Abstract

The mining industry is the leading supplier of raw materials in modern society. This sector of human activity has experienced a severe crisis due to the energy transition and has been revived in recent years due to the need for critical metals that are essential in the post-coal era. In underground and open pit mining, processes such as extraction, transportation, safety, underground ventilation, waste management, and rehabilitation are of major importance, and their “design” is critical to the economic survival of the mine. All the above processes required to operate a mine are strongly reminiscent of an example of nature’s workman: the ant. The sympatric insect uses the same processes as the ones aforementioned during the creation of its nest. The ants dig to “extract material from the ground”, and they transport this material from the nest‘s site to the waste deposition location. The ants ensure the safety of the underground opening and the proper ventilation needed for them to live there for a long time. This article attempts to identify the relations between all the above processes and sub-processes, and how human mining and ant colony development correlate with each other. Furthermore, we examine how an ant colony has aided in the development of mining technology, and what more humans can learn and adopt from a “miner” that is 66 million years old, in order to improve their processes.

1. Introduction

1.1. The Importance of Ants for Human Society

Raw materials that are necessary for humanity’s evolution have been extracted from the Earth’s surface for centuries. More recently, these materials have been obtained through underground mining. Many animals can be characterized as “miners”. Ants, which are one such animal, can be correlated with human activities since they are socially cooperative, gregarious, and robust for their size.

In most terrestrial ecosystems across the world, ants are prevalent. They have numerous significant roles in geomorphology. Specifically, they build underground tunnels and mounds, pattern the ground, contribute to bioturbation, modify the qualities of the soil (such as infiltration rate) and vegetation cover, and impact runoff and erosion [1]. Τhe benefits to humans of coexisting with ants are well known; from improving soil and ecosystems’ health [2,3] to the architectural design of buildings [4], and solving complex engineering problems by mimicking ant behavior. Living with ants has inspired humans over the centuries, creating myths such as Herodotus’ golden ant. Based on information gathered from various travellers, Herodotus (c. 484–425 BC) [5,6] spoke of the gold-digging ant, of a size between a dog and a fox. He spotted it in northern India, where these giant ants dug up gold from sandy areas (Figure 1a). This tale became a legend that survives thousands of years after the original story took place [7]. Another famous tale around the ant is the birth of the myrmidon (from the Greek μύρμηξ, mýrmix); Achilles’ army that fought in Troy [8], as shown in Figure 1b. It has also inspired the film industry with the character Antman in the modern era.

Figure 1.

(a) Herodotus’ giant gold-digger ants chasing gold hunters (available on Wikipedia); (b) the creation of the myrmidons by Zeus (Engraving by Virgil Solis [8]).

The association of the mining industry with the processes carried out in an ant colony stems from the industriousness and other characteristics of this insect, which have been observed since archaic times. A typical example is the myth of the “ant and grasshopper”, in which the ant’s industriousness has been singled out from the whole animal kingdom. Thus, the mining industry is the sector of human activities that stands out as the main contributor to human society. The similarities between ant and human excavations are numerous; they include excavating underground tunnels and ventilation systems, and designing modern robotic automated mining and transport systems that mimic the ant’s kinematics [9]. The adaptability of the insect has helped it thrive in all continents and environments perfectly in parallel with human activities in extreme environments such as the Arctic [10,11], and operations in arid regions with restoration plans in the post-mining era [12].

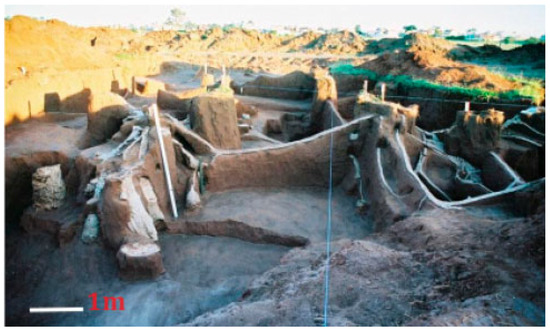

Humans have exploited the ant’s example in many phases of mine design; from mining and transporting material to the development of algorithms that mimic how to select optimal routes to the food source [13,14,15,16,17]. Ants can also help humans after the end of their lives, by providing storage space that humans can use to store not food, but energy [18,19]. Ant colonies that create large populations living underground in labyrinthine tunnel systems that can measure tens of meters. For example, into an ant colony in Brazil [20,21] cement was poured and then excavated to reveal an entire underground state; as shown in Figure 2 below.

Figure 2.

General view of cement-moulded ant “city” in Brazil [21].

Humans use underground excavation for storage and other applications, but rarely for living. It is worth mentioning the example of the underground city at Coober Pedy, Australia [22], which is famous for two reasons: the opal and the fact that most of its inhabitants live underground, taking advantage of the protection from the high desert temperatures provided by the underground tunnel system. Another example is the famous ancient city of Wieliczka Salt Mine near Krakow, Poland, and the historical Derinkuyu underground city in Cappadocia, Turkey [23,24]. In the future, building cities underground can help decongest cities. The advantages of this include saving space and energy for heating or cooling and avoiding noise [23]. In today’s cities, several underground structures such as subway tunnels, rainwater networks, and storage areas offer many advantages, especially in megacities, to save space and decongest surface traffic. This paper highlights the mining industry by drawing a parallel with one of the most successful animal kingdom species, the insect in question.

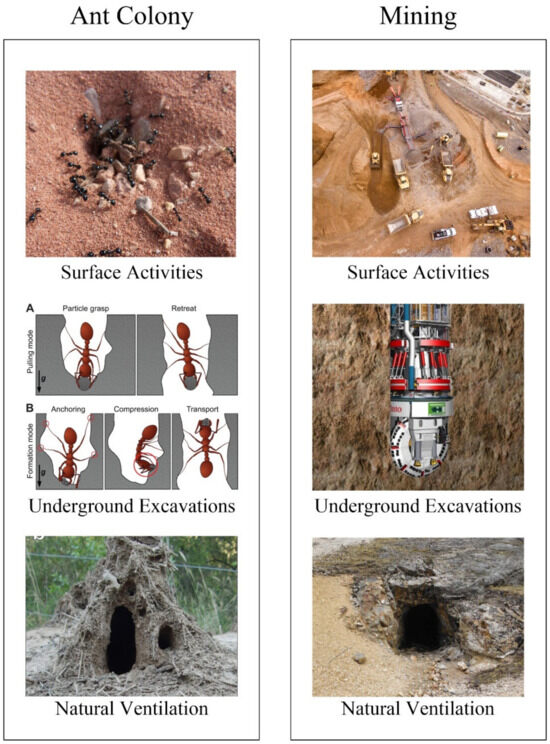

1.2. Processes That Simulate Mining in Ant Colony Operation

Ants are an organized insect society, with a hierarchy and distinct roles for each member to ensure the colony’s well-being, ability to gather food, and function safely. Human mining has a similar structure; specific rules and coordinated functions must be followed for a mine to be sustainable. The similarities between the operation of a mine and the operation of an ant colony are striking in several areas; for example, the excavation of galleries and shafts, the transport of material, the design of entrances to ensure natural ventilation, and the design of galleries to ensure the stability of the underground structures. In Figure 3, a comparison is made between processes carried out in ant colonies and in human exploitations: (a) by comparing surface processes such as hauling, (b) in underground mining of shafts and steep inclines using mechanical mining, and (c) by designing the entrances to ensure natural air flow. For example, the entrance of the ancient mine of Chonta, Peru [25]. Based on the above, the influence of mining design is evident from observing ant behavior during the long-term coexistence of humans with them.

There are also similarities in the operating processes of an ant colony and mining. The following parallelism can be made:

- The main objective of ants is food concentration, whereas, in mining, it can be paralleled with ore concentration.

- The ant nest can be correlated with the mine site.

- For foraging, some ants have the role of scouts and can be paralleled with exploration (geophysical, drilling) for finding deposits, where instead of foraging, the aim is to find exploitable concentrations of minerals.

- The carriers transferring the food to the nest can be associated with trucks transporting the mined material from the mine to the deposit position. It should be noted that transport follows the opposite path in mining operations than ants’ movement from the operation (nest) to the deposition site (food source), as the goal of ants is storage, while in mining operations, it is extraction. Further, in large-scale mining, the fleet of trucks resembles the swarm of ants as they march from and to the nest.

- The workers who excavate and maintain the nest are associated with the drilling, excavation, and support operations of underground and subterranean mining. Therefore, excavators and drillers can be associated with ant workers.

- The guards responsible for protecting the nest can be associated with the mine safety engineers who are responsible for ensuring that all safety rules for the proper operation of the mine are followed.

- Winged ants looking for new places to establish new colonies can be associated with drones and the use of aerial photography to detect new mine sites.

- The queen that in ants creates the entire colony can be related to the rules that govern the operation of exploitations in each state. In Greece, these rules are defined by the Regulations for Mining and Quarrying Operations.

Figure 3.

Parallelism of an ant colony with mining operations from surface activities, underground excavations (reproduced/adapted with permission from https://journals.biologists.com/jeb (accessed on 24 February 2024) [26]) and natural ventilation [25,27].

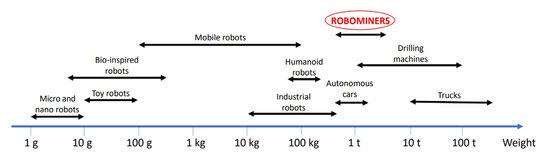

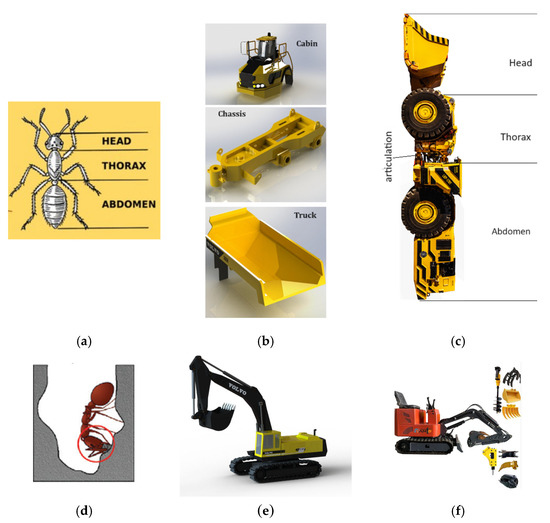

The similarities between ant colonies and mine processes and use of technologies inspired by nature will help the mining industry to develop more efficient equipment. In the current fourth Industrial Revolution and Mining 4.0, machines have been designed to operate autonomously, with the possibility of decision-making based on innovative technologies and big data handling [28,29]. An example of research on a technology inspired by nature is the project ROBOMINERS, funded by the European Union (EU), for future mineral exploration and extraction within Europe [30,31]. The ant is an excellent example of a natural miner that could be used for those purposes (see Figure 4).

Figure 4.

Comparison of robotic systems used in mining (reprinted from [31]).

2. Materials and Methods

In this paper, the review was based on research that focused on seven themes: (1) Firstly, in the introduction, the positive impacts of ants on various aspects of human activities were mentioned; (2) ants have been used since ancient times in gold prospecting, as Herodotus reported about gold deposits in India; (3) ants have also been used as biomarkers to monitor the progress of the rehabilitation of abandoned mines; (4) a parallelization of the mining operations with operations of ant colonies is done; (5) through parallelism, the technologies used in mining are highlighted; (6) a particular category of these technologies is the development of equipment imitating nature, particularly that of ants; (7) a particular reference is made to ant colony algorithms, which is an easily applicable tool that, despite their limitations, can help optimize mining operations.

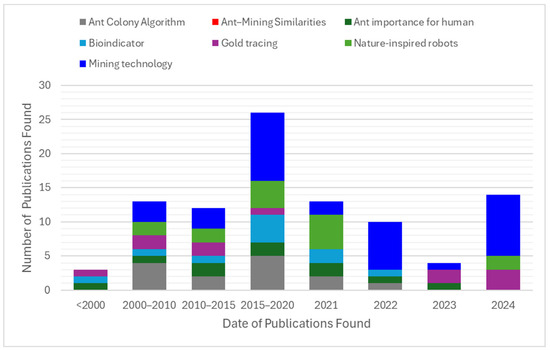

The research identified 122 different sources, of which 68% were full articles, 14% were abstracts or conference articles, 12% were online sources, and the remaining 6% were books, dissertations, or reports. Figure 5 below shows the distribution of these articles by year of publication and by the seven categories mentioned above. Most of the citations were found in the last decade, with the 2024 citations mainly concerning online sources and the most significant percentage concerning mining technologies and modern nature-inspired equipment.

Figure 5.

Distribution of references by year of publication.

The following Section 3 discusses the processes of surface mining and how the ant is used to detect precious metals and in mine reclamation. A parallelism is then drawn with the processes of ant colonies. Section 4 highlights the processes of underground mining compared to processes within the ant colony. Section 5 presents some key elements and uses of ant colony algorithms based on the insect under consideration. Finally, Section 6 discusses the evolution of mining technology, focusing on transport loading systems and the future use of robotic systems inspired by ants’ kinematics and communication modes.

3. Surface Exploitations

3.1. The Myth of Gold-Digging Ants

Herodotus mentions this mythical creature based on descriptions he gathered from the testimonies of various travelers. Thus, in his book “The History” [5,6], he mentions that gold seekers from northern India, particularly from Kaspatyro and the region of Paktiki, were searching for gold in the desert. To find the gold-bearing sands, they used the nests of some giant ants whose size is described as smaller than that of a dog but larger than that of a fox [5,6,32,33]. He also mentions that the king of the Persians had some of these animals, which built their nests like the common ants by raising the golden sand to the surface. The Indians search for these nests to find the gold, and after gettingg it, they run away from these huge ants, as represented in Figure 1a.

Later writers, such as Megasthenes (c. 350–290 BC), also reported on this creature; despite the loss of his reports on Moorish India, later classical writers such as Diodorus of Sicily, Strabo, Pliny, and Arrian quoted various parts of his text. Regarding Ladakh (India), in his Natural History, Pliny the Elder said that Indian ants dug gold out of the earth, not for metal, but to make their nests. The Pakistani archaeologist Dani, referring to Herodotus’ suggestion, considered the northern regions of Pakistan to be the gold-bearing ant’s territory. There needs to be more evidence in the historical sources to favor the case of north Pakistan over that of Ladakh [7]. In his book, Peissel attributes to Ritter the association of the marmot with the gold-digging ants of Herodotus, as it is said that in the Persian language, they were called “mountain ants”. On the other hand, Francke, in his work “Contribution to the question of gold–digging ants”, mentions that Herodotus was right when he called the gold-digging creatures of his story “ants” and not “marmots”. Whatever the animal of legend was, it is proof of historical gold deposits in Ladakh and the neighboring region of Gilgit–Baltistan, where alluvial gold deposits are still being exploited today.

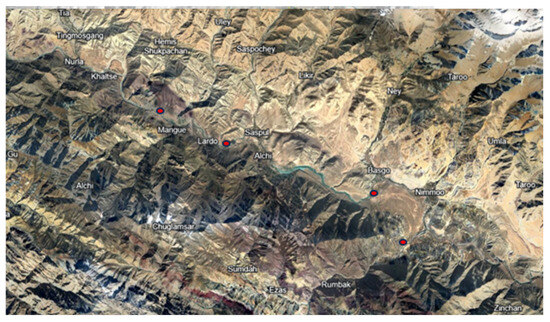

The fact that history holds ants, not marmots, responsible for mining the Indus’s golden sands is a puzzle of history and an identifying feature. The enigmatic aspect comes from the uncertainty of this particular animal species. As Cunningham has suggested in [7], this confusion may stem from a misunderstanding of the local and Sanskrit names of the species in question by Alexander the Great’s soldiers. The map below (Figure 6) shows a map of four ancient surface holdings, all located in lower Ladakh, in North India, in a radius of less than 20 km between Choksti, along the Zanskar River and downstream of the Indus, somewhere between Gadpa Sngonpo and Ulle Tokpo.

Figure 6.

North India’s alluvial gold mines marked on a Google Earth map (red circles) based on the map in [7].

In the modern era, the original story of Herodotus was taken seriously by a Rhodesian prospector in the early 1960s. He surmised that the gold might be found in termite mounds in densely forested areas over rich bedrock. Following a thorough sampling program, he discovered a small gold mine behind 25 m of cover where the termite hills were rich in gold. Later on, the mine was dubbed the Termite Mine [32].

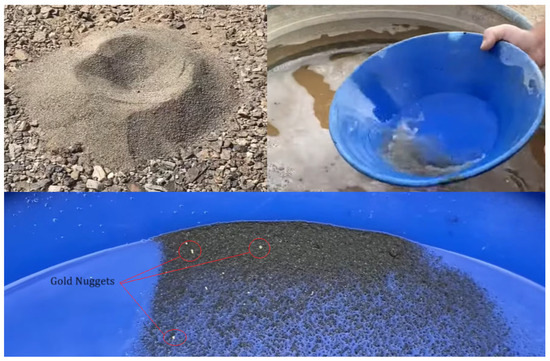

Gold detection by studying ant nests is a well-established tactic to detect underground gold that ants carry to the surface during nest excavation. Some studies [34,35,36] have shown that ants and termites bring gold to the surface from depths as shallow as 5 m; whereas, for some termite species, the nesting depth can be as deep as 30 m. Figure 7 typically demonstrates the existence of gold nuggets in an ant nest after separation using a gold sluice machine and a gold pan [37]. A study by the CSIRO has shown that ants bring gold up to the surface far more efficiently than do termites [38].

Figure 7.

Gold detection in ant nest (extracted from the YouTube channel Gold Fever Adventures and Treasure Hunting [39]).

3.2. Mine Rehabilitation

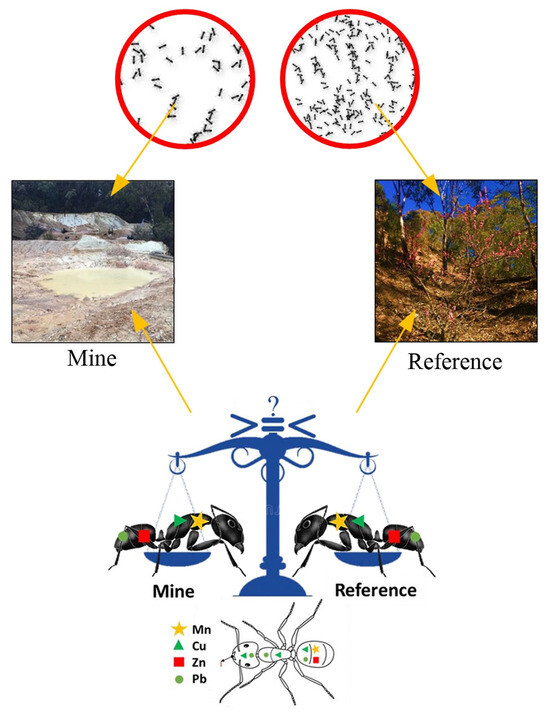

The ant population in areas where human mining is present has been used as a biological indicator of environmental remediation in many studies [40,41,42,43,44] based on the population and the number of species that thrive in the area of mining operations relative to the native species in the area (in the upper part of Figure 8). Special traps are placed in the mine under consideration to measure the ant population, and these are compared with corresponding traps in a reference site from an area without human intervention. More specific examples are given as follows:

- Yeo et al.’s [40] study of mining restoration on Mount Nimba, Guinea, showed that ant populations and species are more affected by the restoration area than vegetation in protected areas without mining.

- The research by Ribas et al. [41] used different ant species as bioindicators to examine the restoration of gold mining tailings from three different mines in Nova Lima, southeastern Brazil and determine the most appropriate restoration method.

- Andersen’s [42] work examines uranium reclamation sites in Australia. It shows that the location of the mine in the natural environment where the ants in question thrive plays a role in ant prevalence.

- Ottonetti et al. [43] suggested suitable ant species for biomarkers in restored Mediterranean mines.

- The same technique was used by Fernandes et al. [44] to study the evolution of bauxite mine reclamation in the Amazon.

- The study of Khazin et al. [45] uses two inhabitant species of ants as bioindicators: Cataglyphis longipedem and Camponotus compressus are used for heavy metal content in soils due to mining two coal sites. The first species increased, while the second decreased with increasing soil pollution.

- Buchori et al. [46] used the diversity of insects (including ants) in post-mining areas to examine their role as bioindicators. This study was conducted in a coal mine in Berau Coal in Binungan, East Kalimantan.

- Dvořáčková et al. [47] use ants as bioindicators to compare the success of rehabilitation in different regimes in the Czech Republic.

Another technique used by Roivainen et al. [48] examined the quantity of radioactive elements in the nests and bodies of ants in restored uranium mines in eastern Finland. Kavehei et al. [49] used a similar technique to monitor contamination from human heavy metal mining activities in Australia. The quantity of heavy metals passing into the food chain through the ants was examined by comparing them with ants from areas without mining activities, as illustrated graphically in the lower part of Figure 8.

Figure 8.

Use of ants as an indicator to monitor the spread of contamination by counting the population of ants and checking for traces of contamination in their bodies (modified from [49]).

Inspired by the simplicity and cooperation of ant swarms and insect swarms in general to solve various problems, Oyekan and Hu [50] proposed an innovative technique for detecting dangerous but invisible emissions using swarms of robotic ants. Specifically, the robotic swarm was used to visually detect the distribution of hazardous concentrations using limited sensing, communication, computational, and memory resources. This application was made to provide a valid pre-warning of hazardous substances in urban environments. However, it may also be applied in mining, especially in underground mining, where many hazardous chemical agents, such as CO, NOx, and methane, pose a risk to miners.

3.3. Surface Mining Geometry and Hauling

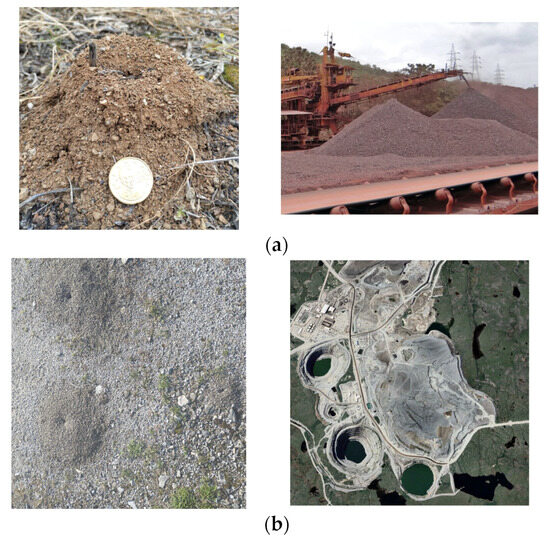

The structure of the entrance of the ant nests, with the transported materials from the excavation of the underground forming piles with the natural slope (correlated with the angle of friction) of the material strongly resembles human ore deposits, as shown in Figure 9a. The design of surface human excavations is done by ensuring the stability of the artificial slopes; in closed-type exploitations on flat terrain, surface structures that strongly resemble the entrances of ant nests are created, as shown in Figure 9b. One such example is the diamond mine at Diavik, Canada, where mining was initially carried out on the surface by creating a series of surface excavations of considerable depth. After the open pit operations were finished, the Panda and Koala pipes were also created and mined underground. The first underground diamond mine in North America, Koala North, officially opened in 2002. The Ekati mine used three main underground mining techniques: incline cave mining, sublevel caving, and open benching [51].

Figure 9.

Comparison of: (a) ore deposits with ant nesting (personal photo); (b) comparison of surface open pit excavations in Diavik diamond mine (Google Earth) with ant nest entries (personal photo).

Observation of the ant colony mode of operation can be used to improve the mining process, with a typical example being the use of ant colony algorithms, which have been used in many areas of operations, and will be discussed in a later section. In this sense, by observing the way ants operate, such as in the research of Goldman’s team [52], it is shown that only 30% of the workers are involved in 70% of the nest creation and also in the nest repairs; this is done to avoid bottlenecks that would make the whole process inefficient. Open pit mining faces similar problems, with a large fleet of machinery moving around the mine site, which creates congestion and delays that increase the exploitation cost. Nowadays much research, such as that of queue theories, tries to improve the mining process by examining the successive arrival of trucks at the service location. The cycle times for each truck (representing the customer) and the loading times of the available loader (servers) are used by many researchers [53,54,55] to improve the transportation loading circuit.

4. Underground Excavations

4.1. Stability

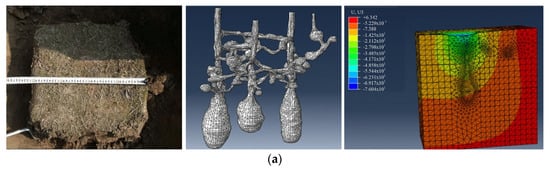

Ants create complex structures and a network of tunnels within surface soil materials with poor mechanical properties. Millions of years of evolution have led to perfection of the mining technique, providing them with the required stability. The intricate network of galleries is reconstructed using a technique in which: (1) abandoned nests are filled with either liquid metal or cement, (2) after solidification, the nest is excavated, and (3) the soil is removed, leaving the ant excavation system exposed. This technique has been used to produce a nest cast and in several published studies a digitized network of galleries is produced (Figure 10a) to determine their stability using 2D and 3D numerical models [56,57,58,59]. These studies help us to understand how ants have achieved the required stability of excavations in loose soil and can subsequently be applied to human operations. This technique allows conclusions to be drawn at the scale of human underground excavations, and it is a first-class analogue experimental solution without the need for complicated apparatus and analogue sandboxes [60]. The size of the ant colonies (relative to their size) exceeds even the deepest excavations, such as in the example of the Pyhiisalmi Mine in Finland, which is the deepest metal mine in Europe, with a depth of 1444 m [61]; and the Mponeng gold mine in South Africa [62], which has reached depths of over 3.6 km and is shown in comparison to the mold of an ant colony [4] in Figure 10b.

Figure 10.

(a) Determination method of ant nest stability (reproduced/adapted with permission from Acta Mechanica Solida Sinica [57]); (b) comparison of ant colony cast [4] with Europe’s deepest copper Pyhiisalmi Mine [61] and the world’s deepest underground gold mine in South Africa [62].

The method of excavating the ants by creating vertical shafts from which the food storage chambers are created can be matched with the methods of exploiting open stopes, with the closest match being the method of room and pillar mining where structures simulating the ant nest are created during the extraction of the ore. Of course, human operations aim to recover as much ore as possible, so the geometry of the excavations has a more regular structure than the more abstract shape of ant excavations.

Several sub-support measures, such as anchors and shotcrete, are available to ensure the stability of the underground excavations. In their research, Schafric et al. [63] presented an autonomous bolting machine supporting underground excavations. Regarding ant nests, it has been observed that ants and the related termite species use their saliva to make the walls of their nests harder and more stable, which is reminiscent of shotcrete in human tunnel support. Some ant species, such as Atta vollenweideri grass-cutting ants, in addition to their underground chambers, create ventilation towers on the surface with a porous structure (50–60%), which are very durable. Research by Cosarinsky and Roces [64] has shown that ants choose the most suitable material to create robust towers, which bring a natural air supply to the underground galleries.

4.2. Excavation

Monaenkova et al. [26] used fire ants to study this insect’s excavation method and create a series of educational videos. Based on their experiments, two modes of excavation were observed (Figure 3), as follows:

- (A)

- Pulling mode, in which the ants grab the material, with the amount being proportional to the size of the grain and the size of the claw, and then they remove it from the gallery.

- (B)

- Formation mode, in which ants shape the material’s grain before removing it with a series of movements. Efficiency in material extraction and flexibility of movement has attracted the interest of mining equipment manufacturers in designing equipment to mimic the ant’s claw geometry, as in the claws and excavation machinery in shafts and high gradient adits.

Some researchers [65,66] have assessed the effectiveness of ants as excavators by experimentally determining the speed of tunnels. At the same time, other research has illustrated excavations’ three-dimensional structure by observing the impressive size and architectural structures [67].

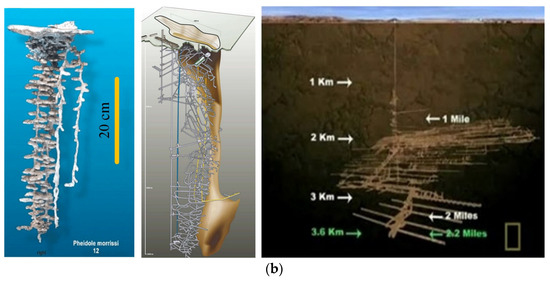

In addition, the body of the ant (Figure 11a) has inspired the creation of articulated vehicles, which makes them more flexible in movement, particularly in underground applications. Figure 11b shows the model of Volvo’s A60H dumper simulating the structure of the ant (Figure 11a). Both are divided into three parts: the cab (head), the chassis (thorax), and the truck (abdomen). The correspondence of the ant’s body is, of course, more pronounced with loaders, as can be seen by comparing the ant body (Figure 11a) with underground LHD [68], separated into the base parts (Figure 11c). In particular, when the ant does excavation in B mode, as suggested by Monaenkova et al. [26] (Figure 11d), the similarity with the excavators is impressive (Figure 11e–f). Although used for small-scale excavations, the mini crawler is characteristic of the Chinese company ANT [69], in which many parts simulate the body parts of the ant to which it owes its name (Figure 11f).

Figure 11.

(a) The ant body (modified from [70]); (b) Volvo’s articulated truck [71]; (c) Underground Mining Loader, LHD [68] (KGHM ZANAM LHD LD1701, www.kghmzanam.com (accessed 24 February 2024)); (d) ant excavation (modified from [26]); (e) 3D Model of Volvo’s EC650 excavator [71]; (f) ANT’s mini excavator [69].

In human operations, there are several efficient mechanical excavators used in mining, with the most common being the following:

- Bucket excavators, in which special claws on the bucket help cut and load loose soil formations. As exemplified by cable excavators, these machines have taken on giant proportions in surface explorations.

- Roadheaders, in which two types of machines are used: the transverse and axial types. These machines have been developed in recent years to excavate in hard formations.

- Mining Tunnel Boring Machine.

- Bucket-wheel excavator, whose primary function is continuous digging in large-scale open pit mining.

- Continuous miners consist of five parts: (a) central body, (b) cutting head, (c) loading mechanism, (d) a conveying system, and (e) rear jib section used for excavating soft materials such as coal.

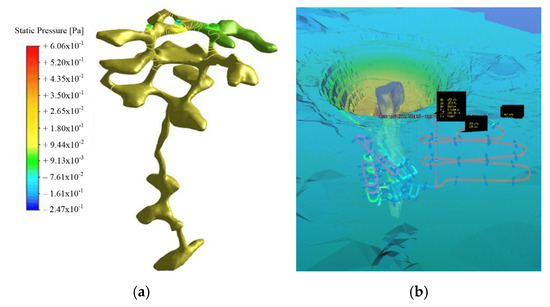

4.3. Ventilation

Some ant species, such as Atta vollenweideri leaf-cutting ants [64] and termites [4,72], build towers on the surface with a series of openings at the entrance/entrances of the nest to assist air to enter naturally into the underground opening, thus regulating the atmosphere and humidity in the underground tunnels and incubation chambers. In the work of Halboth and Roces [27], the ventilation circuit was experimentally tested using ventilation towers at the entrance of the nests of this ant species, where the effectiveness of CO2 removal was demonstrated, especially where there were high concentrations. Another research [73] on the ventilation of the nest of Camponotus japonicus Mayr ants was carried out by 3D imaging using the nest cast technique mentioned in Section 4.1. The digitized model was then entered into the finite element program, FLUENT, where the effect of air flow on the pressures and air flow rates within the nest was examined and based on the analyses, the environment within the nest was found to be constant throughout the nest (Figure 12a). This remarkable similarity is also seen in human mines, where the system of access and ventilation works to assist the air circulation underground. For example, Figure 12b shows the ventilation circuit in the diamond mine in Diavik, which was designed with the Ventsim program [74].

Figure 12.

(a) Natural ventilation modelling in an ant nest [73]; (b) ventilation circuit in a diamond mine [74].

The mechanism of natural ventilation also affects human underground excavations, and research has shown that surface conditions can affect the subsurface. Wang et al. [75] showed in a study of a coal mine in Tangkou, China, that they can cause disasters such as gas overrun, and may even lead to heavy casualties. In human mining, natural ventilation is not adequate as the use of internal combustion machinery, the use of explosives, gases present in the excavated rocks, great depths, and other factors increase the required air flows underground; a useful manual for calculating ventilation parameters has been written by McPherson [76]. Several studies have been conducted to select appropriate ventilation systems in coal mines [77,78,79], where the presence of gases such as methane increases the risk of fires. Another critical factor affecting underground workers is high temperatures, particularly in mines extending to great depths, where cooling and ventilation systems are necessary [80,81]. In some studies, energy recovery and mine cooling have been proposed [82,83].

4.4. Water Drainage

To prevent flooding of their nests, ants create intricate systems of shafts and tunnels that help divert water away from the chambers where food is stored and where their larvae incubate and grow. In this way, they ensure that water does not fill the underground chambers. Another way is to put barriers at the entrances or use their bodies to prevent water from entering. Planning starts with choosing the nest’s location based on the terrain’s morphology. In severe flooding events, ants have alternative nest transport plans.

As far as human underground excavations are concerned, drainage is usually done using a pump system, and in cases where topography allows, tunnels can help to remove water. Such systems effectively remove water and are usually excavated in or under the deposit. Vertical pump well systems can be created in intense flows to effectively remove water [84]. The impacts and difficulties of water flow in a mine, apart from the safety of workers, create delays in mining, disable some types of explosives (e.g., ANFO), increase the cost of mining and supporting the adits, and increase the weight of the ore and therefore the energy required to transport it. It is essential, therefore, to remove water from a mining operation efficiently; various hydrogeological studies exist to design water pumping systems using 3D hydrogeological models [85,86].

4.5. Conclusive Remarks

Observing the similarities between human exploitations and ant behavior and nature in general, as outlined in this section and the previous one, will help the mining industry develop technology that, in the future, will help fully automate and optimize processes. For example, Linevich et al. [87] have built groups of robotic excavators mimicking the collaborative nature of ants, which are capable of performing hours of autonomous tunnel excavation in a model cohesive granular medium. In the following sections, the research concentrates on nature-inspired algorithms; specifically, ant colony algorithms, which can help optimize mining. Furthermore, advances in technology in this area have already been researched by many teams worldwide and are presented in the last chapter of this work (Section 6).

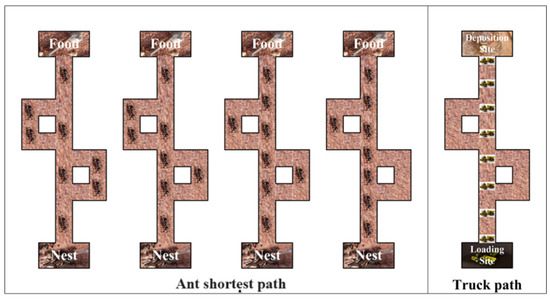

5. Ant Colony Algorithms

Ant Colony Optimization (ACO) algorithms belong to the stochastic methods and are based on the “pheromone” method. The method was developed by observing this insect’s foraging behavior, in which each member’s path towards the food source is random. The colony member that chooses the shortest route will return to the nest faster, resulting in it passing the nest more times and leaving a more significant amount of pheromones that lure more and more colony members to this route, and over time, most ants adopt this route [88]; as illustrated graphically in Figure 13. At the beginning of the algorithm, the first ants choose the path from N to S and vice versa, entirely at random (1); if more ants enter the path, there will be ants on all paths (2). After several paths have been made through self-organization, following the pheromone communication system, the ants will have oriented themselves to the shortest path (3).

Figure 13.

Example of ant colony algorithm of the optimal route definition.

A typical ACO algorithm (Table 1) was presented by Dorigo and Blum [89], where the initial value of the pheromones Ƭ for all possible paths is first determined, and the distances are calculated. Based on these values, the probability is calculated for each path so that the ant randomly chooses the path to follow. Then, once each route has been used, the shortest route is identified. When all the ants () have completed their routes, the value of the “pheromone”  is updated, based on the updated route

is updated, based on the updated route  and the best solution so far , giving a higher value to the most efficient routes so that in the following simulation, they show a higher probability of following that route. A typical ACO algorithm consists of the following parameters that must be defined [90]:

and the best solution so far , giving a higher value to the most efficient routes so that in the following simulation, they show a higher probability of following that route. A typical ACO algorithm consists of the following parameters that must be defined [90]:

is updated, based on the updated route

is updated, based on the updated route  and the best solution so far , giving a higher value to the most efficient routes so that in the following simulation, they show a higher probability of following that route. A typical ACO algorithm consists of the following parameters that must be defined [90]:

and the best solution so far , giving a higher value to the most efficient routes so that in the following simulation, they show a higher probability of following that route. A typical ACO algorithm consists of the following parameters that must be defined [90]:- Pheromone model.

- Heuristic variables , are usually inversely proportional to the distance from point to .

- Ant-routing table, s.

- Stochastic decision policy and selecting the objective function, f.

- Restriction regarding pheromones, .

- Scheduling of the ants.

- Restarting the algorithm after stagnation.

- Optional components, local search.

Table 1.

Basic ACO algorithm (modified from [89]).

Table 1.

Basic ACO algorithm (modified from [89]).

InitializePheromoneValues( ) )while (terminate conditions not met) do  for do ConstructSolution(  ) )if ( is valid) then LocalSearch() {optional} if ( or ) then end if   end if end for  PheromoneUpdate( PheromoneUpdate( , ,  , ) , )end while Output: |

In a typical ACO algorithm, the probability of the ant k to go from point to at iteration t is calculated based on the following Equation (1):

The value of parameters and determines the relative importance of pheromone value and heuristic information , respectively. At the same time, represents the positions that have already been used by the specific ant k. After completing the paths from the pheromone renewal, Equation (2) determines the shape of the ACO.

where pheromone evaporation factor and

Q is a user-defined parameter, route length and the visitation history of kth ant at time t.

There are several variations of these algorithms; some of the most used ACOs are described by Prakasam et al. [91], and are presented by name below:

- Ant system.

- Elitist ant system.

- Max–min ant system.

- Rank-based ant system.

ACO algorithms have a wide range of applications in the mining operations, including, among others, the following:

- In the programming and operation of robotic systems, Song et al. [92].

- Research has been used to optimize long-term productivity planning on open pit exploitations [93,94].

- Another use of the method is the optimum operation of a pump for water distillation in a coal mine that, instead of running at maximum operation, alternates between valleys and peaks [95], significantly reducing costs.

- The optimization of the loading–transport cycle by selecting the most suitable loading location concerning the traffic congestion at the loading and unloading locations [96] is an alternative methodology to that of the queuing theory.

- In their research, Wan and Du [97] use MATLAB to apply a new objective evaluation method to test whether constructing ecological mining sites at the Pingmei Shenma coal mine in China can help develop the economy, society, and the environment.

- Feng et al. [98], in their research, have used an enhanced ant colony algorithm to improve the tracking accuracy of a hydraulic system of a robotic mining excavator.

ACO methods often have difficulty identifying the optimal solution and need many iterations to converge. Examples of alternative methods that can be used are neural networks [99,100], simulation annealing [101], genetic algorithms [102] and evolutionary algorithms [103].

This technique is prevalent in many sectors, including the mining industry, and may be further developed in the future, as based on this research, few published papers were found in this area.

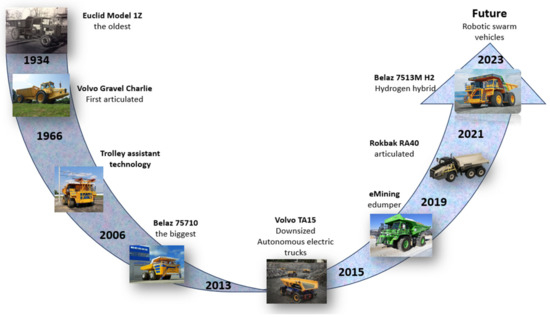

6. Hauling Evolution in Mining

One of the most essential processes in surface and underground mining is ore transportation, which takes up a large part of the cost and has a significant environmental footprint. As mentioned in a previous section, the fleet of trucks during ore transport can be related to the swarm of ants while transporting their food. This section will present the evolution of mining trucks and how the ant example of the ant swarm helps design innovative ore transportation systems.

The development of dumper technology (Figure 14) has helped in efficient ore transportation, with one of the first off-road trucks being the 1934 Euclid model 1Z dumper [104]. In the site of ROKBAK [104], the evolution of dumpers from this initial model to the Terex series in 1968 (from Tera (earth) and Rex (king)) to the first articulated truck produced by Terex 3204 in 1982, until 2021 they use the name ROKBAK for articulated dump Terex Trucks, with 28-ton payload RA30 and 38 t payload RA40 the most productive and efficient articulated haulers [104]. The first articulate truck is considered the 10 ton DR 631, known as Gravel Charlie, released in 1966 by VOLVO. At the end of the 20th century, the crisis in the mining industry forced companies to steadily increase the sizes of trucks to ensure the operation’s viability [105]. The world’s largest mining truck is the BELAZ 75710, which has a Gross Vehicle Weight Rating (GVWR) of 840.5 tons; it was released in 2013 and has gained two records (information from personal communication [106]):

- First, the largest two-axle dump truck with a nominal payload of 450 metric tonnes.

- Second, the largest body of the dump truck with a volume of 645.4 cubic meters.

In the modern era, where there is a need to replace traditional energy sources with more environmentally friendly forms of energy, it is also necessary to modify the mining technology to follow this transition in economic terms. Thus, it has been observed that it is challenging to make this change in bulky conventional machines, as the size of the battery needed by a fully electric vehicle makes its cost prohibitive. The solution to this problem can be found by observing the function of ants who, despite their size, are very efficient transporters. The success of the ant is based on the number of workers and not their size, so the use of a smaller in size but more significant in number fleet of trucks and excavators makes it easier and more economical to supply them with energy according to today’s data; the small size also allows the development of telekinesis technology or robotic systems [107,108]. An example is the downsized 15-ton autonomous truck designed by VOLVO’s engineers in 2015, which has gained a lot of attention in the mining industry [107]. The absence of a cab and a driver reduces the truck’s size and operating cost; this technology has already been developed and applied in various mines, such as Abakansky in Russia, Rio Tinto, and Western Australia [109]. Using electric vehicles with current standards is difficult, as batteries have a short life, and the need for an efficient energy storage system significantly increases the operating costs. Feng and Dong’s [110] research has proposed a method using an artificial neural network (ANN) model and a fuzzy logic controller for the cost-minimization of fully electric trucks using batteries. Hybrid technologies, such as trolley-powered trucks, are more economical and, at the same time, ecological; they were first used in mining in the 1980s due to the fuel oil crisis and were revived again in 2006 [111]. Fully electric trucks are developed by researchers in Switzerland based on Komatsu HB 605–7 [112]. The “e–dumper” was created with a technology that produces its own energy through regenerative braking on downhill runs [113], and it is considered to be the largest electrical dumper with a 4.5-ton battery. It must notice that many companies around the world, already have develop fully electric trucks. Alternative transition technologies for the post-carbon era are presented by the rail system developed by Bluevein or trolley assistant system used to reduce oil consumption when transporting material. In addition, a new alternative technology using hydrogen was introduced by BELAZ company in 2023, with a 130-ton dump truck 7513M H2 Hybrid [106]. It is worth noting that the trolley-assistant technology mentioned above is the most successful electrification solution nowadays, and many different companies manufacture trolley-assist haulage trucks [111]. One of the first uses of this technology is applied in the Aitik mine to reduce fuel oil consumption, corresponding to about 0.4% of the energy of all petroleum-based fuels in Sweden [114]. Additionally, it was successfully applied in Erzberg in Austria with a 5 km trolley line (for the six LIEBHERR T 236 trucks); one of the longest uses of this technology.

Figure 14.

Haulage mining equipment evolution, from Euclid’s model 1Z first off-road truck, to articulated dumpers, electric, hybrid, and robotics vehicles (this diagram contains some different dumper technologies from companies that give permission to use the photos of their trucks).

Today, the rise of Artificial Intelligence (AI) allows researchers to create robotic systems inspired by ants’ motion and communication, such as research at the University of Sheffield where they created a swarm of robots imitating ants [70,115,116,117,118]; this technology will help to automate mining even in challenging environments and in the future may allow humans to expand mining beyond the terrestrial environment. Researchers [119,120] have been inspired by the pheromone communication system of ants [16] and other animals, using a virtual pheromone system. This system was used to mimic the collective behavior of ants in a robot swarm.

The research by NASA [121] for the planning of mining in space is oriented towards the use of robotic systems where each member of the swarm will have distinct roles; detecting, digging, and transporting the material in accordance with the responsibilities of the workers of an ant colony—the communication and synchronization of each member being done by broadcasting wireless signals. Robotic systems should be energy-autonomous by utilizing solar energy to operate in extraterrestrial environments. Robot designs, inspired by nature, show effectiveness in locomotion and energy efficiency compared to traditional approaches and are the future of mining equipment design [31].

7. Discussion

Although, in some cases, the ant’s expansive nature brings it into conflict with humans and some species can be dangerous to them, its coexistence with humans has a more positive influence on th/eir lives. In this research, we have used the ant example to highlight and illustrate the many processes involved in extracting raw materials. In addition to the metaphorical association of the functions of an ant colony with exploitation, there is also the practical one. The sympathetic insect has been used in mining since ancient times [5,6] and is still a source of inspiration for the development of modern mining systems today [119,120,121]. In the future, robotically self-organized vehicle fleets will be adopted in complex environments such as underground [31] and space mining [121], based on the ant colony example. In surface mining, the conditions are different and allow the use of larger vehicles. Various technologies that can help with that have already been developed, as presented in the last section of the current work [109,114]. Ants have been a source of inspiration in many aspects of human activities, from architectural design [4] to the development of optimization algorithms, and many works exist in these areas [88,89,90,91,92,93,94,95,96,97].

In today’s context of the fourth industrial revolution, tools have been developed that allow the evolution of mining technology, which was very difficult to achieve in previous decades. It should be noted that the mining environment is multi-factorial and volatile, which raises many difficulties in full automation, and the human factor will always play a key role. Nevertheless, many research groups [70,115,116,117,118,122] investigate the use of a robotic swarm of mining equipment, such as NASA [121] and ROBOMINERS, which is funded by the EU [30,31]. Also remarkable is the research on this topic by Linevich et al. [87], in which they used the kinematic behavior of insects, specifically ants [26], for designing innovative digging equipment appropriate in confined environments. All research for nature-like equipment will help mining proceed in challenging environments such as deep underground excavations, undersea mining, and space mining. This manuscript attempted to cover a wide range of mining processes and directly correlate them with ant’s lives, aiming to improve the mining industry.

8. Conclusions

Ants are efficient “miners” that, at the same time, have a positive environmental footprint; unlike human exploitation, which still needs much effort to reach the goal of the EU for zero CO2 emissions. Observing how nature and its members work will help to reach this goal faster by gradually substituting diesel-operated technology with self-sufficient robotic equipment. This work is divided into seven fields to examine the importance of the ant in the mining industry: from the importance of ants for human society to gold tracing, rehabilitation, similarities of ants’ lives with mining, ant colony algorithms, mine technology, and design of future nature-like robotic systems. Based on this categorization, the improvement of mining processes can be summarized as follows:

- The development of artificial intelligence allows the ant paradigm to be involved in the design of robotic systems, which will efficiently automate the exploitation process, reducing its environmental footprint. This technology will also help mining in conditions that are difficult for humans, such as the exploitation of underground deposits, especially at great depths, and possible mining in space in the future.

- Ants also have more direct positive effects on mining, such as their use as bioindicators to monitor the impact of mining on the environment.

- They are also used in many cases to locate alluvial gold, as during nest building they have been observed to carry the underground gold to the anthill, revealing a possible underground deposit. This practice has been mentioned in the ancient writings of Herodotus and his gold-digging ant.

- The technique of creating a mold of ant nests, apart from its visual uses, has helped to create 3D models of the tunnel network and can be used for modelling stability, ventilation, and other parameters critical for mining. In addition, we suggest that the nests can be a first-class analogue experimental setup for determining the actual behavior of geomaterials. Nowadays, numerical models are a powerful simulation tool. However, it is challenging to create 3D models that fully reproduce the physical response as they are based on many assumptions. Although the nests are mainly located in the first soil layers with different mechanical behavior from the humans’ underground excavations, studying ant-nest structures can help improve numerical models.

- The functioning of a colony and how pheromone signals from ants are used to self-organize the “exploration” and transportation of food has been adopted from the mining industry with the ant colony algorithms. Many studies have used these algorithms to improve mining production and hauling processes.

- Despite their small size, ants are pretty efficient miners due to the large number of colony members and their cooperation. There are studies on replacing the “large to small” in size and “few to many” in number mining fleet to meet the needs dictated by the post-coal era.

- Today’s mining technology is focused on the transition to electrification and the creation of autonomous systems. At the same time, research has been concentrated on creating collaborative robotic systems that will, in the future, replace current technologies, enabling the expansion of operations into more challenging environments.

- This work shows that the existing mining technology has many similarities with the ant’s body and has already helped the mining industry in the past years. Furthermore, in the future, the connection that ant colony members have with each other will help to design more efficient autonomous systems.

Author Contributions

Conceptualization, G.X.; validation, G.S. and E.M.; investigation, G.X., G.S. and E.M.; writing—original draft preparation, G.X.; writing—review and editing, G.X. and G.S.; visualization, G.S.; supervision, G.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

This is a review paper, and no new data have been produced.

Acknowledgments

We would like to thank the companies of mining equipment for providing information and photos of their machines, which in alphabetical order are: BELAZ, https://belaz.by/en; Buyer Service Team, China Product Manufacturers, https://antsexcavator.en.made-in-china.com; eMining, www.emining.ch; ROKBAK, articulated haulers, www.rokbak.com; Volvo, https://www.volvoautonomoussolutions.com.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Viles, H.A.; Goudie, A.S.; Goudie, A.M. Ants as geomorphological agents: A global assessment. Earth Sci. Rev. 2021, 213, 103469. [Google Scholar] [CrossRef]

- Cammeraat, E.L.H.; Risch, A.C. The impact of ants on mineral soil properties and processes at different spatial scales. J. Appl. Entomol. 2008, 132, 285–294. [Google Scholar] [CrossRef]

- Evans, T.A.; Dawes, T.Z.; Ward, P.R.; Lo, N. Ants and termites increase crop yield in a dry climate. Nat. Commun. 2011, 2, 262. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.; Zhou, W.; Qu, W.; Yao, W.; Zhu, P.; Xu, J. A review of ant nests and their implications for architecture. Buildings 2022, 12, 2225. [Google Scholar] [CrossRef]

- Gren, D., Translator; The History; Translation of Herodotus [c. 430 BC]; University of Chicago Press: Chicago, IL, USA, 1987. [Google Scholar]

- Ancient Greek Language and Literature. The History. Herodotus (-3.97.1-3.105.2). Available online: https://www.greek-language.gr/digitalResources/ancient_greek/library/ (accessed on 5 February 2024).

- Vernier, M. Fertilissimi Sunt Auri Dardae, Setae Vero et Argenti. Notes on some ancient open-air gold mining sites in Ladakh. Études Mongoles Sib. Centrasiatiques Tibét. 2020, 51. [Google Scholar] [CrossRef]

- Ellison, A.M.; Gotelli, N.J. Ants (hymenoptera: Formicidae) and humans: From inspiration and metaphor to 21st-century symbiont. Myrmecol. News 2021, 31, 225–240. [Google Scholar] [CrossRef]

- De Schutter, G.; Theraulaz, G.; Deneubourg, J.L. Animal-Robots collective intelligence. Ann. Math. Artif. Intell. 2001, 31, 223–238. [Google Scholar] [CrossRef]

- Tolvanen, A.; Eilu, P.; Juutinen, A.; Kangas, K.; Kivinen, M.; Markovaara-Koivisto, M.; Naskali, A.; Salokannel, V.; Tuulentie, S.; Similä, J. Mining in the arctic environment—A review from ecological, socioeconomic and legal perspectives. J. Environ. Manag. 2019, 233, 832–844. [Google Scholar] [CrossRef] [PubMed]

- Gubanov, R.S. Development of mining companies in the arctic zone of the Russian federation: Conditions and risks. Ugol 2022, 5, 49–54. [Google Scholar] [CrossRef]

- Xu, H.; Xu, F.; Lin, T.; Xu, Q.; Yu, P.; Wang, C.; Aili, A.; Zhao, X.; Zhao, W.; Zhang, P.; et al. A Systematic Review and Comprehensive Analysis on Ecological Restoration of Mining Areas in the Arid Region of China: Challenge, Capability and Reconsideration. Ecol. Indic. 2023, 154, 110630. [Google Scholar] [CrossRef]

- Riff, M.C.; Moossen, M.; Bonnaire, X. Miner Ants Colony: A New Approach to Solve a Mine Planning Problem. In Proceedings of the Lecture Notes in Computer Science, Istanbul, Turkey, 26–28 October 2005. [Google Scholar]

- Waldner, J.B. Nanocomputers and Swarm Intelligence; Wiley-ISTE: London, UK, 2010. [Google Scholar] [CrossRef]

- Hewawasam, H.S.; Ibrahim, M.Y.; Appuhamillage, G.K. Past, present and future of path-planning algorithms for mobile robot navigation in dynamic environments. IEEE Open J. Ind. Electron. Soc. 2022, 3, 353–365. [Google Scholar] [CrossRef]

- Heyman, Y.; Shental, N.; Brandis, A.; Hefetz, A.; Feinerman, O. Ants regulate colony spatial organization using multiple chemical road-signs. Nat. Commun. 2017, 8, 15414. [Google Scholar] [CrossRef] [PubMed]

- Preve, N. Balanced job scheduling based on ant algorithm for grid network. Int. J. Grid High Perform. Comput. 2010, 2, 34–50. [Google Scholar] [CrossRef]

- Fan, J.; Xie, H.; Chen, J.; Jiang, D.; Li, C.; Ngaha Tiedeu, W.; Ambre, J. Preliminary feasibility analysis of a hybrid pumped-hydro energy storage system using abandoned coal mine Goafs. Appl. Energy 2020, 258, 114007. [Google Scholar] [CrossRef]

- Lyu, X.; Yang, K.; Fang, J.; Tang, J.; Wang, Y. Feasibility study of construction of pumped storage power station using abandoned mines: A case study of the Shitai mine. Energies 2023, 16, 314. [Google Scholar] [CrossRef]

- O’Brien, M.J.; Bentley, R.A. The Role of Food Storage in Human Niche Construction: An Example from Neolithic Europe. Environ. Archaeol. 2015, 20, 364–378. [Google Scholar] [CrossRef]

- Forti, L.C.; de Andrade, A.P.P.; Camargo, R.d.S.; Caldato, N.; Moreira, A.A. Discovering the Giant Nest Architecture of Grass-Cutting Ants, Atta capiguara (Hymenoptera, Formicidae). Insects 2017, 8, 39. [Google Scholar] [CrossRef]

- Gillies, A.D.S.; Mudd, K.E.; Aughenbaugh, N.B. Living conditions in underground houses in Coober Pedy, Australia. In The Potential of Earth-Sheltered and Underground Space; Pergamon: Oxford, UK, 1981. [Google Scholar] [CrossRef]

- Kollarath, R.M.; Raina, S.; Madapur, B. Underground cities: Sustainable urbanism of the future. Int. J. Recent Technol. Eng. 2019, 8, 1754–1757. [Google Scholar] [CrossRef]

- Aydan, Ö.; Ulusay, R. Geomechanical evaluation of Derinkuyu antique underground city and its implications in geoengineering. Rock Mech. Rock Eng. 2013, 46, 731–754. [Google Scholar] [CrossRef]

- Brooks, W.E. Locations of cinnabar-mercury occurrences in Peru: Implications for pre-contact gold production. Archaeol. Discov. 2020, 8, 245–259. [Google Scholar] [CrossRef]

- Monaenkova, D.; Gravish, N.; Rodriguez, G.; Kutner, R.; Goodisman, M.A.D.; Goldman, D.I. Behavioral and mechanical determinants of collective subsurface nest excavation. J. Exp. Biol. 2015, 218, 1295–1305. [Google Scholar] [CrossRef] [PubMed]

- Halboth, F.; Roces, F. The construction of ventilation turrets in Atta Vollenweideri leaf-cutting ants: Carbon dioxide levels in the nest tunnels, but not airflow or air humidity, influence turret structure. PLoS ONE 2017, 12, e0188162. [Google Scholar] [CrossRef] [PubMed]

- Sánchez, F.; Hartlieb, P. Innovation in the Mining Industry: Technological Trends and a Case Study of the Challenges of Disruptive Innovation. Min. Met. Explor. 2020, 37, 1385–1399. [Google Scholar] [CrossRef]

- Zhironkina, O.; Zhironkin, S. Technological and Intellectual Transition to Mining 4.0: A Review. Energies 2023, 16, 1427. [Google Scholar] [CrossRef]

- Koutsopoulou, E.; Servou, A.; Aggelopoulos, G.; Laskaridis, K. Research and Innovation in Exploration and Mining of Raw Materials: The ROBOMINERS Project. Mater. Proc. 2021, 5, 59. [Google Scholar] [CrossRef]

- Lopes, L.; Bodo, B.; Rossi, C.; Henley, S.; Žibret, G.; Kot-Niewiadomska, A.; Correia, V. ROBOMINERS—Developing a Bio-Inspired Modular Robot-Miner for Difficult to Access Mineral Deposits. Adv. Geosci. 2020, 54, 99–108. [Google Scholar] [CrossRef]

- Reimer, T. Larger than Foxes—But smaller than dogs: The gold-digging Ants of Herodotus. Reinardus. Yearb. Int. Reynard Soc. 2007, 19, 167–178. [Google Scholar] [CrossRef]

- Oughton, C.W. Chapter 9: What about the Gold-Digging Ants? The Silences and Irony of Plutarch’s De Herodoti Malignitate. In Plutarch’s Unexpected Silences; Brill: Leiden, The Netherlands, 2023; Volume 10, pp. 151–169. [Google Scholar]

- Stewart, A.D.; Anand, R.R.; Balkau, J. Source of anomalous gold concentrations in termite nests, Moolart Well, Western Australia: Implications for exploration. Geochem. Explor. Environ. Anal. 2012, 12, 327–337. [Google Scholar] [CrossRef]

- Paniz, J.N.G.; Flores, É.M.D.M.; Martins, A.F. Anthill earth as a gold occurrence indicator, and gold determination by solid sampling flame atomic absorption spectrometry. Microchim. Acta 2005, 152, 89–92. [Google Scholar] [CrossRef]

- Stewart, A.D.; Anand, R.R. Anomalies in insect nest structures at the Garden Well gold deposit: Investigation of mound-forming termites, subterranean termites and ants. J. Geochem. Explor. 2014, 140, 77–86. [Google Scholar] [CrossRef]

- Mathioudakis, S.; Xiroudakis, G.; Petrakis, E.; Manoutsoglou, E. Alluvial gold mining technologies from ancient times to the present. Mining 2023, 3, 618–644. [Google Scholar] [CrossRef]

- March, K.; Brewin, R. Ants More Efficient Than Termites in Leading Humans to Gold: Study. Available online: https://www.abc.net.au/ (accessed on 21 January 2024).

- Gold Fever Adventures. Yes Gold in Ant Hills? Testing! Proof Is in the Pan. Available online: https://www.youtube.com/watch?v=v8hS2QjPrXY (accessed on 21 January 2024).

- Yeo, K.; Kouakou, L.M.M.; Touao, M.K.; Gauze, E.; Ouattara, K.; Soro, A.N. Ants response to mining prospection disturbances across vegetation zones in tropical mountain chains of Mount Nimba, Guinea, West Africa. Int. J. Biol. Chem. Sci. 2019, 13, 899. [Google Scholar] [CrossRef]

- Ribas, C.R.; Schmidt, F.A.; Solar, R.R.C.; Campos, R.B.F.; Valentim, C.L.; Schoereder, J.H. Ants as indicators of the success of rehabilitation efforts in deposits of gold mining tailings. Restor. Ecol. 2012, 20, 712–720. [Google Scholar] [CrossRef]

- Andersen, A.N. Ants as indicators of restoration success at a uranium mine in tropical Australia. Restor. Ecol. 1993, 1, 156–167. [Google Scholar] [CrossRef]

- Ottonetti, L.; Tucci, L.; Santini, G. Recolonization patterns of ants in a rehabilitated lignite mine in central Italy: Potential for the use of Mediterranean ants as indicators of restoration processes. Restor. Ecol. 2006, 14, 60–66. [Google Scholar] [CrossRef]

- Fernandes, G.W.; Lana, T.C.; Ribas, C.R.; Schoereder, J.H.; Solar, R.; Majer, J.D.; Cordeiro, E.G.; Delabie, J.H.C.; Vilela, E.F. Changes in epigaeic ant assemblage structure in the Amazon during successional processes after bauxite mining. Sociobiology 2021, 68, 4973. [Google Scholar] [CrossRef]

- Khan, S.R.; Singh, S.K.; Rastogi, N. Heavy Metal Accumulation and Ecosystem Engineering by Two Common Mine Site-Nesting Ant Species: Implications for Pollution-Level Assessment and Bioremediation of Coal Mine Soil. Environ. Monit. Assess. 2017, 189, 195. [Google Scholar] [CrossRef] [PubMed]

- Buchori, D.; Rizali, A.; Rahayu, G.A.; Mansur, I. Insect Diversity in Post-Mining Areas: Investigating Their Potential Role as Bioindicator of Reclamation Success. Biodiversitas 2018, 19, 1696–1702. [Google Scholar] [CrossRef]

- Dvorackova, M.; Pech, P.; Prausová, R.; Horák, J. Diversity of Ant Community in Ore Sedimentation Basin under Different Regimes of Reclamation. Pol. J. Ecol. 2018, 66, 139–152. [Google Scholar] [CrossRef]

- Roivainen, P.; Muurinen, S.M.; Sorvari, J.; Juutilainen, J.; Naarala, J.; Salomaa, S. Transfer of elements into Boreal forest ants at a former uranium mining site. Environ. Pollut. 2022, 304, 119231. [Google Scholar] [CrossRef]

- Kavehei, A.; Gore, D.B.; Wilson, S.P.; Hosseini, M.; Hose, G.C. Assessment of legacy mine metal contamination using ants as indicators of contamination. Environ. Pollut. 2021, 274, 116537. [Google Scholar] [CrossRef] [PubMed]

- Oyekan, J.; Hu, H. Ant robotic swarm for visualizing invisible hazardous substances. Robotics 2013, 2, 1–18. [Google Scholar] [CrossRef]

- Jakubec, J.; Lagace, D.; Boggis, W.; Clark, L.; Lewis, P. Underground Mining at Ekati and Diavik Diamond Mines. In Caving 2018: Proceedings of the Fourth International Symposium on Block and Sublevel Caving, Vancouver, BC, Canada, 5–17 October 2018; Potvin, Y., Jakubec, J., Eds.; Australian Centre for Geomechanics: Perth, WA, Australia, 2018; pp. 73–88. [Google Scholar] [CrossRef]

- Engelking Workers of the World! There Is Efficiency in Idleness. Available online: https://www.discovermagazine.com/ (accessed on 21 January 2024).

- Navidi, S.; Motamedi, M.; Aghsami, A.; Jolai, F. A G/M/C//M Queueing model for revenue management of shovel-truck systems in an open-pit mine considering carbon emission, a case study. Int. J. Manag. Sci. Eng. Manag. 2022, 18, 88–103. [Google Scholar] [CrossRef]

- Paricheh, M.; Osanloo, M. Determination of the Optimum In-Pit Crusher Location in Open-Pit Mining under Production and Operating Cost Uncertainties. In Proceedings of the 16th International Conference on Computer Applications in the Mineral Industries, Instanbul, Turkey, 5–7 October 2016. [Google Scholar]

- Prados-Garzon, J.; Ameigeiras, P.; Ramos-Munoz, J.J.; Navarro-Ortiz, J.; Andres-Maldonado, P.; Lopez-Soler, J.M. Performance modeling of softwarized network services based on queuing theory with experimental validation. IEEE Trans. Mob. Comput. 2021, 20, 1558–1573. [Google Scholar] [CrossRef]

- Frost, J.D.; Roozbahani, M.M.; Jackson, K.; Leonard, L.; Yamamoto, K.; Jones, M.; Martinez, A. Biologically-Inspired Insights into Soil Arching and Tunnel Stability from the Topology of Ant Nests. In Proceedings of the ICSMGE 2017—19th International Conference on Soil Mechanics and Geotechnical Engineering, Seoul, Republic of Korea, 17–21 September 2017. [Google Scholar]

- Qu, W.; Zhou, W.; Zhu, P.; Zhang, Z. Model of underground ant nest structure using static and dynamic finite element analysis. Acta Mech. Solida Sin. 2018, 31, 717–730. [Google Scholar] [CrossRef]

- Yang, G.; Zhou, W.; Xu, J.; Zeng, M.; Kulminskaya, A.A. Static analysis of underground ant nest structures. Appl. Sci. 2022, 12, 12201. [Google Scholar] [CrossRef]

- De Macedo, R.B.; Andò, E.; Joy, S.; Viggiani, G.; Pal, R.K.; Parker, J.; Andrade, J.E. Unearthing real-time 3D ant tunneling mechanics. Proc. Natl. Acad. Sci. USA 2021, 118, e2102267118. [Google Scholar] [CrossRef]

- Vardoulakis, P.; Stavropoulou, M.; Exadaktylos, G. Sandbox modeling of the shallow tunnel face collapse. Riv. Ital. Geotec. 2009, 9–22. [Google Scholar]

- Barakos, G.; De Bueno, M.P.; Luukkanen, S.; Mischo, H.; Zhang, Z.; Gonzalez, M.S.; Holopainen, P.; Remes, A. The Minetrain Project: Developing an Advanced Level Training Program for Mining Industry Professionals in an Actual Deep Mine Site. In Proceedings of the 2019 SME Annual Conference and Expo and CMA 121st National Western Mining Conference, Denver, CO, USA, 24–27 February 2019. [Google Scholar]

- Ptak, M.; Podolska, P.; Podolski, R. Challenges for Science: The Exploitation of Deep Deposits. In Proceedings of the E3S Web of Conferences, Semarang, Indonesia, 8–10 April 2018; Volume 71. [Google Scholar]

- Schafrik, S.; Kolapo, P.; Agioutantis, Z. Development of an Automated Roof Bolting Machine for Underground Coal Mines. In Proceedings of the 32nd SOMP Annual Meeting and Conference, Windhoek, Namibia, 8–14 September 2022; The Southern African Institute of Mining and Metallurgy: Johannesburg, South Africa, 2022. [Google Scholar]

- Cosarinsky, M.I.; Roces, F. The construction of turrets for nest ventilation in the grass-cutting ant Atta vollenweideri: Import and assembly of building materials. J. Insect Behav. 2012, 25, 222–241. [Google Scholar] [CrossRef]

- Bruce, A.I.; Pérez-Escudero, A.; Czaczkes, T.J.; Burd, M. The digging dynamics of ant tunnels: Movement, encounters, and nest space. Insectes Soc. 2019, 66, 119–127. [Google Scholar] [CrossRef]

- Toffin, E.; Di Paolo, D.; Campo, A.; Detrain, C.; Deneubourg, J.L. Shape transition during nest digging in ants. Proc. Natl. Acad. Sci. USA 2009, 106, 18616–18620. [Google Scholar] [CrossRef] [PubMed]

- Tschinkel, W.R. The architecture of subterranean ant nests: Beauty and mystery underfoot. J. Bioecon. 2015, 17, 271–291. [Google Scholar] [CrossRef]

- Banasiewicz, A.; Moosavi, F.; Kotyla, M.; Śliwiński, P.; Krot, P.; Wodecki, J.; Zimroz, R. Forecasting of NOx Emissions of Diesel LHD Vehicles in Underground Mines—An ANN-Based Regression Approach. Appl. Sci. 2023, 13, 9965. [Google Scholar] [CrossRef]

- Made-in-China Buyer Service Team. Available online: https://www.made-in-china.com/ (accessed on 20 February 2024).

- Yeoh, C.E.; Yi, H. Conceptual Design of the combinable legged robot bio-inspired by ants’structure. Appl. Sci. 2021, 11, 1379. [Google Scholar] [CrossRef]

- Mantzareas, K. Kinematic Simulation of Mining—Transport in Surface Exploitation. Diploma Thesis, Technical University of Crete, Crete, Greece, 2024. Unpublished Work. [Google Scholar]

- McKay, G. It’s Not Rocket Science #2: Ventilation. Available online: https://misfitsarchitecture.com/ (accessed on 21 January 2024).

- Yang, G.; Zhou, W.; Xu, J.; Zeng, M.; Wu, S.; You, Y. Ventilation simulation in an underground ant nest structure of Camponotus Japonicus Mayr. Sustainability 2022, 14, 16026. [Google Scholar] [CrossRef]

- VentSim. VentSim 5.0, 3D Mining Ventilation Simulation Software; Howden: Renfrew, UK, 2020. [Google Scholar]

- Wang, E.; Li, X.; Huang, Q.; Wang, G. Research on the influence of natural wind pressure in deep mines on ventilation stability. Adv. Civ. Eng. 2022, 2022, 8789955. [Google Scholar] [CrossRef]

- McPherson, M.J. Subsurface Ventilation Engineering; University of Nottingham, England and University οf California: Berkeley, CA, USA, 2009. [Google Scholar]

- Liang, Y.; Zhang, J.; Ren, T.; Wang, Z.; Song, S. Application of ventilation simulation to spontaneous combustion control in underground coal mine: A case study from Bulianta Colliery. Int. J. Min. Sci. Technol. 2018, 28, 231–242. [Google Scholar] [CrossRef]

- Şuvar, M.; Cioclea, D.; Gherghe, I.; Pǎsculescu, V. Advanced software for mine ventilation networks solving. Environ. Eng. Manag. J. 2012, 11, 1235–1239. [Google Scholar] [CrossRef]

- Shen, G.; Ma, J.; Hu, Y.; Li, J.; Cheng, T.; Wen, J. An air velocity monitor for coal mine ventilation based on vortex-induced triboelectric nanogenerator. Sensors 2022, 22, 4832. [Google Scholar] [CrossRef]

- Guo, P.; He, M.; Zheng, L.; Zhang, N. A Geothermal recycling system for cooling and heating in deep mines. Appl. Therm. Eng. 2017, 116, 833–839. [Google Scholar] [CrossRef]

- Ogunmodede, O.; Lamas, P.; Brickey, A.; Bogin, G.; Newman, A. Underground production scheduling with ventilation and refrigeration considerations. Optim. Eng. 2022, 23, 1677–1705. [Google Scholar] [CrossRef]

- Vosloo, J.; Liebenberg, L.; Velleman, D. Case study: Energy savings for a deep-mine water reticulation system. Appl. Energy 2012, 92, 328–335. [Google Scholar] [CrossRef]

- Du Plessis, G.E.; Liebenberg, L.; Mathews, E.H. Case study: The effects of a variable flow energy saving strategy on a deep-mine cooling system. Appl. Energy 2013, 102, 700–709. [Google Scholar] [CrossRef]

- Rubio, R.F.; Fabregas, A.L.; Carlos, J.; Ubeda, B.; Lorca, D. Underground Mining Drainage. State of the Art. In Proceedings of the International Mine Water Association Symposium, Johannesburg, South Africa, 7–13 September 1998. [Google Scholar]

- Hu, L.; Zhang, M.; Yang, Z.; Fan, Y.; Li, J.; Wang, H.; Lubale, C. Estimating dewatering in an underground mine by using a 3D finite element model. PLoS ONE 2020, 15, e0239682. [Google Scholar] [CrossRef]

- Guzy, A.; Malinowska, A.A. Assessment of the impact of the spatial extent of land subsidence and aquifer system drainage induced by underground mining. Sustainability 2020, 12, 7871. [Google Scholar] [CrossRef]

- Linevich, V.; Monaenkova, D.; Goldman, D.I. Robophysical Study of Excavation in Confined Environments. Artif. Life Robot. 2016, 21, 460–465. [Google Scholar] [CrossRef]

- Ab Wahab, M.N.; Nefti-Meziani, S.; Atyabi, A. A comprehensive review of swarm optimization algorithms. PLoS ONE 2015, 10, e0122827. [Google Scholar] [CrossRef] [PubMed]

- Dorigo, M.; Blum, C. Ant colony optimization theory: A survey. Theor. Comput. Sci. 2005, 344, 243–278. [Google Scholar] [CrossRef]

- Negulescu, S.C.; Kifor, C.V.; Oprean, C. Ant colony solving multiple constrains problem: Vehicle route allocation. Int. J. Comput. Commun. Control 2008, 3, 366. [Google Scholar] [CrossRef][Green Version]

- Prakasam, A.; Savarimuthu, N. Metaheuristic algorithms and probabilistic behaviour: A comprehensive analysis of ant colony optimization and its variants. Artif. Intell. Rev. 2016, 45, 97–130. [Google Scholar] [CrossRef]

- Song, B.; Miao, H.; Xu, L. Path planning for coal mine robot via improved ant colony optimization algorithm. Syst. Sci. Control Eng. 2021, 9, 283–289. [Google Scholar] [CrossRef]

- Shishvan, M.S.; Sattarvand, J. Long Term production planning of open pit mines by ant colony optimization. Eur. J. Oper. Res. 2015, 240, 825–836. [Google Scholar] [CrossRef]

- Gilani, S.O.; Sattarvand, J. Integrating geological uncertainty in long-term open pit mine production Planning by Ant Colony Optimization. Comput. Geosci. 2016, 87, 31–40. [Google Scholar] [CrossRef]

- Sang, J. A Cost-effective pump scheduling method for mine drainage system based on ant colony optimization. J. Eur. Des. Syst. Autom. 2019, 52, 123–128. [Google Scholar] [CrossRef][Green Version]

- Dabbagh, A.; Bagherpour, R. Development of a match factor and comparison of its applicability with ant-colony algorithm in a heterogeneous transportation fleet in an open-pit mine. J. Min. Sci. 2019, 55, 45–56. [Google Scholar] [CrossRef]

- Wan, L.; Du, C. An Approach to evaluation of environmental benefits for ecological mining areas based on ant colony algorithm. Earth Sci. Inf. 2021, 14, 797–808. [Google Scholar] [CrossRef]

- Feng, H.; Yin, C.; Ma, W.; Yu, H.; Cao, D. Parameters Identification and Trajectory Control for a Hydraulic System. ISA Trans. 2019, 92, 228–240. [Google Scholar] [CrossRef] [PubMed]

- Galetakis, M.; Vasileiou, A.; Rogdaki, A.; Deligiorgis, V.; Raka, S. Estimation of mineral resources with machine learning techniques. Mater. Proc. 2022, 5, 122. [Google Scholar] [CrossRef]

- Fang, B. Method for quickly identifying mine water inrush using convolutional neural network in coal mine safety mining. Wirel. Pers. Commun. 2022, 127, 945–962. [Google Scholar] [CrossRef]

- Dagasan, Y.; Renard, P.; Straubhaar, J.; Erten, O.; Topal, E. Automatic parameter tuning of multiple-point statistical simulations for lateritic bauxite deposits. Minerals 2018, 8, 220. [Google Scholar] [CrossRef]

- Wang, H.; Tenorio, V.; Li, G.; Hou, J.; Hu, N. Optimization of trackless equipment scheduling in underground mines using genetic algorithms. Min. Met. Explor. 2020, 37, 1531–1544. [Google Scholar] [CrossRef]

- Palogos, I.; Galetakis, M.; Roumpos, C.; Pavloudakis, F. Selection of optimal land uses for the reclamation of surface mines by using evolutionary algorithms. Int. J. Min. Sci. Technol. 2017, 27, 491–498. [Google Scholar] [CrossRef]

- Rokbak. Our History Carved by a Lifetime of Hard Work. Available online: https://www.rokbak.com/our-history/ (accessed on 6 February 2024).

- Bozorgebrahimi, E.; Hall, R.A.; Blackwell, G.H. Sizing equipment for open pit mining—A review of critical parameters. Min. Technol. 2003, 112, 171–179. [Google Scholar] [CrossRef]

- BELAZ. The Major Manufacturer of Heavy Duty Mining Dump Trucks. Available online: https://belaz.by/en/ (accessed on 12 February 2024).

- Müller, U. How Downsizing through Autonomy Is Changing the Game in Mines and Quarries. Available online: https://www.volvoautonomoussolutions.com (accessed on 17 February 2024).

- Knights, P.; Franklin, D. Autonomous Surface Mining Equipment: Is Bigger Better? In Proceedings of the 2010 Australian Mining Technology Conference: “Technology Changing the Mining Business Footprint”, Perth, WA, Australia, 13–15 September 2010; CRC Mining: Pinjarra Hills, QLD, Australia, 2010. [Google Scholar]

- Khazin, M.L. Directions of career transport development. Perm J. Pet. Min. Eng. 2021, 21, 144–150. [Google Scholar] [CrossRef]

- Feng, Y.; Dong, Z. Optimal energy management with balanced fuel economy and battery life for large hybrid electric mining truck. J. Power Sources 2020, 454, 227948. [Google Scholar] [CrossRef]

- Digging Deep. Trolley Assist Haulage Systems: Championing Decarbonization of the Mining Industry. Available online: https://www.linkedin.com/ (accessed on 7 February 2024).

- eMining. Zero Emission Mining. Available online: www.emining.ch (accessed on 24 February 2024).

- Graham Rapier. This Massive 45-Ton Electric Dump Truck Never Uses More Energy Than It Generates on Its Own—Here’s How That Works. Available online: https://www.businessinsider.com/edumper-121-ton-electric-dump-truck-2019-8 (accessed on 11 February 2024).

- Lindgren, L.; Grauers, A.; Ranggård, J.; Mäki, R. Drive-cycle simulations of battery-electric large haul trucks for open-pit mining with electric roads. Energies 2022, 15, 4871. [Google Scholar] [CrossRef]

- Rubenstein, M.; Ahler, C.; Nagpal, R. Kilobot: A Low Cost Scalable Robot System for Collective Behaviors. In Proceedings of the Proceedings—IEEE International Conference on Robotics and Automation, St. Paul, MN, USA, 14–18 May 2012. [Google Scholar]

- Castelló Ferrer, E. The Blockchain: A New Framework for Robotic Swarm Systems. In Proceedings of the Advances in Intelligent Systems and Computing, Cairo, Egypt, 26–28 October 2019; Volume 881. [Google Scholar]

- Leah, V. BionicANTS Work Together in Swarm Artificial Intelligence. Available online: https://www.machinedesign.com/ (accessed on 21 January 2024).

- Pell, R. AI-Powered Swarm Robots Aim to Disrupt Mining Industry. Available online: https://www.eenewseurope.com/ (accessed on 21 January 2024).

- Na, S.; Qiu, Y.; Turgut, A.E.; Ulrich, J.; Krajník, T.; Yue, S.; Lennox, B.; Arvin, F. Bio-inspired artificial pheromone system for swarm robotics applications. Adapt. Behav. 2021, 29, 395–415. [Google Scholar] [CrossRef]

- Na, S.; Niu, H.; Lennox, B.; Arvin, F. Universal Artificial Pheromone Framework with Deep Reinforcement Learning for Robotic Systems. In Proceedings of the 2021 6th International Conference on Control and Robotics Engineering, ICCRE 2021, Beijing, China, 16–18 April 2021. [Google Scholar]

- Kilic, C.; Bernardo Martinez, R.; Tatsch, C.A.; Beard, J.; Strader, J.; Das, S.; Ross, D.; Gu, Y.; Pereira, G.A.S.; Gross, J.N. NASA space robotics challenge 2 qualification round: An approach to autonomous lunar rover operations. IEEE Aerosp. Electron. Syst. Mag. 2021, 36, 24–41. [Google Scholar] [CrossRef]

- Dubinkin, D.; Sadovets, V.; Syrkin, I.; Chicherin, I. Assessment of the Need to Create Control Sytem of Unmanned Dump Truck. E3S Web Conf. 2020, 177, 03022. [Google Scholar] [CrossRef]