget process formally documented? (q, s)

- A.

- Yes

- B.

- No

References

- World Population Review Cost of Electricity by Country: 2025. Available online: https://worldpopulationreview.com/country-rankings/cost-of-electricity-by-country (accessed on 10 May 2025).

- Ateba, B.B.; Prinsloo, J.J.; Gawlik, R. The significance of electricity supply sustainability to industrial growth in South Africa. Energy Rep. 2019, 5, 1324–1338. [Google Scholar] [CrossRef]

- Davidse, A.; Swart, A.; Padisetti, K.; Ivory, N.; Tyagi, S. Driving Value Through Energy Management in Mining. Deloitte the Bottom Line; Deloitte: London, UK, 2016. [Google Scholar]

- Neingo, P.N.; Tholana, T. Trends in productivity in the South African gold mining industry. J. S. Afr. Inst. Min. Metall. 2016, 116, 283–290. [Google Scholar] [CrossRef]

- Eskom. Schedule of Standard Prices for Eskom Tariffs 2025/26; Eskom Holdings SOC Ltd.: Sandton, South Africa, 2025. [Google Scholar]

- Hong, T.; Pinson, P.; Wang, Y.; Weron, R.; Yang, D.; Zareipour, H. Energy forecasting: A review and outlook. IEEE Open Access J. Power Energy 2020, 7, 376–388. [Google Scholar] [CrossRef]

- Minerals Council of South Africa. Facts and Figures Pocketbook 2023. Available online: https://www.mineralscouncil.org.za/special-features/1374-facts-and-figures-pocketbook-2023 (accessed on 4 April 2025).

- Goosen, P. The Development and Implementation of an Energy Management Information System for Industries. Ph.D. Thesis, North-West University, Potchefstroom, South Africa, 2020. [Google Scholar]

- Avancini, D.B.; Rodrigues, J.J.P.C.; Martins, S.G.B.; Rabêlo, R.A.L.; Al-Muhtadi, J.; Solic, P. Energy meters evolution in smart grids: A review. J. Clean. Prod. 2019, 217, 702–715. [Google Scholar] [CrossRef]

- Zhou, K.; Fu, C.; Yang, S. Big data driven smart energy management: From big data to big insights. Renew. Sustain. Energy Rev. 2016, 56, 215–225. [Google Scholar] [CrossRef]

- Mystakidis, A.; Koukaras, P.; Tsalikidis, N.; Ioannidis, D.; Tjortjis, C. Energy forecasting: A comprehensive review of techniques and technologies. Energies 2024, 17, 1662. [Google Scholar] [CrossRef]

- Jeong, K.; Koo, C.; Hong, T. An estimation model for determining the annual energy cost budget in educational facilities using SARIMA and ANN. Energy 2014, 71, 71–79. [Google Scholar] [CrossRef]

- Fan, G.F.; Wei, X.; Li, Y.T.; Hong, W.C. Forecasting electricity consumption using a novel hybrid model. Sustain. Cities Soc. 2020, 61, 102320. [Google Scholar] [CrossRef]

- Zhao, A.; Chen, M.; Quan, W.; Zhang, S. A hybrid forecasting model for general hospital electricity consumption based on mixed signal decomposition. Energy Build. 2024, 325, 115006. [Google Scholar] [CrossRef]

- Patyk, M.; Bodziony, P. Empirical analysis of mining costs amid energy price volatility for secondary deposits in quarrying. Energies 2024, 17, 718. [Google Scholar] [CrossRef]

- Baker, K.J.; Rylatt, R.M. Improving the prediction of UK domestic energy-demand using annual consumption-data. Appl. Energy 2008, 85, 475–482. [Google Scholar] [CrossRef]

- Gonzales Chavez, S.; Xiberta Bernat, J.; Llaneza Coalla, H. Forecasting of energy production and consumption in Asturias (northern Spain). Energy 1999, 24, 183–198. [Google Scholar] [CrossRef]

- Lee, T.K.; Kim, J.U. A cost-effective and heuristic approach for building energy consumption prediction: BES model calibration and forecasting algorithm. Energy Build. 2024, 303, 113800. [Google Scholar] [CrossRef]

- Zhao, X.; Gao, W.; Qian, F.; Ge, J. Electricity cost comparison of dynamic pricing model based on load forecasting in home energy management system. Energy 2021, 229, 120538. [Google Scholar] [CrossRef]

- Işık, G.; Öğüt, H.; Mutlu, M. Deep learning based electricity demand forecasting to minimize the cost of energy imbalance: A real case application with some fortune 500 companies in Türkiye. Eng. Appl. Artif. Intell. 2023, 118, 105664. [Google Scholar] [CrossRef]

- Krishnamurthy, S.; Adewuyi, O.B.; Luwaca, E.; Ratshitanga, M.; Moodley, P. Artificial intelligence-based forecasting models for integrated energy system management planning: An exploration of the prospects for South Africa. Energy Convers. Manag. X 2024, 24, 100772. [Google Scholar] [CrossRef]

- Vassiljeva, K.; Matson, M.; Belikov, J.; Petlenkov, E. Profiling and schedule based forecast of electricity usage to improve energy performance of administrative buildings. In Proceedings of the 2024 IEEE International Conference on Engineering, Technology, and Innovation (ICE/ITMC), Funchal, Portugal, 17–20 June 2024. [Google Scholar] [CrossRef]

- Pelser, C. Improved Energy Budgeting Process for Mines Using Measurement and Verification Principles. Ph.D. Thesis, North-West University, Potchefstroom, South Africa, 2021. [Google Scholar]

- Goosen, P.; Pelzer, R.; du Plessis, H.J. A method for accurate electricity budget cost calculations for a deep mine. In Proceedings of the 2015 International Conference on the Industrial and Commercial Use of Energy (ICUE), Cape Town, South Africa, 18–19 August 2015. [Google Scholar] [CrossRef]

- Laayati, O.; Bouzi, M.; Chebak, A. Smart energy management: Energy consumption metering, monitoring and prediction for mining industry. In Proceedings of the 2020 IEEE 2nd International Conference on Electronics, Control, Optimization and Computer Science (ICECOCS), Kenitra, Morocco, 2–3 December 2020. [Google Scholar] [CrossRef]

- Bredenkamp, J.I.G.; Mathews, M.J.; Vosloo, J.C. An integrated energy management strategy for the deep-level gold mining industry. In Proceedings of the 2016 International Conference on the Industrial and Commercial Use of Energy (ICUE), Cape Town, South Africa, 16–17 August 2016. [Google Scholar]

- Amasyali, K.; El-Gohary, N.M. A review of data-driven building energy consumption prediction studies. Renew. Sustain. Energy Rev. 2018, 88, 297–325. [Google Scholar] [CrossRef]

- Pitis, C. New approach on energy conservation measures types applied in mining industry. In Proceedings of the 2016 IEEE Electrical Power and Energy Conference (EPEC), Ottawa, ON, Canada, 12–14 October 2016. [Google Scholar] [CrossRef]

- Agioutanis, Z.; Luxbacher, K.; Karmis, M.; Schafrik, S. Development of an atmospheric data-management system for underground coal mines. J. S. Afr. Inst. Min. Metall. 2014, 114, 1059–1063. [Google Scholar]

- Debnath, K.B.; Mourshed, M. Forecasting methods in energy planning models. Renew. Sustain. Energy Rev. 2018, 88, 297–325. [Google Scholar] [CrossRef]

- Marinakis, V. Big data for energy management and energy-efficient buildings. Energies 2020, 13, 1555. [Google Scholar] [CrossRef]

- Shen, H.; Bednarz, T.; Nguyen, H.; Feng, F.; Wyeld, T.; Hoek, P.J.; Lo, E.H. Information visualisation methods and techniques: State-of-the-art and future directions. J. Ind. Inf. Integr. 2019, 16, 100102. [Google Scholar] [CrossRef]

| Step Number | Details |

|---|---|

| Identify boundaries and select resolution |

| Obtain data |

| Calculate expected changes |

| Construct the operational budget |

| Convert the developed usage budget to cost |

| Approve and sign off developed budget |

| Literature Section | Contents | Budget Component |

|---|---|---|

| Boundary selection | Input |

| Data collection | Input | |

| Output boundary selection | Output | |

| Data quality evaluation | Input |

| Adjustments for planned changes | Method |

| Profile creation | Method |

| Costing | Method |

| Result validation | Method |

| Result documentation | Output | |

| Result presentation | Output |

| Question | Budget Component Evaluated |

|---|---|

| Input (a), Output (a) |

| Input (b), Output (b) |

| Input (c) |

| Input (d), Input (e) |

| Input (f) |

| Method (a) |

| Method (b) |

| Method (c) |

| Method (d) |

| Method (e) |

| Output (c) |

| Output (d) |

| Output (e) |

| Problem | Section | Focus Area | Performance | |

|---|---|---|---|---|

| Mines are not implementing methods for accurate electricity cost forecasting available from literature in practice. | Input | (a) | Budgets should be developed per energy-intensive system. | >80% |

| (b) | Input data should be in at least an hourly resolution. | <50% | ||

| (c) | Input data should be of verifiable quality. | >80% | ||

| (d) | Electricity usage data should be used for most systems. | 50–80% | ||

| (e) | Production data can be used for certain systems. | 50–80% | ||

| (f) | Relevant data should be used for adjustments to the baseline. | 50–80% | ||

| Method | (a) | Budget should be developed by an informed person. | 50–80% | |

| (b) | TOU should be accounted for. | <50% | ||

| (c) | Relevant tariff structure should be applied. | >80% | ||

| (d) | Method should be scalable and adaptable. | <50% | ||

| (e) | Results should be validated. | >80% | ||

| Output | (a) | Result should be per energy intensive system. | >80% | |

| (b) | Result should be in at least hourly resolution. | <50% | ||

| (c) | Cost and tariff should be separate per system. | <50% | ||

| (d) | Deviations from historic patterns should be documented. | <50% | ||

| (e) | Results should be well presented and visualized. | >80% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cronje, A.; van Laar, J.H.; van Rensburg, J.F.; Vosloo, J.C. Electricity Cost Forecasting in the South African Mining Industry: A Gap Analysis. Mining 2025, 5, 34. https://doi.org/10.3390/mining5020034

Cronje A, van Laar JH, van Rensburg JF, Vosloo JC. Electricity Cost Forecasting in the South African Mining Industry: A Gap Analysis. Mining. 2025; 5(2):34. https://doi.org/10.3390/mining5020034

Chicago/Turabian StyleCronje, Andrea, Jean H. van Laar, Johann F. van Rensburg, and Jan C. Vosloo. 2025. "Electricity Cost Forecasting in the South African Mining Industry: A Gap Analysis" Mining 5, no. 2: 34. https://doi.org/10.3390/mining5020034

APA StyleCronje, A., van Laar, J. H., van Rensburg, J. F., & Vosloo, J. C. (2025). Electricity Cost Forecasting in the South African Mining Industry: A Gap Analysis. Mining, 5(2), 34. https://doi.org/10.3390/mining5020034