Managerial Practices for the Digital Transformation of Manufacturers

Abstract

1. Introduction

2. Theoretical Background

2.1. Digitalization and Digital Transformation

2.2. Theoretical Perspective on Manager Competencies and Roles in Digital Transformations

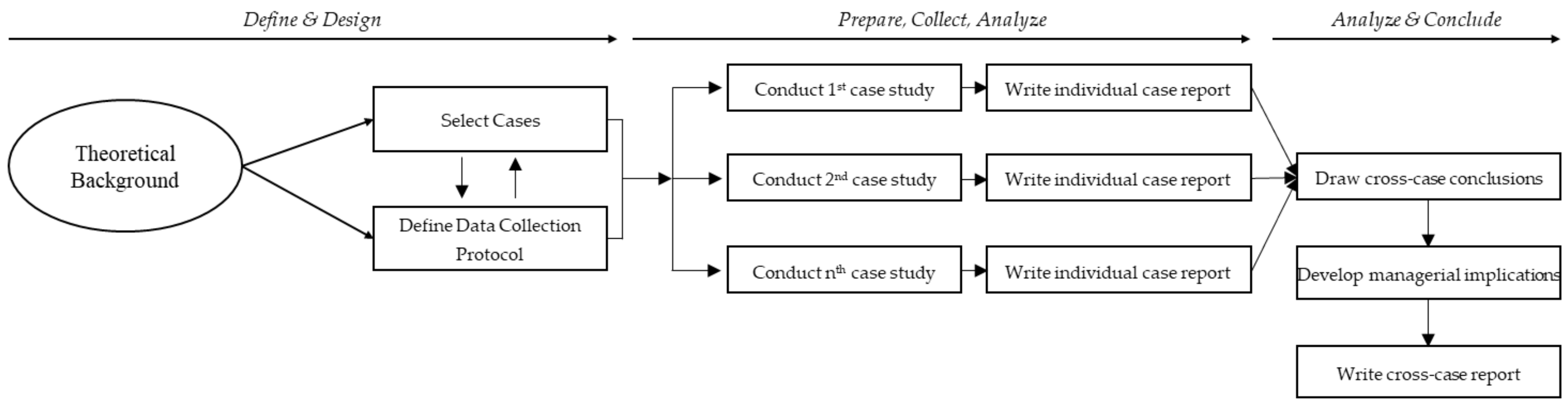

3. Method

3.1. Case Selection

- Drivers of digital transformations (e.g., customization pressure, technology change, etc.);

- Barriers along transformation (e.g., lack of capabilities, lack of management commitment, etc.);

- Number of finished and ongoing digital technology projects (e.g., cloud, big data, etc.).

3.2. Data Gathering

3.2.1. Semi-Structured Interviews

3.2.2. Printed and Quantitative Data

3.2.3. Conference

3.3. Data Analysis

4. Results

4.1. Case Description

- Drivers for the digital transformation;

- Challenges in the digital transformation process;

- Needed competences and managerial practices used to overcome these challenges;

- The outcome/results.

4.2. Case Analysis

4.2.1. Strategic Approaches

4.2.2. Collaborations

4.2.3. Cross-Functionality

4.2.4. Usage of Data

4.2.5. Project Organization and Learning

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Osterrieder, P.; Budde, L.; Friedli, T. The Smart Factory as a Key Construct of Industry 4.0: A Systematic Literature Review. Int. J. Prod. Econ. 2019, 221, 107476. [Google Scholar] [CrossRef]

- Yoo, Y.; Boland, R.J.; Lyytinen, K.; Majchrzak, A. Organizing for Innovation in the Digitized World. Organ. Sci. 2012, 23, 1398–1408. [Google Scholar] [CrossRef]

- Berghaus, S.; Back, A. Stages in Digital Business Transformation: Results of an Empirical Maturity Study. In Proceedings of the 10th Mediterranean Conference on Information Systems (MCIS), Paphos, Cyprus, 4–6 September 2016. [Google Scholar]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The Expected Contribution of Industry 4.0 Technologies for Industrial Performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Müller, J.M. Business Model Innovation in Small- and Medium-Sized Enterprises: Strategies for Industry 4.0 Providers and Users. J. Manuf. Technol. Manag. 2019, 30, 1127–1142. [Google Scholar] [CrossRef]

- Brynjolfsson, E.; Mcafee, A. The Second Machine Age—Work, Progress, and Prosperity in a Time of Brilliant Technologies; W.W. Norton & Company: New York, NY, USA, 2014. [Google Scholar]

- Kang, H.S.; Lee, J.Y.; Choi, S.; Kim, H.; Park, J.H.; Son, J.Y.; Kim, B.H.; Noh, S. Do Smart Manufacturing: Past Research, Present Findings, and Future Directions. Int. J. Precis. Eng. Manuf.-Green Technol. 2016, 3, 111–128. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 Technologies: Implementation Patterns in Manufacturing Companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the Current Status as Well as Future Prospects on Logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Yoo, Y.; Henfridsson, O.; Lyytinen, K. The New Organizing Logic of Digital Innovation: An Agenda for Information Systems Research. Inf. Syst. Res. 2010, 21, 724–735. [Google Scholar] [CrossRef]

- Bokrantz, J.; Skoogh, A.; Berlin, C.; Stahre, J. Maintenance in Digitalised Manufacturing: Delphi-Based Scenarios for 2030. Int. J. Prod. Econ. 2017, 191, 154–169. [Google Scholar] [CrossRef]

- Thoben, K.-D.; Wiesner, S.; Wuest, T. “Industrie 4.0” and Smart Manufacturing—A Review of Research Issues and Application Examples. Int. J. Autom. Technol. 2017, 11, 4–16. [Google Scholar] [CrossRef]

- Demeter, K. Research in Global Operations Management: Some Highlights and Potential Future Trends. J. Manuf. Technol. Manag. 2017, 28, 324–333. [Google Scholar] [CrossRef]

- Matt, C.; Hess, T.; Benlian, A. Digital Transformation Strategies. Bus. Inf. Syst. Eng. 2015, 57, 339–343. [Google Scholar] [CrossRef]

- Bharadwaj, A.; El Sawy, O.A.; Pavlou, P.A.; Venkatraman, N. Digital Business Strategy: Toward a next Generation of Insights. MIS Q. 2013, 37, 471–482. [Google Scholar] [CrossRef]

- Loebbecke, C.; Picot, A. Reflections on Societal and Business Model Transformation Arising from Digitization and Big Data Analytics: A Research Agenda. J. Strateg. Inf. Syst. 2015, 24, 149–157. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The Future of Manufacturing Industry: A Strategic Roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Veile, J.W.; Kiel, D.; Müller, J.M.; Voigt, K.-I. Lessons Learned from Industry 4.0 Implementation in the German Manufacturing Industry. J. Manuf. Technol. Manag. 2019, 31, 977–997. [Google Scholar] [CrossRef]

- Weill, P.; Woerner, S.L. The Future of the CIO in a Digital Economy. MIS Q. Exec. 2013, 12, 65–75. [Google Scholar]

- Horlacher, A.; Hess, T. What Does a Chief Digital Officer Do? Managerial Tasks and Roles of a New C-Level Position in the Context of Digital Transformation. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 5126–5135. [Google Scholar]

- Henfridsson, O.; Mathiassen, L.; Svahn, F. Managing Technological Change in the Digital Age: The Role of Architectural Frames. J. Inf. Technol. 2014, 29, 27–43. [Google Scholar] [CrossRef]

- Neumeyer, X.; Santos, S.C.; Morris, M.H. Overcoming Barriers to Technology Adoption When Fostering Entrepreneurship Among the Poor: The Role of Technology and Digital Literacy. IEEE Trans. Eng. Manag. 2021, 68, 1605–1618. [Google Scholar] [CrossRef]

- Neumeyer, X.; Liu, M. Managerial Competencies and Development in the Digital Age. IEEE Eng. Manag. Rev. 2021, 49, 49–55. [Google Scholar] [CrossRef]

- Besson, P.; Rowe, F. Strategizing Information Systems-Enabled Organizational Transformation: A Transdisciplinary Review and New Directions. J. Strateg. Inf. Syst. 2012, 21, 103–124. [Google Scholar] [CrossRef]

- Ortt, R.; Stolwijk, C.; Punter, M. Implementing Industry 4.0: Assessing the Current State. J. Manuf. Technol. Manag. 2020, 31, 825–836. [Google Scholar] [CrossRef]

- Legner, C.; Eymann, T.; Hess, T.; Matt, C.; Böhmann, T.; Drews, P.; Mädche, A.; Urbach, N.; Ahlemann, F. Digitalization: Opportunity and Challenge for the Business and Information Systems Engineering Community. Bus. Inf. Syst. Eng. 2017, 59, 301–308. [Google Scholar] [CrossRef]

- Hagberg, J.; Sundstrom, M.; Egels-Zandén, N. The Digitalization of Retailing: An Exploratory Framework. Int. J. Retail Distrib. Manag. 2016, 44, 694–712. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Foropon, C.; Godinho Filho, M. When Titans Meet—Can Industry 4.0 Revolutionise the Environmentally-Sustainable Manufacturing Wave? The Role of Critical Success Factors. Technol. Forecast. Soc. Change 2018, 132, 18–25. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.-A. A Cyber-Physical Systems Architecture for Industry 4.0-Based Manufacturing Systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Wischnevsky, J.D.; Damanpour, F. Organizational Transformation and Performance: An Examination of Three Perspectives. J. Manag. Issues 2006, 18, 104–128. [Google Scholar]

- Davis, E.B.; Kee, J.; Newcomer, K. Strategic Transformation Process: Toward Purpose, People, Process and Power. Organ. Manag. J. 2010, 7, 66–80. [Google Scholar] [CrossRef]

- Farias, G.; Johnson, H. Organizational Development and Change Management - Setting the Record Straight. J. Appl. Behav. Sci. 2000, 36, 376–379. [Google Scholar] [CrossRef]

- Kettinger, W.J.; Grover, V. Toward a Theory of Business Process Change Management. J. Manag. Inf. Syst. 1995, 12, 9–30. [Google Scholar] [CrossRef]

- Nelson, L. A Case Study in Organisational Change: Implications for Theory. Learn. Organ. 2003, 10, 18–30. [Google Scholar] [CrossRef]

- Buchanan, D.; Claydon, T.; Doyle, M. Organisation Development and Change: The Legacy of the Nineties. Hum. Resour. Manag. J. 1999, 9, 20–37. [Google Scholar] [CrossRef]

- Berman, S.J. Digital Transformation: Opportunities to Create New Business Models. Strategy Leadersh. 2012, 40, 16–24. [Google Scholar] [CrossRef]

- Burnes, B. Managing Change: A Strategic Approach to Organisational Dynamics, 4th ed.; Prentice-Hall Inc.: Harlow, UK, 2004. [Google Scholar]

- Kotter, J.P. Leading Change; Harvard Business School Press: Boston, MA, USA, 1996. [Google Scholar]

- Carnall, C.A. Managing Change in Organizations, 4th ed.; Prentice-Hall Inc.: Harlow, UK, 2003. [Google Scholar]

- Lewin, K. Frontiers in Group Dynamics: Concept, Method and Reality in Social Science; Social Equilibria and Social Change. Hum. Relat. 1947, 1, 5–41. [Google Scholar] [CrossRef]

- Bamford, D.R.; Forrester, P.L. Managing Planned and Emergent Change within an Operations Management Environment. Int. J. Oper. Prod. Manag. 2003, 23, 546–564. [Google Scholar] [CrossRef]

- Todnem By, R. Organisational Change Management: A Critical Review. J. Change Manag. 2005, 5, 369–380. [Google Scholar]

- Burnes, B. No Such Thing as… a “One Best Way” to Manage Organizational Change. Manag. Decis. 1996, 34, 11–18. [Google Scholar] [CrossRef]

- Dawson, P. Organizational Change: A Processual Approach; Paul Chapman: London, UK, 1994. [Google Scholar]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine That Changed the World; Harper Perennial: New York, NY, USA, 1991. [Google Scholar]

- Lyytinen, K.; Newman, M. Explaining Information Systems Change: A Punctuated Socio-Technical Change Model. Eur. J. Inf. Syst. 2008, 17, 589–613. [Google Scholar] [CrossRef]

- Williams, S.P.; Schubert, P. An Empirical Study of Enterprise 2.0 in Context. BLED 2011 Proc. 2011, 44, 42–55. [Google Scholar]

- Kuettner, T.; Diehl, R.; Schubert, P. Change Factors in Enterprise 2.0 Initiatives: Can We Learn from ERP? Electron. Mark. 2013, 23, 329–340. [Google Scholar] [CrossRef]

- Motwani, J.; Mirchandani, D.; Madan, M.; Gunasekaran, A. Successful Implementation of ERP Projects: Evidence from Two Case Studies. Int. J. Prod. Econ. 2002, 75, 83–96. [Google Scholar] [CrossRef]

- Aladwani, A.M. Change Management Strategies for Successful ERP Implementation. Bus. Process Manag. J. 2001, 7, 266–275. [Google Scholar] [CrossRef]

- Finney, S.; Corbett, M. ERP Implementation: A Compilation and Analysis of Critical Success Factors. Bus. Process Manag. J. 2007, 13, 329–347. [Google Scholar] [CrossRef]

- Holland, C.R.; Light, B. A Critical Success Factors Model for ERP Implementation. IEEE Softw. 1999, 16, 30–36. [Google Scholar] [CrossRef]

- Kezar, A.; Eckel, P. Examining the Institutional Transformation Process: The Importance of Sensemaking, Interrelated Strategies, and Balance. Res. High. Educ. 2002, 43, 295–328. [Google Scholar] [CrossRef]

- Somers, T.M.; Nelson, K. The Impact of Critical Success Factors across the Stages of Enterprise Resource Planning Implementations. In Proceedings of the 34th Annual Hawaii International Conference on System Sciences, Maui, HI, USA, 6 January 2001; p. 10. [Google Scholar]

- Kanter, R.M. Challenge of Organizational Change: How Companies Experience It and Leaders Guide It; Simon and Schuster: New York, NY, USA, 1992; ISBN 978-0-7432-5446-5. [Google Scholar]

- Luecke, R. Managing Change and Transition; Harvard Business Press: Boston, MA, USA, 2003; ISBN 978-1-57851-874-6. [Google Scholar]

- Kretschmer, T.; Khashabi, P. Digital Transformation and Organization Design: An Integrated Approach. Calif. Manage. Rev. 2020, 62, 86–104. [Google Scholar] [CrossRef]

- Ghadge, A.; Er Kara, M.; Moradlou, H.; Goswami, M. The Impact of Industry 4.0 Implementation on Supply Chains. J. Manuf. Technol. Manag. 2020, 31, 669–686. [Google Scholar] [CrossRef]

- Pessot, E.; Zangiacomi, A.; Battistella, C.; Rocchi, V.; Sala, A.; Sacco, M. What Matters in Implementing the Factory of the Future: Insights from a Survey in European Manufacturing Regions. J. Manuf. Technol. Manag. 2020. ahead-of-print. [Google Scholar] [CrossRef]

- Voss, C.A.; Tsikriktsis, N.; Frohlich, M. Case Research in Operations Management. Int. J. Oper. Prod. Manag. 2002, 22, 195–219. [Google Scholar] [CrossRef]

- Eisenhardt, K.M. Building Theories from Case Study Research. Acad. Manage. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research: Design and Methods, 4th ed.; SAGE Publications: Los Angeles, CA, USA, 2009. [Google Scholar]

- Meredith, J. Building Operations Management Theory through Case and Field Research. J. Oper. Manag. 1998, 16, 441–454. [Google Scholar] [CrossRef]

- Miles, M.B.; Huberman, A.M. Drawing Valid Meaning from Qualitative Data: Toward a Shared Craft. Educ. Res. 1984, 13, 20–30. [Google Scholar] [CrossRef]

- Miles, M.B.; Huberman, A.M.; Saldana, J. Qualitative Data Analysis: A Methods Sourcebook, 3rd ed.; SAGE Publications: Los Angeles, CA, USA, 2014. [Google Scholar]

- Archibald, M.M. Investigator Triangulation: A Collaborative Strategy with Potential for Mixed Methods Research. J. Mix. Methods Res. 2016, 10, 228–250. [Google Scholar] [CrossRef]

- Patton, E.; Appelbaum, S.H. The Case for Case Studies in Management Research. Manag. Res. News 2003, 26, 60–71. [Google Scholar] [CrossRef]

- Cachia, M.; Millward, L. The Telephone Medium and Semi-structured Interviews: A Complementary Fit. Qual. Res. Organ. Manag. Int. J. 2011, 6, 265–277. [Google Scholar] [CrossRef]

- Eisenhardt, K.M.; Bourgeois, L.J. Politics of Strategic Decision Making in High-Velocity Environments: Toward a Midrange Theory. Acad. Manage. J. 1988, 31, 737–770. [Google Scholar]

- Patton, M.Q. Qualitative Evaluation and Research Methods, 2nd ed.; SAGE Publications: Beverly Hills, CA, USA, 1990. [Google Scholar]

- Adler, P.S. Interdepartmental Interdependence and Coordination: The Case of the Design/Manufacturing Interface. Organ. Sci. 1995, 6, 147–167. [Google Scholar] [CrossRef]

- Hänggi, R.; Fimpel, A.; Siegenthaler, R. LEAN Production—Easy and Comprehensive: A Practical Guide to Lean Processes Explained with Pictures; Springer: Berlin/Heidelberg, Germany, 2022; ISBN 978-3-662-64526-0. [Google Scholar]

- Cennamo, C.; Santaló, J. Generativity Tension and Value Creation in Platform Ecosystems. Organ. Sci. 2019, 30, 617–641. [Google Scholar] [CrossRef]

- Panico, C.; Cennamo, C. User Preferences and Strategic Interactions in Platform Ecosystems. Strateg. Manag. J. 2022, 43, 507–529. [Google Scholar] [CrossRef]

- Vivek, S.D.; Beatty, S.E.; Morgan, R.M. Customer Engagement: Exploring Customer Relationships beyond Purchase. J. Mark. Theory Pract. 2012, 20, 122–146. [Google Scholar] [CrossRef]

- Moyano-Fuentes, J.; Sacristán-Díaz, M.; Martínez-Jurado, P.J. Cooperation in the Supply Chain and Lean Production Adoption. Int. J. Oper. Prod. Manag. 2012, 32, 1075–1096. [Google Scholar] [CrossRef]

- Turel, O.; Bart, C. Board-Level IT Governance and Organizational Performance. Eur. J. Inf. Syst. 2014, 23, 223–239. [Google Scholar] [CrossRef]

- Bassellier, G.; Benbasat, I. Business Competence of Information Technology Professionals: Conceptual Development and Influence on IT-Business Partnerships. MIS Q. 2004, 28, 673–694. [Google Scholar] [CrossRef]

| Technological and Commercial Factors | WPC | ASC | PPC | EMC | AGC | MFC | ABC | PTC |

|---|---|---|---|---|---|---|---|---|

| Cost pressure | → | → | ↗ | → | ↑ | ↑ | → | → |

| Delivery speed | ↑ | ↗ | ↗ | → | ↘ | → | → | ↘ |

| Quality | ↗ | ↗ | ↑ | ↑ | ↑ | ↑ | → | ↑ |

| Flexibility | ↘ | → | → | ↗ | → | ↗ | ↘ | → |

| Innovativeness (product, process) | → | ↑ | ↑ | ↗ | ↗ | ↑ | ↗ | ↗ |

| Overcome/face barriers in the digital transformation (lack of capabilities, feasibility, resistance,…) | 3/6 | 7/12 | 0/7 | 4/8 | 7/10 | 5/12 | 3/13 | 5/9 |

| Finished/ongoing projects related to digital transformation | 5/3 | 10/30 | 5/10 | 5/15 | 50/200 | 6/8 | 20/10 | 10/5 |

| Market diversity/demand variety | ↗ | → | ↘ | ↘ | ↗ | ↗ | → | ↘ |

| Product diversity | → | ↗ | ↘ | ↘ | ↗ | ↗ | → | ↘ |

| Employees (FTE) | 8200 | 18,800 | 11,500 | 36,300 | 29,500 | 9000 | 6200 | 37,200 |

| FTE dedicated to digitalization | 30 | 20 | 30 | 120 | 50 | 30 | 20 | 90 |

| Revenue (in bn USD) | 2.81 | 3.23 | 2.95 | 7.63 | 5.89 | 1.00 | 1.5 | 11.6 |

| 4-year revenue development (CAGR) | +2.1% | +3.2% | +2.2% | +11.7% | −3.1% | +1.7% | +6.3% | −2.5% |

| R&D expenditures of revenue | 9.2% | 8.0% | 4.7% | 11.9% | 6.5% | 3.0% | n/a | 4.2% |

| Digitalization invests of revenue | 0.5% | 1.0% | 10% | 1.0% | 0.3% | 2.0% | 0.5% | 0.1% |

| Company | Industry Type | Position | Workshop | Durations (min) |

|---|---|---|---|---|

| WPC | Wood Processing Industry | COO, Head of Operational Excellence and Projects | 1-day on-site plant tour | 1 × 30, 1 × 90, 1 × 30 |

| ASC | Automation Solution | Chief Digital Officer, Lean Team | 1-day on-site plant tour | 1 × 60, 1 × 100, 1 × 30 |

| PPC | Precision Printing | Lean Manager | 1-day on-site plant tour | 1 × 90, 1 × 30, 1 × 30 |

| EMC | Electronic Miniature | Plant Manager, Head of Lean | 1-day on-site plant tour | 1 × 60, 1 × 90, 1 × 30 |

| AGC | Automotive Gear | CEO of Division, Lean Team | 1-day on-site plant tour | 1 × 60, 1 × 60, 1 × 30 |

| MFC | Mechanical Fastening | COO | 1-day on-site plant tour | 1 × 90, 1 × 30 |

| ABC | Advanced Building | COO | 1-day on-site plant tour | 1 × 90, 1 × 30 |

| PTC | Power Transformation | CEO, Head of Operational Excellence | 1-day on-site plant tour | 1 × 30, 1 × 90, 1 × 30 |

| Industry | WPC | ASC | PPC | EMC | AGC | MFC | ABC | PTC |

|---|---|---|---|---|---|---|---|---|

| Dominance | ↑ | ↗ | ↑ | → | ↑ | → | → | ↑ |

| Growth | → | ↗ | ↘ | → | ↑ | → | ↻ | → |

| Market characteristics | ||||||||

| Product customization | ↑ | ↗ | → | → | ↗ | ↓ | ↑ | ↘ |

| Product life-cycle duration | → | ↗ | ↑ | → | → | → | ↑ | → |

| Organization | ||||||||

| Degree of centralization | ↗ | ↗ | → | ↘ | → | → | ↘ | → |

| Digitalization emphasis | ↑ | ↑ | ↗ | ↗ | → | ↗ | ↓ | ↘ |

| Barriers | ||||||||

| Budget restrictions | ✓ | X | X | X | X | X | ||

| Time pressure | ✓ | X | X | ✓ | ||||

| Shortage of manpower | X | X | X | ✓ | X | X | X | X |

| Lack of capabilities | X | X | ✓ | ✓ | X | X | ✓ | |

| Expensive technologies | ✓ | X | ✓ | X | X | |||

| Existing infrastructures restrictions | ✓ | X | X | ✓ | X | X | ||

| Technical feasibility | ✓ | X | ✓ | ✓ | ✓ | ✓ | ||

| Missing norms and standards | X | X | X | ✓ | X | X | ||

| IT security | X | X | X | ✓ | X | X | X | X |

| Lack of management commitment | ✓ | ✓ | X | ✓ | X | X | ✓ | |

| Resistance of employees | ✓ | ✓ | ✓ | ✓ | ✓ | X | ✓ | |

| Timing | ✓ | X | ✓ | ✓ | ✓ | |||

| Strategic digitalization approach | ||||||||

| Top-down ↓/bottom-up ↑ | ↓ and ↑ | ↓ and ↑ | ↓ and ↑ | ↓ and ↑ | ↓ and ↑ | ↑ | ↓ | ↓ and ↑ |

| Growth emphasis | ↗ | ↗ | ↑ | ↑ | ↗ | ↑ | ↗ | ↗ |

| Production emphasis | ↑ | ↗ | ↗ | ↗ | ↗ | → | ↘ | ↗ |

| Collaboration with | ||||||||

| Customers | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Suppliers | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| research institutions | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Associations | ✓ | ✓ | ✓ | ✓ | ||||

| work councils | ✓ | |||||||

| competitors | ✓ | ✓ | ||||||

| Data usage and management | ||||||||

| Production data | A/P | A/P | A/P | A/P | A/P | P | P | P |

| Logistics data | A | A/P | P | A/P | P | A/P | A/P | |

| Field data | P | A/P | A/P | A | A/P | |||

| IT Systems | ||||||||

| Integration level | ↑ | ↑ | ↑ | ↑ | ↘ | ↓ | ↑ | ↓ |

| Mobile devices on shop-floor | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| Process and product maturity | ||||||||

| Digitally advanced products | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Digitally advanced processes | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Effect on productivity | ||||||||

| Direct labor hours | ↓ | ↓ | ↓ | ↘ | ↓ | ↓ | ↓ | |

| Raw material input | ↓ | ↓ | ↓ | |||||

| Energy consumption | ↓ | ↓ | ↓ | |||||

| Machine hours | ↘ | ↘ | ||||||

| Indirect labor hours | ↓ | ↘ |

| Theoretical Foundation (Based on Kotter 1996) | Barriers | Managerial Practices for Digital Transformation | Managerial Competencies for Digital Transformation | Propositions |

|---|---|---|---|---|

| Create a sense of urgency | No specific challenge identified |

|

| PA |

| Build a guiding coalition | Variety of needed capabilities |

|

| |

| Form a strategic vision and initiatives | Variety of opportunities, uncertain ROI |

|

| |

| Enlist a volunteer army | Options of organizational forms |

|

| |

| Enable action by removing barrier | Resistance of employees (e.g., job danger) |

|

| |

| Enable action by removing barrier | Variety and interdependencies of digital technologies, existing infrastructures restrictions and technical feasibilty |

|

| PA |

| Lack of capabilities, shortage of manpower |

|

| PB | |

| Organizational silos |

|

| PC | |

| Increasing decentralization reduces manageability |

|

| ||

| Enable action by removing barrier | Willingness to learn from and share mistakes |

|

| PD |

| Risks of investments, uncertain ROI (Budget restrictions) |

|

| ||

| Generate short-term wins | Uncertain ROI |

|

| PA |

| Sustain acceleration | Variety of prerequisites for local implementations |

|

| PA |

| Institute change | Sustain new ways of working and behaviors |

|

| PD |

| Aggregated Competencies for Managers to Foster Digital Transformation |

|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Budde, L.; Benninghaus, C.; Hänggi, R.; Friedli, T. Managerial Practices for the Digital Transformation of Manufacturers. Digital 2022, 2, 463-483. https://doi.org/10.3390/digital2040025

Budde L, Benninghaus C, Hänggi R, Friedli T. Managerial Practices for the Digital Transformation of Manufacturers. Digital. 2022; 2(4):463-483. https://doi.org/10.3390/digital2040025

Chicago/Turabian StyleBudde, Lukas, Christoph Benninghaus, Roman Hänggi, and Thomas Friedli. 2022. "Managerial Practices for the Digital Transformation of Manufacturers" Digital 2, no. 4: 463-483. https://doi.org/10.3390/digital2040025

APA StyleBudde, L., Benninghaus, C., Hänggi, R., & Friedli, T. (2022). Managerial Practices for the Digital Transformation of Manufacturers. Digital, 2(4), 463-483. https://doi.org/10.3390/digital2040025