Structural, Thermal and Mechanical Assessment of Green Compounds with Natural Rubber

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Devulcanization of GTR

2.3. Samples Preparation

2.4. Measurements

3. Results

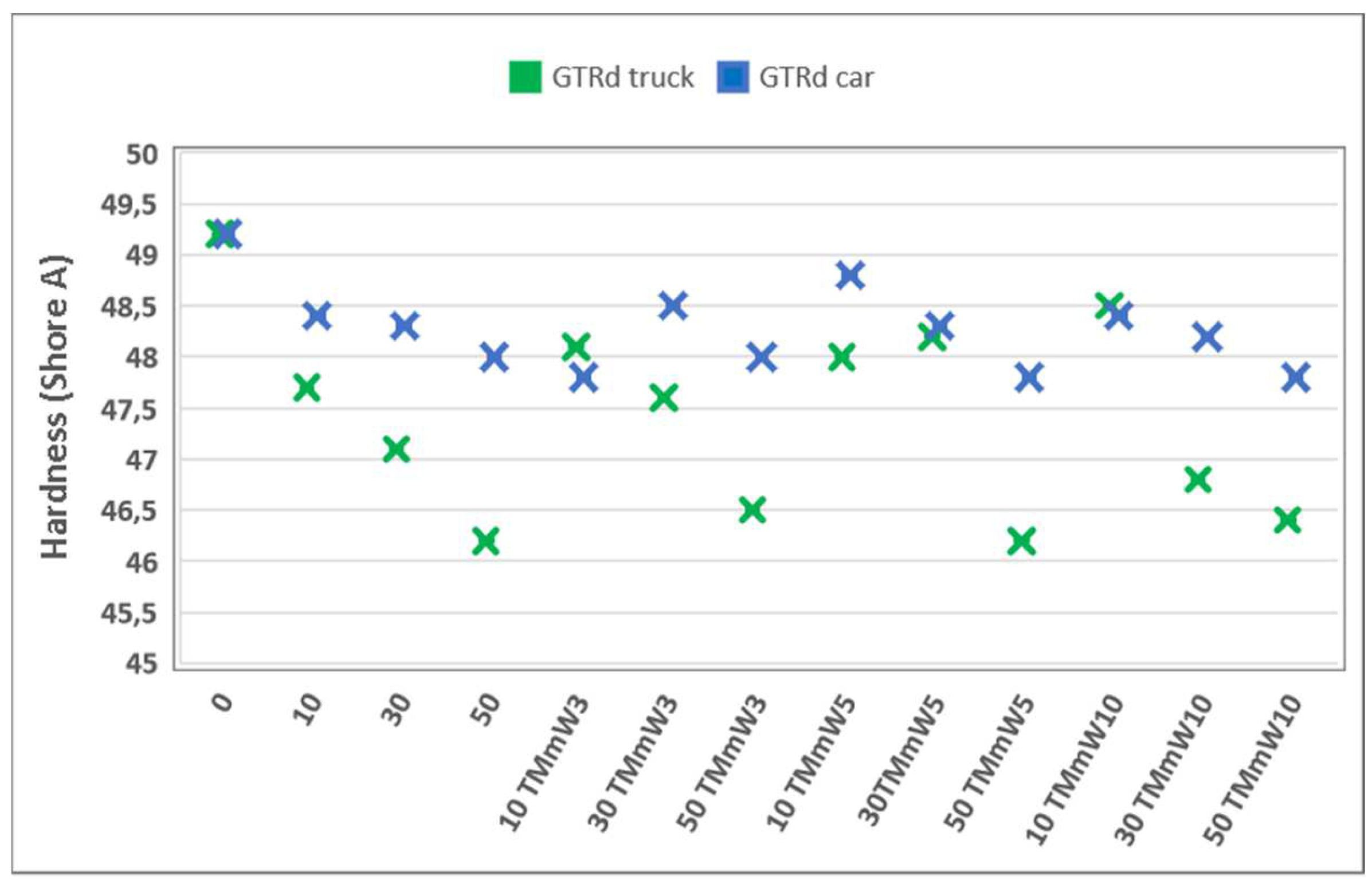

3.1. Mechanical Properties

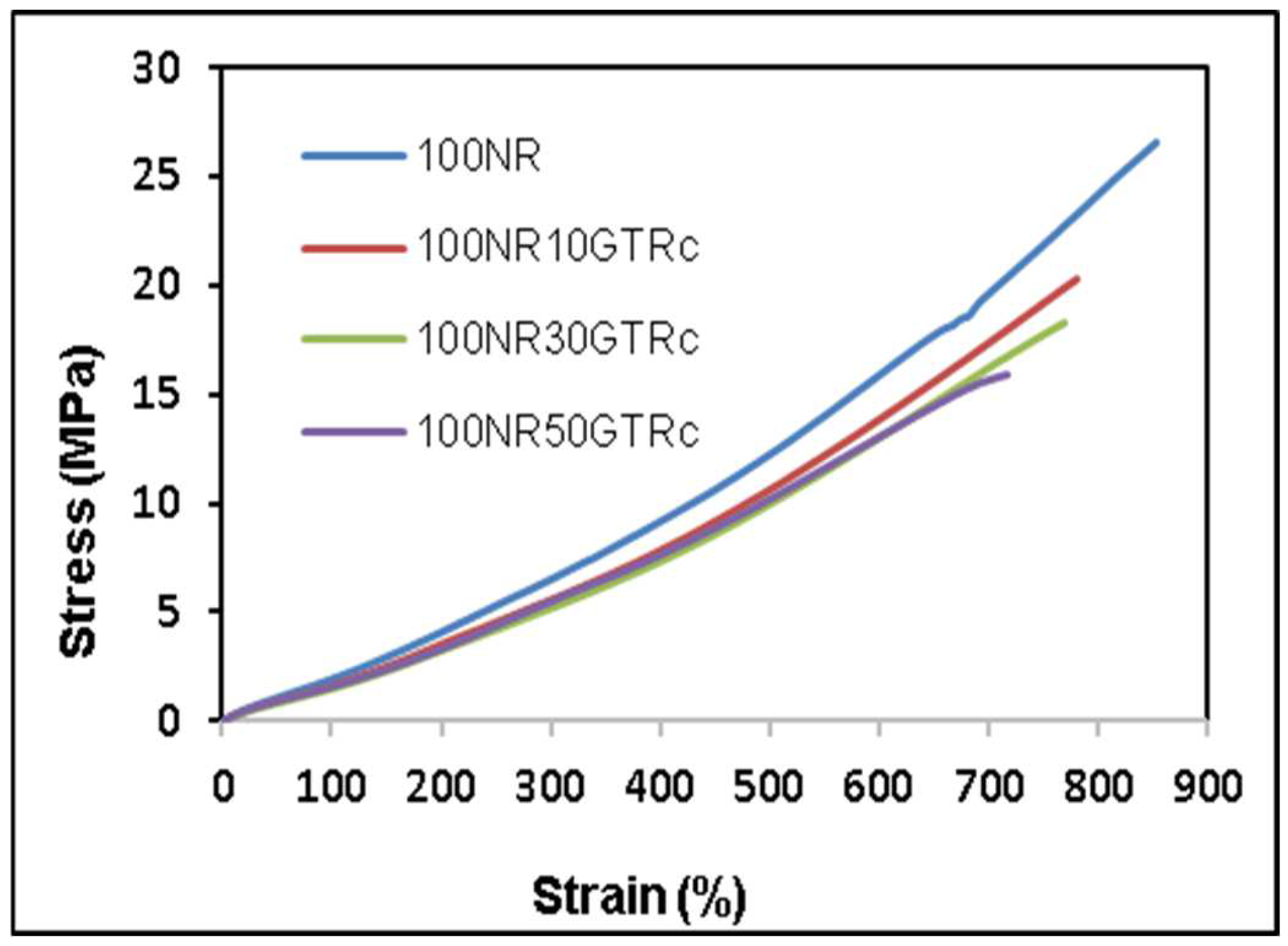

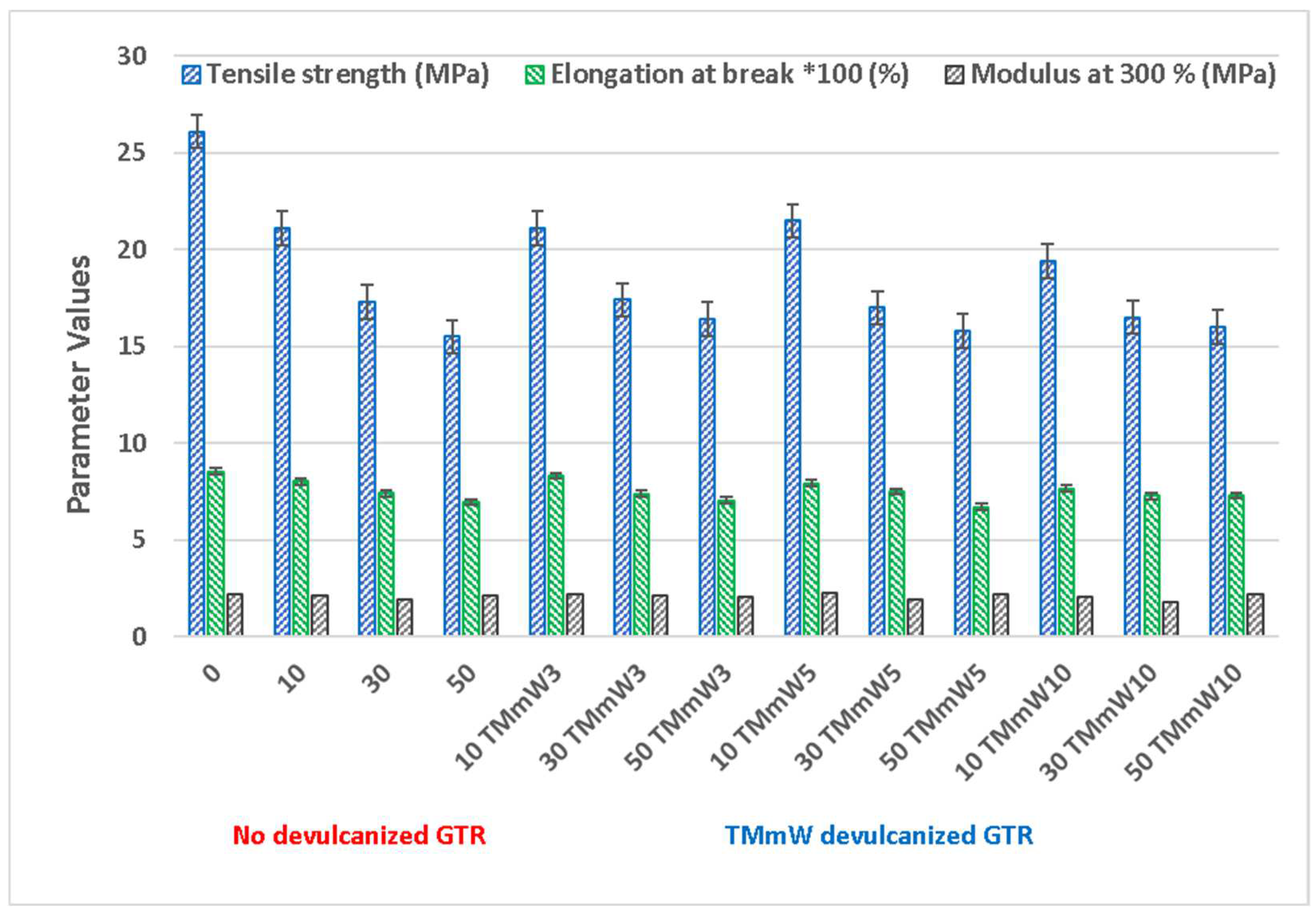

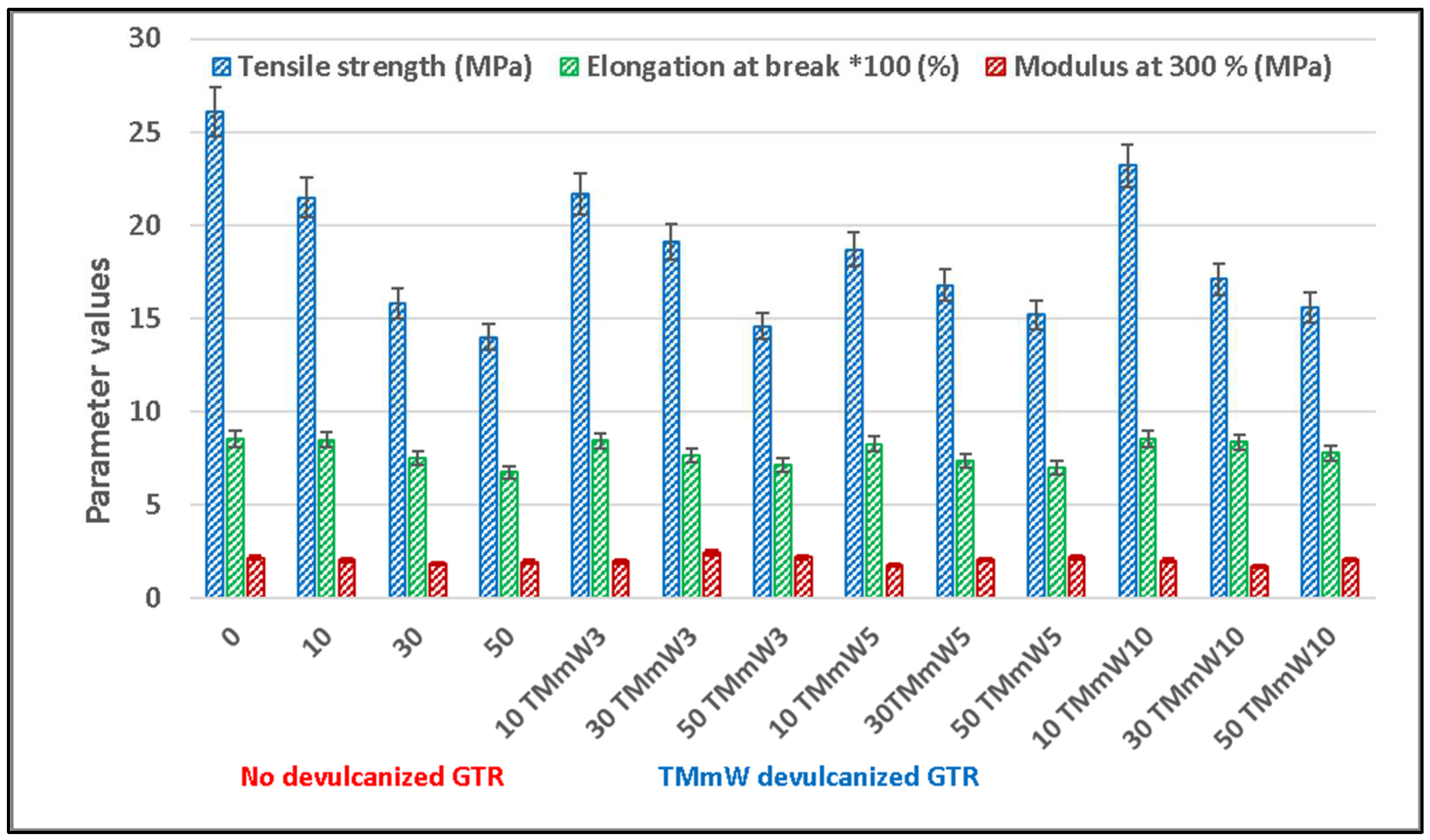

3.1.1. Compounds including Non-Devulcanized GTR

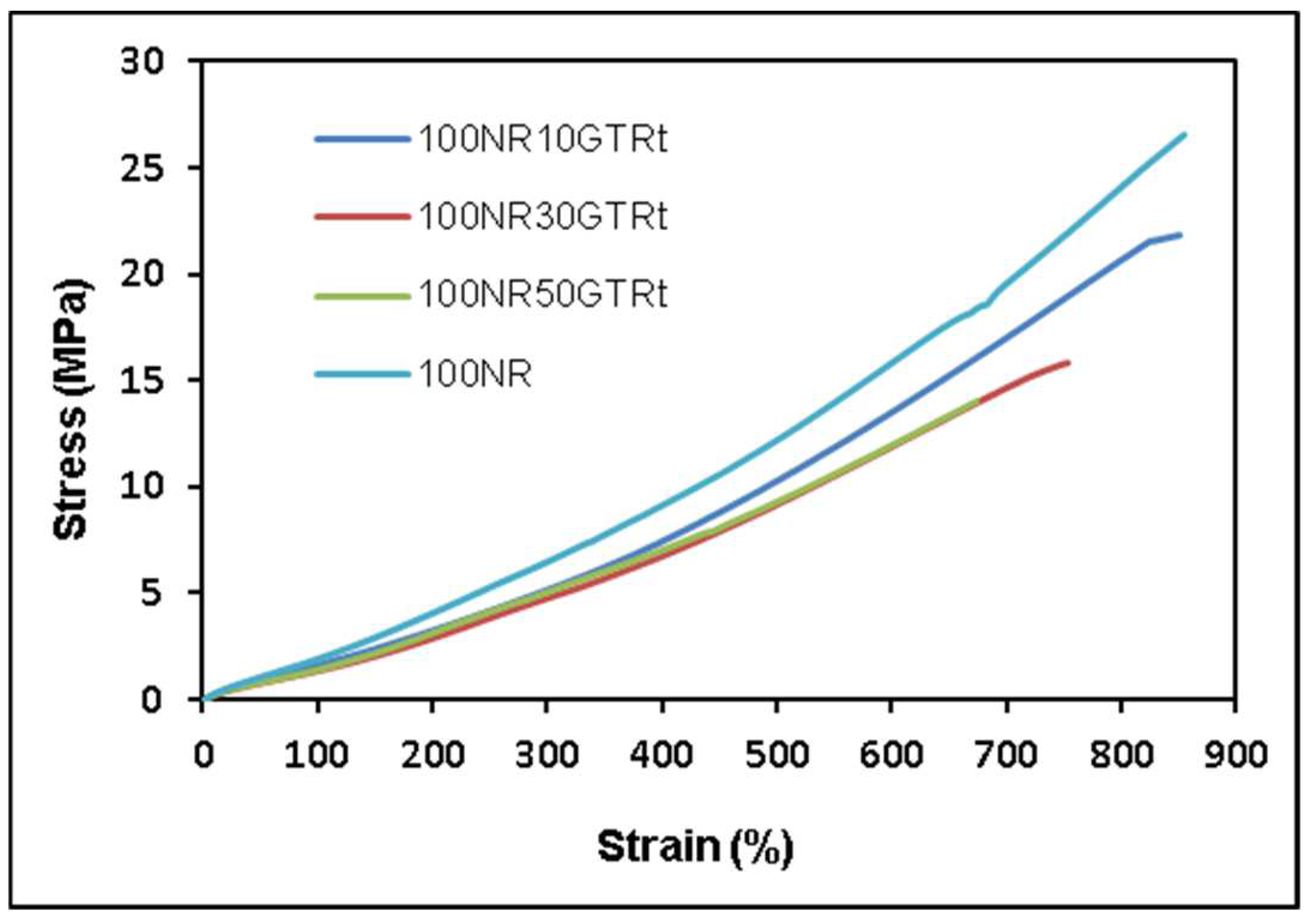

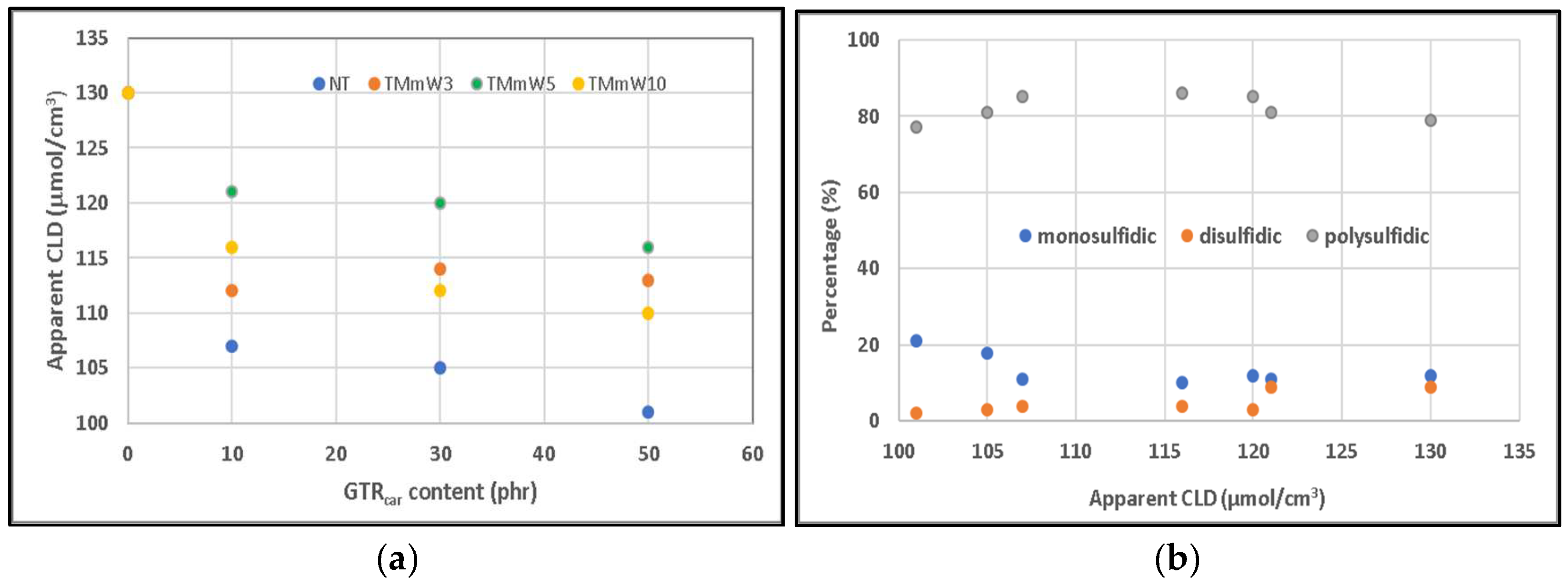

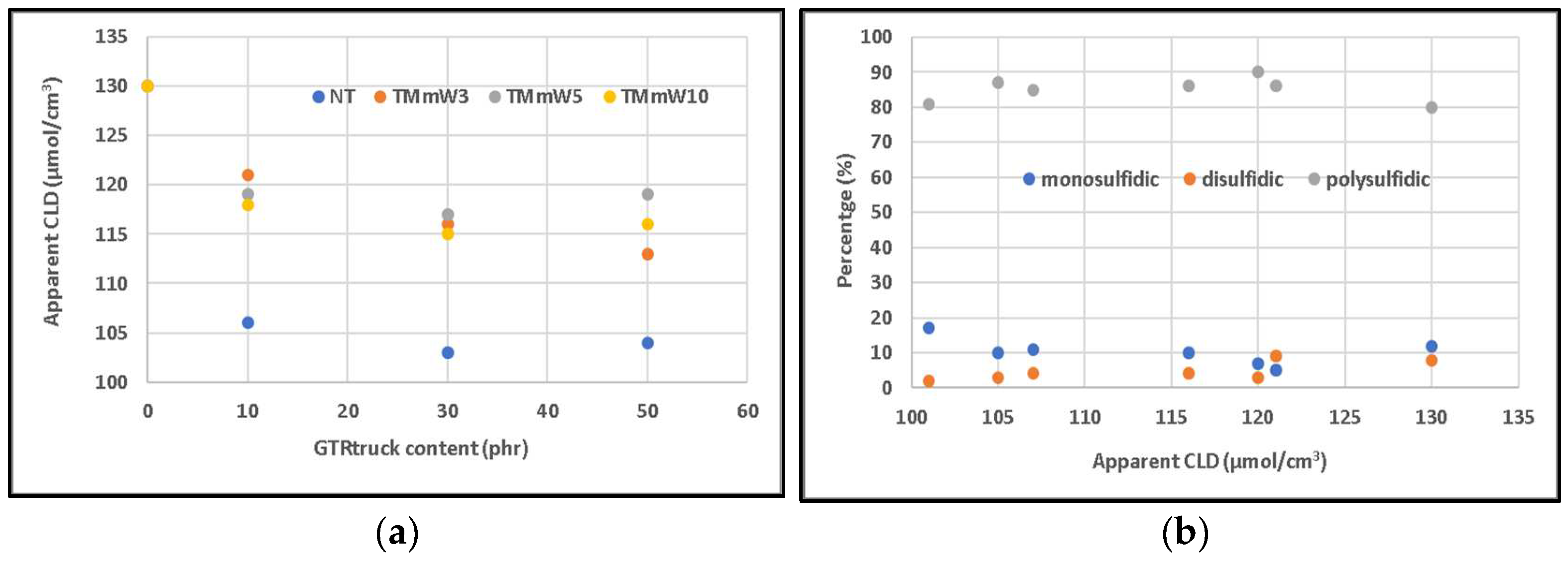

3.1.2. Compounds including Devulcanized GTR

3.2. Spectroscopy Characterization

3.3. Thermogravimetric Analysis

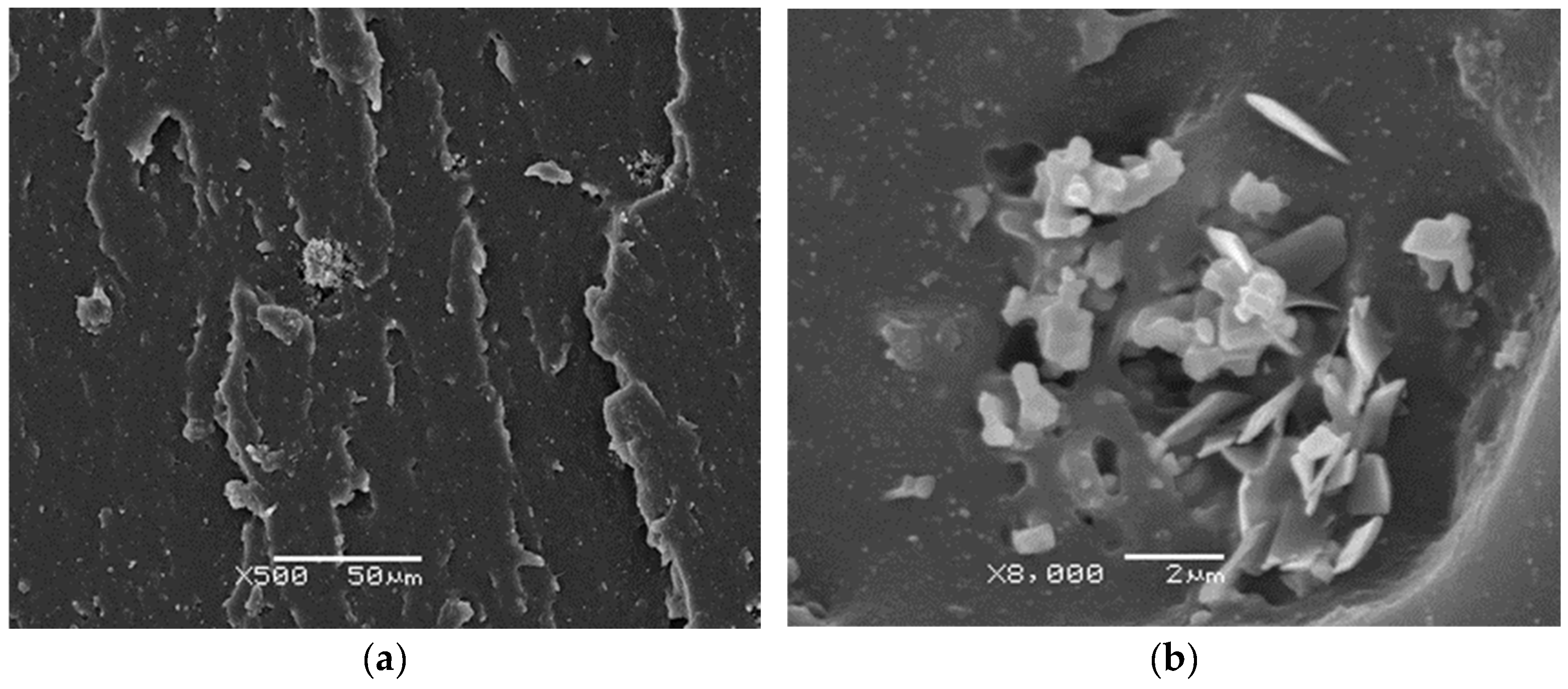

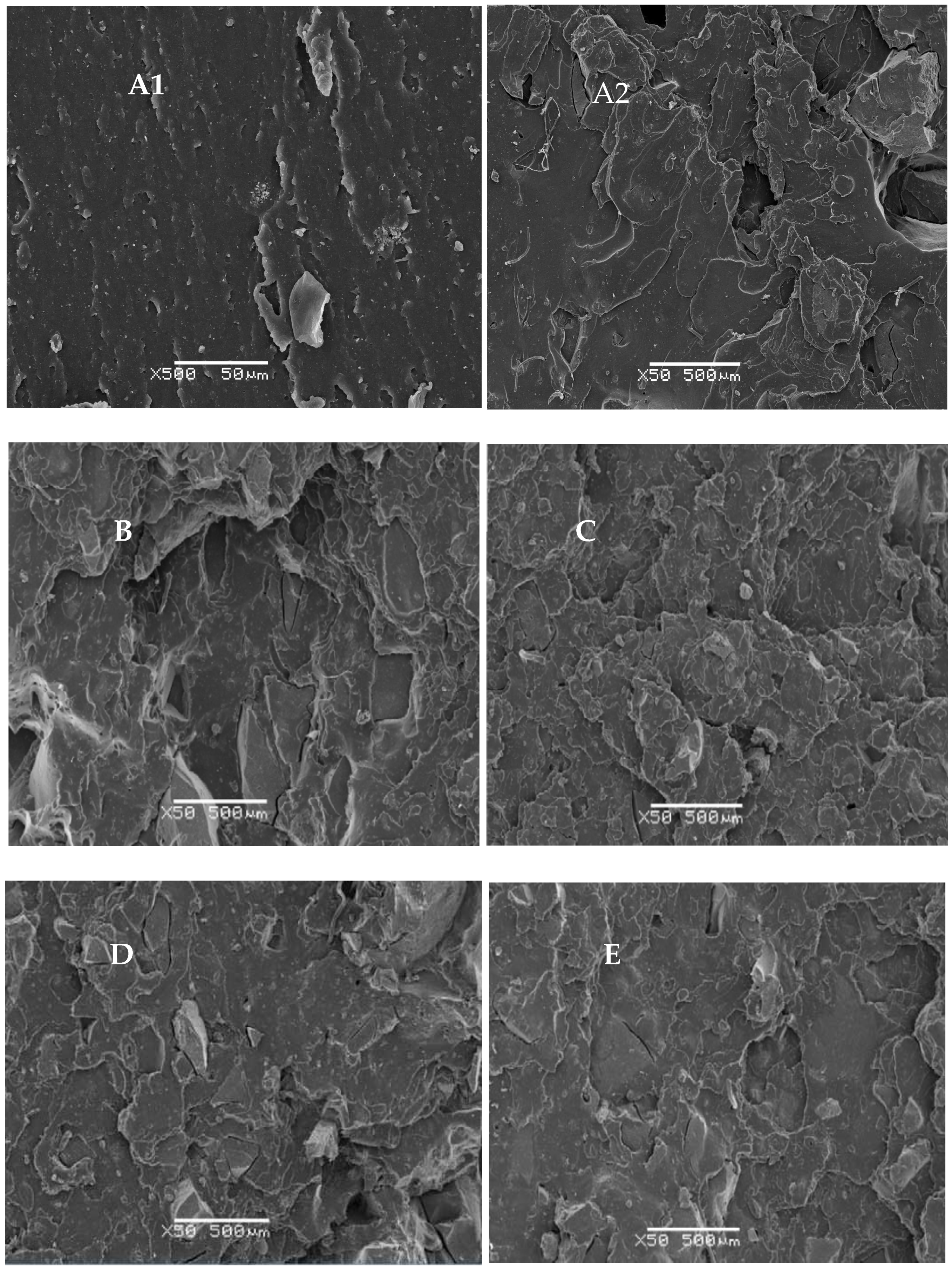

3.4. SEM Studies of NR-GTR

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Tyre and Rubber Manufacturers Association. Annual Report 2020/2021 and End Life Tyre Reports; European Tyre and Rubber Manufacturers Association: Bruxelles, Belgium, 2021. [Google Scholar]

- Chen, S.-J.; Su, H.-B.; Chang, J.-E.; Lee, W.-J.; Huang, K.-L.; Hsieh, L.-T.; Huang, Y.-C.; Lin, W.-Y.; Lin, C.-C. Emissions of polycyclic aromatic hydrocarbons (PAHs) from the pyrolysis of scrap tires. Atmos. Environ. 2007, 41, 1209. [Google Scholar] [CrossRef]

- Korger-Kocsis, J. Editorial corner-a personal view Waste tyre rubber—What to do next? Express Polym. Lett. 2013, 7, 406. [Google Scholar] [CrossRef]

- Kojima, M.; Tosaka, M.; Ikeda, Y.; Kohjiya, S. Devulcanization of Carbon Black filled Natural Rubber using Supercritical Carbon Dioxide. J. Appl. Polym. Sci. 2005, 95, 137. [Google Scholar] [CrossRef]

- Sun, X.; Isayev, A.I. Ultrasound devulcanization: Comparison of synthetic isoprene and natural rubbers. J. Mater. Sci. 2007, 42, 7520. [Google Scholar] [CrossRef]

- Formela, K.; Klein, M.; Colom, X.; Saeb, M.R. Investigating the combined impact of plasticizer and shear force on the efficiency of low temperature reclaiming of ground tire rubber. Polym. Degrad. Stab. 2016, 125, 1. [Google Scholar] [CrossRef]

- De, D.; Panda, P.K.; Roy, M.; Bhunia, S. Reinforcing effect of reclaim rubber on natural rubber/polybutadiene rubber blends. Mater. Des. 2013, 46, 142. [Google Scholar] [CrossRef]

- Rooj, S.; Basak, G.C.; Maji, P.K.; Bhowmnick, A.K. New Route for devulcanization of Natural Rubber and the properties of devulcanized rubber. J. Polym. Environ. 2011, 19, 382. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, S.; Wang, Y. Improvement of the properties of natural rubber/ground tire rubber composites through biological desulfuration of GTR. J. Polym. Res. 2012, 19, 9864. [Google Scholar] [CrossRef]

- Colom, X.; Carrillo-Navarrete, F.; Saeb, M.R.; Marin, M.; Formela, K.; Cañavate, J. Evaluation and rationale of the performance of several elastomeric composites incorporating devulcanized EPDM. Polym. Test. 2023, 121, 107976. [Google Scholar] [CrossRef]

- Colom, X.; Saeb, M.R.; Cañavate, J. Microstructural phenomena in ground tire rubber (GTR) devulcanized via combined Thermochem mechanical and microwave processes monitored by FTIR and DTGA assisted by other techniques. Express Polym. Lett. 2024, 18, 950. [Google Scholar] [CrossRef]

- Kleps, T.; Piaskiewicz, M.; Parasiewicz, W. The use of thermogravimetry in the study of rubber devulcanization. J. Therm. Anal. Calorim. 2000, 60, 271. [Google Scholar] [CrossRef]

- Scuracchio, C.H.; Waki, D.A.; da Silva, M.L.P. Thermal analysis of ground tire rubber devulcanized by Microwave. J. Therm. Anal. Calorim. 2007, 87, 893. [Google Scholar] [CrossRef]

- Garcia, P.S.; de Sousa, F.D.B.; de Lima, J.A.; Cruz, S.A.; Scuracchio, C.H. Devulcanization of ground tire rubber: Physical and Chemical changes after different microwave exposure times. Express Polym. Lett. 2015, 9, 1015. [Google Scholar] [CrossRef]

- Colom, X.; Faliq, A.; Formela, K.; Cañavate, J. FTIR spectroscopic and thermogravimetric characterization of ground tyre rubber devulcanized by microwave treatment. Polym. Test. 2016, 52, 200. [Google Scholar] [CrossRef]

- Aprem, A.S.; Joseph, K.; Thomas, S. Recent developments in crosslinking of elastomers. Rubber Chem. Technol. 2005, 78, 458–488. [Google Scholar] [CrossRef]

- Ismail, H.; Nodin, R.; Noor, A.M. Cure characteristics, tensile properties and swelling bahaviour of recycled rubber powder-filled natural rubber compounds. Polym. Test. 2002, 21, 565. [Google Scholar] [CrossRef]

- Mangili, I.; Lasagni, M.; Anzano, M.; Collina, E.; Tatangelo, V.; Franzetti, A.; Caracino, P.; Isayev, A.I. Mechanical and rheological properties of natural rubber compounds containing devulcanization ground tire rubber from several methods. Polym. Degrad. Stab. 2015, 121, 369. [Google Scholar] [CrossRef]

- ISO 37; Rubber, Vulcanised or Thermoplastic—Determination of Tensile Stress-Strain Properties. ISO: Geneva, Switzerland, 2013.

- ISO 7619-1; Rubber, Vulcanized or Thermoplastic—Determination of Indentation Hardness—Part 1: Durometer Method (Shore Hardness). ISO: Geneva, Switzerland, 2011.

- ASTM D6814-02; Standard Test Method for Determination of Percent Devulcanization of Crumb Rubber Based on Crosslink Density. ASTM International: West Conshohocken, PA, USA, 2018.

- Flory, P.J.; Rehner, J. Statistical mechanics of cross-linked polymer networks I. Rubberlike elasticity. J. Chem. Phys. 1943, 11, 512. [Google Scholar] [CrossRef]

- Kim, D.Y.; Park, J.W.; Lee, D.Y.; Seo, K.H. Correlation between the crosslink characteristics and mechanical properties of natural rubber compound via accelerators and reinforcement. Polymers 2020, 12, 2020. [Google Scholar] [CrossRef]

- Kraus, G.J. Swelling of filler-reinforced vulcanizates. J. Appl. Polym. Sci. 1963, 7, 861. [Google Scholar] [CrossRef]

- Saiwari, S.; Dierkes, W.K.; Noordermeer, J.W.M. Recycling of individual waste rubbers. In Rubber Recycling; Royal Society of Chemistry: Cambridge, UK, 2019; pp. 186–232. [Google Scholar]

- ISO 2781; Rubber, Vulcanized or Thermoplastic—Determination of Density. ISO: Geneva, Switzerland, 2015.

- Bilgili, E.; Arastoopour, H.; Bernstein, B. Pulverization of rubber granulates using the solid-state shear extrusion process: Part II. Powder characterization. Powder Technol. 2001, 115, 277–289. [Google Scholar] [CrossRef]

- Colom, X.; Cañavate, J.; Carrillo, F.; Suñol, J.J. Effect of the Particle Size and Acid pretreatments on Compatibility and Properties of Recycled HDPE Plastic Bottles Filled with Ground Tyre Powder. J. Appl. Polym. Sci. 2009, 112, 1882. [Google Scholar] [CrossRef]

- Pehlken, A.; Essadiqi, E. Scrap Tire Recycling in Canada; Technical Report; CANMET Materials Technology Laboratory: Hamilton, ON, Canada, 2005. [Google Scholar] [CrossRef]

- Formela, K.; Haponiuk, J.T. Curing characteristics, mechanical properties and morphology of butyl rubber filled with ground tire rubber (GTR). Iran Polym. J. 2014, 23, 185. [Google Scholar] [CrossRef]

- Sambastsompop, N.; Kumnuantip, C. Rheology, Cure characteristics, Physical and Mechanical properties of Tire Tread Reclaimed Rubber/Natural Rubber Compounds. J. Appl. Polym. Sci. 2003, 87, 1723. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, C.; Liang, M. Properties of natural rubber vulcanizates containing mechanochemically devulcanized ground tire rubber. J. Polym. Res. 2009, 16, 411. [Google Scholar] [CrossRef]

- Heideman, G.; Datta, R.N.; Noordermeer, J.W.M.; Van Baarle, B. Influence of Zinc Oxide during Different Stages of Sulfur Vulcanization. Elucidated by Model Compound Studies. J. Appl. Polym. Sci. 2005, 95, 1388. [Google Scholar] [CrossRef]

- Cañavate, J.; Carrillo, F.; Casas, P.; Colom, X.; Suñol, J.J. The Use of Waxes and Wetting Additives to Improve Compatibility Between HDPE and Ground Tyre Rubber. J. Compos. Mater. 2010, 44, 1233–1245. [Google Scholar] [CrossRef]

- Gonen, M.; Balkose, D.; Inal, F.; Ulku, S. Zinc Stearate Production by Precipitation and Fusion Processes. Ind. Eng. Chem. Res. 2005, 44, 1627. [Google Scholar] [CrossRef]

| Sample | Tm (°C) NR | Tm (°C) SynR | Char Residue |

|---|---|---|---|

| 100NR | 398.5 | - | 516.0 |

| 100NR10GTRc | 401.3 | 458.0 | 517.5 |

| 100NR30GTRc | 402.1 | 459.0 | 517.1 |

| 100NR50GTRc | 402.9 | 459.3 | 518.3 |

| 100NR10GTRc5 | 407.1 | 460.1 | 519.3 |

| 100NR30GTRc5 | 408.3 | 459.6 | 520.8 |

| 100NR50GTRc5 | 408.5 | 460.3 | 520.6 |

| 100NR10GTRc10 | 406.3 | 458.9 | 519.9 |

| 100NR30GTRc10 | 406.7 | 459.1 | 520.0 |

| 100NR50GTRc10 | 406.0 | 459.8 | 520.3 |

| 100NR10GTRt | 401.1 | 457.1 | 517.1 |

| 100NR30GTRt | 401.8 | 458.4 | 517.1 |

| 100NR50GTRt | 402.1 | 459.0 | 518.3 |

| 100NR10GTRt5 | 407.2 | 459.3 | 519.4 |

| 100NR30GTRt5 | 408.0 | 459.0 | 519.8 |

| 100NR50GTRt5 | 408.1 | 459.1 | 520.1 |

| 100NR10GTRt10 | 406.2 | 458.9 | 520.3 |

| 100NR30GTRt10 | 406.1 | 459.3 | 520.1 |

| 100NR50GTRt10 | 405.6 | 458.8 | 520.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colom, X.; Sans, J.; de Bruijn, F.; Carrillo, F.; Cañavate, J. Structural, Thermal and Mechanical Assessment of Green Compounds with Natural Rubber. Macromol 2024, 4, 566-581. https://doi.org/10.3390/macromol4030034

Colom X, Sans J, de Bruijn F, Carrillo F, Cañavate J. Structural, Thermal and Mechanical Assessment of Green Compounds with Natural Rubber. Macromol. 2024; 4(3):566-581. https://doi.org/10.3390/macromol4030034

Chicago/Turabian StyleColom, Xavier, Jordi Sans, Frederic de Bruijn, Fernando Carrillo, and Javier Cañavate. 2024. "Structural, Thermal and Mechanical Assessment of Green Compounds with Natural Rubber" Macromol 4, no. 3: 566-581. https://doi.org/10.3390/macromol4030034

APA StyleColom, X., Sans, J., de Bruijn, F., Carrillo, F., & Cañavate, J. (2024). Structural, Thermal and Mechanical Assessment of Green Compounds with Natural Rubber. Macromol, 4(3), 566-581. https://doi.org/10.3390/macromol4030034