Maximizing Mining Operations: Unlocking the Crucial Role of Intelligent Fleet Management Systems in Surface Mining’s Value Chain

Abstract

:1. Introduction

2. Literature Review

2.1. FMSs: The Concept

2.2. Mining FMSs

2.2.1. Conventional Systems

2.2.2. Intelligent FMSs

3. Materials and Methods

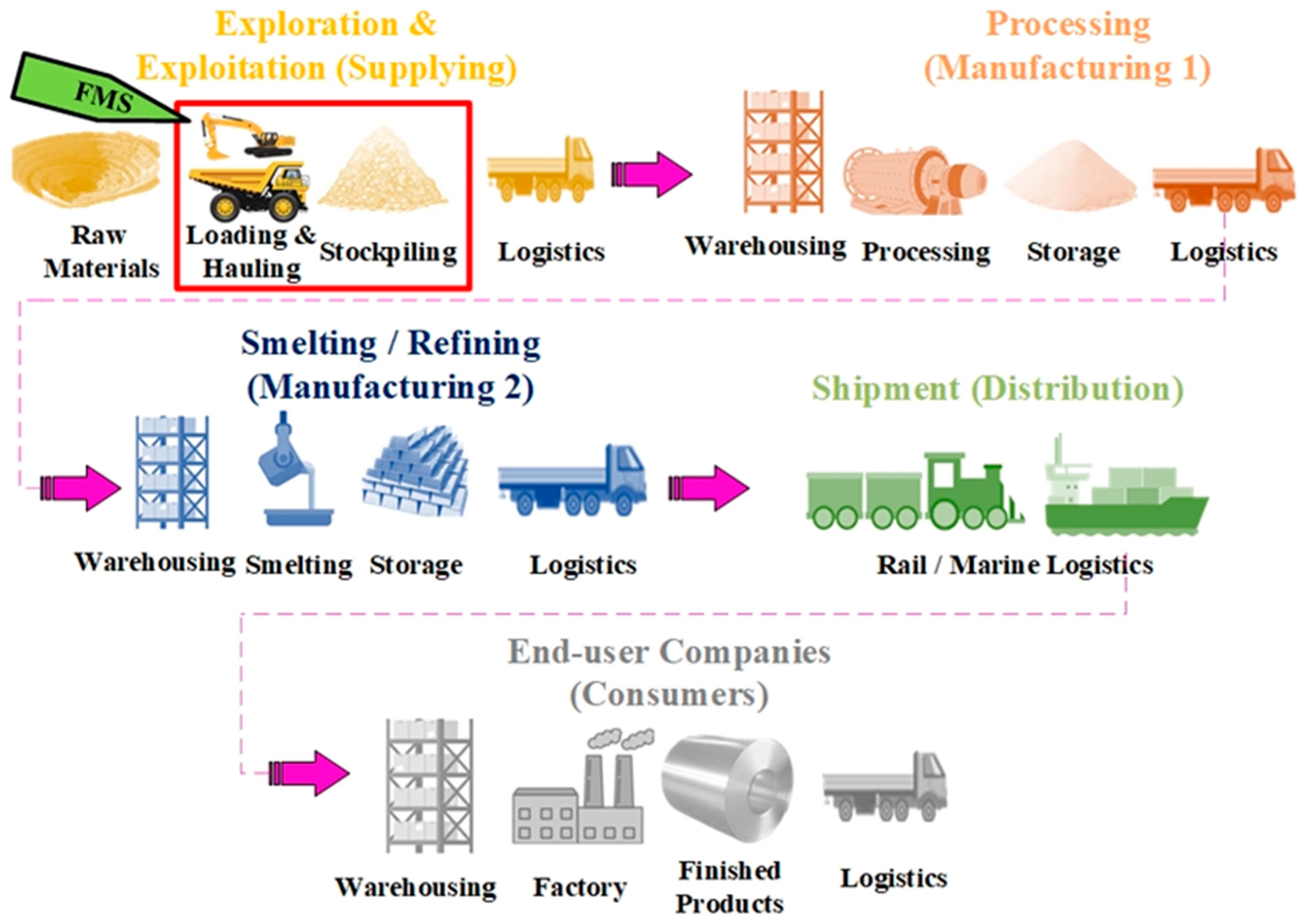

3.1. The Mining Supply Chain

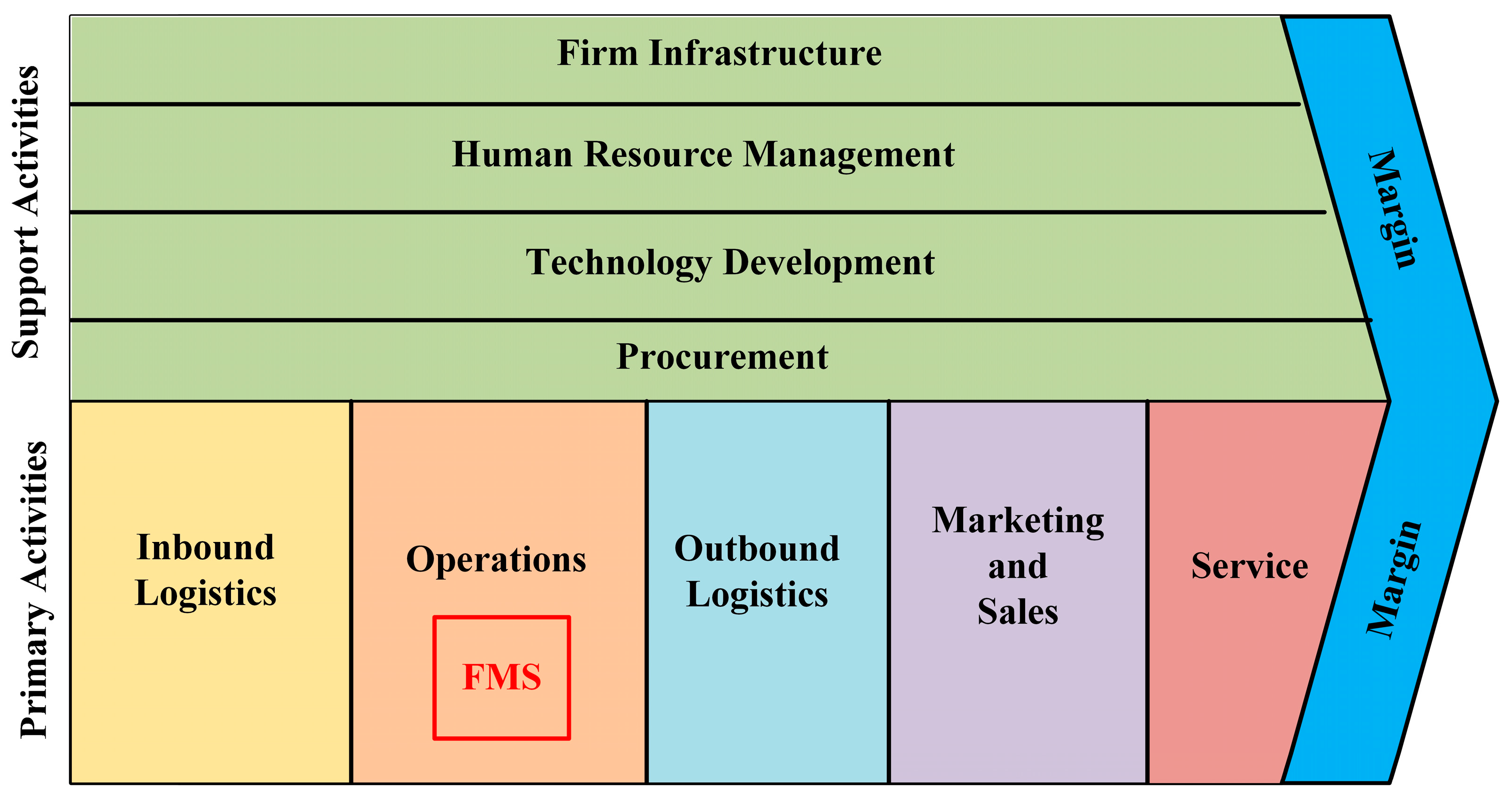

3.2. The Surface Mining’s Value Chain Analysis

4. Discussion and Conclusions

- Define the specific challenges and inefficiencies in mineral extraction processes within the mining complex.

- Identify areas where intelligent FMSs could potentially enhance efficiency, safety, and productivity.

- Conduct an extensive literature review to understand existing methodologies and technologies used in mining and FMSs.

- Assess various intelligent systems, such as GPS tracking, telematics, predictive analytics, and the Internet of Things, to determine their applicability in mineral extraction processes.

- Gather relevant data from the mining complex, including equipment performance, operational data, geospatial information, and historical records.

- Integrate FMSs with the existing infrastructure, ensuring compatibility and seamless data flow.

- Implement the selected intelligent systems within the extraction phase of the mining complex.

- Conduct comprehensive testing and validation to assess the functionality and performance of these systems in real-time mining operations.

- Monitor and evaluate the performance metrics, including equipment uptime, fuel efficiency, maintenance schedules, and safety records.

- Analyze the collected data to quantify the impact of intelligent systems on productivity, cost-effectiveness, and safety protocols during mineral extraction.

- Gather feedback from stakeholders, operators, and system users regarding the effectiveness and usability of the implemented intelligent systems.

- Incorporate feedback to refine and optimize the systems for better integration and operational efficiency within the mining complex.

- Document the entire research process, including methodologies, findings, challenges faced, and recommendations for future implementations.

- Prepare a detailed report outlining the outcomes, insights, and potential areas for further research using intelligent systems in mineral extraction processes.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Statista. Mining Industry Worldwide—Statistics & Facts. 2022. Available online: https://www.statista.com/ (accessed on 15 January 2023).

- Chen, J.; Liu, L.; Zeng, B.; Tao, K.; Zhang, C.; Zhao, H.; Li, D.; Zhang, J. A Constitutive Model to Reveal the Anchorage Mechanism of Fully Bonded Bolts. Rock Mech. Rock Eng. 2022, 56, 1739–1757. [Google Scholar] [CrossRef]

- Hazrathosseini, A. Selection of the Most Compatible Safety Risk Analysis Technique with the Nature, Requirements and Resources of Mining Projects Using an Integrated Folchi-Ahp Method. Rud.-Geol.-Naft. Zb. 2022, 37, 43–53. [Google Scholar] [CrossRef]

- Feller, A.; Shunk, D.; Callarman, T. Value Chains Versus Supply Chains. BP Trends 2006, 1, 1–7. [Google Scholar]

- Beamon, B.M. Supply Chain Design and Analysis: Models and Methods. Int. J. Prod. Econ. 1998, 55, 281–294. [Google Scholar] [CrossRef]

- Zijm, H.; Klumpp, M.; Heragu, S.; Regattieri, A. Operations, Logistics and Supply Chain Management: Definitions and Objectives. In Operations, Logistics and Supply Chain Management; Spring: Berlin/Heidelberg, Germany, 2019; pp. 27–42. [Google Scholar] [CrossRef]

- Bacheldor, B. Supply Chain Management Still a Work in Progress. Inf. Week 2003, 23. [Google Scholar]

- Janvier-James, A.M. A New Introduction to Supply Chains and Supply Chain Management: Definitions and Theories Perspective. Int. Bus. Res. 2011, 5, 194–207. [Google Scholar] [CrossRef]

- Simchi-Levi, D.; Kaminsky, P.; Simchi-Levi, E.; Ji, J. Designing and Managing the Supply Chain; McGraw-Hill/Irwin: Irvine, CA, USA, 2000. [Google Scholar]

- Sener, E.; Iseley, D.T. Construction Equipment Fleet Management Using Telematics Technology: Research and Resultant Educational Perspectives. In Proceedings of the 2009 Annual Conference & Exposition, Austin, TX, USA, 14 June 2009. [Google Scholar]

- Auernhammer, H. Precision Farming—The Environmental Challenge. Comput. Electron. Agric. 2001, 30, 31–43. [Google Scholar] [CrossRef]

- Dabbiere, A.J. Methods and Devices Utilizing a Gps Tracking System. Google Patents US6226622B1, 1 May 2001. [Google Scholar]

- Billhardt, H.; Fernández, A.; Lemus, L.; Lujak, M.; Osman, N.; Ossowski, S.; Sierra, C. Dynamic Coordination in Fleet Management Systems: Toward Smart Cyber Fleets. IEEE Intell. Syst. 2014, 29, 70–76. [Google Scholar] [CrossRef]

- Škabić, B.; Kurelović, E.K.; Tomljanović, J. Comparison of Fleet Management Systems. Zb. Veleučilišta U Rijeci 2018, 6, 357–370. [Google Scholar] [CrossRef]

- Jagushte, V. Usability Review of Telematics for Construction Equipment Fleet Management. Master’s Thesis, University of Florida, Gainesville, FL, USA, 2017. [Google Scholar]

- GPSINSIGHT. How Fleet Telematics Works. 2022. Available online: https://www.gpsinsight.com/how-fleet-telematics-works/ (accessed on 15 December 2022).

- Systematics Cambridge. Commercial Vehicle Fleet Management and Information Systems. In Technical Memorandum 2: Summary of Case Study Interviews; Systematics Cambridge: Medford, MA, USA, 1997. [Google Scholar]

- Flatberg, T.; Hasle, G.; Kloster, O.; Nilssen, E.J.; Riise, A. Dynamic and Stochastic Vehicle Routing in Practice. In Dynamic Fleet Management: Concepts, Systems, Algorithms & Case Studies; Spring: Berlin/Heidelberg, Germany, 2007; pp. 41–63. [Google Scholar] [CrossRef]

- Powell, W.B.; Jaillet, P.; Odoni, A. Stochastic and Dynamic Networks and Routing. Handb. Oper. Res. Manag. Sci. 1995, 8, 141–295. [Google Scholar] [CrossRef]

- Larsen, A.; Madsen, O.B.G.; Solomon, M.M. Classification of Dynamic Vehicle Routing Systems. In Dynamic Fleet Management: Concepts, Systems, Algorithms & Case Studies; Zeimpekis, V., Tarantilis, C.D., Giaglis, G.M., Minis, I., Eds.; Springer: Boston, MA, USA, 2007; pp. 19–40. [Google Scholar]

- Psaraftis, H.N. Dynamic Vehicle Routing: Status and Prospects. Ann. Oper. Res. 1995, 61, 143–164. [Google Scholar] [CrossRef]

- Larsen, A.; Madsen, O.B.D.; Solomon, M. Partially Dynamic Vehicle Routing—Models and Algorithms. J. Oper. Res. Soc. 2002, 53, 637–646. [Google Scholar] [CrossRef]

- Sørensen, C.; Bochtis, D. Conceptual Model of Fleet Management in Agriculture. Biosyst. Eng. 2010, 105, 41–50. [Google Scholar] [CrossRef]

- Spüntrup, F.S.; Imsland, L. Asset Fleet Management in the Process Industry-a Conceptual Model. IFAC-PapersOnLine 2018, 51, 281–286. [Google Scholar] [CrossRef]

- Tamási, T.; Kis, T. Decentralized and Prioritized Algorithm for Agv Fleet Management. IFAC-PapersOnLine 2021, 54, 98–103. [Google Scholar] [CrossRef]

- Crainic, T.G.; Laporte, G. Fleet Management and Logistics; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Van der Heijden, R.; Marchau, V. Innovating Road Traffic Management by Its: A Future Perspective. Int. J. Technol. Policy Manag. 2002, 2, 20–39. [Google Scholar] [CrossRef]

- Hazrathosseini, A.; Afrapoli, A.M. The Advent of Digital Twins in Surface Mining: Its Time Has Finally Arrived. Resour. Policy 2023, 80, 103155. [Google Scholar] [CrossRef]

- Hazrathosseini, A.; Afrapoli, A.M. Intelligent Fleet Management Systems in Surface Mining: Status, Threats, and Opportunities. Min. Met. Explor. 2023, 40, 2087–2106. [Google Scholar] [CrossRef]

- Afrapoli, A.M.; Nasab, H.A. A Stochastic Integrated Simulation and Mixed Integer Linear Programming Optimisation Framework for Truck Dispatching Problem in Surface Mines. Int. J. Min. Miner. Eng. 2020, 11, 257–284. [Google Scholar] [CrossRef]

- Alarie, S.; Gamache, M. Overview of Solution Strategies Used in Truck Dispatching Systems for Open Pit Mines. Int. J. Surf. Min. Reclam. Environ. 2002, 16, 59–76. [Google Scholar] [CrossRef]

- Yokoi, R.; Watari, T.; Motoshita, M. Future Greenhouse Gas Emissions from Metal Production: Gaps and Opportunities towards Climate Goals. Energy Environ. Sci. 2021, 15, 146–157. [Google Scholar] [CrossRef]

- Afrapoli, A.M.; Askari-Nasab, H. Mining Fleet Management Systems: A Review of Models and Algorithms. Int. J. Min. Reclam. Environ. 2019, 33, 42–60. [Google Scholar] [CrossRef]

- Dallaire, R.; Laplante, A.R.; Elbrond, J. Humphrey’s Spiral Tolerance to Feed Variations. Can. Min. Metall. Bull. 1978, 71, 128–134. [Google Scholar]

- Kappas, G.; Yegulalp, T.M. An Application of Closed Queueing Networks Theory in Truck-Shovel Systems. Int. J. Surf. Min. Reclam. Environ. 1991, 5, 45–51. [Google Scholar] [CrossRef]

- Ercelebi, S.G.; Bascetin, A. Optimization of Shovel-Truck System for Surface Mining. J. S. Afr. Inst. Min. Metall. 2009, 109, 433–439. [Google Scholar]

- Gurgur, C.Z.; Dagdelen, K.; Artittong, S. Optimisation of a Real-Time Multi-Period Truck Dispatching System in Mining Operations. Int. J. Appl. Decis. Sci. 2011, 4, 57–79. [Google Scholar] [CrossRef]

- White, J.W.; Olson, J.P. Computer-Based Dispatching in Mines with Concurrent Operating Objectives. Min. Eng. 1986, 38, 11. [Google Scholar]

- Ta, C.H.; Ingolfsson, A.; Doucette, J. A Linear Model for Surface Mining Haul Truck Allocation Incorporating Shovel Idle Probabilities. Eur. J. Oper. Res. 2013, 231, 770–778. [Google Scholar] [CrossRef]

- Chang, Y.; Ren, H.; Wang, S. Modelling and Optimizing an Open-Pit Truck Scheduling Problem. Discret. Dyn. Nat. Soc. 2015, 2015, 745378. [Google Scholar] [CrossRef]

- Temeng, V.A.; Otuonye, F.O.; Frendewey, J.O. A Nonpreemptive Goal Programming Approach to Truck Dispatching in Open Pit Mines. Miner. Resour. Eng. 1998, 7, 59–67. [Google Scholar] [CrossRef]

- Mohtasham, M.; Mirzaei-Nasirabad, H.; Alizadeh, B. Optimization of Truck-Shovel Allocation in Open-Pit Mines under Uncertainty: A Chance-Constrained Goal Programming Approach. Min. Technol. 2021, 130, 81–100. [Google Scholar] [CrossRef]

- Soumis, F.; Ethier, J.; Elbrond, J. Evaluation of the New Truck Dispatching in the Mount Wright Mine. In Application of Computers and Operations Research in the Mineral Industry; Littleton, Colo, Society of Mining Engineers of AIME: New York, NY, USA, 1989; pp. 674–682. [Google Scholar]

- Temeng, V.A.; Otuonye, F.O.; Frendewey, J.O., Jr. Real-Time Truck Dispatching Using a Transportation Algorithm. Int. J. Surf. Min. Reclam. Environ. 1997, 11, 203–207. [Google Scholar] [CrossRef]

- Dabbagh, A.; Bagherpour, R. Investigating the Applicability of Imperialist Competitive Algorithm in the Problem of Allocating Truck to the Open Pit Mine. Rud.-Geol.-Naft. Zb. 2019, 34, 35–42. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, L.; Ai, Y.; Tian, B.; Cao, D.; Li, L. Scheduling of Autonomous Mining Trucks: Allocation Model Based Tabu Search Algorithm Development. In Proceedings of the 2021 IEEE International Intelligent Transportation Systems Conference (ITSC), Indianapolis, IN, USA, 19–22 September 2021. [Google Scholar]

- Yuan, W.; Li, D.; Jiang, D.; Jia, Y.; Liu, Z.; Bian, W. Research on Real-Time Truck Dispatching Model in Open-Pit Mine Based on Improved Genetic Algorithm. In Proceedings of the 2022 International Conference on Cyber-Physical Social Intelligence (ICCSI), Nanjing, China, 18–21 November 2022; pp. 234–239. [Google Scholar] [CrossRef]

- Choi, Y.; Nguyen, H.; Bui, X.-N.; Nguyen-Thoi, T. Optimization of Haulage-Truck System Performance for Ore Production in Open-Pit Mines Using Big Data and Machine Learning-Based Methods. Resour. Policy 2022, 75, 102522. [Google Scholar] [CrossRef]

- Choi, Y.; Nguyen, H.; Bui, X.-N.; Nguyen-Thoi, T.; Park, S. Estimating Ore Production in Open-Pit Mines Using Various Machine Learning Algorithms Based on a Truck-Haulage System and Support of Internet of Things. Nat. Resour. Res. 2021, 30, 1141–1173. [Google Scholar] [CrossRef]

- Choudhury, S.; Naik, H. Use of Machine Learning Algorithm Models to Optimize the Fleet Management System in Opencast Mines. In Proceedings of the the 2022 IEEE 7th International Conference for Convergence in Technology (I2CT), Mumbai, India, 7–9 April 2022. [Google Scholar]

- Nobahar, P.; Pourrahimian, Y.; Koshki, F.M. Optimum Fleet Selection Using Machine Learning Algorithms—Case Study: Zenouz Kaolin Mine. Mining 2022, 2, 528–541. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, H.; Tian, F.; Yang, L. The Use of a Machine Learning Method to Predict the Real-Time Link Travel Time of Open-Pit Trucks. Math. Probl. Eng. 2018, 2018, 4368045. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, R.; Wang, Y.; Lv, S. Machine Learning-Based Driving Style Identification of Truck Drivers in Open-Pit Mines. Electronics 2019, 9, 19. [Google Scholar] [CrossRef]

- Klyuev, R.V.; Morgoev, I.D.; Morgoeva, A.D.; Gavrina, O.A.; Martyushev, N.V.; Efremenkov, E.A.; Mengxu, Q. Methods of Forecasting Electric Energy Consumption: A Literature Review. Energies 2022, 15, 8919. [Google Scholar] [CrossRef]

- Lu, X.; Zhou, W.; Ly, H.B.; Qi, C.; Nguyen, T.-A.; Nguyen, M.H.; Huang, J.; Pham, B.T. Optimization of Neural Network Parameters in Improvement of Particulate Matter Concentration Prediction of Open-Pit Mining. Appl. Soft Comput. 2023, 147, 110769. [Google Scholar] [CrossRef]

- Lin, K.; Zhao, R.; Xu, Z.; Zhou, J. Efficient Large-Scale Fleet Management Via Multi-Agent Deep Reinforcement Learning. In Proceedings of the 24th ACM SIGKDD International Conference on Knowledge Discovery & Data Mining, London, UK, 19–23 August 2018; pp. 1774–1783. [Google Scholar] [CrossRef]

- Bastos, G.S.; Souza, L.E.; Ramos, F.T.; Ribeiro, C.H.C. A Single-Dependent Agent Approach for Stochastic Time-Dependent Truck Dispatching in Open-Pit Mining. In Proceedings of the 2011 14th International IEEE Conference on Intelligent Transportation Systems (ITSC), Washington, DC, USA, 5–7 October 2011. [Google Scholar]

- Zhang, C.; Odonkor, P.; Zheng, S.; Khorasgani, H.; Serita, S.; Gupta, C.; Wang, H. Dynamic Dispatching for Large-Scale Heterogeneous Fleet Via Multi-Agent Deep Reinforcement Learning. In Proceedings of the 2020 IEEE International Conference on Big Data (Big Data), Atlanta, GA, USA, 10–13 December 2020. [Google Scholar]

- De Carvalho, J.P.; Dimitrakopoulos, R. Integrating Production Planning with Truck-Dispatching Decisions through Reinforcement Learning While Managing Uncertainty. Minerals 2021, 11, 587. [Google Scholar] [CrossRef]

- Huo, D.; Sari, Y.A.; Kealey, R.; Zhang, Q. Reinforcement Learning-Based Fleet Dispatching for Greenhouse Gas Emission Reduction in Open-Pit Mining Operations. Resour. Conserv. Recycl. 2023, 188, 106664. [Google Scholar] [CrossRef]

- Hazrathosseini, A.; Afrapoli, A.M. Transition to Intelligent Fleet Management Systems in Open Pit Mines: A Critical Review on Application of Reinforcement-Learning-Based Systems. Min. Technol. 2023, in press.

- Porter, M.E. Competitive Strategy: Creating and Sustaining Superior Performance; The Free: New York, NY, USA, 1985. [Google Scholar]

- Munirathinam, S. Industry 4.0: Industrial Internet of Things (Iiot). Adv. Comput. 2020, 117, 129–164. [Google Scholar] [CrossRef]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries. Boston Consult. Group 2015, 9, 54–89. [Google Scholar]

- Hazrathosseini, A. A Retrospective-Prospective Survey on the Introduction of Digital Twins to Mining Industry. Min. Optim. Lab. 2022, 1, 410. [Google Scholar]

| Type | Activities | Description |

|---|---|---|

| Support activities | Firm infrastructure | Finance, accounting, legal permits, buildings, equipment. |

| Human Resource Management | Recruiting, training, career development, fringe benefits, retention, compensation, safety and health assessment. | |

| Technology Development | Mining 4.0 enablers (Data mining, robots, simulation, system integration, Internet of Things, cyber security, cloud computing, augmented reality, artificial intelligence, digital twin, cyber-physical systems, quantum computing, 3D printing, research and development, autonomous vehicles, drones, etc.). | |

| Procurement | Supplier management, negotiation, and subcontracting of equipment and services. | |

| Primary activities | Inbound logistics | Utilities (e.g., fuel, electricity), spare parts, explosives, errands (e.g., food, office affairs). |

| Operations | Development of new working faces, drilling, blasting, loading, hauling, stockpiling, crushers’ feeding. | |

| Outbound logistics | Ore dumps management, grade control, blending, order handling, invoicing, and shipment. | |

| Marketing and sales | Multimedia advertisement, domestic and international exhibitions, branding, sales analysis, and market research. | |

| Services | After-sales services in case of grade fluctuations, consulting. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hazrathosseini, A.; Moradi Afrapoli, A. Maximizing Mining Operations: Unlocking the Crucial Role of Intelligent Fleet Management Systems in Surface Mining’s Value Chain. Mining 2024, 4, 7-20. https://doi.org/10.3390/mining4010002

Hazrathosseini A, Moradi Afrapoli A. Maximizing Mining Operations: Unlocking the Crucial Role of Intelligent Fleet Management Systems in Surface Mining’s Value Chain. Mining. 2024; 4(1):7-20. https://doi.org/10.3390/mining4010002

Chicago/Turabian StyleHazrathosseini, Arman, and Ali Moradi Afrapoli. 2024. "Maximizing Mining Operations: Unlocking the Crucial Role of Intelligent Fleet Management Systems in Surface Mining’s Value Chain" Mining 4, no. 1: 7-20. https://doi.org/10.3390/mining4010002

APA StyleHazrathosseini, A., & Moradi Afrapoli, A. (2024). Maximizing Mining Operations: Unlocking the Crucial Role of Intelligent Fleet Management Systems in Surface Mining’s Value Chain. Mining, 4(1), 7-20. https://doi.org/10.3390/mining4010002