Application of SAP to Improve the Handling Properties of Iron Ore Tailings of High Cohesiveness: Could a Reagent Help the Decommissioning Process of a Dam?

Abstract

1. Introduction

2. Materials and Methods

2.1. Iron Ore Tailings (IOT) and Superabsorbent Polymer (SAP)

2.2. IOT and SAP Mixing

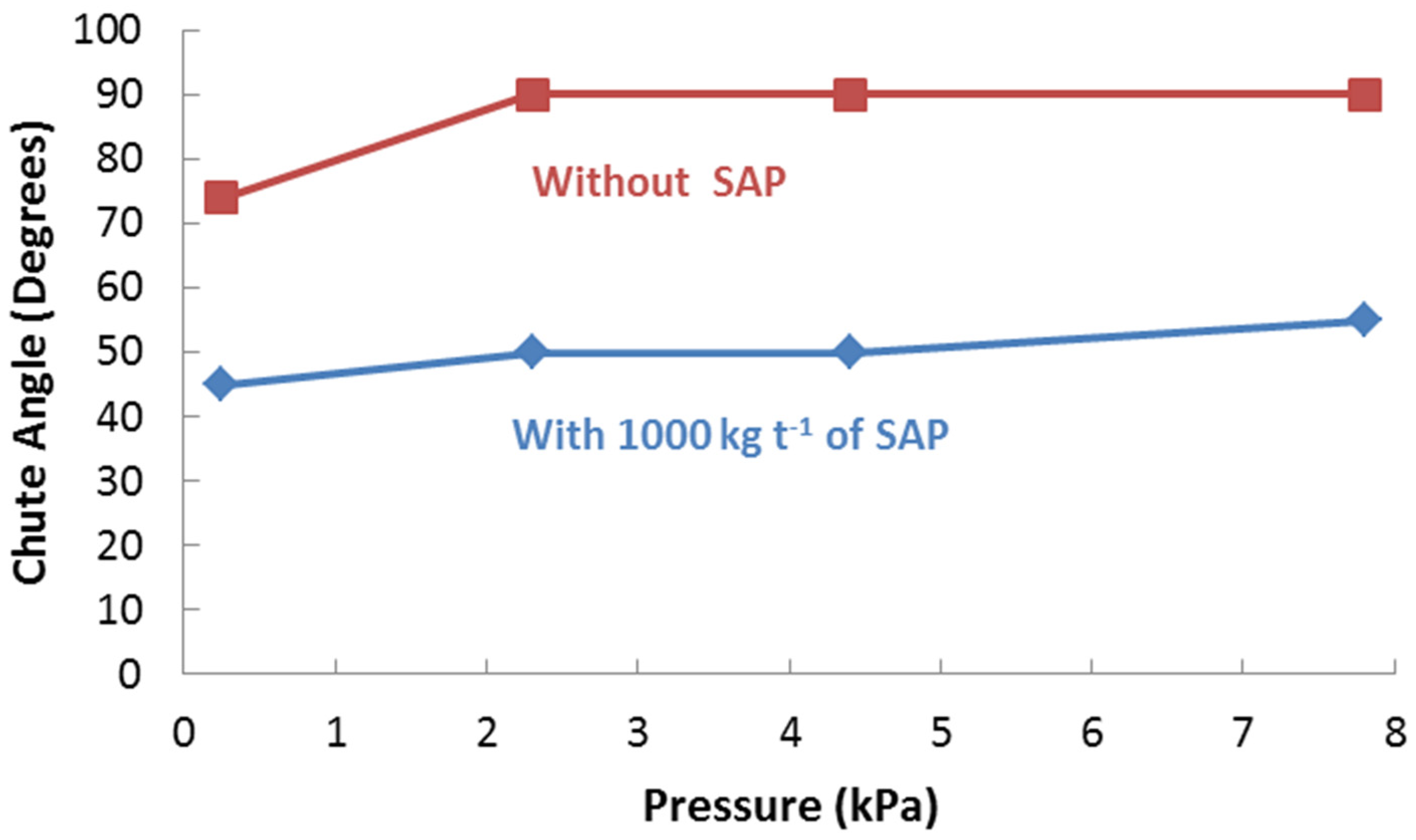

3. Hausner Ratio and Carr Compressibility Index

4. Uniaxial Compression Test

5. Atterberg Limits

6. Chute Angle

7. Results and Discussion

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Plinke, J.; Prigge, J.-D.; Williams, K.C. Development of new analysis methods for the characterization and classification of wet stick ores. Powder Technol. 2016, 294, 252–258. [Google Scholar] [CrossRef]

- Torsten, G.; Tuzun, U.; Heyes, D. Modelling and measuring of cohesion in wet granular materials. Powder Technol. 2003, 133, 203–215. [Google Scholar]

- Cabrejos, F. Effect of moisture content on the flowability of crushed ores. Powder Grains 2017, 140, 08011. [Google Scholar] [CrossRef]

- Schwedes, J. Review on testers for measuring flow properties of bulk solids. Granul. Matter 2003, 5, 1–43. [Google Scholar] [CrossRef]

- Chen, W.; Donohue, T.; Williams, K.; Katterfeld, A.; Roessler, T. Modelling cohesion and adhesion of wet, sticky iron ore in discrete element modeling for material handling processes. In Proceedings of the Conference Proceedings, Iron Ore 2015, Perth, Australia, 13–15 July 2015. [Google Scholar]

- Mignon, A.; De Belie, N.; Dubruel, P.; Vlierberghe, S.V. Superabsorbent polymers: A review on the characteristics and applications of synthetic, polysaccharide-based, semi-synthetic and ‘smart’ derivatives. Eur. Polym. J. 2019, 117, 165–178. [Google Scholar] [CrossRef]

- Yang, M.; Wu, J.; Graham, G.M.; Lin, J.; Huang, M. Hotspots, frontiers, and emerging trends of superabsorbent polymer research: A comprehensive review. Front. Chem. 2021, 9, 688127. [Google Scholar] [CrossRef]

- Dzinowmwa, G.P.T.; Wood, C.J.; Hill, D.J.T. Fine coal dewatering using pH_ and temperature sensitive superabsorbent polymer. Polym. Adv. Technol. 1997, 8, 2135–2143. [Google Scholar]

- Peer, F.; Venter, T. Dewatering of coal fines using a super absorbent polymer. J. S. Afr. Inst. Min. Metall. 2003, 103, 403–409. [Google Scholar]

- Farkish, A.; Fall, M. Rapid dewatering of oil sand mature fine tailings using super absorbent polymer (SAP). Miner. Eng. 2013, 50–51, 38–47. [Google Scholar] [CrossRef]

- Joseph-Soly, S.; Nosrati, A.; Addai-Mensah, J. Improved dewatering of nickel laterite ore slurries using superabsorbent polymers. Adv. Powder Technol. 2016, 27, 2308–2316. [Google Scholar] [CrossRef]

- Sahi, A.; Mahboub, K.E.; Belem, T.; Mqsoud, A.; Mbonimpa, M. Dewatering of mine tailings slurries using superabsorbent polymers (SAPs) reclaimed from industrial rejects of baby diapers: A preliminary study. Minerals 2019, 9, 785. [Google Scholar] [CrossRef]

- Srikakulapu, N.G.; Srikar, C.S.S.; Makhija, D.; Narayan, S. Improved flowability of iron ore using superabsorbent polymers. Powder Technol. 2020, 364, 321–331. [Google Scholar] [CrossRef]

- Srikakulapu, N.G.; Cheela, S.S.; Bari, V.K.; Mukherjee, A.K.; Bhatnagar, A.K. Effect of polymer flow aids on LD iron ore flowability. Powder Technol. 2021, 377, 523–533. [Google Scholar] [CrossRef]

- Rissoli, A.L.C.; Pereira, G.S.; Mendes, A.J.C.; Scheuermann Fillho, H.C.; Carvalho, J.V.A.; Wagner, A.C.; Silva, J.P.S.; Consoli, N.C. Dry stacking of filtered iron ore tailings: Comparisionon-field performance of two drying methods. Geotech. Geol. Eng. 2024, 42, 2937–2948. [Google Scholar] [CrossRef]

- Associação Brasileira de Normas Técnicas. NBR 16372: Portland Cement and Other Powdered Materials—Determination of Fineness by the Air Permeability Method (Blaine Method); Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2015; p. 11. (In Portuguese) [Google Scholar]

- Gomes, O.F.M.; Iglesias, J.C.A.; Paciornik, S.; Vieira, M.B. Classification of hematite types in iron ores through circularly polarized light microscopy and image analysis. Miner. Eng. 2013, 52, 191–197. [Google Scholar] [CrossRef]

- ISO 3087:2020; Iron Ores—Determination of the Moisture Content of a Lot. International Organization for Standardization: Geneva, Switzerland, 2020; p. 35.

- Carr, R.L. Evaluating flow properties of solids. Chem. Eng. J. 1965, 72, 163–168. [Google Scholar]

- The Institution of Chemical Engineers. Standard Shear Testing Technique for Particulate Solids Using the Jenike Shear Cell; The Institution of Chemical Engineers: Rugby, UK, 1989. [Google Scholar]

- ASTM D4318-17; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM international: Montgomery County, PA, USA, 2017.

- Fritella, A.; Smit, A. Chute design essentials—How to design and implement chutes in bulk solids handling systems. UreaKnowHow 2021, 35, 1–27. [Google Scholar]

- Mitchell, J.R.; Soga, K. Fundamentals of Soil Behavior, 3rd ed.; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Rose, R.L.; Mugi, S.R.; Saleh, J.H. Accident investigation and lessons not learned: AcciMap analysis of successive tailings dam collapses in Brazil. Reliab. Eng. Syst. Saf. 2023, 236, 109308. [Google Scholar] [CrossRef]

- Koppe, J. Lessons learned from the two major tailings dam accidents in Brazil. Mine Water Environ. 2021, 40, 166–173. [Google Scholar] [CrossRef]

- Pacetti, T.; Lompi, M.; Petri, C.; Caporali, E. Mining activity impacts on soil erodibility and reservoirs silting: Evaluation of mining decommissioning strategies. J. Hydrol. 2020, 589, 125107. [Google Scholar] [CrossRef]

- Almeida, V.O.; Lima, N.; Schneider, I.A.H. Simplified hydrometallurgical route for the synthesis of silica-free hematite from iron ore tailings. Miner. Eng. 2023, 200, 108140. [Google Scholar] [CrossRef]

- Armstrong, M.; Langrané, N.; Petter, R.; Chen, W.; Petter, C. Accounting for tailings dam failures in the valuation of mining projects. Resour. Policy 2019, 63, 101461. [Google Scholar] [CrossRef]

- Ruan, W.; Zou, B. Optimal strategies of critical mineral depletion and recycling. Resour. Conserv. Recycl. 2024, 209, 107793. [Google Scholar] [CrossRef]

- Aasly, K. Process mineralogy of unconventional mineral deposits examples of applications and challenges. Miner. Eng. 2024, 209, 108649. [Google Scholar] [CrossRef]

- Yong, Y.; Ahmed, Z.; Wang, S.; Rjoub, H.; Bilan, Y. Minerals, natural resources, government instability, and growing ecological challenges: Can we achive SDGs 12 and 13? Resour. Policy 2024, 88, 104507. [Google Scholar] [CrossRef]

- Tang, U.; Yang, S. Mineral resource sustainability in the face of the resource exploitation and green recovery: Challenges and solutions. Resour. Policy 2024, 88, 104535. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Q.; Dai, B.; Wang, D. Guidance and review: Advancing mining technology for enhanced production and supply of strategic minerals in China. Green Smart Min. Eng. 2024, 1, 2–11. [Google Scholar] [CrossRef]

- Azadi, A.; Irani, A.E.; Azarafza, M.; Bonab, M.H.; Sarand, F.B.; Derakhshani, R. Coupled numerical and analytical stability analysis charts for an earth-fill dam under rapid drawndown conditions. Appl. Sci. 2022, 12, 4550. [Google Scholar] [CrossRef]

- Mehrabi, A.; Derakhshani, R.; Nilfouroushan, F.; Rahnamarad, J.; Azarafza, M. Spatiotemporal subsidence over Pabdana coal mine Kerman Province, central Iran using time-series of Sentinel-1 remote sensing imagery. Episode 2022, 46, 19–33. [Google Scholar] [CrossRef]

- Sinclair, L.; Coe, N.M. Critical mineral strategies ina Australia: Industrial upgrading without environmental or social upgrading. Resour. Policy 2024, 91, 104860. [Google Scholar] [CrossRef]

- An, Z.; Zhao, Y.; Zhang, Y. Mineral exploration and the green transition: Opportunities and challenges for the mining industry. Resour. Policy 2023, 86, 104263. [Google Scholar] [CrossRef]

- Luco, C.; Liu, Y.; Pan, L.; Yang, F. Navigating mineral policy development challenges in the global south using analytic hierarchy process. Resour. Policy 2024, 90, 104797. [Google Scholar]

- Li, C.; Sun, H.; Bai, J.; Li, L. Innovative methodology for comprehensive utilization of iron ore tailings. Part 1. The recovery of iron from iron ore tailings using magnetic separation after magnetizing roasting. J. Hazard. Mater. 2010, 174, 71–77. [Google Scholar] [CrossRef] [PubMed]

- Carmignano, O.R.; Vieira, S.S.; Teixeira, A.P.C.; Lameiras, F.S.; Brandão, P.R.G.; Lago, R.M. Iron ore tailings: Characterization and applications. J. Braz. Chem. Soc. 2021, 32, 1895–1911. [Google Scholar] [CrossRef]

- Long, H.; Zhu, D.; Pan, J.; Li, S.; Yang, C.; Guo, Z.; Xu, X. A critical review on metallurgical recovery of iron from iron ore tailings. J. Environ. Chem. Eng. 2024, 12, 112140. [Google Scholar] [CrossRef]

- Vilaça, A.S.I.; Simão, L.; Montedo, O.R.K.; Novaes de Oliveira, A.P.; Raupp-Pereira, F. Waste valorization of iron ore tailings in Brazil: Assessment metrics from a circular economy perspective. Resour. Policy 2022, 75, 102477. [Google Scholar] [CrossRef]

- Bosikov, I.I.; Klyuev, R.V.; Revazov, V.C.; Martyushev, N.V. Analysis and evaluation of prospects for highquality quartz resources in the North Caucasus. Min. Sci. Technol. 2023, 8, 278–289. [Google Scholar]

| Ore | How It Was Used | Key Observations | Reference |

|---|---|---|---|

| Coal fines | Direct method | It was possible to dewater fine coal from a moisture content of 29.4% to 12–14% using a pH-sensitive SAP (2 wt.%) within a 4 h contact time. | Dzinomwa et al. (1997) [8] |

| Coal slurry | Indirect method (in sachets) | Different coal moisture levels and SAP dosages were applied. Under one condition, e.g., the moisture content of the coal slurry dropped from 30% to 7% with an SAP dosage of 2 wt.%. Thermal and pH-induced regeneration procedures were investigated. The methods can be effective, but they still present economic and technical issues to be addressed. | Peer and Venter (2003) [9] |

| Tailings from oil sand (<0.1 mm) | Direct and indirect method (in sachets) | Rapid and significant dewatering, as well as an increase in the undrained shear strength and solid content of mature fine tailings, can be achieved using SAP dewatering and densification methods (direct or indirect). Better performance with regard to dewatering and an increase in strength are obtained with the indirect method. The SAP dosages applied varied from 1 to 3 wt.%, with a contact time on the order of days. | Farkish and Fall (2013) [10] |

| Three types of low-grade nickel laterite (<0.1 mm) | Both direct addition mode and sealed in a water permeable polyester bag | The direct addition method was not successful due to the attachment of the laterite particles to the surface of the swollen SAP granules and the retrieval of water from the superabsorbent hydrogel. The SAP provided a favourable dewatering. The best performance was achieved at dosages of 2% to 3% within an 8 h contact time. | Joseph-Soly et al. (2016) [11] |

| Mine tailings (<0.3 mm) | Both direct addition mode and in geotextile bags | The preliminary results showed that an SAP volume dosage of 10 to 13 kg m−3 of slurry resulted in a final solids mass concentration (Cw%_final) ≥ 70%. The occurrence of a gel-blocking phenomenon was observed. | Sahi et al. (2019) [12] |

| Iron ore (<1 mm) | Direct addition mode | Flow function curves for 12% moisture iron ore showed the change in the flow regime from cohesive to easy flow in the presence of the SAP. A dosage of 100 g ton−1 and retention time of 30 min were obtained and incorporated during plant trials. | Srikakulapu et al. (2020) [13] |

| Lump iron ore (<40 mm) | Direct addition mode | Iron ore changed its flow behaviour from the poor flow to the easy flow regime with SAP dosages of 1200 g t−1, 1400 g t−1, and 1800 g t−1 for moisture contents of 8%, 10%, and 12%, respectively. A 40% increase in production was achieved during trials and a 24% increase in long-term implementation of SAP during monsoons by improving the fluidity of LD iron ore. | Srikakulapu et al. (2021) [14] |

| Iron ore tailings | Direct addition mode | SAP was studied comparatively with quicklime as agents for water removal and compaction of iron ore tailings for dry stacking disposal. SAP did not improved the compaction properties of the IOT and lime did. | Rissoli et al. (2024) [15] |

| Minerals | % (in Volume) |

|---|---|

| Hematite-lamellar | 53.9 |

| Hematite-granular | 22.2 |

| Hematite-lobular | 4.4 |

| Martite | 0.4 |

| Goethite | 16.0 |

| Quartz | 1.5 |

| Gibbsite | 1.3 |

| Other | 0.3 |

| Mixing Time | Bulk Density (kg m−3) | Tapped Density (kg m−3) | Hausner Ratio | Carr Index |

|---|---|---|---|---|

| 0 (g t−1) | 1340 | 2418 | 1.80 | 44.6 |

| 500 (g t−1) | 1300 | 2354 | 1.81 | 44.8 |

| 1000 (g t−1) | 1400 | 2300 | 1.64 | 39.1 |

| 1500 (g t−1) | 1290 | 2197 | 1.70 | 41.3 |

| SAP Dosage | Bulk Density (kg m−3) | Tapped Density (kg m−3) | Hausner Ratio | Carr Index |

|---|---|---|---|---|

| 1 (min) | 1400 | 2300 | 1.64 | 39.1 |

| 5 (min) | 1380 | 2390 | 1.73 | 42.3 |

| 10 (min) | 1340 | 2349 | 1.75 | 43.0 |

| SAP Dosage | Parameters for Determination Jenike’s Flow Function Index (ff) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| σ1 (kP) | σc (kPa) | ff | σ1 (kPA) | σc (kPa) | ff | σ1 (kPa) | σc (kPa) | ff | |

| 0 (g t−1) | 105 | 43.7 | 2.4 | 185 | 51.4 | 3.6 | 260 | 55.3 | 4.7 |

| 500 (g t−1) | 105 | 35.0 | 3.0 | 185 | 46.3 | 4.0 | 260 | 53.1 | 4.9 |

| 1000 (g t−1) | 105 | 31.8 | 3.3 | 185 | 36.3 | 5.1 | 260 | 44.1 | 5.9 |

| 1500 (g t−1) | 105 | 33.8 | 3.1 | 185 | 39.4 | 4.7 | 260 | 46.4 | 5.6 |

| Mixing Time | Parameters for Determination Jenike’s Flow Function Index (ff) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| σ1 (kP) | σc (kPa) | ff | σ1 (kPA) | σc (kPa) | ff | σ1 (kPa) | σc (kPa) | ff | |

| 1 (min) | 105 | 31.8 | 3.3 | 185 | 36.3 | 5.1 | 260 | 44.1 | 5.9 |

| 5 (min) | 105 | 35.0 | 3.0 | 185 | 41.1 | 4.5 | 260 | 44.8 | 5.8 |

| 10 (min) | 105 | 33.9 | 3.1 | 185 | 41.1 | 4.5 | 260 | 47.3 | 5.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gurgel, H.S.; Schneider, I.A.H. Application of SAP to Improve the Handling Properties of Iron Ore Tailings of High Cohesiveness: Could a Reagent Help the Decommissioning Process of a Dam? Mining 2024, 4, 733-746. https://doi.org/10.3390/mining4040041

Gurgel HS, Schneider IAH. Application of SAP to Improve the Handling Properties of Iron Ore Tailings of High Cohesiveness: Could a Reagent Help the Decommissioning Process of a Dam? Mining. 2024; 4(4):733-746. https://doi.org/10.3390/mining4040041

Chicago/Turabian StyleGurgel, Hely Simões, and Ivo André Homrich Schneider. 2024. "Application of SAP to Improve the Handling Properties of Iron Ore Tailings of High Cohesiveness: Could a Reagent Help the Decommissioning Process of a Dam?" Mining 4, no. 4: 733-746. https://doi.org/10.3390/mining4040041

APA StyleGurgel, H. S., & Schneider, I. A. H. (2024). Application of SAP to Improve the Handling Properties of Iron Ore Tailings of High Cohesiveness: Could a Reagent Help the Decommissioning Process of a Dam? Mining, 4(4), 733-746. https://doi.org/10.3390/mining4040041