Environmental Management Strategies in the Copper Mining Industry in Chile to Address Water and Energy Challenges—Review

Abstract

:1. Introduction

- (1)

- What are the water and energy challenges that Chile’s copper mining industry is facing?

- (2)

- What are the relevant EMIs that the copper mining industry in Chile uses to address the identified challenges?

- (3)

- How can mining companies benefit from EMIs?

- (4)

- The results of this research were outlined according to these research questions.

2. Literature Review

2.1. The Mining Industry in Chile

2.2. Sustainability Effort

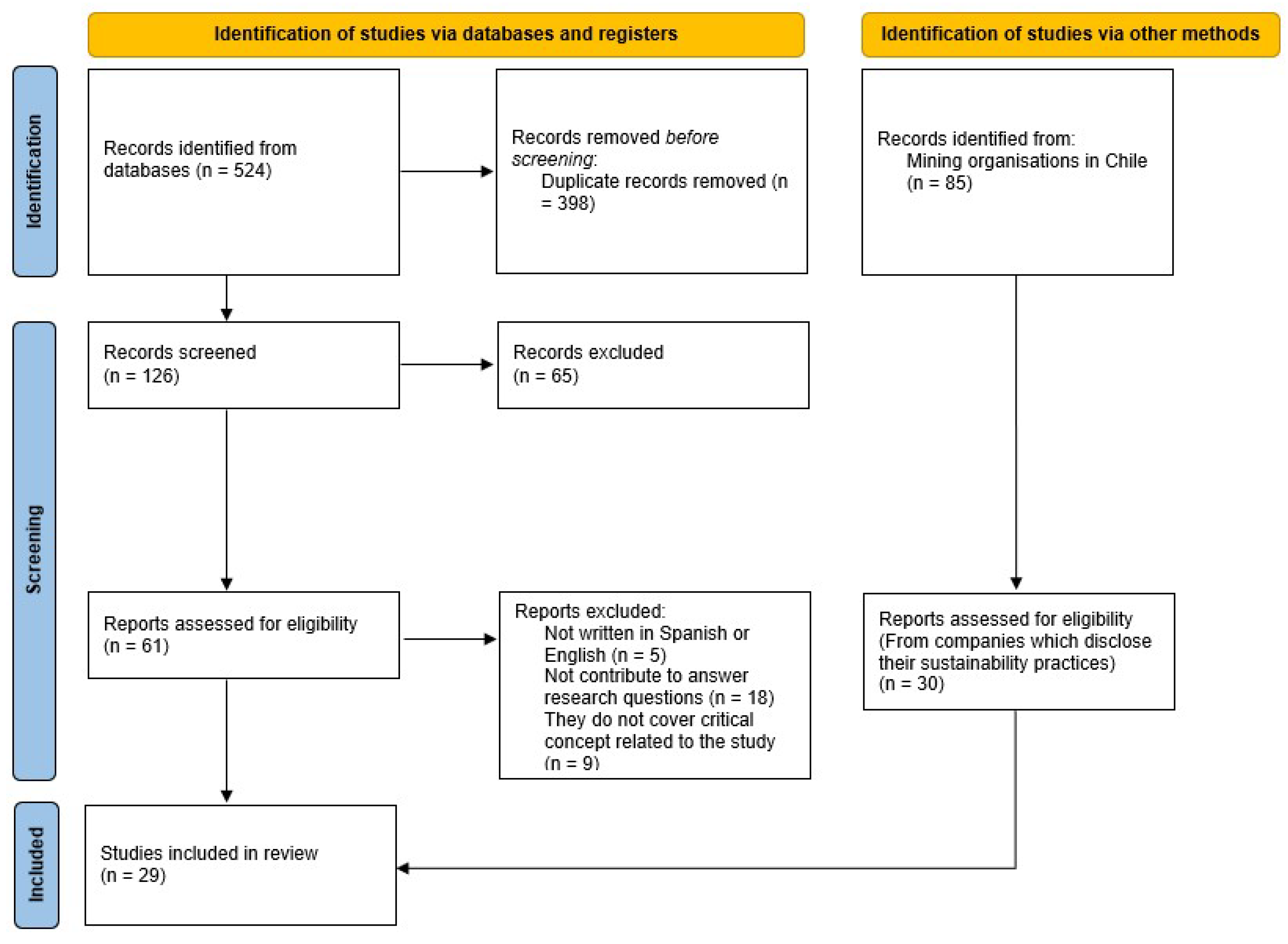

3. Materials and Methods

3.1. Scope of the Study, Data, and Method

3.2. Database Selection

| Topic | Relevant Aspects | Authors |

|---|---|---|

| Environmental management strategies | Evidence regarding the use of seawater in mining with an emphasis on its use in Chile. | [9] |

| Relevance of water-related data disclosures presented in corporate sustainability reports. Use the water footprint as a tool to standardise the impact associated with the mining process. | [45] | |

| Potential water supply solution to an integrated system. One relevant alternative is to improve the recirculation water system from tailings storage. | [46] | |

| Assessment of water risk and the climate change exposition. Relevance of the resilience that mining companies need to create. | [10] | |

| A review of sustainable development in the Chilean mining industry: past, present, and future. | [17] | |

| Diverse and sustainable strategies for the Chilean mining industry through a local model according to the region. | [26] | |

| Diverse study cases regarding sustainable practices and efficient use of water in the mining industry. | [7] | |

| Innovation as a drive to keep the competitiveness in the mining industry in Chile, and the need to encourage public–private partnerships. | [47] | |

| A study regarding the minerals industry’s response to sustainable development in waste disposal. | [48] | |

| Discussion for diverse issues and drivers to implement solar technologies in the mining industry in Chile. | [13] | |

| A study of Life Cycle Assessment (LCA) regarding the impact of energy production and the analysis of the integration of solar technologies. | [12] | |

| This research compares and studies the corporate-sponsored community development and social legitimacy of two mining operations as a study of cases in Chile. | [25] | |

| A study of solar thermal technologies. | [49] | |

| Mining sector in Chile | This work presents a multi-objective optimisation approach to designing integrated water supply systems for the mining industry. | [50] |

| Potential model to predict copper demand which evaluates challenges of the industry such as ore grades, energy and water consumptions, GHG emissions, and generation and disposal of tailings. | [51] | |

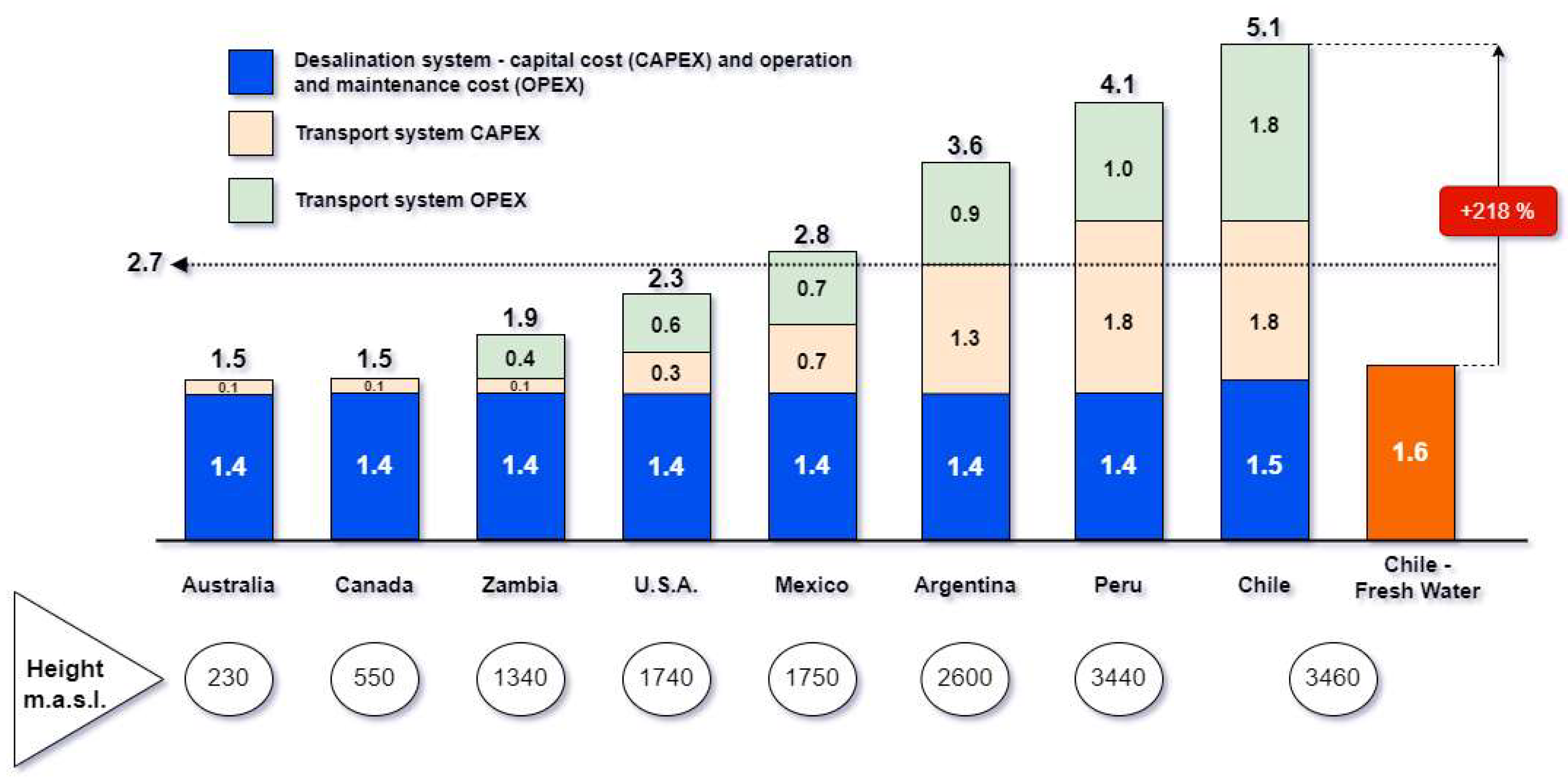

| Cost analysis regarding water consumption and diverse alternatives. | [52] | |

| Water and energy challenges | Lack of water in the northern territory in Chile and desalination plants can be an alternative to supplying water. | [32] |

| Problems regarding water scarcity and sustainability, which generate the conflict between diverse stakeholders regarding water access. | [53] | |

| Information about the decline of the copper ore grade, which will continue. Thus, because of the ore grade reduction, the energy requirements will increase. | [54] | |

| Study regarding water conflict between different stakeholders and the lack of water availability. | [20] | |

| Study regarding mining and glaciers. | [55] | |

| Scientific evidence about glacier changes and the conflict because of the Pascua Lama mining project. | [56] | |

| Two industries that generate a decline in water quality in Elqui River are the mining and agriculture industry—Water Quality Assessment. | [57] | |

| Different legal problems related to conflicts between different stakeholders because of the use of water. | [58] | |

| Proofs that climate change, and mining activity, can put these water sources at risk. | [59] | |

| Study of glaciers and the sustainability issues with mining operations. | [60] | |

| Water conflict between diverse stakeholders, especially mining and agricultural industries. An analysis of the water scarcity index for different regions in Chile. | [8] | |

| An analysis of the fossil fuel dependency of the energy system in Chile. | [15] | |

| Impact of the mining industry on settlements and communities, a mining space characterisation. | [5] |

3.3. Analysis of Data

4. Results

4.1. Water and Energy Challenges of Chilean Mining Companies

4.2. Water Challenges

4.3. Energy Challenges

4.4. Initiatives Taken by the Companies to Address Water and Energy Challenges

4.4.1. Initiatives for Water Challenges

4.4.2. Initiatives for Energy Challenges

5. Discussion

5.1. Initiatives for Water Challenges and Their Benefits

5.2. Initiatives for Energy Challenges and Their Benefits

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Diagram for the Research Process

References

- Ryskie, S.; Neculita, C.M.; Rosa, E.; Coudert, L.; Couture, P. Active Treatment of Contaminants of Emerging Concern in Cold Mine Water Using Advanced Oxidation and Membrane-Related Processes: A Review. Minerals 2021, 11, 259. [Google Scholar] [CrossRef]

- Pactwa, K.; Woźniak, J.; Strempski, A. Sustainable mining–Challenge of Polish mines. Resour. Policy 2021, 74, 101269. [Google Scholar] [CrossRef]

- Ruokonen, E.; Temmes, A. The Approaches of Strategic Environmental Management Used by Mining Companies in Finland. J. Clean. Prod. 2019, 210, 466–476. [Google Scholar] [CrossRef]

- Aznar-Sánchez, J.A.; García-Gómez, J.J.; Velasco-Muñoz, J.F.; Carretero-Gómez, A. Mining Waste and Its Sustainable Management: Advances in Worldwide Research. Minerals 2018, 8, 284. [Google Scholar] [CrossRef] [Green Version]

- Devenin, V.; Bianchi, C. Characterizing a Mining Space: Analysis from Case Studies in Chile and Australia. Resour. Policy 2019, 63, 101402. [Google Scholar] [CrossRef]

- Ossa-Moreno, J.; McIntyre, N.; Ali, S.; Smart, J.C.R.; Rivera, D.; Lall, U.; Keir, G. The Hydro-Economics of Mining. Ecol. Econ. 2018, 145, 368–379. [Google Scholar] [CrossRef]

- Brantes, R.; Olivares, G. Best practices and efficient use of water in the mining industry. Chilean Copper Commission publication no. 176715; The Chilean Copper Commission: Santiago, Chile, 2008. [Google Scholar]

- Aitken, D.; Rivera, D.; Godoy-Faúndez, A.; Holzapfel, E. Water Scarcity and the Impact of the Mining and Agricultural Sectors in Chile. Sustainability 2016, 8, 128. [Google Scholar] [CrossRef] [Green Version]

- Cisternas, L.A.; Gálvez, E.D. The Use of Seawater in Mining. Miner. Process. Extr. Metall. Rev. 2018, 39, 18–33. [Google Scholar] [CrossRef]

- Northey, S.A.; Mudd, G.M.; Werner, T.T.; Jowitt, S.M.; Haque, N.; Yellishetty, M.; Weng, Z. The Exposure of Global Base Metal Resources to Water Criticality, Scarcity and Climate Change. Glob. Environ. Chang. 2017, 44, 109–124. [Google Scholar] [CrossRef]

- Ilankoon, I.M.S.K.; Tang, Y.; Ghorbani, Y.; Northey, S.; Yellishetty, M.; Deng, X.; McBride, D. The Current State and Future Directions of Percolation Leaching in the Chinese Mining Industry: Challenges and Opportunities. Miner. Eng. 2018, 125, 206–222. [Google Scholar] [CrossRef] [Green Version]

- Moreno-Leiva, S.; Díaz-Ferrán, G.; Haas, J.; Telsnig, T.; Díaz-Alvarado, F.A.; Palma-Behnke, R.; Kracht, W.; Román, R.; Chudinzow, D.; Eltrop, L. Towards Solar Power Supply for Copper Production in Chile: Assessment of Global Warming Potential Using a Life-Cycle Approach. J. Clean. Prod. 2017, 164, 242–249. [Google Scholar] [CrossRef]

- Nasirov, S.; Agostini, C.A. Mining Experts’ Perspectives on the Determinants of Solar Technologies Adoption in the Chilean Mining Industry. Renew. Sustain. Energy Rev. 2018, 95, 194–202. [Google Scholar] [CrossRef]

- Simpson, M.; Aravena, E.; Deverell, J. The Future of Mining in Chile; CSIRO Futures: Santiago de Chile, Chile, 2014. [Google Scholar]

- Vega-Coloma, M.; Zaror, C.A. Environmental Impact Profile of Electricity Generation in Chile: A Baseline Study over Two Decades. Renew. Sustain. Energy Rev. 2018, 94, 154–167. [Google Scholar] [CrossRef]

- Ediriweera, A.; Wiewiora, A. Barriers and Enablers of Technology Adoption in the Mining Industry. Resour. Policy 2021, 73, 102188. [Google Scholar] [CrossRef]

- Ghorbani, Y.; Kuan, S.H. A Review of Sustainable Development in the Chilean Mining Sector: Past, Present and Future. Int. J. Min. Reclam. Environ. 2017, 31, 137–165. [Google Scholar] [CrossRef]

- Carkovic, A.B.; Calcagni, M.S.; Vega, A.S.; Coquery, M.; Moya, P.M.; Bonilla, C.A.; Pastén, P.A. Active and Legacy Mining in an Arid Urban Environment: Challenges and Perspectives for Copiapó, Northern Chile. Environ. Geochem Health 2016, 38, 1001–1014. [Google Scholar] [CrossRef]

- Arango-Aramburo, S.; Smith, R.; Jaramillo, P.; Olaya, Y.; Saldarriaga, A.; Restrepo, O.J.; Arboleda, Y.; Rua, C.; Bernal, S.; Londono, P.E.; et al. In Search of a Future for Mining: Participative Scenarios for Colombia. J. Sustain. Min. 2020, 19, 72–87. [Google Scholar] [CrossRef]

- Oyarzún, J.; Oyarzún, R. Sustainable Development Threats, Inter-Sector Conflicts and Environmental Policy Requirements in the Arid, Mining Rich, Northern Chile Territory. Sustain. Dev. 2011, 19, 263–274. [Google Scholar] [CrossRef]

- Adiansyah, J.S.; Rosano, M.; Vink, S.; Keir, G.; Stokes, J.R. Synergising Water and Energy Requirements to Improve Sustainability Performance in Mine Tailings Management. J. Clean. Prod. 2016, 133, 5–17. [Google Scholar] [CrossRef] [Green Version]

- COCHILCO. Projection of Water Consumption in Copper Mining 2020–2031; Chilean Copper Commission: Santiago, Chile, 2020; Available online: https://www.cochilco.cl/Paginas/Estudios/Mercados%20de%20metales%20e%20insumos%20estrat%C3%A9gicos/Agua.aspx (accessed on 10 October 2021). (In Spanish)

- COCHILCO. Projection of Energy Consumption Electricity in Copper Mining 2020–2031; Chilean Copper Commission: Santiago, Chile, 2021; Available online: https://www.cochilco.cl/Paginas/Estudios/Mercados%20de%20metales%20e%20insumos%20estrat%C3%A9gicos/Energ%C3%ADa.aspx (accessed on 24 March 2022). (In Spanish)

- Valdivieso, P. Municipal Governance, Environmental Management and Disaster Risk Reduction in Chile. Bull. Lat. Am. Res. 2017, 36, 440–458. [Google Scholar] [CrossRef]

- Martinez, C.; Franks, D.M. Does Mining Company-Sponsored Community Development Influence Social Licence to Operate? Evidence from Private and State-Owned Companies in Chile. Impact Assess. Proj. Apprais. 2014, 32, 294–303. [Google Scholar] [CrossRef] [Green Version]

- Brandt, M.; Bieritz, L.; Mönnig, A.; Großmann, A.; Grossmann, A. Development of Sustainable Mining Strategies in Chile with a Regionalized National Model Project Introduction and Overview; GWS - Institute of Economic Structures Research: Osnabrück, Germany, 2017. [Google Scholar]

- Wessman, H.; Salmi, O.; Kohl, J.; Kinnunen, P.; Saarivuori, E.; Mroueh, U.M. Water and Society: Mutual Challenges for Eco-Efficient and Socially Acceptable Mining in Finland. J. Clean. Prod. 2014, 84, 289–298. [Google Scholar] [CrossRef]

- Kinnunen, P.; Obenaus-Emler, R.; Raatikainen, J.; Guignot, S.; Guimerà, J.; Ciroth, A.; Heiskanen, K. Review of Closed Water Loops with Ore Sorting and Tailings Valorisation for a More Sustainable Mining Industry. J. Clean. Prod. 2021, 278, 123237. [Google Scholar] [CrossRef]

- Askham, T.M.; Van der Poll, H.M. Water Sustainability of Selected Mining Companies in South Africa. Sustainability 2017, 9, 957. [Google Scholar] [CrossRef] [Green Version]

- Asr, E.T.; Kakaie, R.; Ataei, M.; Tavakoli Mohammadi, M.R. A Review of Studies on Sustainable Development in Mining Life Cycle. J. Clean. Prod. 2019, 229, 213–231. [Google Scholar] [CrossRef]

- Levesque, M.; Millar, D.; Paraszczak, J. Energy and Mining—The Home Truths. J. Clean. Prod. 2014, 84, 233–255. [Google Scholar] [CrossRef]

- Dixon, R.E. Northern Chile and Peru: A Hotspot for Desalination. Desalin. Water Treat. 2013, 51, 5–10. [Google Scholar] [CrossRef]

- Heihsel, M.; Lenzen, M.; Behrendt, F. Desalination and Sustainability: A Triple Bottom Line Study of Australia. Environ. Res. Lett. 2020, 15, 114044. [Google Scholar] [CrossRef]

- Mitko, K.; Turek, M. Membrane-Based Solutions for the Polish Coal Mining Industry. Membranes 2021, 11, 638. [Google Scholar] [CrossRef]

- Vintró, C.; Sanmiquel, L.; Freijo, M. Environmental Sustainability in the Mining Sector: Evidence from Catalan Companies. J. Clean. Prod. 2014, 84, 155–163. [Google Scholar] [CrossRef] [Green Version]

- Betancur-Corredor, B.; Loaiza-Usuga, J.C.; Denich, M.; Borgemeister, C. Gold Mining as a Potential Driver of Development in Colombia: Challenges and Opportunities. J. Clean. Prod. 2018, 199, 538–553. [Google Scholar] [CrossRef]

- McLellan, B.C.; Corder, G.D.; Giurco, D.P.; Ishihara, K.N. Renewable Energy in the Minerals Industry: A Review of Global Potential. J. Clean. Prod. 2012, 32, 32–44. [Google Scholar] [CrossRef]

- Farjana, S.H.; Huda, N.; Mahmud, M.A.P.; Lang, C. Life-Cycle Assessment of Solar Integrated Mining Processes: A Sustainable Future. J. Clean. Prod. 2019, 236, 117610. [Google Scholar] [CrossRef]

- Behar, O.; Peña, R.; Kouro, S.; Kracht, W.; Fuentealba, E.; Moran, L.; Sbarbaro, D. The Use of Solar Energy in the Copper Mining Processes: A Comprehensive Review. Clean. Eng. Technol. 2021, 4, 100259. [Google Scholar] [CrossRef]

- Aznar-Sánchez, J.A.; Velasco-Muñoz, J.F.; Belmonte-Ureña, L.J.; Manzano-Agugliaro, F. Innovation and Technology for Sustainable Mining Activity: A Worldwide Research Assessment. J. Clean. Prod. 2019, 221, 38–54. [Google Scholar] [CrossRef]

- Basu, A.J.; Kumar, U. Innovation and Technology Driven Sustainability Performance Management Framework (ITSPM) for the Mining and Minerals Sector. Int. J. Surf. Min. 2010, 18, 135–149. [Google Scholar] [CrossRef]

- Jang, H.; Topal, E. Transformation of the Australian Mining Industry and Future Prospects. Min. Technol. 2020, 120, 120–134. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Changxin Wang, C.; Tam, V.W.Y. A Conceptual Foundation for Effective Construction and Demolition Waste Management. Clean. Eng. Technol. 2020, 1, 100019. [Google Scholar] [CrossRef]

- Dong, Y.; Zhao, Y.; Hossain, M.U.; He, Y.; Liu, P. Life Cycle Assessment of Vehicle Tires: A Systematic Review. Clean. Environ. Syst. 2021, 2, 100033. [Google Scholar] [CrossRef]

- Northey, S.A.; Mudd, G.M.; Saarivuori, E.; Wessman-Jääskeläinen, H.; Haque, N. Water Footprinting and Mining: Where Are the Limitations and Opportunities? J. Clean. Prod. 2016, 135, 1098–1116. [Google Scholar] [CrossRef]

- Correa-Ibanez, R.; Keir, G.; McIntyre, N. Climate-Resilient Water Supply for a Mine in the Chilean Andes. Proc. Inst. Civ. Eng.-Water Manag. 2018, 171, 203–215. [Google Scholar] [CrossRef]

- Barton, J.R.; Román, Á.; Rehner, J. Responsible Research and Innovation (RRI) in Chile: From a Neostructural Productivist Imperative to Sustainable Regional Development? Eur. Plan. Stud. 2019, 27, 2510–2532. [Google Scholar] [CrossRef]

- Franks, D.M.; Boger, D.V.; Côte, C.M.; Mulligan, D.R. Sustainable Development Principles for the Disposal of Mining and Mineral Processing Wastes. Resour. Policy 2011, 36, 114–122. [Google Scholar] [CrossRef]

- Chandia, E.; Zaversky, F.; Sallaberry, F.; Sánchez, M. Analysis of the Energy Demand of the Chilean Mining Industry and Its Coverage with Solar Thermal Technologies. Int. J. Sustain. Eng. 2016, 9, 240–250. [Google Scholar] [CrossRef]

- Herrera-León, S.; Lucay, F.A.; Cisternas, L.A.; Kraslawski, A. Applying a Multi-Objective Optimization Approach in Designing Water Supply Systems for Mining Industries. The Case of Chile. J. Clean. Prod. 2019, 210, 994–1004. [Google Scholar] [CrossRef]

- Lagos, G.; Peters, D.; Lima, M.; Jara, J.J. Potential Copper Production through 2035 in Chile. Miner. Econ. 2020, 33, 43–56. [Google Scholar] [CrossRef]

- Ihle, C.F.; Kracht, W. The Relevance of Water Recirculation in Large Scale Mineral Processing Plants with a Remote Water Supply. J. Clean. Prod. 2018, 177, 34–51. [Google Scholar] [CrossRef]

- Salinas, C.X.; Gironás, J.; Pinto, M. Water Security as a Challenge for the Sustainability of La Serena-Coquimbo Conurbation in Northern Chile: Global Perspectives and Adaptation. Mitig. Adapt. Strateg. Glob. Chang. 2016, 21, 1235–1246. [Google Scholar] [CrossRef]

- Lagos, G.; Peters, D.; Videla, A.; Jara, J.J. The Effect of Mine Aging on the Evolution of Environmental Footprint Indicators in the Chilean Copper Mining Industry 2001–2015. J. Clean. Prod. 2018, 174, 389–400. [Google Scholar] [CrossRef]

- Brenning, A.; Azócar, G.F. Mining and Rock Glaciers: Environmental Impacts, Political and Legal Situation, and Future Perspectives. Rev. Geogr. Norte Gd. 2010, 47, 143–158. [Google Scholar]

- Hess, K.; Schmidt, S.; Nüsser, M.; Zang, C.; Dame, J. Glacier Changes in the Semi-Arid Huasco Valley, Chile, between 1986 and 2016. Geosciences 2020, 10, 429. [Google Scholar] [CrossRef]

- Ribeiro, L.; Kretschmer, N.; Nascimento, J.; Buxo, A.; Rötting, T.; Soto, G.; Soto, M.; Oyarzú, J.; Maturana, H.; Oyarzú, R. Water Quality Assessment of the Mining-Impacted Elqui River Basin, Chile. Mine Water Environ. 2014, 33, 165–176. [Google Scholar] [CrossRef]

- Rivera, D.; Godoy-Faúndez, A.; Lillo, M.; Alvez, A.; Delgado, V.; Gonzalo-Martín, C.; Menasalvas, E.; Costumero, R.; García-Pedrero, Á. Legal Disputes as a Proxy for Regional Conflicts over Water Rights in Chile. J. Hydrol. 2016, 535, 36–45. [Google Scholar] [CrossRef]

- Navarro, H.F. Chilean Semiarid Glaciers in Context of Climate Change and Mining Explotation. Espacios 2017, 7, 17–26. [Google Scholar] [CrossRef]

- Bellisario, A.; Ferrando, F.; Janke, J. Water Resources in Chile: The Critical Relation between Glaciers and Mining for Sustainable Water Management. Investig. Geográficas 2013, 46, 3. [Google Scholar] [CrossRef] [Green Version]

- Elo, S.; Kääriäinen, M.; Kanste, O.; Pölkki, T.; Utriainen, K.; Kyngäs, H. Qualitative Content Analysis: A Focus on Trustworthiness. SAGE Open 2014, 4, 215824401452263. [Google Scholar] [CrossRef]

- Taylor-Powell, E.; Renner, M. Analyzing Qualitative Data; The Chilean Copper Commission: Santiago, Chile, 2003; pp. 1–10. [Google Scholar]

- DGA. Water Atlas of Chile; General Water Directorate, Ministry of Public Works, General Directorate of Water: Santiago, Chile, 2016. [Google Scholar]

- COCHILCO. Electric Power Consumption Projection 2019–2030; The Chilean Copper Commission: Santiago, Chile, 2019. [Google Scholar]

- COCHILCO. Copper Mining Energy Consumption in 2019; The Chilean Copper Commission: Santiago, Chile, 2020. [Google Scholar]

- Odell, S.D.; Bebbington, A.; Frey, K.E. Mining and Climate Change: A Review and Framework for Analysis. Extr. Ind. Soc. 2018, 5, 201–214. [Google Scholar] [CrossRef]

- CNP. Productivity in the Large Copper Mining; National Productivity Commission: Santiago, Chile, 2017. [Google Scholar]

- Berland, A. Glaciers in Semi-Arid Chile: Climate Change, Mining and Water Security, Sustainable Chile; Sustainable Chile Program: Santiago, Chile, 2016. [Google Scholar]

- Donoso, G. Water Policy in Chile. Global Issues in Water Policy; Springer International Publishing: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- SONAMI. Fundamentals and Challenges for Mining Development; National Mining Society: Santiago, Chile, 2017; Available online: https://www.sonami.cl/v2/wp-content/uploads/2017/06/Fundamentos-y-Desaf%C3%ADos-para-el-Desarrollo-Minero-2017.pdf (accessed on 20 February 2022).

- Consejo Minero. Mining, Water and Sustainability; Mining Council Chile: Santiago, Chile, 2016; Available online: https://consejominero.cl/wp-content/uploads/2019/07/Presentacion-CM-reforma-Codigo-de-Aguas.pdf (accessed on 20 February 2022).

- Vyhmeister, E.; Aleixendri Muñoz, C.; Bermúdez Miquel, J.M.; Pina Moya, J.; Fúnez Guerra, C.; Rodríguez Mayor, L.; Godoy-Faúndez, A.; Higueras, P.; Clemente-Jul, C.; Valdés-González, H.; et al. A Combined Photovoltaic and Novel Renewable Energy System: An Optimized Techno-Economic Analysis for Mining Industry Applications. J. Clean. Prod. 2017, 149, 999–1010. [Google Scholar] [CrossRef]

- Awuah-Offei, K. Energy Efficiency in Mining: A Review with Emphasis on the Role of Operators in Loading and Hauling Operations. J. Clean. Prod. 2016, 117, 89–97. [Google Scholar] [CrossRef]

- Anglo American. Progress Report of the Cooperation Agreement between the Ministry of Energy and the Mining Council; Anglo American: Santiago, Chile, 2018. [Google Scholar]

- Anglo American. SEAT Los Bronces 2016 Application Report; Anglo American: Santiago, Chile, 2016. [Google Scholar]

- Anglo American. Sustainability Report 2017: “Building on Solid Foundations Delivering a Sustainable Future”; Anglo American: Santiago, Chile, 2018. [Google Scholar]

- Anglo American. Sustainability Report 2018, Unfolding All Our Potential: Growth for a Sustainable Future; Anglo American: Santiago, Chile, 2019. [Google Scholar]

- Collahuasi. Sustainable Development Report 2017; COLLAHUASI: Tarapacá, Chile, 2018. [Google Scholar]

- Collahuasi. Sustainability Report 2018, Because We Are Much More than Copper; COLLAHUASI: Tarapacá, Chile, 2019. [Google Scholar]

- Galaz, J. State of the Art in the Disposal of Thickened Tailings, MYMA. Available online: http://www.sonami.cl/v2/wp-content/uploads/2016/05/10.-Estado-del-Arte-en-Disposición-de-Relaves-Espesados.pdf (accessed on 10 December 2019).

- Collahuasi. Sustainability Report 2020, Because We Are Much More than Copper; COLLAHUASI: Santiago, Chile, 2021; Available online: https://www.collahuasi.cl/en/sustentabilidad/sustentabilidad-en-collahuasi/ (accessed on 24 March 2022). (In Spanish)

- Antofagasta PLC. Sustainability Report 2017; Antofagasta Minerals Chile: Santiago, Chile, 2018. [Google Scholar]

- Antofagasta PLC. Sustainability Report 2018, We Develop Mining for a Better Future; Antofagasta Minerals Chile: Santiago, Chile, 2019. [Google Scholar]

- Antofagasta PLC. Sustainability Report 2016; Antofagasta Minerals Chile: Santiago, Chile, 2017. [Google Scholar]

- Antofagasta Minerals Los Pelambres Mining Project Seeks to Strengthen Milling System, Antofagasta Minerals, Antofagasta Minerals Chile. Available online: https://web.pelambres.cl/comunicaciones/noticias/2016/015-proyecto-de-minera-los-pelambres-busca-reforzar-sistema-de-molienda-y-construir-planta-desalinizadora/ (accessed on 20 March 2020).

- Antofagasta Minerals. Sustainability Report 2020, Developing Mining for a Better Future; Antofagasta Minerals Chile: Santiago, Chile, 2021; Available online: https://www.aminerals.cl/comunicaciones/documentos/ (accessed on 24 March 2022).

- BHP. Sustainability Report 2018, Minera Escondida y Pampa Norte; Escondida Mining BHP Chile: Santiago, Chile, 2019. [Google Scholar]

- BHP. Water Report 2018; Escondida Mining BHP Chile: Las Condes, Chile, 2019. [Google Scholar]

- BHP. Annual Report 2021, the Future Is Clear; Escondida Mining BHP Chile: Santiago, Chile, 2021; Available online: https://www.bhp.com/es/sustainability/environment (accessed on 24 March 2022).

- CODELCO. Sustainability Report 2017; CODELCO: Santiago, Chile, 2018. [Google Scholar]

- Reporte Minero Codelco Thinks Alternatives to Avoid a New Tender for Its Desalination Plant, Portal Minero. Available online: https://www.reporteminero.cl/noticia/noticias/2020/05/codelco-piensa-en-alternativas-para-evitar-nueva-licitacion-para-su-planta-desaladora (accessed on 15 October 2020).

- CODELCO. Sustainability Report 2018; CODELCO: Santiago, Chile, 2019. [Google Scholar]

- CODELCO. Progress Report of the Cooperation Agreement between the Ministry of Energy and the Mining Council; CODELCO: Santiago, Chile, 2018. [Google Scholar]

- CODELCO. Sustainability Report 2020, Transforming the Mining for the Future of the Country; CODELCO: Santiago, Chile, 2021; Available online: https://www.codelco.com/prontus_codelco/site/edic/base/port/reportes_sustentabilidad.html# (accessed on 24 March 2022). (In Spanish)

- Teck. Sustainability Report 2017; TECK: Vancouver, BC, Canada, 2018. [Google Scholar]

- Teck. Sustainability Report 2018; TECK: Vancouver, BC, Canada, 2019. [Google Scholar]

- Teck. Sustainability Report 2020, Moving forward Together; TECK: Vancouver, BC, Canada, 2021; Available online: https://www.teck.com/sustentabilidad-es/ (accessed on 24 March 2022). (In Spanish)

- Sierra Gorda. Sustainability Report 2018; Sierra Gorda: Santiago, Chile, 2019; Available online: https://www.sgscm.cl/es/sustentabilidad (accessed on 24 March 2022).

- Consejo Minero. Water Withdrawals from Companies Associated with the Mining Councils; Consejo Minero: Santiago, Chile, 2021; Available online: https://consejominero.cl/agua/ii-region-2020/ (accessed on 29 March 2022). (In Spanish)

- Anglo American. Progress Report of the Cooperation Agreement between the Ministry of Energy and the Mining Council; Anglo American: Santiago, Chile, 2019. [Google Scholar]

- Anglo American. Sustainability Report-2020; Anglo American: Santiago, Chile, 2021; Available online: https://chile.angloamerican.com/media/reportes.aspx (accessed on 24 March 2022). (In Spanish)

- Solarpack. Solarpack’s Photovoltaic Plants in Chile, Solar Pack. Available online: https://www.solarpack.es/pais/chile/ (accessed on 20 January 2020).

- Antofagasta Minerals. Progress Report of the Cooperation Agreement between the Ministry of Energy and the Mining Council; Antofagasta Minerals S.A.: Santiago, Chile, 2018. [Google Scholar]

- World Energy Trade The Energy at the Antofagasta Minerals Centinela Mine Will Be 100% Renewable. Available online: https://www.worldenergytrade.com/energias-alternativas/general/chile-la-energia-en-la-mina-centinela-de-antofagasta-minerals-sera-100-renovable (accessed on 20 June 2020).

- Antofagasta Minerals. Progress Report of the Cooperation Agreement between the Ministry of Energy and the Mining Council, Energy management Antofagasta Minerals; 2021. Available online: https://consejominero.cl/wp-content/uploads/2020/08/reporte_EE_AMSA2019.pdf (accessed on 26 March 2022). (In Spanish).

- Palma, R.; Araneda, J.; Brokering, W.; Jiménez, G.; Morán, L.; Rudnick, H. Development of a Conveyor Belt System with the Capacity to Regenerate Electrical Energy; Pontificia Universidad Católica de Chile: Santiago, Chile, 2012. [Google Scholar]

- Pereira, M.; Schröer, R.; Vásquez, R.; Hueichapán, J. Energy in Mining Pyrometallurgy. 2021. Available online: http://www.energiaenmineria.cl/wp-content/uploads/2021/04/Reporte-plataforma-pirometalurgia-marzo2021.pdf (accessed on 28 March 2022). (In Spanish).

- Minera Escondida. Progress Report of the Cooperation Agreement between the Ministry of Energy and the Mining Council; Minera Escondida: Antofagasta, Chile, 2018. [Google Scholar]

- BHP. Progress Report of the Cooperation Agreement between the Ministry of Energy and the Mining Council; BHP Chile: Santiago, Chile, 2021; Available online: https://consejominero.cl/wp-content/uploads/2020/09/reporte_EE_BHP2019.pdf (accessed on 26 March 2022). (In Spanish)

- Madriaga, L. Use of Energy in Tailings Channels by Means of Hydraulic Turbines; CONICYT: Santiago, Chile, 2017. [Google Scholar]

- Llanca, J.; Hurtado, E.; Acuña, A.; Diaz, A. Implementation of a Ventilation System on Demand in the Andina Division, Ibero-American Congress on Underground and Open Pit Mining; Universidad de Chile: Santiago, Chile, 2018; pp. 1–12. [Google Scholar]

- Teck. Progress Report of the Cooperation Agreement between the Ministry of Energy and the Mining Council; Teck Resources Chile: Coquimbo, Chile, 2019. [Google Scholar]

- Teck. Progress Report of the Cooperation Agreement between the Ministry of Energy and the Mining Council, Teck Resources Chile 2020; 2021. Available online: https://consejominero.cl/wp-content/uploads/2020/08/reporte_EE_Teck2019.pdf (accessed on 30 March 2022). (In Spanish).

- Mineria Chilena Extreme Drought Forces Codelco’s Largest Division to Halt Production Processes, Chilean Mining. Available online: https://www.mch.cl/2020/06/08/sequia-extrema-obliga-a-division-mas-grande-de-codelco-a-detener-procesos-productivos/ (accessed on 25 June 2020).

- Dell’Angelo, J.; Rulli, M.C.; D’Odorico, P. The Global Water Grabbing Syndrome. Ecol. Econ. 2018, 143, 276–285. [Google Scholar] [CrossRef]

- Gude, V.G. Desalination and Water Reuse to Address Global Water Scarcity. Rev. Environ. Sci. Biotechnol. 2017, 16, 591–609. [Google Scholar] [CrossRef]

- Garcia, N. Economic Analysis of Aspects Associated with Water Desalination in Mining; Library of the National Congress of Chile: Valparaíso, Chile, 2017. [Google Scholar]

- Custodio, E.; Andreu-Rodes, J.M.; Aragón, R.; Estrela, T.; Ferrer, J.; García-Aróstegui, J.L.; Manzano, M.; Rodríguez-Hernández, L.; Sahuquillo, A.; del Villar, A. Groundwater Intensive Use and Mining in South-Eastern Peninsular Spain: Hydrogeological, Economic and Social Aspects. Sci. Total Environ. 2016, 559, 302–316. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dos Santos, S.; Adams, E.A.; Neville, G.; Wada, Y.; de Sherbinin, A.; Mullin Bernhardt, E.; Adamo, S.B. Urban Growth and Water Access in Sub-Saharan Africa: Progress, Challenges, and Emerging Research Directions. Sci. Total Environ. 2017, 607, 497–508. [Google Scholar] [CrossRef] [PubMed]

- Sinan Erzurumlu, S.; Erzurumlu, Y.O. Sustainable Mining Development with Community Using Design Thinking and Multi-Criteria Decision Analysis. Resour. Policy 2015, 46, 6–14. [Google Scholar] [CrossRef]

- Nguyen, M.T.; Vink, S.; Ziemski, M.; Barrett, D.J. Water and Energy Synergy and Trade-off Potentials in Mine Water Management. J. Clean. Prod. 2014, 84, 629–638. [Google Scholar] [CrossRef]

- Owusu, P.A.; Asumadu-Sarkodie, S.; Ameyo, P. A Review of Ghana’s Water Resource Management and the Future Prospect. Cogent Eng. 2016, 3, 1164275. [Google Scholar] [CrossRef]

- Schaffer, N.; MacDonell, S. Brief Communication: A Framework to Classify Glaciers for Water Resource Evaluation and Management in the Southern Andes. Cryosphere Discuss. 2021. in review. [Google Scholar] [CrossRef]

- MCH Large Mining Companies Warn of Glacier Project, Meet with Government and Senate Starts Discussion, Chilean Mining. Available online: https://www.mch.cl/2018/09/04/grandes-mineras-alertan-proyecto-glaciares-se-reunen-gobierno-senado-inicia-discusion/# (accessed on 20 March 2020).

- Sganzerla, C.; Seixas, C.; Conti, A. Disruptive Innovation in Digital Mining. Procedia Eng. 2016, 138, 64–71. [Google Scholar] [CrossRef] [Green Version]

- Molaei, F.; Siavoshi, H. The Role of Nanofluids on Enhancing the Solar Energy Performance with Focusing on the Mining Industry. Int. J. Energy Res. 2021, 45, 14414–14435. [Google Scholar] [CrossRef]

- Choi, Y.; Song, J. Review of Photovoltaic and Wind Power Systems Utilized in the Mining Industry. Renew. Sustain. Energy Rev. 2017, 75, 1386–1391. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

| Organisation | Operation | Environmental Management Initiatives | Water Scarcity | Collaboration with Stakeholders in Hydric Aspects | Improve Glaciers’ Management | Water Pollution | Water Quality |

|---|---|---|---|---|---|---|---|

| Anglo American | All operations | WM system | √ | - | - | √ | √ |

| Application SEAT | - | √ | - | √ | √ | ||

| El Soldado | Community strategic plan | √ | √ | - | - | √ | |

| Coarse particle flotation (CPF) | √ | - | - | - | - | ||

| Los Bronces | Water recirculation system | √ | - | - | √ | - | |

| Water balance | √ | - | - | - | √ | ||

| Improvement in a rural water system | √ | √ | - | - | √ | ||

| Collahuasi | Collahuasi | WM system | √ | - | - | √ | √ |

| Water recirculation system | √ | - | - | √ | - | ||

| Community strategic plan | √ | √ | - | √ | √ | ||

| Seawater use | √ | √ | - | √ | √ | ||

| Antofagasta Minerals | All operations | Community strategic plan | √ | √ | - | √ | √ |

| WM system | √ | - | - | √ | √ | ||

| Water balance | √ | - | - | - | √ | ||

| Monitoring quality of water | - | √ | - | √ | √ | ||

| Water recirculation system | √ | - | - | √ | - | ||

| A pilot project to protect glaciers | - | - | √ | - | - | ||

| Antucoya | Seawater use | √ | √ | - | √ | √ | |

| Centinela | Seawater use | √ | √ | - | √ | √ | |

| Thickened tailings technology | √ | - | - | √ | - | ||

| Los Pelambres | Research new treatment of acidic water | - | - | - | √ | √ | |

| Seawater use—project | √ | √ | - | √ | √ | ||

| BHP Chile | All operations | WM system | √ | - | - | √ | √ |

| Water balance | √ | - | - | - | √ | ||

| Monitoring quality of water | - | √ | - | √ | √ | ||

| Escondida | Seawater use | √ | √ | - | √ | √ | |

| Cerro Colorado | Wetland recovery | √ | √ | - | - | - | |

| Spence | Seawater use—project | √ | √ | - | √ | √ | |

| CODELCO | All operations | Environmental risks management system | √ | - | - | √ | √ |

| Monitoring quality of water | - | √ | - | √ | √ | ||

| Water recirculation system | √ | - | - | √ | - | ||

| Seawater use—project | √ | √ | - | √ | √ | ||

| Andina | Modification of current open pit | - | √ | √ | - | - | |

| Community strategic plan | √ | √ | - | √ | √ | ||

| Salvador | Community strategic plan | √ | √ | - | √ | √ | |

| Radomiro Tomic | Use of thermal film—water reduction | √ | - | - | - | - | |

| Thickened tailings technology—project | √ | - | - | √ | - | ||

| Teck Chile | All operations | Environmental Management System | √ | - | - | √ | √ |

| Community strategic plan | √ | √ | - | √ | √ | ||

| Quebrada Blanca | Seawater use—project | √ | √ | - | √ | √ | |

| KGHM International | Sierra Gorda | Seawater use without desalination process | √ | √ | - | √ | √ |

| Thickened tailings technology—project | √ | - | - | √ | - |

| Operation | Continental Water (Millions of m3) 1 | Seawater (Millions of m3) 1 | Total Water Use (Millions of m3) 1 | Water Reuse | The Main EMIs to Face Water Challenges Detected | Benefits Associated to EMIs |

|---|---|---|---|---|---|---|

| Anglo American. All global operations | 34.24 | - | 34.24 | 89% | Work with communities and authorities program. | Reduction in water conflicts with stakeholders—enhance the relationship. |

| Water Management System. | By 2017 1.4 million m3 less than in 2017. | |||||

| Anglo American, El Soldado | 6.56 | - | 6.56 | 80% | Coarse particle flotation (CPF). | It is expected to save around 20% of water consumption. |

| Anglo American, Los Bronces | 26.5 | - | 26.54 | 85% | Improvement in a rural water system. | In 2020, water availability for communities incremented by 20%. |

| Recirculation System from concentrator plant to grinding process—pumping system. | Reduction in water consumption was around 48% by 2013. | |||||

| Anglo American, Chagres | 1.14 | - | 1.14 | 99% | - | - |

| Collahuasi | 33 | - | 33.17 | 76.7% | A new project of a desalination plant. | By 2025, it expects to reduce by 70% the water extraction rates from the water basin. |

| TTD technology | To reduce the percentage of water in tailings. | |||||

| Project to enhance drinking water and irrigation systems for communities under the influence. | 14 Km of irrigation canals for communities, reducing water conflicts with diverse stakeholders. | |||||

| Community strategic plan. | Reduction in water conflicts with stakeholders—enhance the relationship. | |||||

| Antofagasta Minerals, all global operations | 30.6 | 34.7 | 65.4 | 80–96% | The seawater as the focus for reducing continental water use. | The seawater use will account for 90% of total water consumption in 2025. It helps to reduce the hydric stress and conflict with water rights. |

| Community strategic plan. | Reduction in water conflicts with stakeholders—enhance the relationship. | |||||

| Antofagasta Minerals, Antucoya | 0.0 | 5.8 | 5.78 | - | Seawater use. Antucoya uses 100% without desalination for all the operation. | Reduce the hydric stress and conflict with water rights. |

| Antofagasta Minerals, Centinela | 2.7 | 29.0 | 31.62 | - | Seawater—around 90% from desalination process. | Reduce the hydric stress and conflict with water rights. |

| TTD technology | Increase the percentages of solids in the tailings to around 65%, reducing water consumption in the tailing dam. | |||||

| Antofagasta Minerals, Los Pelambres | 21.2 | - | 21.25 | - | Desalination plant with a capacity of 800 L/s by 2025. | Reduction to 100% of the use of continental water and the dependency of water rights. |

| The project “Somos Choapa” with local communities. | Enhanced water access for communities under the influence—34 Km of irrigation canals for communities. Reduction in water conflicts with stakeholders—enhance the relationship. | |||||

| Research a new treatment of acidic water. | Define a long-term sustainable treatment system—competitive advantages. | |||||

| Antofagasta Minerals, Zaldivar | 6.7 | - | 6.72 | - | - | - |

| BHP, Global all operation | 14.4 | 96.7 | 111.2 | - | Management system based on water stewardship framework from ICMM. | Risk identification and associated action plans. |

| Water balance for all operations in Chile. | To improve stakeholder collaborations and transparency. | |||||

| Monitoring systems in diverse points. | Reduction in water conflicts with stakeholders—ensure no polluted water, avoid fines. | |||||

| BHP, Escondida | 3.9 | 96.7 | 100.68 | - | Seawater use—two desalination plants—one of the largest in South America 2500 L/s. | Reduction in superficial and/or underground water consumption—ensuring water availability and reducing problem with water rights. |

| BHP, Cerro Colorado | 4.1 | - | 4.07 | - | To recover an aquifer, ensuring the ecology flow. | Reduction in water conflicts with stakeholders—enhance the relationship. |

| BHP, Spence | 6.4 | - | 6.41 | - | Seawater use. Project to build a new desalination plant, 1000 L/s. | Reduction in superficial and/or underground water consumption—ensuring water availability for the expansion project. |

| CODELCO, all global operations | 186.4 | - | 186.4 | 76.9% | WM strategy to ensure efficient use of the hydric resources. | Plan strategies to reduce 10% of freshwater consumption. |

| Monitoring systems in diverse extraction points. | Reduction in water conflicts with stakeholders—ensure no polluted water, avoid fines. | |||||

| Project to build a new desalination plant, 800 L/s to supply water to the northern operations. | Reduction in freshwater consumption—ensuring water availability. | |||||

| CODELCO, Teniente | 59.6 | - | 59.65 | - | - | - |

| CODELCO, Chuquicamata | 65.3 | - | 65.30 | 87% | - | - |

| CODELCO, Gaby | 5.9 | - | 5.90 | 87% | - | - |

| CODELCO, Andina | 25.9 | - | 25.88 | Modification of the current open-pit mine—moving it to another area. | To avoid the destruction of glaciers—ensuring a sustainable operation and avoid fines. | |

| Improvement in the rural drinking water system for some communities. | Reduction in water conflicts with stakeholders—enhance the relationship. | |||||

| CODELCO, Salvador | 20.2 | - | 20.17 | - | ||

| CODELCO, Radomiro Tomic | 9.5 | - | 9.50 | 90% | Use of thermal film on the dynamic leach piles. | Save around 70% to 80% of the water used to leach. |

| Thickened tailings technology—percentages of solid can reach 67%. | More stable tailings and higher percentages of water recovery. | |||||

| TECK, all global operations | 12.4 | - | 12.4 | - | Cooperation with stakeholders regarding hydric resources. | Improve the water scarcity condition in the area with different stakeholders. |

| TECK, Quebrada Blanca | 1.7 | - | 1.74 | - | Project to build a new desalination plant, 1300 L/s. | Reduction in continental water consumption. |

| TECK, Carmen de Andacollo | 10.7 | - | 10.67 | - | - | - |

| Sierra Gorda | 0.95 | 30.6 | 31.59 | - | The use of seawater, without desalination in its process, from the cooling operation of a thermoelectric plant. | 100% of the total water from the sea—a reduction in hydric stress. |

| Organisation | Operation | Environmental Management Initiatives | Reduction in Energy Consumption | Energy Cost Reduction | Improve Energy Efficiency | Reduce Fossil Fuels Dependency | Climate Change |

|---|---|---|---|---|---|---|---|

| Anglo American | All operations | Energy and climate change management system | √ | √ | √ | √ | √ |

| NCRE agreements | - | - | - | √ | √ | ||

| El Soldado | Optimisation of processes | √ | √ | √ | - | - | |

| Los Bronces | Optimisation of processes | √ | √ | √ | - | - | |

| Innovation project | √ | √ | √ | √ | √ | ||

| Energy efficiency plan | √ | √ | √ | - | - | ||

| Pilot floating photovoltaic | √ | √ | - | √ | √ | ||

| Chagres | Plan of reduction in energy consumption | √ | √ | √ | - | √ | |

| Collahuasi | Collahuasi | Energy and climate change management system | √ | √ | √ | √ | √ |

| Platform—online measurement of variables | √ | - | √ | - | - | ||

| Use of NCRE | - | √ | - | √ | √ | ||

| Carbon footprint measure | - | - | - | √ | √ | ||

| Antofagasta Minerals | All operations | Energy and climate change management system | √ | √ | √ | √ | √ |

| Use of NCRE | - | √ | - | √ | √ | ||

| Los Pelambres | Use of NCRE | - | √ | - | √ | √ | |

| Use of NCRE | - | √ | - | √ | √ | ||

| Innovation project | √ | √ | √ | √ | √ | ||

| Optimisation of processes | √ | √ | √ | - | √ | ||

| Centinela | Use of NCRE | - | √ | - | √ | √ | |

| NCRE agreements | - | - | - | √ | √ | ||

| Optimisation of processes | √ | √ | √ | - | √ | ||

| Zaldivar | Use of NCRE | - | √ | √ | √ | √ | |

| NCRE agreements | - | - | - | √ | √ | ||

| Antucoya | Optimisation of processes | √ | √ | - | √ | √ | |

| BHP Chile | All operations | Climate change management system | √ | √ | √ | √ | √ |

| Escondida | Electric central to natural gas | - | - | - | - | √ | |

| Energy efficiency plan | √ | √ | √ | - | - | ||

| Energy balance | √ | √ | √ | - | - | ||

| Optimisation of processes | √ | √ | √ | - | - | ||

| NCRE agreements | - | √ | - | √ | √ | ||

| Spence | NCRE agreements | - | √ | - | √ | √ | |

| Energy efficiency plan | √ | √ | √ | - | - | ||

| CODELCO | All operations | Energy and climate change management system | √ | √ | √ | - | √ |

| NCRE agreements | - | - | - | √ | √ | ||

| Electric vehicles | - | √ | - | √ | √ | ||

| Teniente | Innovation project | √ | √ | √ | √ | √ | |

| Hybrid LHD | - | √ | - | √ | √ | ||

| Chuquicamata | Use of NCRE | - | √ | - | √ | √ | |

| Optimisation of processes | √ | √ | √ | - | √ | ||

| Andina | Optimisation of processes | √ | √ | √ | - | √ | |

| Gaby | Use of NCRE | √ | √ | - | √ | √ | |

| Salvador | Innovation project | - | √ | - | √ | √ | |

| Teck Chile | All operations | Energy efficiency plan | √ | √ | √ | - | - |

| Quebrada Blanca | Use of NCRE | - | √ | - | √ | √ | |

| Carmen de Andacollo | Optimisation of processes | √ | √ | √ | - | √ | |

| Use of NCRE | - | √ | - | √ | √ |

| Operation | Energy Consumption Miles GJ 2,3 | Energy Efficiency GJ/tCu 1,2 | GHG Emissions tCO2e 2 | GHG Emissions Intensity tCO2e/tCu 1,2 | The Main EMIs to Face Energy Challenges Detected | Benefits Associated to EMIs |

|---|---|---|---|---|---|---|

| Anglo American, All global operations | 11,337.0 | 30.6 | 1,065,008.0 | 2.9 | NCRE agreement, 3 terawatt-hours per year. | CO2 emissions by around 70%. |

| Anglo American, El Soldado | - | - | Improvement in the energy efficiency of haul trucks by reducing RPM of the engine. | Reduce operational cost and improve energy efficiency. | ||

| Anglo American, Los Bronces | - | - | - | - | Energy Management System. | Reduction of 4.9% in its energy during 2017. In addition, it helps to reduce GHG by 4.0%. |

| A prototype of start/stop for trucks. | A reduction in fuel consumption of 0.5% by 2016. | |||||

| Photovoltaic plant on a tailings dam. | By 2020 it generated 510 GJ and reduced 54 tCO2e. | |||||

| Big Data—computational tools. | By 2017 a reduction of 3% in energy consumption. | |||||

| Anglo American, Chagres | - | - | Energy efficiency plan. | A reduction of 6.4% energy consumed and 4.4% in tCO2e by 2017. | ||

| Collahuasi | 11,576.0 | 20.5 | 1,853,287.0 | 2.9 | Increased boiler efficiency by 10%. | Expected reduction of 700,000 kWh/year. |

| NCRE agreement. | By 2025, 100% of the electrical energy will be from renewable energy. It would allow the company to reduce around 394 thousand tons of GHG from scope 2. | |||||

| Antofagasta Minerals, all global operations | 24,121.0 | 31.3 | 2,345,212.0 | 3.2 | Use of NCRE. | Around 21% of the company’s total energy comes from NCRE. |

| Antofagasta Minerals, Antucoya | 2143.0 | 29.8 | 272,664.0 | 3.4 | Reduction in fuel consumption in the mining haul trucks by a logistic strategy. | A reduction of 2161 m3 of diesel a year, which is around 6461 tCO2e/year. |

| A reduction in the size of ore feed by optimizing its processes. | An energy saving of 2744 MWh and a reduction in emissions of 1088 tCO2e per year. | |||||

| Antofagasta Minerals, Centinela | 10,398.0 | 37.6 | 1,034,516.0 | 4.2 | Solar thermal—substitution of around 55% of the diesel consumed for solar energy. | Saving around USD 2,000,000 per year. |

| NCRE agreement. | All its energy from renewable sources by 2022. | |||||

| Optimization of processes by Mine to Mill initiative. | A reduction of 58,148 MWh/year in electricity and 23,421 tCO2e a year. | |||||

| Antofagasta Minerals, Los Pelambres | 8120.0 | 22.3 | 722,293.0 | 2.0 | Solar energy—energy generation from a photovoltaic plant. | Solar and wind energy produce 59% of the total energy required—reduction in GHG of the mining production |

| Wind energy—energy generation from a wind farm “El Arrayan”. | Solar and wind energy produce 59% of the total energy required—reduction in GHG of the mining production. | |||||

| Innovative system, energy generation by its conveyor belts. | Around 10% of the total energy requirement. | |||||

| VFD installed on one of the impulsion pumps. | This strategy represented a saving of 1548 MWh/year and a reduction of 587 tCO2e/year in emissions. | |||||

| Optimization of processes with different actions such as a performance increment SAG or in the efficiency of the coarse ore transport system. | A reduction of 87,463 MWh/year in electricity, 37,764 tCO2e/year and 674,409 L of diesel a year. | |||||

| Antofagasta Minerals, Zaldivar | 3460.0 | 29.8 | 315,028.0 | 3.3 | Biomass—creation of centre called CEADA. | Reducing the GHG and generating adaptation for some species in arid zones. |

| Renewable energy agreement with Colbun S.A (electricity generator and distributor). | From 2020, the operation uses only electricity from renewable sources. Reduction in scope 2 GHG emissions by 67,615 tCO2e. | |||||

| BHP, all global operations | 39,668.8 | 28.91 | 5,024,000.0 | 3.7 | Management system—to identify different risks and implement activities to reduce GHG Emission. | Reduce cost and GHG emissions—seeking new energy resources. |

| BHP, Escondida | 32,334.1 | 27.97 | 4,180,000.0 | 3.9 | The organization modified the project into a natural gas combined-cycle unit (Kelar). | By 2017, they Reduced around 203,344 tCO2e per year. |

| Hecker project cathode—alternating current for the copper deposition (electrowinning process). | A reduction of around 11 GWh a year. | |||||

| An agreement with an electricity supplier to ensure a 100% renewable power source. | A reduction in GHG, seeking zero GHG emissions from scope 2. This change would reduce around 3320 k tCO2e. | |||||

| Change to the design and materials of ball mills. | Energy consumption reduction between 3 to 5%, which represents 30,000 MWh/year. | |||||

| BHP, Cerro Colorado | 2976.0 | 43.19 | 244,000.0 | 3.7 | - | - |

| BHP, Spence | 4358.7 | 29.73 | 600,000.0 | 3.4 | Energy efficiency strategy to improve the EW process. | Savings of 5% per year in electrical energy in the EW process, which is around 7,431,026 kWh/year. |

| Change in mining trucks to Komatsu 980E electric trucks. | Saving of 7% in fuel for trucks. | |||||

| An agreement with an electricity supplier to ensure a 100% renewable power source. | A reduction in GHG, seeking zero GHG emissions from scope 2. This change would reduce around 400 k tCO2e. | |||||

| CODELCO, all global operations | 51,954 | 32.11 | 4,532,359 | 2.8 | KPIs regarding energy efficiency and a corporate regulation about this topic for new projects. | Reduce cost and GHG emissions—seeking new energy resources and to foster energy efficiency. |

| The organization modified some agreements of electric supply for the northern operations. | Around 22.5% of the total energy consumed will be from renewable energy sources. | |||||

| CODELCO, Teniente | 9642 | 21.8 | 888,081.0 | 2.0 | Use of renewable energy—a runoff river mini-power plant which uses tailing as an energy source. | Plant produces 2.4 MW (around 20,000 MWh/year). |

| Hybrid LHD. | A reduction in diesel consumption of over 25% and operational cost of 30%. | |||||

| CODELCO, Chuquicamata | 12,988 | 32.4 | 1,155,199 | 2.9 | Solar energy—energy generation from a solar plant (Calama Solar 3). | Plants provide 1.1 MWp and a reduction of 1680 tons of CO2 a year. |

| VOD—automatically distributes the air according to the instant demand in the mine. | Reduction of around 20% to 50% of the energy consumed. | |||||

| NCRE agreement for the electricity supply contract. | 80% of the supply comes from NCRE and it allows a reduction in GHG from scope 2. | |||||

| CODELCO, Gaby | 3212 | 31.5 | 269,019 | 2.6 | Solar thermal—a solar thermal plant called Pampa Elvira Solar. | Reduction of around 15,000 tons of CO2 annually. |

| CODELCO, Andina | 4982 | 27.0 | 444,227 | 2.41 | VOD—automatically distributes the air according to the instant demand in the mine. | Reduction of around 25% of the energy consumed. |

| CODELCO, Salvador | 2688 | 47.7 | 300,059 | 5.33 | New technology through hydrogen as a catalyst in mining haul trucks’ engines—hybrid use of diesel | A reduction of around 10 to 20% of the cost. |

| CODELCO, Radomiro Tomic | 9840 | 37.8 | 752,756 | 2.89 | - | - |

| CODELCO, Vetanas | 3004 | - | 211,206 | - | - | - |

| CODELCO, Ministro Hales | 5597 | 32.8 | 511,812 | 3.00 | - | - |

| Teck, Quebrada Blanca | - | 49.7 ** | - | 5.99 ** | Solar energy—agreement with AES Gener to supply energy from renewable sources. | 30% of the total energy consumed for Quebrada Blanca—reduce GHG. |

| NCRE agreement for the electricity supply contract. | For the new project QB2, 50% of total operational needs will come from renewable resources. A reduction of 800,000 tCO2e per year. | |||||

| Teck, Carmen de Andacollo | 2104 | 34.5 | 211,316 | 3.46 | Optimization in grinding and blasting process—identifies the different hardness in the rock. | Saving around 600,000 USD per year and 2060 tCO2e. |

| NCRE agreement for the electricity supply contract. | 100% of renewable energy for the operation. A reduction of 200,000 tCO2e per year. | |||||

| Change in medium to fine liners in the lining of the 20 K Plant cone crushers. | A reduction of 4.1 TJ and 471 tCO2e per year. | |||||

| The installation of a sizer-type crusher. | An energy reduction of 8.9 TJ and 1042 tCO2e per year. | |||||

| Optimization of the lifter angle of the SAG mill. | A reduction of 12.2 TJ of energy and 1413 tCO2e per year. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leiva González, J.; Onederra, I. Environmental Management Strategies in the Copper Mining Industry in Chile to Address Water and Energy Challenges—Review. Mining 2022, 2, 197-232. https://doi.org/10.3390/mining2020012

Leiva González J, Onederra I. Environmental Management Strategies in the Copper Mining Industry in Chile to Address Water and Energy Challenges—Review. Mining. 2022; 2(2):197-232. https://doi.org/10.3390/mining2020012

Chicago/Turabian StyleLeiva González, Jorge, and Italo Onederra. 2022. "Environmental Management Strategies in the Copper Mining Industry in Chile to Address Water and Energy Challenges—Review" Mining 2, no. 2: 197-232. https://doi.org/10.3390/mining2020012

APA StyleLeiva González, J., & Onederra, I. (2022). Environmental Management Strategies in the Copper Mining Industry in Chile to Address Water and Energy Challenges—Review. Mining, 2(2), 197-232. https://doi.org/10.3390/mining2020012