Toughened Bio-Polyamide 11 for Impact-Resistant Intraply Basalt/Flax Hybrid Composites

Abstract

:1. Introduction

2. Materials and Methods

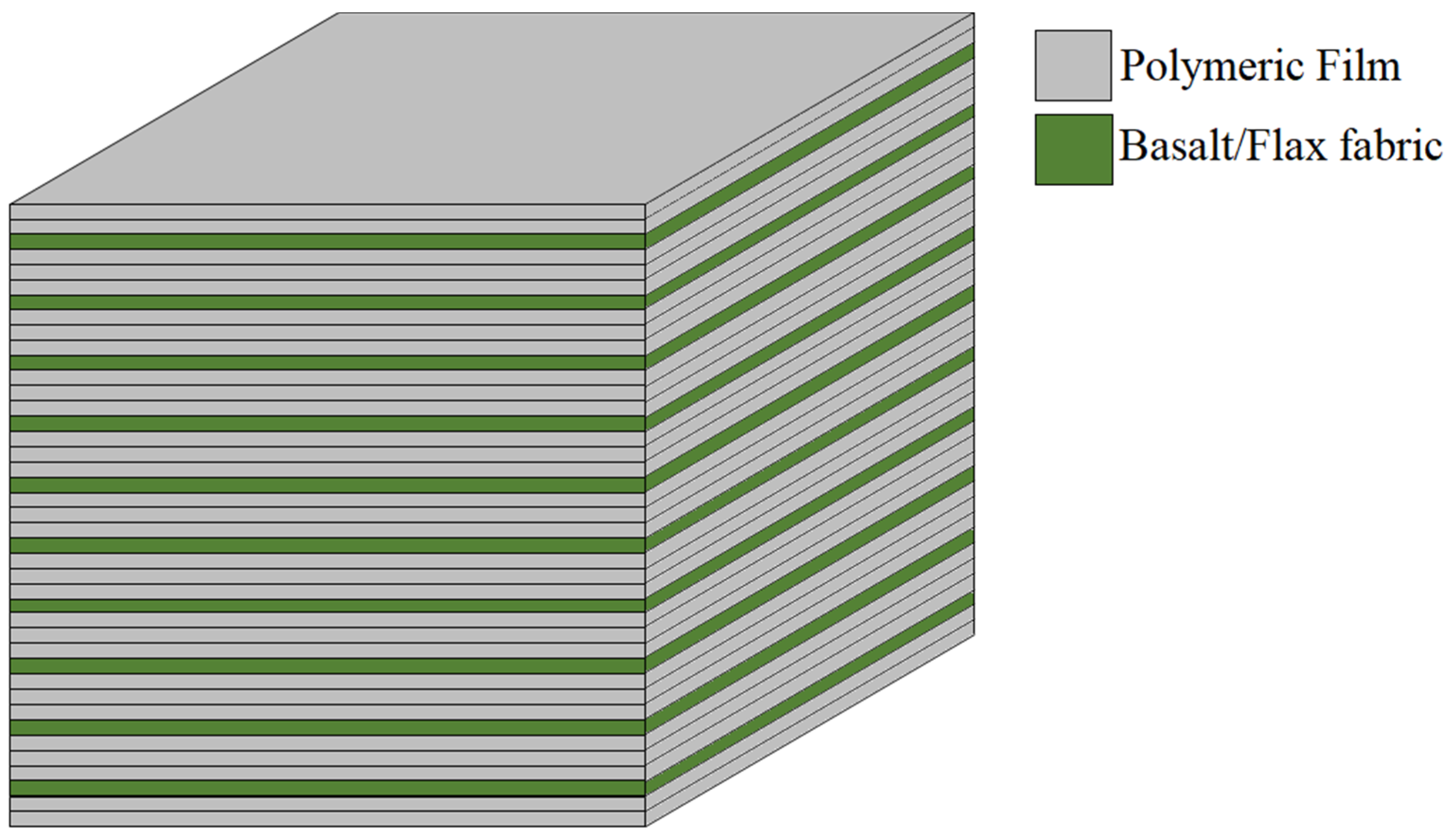

2.1. Materials and Composite Manufacturing

2.2. Preliminary Thermal and Structural Characterizations

2.3. Impact and Post-Impact Analysis: Low-Velocity Impacts and Profilometry

3. Results and Discussion

3.1. Preliminary Characterization

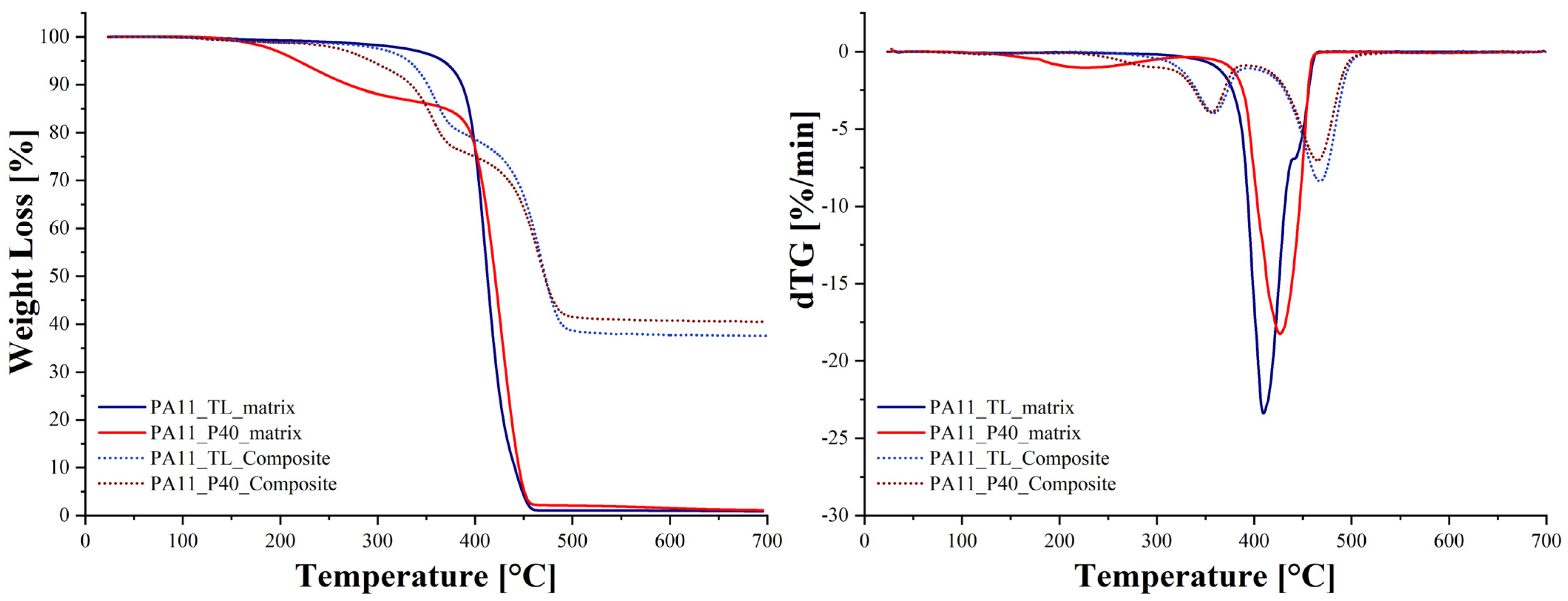

3.1.1. TGA

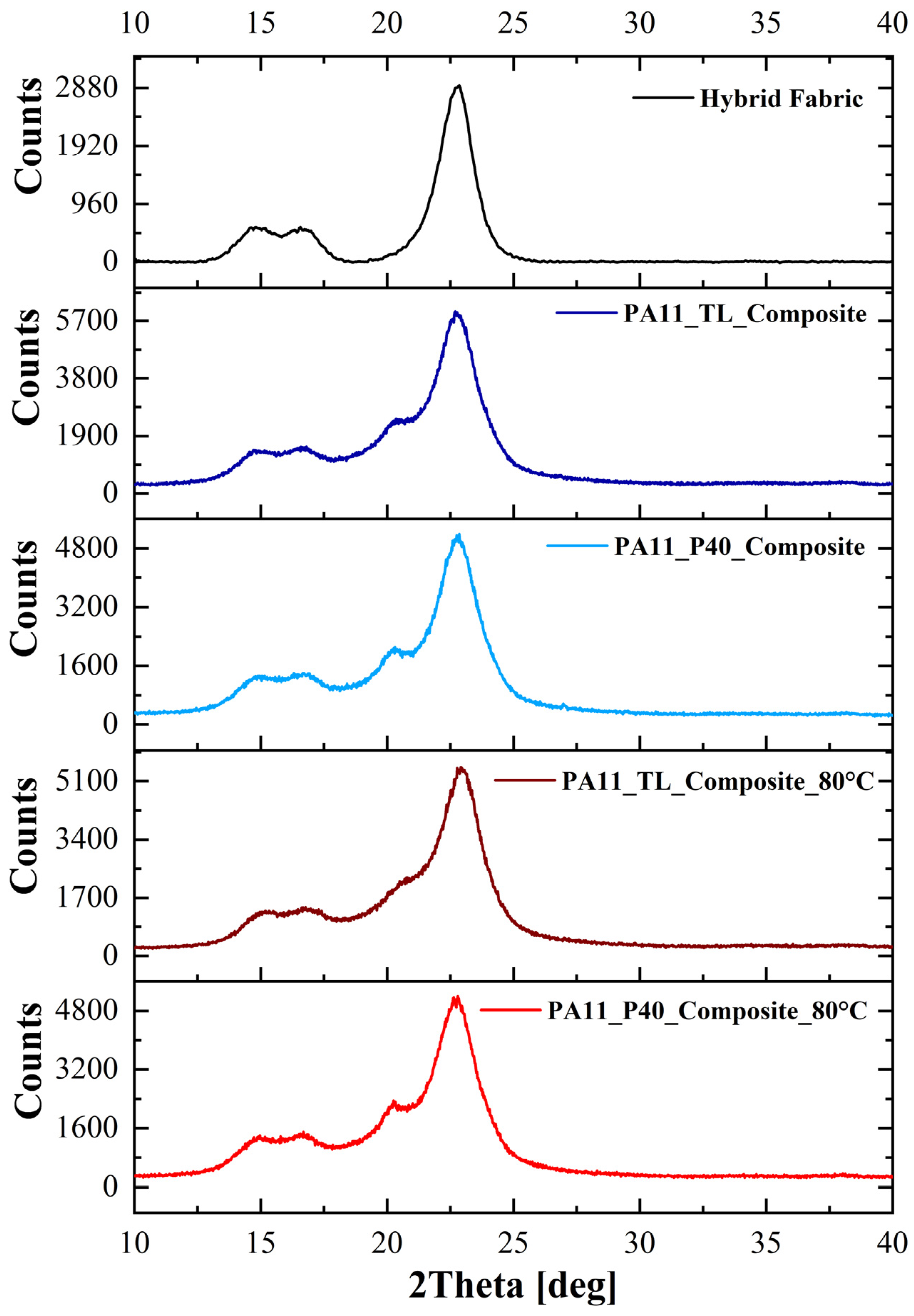

3.1.2. DSC and XRD

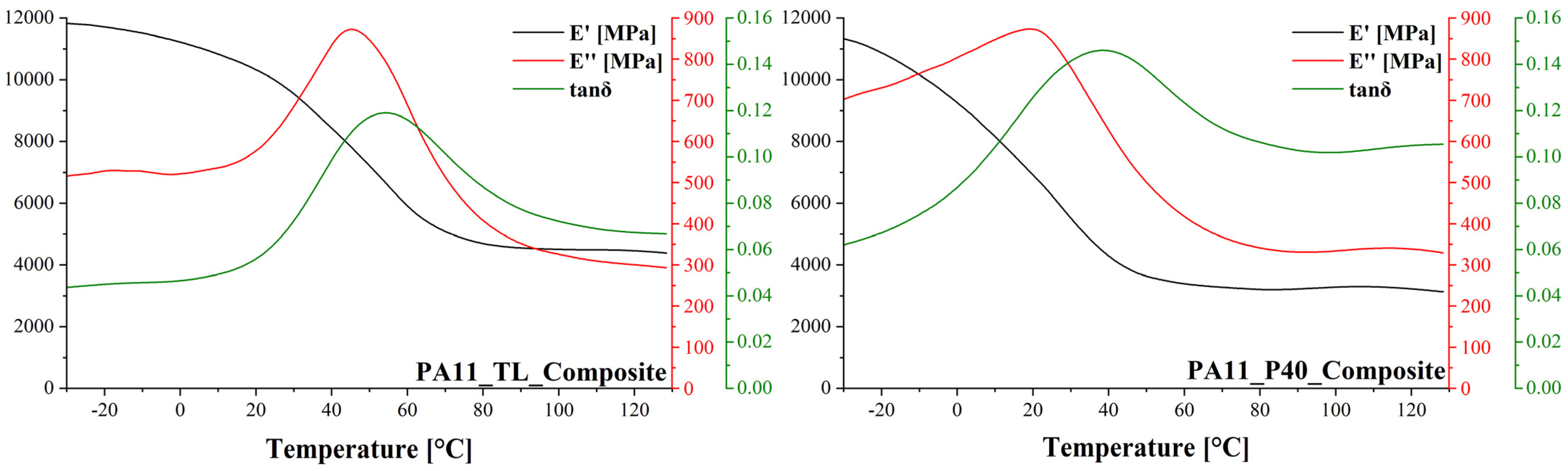

3.1.3. DMA

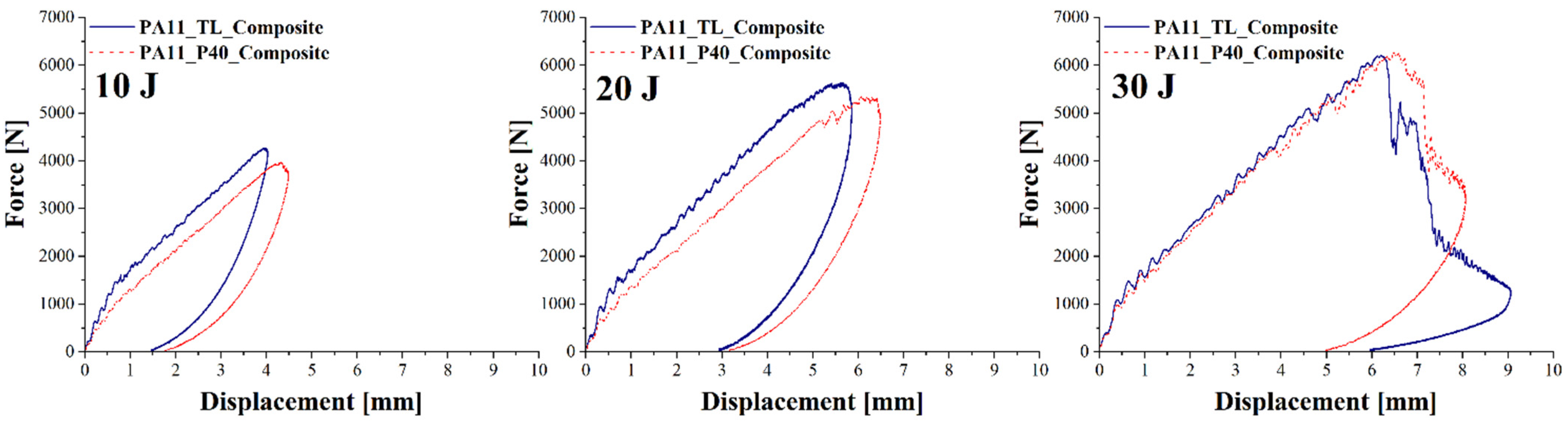

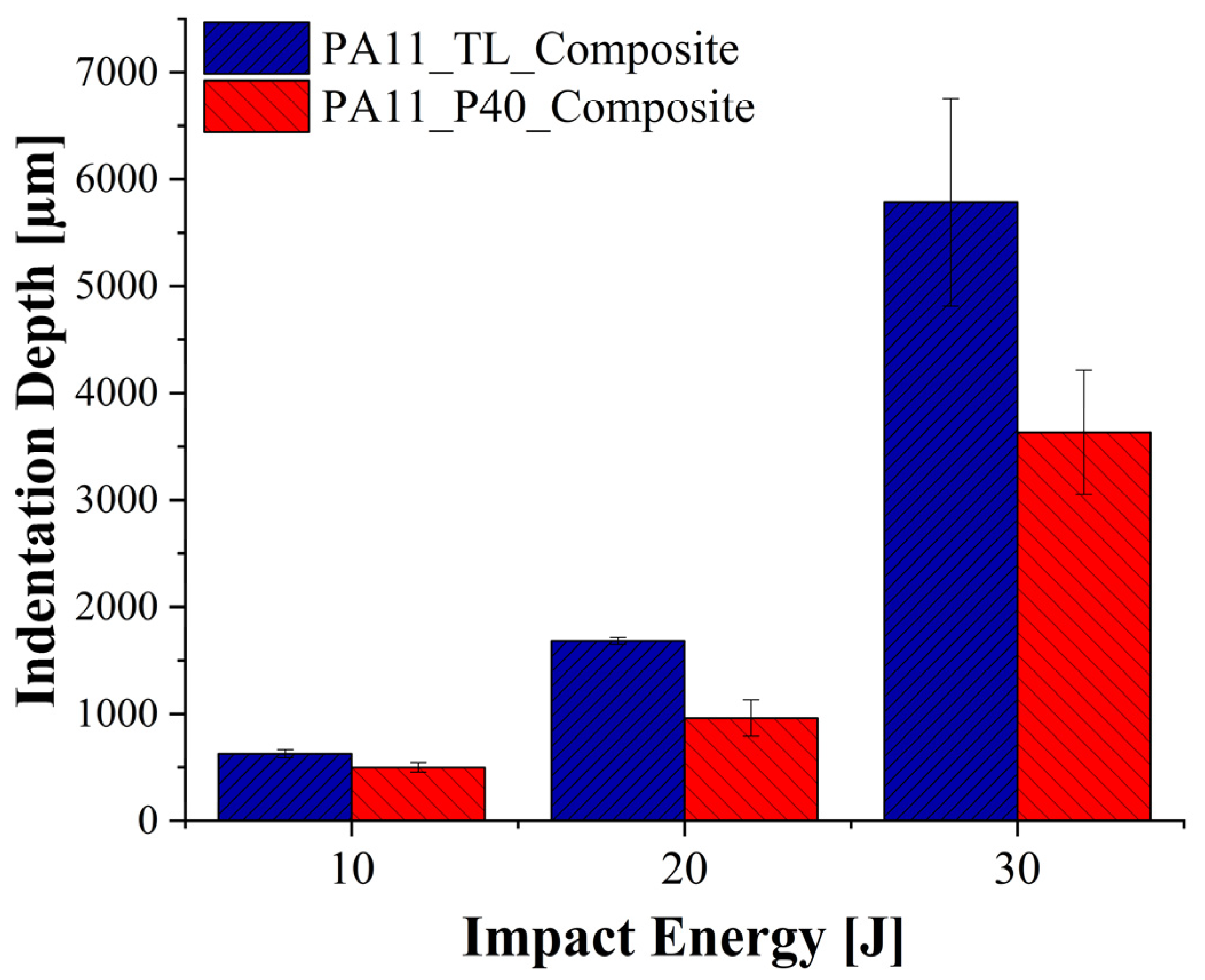

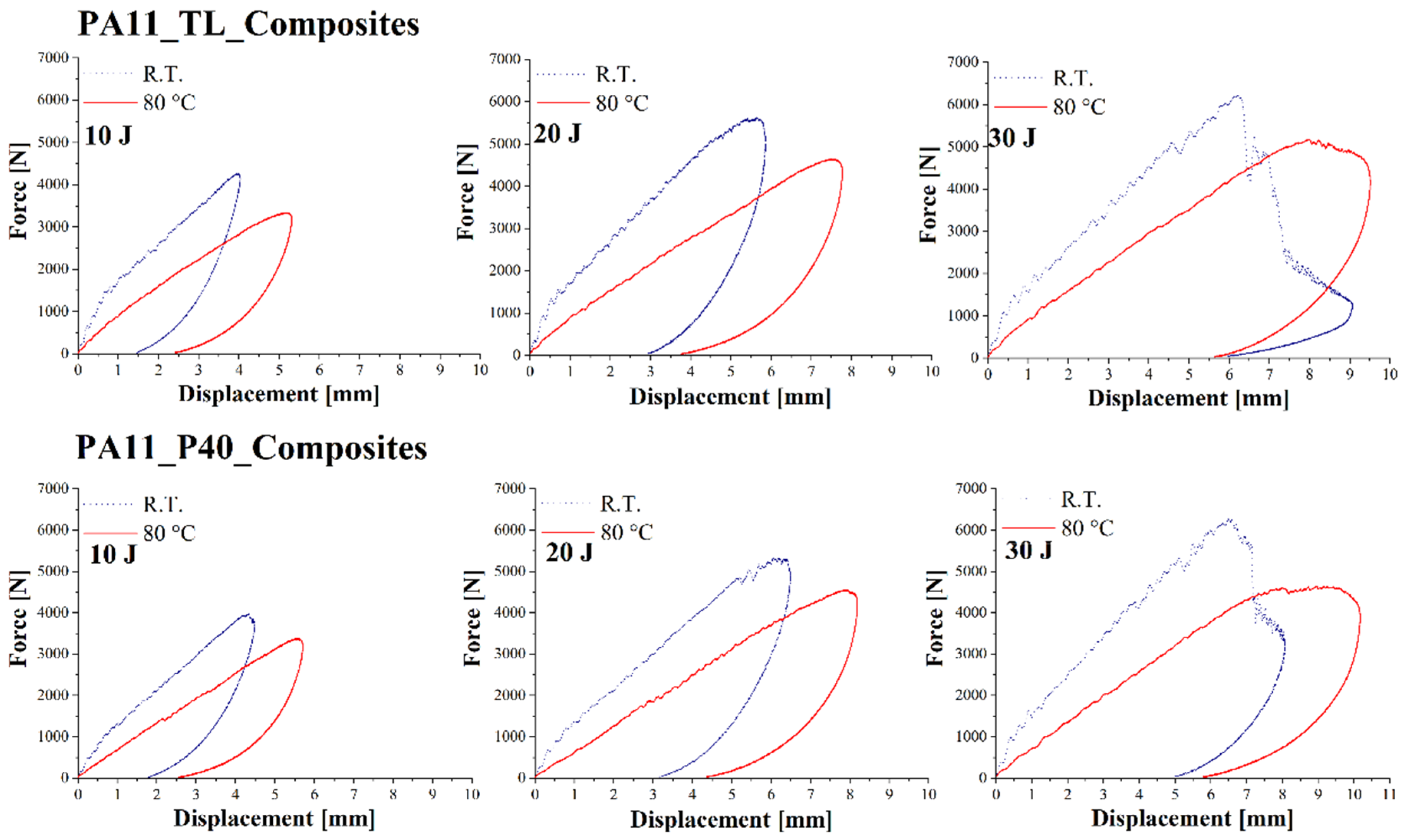

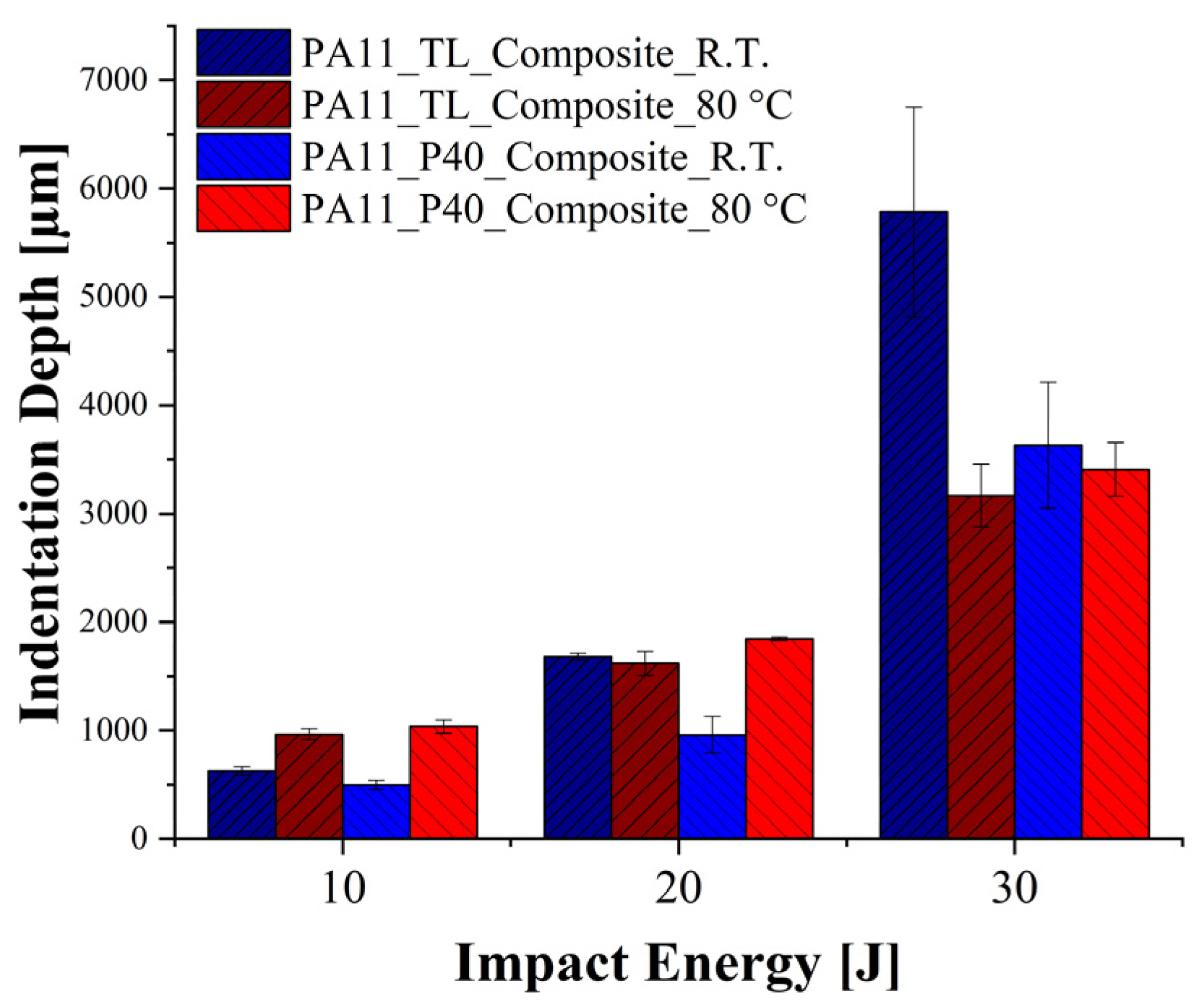

3.2. Low-Velocity Impacts

4. Conclusions

- A decrease in melting and crystallization temperatures resulting from thermal analysis as a result of plasticizer introduction, with clear advantages in terms of processability and composite manufacturing.

- A reduction in the laminates’ glass transition temperature as a consequence of hydrogen bond ruptures between amide groups, thus entailing the increased flexibility of the laminates.

- A great potential to replace traditional synthetic composites in terms of dynamic loading, displaying an impact response comparable to that of PP/glass fibers reported in the literature.

- A significant improvement in impact resistance with respect to PA11/flax composite and slightly lower performance than PA11/basalt laminates was reported in previous works, thus proving that hybridization is the best compromise between good mechanical properties and composite sustainability.

- Plasticizer addition provides a significant improvement in composite toughness, especially at room temperature, with a decrease in the permanent indentation and a delay of penetration phenomena fundamental to preserving the laminates’ integrity and damage tolerance.

- The plasticizer effect is less prominent at +80 °C due to the matrix transition from a glassy to a rubbery state.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Plastic Europe; Association of Plastics Manufacturers. Plastics—The Facts 2021. An Analysis of European Plastics Production, Demand and Waste Data. 2021, p. 34. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2021/ (accessed on 1 March 2022).

- Market Research Report by Fortune Business Insights. In Nylon Market Size by Type, by Application and Regional Forecast, 2020–2027; Fortune Business Insights: Baner, India, 2020; p. 135. Available online: https://www.fortunebusinessinsights.com/nylon-market-102007 (accessed on 1 March 2022).

- Winnacker, M.; Rieger, B. Biobased Polyamides: Recent Advances in Basic and Applied Research. Macromol. Rapid Commun. 2016, 37, 1391–1413. [Google Scholar] [CrossRef] [PubMed]

- Armioun, S.; Pervaiz, M.; Sain, M. Biopolyamides and High-Performance Natural Fiber-Reinforced Biocomposites. In Handbook of Composite from Renewable Materials; Scrivener Publishing: Salem, MA, USA, 2017; Volume 3, pp. 253–270. [Google Scholar]

- Holbery, J.; Houston, D. Natural-Fiber-Reinforced Polymer Composites in Automotive Applications. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Boland, C.S.; De Kleine, R.; Keoleian, G.A.; Lee, E.C.; Kim, H.C.; Wallington, T.J. Life Cycle Impacts of Natural Fiber Composites for Automotive Applications: Effects of Renewable Energy Content and Lightweighting. J. Ind. Ecol. 2016, 20, 179–189. [Google Scholar] [CrossRef]

- Li, M.; Pu, Y.; Thomas, V.M.; Yoo, C.G.; Ozcan, S.; Deng, Y.; Nelson, K.; Ragauskas, A.J. Recent advancements of plant-based natural fiber–reinforced composites and their applications. Compos. Part B Eng. 2020, 200, 108254. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Ray, D.; Mohanty, A.K.; Mishra, M. Natural-fiber composites in the automotive sector. In Properties and Performance of Natural-Fibre Composites; Pickering, K.L., Ed.; Woodhead Publishing: Sawston, UK, 2008; pp. 221–268. ISBN 9781845692674. [Google Scholar]

- Shahzad, A. Hemp fiber and its composites—A review. J. Compos. Mater. 2012, 46, 973–986. [Google Scholar] [CrossRef]

- Amico, S.C.; D’Almeida, J.R.M.; De Carvalho, L.H.; Cioffi, M.O.H. Hybrid Vegetable/Glass fiber composites. In Lignocellulosic Polymer Composites: Processing, Characterization, and Properties; Scrivener Publishing: Salem, MA, USA, 2014; pp. 63–81. [Google Scholar]

- Nurazzi, N.M.; Asyraf, M.R.M.; Fatimah Athiyah, S.; Shazleen, S.S.; Ayu Rafiqah, S.; Harussani, M.M.; Kamarudin, S.H.; Razman, M.R.; Rahmah, M.; Zainudin, E.S.; et al. A review on mechanical performance of hybrid natural fiber polymer composites for structural applications. Polymers 2021, 13, 2170. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.P.S. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Boria, S.; Pavlovic, A.; Fragassa, C.; Santulli, C. Modeling of Falling Weight Impact Behavior of Hybrid Basalt/Flax Vinylester Composites. Procedia Eng. 2016, 167, 223–230. [Google Scholar] [CrossRef]

- Zivkovi, I.; Fragassa, C.; Pavlovi, A.; Brugo, T. Influence of moisture absorption on the impact properties of flax, basalt and hybrid flax/basalt fiber reinforced green composites. Compos. Part B 2017, 111, 148–164. [Google Scholar] [CrossRef]

- Almansour, F.A.; Dhakal, H.N.; Zhang, Z.Y. Investigation into Mode II interlaminar fracture toughness characteristics of flax/basalt reinforced vinyl ester hybrid composites. Compos. Sci. Technol. 2018, 154, 117–127. [Google Scholar] [CrossRef] [Green Version]

- Prasath, K.A.; Krishnan, B.R. Mechanical Properties of Woven Fabric Basalt/Jute Fibre Reinforced Polymer Hybrid Composites. Int. J. Mech. Eng. Robot. Res. 2013, 2, 279–290. [Google Scholar]

- Pandian, A.; Vairavan, M.; Winowlin, J.T.; Uthayakumar, M. Influence of stacking sequence on mechanical properties of basalt-jute fiber-reinforced polymer hybrid composites. J. Polym. Eng. 2012, 32, 547–554. [Google Scholar] [CrossRef]

- Suresh Kumar, C.; Arumugam, V.; Dhakal, H.N.; John, R. Effect of temperature and hybridisation on the low velocity impact behavior of hemp-basalt/epoxy composites. Compos. Struct. 2015, 125, 407–416. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Sarasini, F.; Santulli, C.; Tirillò, J.; Zhang, Z.; Arumugam, V. Effect of basalt fibre hybridisation on post-impact mechanical behaviour of hemp fibre reinforced composites. Compos. Part A Appl. Sci. Manuf. 2015, 75, 54–67. [Google Scholar] [CrossRef]

- Bazan, P.; Nosal, P.; Wierzbicka-Miernik, A.; Kuciel, S. A novel hybrid composites based on biopolyamide 10.10 with basalt / aramid fibers: Mechanical and thermal investigation. Compos. Part B 2021, 223, 109125. [Google Scholar] [CrossRef]

- Armioun, S.; Panthapulakkal, S.; Scheel, J.; Tjong, J.; Sain, M. Biopolyamide hybrid composites for high performance applications. J. Appl. Polym. Sci. 2016, 43595, 1–9. [Google Scholar] [CrossRef]

- Russo, P.; Simeoli, G.; Vitiello, L.; Filippone, G. Bio-Polyamide 11 Hybrid Composites Reinforced with Basalt/Flax Interwoven Fibers: A Tough Green Composite for Semi-Structural Applications. Fibers 2019, 7, 41. [Google Scholar] [CrossRef] [Green Version]

- Oliver-Ortega, H.; Méndez, J.A.; Mutjé, P.; Tarrés, Q.; Espinach, F.X.; Ardanuy, M. Evaluation of thermal and thermomechanical behaviour of bio-based polyamide 11 based composites reinforced with lignocellulosic fibres. Polymers 2017, 9, 522. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ambrosio, J.D.; Balarim, C.V.M.; de Carvalho, G.B. Preparation, Characterization, and Mechanical/Tribological Properties of Polyamide11/Titanium Dioxide Nanocomposites. Polym. Compos. 2016, 37, 1415–1424. [Google Scholar] [CrossRef]

- Adole, O.; Anguilano, L.; Minton, T.; Campbell, J.; Sean, L.; Valisios, S.; Tarverdi, K. Basalt fibre-reinforced high density polyethylene composite development using the twin screw extrusion process. Polym. Test. 2020, 91, 106467. [Google Scholar] [CrossRef]

- Wang, S.; Zhong, J.; Gu, Y.; Li, G.; Cui, J. Mechanical properties, flame retardancy, and thermal stability of basalt fiber reinforced polypropylene composites. Polym. Compos. 2020, 41, 4181–4191. [Google Scholar] [CrossRef]

- Kandemir, A.; Pozegic, T.R.; Hamerton, I.; Eichhorn, S.J.; Longana, M.L. Characterisation of natural fibres for sustainable discontinuous fibre composite materials. Materials 2020, 13, 2129. [Google Scholar] [CrossRef]

- Kannan, T.G.; Wu, C.M.; Cheng, K.B.; Wang, C.Y. Effect of reinforcement on the mechanical and thermal properties of flax/polypropylene interwoven fabric composites. J. Ind. Text. 2013, 42, 417–433. [Google Scholar] [CrossRef]

- Lafranche, E.; Oliveira, V.M.; Martins, C.I.; Krawczak, P. Prediction of injection-moulded flax fibre reinforced polypropylene tensile properties through a micro-morphology analysis. J. Compos. Mater. 2015, 49, 113–128. [Google Scholar] [CrossRef]

- Xiao, X.; Cai, Z.; Qian, K. Structure evolution of polyamide (11)’s crystalline phase under uniaxial stretching and increasing temperature. J. Polym. Res. 2017, 24, 81. [Google Scholar] [CrossRef]

- Ricou, P.; Pinel, E.; Juhasz, N. Temperature Experiments for Improved Accuracy in the Calculation of Polyamide-11 Crystallinity By X-ray Diffraction. Denver X-ray Conf. Appl. X-ray Anal. 2005, 48, 170–175. [Google Scholar]

- Tey, W.S.; Cai, C.; Zhou, K. A Comprehensive Investigation on 3D Printing of Polyamide 11 and Thermoplastic Polyurethane via Multi Jet Fusion. Polymers 2021, 13, 2139. [Google Scholar] [CrossRef]

- Latko, P.; Kolbuk, D.; Kozera, R.; Boczkowska, A. Microstructural Characterization and Mechanical Properties of PA11 Nanocomposite Fibers. J. Mater. Eng. Perform. 2016, 25, 68–75. [Google Scholar] [CrossRef] [Green Version]

- Terinte, N.; Ibbett, R.; Schuster, K.C. Overview on native cellulose and microcrystalline cellulose I structure studied by X-ray diffraction (WAXD): Comparison between measurement techniques. Lenzing. Ber. 2011, 89, 118–131. [Google Scholar]

- De Groote, P.; Rouxhet, P.; Devaux, J.; Godard, P. Infrared Study of the Hydrogen Bonding Association in Polyamides Plasticized by Benzenesulfonamides. Part I: Self-Association in Amide and Sulfonamide Systems; Part II: Amide–Sulfonamide Interaction. Appl. Spectrosc. 2001, 55, 877–887. [Google Scholar] [CrossRef]

- De Groote, P.; Devaux, J.; Godard, P. The effect of benzenesulfonamide plasticizers on the glass transition temperature of an amorphous aliphatic polyamide. Polym. Int. 2002, 51, 40–49. [Google Scholar] [CrossRef]

- Trudel-Boucher, D.; Bureau, M.N.; Denault, J.; Fisa, B. Low-Velocity Impacts in Continuous Glass Fiber/Polypropylene Composites. Polym. Compos. 2003, 24, 499–511. [Google Scholar] [CrossRef]

- Zhao, Z.; Yang, Z.; Zhang, W.; Liu, D.; Li, Y.; Chen, J. Low-velocity impact response and infrared radiation characteristics of thermoplastic/thermoset composites. Chin. J. Aeronaut. 2022, in press. [CrossRef]

- Simeoli, G.; Acierno, D.; Meola, C.; Sorrentino, L.; Iannace, S.; Russo, P. The role of interface strength on the low velocity impact behaviour of PP/glass fibre laminates. Compos. Part B Eng. 2014, 62, 88–96. [Google Scholar] [CrossRef]

- Zulkafli, N.; Malingam, S.D.; Sheikh Md Fadzullah, S.H.; Razali, N. Quasi and dynamic impact performance of hybrid cross-ply banana/glass fibre reinforced polypropylene composites. Mater. Res. Express 2019, 6, 125344. [Google Scholar] [CrossRef]

- Lebaupin, Y.; Hoang, T.T.; Chauvin, M.; Touchard, F. Influence of the stacking sequence on the low-energy impact resistance of flax / PA11 composite. J. Compos. Mater. 2019, 53, 3187–3198. [Google Scholar] [CrossRef]

- Vitiello, L.; Russo, P.; Papa, I.; Lopresto, V.; Mocerino, D.; Filippone, G. Flexural properties and low-velocity impact behavior of polyamide 11/basalt fiber fabric laminates. Polymers 2021, 13, 1055. [Google Scholar] [CrossRef]

- Sergi, C.; Sarasini, F.; Russo, P.; Vitiello, L.; Barbero, E.; Sanchez-Saez, S.; Tirillò, J. Effect of temperature on the low-velocity impact response of environmentally friendly cork sandwich structures. J. Sandw. Struct. Mater. 2022, 24, 1099–1121. [Google Scholar] [CrossRef]

| Tc (°C) | Tm_lower (°C) | Tm_higher (°C) | |

|---|---|---|---|

| PA11_TL_Composite | 161.0 ± 0.1 | 182.8 ±0.3 | 190.6 ± 0.2 |

| PA11_P40_Composite | 153.3 ± 0.1 | 172.1 ± 1.3 | 184.1 ± 0.2 |

| Tg_tanδ (°C) | E′ @ −20 °C (MPa) | E′ @ 0 °C (MPa) | E′ @ 20 °C (MPa) | E′ @ 40 °C (MPa) | E′ @ 60 °C (MPa) | |

|---|---|---|---|---|---|---|

| PA11_TL_Composite | 55.2 ± 0.3 | 11,723.8 ± 8.3 | 11,225.1 ± 12.3 | 10,329.8 ± 21.3 | 8441.7 ± 41.2 | 5924.4 ± 40.4 |

| PA11_P40_Composite | 39.8 ± 0.5 | 10,884.6 ± 20.8 | 9220.1 ± 35.4 | 6936.4 ± 44.2 | 4306.1 ± 34.3 | 3394.9 ± 5.8 |

| Peak Force [N] | Max. Displacement [mm] | Damage Degree | |

|---|---|---|---|

| PA11_TL_Composite_10J | 4257.17 ± 23.84 | 4.00 ± 0.04 | 0.67 ± 0.01 |

| PA11_P40_Composite_10J | 4004.27 ± 44.40 | 4.41 ± 0.10 | 0.69 ± 0.01 |

| PA11_TL_Composite_20J | 5657.17 ± 27.50 | 5.86 ± 0.01 | 0.79 ± 0.01 |

| PA11_P40_Composite_20J | 5503.34 ± 215.42 | 6.36 ± 0.18 | 0.74 ± 0.03 |

| PA11_TL_Composite_30J | 6044.50 ± 247.95 | 9.73 ± 0.95 | 0.97 ± 0.01 |

| PA11_P40_Composite_30J | 6081.62 ± 270.55 | 8.79 ± 1.01 | 0.93 ± 0.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sergi, C.; Vitiello, L.; Russo, P.; Tirillò, J.; Sarasini, F. Toughened Bio-Polyamide 11 for Impact-Resistant Intraply Basalt/Flax Hybrid Composites. Macromol 2022, 2, 154-167. https://doi.org/10.3390/macromol2020010

Sergi C, Vitiello L, Russo P, Tirillò J, Sarasini F. Toughened Bio-Polyamide 11 for Impact-Resistant Intraply Basalt/Flax Hybrid Composites. Macromol. 2022; 2(2):154-167. https://doi.org/10.3390/macromol2020010

Chicago/Turabian StyleSergi, Claudia, Libera Vitiello, Pietro Russo, Jacopo Tirillò, and Fabrizio Sarasini. 2022. "Toughened Bio-Polyamide 11 for Impact-Resistant Intraply Basalt/Flax Hybrid Composites" Macromol 2, no. 2: 154-167. https://doi.org/10.3390/macromol2020010

APA StyleSergi, C., Vitiello, L., Russo, P., Tirillò, J., & Sarasini, F. (2022). Toughened Bio-Polyamide 11 for Impact-Resistant Intraply Basalt/Flax Hybrid Composites. Macromol, 2(2), 154-167. https://doi.org/10.3390/macromol2020010