Heat Emissions from Mining Machinery: Implications for Microclimatic Conditions in Underground Workings

Abstract

:1. Introduction

- Rock mass temperature, as determined by the geothermal characteristics of the area and the history of heat transfer between the mine air and rock mass.

- Temperature and humidity of the atmospheric air at the surface.

- Hydrostatic compression or expansion of air when moving along vertical or inclined mine workings.

- Moisture condensation and absorption in the air.

- Latent heat of ore oxidation.

- Heat exchange with compressed air pipelines.

- Metabolic heat produced by miners.

- Local sources of heat: mechanized equipment (machines, fans), blasting operations, and heat from the hydration of backfill materials.

- The energy used to perform useful work by the engine.

- Energy consumed in the form of heat loss through the exhaust system.

- Energy released in the form of heat loss through the cooling system and the motor housing.

2. Experimental Study of the Thermal Regime of Mines

2.1. Objects of Study

- Copper–nickel mines of the Talnakh and Oktyabrsky deposits in the Norilsk industrial region, which use room-and-pillar methods with full backfilling of the worked-out area and the drilling-and-blasting technique.

- Potash mines of the Starobinsky deposit in the Republic of Belarus, which use the board-and-pillar method with long working faces and complete collapse of the worked-out area—mechanized mining.

- A potash mine of the Gremyachinskoye deposit in the Volgograd region, which uses the room-and-pillar method with full backfilling of the worked-out area—combination of mechanized mining and drilling-and-blasting operations.

2.2. Experimental Techniques and Tools

- Temperature Humidity Meter Fluke 971. The absolute error in measuring the temperature in the interval from −20 °C to +60 °C is 0.1 °C and the absolute error in measuring the relative humidity in the interval from 5 to 95% is 2.5%. Purpose: measurement of air temperature and relative humidity in mine workings.

- Infrared and Contact Thermometer Fluke 568. The absolute measurement error of the infrared channel is ±0.1 °C for negative temperatures (t < 0 °C) and ±1.0 °C for positive temperatures (t > 0 °C). Purpose: determination of the surface temperature of the local sources of heat release.

- Anemometer APR-2, manufactured by the “NPF Ecotechinvest” company. The absolute error of the APR-2 anemometer is ∆ = 0.2 + 0.05v, where v is the air speed, m/s. Purpose: determination of the mean air velocity in the cross section of mine workings.

- Laser distance meter Leica DISTO D2. The absolute error of the distance measurements is 1.5 mm under normal conditions; under unfavorable conditions, such as bright sunlight or measuring uneven surfaces, ∆ = 0.15L mm (L is the measured length, m). Purpose: determination of the cross-sectional area of mine workings.

- Handheld weather station Kestrel 5000AG. Absolute error of temperature measurements: ±0.5 °C; absolute error of humidity measurements: ±2%. Purpose: measurement of the temporal dynamics of air temperature and humidity in the working areas of mines.

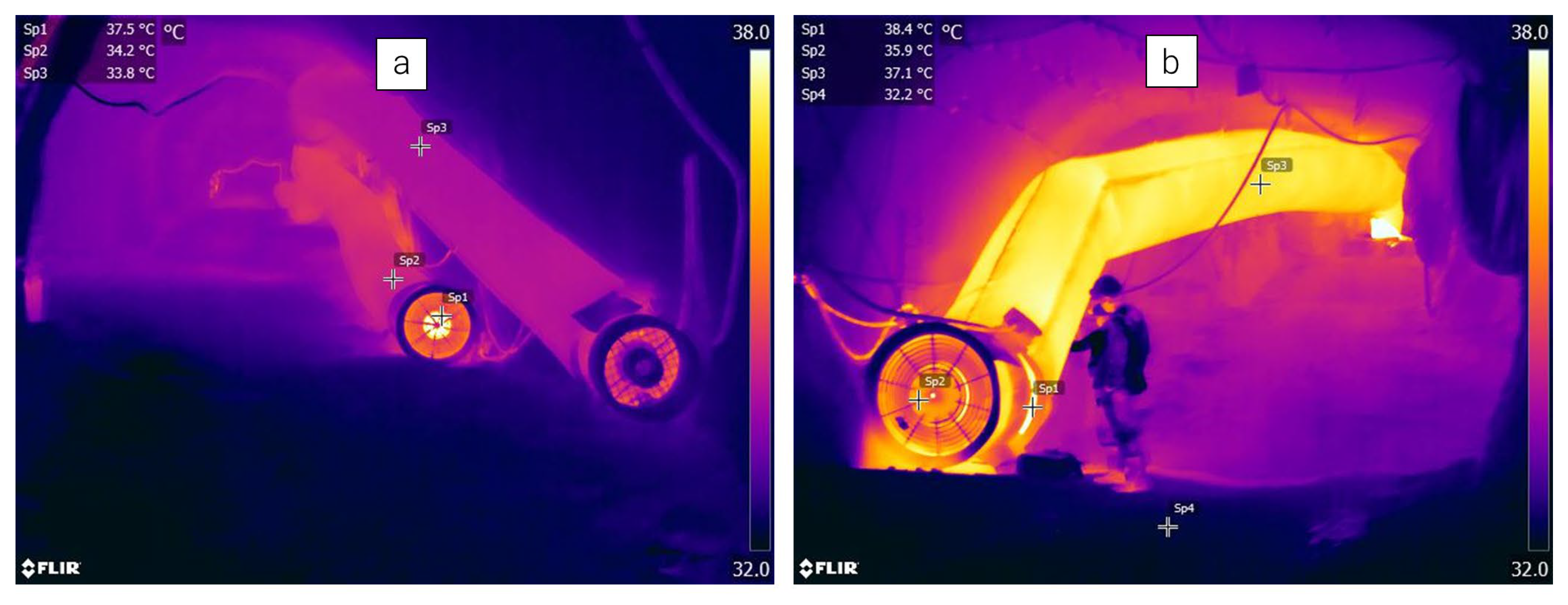

- FLIR 660 thermal imager. This portable device allows for measuring the temperature field with a spatial resolution of 640 by 480 points and has an acceptable accuracy (less than 2%) within the temperature range we consider in this study (from +2 to +50 °C). Purpose: determination of temperature distribution on the surfaces of heat sources.

2.3. Consolidated Results of Experimental Studies

3. Technogenic Sources of Heat Release in Mines

- Vehicles with ICEs;

- Vehicles with EEs;

- Auxiliary fans.

3.1. Vehicles with Internal Combustion Engines

- The difference between the actual power and the rated power of the vehicle;

- Variable load on the engine over time;

- The influence of moisture exchange processes (i.e., increasing the moisture content of the air);

- Partial absorption of released heat by the surrounding rocks at the section of the mine working between the measuring points.

3.2. Vehicles with Electric Engines

3.3. Conveyors with Electric Engines

- The difference between the actual power consumption and the rated one;

- Variable loads on the EEs;

- Partial absorption of heat release by the surrounding rock mass.

3.4. Auxiliary Fans

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shcherban, A.N.; Kremnev, O.A.; Zhuravlenko, V.Y. Guidance on Regulation of Thermal Regime of Mines; Nedra: Moscow, Russia, 1977. [Google Scholar]

- Zaitsev, A.V.; Levin, L.Y.; Kazakov, B.P.; Klyukin, Y.A. Thermotechnical systems for normalization of microclimate parameters in deep mines of Nornickel’s Polar Division. Gorn. Zhurnal 2018, 6, 34–40. [Google Scholar] [CrossRef]

- Qiaoyun, H.; Yi, Z.; Kongqing, L.; Shenghua, Z. Computational evaluation of cooling system under deep hot and humid coal mine in China: A thermal comfort study. Tunn. Undergr. Space Technol. 2019, 90, 394–403. [Google Scholar] [CrossRef]

- Wei, D.; Du, C.; Lin, Y.; Chang, B.; Wang, Y. Thermal environment assessment of deep mine based on analytic hierarchy process and fuzzy comprehensive evaluation. Case Stud. Therm. Eng. 2020, 19, 100618. [Google Scholar] [CrossRef]

- Feng, X.P.; Jia, Z.; Liang, H.; Wang, Z.; Wang, B.; Jiang, X.; Cao, H.; Sun, X. A full air cooling and heating system based on mine water source. Appl. Therm. Eng. 2018, 145, 610–617. [Google Scholar] [CrossRef]

- Brake, D.J. Mine Ventilation. A Practitioner’s Manual; Mine Ventilation Australia: Brisbane, Australia, 2012. [Google Scholar]

- Zhang, W.; Wang, T.; Zhang, D.; Tang, J.; Xu, P.; Duan, X. A Comprehensive Set of Cooling Measures for the Overall Control and Reduction of High Temperature-Induced Thermal Damage in Oversize Deep Mines: A Case Study. Sustainability 2020, 12, 2489. [Google Scholar] [CrossRef]

- Li, W.; Zou, S.; Yang, W.; Hu, Q. Model of Heat and Mass Exchange between a Downcast Shaft and the Air Flow to the Mine. Geofluids 2020, 2020, 8853839. [Google Scholar] [CrossRef]

- Lu, T.; Zhang, G.; Liu, S.; Zheng, B.; Zhang, X. Numerical investigation of the temperature field and thermal insulation design of cold-region tunnels considering airflow effect. Appl. Therm. Eng. 2021, 191, 116923. [Google Scholar] [CrossRef]

- Levin, L.Y.; Semin, M.A.; Zaitsev, A.V. Mathematical methods of forecasting microclimate conditions in an arbitrary layout network of underground excavations. J. Min. Sci. 2014, 50, 371–378. [Google Scholar] [CrossRef]

- Galkin, A.; Pankov, V. Forecasting of Thermal Regime in an Oil Mine. In Technological Advancements in Construction; Mottaeva, A., Ed.; Lecture Notes in Civil Engineering; Springer: Cham, Switzerland, 2022; Volume 180. [Google Scholar] [CrossRef]

- Zhu, S.; Wu, S.; Cheng, J.; Li, S.; Li, M. An underground air-route temperature prediction model for ultra-deep coal mines. Minerals 2015, 5, 527–545. [Google Scholar] [CrossRef]

- McPherson, M.J. Subsurface Ventilation and Environmental Engineering; Springer Science & Business Media: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Ghoreishi-Madiseh, S.A.; Hassani, F.; Mohammadian, A.; Abbasy, F. Numerical modeling of thawing in frozen rocks of underground mines caused by backfilling. Int. J. Rock Mech. Min. Sci. 2011, 48, 1068–1076. [Google Scholar] [CrossRef]

- Khokholov, Y.A.; Kurilko, A.S. Heat exchange of rock and filling masses in kimberlite mining. J. Min. Sci. 2004, 40, 31–36. [Google Scholar] [CrossRef]

- Nasir, O.; Fall, M. Modeling the heat development in hydrating CPB structures. Comput. Geotech. 2009, 36, 1207–1218. [Google Scholar] [CrossRef]

- Mazepa, E.E.; Kusainov, P.I.; Krainov, A.Y.; Lukashov, O.Y. Modeling the propagation of air blast waves in mine workings. J. Phys. Conf. Ser. 2021, 1749, 012041. [Google Scholar] [CrossRef]

- Baganina, A.E.; Paleev, D.Y.; Beglyakov, V.Y. Numerical Study of Shock Wave Interaction with Protective Stopping with Regard to the Type of Its Setting. Appl. Mech. Mater. 2015, 756, 465–468. [Google Scholar] [CrossRef]

- Kurnia, J.C.; Sasmito, A.P.; Wong, W.Y.; Mujumdar, A.S. Prediction and innovative control strategies for oxygen and hazardous gases from diesel emission in underground mines. Sci. Total Environ. 2014, 481, 317–334. [Google Scholar] [CrossRef]

- Sasmito, A.P.; Kurnia, J.C.; Birgersson, E.; Mujumdar, A.S. Computational evaluation of thermal management strategies in an underground mine. Appl. Therm. Eng. 2015, 90, 1144–1150. [Google Scholar] [CrossRef]

- Nie, X.; Wei, X.; Li, X.; Lu, C. Heat treatment and ventilation optimization in a deep mine. Adv. Civ. Eng. 2018, 2018, 1529490. [Google Scholar] [CrossRef]

- McPherson, M.J. The analysis and simulation of heat flow into underground airways. Int. J. Min. Geol. Eng. 1986, 4, 165–195. [Google Scholar] [CrossRef]

- Maurya, T.; Karena, K.; Vardhan, H.; Aruna, M.; Raj, M.G. Potential sources of heat in underground mines—A review. Procedia Earth Planet. Sci. 2015, 11, 463–468. [Google Scholar] [CrossRef]

- Zheng, Y.; Lan, H.; Thiruvengadam, M.; Tien, J.C.; Li, Y. Effect of single dead end entry inclination on DPM plume dispersion. Int. J. Min. Sci. Technol. 2017, 27, 401–406. [Google Scholar] [CrossRef]

- Bugarski, A.D.; Cauda, E.G.; Janisko, S.J.; Hummer, J.A.; Patts, L.D. Aerosols emitted in underground mine air by diesel engine fueled with biodiesel. J. Air Waste Manag. Assoc. 2010, 60, 237–244. [Google Scholar] [CrossRef] [PubMed]

- Hargreaves, D.M.; Lowndes, I.S. The computational modeling of the ventilation flows within a rapid development drivage. Tunn. Undergr. Space Technol. 2007, 22, 150–160. [Google Scholar] [CrossRef]

- Thiruvengadam, M.; Zheng, Y.; Tien, J.C. DPM simulation in an underground entry: Comparison between particle and species models. Int. J. Min. Sci. Technol. 2016, 26, 487–494. [Google Scholar] [CrossRef]

- Zheng, Y.; Thiruvengadam, M.; Lan, H.; Tien, C.J. Effect of auxiliary ventilations on diesel particulate matter dispersion inside a dead-end entry. Int. J. Min. Sci. Technol. 2015, 25, 927–932. [Google Scholar] [CrossRef]

- Hansen, R. Analysis of methodologies for calculating the heat release rates of mining vehicle fires in underground mines. Fire Saf. J. 2015, 71, 194–216. [Google Scholar] [CrossRef]

- Li, C.; Zhang, H.; Li, M.; Zhang, C.; Wang, W.; Zhang, N.; Yuan, S.; Yang, W. Numerical study on dust suppression and cooling performance of an external spray system in load-haul-dump vehicles. Case Stud. Therm. Eng. 2021, 27, 101332. [Google Scholar] [CrossRef]

- Zaitsev, A.V.; Levin, L.Y.; Butakov, S.V.; Semin, M.A. Normalization of microclimate in deep potash mines. Gorn. Zhurnal 2018, 8, 97–102. [Google Scholar] [CrossRef]

- Roy, S.; Mishra, D.P.; Bhattacharjee, R.M.; Agrawal, H. Genetic programming for prediction of heat stress hazard in underground coal mine environment. Nat. Hazards 2022, 114, 2527–2543. [Google Scholar] [CrossRef]

- Semin, M.; Kormshchikov, D. Application of artificial intelligence in mine ventilation: A brief review. Front. Artif. Intell. 2024, 7, 1402555. [Google Scholar] [CrossRef]

- Abdel-Rahman, A.A. On the emissions from internal-combustion engines: A review. Int. J. Energy Res. 1998, 22, 483–513. [Google Scholar] [CrossRef]

- Pulkrabek, W. Engineering Fundamentals of the Internal Combustion Engine, 2nd ed.; Pearson: London, UK, 1955; 504p. [Google Scholar]

- Xin, S.; Wang, W.; Zhang, N.; Zhang, C.; Yuan, S.; Li, H.; Yang, W. Comparative studies on control of thermal environment in development headings using force/exhaust overlap ventilation systems. J. Build. Eng. 2021, 38, 102227. [Google Scholar] [CrossRef]

- Yi, H.; Kim, M.; Lee, D.; Park, J. Applications of Computational Fluid Dynamics for Mine Ventilation in Mineral Development. Energies 2022, 15, 8405. [Google Scholar] [CrossRef]

- Zhikharev, S.Y.; Tsygankov, V.D.; Rodionov, V.A.; Isaevich, A.G. Optimization of dust suppression processes during underground mining based on full-scale experimentation and ANSYS Fluent simulation. Gorn. Zhurnal 2023, 70–75. [Google Scholar] [CrossRef]

- Zhang, S.; Lu, P.; Wang, H. Numerical simulation analysis of unsteady temperature in thermal insulation supporting roadway. Math. Probl. Eng. 2019, 2019, 6279164. [Google Scholar] [CrossRef]

- Zhou, L.; Bahrami, D. A Derivative Method to Calculate Resistance Sensitivity for Mine Ventilation Networks. Min. Metall. Explor. 2022, 39, 1833–1839. [Google Scholar] [CrossRef]

- Semin, M.; Levin, L. Mathematical Modeling of Air Distribution in Mines Considering Different Ventilation Modes. Mathematics 2023, 11, 989. [Google Scholar] [CrossRef]

- Semin, M.; Zaitsev, A. On a possible mechanism for the water build-up formation in mine ventilation shafts. Therm. Sci. Eng. Prog. 2020, 20, 100760. [Google Scholar] [CrossRef]

- Danko, G.L. Subsurface flow and transport process model for time dependent mine ventilation simulations. Min. Technol. 2013, 122, 134–144. [Google Scholar] [CrossRef]

- Bascompta, M.; Sanmiquel, L.; Anticoi, H.F.; Oliva, J. Ventilation friction factor determination and comparison: Two case studies of potash mining. J. S. Afr. Inst. Min. Metall. 2019, 119, 865–870. [Google Scholar] [CrossRef]

- Gendler, S.G.; Sinyavina, S.V. Method of determining characteristics for air heating system in railway tunnels in harsh climatic conditions. J. Min. Inst. 2017, 224, 215–222. [Google Scholar]

| Vehicle Type and Name | Air Flow Rate, m3/s | Temperature Increase, °C | Power of Heat Emission, kW | Rated Power, kW | Maximum Heating Power from Fuel Combustion, kW | Coefficient |

|---|---|---|---|---|---|---|

| MoA3-7405-9586 dump truck | 17 | 5.6 | 123 | 140 | 336 | 0.31 |

| MT 433R dump truck | 21 | 8.9 | 242 | 260 | 723 | 0.28 |

| TORO 400D LHD | 19 | 6.7 | 165 | 170 | 473 | 0.30 |

| TORO 151D LHD | 18 | 3.9 | 91 | 110 | 244 | 0.32 |

| PAUS PFL30S LHD | 28 | 2.8 | 101 | 109 | 303 | 0.28 |

| ML-110 LHD | 23 | 6,4 | 191 | 235 | 540 | 0.30 |

| Sandvik LH-410 LHD | 30 | 5.0 | 194 | 235 | 540 | 0.31 |

| ST-14 LHD | 25 | 7.5 | 243 | 275 | 638 | 0.32 |

| ST-1030 LHD | 21 | 6.5 | 177 | 220 | 488 | 0.31 |

| Boomer H282 drilling rig | 18 | 3.0 | 70 | 80 | 177 | 0.34 |

| Sandvik DD311d drilling rig | 10 | 4.5 | 58 | 85 | 189 | 0.26 |

| Mean value: | 0.3 | |||||

| Vehicle Type and Name | Rated Power, kW | Power of Heat Emission, kW | Coefficient |

|---|---|---|---|

| SL-300/400 cutter–loader | 1901 * | 72 | 0.038 |

| SL-500C cutter–loader | 1749 * | 84 | 0.048 |

| Ural-20R cutter–loader | 710 | 28 | 0.039 |

| Ural-20R cutter–loader | 710 | 24 | 0.034 |

| Sandvik DD311 drilling rig | 70 | 5 | 0.071 |

| DHMS BTP1-P drilling rig | 110 | 13 | 0.118 |

| Mean value: | 0.058 | ||

| Conveyor Drive | Air Flow Rate, m3/s | Temperature Increase, °C | Power of Heat Emission, kW | Rated Power, kW | Coefficient |

|---|---|---|---|---|---|

| KLSh-1000 | 5.1 | 1.8 | 12 | 150 | 0.080 |

| KLSh-1000 | 3.9 | 1.9 | 10 | 150 | 0.067 |

| KLSh-1000 | 2.8 | 3.0 | 11 | 150 | 0.073 |

| KL-600 | 4.1 | 1.1 | 6 | 150 | 0.040 |

| KL-600 | 2.0 | 3.0 | 8 | 150 | 0.053 |

| Mean value: | 0.063 | ||||

| Fan | Air Flow Rate, m3/s | Temperature Increase, °C | Power of Heat Emission, kW | Rated Power, kW | Coefficient |

|---|---|---|---|---|---|

| VME-6 | 7 | 2.6 | 23 | 25 | 0.92 |

| VME-8 | 10 | 3.7 | 47 | 50 | 0.94 |

| VME-10 | 15 | 5.30 | 101 | 110 | 0.91 |

| VME-12 | 21 | 4.1 | 109 | 110 | 0.99 |

| KorfmannGAL 7-300/300 | 8 | 5.2 | 54 | 60 | 0.90 |

| FBD No. 8.0/2*55 | 13 | 3.0 | 49 | 55 | 0.89 |

| Mean value: | 0.93 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaitsev, A.; Parshakov, O.; Semin, M. Heat Emissions from Mining Machinery: Implications for Microclimatic Conditions in Underground Workings. Mining 2024, 4, 1075-1092. https://doi.org/10.3390/mining4040059

Zaitsev A, Parshakov O, Semin M. Heat Emissions from Mining Machinery: Implications for Microclimatic Conditions in Underground Workings. Mining. 2024; 4(4):1075-1092. https://doi.org/10.3390/mining4040059

Chicago/Turabian StyleZaitsev, Artem, Oleg Parshakov, and Mikhail Semin. 2024. "Heat Emissions from Mining Machinery: Implications for Microclimatic Conditions in Underground Workings" Mining 4, no. 4: 1075-1092. https://doi.org/10.3390/mining4040059

APA StyleZaitsev, A., Parshakov, O., & Semin, M. (2024). Heat Emissions from Mining Machinery: Implications for Microclimatic Conditions in Underground Workings. Mining, 4(4), 1075-1092. https://doi.org/10.3390/mining4040059