1. Introduction

Using sustainable materials in all applications is a guideline which has become increasingly important over the last several years. High greenhouse gas emissions, rapid resource consumption and the significant issues of waste streams and litter in the environment are reasons for that, and also reasons why the broader public is interested in sustainable materials. One approach that is often adopted is the use of biobased and/or biodegradable materials. While the former can help to reduce energy consumption in production and thus reduce CO2 emissions, the latter is more an approach towards the lack of proper waste management or to combat problems with littering.

Wood–plastic composites (WPCs) consist of wood particles (or other lignocellulosic fillers), a thermoplastic processable matrix and various additives. If the matrix is a biodegradable material, e.g., polylactic acid, the WPC can also be biodegradable (if the additives do not prohibit that) [

1]. Only adding the wood to a non-biodegradable matrix does not result in biodegradable materials, as the matrix will not be chemically altered and therefore will not be degradable [

2,

3]. In addition, as a WPC is a composite material, and composites are mostly used for durable applications, biodegradability is most likely not a desired property. Additionally, in light of improving sustainability, rather than discarding a material or recovering the energy during end-of-life scenarios, a better approach is to recycle the material, as this is beneficial in terms of energy consumption and CO

2 emissions. As WPCs are usually based on thermoplastic polymers, mechanical recycling (i.e., using a re-melting process in combination with cleaning, separation and size reduction steps to yield a recyclate) seems to be a viable path.

When looking into recycling and WPCs, most of the available literature reports on the use of recycled thermoplastics as the matrix material; examples using recycled high-density polyethylene (HDPE) [

4,

5], recycled polypropylene (PP) [

6], recycled polyvinylchloride (PVC) [

7,

8], recycled mixed polyolefins [

9], recycled polyethylene terephthalate (PET) [

10] and recycled polystyrene (PS) [

11] can be found, to name just a few examples. A WPC is often seen as a good application for recyclates (which are often used to reduce materials cost), as the extruded boards are thick walled; thus, mechanical properties, purity or overall quality do not matter that much. However, this is not true, especially when considering the durability of such products in outdoor applications, the matrix needs to be properly stabilized and exhibit sufficiently long polymer chains to withstand degradation. In addition, some of these studies can be disregarded if the matrix is a proper fit for a WPC. In the case of using recycled PET, hydrolysis stability of the matrix will be a big issue in melt processing, as PET is already susceptible to hydrolysis at low moisture concentrations. Wood or other lignocelluloses, even if pre-dried thoroughly, will always bring water into the mixture, which leads to the rapid degradation of PET, in addition to thermal wood degradation at the processing temperatures of PET.

Literature on the subject of recycling WPCs is scarce (literature on using recyclates as raw materials for WPC are not considered here, as these are outside of the scope of this work). One early publication from researchers from the USDA Forest Products Laboratory discusses the potential of WPCs to be recycled, especially as WPCs are used a lot in the US market for decking boards and building products. They point out that besides the challenges in reprocessing and adding the proper amount of stabilizers to yield recycled products which fulfill the requirements of the application, collection and sorting by matrix type as well as cleaning off the residues from the first life cycle also need to be considered [

12]. Another study looked into PVC based WPCs and their closed loop recycling. The WPC was reprocessed in an industrial-scale extruder up to seven times, and then mechanical properties as well as molecular weight were investigated. The authors found a reduction in the mechanical properties between the first and second reprocessing, and then a more or less stable performance. They found that a mixture with 30 wt% of recycled WPC was the most appropriate mixture regarding its mechanical properties [

13]. Based on these few results, other authors have also pointed out that although WPCs can be made from recycled materials and industrial by-products (i.e., the wood particles or other lignocellulosic wastes), an additional recycling step or cascading use is beneficial in regard to the CO

2 footprint, and they have also pointed out that the topic of recycling WPCs is insufficiently researched [

14,

15]. Some more recent publications have explored the topic of reprocessing HDPE based WPC up to eight [

16] and reprocessing PP based WPC up to nine times [

17]. Both publications showed that fiber degradation happens throughout the process, and that mechanical properties are reduced to some extent, but not critically.

Overall, there are not a lot of publications available on the topic of recycling WPCs. In our opinion, this is due to the fact that WPCs are used in durable applications in which the end-of-life is not as high pressure as for packaging applications, where the life span is much shorter and the waste streams are more prominently discussed in the media and have higher public attention. In our opinion, recycling or more specific reprocessing should be considered as in-house production waste and cut offs from fabrication and installation are valuable materials which should not go to waste.

Therefore, the aim of this work is to investigate the influence of reprocessing on the property profile of polypropylene-based wood–plastic composites. Two formulations, based on PP with different viscosity but the same wood share, are investigated while being reprocessed for up to five cycles. The approach to using 100% of the reprocessed material for the next cycle is the worst-case approach. Although we are aware that in real life application the reprocessed material always will be “diluted” by virgin material, the effects of reprocessing are more pronounced when using the highest possible reprocessed materials share. In addition, if the reduction in the properties in that scenario is low enough so that a material can properly perform in the application, then a lower share will not cause any problems, especially considering reprocessing or closed loop recycling, where the overall properties between unprocessed and reprocessed materials will not differ enough to give rise to issues in mixing homogeneity. Besides mechanical properties and fiber length, our study also investigates the influence of reprocessing on water uptake and weathering stability, which, to our knowledge, has not been reported in the literature so far.

2. Materials and Methods

In this study, two polypropylene homopolymers were used. The first was extrusion-grade with a low melt flow rate of 2 g/10 min (grade HB600TF, Borealis, Vienna, Austria); the second was injection-molding-grade with a high melt flow rate (MFR) of 55 g/10 min (grade HJ325MO, Borealis, Vienna, Austria). Both MFR values are given for 230 °C and 2.16 kg piston weight. Throughout this work the two grades will be referred to as PP-2 and PP-55, respectively. These two grades were chosen as matrix materials as PP based WPCs are most common in Europe, and to investigate the influence of viscosity on reprocessing. As the reinforcement, softwood particles with the major share of particles between 180 and 500 µm sieve size (grade CB35E, LaSoLe Est. Srl., Percoto, Italy) were used. To improve the wetting of the wood particles with the PP and adhesion between the components, a maleic anhydride grafted PP (grade Exxelor PO1020, Exxon Mobile Chemical Company, Houston, TX, USA) was used as a compatibilizer.

With these materials, 40 wt% of wood particles and 4 wt% of compatibilizer (as previous experience showed that a compatibilizer concentration of 1/10 of the wood particle share is most beneficial) were used to produce compounds with both PP grades. These materials will be referred to as WPC-2 and WPC-55, respectively, as the number refers to the MFR value of the base PP. We chose 40 wt% of wood particles as the share of wood is high enough to see any effects on the composite performance because changes in the wood particles are pronounced enough, but it is not so high that the wood particles are not sufficiently wetted by the matrix, or that the major degradation mechanism is particle–particle interaction. In addition, the unreinforced PP grades were subjected to the same treatments as the WPC materials.

The compounds were produced and reprocessed by means of a co-rotating 24 mm twin screw extruder (TSE24MC, ThermoPrism, Karlsruhe, Germany), with a processing length of 40 L/D (length to diameter ratio of the screw), a throughput of 10 kg/h at a screw speed of 300 rpm and a maximum barrel temperature of 230 °C (PP-2) or 210 °C (PP-55). The wood particles were dosed into the already molten PP after 8 L/D by means of a side feeder. For all following steps, the dosing of the granules happened into the intake of the extruder, therefore applying the whole 40 L/D to all the components. The extruded strands were cooled via a water bath and afterwards cut to 4 mm long granules by a strand cutter; then they were dried in drying hoppers (Luxor 120, Motan, Konstanz, Germany) at 80 °C for at least 6 h. Following that step, part of the material was used for injection molding, while the rest was reprocessed up to 5 times. After cycles 1, 2, 3 and 5 (which will be referred to as “number of extrusions”), samples were injection molded (Victory 80, Engel, Schwertberg, Austria) with a maximum barrel temperature of 230 °C (PP-2) and 210 °C (PP-55) and a mold temperature of 40 °C to retrieve universal test specimen (specimen geometry according to ISO-527). Before further material characterization was carried out, the specimens were stored in a standard climate (23 °C, 50% r.h., KBF 720, Binder, Tuttlingen, Germany) for at least 96 h to ensure cooling down and post crystallisation of the samples.

Tensile properties were recorded in accordance with ISO-527 [

18] with a crosshead speed of 1 mm/min until the elastic modulus could be determined and afterwards with 5 mm/min until the breaking of the samples on a 20 kN universal test machine (Z020, Zwick-Roell, Ulm, Germany). For each sample series, 5 replicates were tested. Unnotched Charpy impact properties were recorded on prismatic specimen (80 × 10 × 4 mm

3) punched out from the parallel part of the universal test specimen in accordance with ISO-179 [

19] on a pendulum impact tester (5113.300, Zwick-Roell, Ulm, Germany). For measuring notched impact strength, the same standard and setup were used, but the specimens were notched with a V-notch brought into the sample by means of a precision table saw (Diadisc 4200, Mutronic Präzisionsgerätebau, Rieden a.F., Germany) equipped with a notching blade. Per sample series and impact test, 5 replicates were tested.

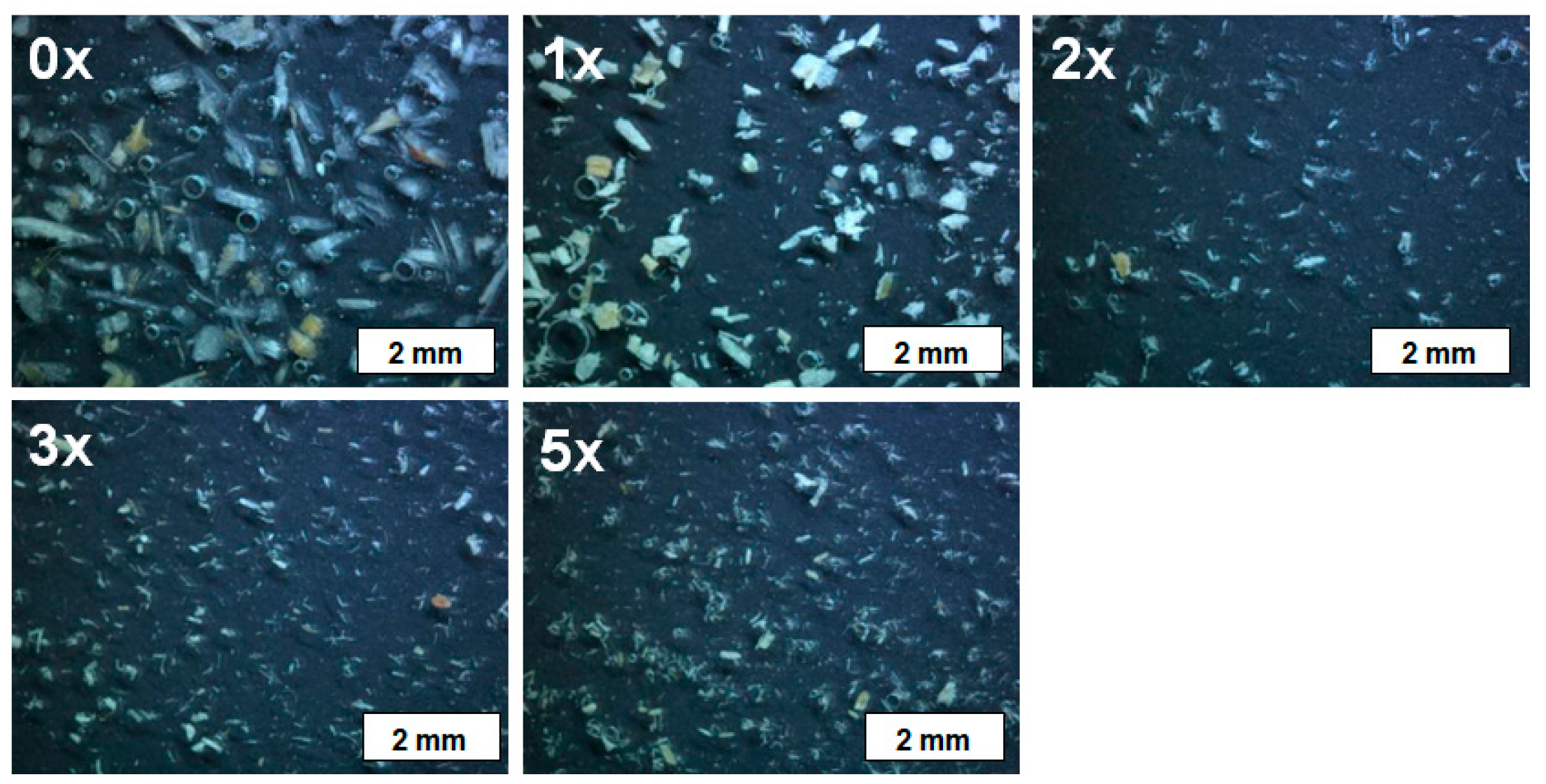

Fiber length and the width of selected samples were determined by measuring at least 500 fibers on microscopic pictures of the wood particles after extraction from the parallel part of the universal test specimens. Extraction was carried out in boiling xylene (100 mL xylene, technical grade, per 1 g of WPC sample) under reflux for 4 h. After that, the whole solution was vacuum filtered and washed with hot xylene to yield the wood particles. After drying the wood particles (at 105 °C for 2 h in a hot air cabinet), the samples were spread on microscopic slides and fixed with an aqueous mounting agent (Aquatex®, Merck kgaA, Darmstadt, Germany) before measuring.

Water uptake of the samples was determined on prismatic specimen (80 × 10 × 4 mm

3) punched from the parallel part of the universal test specimen, with three replicates per material. The samples were labeled, weighed and stored in deionized water at 23 °C for up to 28 d, while being taken from the water bath, dried superficially and weighed after 24, 48, 196 h and 28 d of storage. Color (Lab-color sphere) of the samples was measured at the shoulder part of the universal test specimen by a combined color and gloss measuring device (spectro-guide sphere gloss, Byk Additives and Instruments, Wesel, Germany). Accelerated weathering of the samples was carried out in accordance with ISO-4892-2, cycle 1 [

20], by means of a Weather-o-Meter (Ci 4000, Atlas Materials Testing, Mount Prospect, IL, USA) for up to 1000 h. These samples were then investigated by tensile tests as described previously in this paper.

The zero-shear viscosity of the unreinforced PP grades was measured at 230 °C under nitrogen flush in a plate–plate rheometer (Physica MCR 501, Anton Paar, Graz, Austria) using 25 mm diameter plates with 1 mm measurement distance in the shear-rate region of 0.1–628 s−1 and an amplitude ramp of 2% (at 628 s−1) to 20% (at 0.1 s−1). The data were evaluated using a Carreau–Yosida fit for the zero-shear viscosity.

In all the figures, error bars representing +/− one standard deviation of the average value are given. In most of the figures, these are smaller than the symbols used. Symbol size was chosen for legibility.

3. Results and Discussion

In the following, the influence of the number of reprocessing cycles on the different material properties of WPCs and the base PP grades are discussed. We are aware that different scales of machines and different processing routes (e.g., running full extrusion and molding cycles vs. multiple extrusion cycles) will yield different absolute values, but our approach here shows how the properties change with the influence of temperature and shear. In addition, our approach suggests that a reprocessing rate of 100% is the worst-case scenario, which does not fully reflect the situation in recycling, as usually there will be a share of virgin material. Nevertheless, if a material holds up in this scenario, one is safe to say that it will be unproblematic in the usual case, where virgin material is added.

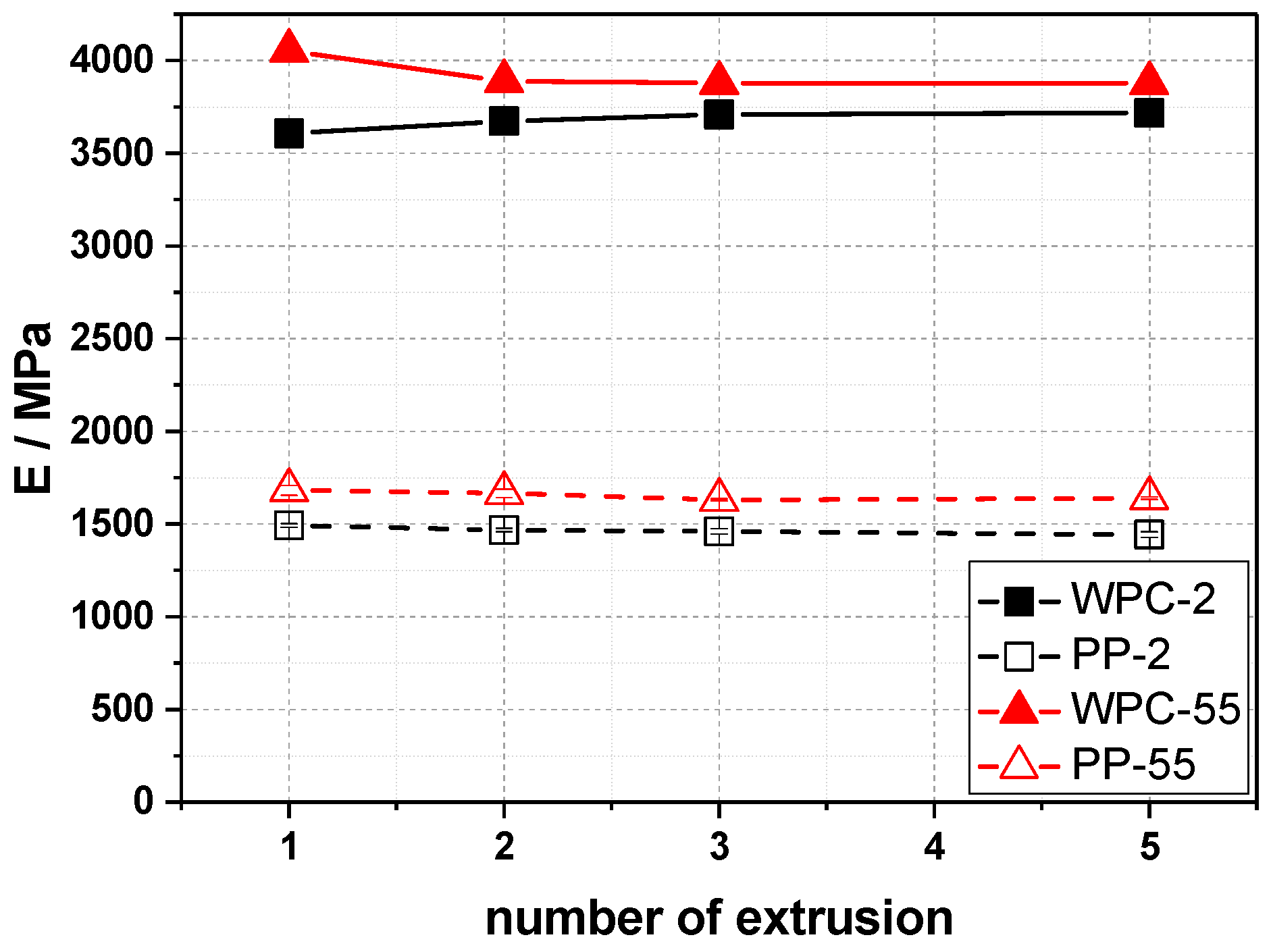

The first property to look at in this study is the elastic modulus (

Figure 1). The WPC-55 yields slightly higher values than the WPC-2, while both yield higher values than the base PP grades. The higher moduli for WPC-55 can be explained by the higher base modulus of the PP-55, most likely due to higher crystallinity, as the shorter chains can crystallize better than the longer chains in the PP-2, especially during injection molding, where the outer layer closer to the wall crystallizes less due to shear and cooling rate; this has a more pronounced influence in PP-2 due to the chain lengths and higher viscosity. Another influence in composites is the wetting of the reinforcement with the matrix, which should be higher for the PP-55. Over the different cycles, one can see that the elastic moduli do not change all that much for both WPC formulations. With WPC-55, a slight reduction from the first to the second reprocessing can be seen, which is due to the reduction in wood particle size (

Figure 2). For WPC-2, a slight improvement can be found between the first and second processing cycles, most likely due to improved wetting, as the high viscosity PP-2 will be degraded somewhat by the shear applied. The unreinforced PP grades do not show any technical relevant change in elastic modulus due to multiple extrusions.

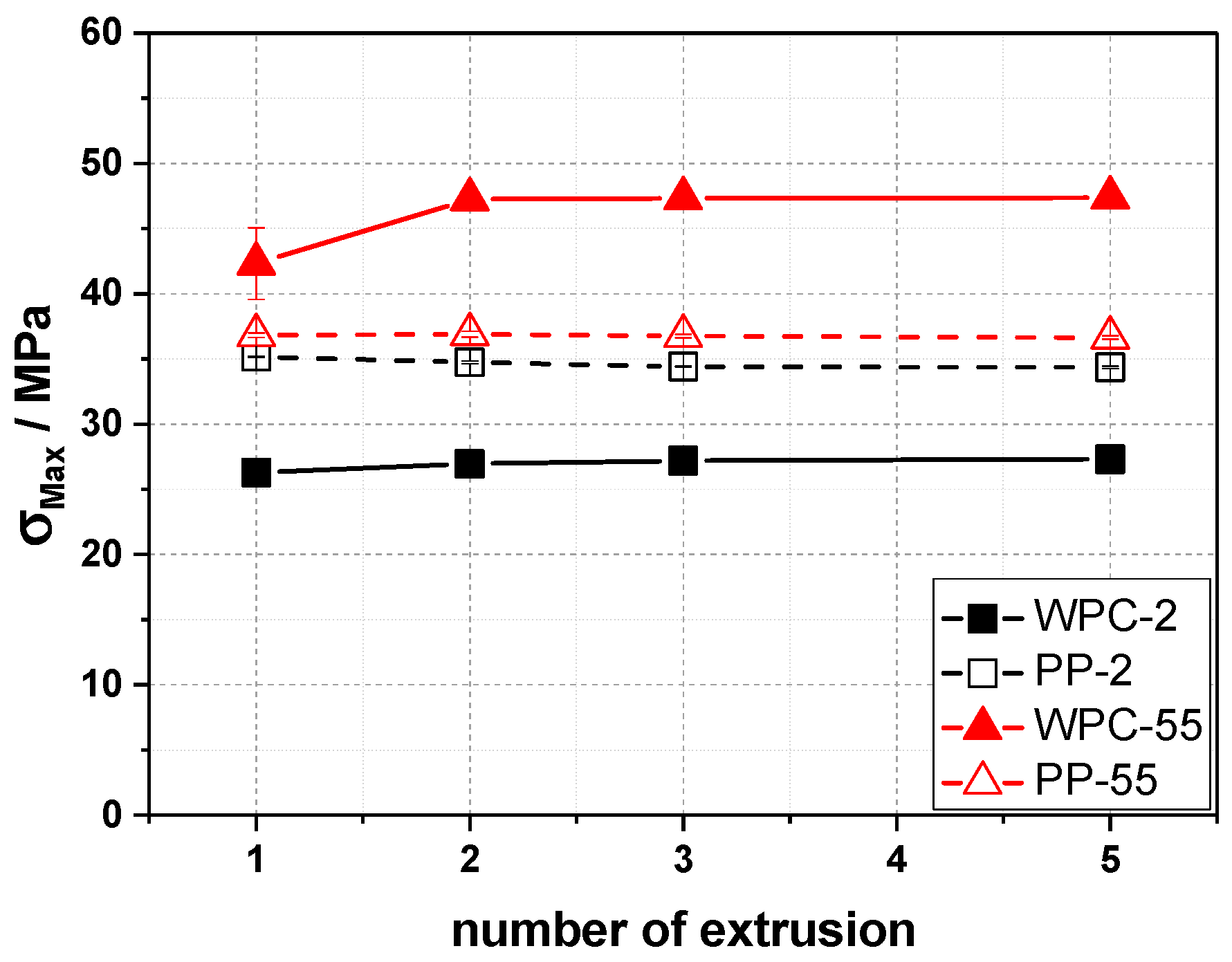

In the case of the tensile strength (

Figure 3), again the values for the unreinforced PP grades do not change significantly in the investigated region. The WPC-55 shows a higher tensile strength than the base PP grade, while for WPC-2 a lower tensile strength can be found. This is due to improved wetting with the WPC-55. In addition, for PP-2, the tensile strength shows some yielding, which is reduced by adding solid particles, thus leading to the reduction in the strength value. The number of processing cycles only shows the influence between the first and second processing cycles as here the wood particle size is reduced the most, thus, the tensile strength is increased as the finer particles exhibit higher specific surface and can therefore carry a higher load. This is a pronounced effect for the WPC-55, but is also visible to a smaller extent for the WPC-2—the difference between these two again being the wetting of the particles by the matrix. Afterwards the values stay the same; the wood particle size does not change too much after that either (

Figure 3).

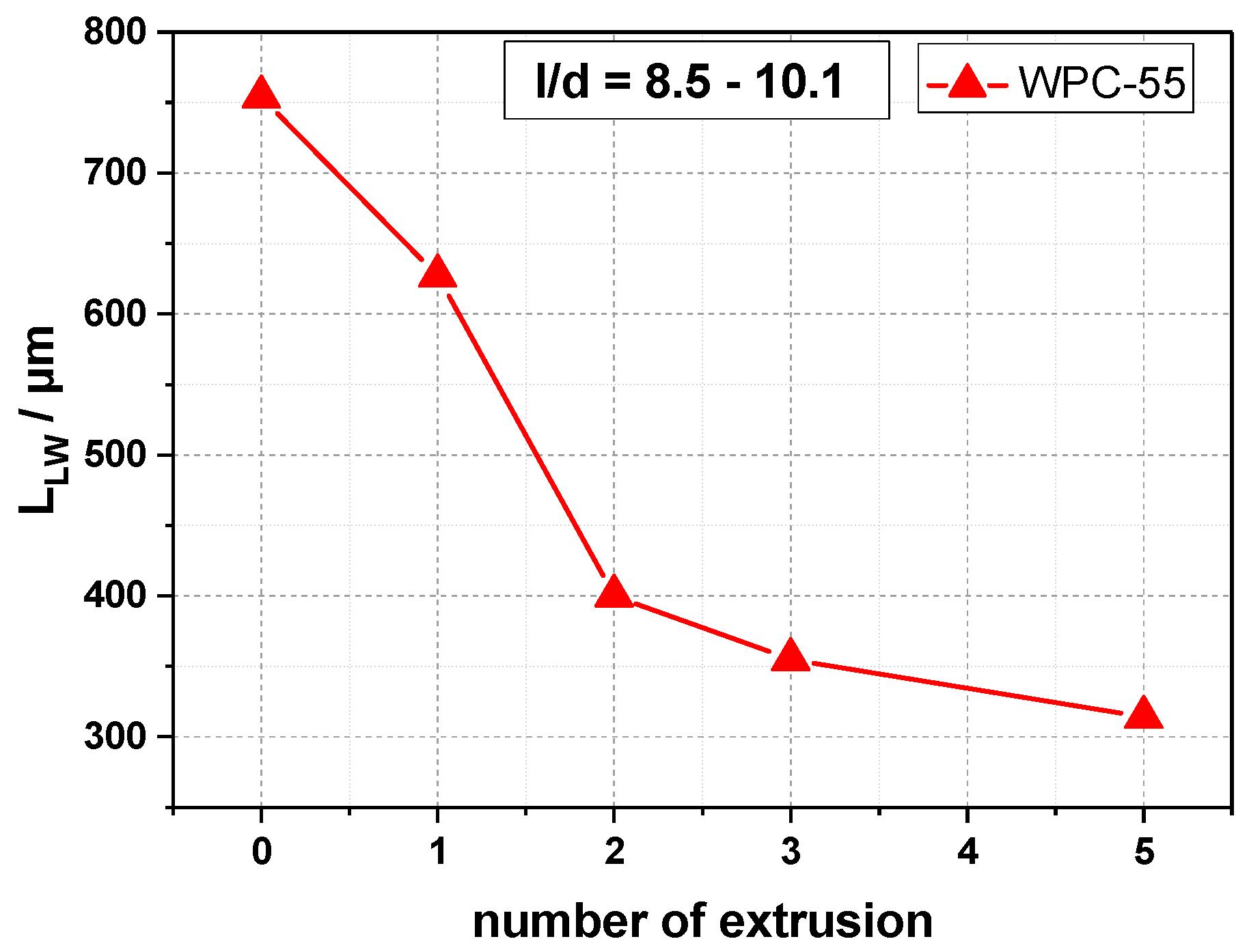

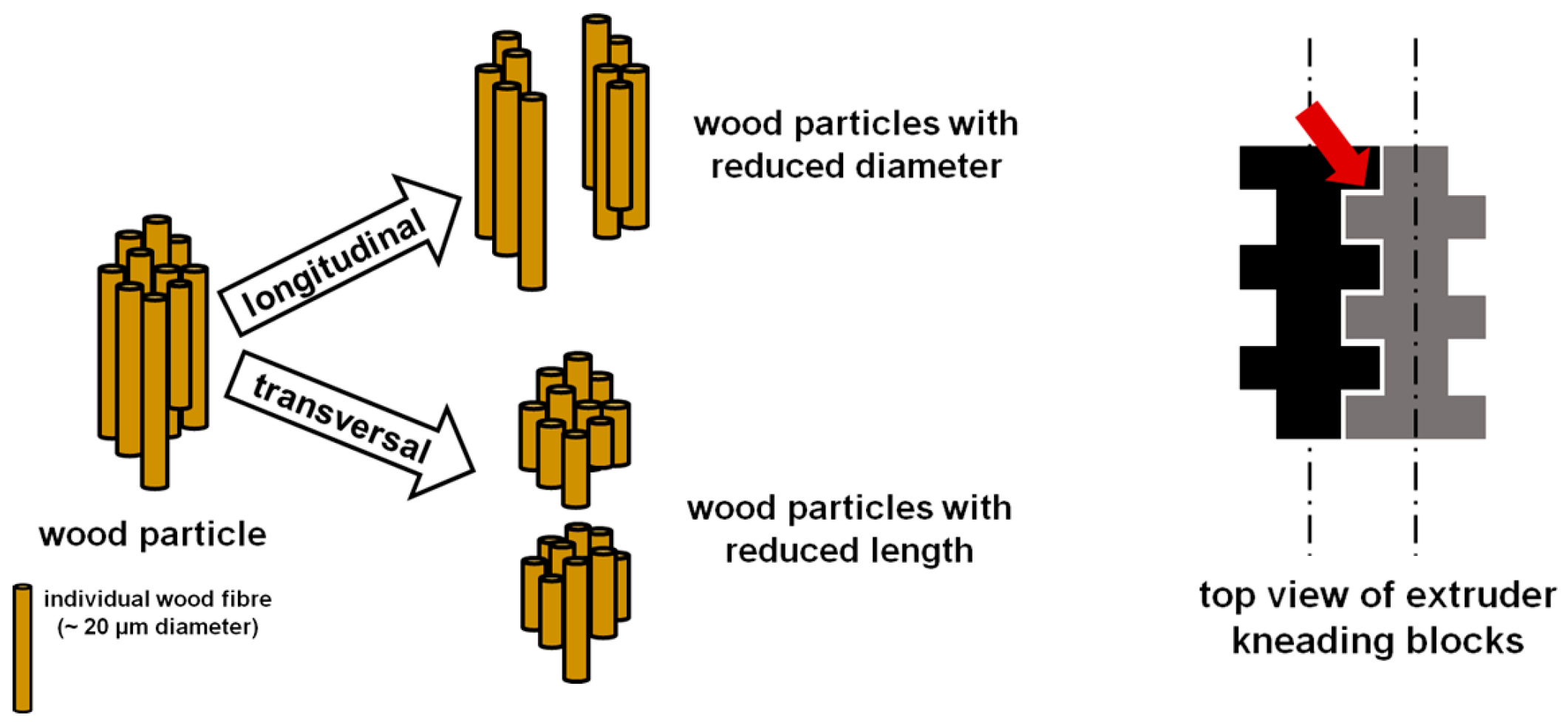

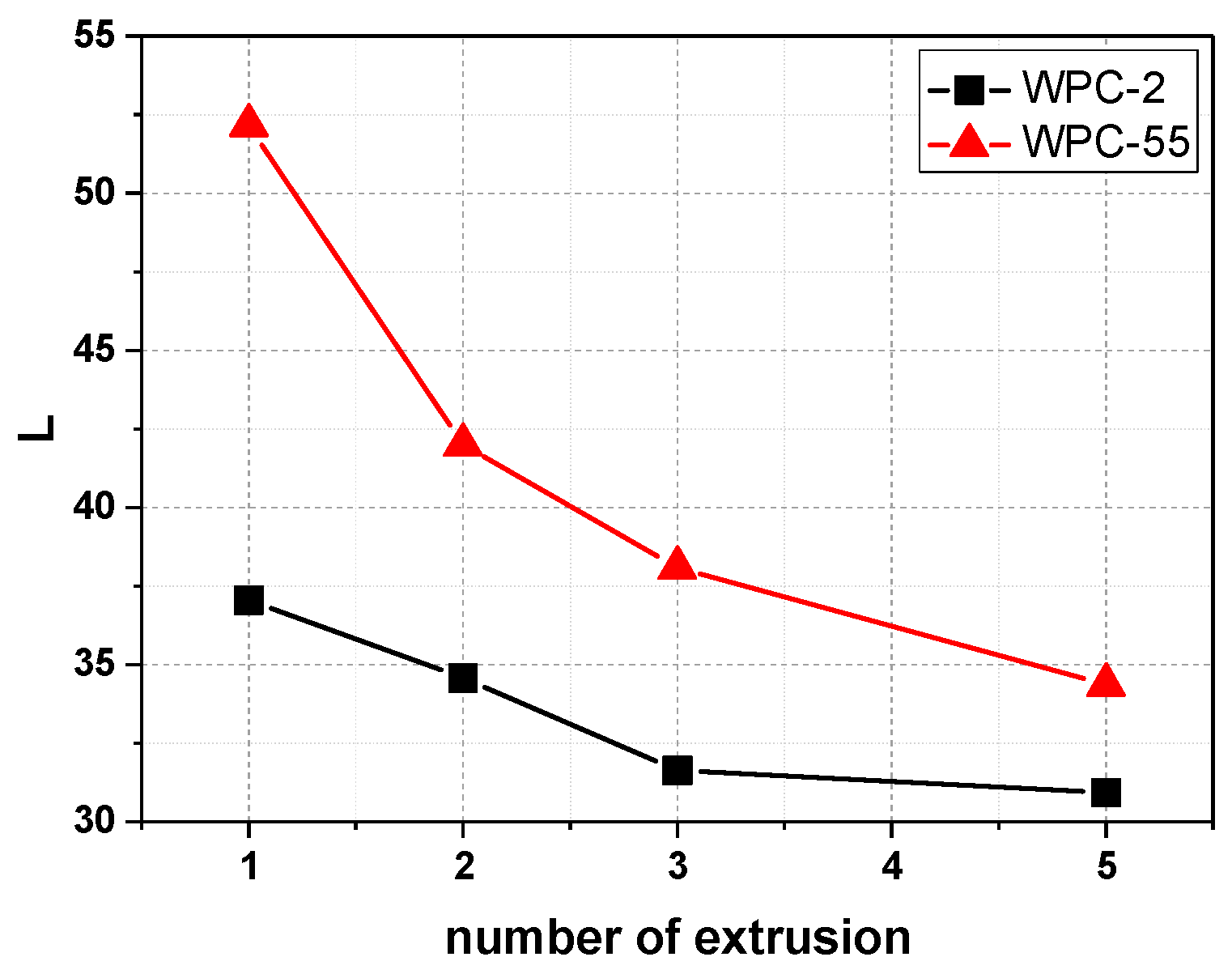

The wood particle size (determined here only for WPC-55) shows the most pronounced decrease between the first and second reprocessing cycles (

Figure 2). This is due to the fact that, in the first processing cycle, the wood particles need to be mixed with and wetted by the PP, so a reduced processing length is available where shear is applied to the wood particles via the PP matrix. This effect is intensified by the fact that, in the first step, the wood particles are dosed via a side feeder into the melt, therefore reducing the available processing length by about 20%. In the second step, the whole mixture is already established, therefore shear is applied to the wood particles over the whole processing length. Following this, the wood particle size does not degrade that much further. On the one hand, the smaller wood particles are harder to shear off as the force being transferred into the particles is reduced due to the reduced size. On the other hand, the size of the particles gets closer to the smallest slit width in the compounder used, which is the distance between neighboring kneading blocks (about 250 µm), and therefore the milling action of the kneading blocks is also reduced. In terms of the aspect ratio—as the wood particles are fiber bundles after all and can either be sheared longitudinal or broken transversal (

Figure 4)—we found that this lies between 8.5 and 10.1. This means that the shape of the wood particles stays approximately the same, which is also visible from the micrographs of the wood particles in

Figure 5. This also means that, considering the size reduction and approximating the wood particles as cylinders (and using l/d of 10), the specific surface (i.e., the surface to volume ratio) is increased by about 50% between the first and second extrusion, which explains the increase found in the mechanical properties. Any further increases did not translate to a further increase in mechanical properties, which could be due to a decrease in the interaction between the wood particles and the matrix as the thermal degradation of the wood progresses with the number of processing cycles.

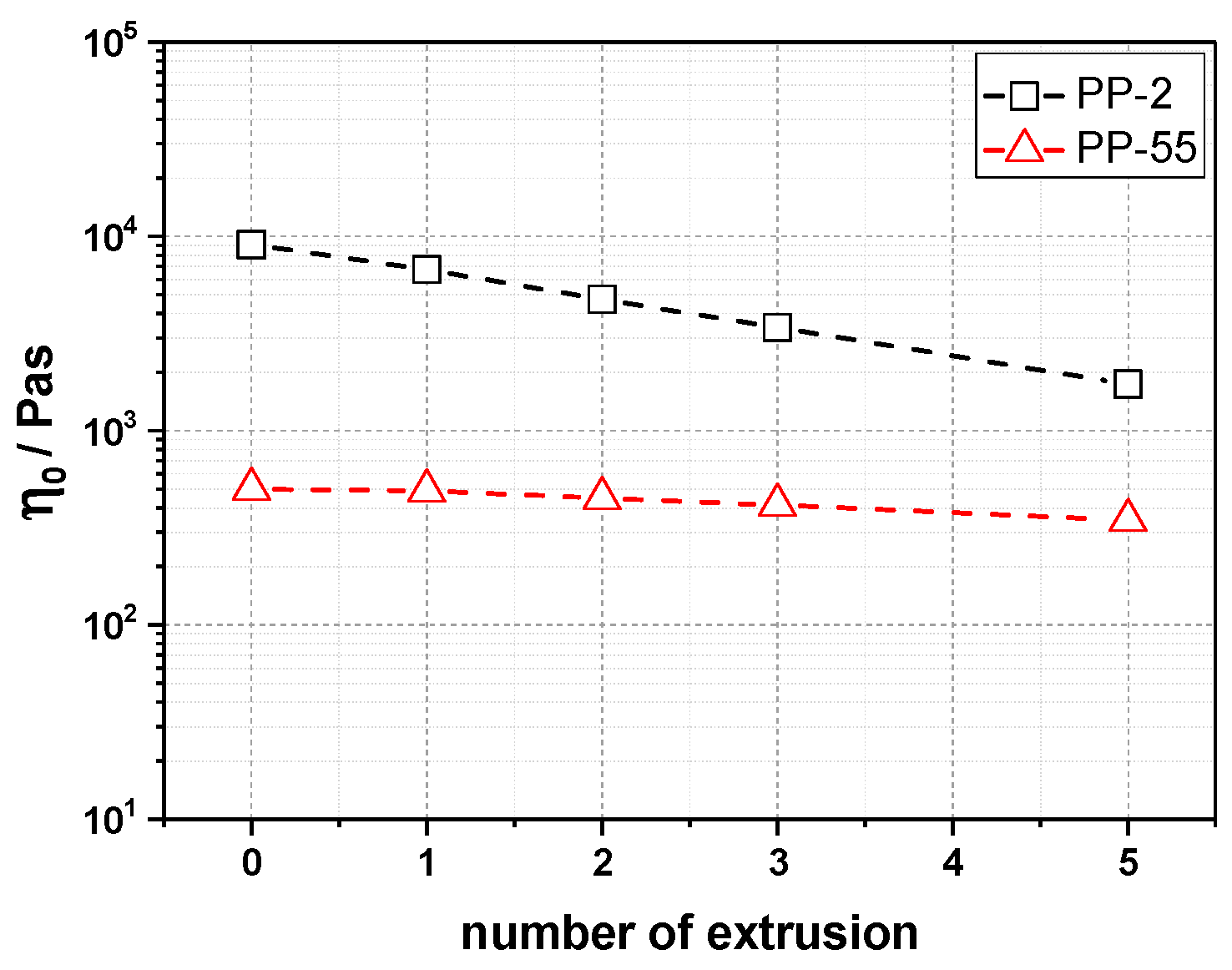

The zero-shear viscosity of the two PP grades was determined to assess the degradation of the polymers. We only investigated the unreinforced PP grades here, although the authors are aware that the degradation mechanisms can alter with the presence of the wood particles, as these introduce moisture, oxygen and other chemical elements and compounds into the PP, and the shear relations will change when solid particles are present in the melt. Nevertheless, for a properly conducted rheological investigation, the wood particles need to be separated from the matrix, and with a step such as, e.g., extracting the PP with boiling xylene. Additionally, the material will be altered, which needs to be assessed; however, such an investigation would have gone beyond the scope of this paper.

Looking at the zero-shear viscosity (

Figure 6), one can see that it is reduced for both PP-55 and PP-2 over the number of processing cycles. The reduction is more severe with PP-2, as this material exhibits the longer chains and therefore the higher viscosity—which also means that more shear can be applied to the material. The viscosity reduction for PP-55 is less pronounced. Overall, PP-2 exhibits significantly higher viscosity than PP-55, also after 5 extrusion cycles. This viscosity difference also explains part of the mechanical behavior, as well as the thermal degradation discussed later in the paper.

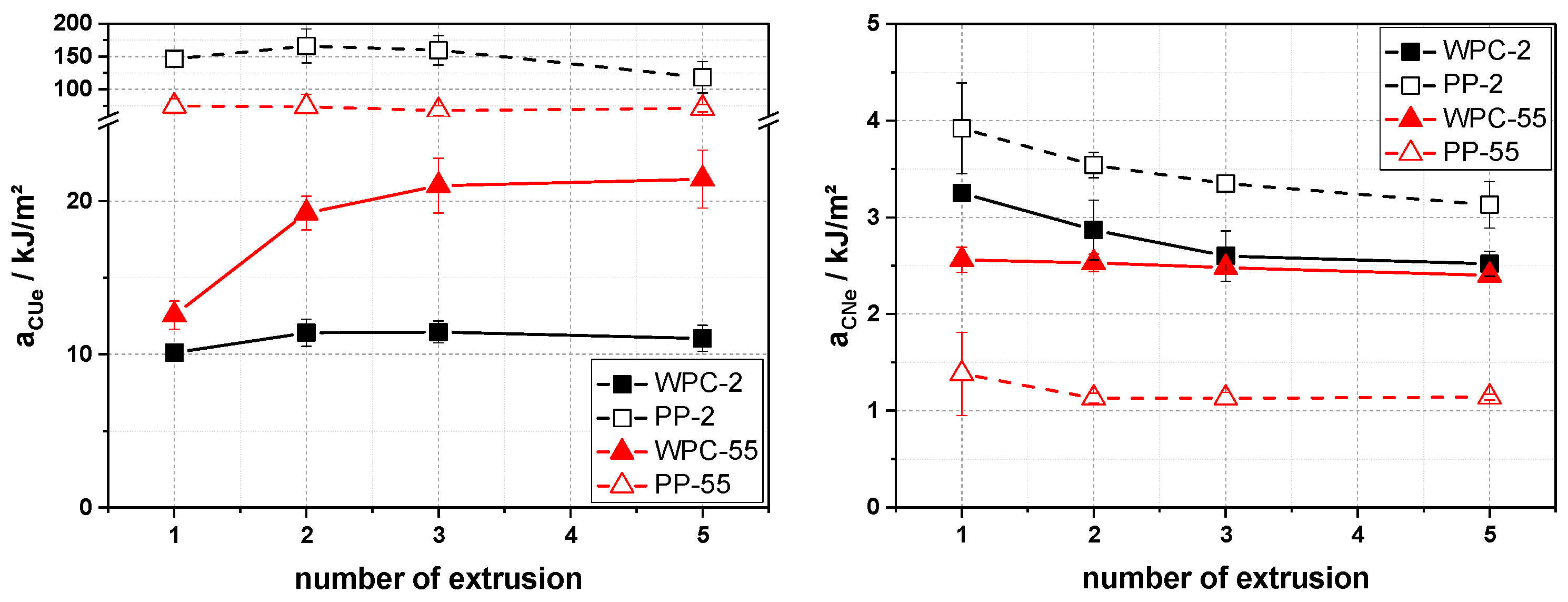

The impact behavior of the different samples was investigated by applying unnotched and notched Charpy impact tests (

Figure 7). In the case of the unnotched impact strength, the WPC showed lower values than the unreinforced PP grades, which is due to the fact that the fracture mechanism is altered. While the PP specimen flex more (due to their lower elastic modulus) and typically show a non-break behavior, the WPC are much stiffer and break completely in this test. With the increased number of cycles, an increase in unnotched impact strength can be seen; this is due to the reduction in particle size (

Figure 3), as this reduces the stress concentrations, and therefore more energy is needed to fracture the sample. This is more pronounced in the WPC-55 than the WPC-2, which we again attribute to the higher wetting of the particles in WPC-55. Looking at the notched impact strength (

Figure 7), a different picture can be seen. Here, PP-2 shows higher values than PP-55 due to the higher chain lengths, which need more energy in crack propagation through the specimen. The notched impact values for the WPC are in the middle of the values for the unreinforced PP; with the shorter PP chains (WPC-55), the wood particles provide some additional reinforcement, but with the longer chains (WPC-2), the wood particles provide a less-resistant crack pathway (as in PP-2 the chain length is the dominating factor here) most likely by hindering polymer chain entanglement and movement. With an increasing number of processing cycles, PP-2 and WPC-2 show some reduction in notched impact strength, which we attribute to polymer degradation, as also shown by the viscosity measurements (

Figure 6). For PP-55 and WPC-55 the notched impact strength does not change significantly in the investigated region, but here, polymer chain degradation is less severe as these are much shorter to begin with.

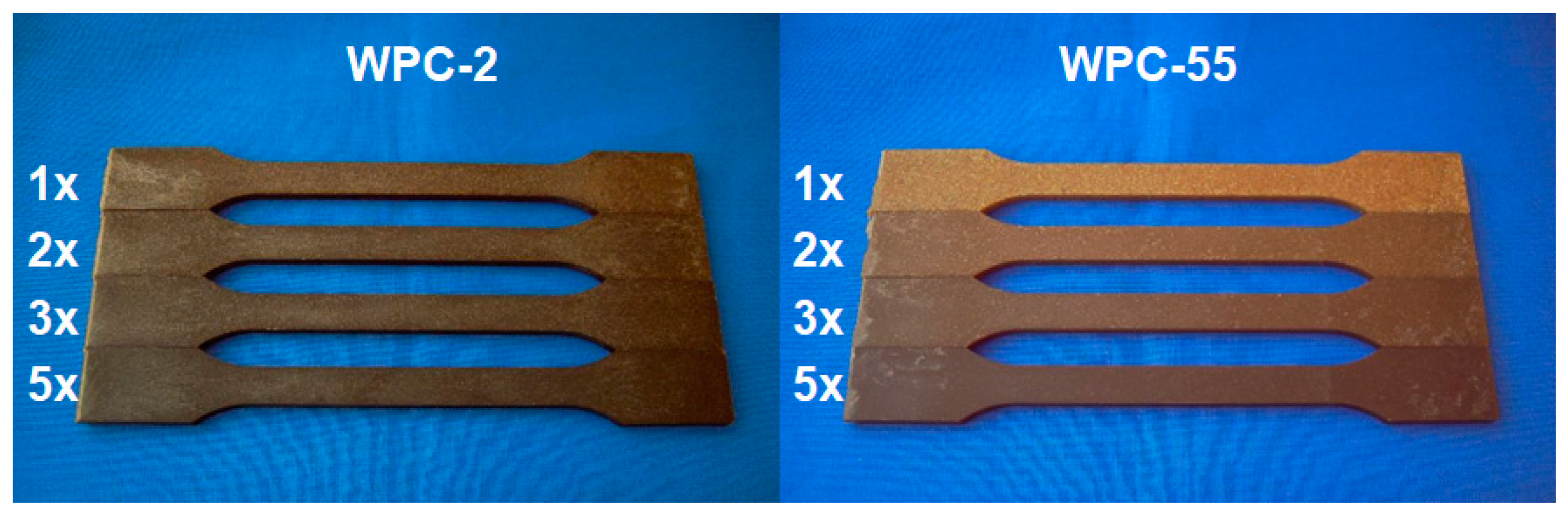

One very pronounced effect we found due to processing cycles is the degradation of color, specifically the darkening of the materials. This is due to thermal degradation, and is also induced by shear, as can be seen in

Figure 8. The specimens for WPC-2 are darker to begin with, although the wood particles are exactly the same, and also both virgin PP grades look very similar in terms of color. The specimen for WPC-2 also required a higher temperature in the molding of the samples, as the polymer exhibits much higher viscosity than in the WPC-55. This is also shown by the lightness values (we omitted the a- and b-values here due to their limited informative value) for color measurement (

Figure 9), where the WPC-55 after five processing cycles exhibits a value as low as the WPC-2 after two processing cycles. As we did not find a deterioration in the tensile strength with the darker color, we can conclude that the wood is not degraded to a point where its mechanical properties are influenced, and only the appearance changed.

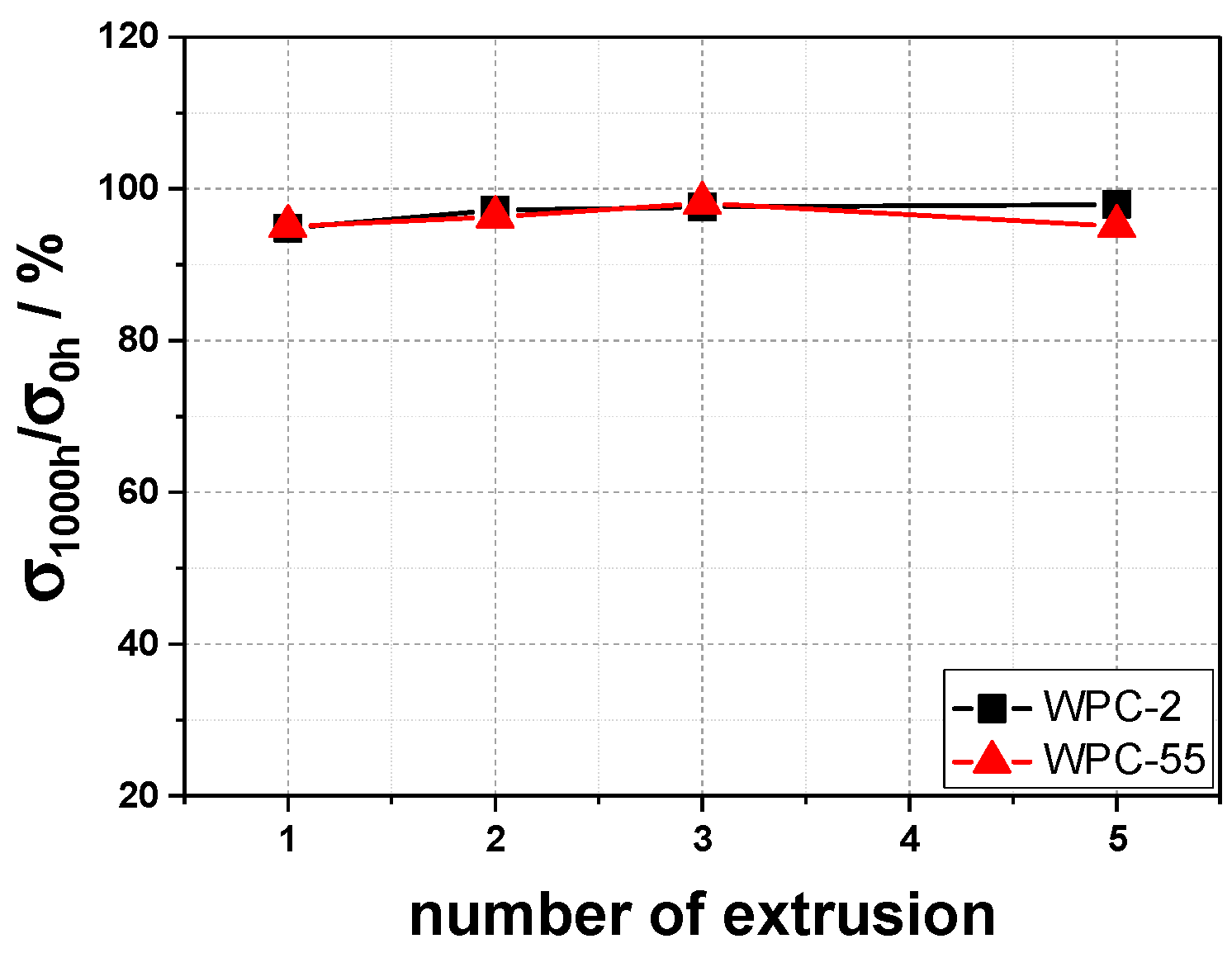

Another important property for a composite is the measure of durability in service, as such materials are usually applied for longer periods of time. As every process step inflicts shear and heat on the material, stabilizers are depleted; these same stabilizers, like radical scavengers, are also needed for stabilizing the material against degradation and weathering. To assess if there is an influence on durability, we looked at the behavior of the material after accelerated weathering. Specifically, we looked at the tensile strength, as strength values are more sensitive to degradation via weathering than modulus values. We compared the tensile strength after 1000 h of weathering with the value before the weathering. As shown in

Figure 10, the tensile strength stays the same regardless of the number of processing cycles. This was not completely to be expected—although we are aware that not all stabilizers work over the whole temperature range, and the ones which are depleted at processing temperatures are not necessarily the ones effective at temperature conditions in the application—but shows that, when the overall degradation (as shown by the different properties before) is not too high, weathering stability should be sufficient if we consider the unweathered material being the proper choice in regard to weathering stability.

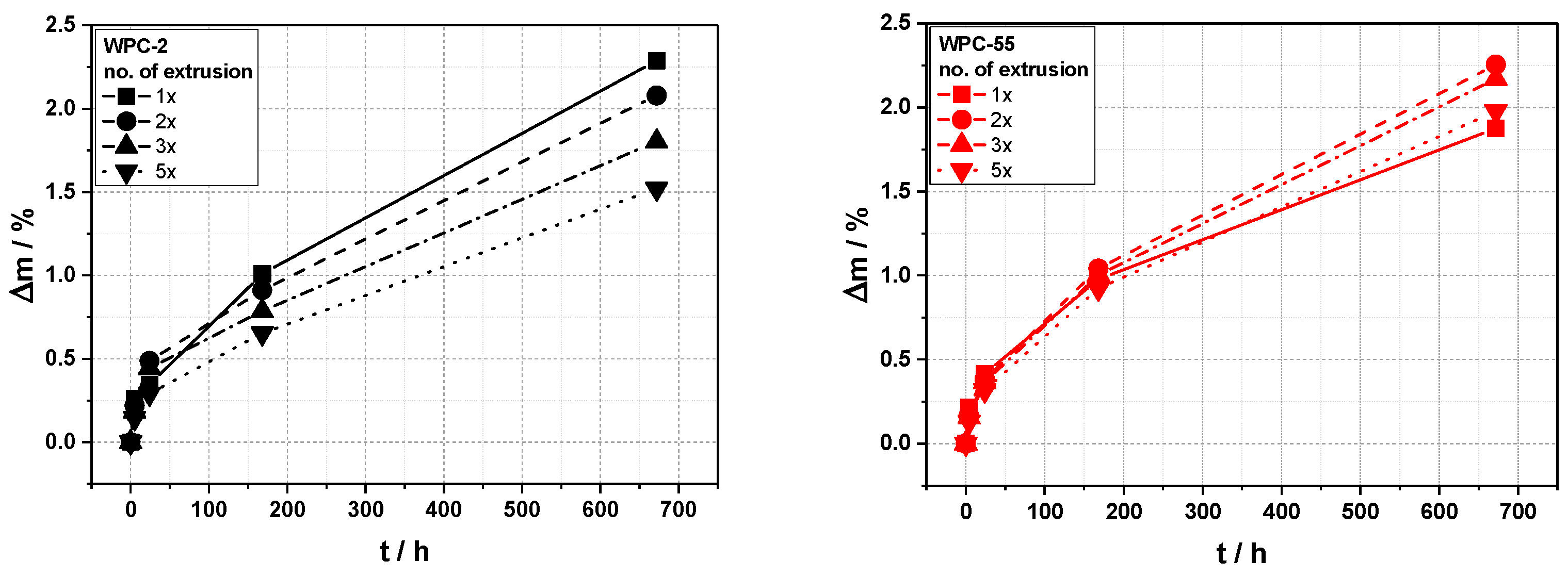

The last property investigated in this paper is the water uptake behavior of the WPCs. This is often a detrimental factor in durability as high levels of water uptake diminish mechanical properties, and can also accelerate weathering effects (e.g., by washing out degraded wood components). Looking at the water uptake (

Figure 11) for WPC-2, there is a reduction in the water uptake with the increasing number of processing cycles. This is due to the fact that, with increasing processing cycles, the viscosity of PP-2 is reduced, thus yielding better wetting, and therefore, less water uptake. For WPC-55, the effect found is more an increase in water uptake, but only with long storage time. This effect could be due to the reduction in wood particle size during processing, which results in a higher specific surface and in more water pathways throughout the composite. Nevertheless, the effect here is not that pronounced, and would need more detailed investigations to look into the causes. Overall, the effect of multiple processing on the water uptake of WPC is limited in both cases.

4. Conclusions

In this paper, we investigated the effect of multiple processing cycles on the different properties of two wood–plastic composites (WPC) with 40 wt% of wood and two different polypropylene (PP) grades, one with high and the other with lower viscosity, respectively. From our investigations, we found that up to five processing cycles exhibit only a slight influence on mechanical properties such as tensile strength or elastic modulus. Wood particle size is reduced, especially within the first two cycles, but after that the size reduction is also limited. Due to the breaking of wood particles across the fibers, but also along the fibers due to shear, the aspect ratio was found to be within a limited range, which explains the limited influence on the mechanical properties. Further, weathering stability was uninfluenced, while water uptake improved at least for the WPC with the PP matrix with higher viscosity, as here, wetting is improved with increasing processing cycles. The most pronounced influence of multiple processing found in our study was the color degradation of WPC, which is more severe if the PP matrix has a higher viscosity as then shear input is higher, and the processing temperatures need to be increased during compounding and injection molding.

Overall, our work shows that WPCs can be reprocessed up to five times without any major degradation, color aside. As this study was carried out at a reprocessing rate of 100%, which will be much lower in real life application as the return material, like cut-offs from production or other post-industrial waste material, will most likely be mixed with virgin material, further mitigating any negative effects the reprocessing can impose. From that point of view, a general recyclability for WPCs can be confirmed taking into account that streams with different polymer bases are not commingled. Recyclability after an application in the field would require more detailed investigations, as degradation products from weathering, but also potential biological decay (like algae), need to be accounted for.