Abstract

The inadequate disposal of tires poses a significant threat to human health and requires effective recycling solutions. The crosslinked structure of rubber, formed through sulfur bridges during vulcanization, presents a major challenge for recycling because it prevents the rubber scraps from being reshaped thermoplastically. Reclaiming or devulcanization aims to reverse this crosslinking, allowing waste rubber to be transformed into products that can be reprocessed and revulcanized, thereby saving costs and preserving resources. Microwave technology shows promise for devulcanization due to its ability to break sulfur crosslinks. In this study, we investigate the devulcanization of ground tire rubber (GTR) through a combined process applied to samples from both car and truck tires subjected to varying periods of microwave irradiation (0, 3, 5 and 10 min). The devulcanized GTR was then blended with natural rubber (NR) and underwent a new vulcanization process, simulating recycling for novel applications. The GTR was mixed with NR in proportions of 0, 10, 30 and 50 parts per hundred rubber (phr). This study also examines the differences between the GTR from car tires and GTR from truck tires. The results showed that the treatment effectively breaks the crosslinks in the GTR, creating double bonds (C=C) and improving the mechanical properties of the revulcanized samples. The crosslinking density and related properties of the samples increased with treatment time, reaching a maximum at 5 min of microwave treatment, followed by a decrease at 10 min. Additionally, the incorporation of GTR enhanced the thermal stability of the resulting materials.

1. Introduction

The global demand for industrial rubber products is very high and expected to grow. This is the main reason that leads to the production of huge amounts of post-consumer scrap rubber. In 2022 a little more than 3.1 million tons of tires in Europe and 17.3 million tons worldwide were managed in an environmentally sound and economically viable manner [1]. This big amount of waste is an important issue in terms of environmental protection, energy recovery and management. It is well known that the inadequate disposal of scrap rubber, especially tires, may pose a potential threat to human health. Tires can emit polycyclic aromatic hydrocarbons (PAHs) [2], which can be cancerous, like benzopyrene, or affect dermal, hepatic or immunological systems. The EU has already had cases of used tires that have been illegally dumped or stockpiled in landfills and have generated problems. In 2016 a massive blaze at an illegal tire dump took place in the town of Seseña near Madrid (Spain), and 9000 people were evacuated from their homes amid fear of carcinogenic compounds present in the smoke. Currently, tires at the end of their life are processed in specialized plants to produce a powder known as ground tire rubber (GTR). Recycling this residue presents a significant challenge that has captured the attention of research groups worldwide.

While research in the field of genetics, cell biology and other bio areas are making discoveries that increase the quality of life and longevity, the reuse and recovery of hazardous materials such as tires is also an effective way to prevent and avoid situations that undoubtedly have a negative impact on human health. Fortunately, as mentioned earlier, the scientific community is continuously exploring new recycling methods to offer more efficient solutions for managing waste.

Elastomers are characterized by their crosslinked structure, which is established during the vulcanization process. This process involves the formation of disulfur bridges (-S-S-) that link the macromolecular chains of the polymer. The majority of elastomer properties stem from this crosslinked structure. However, these crosslinks also pose a challenge for recycling, as they prevent the polymer from melting and being reshaped thermoplastically.

Reclaiming is a process aimed at breaking the crosslinked structure of the elastomers, which transforms scrap and waste rubber in products that can be processed and vulcanized again, simultaneously saving costs in raw materials and preserving both natural resources and the environment. In this way reclaimed elastomers can be incorporated in blends with fresh rubber, forming compounds able to be used in diverse applications [3]. The incorporation and dispersion of the reclaimed rubber play important roles concerning product quality, the production economy and market competition.

Reclaiming is also called devulcanization, and the term refers to the process of reversing the creation of disulfur and/or polysulfur bridges in elastomers. Specifically, devulcanization targets the breaking of these bridges, whereas reclaiming generally involves breaking down the chains that form the elastomeric network in a less specific manner.

To achieve the process of devulcanization, the breaking of the intermolecular chains that crosslink the elastomers, several methods based on supercritical CO2 [4], ultrasounds [5], mechanochemical [6,7,8] or microbial methods [9], have been proposed. Some of these techniques require reactions that involve organic compounds, oils and solvents and may imply risks for health and the environment. Our proposal is using a technique based on a thermomechanical treatment with the addition of BPO (peroxide of benzoyl) as a chemical agent, combined with microwave irradiation. This process, moderately energy consuming, can provide an alternative to other systems of reclaiming/devulcanizing, either from economical or environmental perspectives.

The use of combined processes, thermomechanical and microwave, as a devulcanization method has been proposed and used by our group in previous experiments with ethylene propylene diene monomer rubber (EPDM) [10] and ground tire rubber (GTR) [11]. The idea behind the application of this combined process consists in breaking the crosslinking of the vulcanized rubber through mechanical action (more aggressive and therefore less specific on the disulfur bridges) for a short period of time and then heating the sample with microwaves (more selective on the bonds -S-S-). The selectivity of microwave systems stems from their ability to generate a precise, rapid and uniform temperature increase, surpassing conventional heating methods like convection or conduction. The microwave process has been used by different research groups. Kleps et al. used thermogravimetric analysis to study the changes that occur in rubber vulcanizates: natural rubber (NR), styrene butadiene rubber (SBR) and EPDM [12]. Scuracchio et al. analyzed the chemical and physical changes in GTR after various periods of microwave exposure [13,14]. Colom et al., in a previous work, studied the chemical structure of different types of GTR and the influence of their components and formulations on microwave devulcanization [15].

In this study, we examine the devulcanization of ground tire rubber (GTR) using a combined process applied to samples derived from two main sources: car tires and truck tires subjected to varying periods of microwave irradiation (0, 3, 5 and 10 min). The devulcanized GTR was then blended with natural rubber (NR) and underwent a new vulcanization process, simulating recycling for a novel application. The GTR was mixed with NR in proportions of 0, 10, 30, and 50 parts per hundred rubber (phr).

The macroscopic properties and microstructural changes of these rubber compounds were investigated through analysis of their thermal properties, mechanical properties and morphology. The results were compared under identical manufacturing conditions with fresh natural rubber. This study aims not only to describe the behavior of these samples but also to provide insights into how the treatment affects the molecular chains of the polymers involved.

2. Materials and Methods

2.1. Materials

NR SVR CV (Vietnam Natural Rubber), ash content max. 0.4% wt, volatile matter 0.8% wt, Plasticity Retention Index (PRI) 60, density 0.92 g/cm3 was supplied by VIGAR HEXPOL Compounding SLU, Rubí (Barcelona, Spain).

Ground tire rubber (GTR) from passenger cars (GTRcar) and GTR from trucks (GTRtruck) were supplied by GMN Maials (Lleida, Spain), with an average particle size of 320 micros for car tires and 354 microns for truck tires.

Vulcanization accelerators (TBBS: N-tert-butyl-2-benzothiazole sulfonamide, TMTD: tetramethylthiuram disulfide), carbon black N-330, benzoyl peroxide (BPO), stearic acid, zinc oxide and sulfur with technical purity were supplied by VIGAR HEXPOL Compounding SLU, Rubí (Barcelona, Spain).

2.2. Devulcanization of GTR

GTR was devulcanized in a two-step system consisting of a thermomechanical treatment followed by irradiation in a microwave oven.

The thermomechanical treatment was carried out in a Brabender plastograph at 80 °C and 80 rpm, including the addition of 2 phr of benzoyl peroxide (BPO) as devulcanizing agent for 30 min. BPO, commonly used in these treatments, facilitates thermomechanical devulcanization. Some authors refer to this process as thermochemomechanical, although generally, thermomechanical processes involve the use of BPO.

The microwave irradiation took place in a prototype microwave oven with a motorized PTFE stirring system adapted in our laboratory. The devulcanization process was performed setting the magnetron power to 700 W, with stirring at 80 rpm and 3, 5 and 10 min of microwave (mW) exposure. The resulting materials after this process have been named GTRd car and GTRd truck (where “d” stands for devulcanized).

The conditions of these procedures have been tested in previous studies [16].

2.3. Samples Preparation

Elastomeric samples were prepared using a Brabender plastograph batch mixer. The temperature was set at 70 °C; rotational speed of the rollers was 100 rpm. The mixing time was 8 min, which included 2 min of preliminary plasticization of natural rubber, 4 min of mixing with 30 phr of carbon black and GTR or devulcanized GTR, and 2 min of mixing the blend with the sulfur curing system.

The GTR content in the samples was 0, 10, 30 and 50 parts per hundred of rubber (phr). The same curing system was used for all samples. The curing system composition (phr) was defined as a conventional vulcanization (CV) formulation [16]: zinc oxide 5.0; stearic acid 3.0; TBBS 1.5; TMTD 0.25; sulfur 2.0.

The obtained rubber composites were compression molded into 3 mm thick samples at 160 °C and 4.9 MPa according to the determined optimal vulcanization time [17,18]. Unfilled natural rubber samples were processed in the same conditions and used as a reference.

2.4. Measurements

Chemical structure of rubber composites (RCs) was determined using Fourier transform infrared spectroscopy (FTIR) analysis performed by means of a Spectrum Two spectrometer from Perkin Elmer (Waltham, MA, USA). The device had an ATR attachment with a diamond crystal. Measurements were performed with 2 cm−1 resolution in the range 550–4000 cm−1.

Tensile strength and elongation at break of the obtained vulcanized rubber composites were tested according to the standard ISO 37 [19] using an Instron testing machine with pneumatic cell load capacity of 2 kN. Tensile tests were performed at a crosshead speed of 500 mm/min. Direct extension measurements were conducted periodically using an extensometer with sensor arms. Hardness was determined using a Zwick 3130 durometer Shore A (Ulm, Germany) in accordance with the standard ISO 7619-1 [20]. The reported results are the average of 5 measurements per sample.

The crosslinking density (CLD) calculation is based on the equilibrium swelling theory, which is defined by Kraus, and modified Flory–Rehner equation for filled rubber vulcanizate. The crosslink density was determined according to the ASTM D6814-02 [21] standard method, through swelling measurements of the rubber composites which were let to swell in cold toluene for 72 h, refreshing the solvent every 24 h, followed by drying to constant mass at 80 °C. The Flory–Rehner Equation (2) [22] was used to calculate the crosslink density. X is Flory–Huggins parameter interaction of the polymer–solvent set equal to 0.414 [23], considering NR as main polymer and toluene as solvent.

where ve = crosslink density, mol/cm3; Vr = gel volume in the swollen sample; V1 = solvent molar volume (toluene = 106.2 cm3/mol);

where mp is mass of the dry polymer, ρs is density of the solvent (toluene 0.8662 g/cm3), ms is mass of the solvent absorbed by the swollen sample, ρp is density of the polymer. The rubber density was 0.92 g/cm3 (NR), 0.945 g/cm3 (10 phrGTR), 0.985 g/cm3 (30 phrGTR), 1.013 g/cm3 (50 phrGTr).

The Kraus correction model was applied due to the presence of carbon black as a filler. The carbon black density was chosen equal to 1.85 g/cm3. The total apparent crosslink density (vtotal) with Kraus correction was calculated according to Equations (3) and (4):

where ve = measured chemical crosslink density, mol/cm3; vtotal = actual chemical crosslink density, mol/cm3; K = constant characteristic of the filler, but which, independent of the solvent, was chosen to be 1.17 [24]; φf = volume fraction of filler in the sample which is calculated; ρr = density of studied compound, g/cm3; m0 = weight of sample before extraction, g; ρf = density of filler, g/cm3; mdry = weight of sample after extraction, g.

In addition to the total crosslink density values, the distribution of sulfur bonds (monosulfidic, disulfidic and polysulfidic) in the cured rubber was determined using a two-step thiol–amine reaction [25].

The distribution of polysulfidic bonds (defined as vpolysulfidic) was determined from the difference between the total apparent crosslinking density CLD (vtotal) and the value obtained after first step treatment (vMD) and can be expressed according to Equation (5),

vpolysulfidic = vtotal − vMD

In the second step the crosslinking value M (vM) obtained is used to calculate the crosslinking disulfidic bonds according to Equation (6),

vdisulfidic = vMD − vM

The density of the samples was measured based on the Archimedes method, as described in ISO 2781 [26]. Accordingly, all measurements were carried out at room temperature in methanol medium.

Thermogravimetric analysis (TGA) was performed on a Perkin Elmer 8000 apparatus. Rubber composites weighing approx. 15–20 mg were placed in a corundum dish. The measurement was conducted in the temperature range 50–600 °C and under a nitrogen atmosphere (30 mL/min), at a heating rate of 20 °C/min.

The morphology of rubber composites after extraction in toluene (at room temperature, 72 h) was observed with a JEOL 5610 scanning electron microscope (Tokyo, Japan). Before measurement the samples were covered with a fine gold–palladium layer to increase their conductivity in a vacuum chamber.

3. Results

3.1. Mechanical Properties

3.1.1. Compounds including Non-Devulcanized GTR

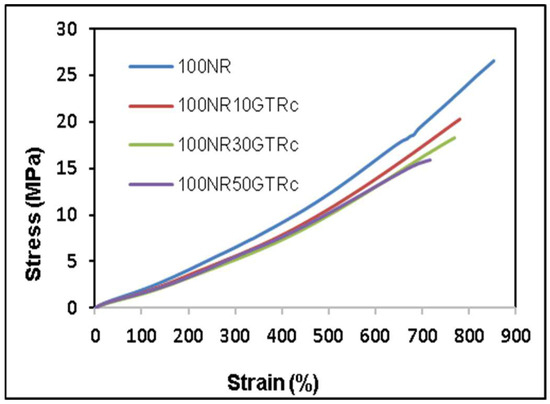

The stress–strain curves for NR vulcanizates with different amounts (10, 30 and 50 phr) of non-devulcanized GTRcar (GTRc) and GTRtruck (GTRt) are shown in Figure 1 and Figure 2. When compared to pure NR vulcanizates, the modulus at 300% of elongation decreases in all compositions of NR/GTRcar and NR/GTRtruck.

Figure 1.

Stress–strain curves for NR vulcanizates with different amounts (0,10, 30 and 50 phr) of non-devulcanized GTRcar (GTRc).

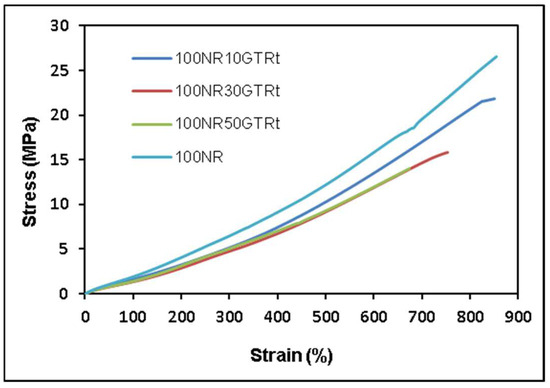

Figure 2.

Stress–strain curves for NR vulcanizates with different amounts (0,10, 30 and 50 phr) of non-devulcanized GTRtruck (GTRt).

Moreover, the deformation at break decreased with the increase of GTR (non-devulcanized) content, especially in the case of GTRt from trucks. For 100NR the maximum elongation at break was 854% with a tensile strength of 26.1 MPa, but when NR was filled with 50 phr of GTR, the elongation at break and tensile strength decreased to 695% and 15.5 MPa for GTRcar and 675% elongation, 14.1 MPa tensile strength for GTRtruck. The decreasing of tensile properties in all NR/GTR blends is attributed to the lack of bonding between GTR and NR. The GTR does not disperse well in the continuous elastomeric matrix, which creates weak sites on stress transmission, resulting in a decrease of tensile properties.

3.1.2. Compounds including Devulcanized GTR

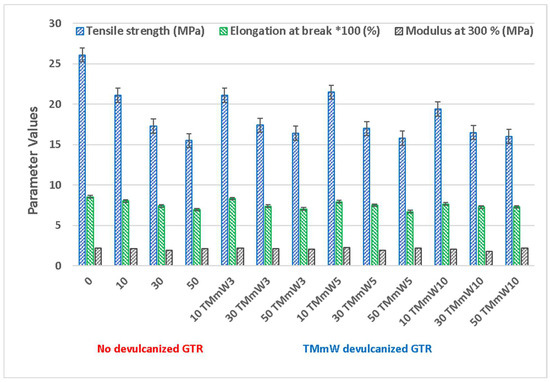

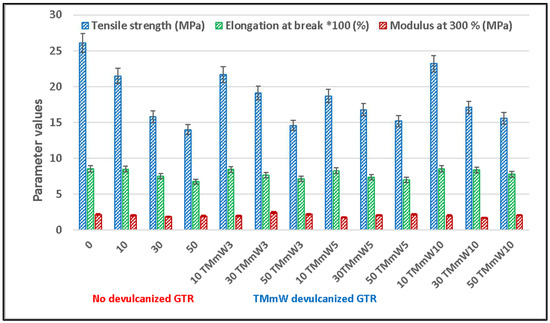

The mechanical properties of the rubber composites obtained with GTR previously devulcanized are shown in Figure 3 and Figure 4.

Figure 3.

Tensile properties of NR/GTRcar compounds.

Figure 4.

Tensile properties of NR/GTRtruck compounds.

The tensile properties of compounds of GTR devulcanized with the combined process were much better than those of non-devulcanized GTR. In rubber composites with 50 phr of GTRcar and GTRtruck treated by microwave for 10′, the elongation at break increased from 695% to 728% and 675% to 779%. This improvement of tensile properties, of 5% and 13.5%, respectively, is due to the devulcanization of GTR, which provides better bonding between GTR and NR and an increase in the roughness and specific surface of the devulcanized particles [27,28]. As Figure 3 and Figure 4 show, the mechanical properties of the GTRcar and GTRtruck compounds are very similar, regardless of the type of devulcanization (time of mW) that has been carried out on each of the samples. However, the tensile strength obtained by the GTRtruck samples is slightly higher than that of the GTRcar. The elongation at break and the modulus of Young at 300% present very similar values regardless of the amount of GTR used (phr) and the type (car or truck), but in any case they are higher than the samples with non-devulcanized GTR.

The differences in the results of GTRcar and GTRtruck are related to the composition of each type of GTR. GTRtruck has a higher content of NR than GTRcar (27% and 14%) [29] and SiO2 (9.8% and 7.3%, respectively). As reported in a previous studies [14], GTR samples with a high content of SiO2 are easier to devulcanize than samples with low content of SiO2. This means that SiO2 acts as a catalyzer in the devulcanization process by microwaves. Higher compatibility between GTRtruck and NR is then achieved due to the better devulcanization and the similar composition of both components, which explain the tensile results.

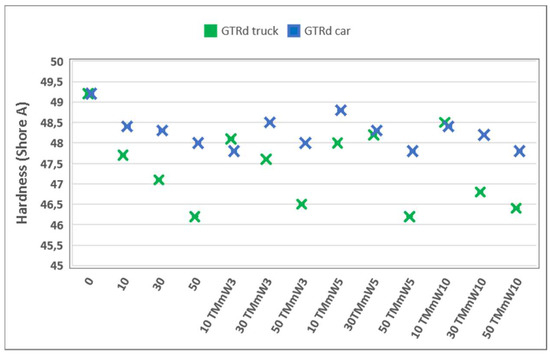

Figure 5 shows that the hardness values for the different samples of each type of GTR are analogous. Likewise, it is also worth noting that the values of the GTRtruck show greater dispersion and are lower than those of the GTRcar. This is mainly due to the components of each type of GTR; the GTRcar has a higher content of synthetic elastomers than the GTRtruck, these being more rigid than natural rubber. The type of devulcanization treatment does not have a significant influence, although the hardness decreases with the GTRd content, significantly for the GTRtruck.

Figure 5.

Hardness average values of different samples.

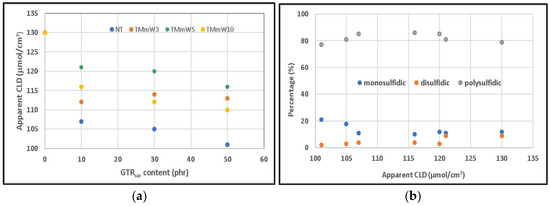

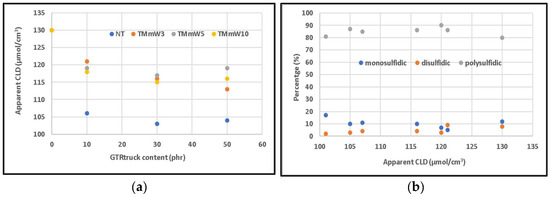

The results of the crosslink density and percentage of sulfidic bridges for GTRcar and GTRtruck rubber composites are shown in Figure 6 and Figure 7.

Figure 6.

(a) Apparent crosslink density of GTRcar vulcanizate samples (µmol/cm3); (b) percentage (%) of mono-, di- and polysulfidic bonds correlated with apparent CLD for non-treated (NT) and TMmW5 compounds.

Figure 7.

(a) Apparent crosslink density of GTRtruck vulcanizate samples (µmol/cm3); (b) percentage (%) of mono-, di- and polysulfidic bonds correlated apparent CLD for non-treated (NT) and TMmW5 compounds.

The maximum value for crosslinking has been obtained for fresh natural rubber (reference sample) at 130 μmol/cm−3. The crosslink density was found independent of the type of GTR used (car or truck). For all quantities of GTR present in the rubber compounds, the crosslink density increased as a function of the time of treatment, with a maximum value obtained at TMmW5 and a subsequent decrease at TMmW10 treatment more obvious when using GTR from cars than GTRtruck. As can be observed in Figure 6b and Figure 7b, the percentage of polysulfidic bonds is much higher than that of mono- and disulfidic bonds, completely in accordance with what is known as conventional vulcanization, when A/S (accelerator/sulphur) ratios are lower than 0.7. The TMmW devulcanization process breaks mainly the S-S bridges and, randomly, some parts of the main elastomer chain, as demonstrated by the Horikx plot obtained in several studies [30,31]. Fourier transform infrared spectroscopy (FTIR) analysis revealed that this breaking of the main polymeric chain increases the number of double bonds and then the ability to generate more crosslinking (with percentages of polysulfidic bonds higher than 80%). The power of the TMmW10 treatment is what causes the apparent CLD to decrease for TMmW treatments greater than 5′. GTR is undergoing a thermal degradation produced by an excess of devulcanization time which is counterproductive and reduces the ability to generate more crosslinking [32].

The results obtained for the type of sulfur bridge (Figure 6b and Figure 7b) in both samples, GTRcar and GTRtruck, show that crosslinking presents very high percentages of polysulfide bridges. The graphs also show that the percentage of polysulfidic bonds in the GTRtruck samples is slightly higher (average 2%) than in the GTRcar samples. This makes it possibile that the GTRtruck samples have greater lengths in the crosslinking bridges than the GTRcar, which would favor the mechanical properties of the GTRtruck samples.

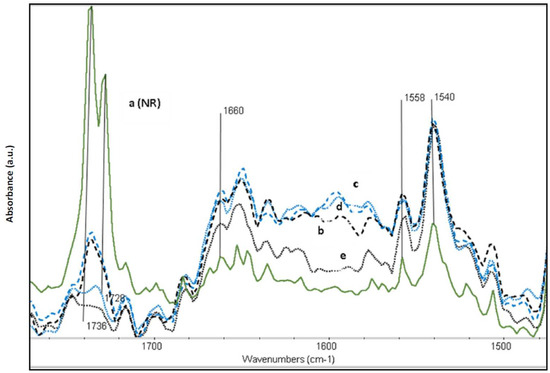

3.2. Spectroscopy Characterization

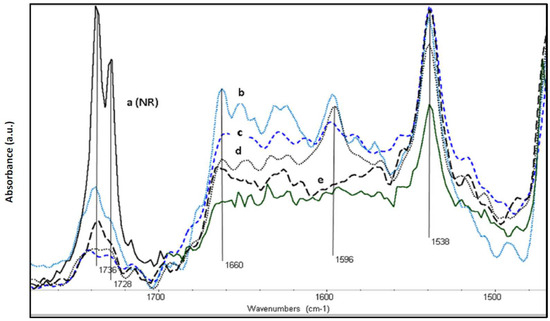

To obtain information on the microstructure of rubber composites, FTIR/ATR spectroscopic studies were conducted. Figure 8 and Figure 9 show the spectral area comprised between 1800 and 1450 cm−1. The spectra of natural rubber samples filled with 50 phr of GTR from cars and trucks devulcanized by microwaves are compared.

Figure 8.

Spectral area of 100NR with 50 phr GTRcar devulcanized by microwaves for different periods of time: (a) NR, (b) 50GTRc(NT)/NR, (c) 50GTRc(TMmW3)/NR, (d) 50GTRc(TMmW5)/NR and (e) 50GTRc(TMmW10)/NR.

Figure 9.

Spectral area of 100NR with 50 phr GTRtruck devulcanized by microwaves for different periods of time: (a) NR, (b) 50GTRt(NT)/NR, (c) 50GTRt(TMmW3)/NR, (d) 50GTRt(TMmW5)/NR and (e) 50GTRt(TMmW10)/NR.

Two bands appearing at 1736 cm−1 and 1728 cm−1 are present in the spectra. These bands are related to the stearic acid included in the sample, which migrates from the core to the surface as exudation. The band at 1736 cm−1 is assigned to the free carbonyl group, and the band at 1728 cm−1 is attributed to a carbonyl group bonded with water molecules from the environment or other polar groups. These bands are bigger in NR than in NR filled with GTR because the presence of GTR avoids the movement of the stearic acid chain through the rubber structure, producing more impediment to reach the surface. The band at 1538 cm−1 assigned to zinc stearate (ZnSt2) appears due to the reaction between ZnO and stearic acid during the manufacturing process [33], and it is related to the crosslink density and due to the amount of stearic acid that has been able to react. When the crosslinking decreases, there is an increase in the amount of ZnSt2 on the surface that causes a high band at 1538 cm−1. This is indicative of the facility of the molecule of ZnSt2 to pass through the elastomeric structure. TMmW5 treatment, and in minor measure TMmW10 treatment, improve the ability of the sample to create more polysulfidic bridges and avoid the movement of ZnSt2 (see Figure 9). After 10′ min of treatment, as commented above, the degradation of the main elastomeric chains results in a loss of mechanical properties.

Another interesting group of bands appear from 1596 to 1660 cm−1 and are related to the double bonds C=C. NR spectra show lower absorbance values of C=C than samples with GTR. In samples with GTR devulcanized, these values increase with the treatment time. This means that, as mentioned previously, there is a scission of the main chain of the polymer produced by the devulcanization, and double bonds are generated with TMmW treatment, although not all C=C react subsequently with S to create sulfur bridges during the revulcanization. Some of them remain unreacted.

The spectra of the samples of rubber composites with GTR from trucks show little difference compared to the samples of GTR from cars. The presence of ZnSt2 on the surface of samples with GTR from trucks is lower than that on samples from cars. This means that, as found in the swelling results, the crosslink degree in samples with GTRtruck is higher, avoiding the diffusion of zinc stearate from the core to the surface [34]. Also, the amount of double bonds (C=C) is lower in samples with GTR from trucks because the TMmW devulcanization treatment is more efficient and allowed the formation of more sulfur bridges than in case of GTR from cars.

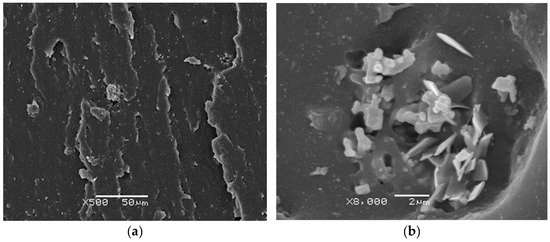

Figure 10a shows the particles of zinc stearate on the surface of 0 GTRc (NT)/NR. Figure 10b shows a magnification of 8000X; the scanning electron micrograph, SEM, reveals the structural morphology displayed by the crystalline shape of ZnSt2. It is a random platelike crystal with a size that varies between 1 and 3 microns [35].

Figure 10.

SEM pictures of crystal morphology of ZnSt2 on 0GTRc(NT)/NR surface: (a) (×500) and (b) (×8000).

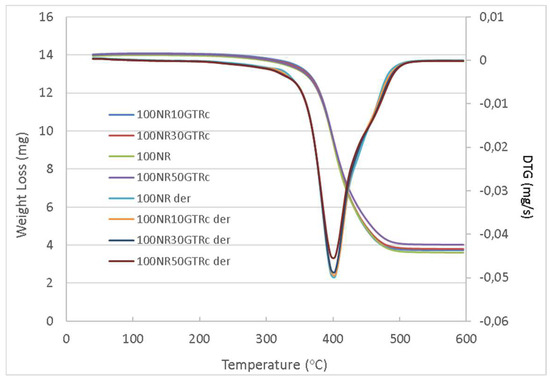

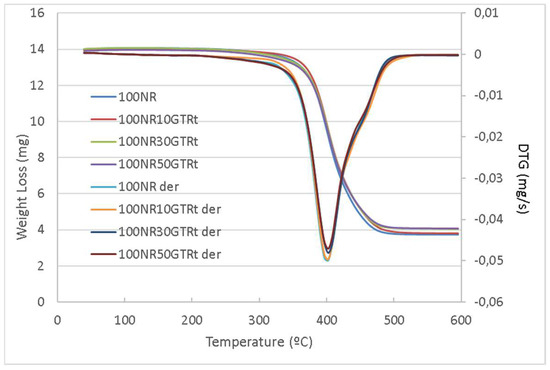

3.3. Thermogravimetric Analysis

Thermogravimetric analysis of natural rubber blended with different amounts of GTR from cars and trucks was conducted in a nitrogen atmosphere. These conditions allow only thermal degradation, avoiding the combined effect of thermal- and thermo-oxidative degradation in the presence of oxygen.

The obtained results are presented in Figure 11 and Figure 12 and summarized in Table 1. The data indicate an increase in thermal stability with the addition of GTR, regardless of the type of GTR used (car or truck), which is related to the better thermal stability of GTR in comparison to natural rubber. Likewise, the maximum decomposition temperature, estimated from derivative thermogravimetry (DTG), increases as a function of the amount of GTR, where the reference sample 100NR has a peak at 398.5 °C, sample 100NR50GTRcar has a peak at 402.9 °C and sample 100NR50GTRtruck has a peak at 402.1 °C, respectively. This phenomenon is also related to the difference of compositions of GTR from cars and trucks. According to reference [30] GTRcar has an average composition of 14% of NR and 27% of SynR (synthetic rubber), while GTRtruck contains 27% of NR and 14% of SynR. The presence of synthetic rubber in particles of GTR increases the thermal stability, because the decomposition temperature is higher for SBR (main component of SynR) than in NR.

Figure 11.

TGA and DTG curves of 100NR, 100NR10GTRc, 100NR30GTRc and 100NR50GTRc. All the samples have been treated for 10′ with microwaves.

Figure 12.

TGA and DTG curves of 100NR, 100NR10GTRt, 100NR30GTRt and 100NR50GTRt. All the samples have been treated for 10′ with microwaves.

Table 1.

Temperature values obtained from TGA/DTG curves of different NR/GTR car and truck rubber composites.

The thermal stability of different rubber composites can also be affected by the interaction between natural rubber and devulcanized GTR. Table 1 shows the temperature values obtained from TGA/DTG curves of different NR/GTR car and truck composites. Several intervals can be observed: (a) from 320 °C to 410 °C, decomposition of natural rubber (fresh elastomer and NR from GTR); (b) from 410 °C to 516 °C, decomposition of synthetic rubber (mainly SBR and other rubber components of GTR) and (c) upwards of 516 °C, char residue (carbon black and other inorganic materials). The results for each sample show a displacement of temperatures as a function of devulcanization time and type of GTR. As mentioned previously, thermal stability tends to increase slightly with devulcanization time. The maximum values of temperature are 408.5 °C and 408.1 °C for the samples of 100NR50GTRc5′ and 100NR50GTRt5′, respectively. Temperature values assigned to the decomposition of the synthetic components of GTR are more similar for all samples (459 to 460 °C).

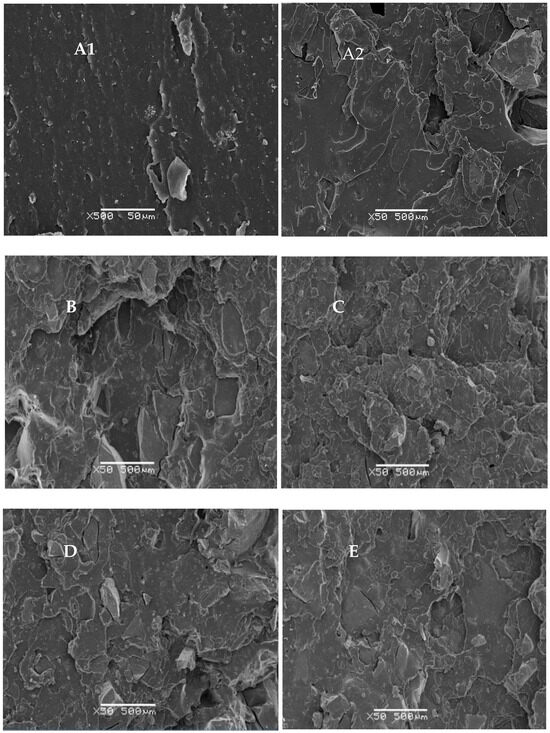

3.4. SEM Studies of NR-GTR

Figure 13 shows SEM photographs of the tensile fracture surface of the rubber composites. The micrograph of pure natural rubber (A) shows a homogeneous structure with dispersed ZnSt2 crystals. Micrographs (B) and (C) show the surface fracture of samples NR50GTRc0 and NR50GTRc10. In both pictures, the GTRcar particles embedded in the NR matrix are visible. In sample (B), where the GTR has not been submitted to microwave treatment there are some visible cracks, pores and many cavities, which means that the adhesion was rather poor. In this case, the lack of compatibility results in a decrease of mechanical properties. Picture (C) depicts the influence of GTR with combined treatment on the interaction between NR and GTRcar particles. The surfaces are smoother. The results suggest an increase in the degree of crosslinking between NR and GTR, which is in agreement with the revulcanization and further crosslink reaction between GTR10′ and the NR matrix, due to the existence of much more active sites to participate in the revulcanization process. Pictures (D) and (E) describe a similar trend, although sample NR50GTRt(NT) shows better behavior than NR50GTRc(NT). This is due to the different composition of GTR from cars and trucks, as previously discussed.

Figure 13.

SEM microphotographs of the tensile fracture surface of the composites: (A1) natural rubber (×500); (A2) natural rubber (×50); (B) NR50GTRc(NT); (C) NR50GTRc10; (D) NR50GTRt(NT); (E) NR50GTRc10.

4. Conclusions

The use of a combined process as a devulcanization treatment produces the breaking of the crosslinking of the GTR and improves the mechanical properties of the revulcanized samples, because of the increase in compatibility and the higher density of crosslinking achieved.

The samples including GTRtruck rubber showed better mechanical properties than for GTRcar rubber, because of higher NR content NR in the composition of the GTRtruck rubber.

The crosslink density of the samples increased as a function of the time of treatment, with a maximum value obtained at 5′ and a decrease at 10′ of mW treatment. The microwave process breaks preferentially the S-S bridges, but when applied for long periods of time may also produce thermal degradation of the main chain of the elastomers, which is counterproductive and reduces the final crosslinking.

The devulcanizing process results in an increase of the double bonds C=C, subsequently increasing the ability to generate crosslinking. GTRtruck rubber has a higher proportion of NR in its composition, which allows the generation of more crosslinks.

FTIR results show a migration to the surface of the stearic acid and zinc stearate included in the sample. The migration is consequently related to the degree of crosslinking obtained in the manufacturing of the composites. The combined treatment improves the ability of the sample in creating more sulfur bridges and avoids the movement of ZnSt2.

There is an increase in thermal stability with the addition of GTR, associated with the higher thermal stability of GTR compared to natural rubber. The increase of devulcanization time induces a displacement of temperatures which is related to the development of an effective interaction between the components.

A morphologic study of the samples agreed with the previous data, as the fracture surface of devulcanized samples was smoother and showed less cracks or pores.

Author Contributions

Conceptualization, X.C. and J.C.; methodology, X.C. and J.C.; validation, formal analysis, X.C., J.C., F.d.B. and F.C.; investigation, X.C., J.C., J.S. and F.C.; data curation, J.S, J.C., F.d.B. and F.C.; writing—original draft preparation, X.C.; writing—review and editing, X.C.; supervision, J.C.; project administration, X.C. and J.C.; funding acquisition, X.C. and J.C. All authors have read and agreed to the published version of the manuscript.

Funding

This publication is a part of grant PID2021-126165OB-I00 founded by MCIN/AEI/10.13039/501100011033 and by ERDF A way of making Europe by the European Union.

Data Availability Statement

Data are contained within the article.

Acknowledgments

We appreciate the collaboration and work carried out by Robert Blazquez and Patricia Muñoz from the Department of Chemical Engineering, Universitat Politècnica de Catalunya, BarcelonaTech, (ETSEIAAT) Terrassa, Spain.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of this study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- European Tyre and Rubber Manufacturers Association. Annual Report 2020/2021 and End Life Tyre Reports; European Tyre and Rubber Manufacturers Association: Bruxelles, Belgium, 2021. [Google Scholar]

- Chen, S.-J.; Su, H.-B.; Chang, J.-E.; Lee, W.-J.; Huang, K.-L.; Hsieh, L.-T.; Huang, Y.-C.; Lin, W.-Y.; Lin, C.-C. Emissions of polycyclic aromatic hydrocarbons (PAHs) from the pyrolysis of scrap tires. Atmos. Environ. 2007, 41, 1209. [Google Scholar] [CrossRef]

- Korger-Kocsis, J. Editorial corner-a personal view Waste tyre rubber—What to do next? Express Polym. Lett. 2013, 7, 406. [Google Scholar] [CrossRef]

- Kojima, M.; Tosaka, M.; Ikeda, Y.; Kohjiya, S. Devulcanization of Carbon Black filled Natural Rubber using Supercritical Carbon Dioxide. J. Appl. Polym. Sci. 2005, 95, 137. [Google Scholar] [CrossRef]

- Sun, X.; Isayev, A.I. Ultrasound devulcanization: Comparison of synthetic isoprene and natural rubbers. J. Mater. Sci. 2007, 42, 7520. [Google Scholar] [CrossRef]

- Formela, K.; Klein, M.; Colom, X.; Saeb, M.R. Investigating the combined impact of plasticizer and shear force on the efficiency of low temperature reclaiming of ground tire rubber. Polym. Degrad. Stab. 2016, 125, 1. [Google Scholar] [CrossRef]

- De, D.; Panda, P.K.; Roy, M.; Bhunia, S. Reinforcing effect of reclaim rubber on natural rubber/polybutadiene rubber blends. Mater. Des. 2013, 46, 142. [Google Scholar] [CrossRef]

- Rooj, S.; Basak, G.C.; Maji, P.K.; Bhowmnick, A.K. New Route for devulcanization of Natural Rubber and the properties of devulcanized rubber. J. Polym. Environ. 2011, 19, 382. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, S.; Wang, Y. Improvement of the properties of natural rubber/ground tire rubber composites through biological desulfuration of GTR. J. Polym. Res. 2012, 19, 9864. [Google Scholar] [CrossRef]

- Colom, X.; Carrillo-Navarrete, F.; Saeb, M.R.; Marin, M.; Formela, K.; Cañavate, J. Evaluation and rationale of the performance of several elastomeric composites incorporating devulcanized EPDM. Polym. Test. 2023, 121, 107976. [Google Scholar] [CrossRef]

- Colom, X.; Saeb, M.R.; Cañavate, J. Microstructural phenomena in ground tire rubber (GTR) devulcanized via combined Thermochem mechanical and microwave processes monitored by FTIR and DTGA assisted by other techniques. Express Polym. Lett. 2024, 18, 950. [Google Scholar] [CrossRef]

- Kleps, T.; Piaskiewicz, M.; Parasiewicz, W. The use of thermogravimetry in the study of rubber devulcanization. J. Therm. Anal. Calorim. 2000, 60, 271. [Google Scholar] [CrossRef]

- Scuracchio, C.H.; Waki, D.A.; da Silva, M.L.P. Thermal analysis of ground tire rubber devulcanized by Microwave. J. Therm. Anal. Calorim. 2007, 87, 893. [Google Scholar] [CrossRef]

- Garcia, P.S.; de Sousa, F.D.B.; de Lima, J.A.; Cruz, S.A.; Scuracchio, C.H. Devulcanization of ground tire rubber: Physical and Chemical changes after different microwave exposure times. Express Polym. Lett. 2015, 9, 1015. [Google Scholar] [CrossRef]

- Colom, X.; Faliq, A.; Formela, K.; Cañavate, J. FTIR spectroscopic and thermogravimetric characterization of ground tyre rubber devulcanized by microwave treatment. Polym. Test. 2016, 52, 200. [Google Scholar] [CrossRef]

- Aprem, A.S.; Joseph, K.; Thomas, S. Recent developments in crosslinking of elastomers. Rubber Chem. Technol. 2005, 78, 458–488. [Google Scholar] [CrossRef]

- Ismail, H.; Nodin, R.; Noor, A.M. Cure characteristics, tensile properties and swelling bahaviour of recycled rubber powder-filled natural rubber compounds. Polym. Test. 2002, 21, 565. [Google Scholar] [CrossRef]

- Mangili, I.; Lasagni, M.; Anzano, M.; Collina, E.; Tatangelo, V.; Franzetti, A.; Caracino, P.; Isayev, A.I. Mechanical and rheological properties of natural rubber compounds containing devulcanization ground tire rubber from several methods. Polym. Degrad. Stab. 2015, 121, 369. [Google Scholar] [CrossRef]

- ISO 37; Rubber, Vulcanised or Thermoplastic—Determination of Tensile Stress-Strain Properties. ISO: Geneva, Switzerland, 2013.

- ISO 7619-1; Rubber, Vulcanized or Thermoplastic—Determination of Indentation Hardness—Part 1: Durometer Method (Shore Hardness). ISO: Geneva, Switzerland, 2011.

- ASTM D6814-02; Standard Test Method for Determination of Percent Devulcanization of Crumb Rubber Based on Crosslink Density. ASTM International: West Conshohocken, PA, USA, 2018.

- Flory, P.J.; Rehner, J. Statistical mechanics of cross-linked polymer networks I. Rubberlike elasticity. J. Chem. Phys. 1943, 11, 512. [Google Scholar] [CrossRef]

- Kim, D.Y.; Park, J.W.; Lee, D.Y.; Seo, K.H. Correlation between the crosslink characteristics and mechanical properties of natural rubber compound via accelerators and reinforcement. Polymers 2020, 12, 2020. [Google Scholar] [CrossRef]

- Kraus, G.J. Swelling of filler-reinforced vulcanizates. J. Appl. Polym. Sci. 1963, 7, 861. [Google Scholar] [CrossRef]

- Saiwari, S.; Dierkes, W.K.; Noordermeer, J.W.M. Recycling of individual waste rubbers. In Rubber Recycling; Royal Society of Chemistry: Cambridge, UK, 2019; pp. 186–232. [Google Scholar]

- ISO 2781; Rubber, Vulcanized or Thermoplastic—Determination of Density. ISO: Geneva, Switzerland, 2015.

- Bilgili, E.; Arastoopour, H.; Bernstein, B. Pulverization of rubber granulates using the solid-state shear extrusion process: Part II. Powder characterization. Powder Technol. 2001, 115, 277–289. [Google Scholar] [CrossRef]

- Colom, X.; Cañavate, J.; Carrillo, F.; Suñol, J.J. Effect of the Particle Size and Acid pretreatments on Compatibility and Properties of Recycled HDPE Plastic Bottles Filled with Ground Tyre Powder. J. Appl. Polym. Sci. 2009, 112, 1882. [Google Scholar] [CrossRef]

- Pehlken, A.; Essadiqi, E. Scrap Tire Recycling in Canada; Technical Report; CANMET Materials Technology Laboratory: Hamilton, ON, Canada, 2005. [Google Scholar] [CrossRef]

- Formela, K.; Haponiuk, J.T. Curing characteristics, mechanical properties and morphology of butyl rubber filled with ground tire rubber (GTR). Iran Polym. J. 2014, 23, 185. [Google Scholar] [CrossRef]

- Sambastsompop, N.; Kumnuantip, C. Rheology, Cure characteristics, Physical and Mechanical properties of Tire Tread Reclaimed Rubber/Natural Rubber Compounds. J. Appl. Polym. Sci. 2003, 87, 1723. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, C.; Liang, M. Properties of natural rubber vulcanizates containing mechanochemically devulcanized ground tire rubber. J. Polym. Res. 2009, 16, 411. [Google Scholar] [CrossRef]

- Heideman, G.; Datta, R.N.; Noordermeer, J.W.M.; Van Baarle, B. Influence of Zinc Oxide during Different Stages of Sulfur Vulcanization. Elucidated by Model Compound Studies. J. Appl. Polym. Sci. 2005, 95, 1388. [Google Scholar] [CrossRef]

- Cañavate, J.; Carrillo, F.; Casas, P.; Colom, X.; Suñol, J.J. The Use of Waxes and Wetting Additives to Improve Compatibility Between HDPE and Ground Tyre Rubber. J. Compos. Mater. 2010, 44, 1233–1245. [Google Scholar] [CrossRef]

- Gonen, M.; Balkose, D.; Inal, F.; Ulku, S. Zinc Stearate Production by Precipitation and Fusion Processes. Ind. Eng. Chem. Res. 2005, 44, 1627. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).