Physical and Numerical Modeling of a Flow Control Layer Made with a Sludge and Slag Mixture for Use in Waste Rock Pile Reclamation

Abstract

:1. Introduction

1.1. Mine Site Reclamation

1.1.1. Oxygen Barrier

- The elevated water table combined with a monolayer cover technique aims to maintain reactive tailings saturated or close to saturation (Sr = 1) by keeping the water table at a higher level and close to interface cover-reactive tailings. This technique is similar to water covers in that it provides a barrier to oxygen migration [10,11,12];

1.1.2. Hydraulic Barrier

1.1.3. Flow Control Layer

2. Materials and Methods

2.1. Physical Characterization

2.2. Hydrogeological Characterization

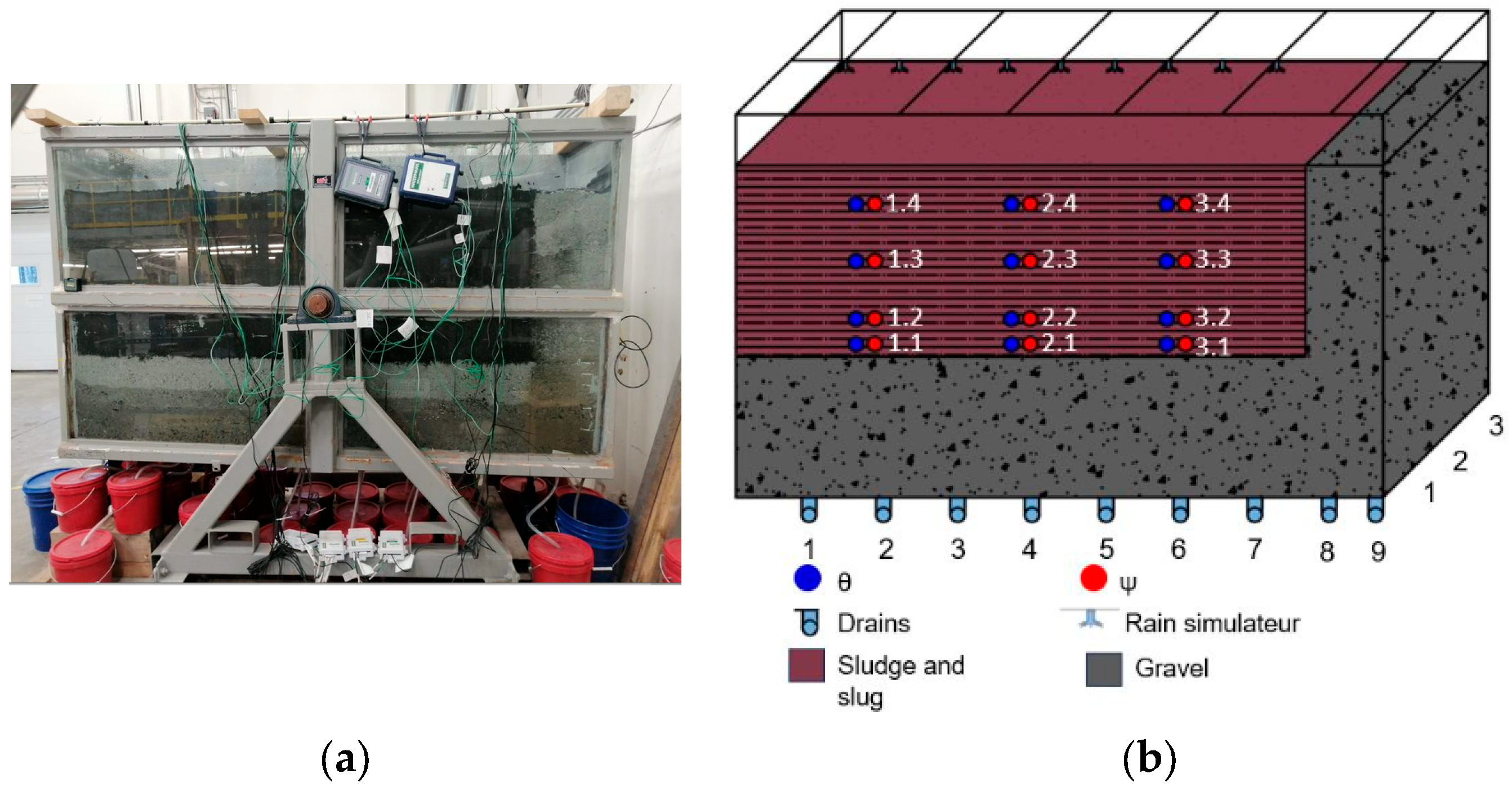

2.3. Experimental Setup and Physical Modeling

2.4. Numerical Simulation Modeling

3. Results

3.1. Infiltration and Runoff

3.2. Volumetric Water Content and Suction

3.3. Numerical Simulation Results

4. Final Remark

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kahlaoui, S. Évaluation des Échanges Hydrogéochimiques Entre un parc à Résidus Miniers et les Aquifères Périphériques. Ph.D. Thesis, Polytechnique Montréal, Montréal, QC, Canada, 2022. [Google Scholar]

- Aubertin, M.; Pabst, T.; Bussière, B.; James, M.; Mbonimpa, M.; Benzaazoua, M.; Maqsoud, A. Revue des meilleures pratiques de restauration des sites d’entreposage de rejets miniers générateurs de DMA. In Proceedings of the Symposium 2015 Sur L’environnement et les Mines, Rouyn-Noranda, QC, Canada, 14–17 June 2015. [Google Scholar]

- Bossé, B.; Bussière, B.; Hakkou, R.; Maqsoud, A.; Benzaazoua, M. Field experimental cells to assess hydrogeological behaviour of store-and-release covers made with phosphate mine waste. Can. Geotech. J. 2015, 52, 1255–1269. [Google Scholar] [CrossRef]

- Knidiri, J.; Bussière, B.; Hakkou, R.; Bossé, B.; Maqsoud, A.; Benzaazoua, M. Hydrogeological behaviour of an inclined store-and-release cover experimental cell made with phosphate mine wastes. Can. Geotech. J. 2017, 54, 102–116. [Google Scholar] [CrossRef]

- Wilson, G.W.; Williams, D.J.; Rykaart, E.M. The integrity of cover systems—An update. In Proceedings of the 6th International Conference for Acid Rock Drainage, Cairns, QLD, Australia, 14–17 July 2003; Australian Institute of Mining & Metallurgy: Carlton, VIC, Australia, 2003; pp. 445–451. [Google Scholar]

- Zhan, G.; Mayer, A.; McMullen, J.; Aubertin, M. Capillary cover design for a spent leach pad. In Proceedings of the International Symposium on Hydrogeology and the Environment, Wuhan, China, 17 October 2000; pp. 17–21. [Google Scholar]

- El Hamidi, M.-J.; Maqsoud, A.; Belem, T.; Viger, M.-E.; Çiner, A.; Khari, M.F.; Kallel, M.; Rodrigo-Comino, J.; Parise, M.; Barzagar, R.; et al. A Kinetic test method to assess the long-term acid generation behavior of sludge/slag and mine tailings of Quemont 2 (Quebec, Canada). In Recent Research on Sedimentology, Stratigraphy, Paleontology, Geochemistry, Volcanology, Tectonics, and Petroleum Geology, Advances in Science, Technology & Innovation; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Amyot, G.; Vézina, S. Flooding as a reclamation solution to an acidic tailings pond-the Solbec case. In Proceedings of the 4th International Conference on Acid Rock Drainage, Vancouver, BC, Canada, 31 May–6 June 1997; Volume 31, pp. 681–696. [Google Scholar]

- Awoh, A.S. Étude Expérimentale du Comportement Géochimique de Résidus Miniers Hautement Sulfureux Sous un Recouvrement en Eau; Universite du Quebec en Abitibi-Temiscamingue (Canada): Rouyn-Noranda, QC, Canada, 2012. [Google Scholar]

- Demers, I. Performance d’une Barrière à L’oxygène Constituée de Résidus Miniers Faiblement Sulfureux Pour Contrôler la Production de Drainage Minier Acide; Université du Québec en Abitibi-Témiscamingue: Rouyn-Noranda, QC, Canada, 2008. [Google Scholar]

- Ethier, M.-P. Évaluation de la Performance d’un Système de Recouvrement Monocouche Avec Nappe Surélevée Pour la Restauration d’un parc à Résidus Miniers Abandonné; Université du Québec en Abitibi-Témiscamingue: Rouyn-Noranda, QC, Canada, 2018. [Google Scholar]

- Ouangrawa, M.; Aubertin, M.; Molson, J.; Zagury, G.; Bussière, B. An evaluation of the elevated water table concept using laboratory columns with sulphidic tailings. In Proceedings of the Geosask2005, 58th Canadian Geotechnical Conference and 6th Joint IAHC-NC, Saskatoon, SK, Canada, 18–21 September 2005. [Google Scholar]

- Aubertin, M.; Chapuis, R. Considérations hydro-géotechniques pour l’entreposage des résidus miniers dans le nord-ouest du Québec. In Proceedings of the Second International Conference on the Abatement of Acidic Drainage, Montreal, QC, Canada, 16–18 September 1991; MEND/Canmet. Volume 3, pp. 1–22. [Google Scholar]

- Nicholson, R.V.; Gillham, R.W.; Cherry, J.A.; Reardon, E.J. Reduction of acid generation in mine tailings through the use of moisture-retaining cover layers as oxygen barriers. Can. Geotech. J. 1989, 26, 1–8. [Google Scholar] [CrossRef]

- Ricard, J.; Aubertin, M.; Firlotte, F.; Knapp, R.; McMullen, J.; Julien, M. Design and construction of a dry cover made of tailings for the closure of Les Terrains Aurifères site, Malartic, Québec, Canada. In Proceedings of the 4th International Conference on Acid Rock Drainage, Vancouver, BC, Canada, 31 May–6 June 1997; Volume 31, pp. 1515–1530. [Google Scholar]

- Rakotonimaro, T.V.; Neculita, C.M.; Bussière, B.; Benzaazoua, M.; Zagury, G.J. Recovery and reuse of sludge from active and passive treatment of mine drainage-impacted waters: A review. Environ. Sci. Pollut. Res. 2017, 24, 73–91. [Google Scholar] [CrossRef] [PubMed]

- Tassé, N.; Germain, D.; Dufour, C.; Tremblay, R. Le recouvrement de résidus organiques au parc East Suillivan: Au delà de la barrière d’oxygène. In Proceedings of the Colloque sur le Programme de Neutralisation des Eaux de Drainage dans l’Environnement Minier, Rouyn-Noranda, QC, Canada, 29–30 October 1996; Ministère des Ressources Naturelles Quebec: Québec, QC, USA, 1996; pp. 106–128. [Google Scholar]

- Albright, W.H.; Benson, C.H.; Gee, G.W.; Abichou, T.; McDonald, E.V.; Tyler, S.W.; Rock, S.A. Field performance of a compacted clay landfill final cover at a humid site. J. Geotech. Geoenviron. Eng. 2006, 132, 1393–1403. [Google Scholar] [CrossRef]

- Maqsoud, A.; Bussière, B.; Mbonimpa, M. Low saturated hydraulic conductivity covers. In Hard Rock Mine Reclamation: From Prediction to Management of Acid Mine Drainage; Bussière, B., Guittonny, M., Eds.; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Rarison, R.F. Évaluation des Propriétés Chimiques, Mécaniques et Hydrogéologiques de Géomembranes Utilisées Comme Matériaux de Recouvrement Pour Restaurer des Sites Miniers en Milieu Froid et Acide; Polytechnique Montréal: Montréal, QC, Canada, 2021. [Google Scholar]

- Aubertin, M.; Cifuentes, E.; Apithy, S.; Bussière, B.; Molson, J.; Chapuis, R. Analyses of water diversion along inclined covers with capillary barrier effects. Can. Geotech. J. 2009, 46, 1146–1164. [Google Scholar] [CrossRef]

- Bussière, B.; Plante, B.; Broda, S.; Aubertin, M.; Chen, D.; Medina, F. Contrôle des infiltrations d’eau dans les haldes à stériles à l’aide des effets de barrière capillaire: Design, construction et instrumentation de la halde expérimentale de la mine Tio. In Proceedings of the Symposium sur L’environnement et Les Mines, Rouyn-Noranda, QC, Canada, 14–17 June 2015; pp. 14–17. [Google Scholar]

- Dimech, A.; Chouteau, M.; Aubertin, M.; Bussière, B.; Martin, V.; Plante, B. Three-dimensional time-lapse geoelectrical monitoring of water infiltration in an experimental mine waste rock pile. Vadose Zone J. 2019, 18, 1–19. [Google Scholar] [CrossRef]

- Ait Khouia, A. Évaluation de la Capacité de Déviation Latérale de la Couche de Contrôle des Écoulements d’eau Dans un Modèle physique au Laboratoire; Ecole Polytechnique: Montreal, QC, Canada, 2018. [Google Scholar]

- Martin, V.; Bussière, B.; Plante, B.; Pabst, T.; Aubertin, M.; Medina, F.; Bréard-Lanoix, M.L.; Dimech, A.; Dubuc, J.; Poaty, B.; et al. Controlling water infiltration in waste rock piles: Design, construction, and monitoring of a large-scale in-situ pilot test pile. In Proceedings of the 70th Canadian Geotechnical Society Conference, Ottawa, ON, Canada, 1–4 October 2017; Volume 70. [Google Scholar]

- Crouzal, T.; Pabst, T. A black-box automated approach to calibrate numerical simulations and optimize cover design: Application to a flow control layer constructed on an experimental waste rock pile. Vadose Zone J. 2021, 20, e20130. [Google Scholar] [CrossRef]

- Dubuc, J. Étude du Comportement Hydrogéologique d’une Couche de Contrôle des Écoulements Placée à la Surface d’une Halde à Stériles Expérimentale; Ecole Polytechnique: Montreal, QC, Canada, 2018. [Google Scholar]

- Poaty, B.; Plante, B.; Bussière, B.; Benzaazoua, M. Assessment of hydrogeochemical behavior of layered waste rock stockpiles: A meso-scale laboratory experiment. Appl. Geochem. 2022, 136, 105154. [Google Scholar] [CrossRef]

- Raymond, K.E.; Seigneur, N.; Su, D.; Poaty, B.; Plante, B.; Bussière, B.; Mayer, K.U. Numerical modeling of a laboratory-scale waste rock pile featuring an engineered cover system. Minerals 2020, 10, 652. [Google Scholar] [CrossRef]

- Rossit, M. Utilisation des Stériles Miniers Concassés et Compactés Comme Couche de Contrôle des Écoulements Pour Contrôler le DMA; Ecole Polytechnique: Montreal, QC, Canada, 2020. [Google Scholar]

- Tremblay, D.; Robitaille, V. Mécanique des Sols: Théorie et Pratique, 2nd ed.; Groupe Modulo: Quebec, QC, Canada, 2014; ISBN 978-2-89650-627-9. [Google Scholar]

- ASTM D4318-17e1; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. American Society for Testing of Materials (ASTM): West Conshohocken, PA, USA, 2017.

- ASTM D1557-12(2021); Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft3 (2,700 kN-m/m3)). American Society for Testing of Materials (ASTM): West Conshohocken, PA, USA, 2021.

- Delage, P.; Cui, Y.-J. L’eau Dans les Sols; Edition Technique de l’ingénieur: Paris, France, 2000; Volume C2. [Google Scholar]

- ASTM D2434-22; Standard Test Methods for Measurement of Hydraulic Conductivity of Coarse-Grained Soils. American Society for Testing of Materials (ASTM): West Conshohocken, PA, USA, 2022.

- Van Genuchten, M.T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef]

- Aubertin, M.; Mbonimpa, M.; Bussière, B.; Chapuis, R.-P. A model to predict the water retention curve from basic geotechnical properties. Can. Geotech. J. 2003, 40, 1104–1122. [Google Scholar] [CrossRef]

- Mbonimpa, M.; Aubertin, M.; Bussière, B. Predicting the unsaturated hydraulic conductivity of granular soils from basic geotechnical properties using the modified Kovacs (MK) model and statistical models. Can. Geotech. J. 2006, 43, 773–787. [Google Scholar] [CrossRef]

- Otalora, C.; Maqsoud, A.; Belem, T. Evaluation of the Sludge and Slag Mixture to Act Flow Control Layer in the Waste Rock Pile Reclamation; A Springer Book Series Advances in Science, Technology & Innovation; Springer: Berlin/Heidelberg, Germany, 2024. [Google Scholar]

- GEOSLOPE International Ltd. Heat and Mass Transfer Modeling with GeoStudio 2020, 1st ed.; GEOSLOPE International Ltd.: Calgary, AB, Canada, 2020. [Google Scholar]

| Material | % Clay | % Silt | % Sand | D10 (mm) | D30 (mm) | D60 (mm) | CU | CC |

|---|---|---|---|---|---|---|---|---|

| Sludge and slag | 3 | 82 | 15 | 0.006 | 0.02 | 0.04 | 7.6 | 1.7 |

| Gravel | 2 | 9 | 49 | 0.11 | 1.5 | 5 | 45.4 | 4.1 |

| Thickness Layers | Slope Used | Precipitation Rate (mm/h) |

|---|---|---|

| 25 cm | 2.5° 5° | 60.6 (100 years) 46.8 (25 years) |

| 50 cm | ||

| 75 cm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Otalora Vasquez, N.C.; Maqsoud, A.; Belem, T. Physical and Numerical Modeling of a Flow Control Layer Made with a Sludge and Slag Mixture for Use in Waste Rock Pile Reclamation. Mining 2024, 4, 841-862. https://doi.org/10.3390/mining4040047

Otalora Vasquez NC, Maqsoud A, Belem T. Physical and Numerical Modeling of a Flow Control Layer Made with a Sludge and Slag Mixture for Use in Waste Rock Pile Reclamation. Mining. 2024; 4(4):841-862. https://doi.org/10.3390/mining4040047

Chicago/Turabian StyleOtalora Vasquez, Nelcy Carolina, Abdelkabir Maqsoud, and Tikou Belem. 2024. "Physical and Numerical Modeling of a Flow Control Layer Made with a Sludge and Slag Mixture for Use in Waste Rock Pile Reclamation" Mining 4, no. 4: 841-862. https://doi.org/10.3390/mining4040047

APA StyleOtalora Vasquez, N. C., Maqsoud, A., & Belem, T. (2024). Physical and Numerical Modeling of a Flow Control Layer Made with a Sludge and Slag Mixture for Use in Waste Rock Pile Reclamation. Mining, 4(4), 841-862. https://doi.org/10.3390/mining4040047