Abstract

This study assesses the potential for biogas production from wastewater treatment plants (WWTPs) in Adana, Türkiye, and evaluates the feasibility of transitioning a fleet of 83 municipal buses (ranging from 15 to 24 years old) to operate exclusively on biogas generated from these WWTPs. Biogas production data from three distinct WWTPs in Adana were analyzed, revealing a total annual biogas production of 5,394,346 Nm3. Replacing the diesel fleet with biogas-powered buses was found to yield a significant reduction in environmental impacts. CO2 emissions were reduced by 84%, particulate matter emissions decreased by 84.4%, and nitrogen oxides (NOX) dropped by 80%. These findings highlight the substantial potential of wastewater-derived biogas as a renewable energy source in public transportation, not only reducing reliance on non-renewable fuels but also contributing to improved air quality and energy efficiency. Transitioning to biogas-powered buses presents a promising model for sustainable public transportation, with broader implications for reducing the environmental footprint of urban transit systems.

1. Introduction

The global population’s constant growth has led to an energy demand surpassing the current energy supply. Conventional energy sources like coal, natural gas, and oil, which are routinely relied upon, are depleting and releasing greenhouse gases, exacerbating climate change [1].

By the year 2050, it is anticipated that nearly 7 billion individuals will call urban areas home. There were about 7.6 billion people on the planet as of 2018, of whom 4.2 billion lived in cities and 3.4 billion in rural areas [2]. As global energy consumption continues to rise and our finite resources become scarcer, the significance of sustainable energy production becomes more pronounced.

Biogas technology emerges as a promising solution for transforming organic residues into both renewable energy and valuable fertilizers.

Because of its nature and growing amount, wastewater treatment plant waste is a crucial type of waste. Sewage sludge output has dramatically increased due to the fast urban population expansion and industrial operations that these facilities support. In terms of waste management and resource recovery, this substance, which is a result of treating industrial and municipal wastewater, offers both potential and problems. In order to minimize environmental effects and maximize its potential as a source of energy and nutrient recovery, its management calls for sophisticated techniques [3]. The most popular waste management approach supports sustainable development and is consistent with the circular economy’s tenets. The circular economy prioritizes the upper tiers of the waste hierarchy, such as avoidance, reuse, and recycling, since they encourage cleaner production and less waste generation [4]. Importantly, worries about resource depletion and the negative environmental effects causing climate change are addressed by the global adoption of a circular economy model [5]. By focusing on recycling, a circular economy, on the other hand, aims to reduce waste and pollution, conserving the environment [6,7].

Sewage sludge is a byproduct of wastewater treatment, comprising a mixture of organic matter, heavy metals, nutrients, and microorganisms. The sewage sludge contains concentrations mainly between 10−5 and 10−7 CFU g−1 of total coliforms, Escherichia coli, Staphylococcus aureus, Enterococcus sp., Pseudomonas sp., and total mesophilic bacteria [8]. Pathogenic organisms, including Ascaris lumbricoides, Cryptosporidium, and Giardia, can persist in untreated sludge, posing health risks. Helminth eggs, in particular, remain viable for 3–5 years in sludge under unfavorable conditions [9]. Standard disinfection techniques, such as thermal treatment (>70 °C), lime stabilization (pH > 12), and anaerobic digestion (20–30 days at 35–55 °C), significantly reduce pathogen loads, though short-term storage (<1 year) is inadequate for complete deactivation.

In terms of composition, sewage sludge typically contains 40–70% organic matter, 2–7% nitrogen, 0.5–4% phosphorus, and essential micronutrients such as zinc, copper, and iron. The phosphorus availability depends on sludge processing; fresh sludge provides phosphorus comparable to monocalcium phosphate, while dried sludge exhibits lower bioavailability [10]. Over a 2–3 year mineralization period, phosphorus content increases by 20–30%.

Nitrogen in sewage sludge primarily exists in organic forms (60–90%), with ammonium as the dominant inorganic fraction. This enhances soil nitrogen availability, promoting root development and microbial activity. Studies indicate that sewage sludge application can increase soil nitrogen uptake by 15–20%, improving crop yield and soil fertility. However, heavy metal accumulation (e.g., Pb, Cd, Hg) must be monitored to ensure safe agricultural use [11].

Sewage sludge can be treated by wastewater treatment facilities to recover solids, organic materials, and nutrients like phosphorus and nitrogen. After additional processing, the sewage sludge can be fed into an anaerobic digester to create biogas. One sustainable energy source is the biogas created when sewage sludge is anaerobically digested (AD) in municipal wastewater treatment facilities. The organic content in the sludge is broken down by microorganisms in this process, turning it into biogas, which is mostly made up of carbon dioxide and methane. This biogas may be used to produce biofuel, heat, and power. Additionally, AD stabilizes the sludge and reduces its dry matter content. AD is a well-established technique in many nations, and its advantages for treating sewage sludge are widely recognized. A significant portion of the biogas generated in AD plants is now supplied by municipal wastewater treatment facilities, underscoring the vast global potential that is only waiting to be fulfilled [12].

The biogas yield depends on sludge composition, digestion conditions, and process optimization. Typically, the methane content in biogas from sewage sludge ranges between 55 and 65%, with carbon dioxide making up the remaining 35–45% [13]. The biogas yield varies between 200–400 m3 per ton of volatile solids (VSs) added, depending on the retention time, organic loading rate, and temperature [14]. Mesophilic digestion (35–40 °C) is the most common, with a hydraulic retention time (HRT) of 15–30 days, whereas thermophilic digestion (50–55 °C) enhances biogas production but requires more energy input [15].

The organic fraction of sewage sludge consists mainly of proteins, carbohydrates, and lipids, with volatile solids (VSs) content ranging from 60 to 80% of total solids (TS) [16]. The biochemical methane potential (BMP) of primary sludge is higher (300–450 m3 CH4/t VS), while waste-activated sludge (WAS) has a lower BMP (150–250 m3 CH4/t VS) due to its higher microbial cell content and lower biodegradability [13,17]. Co-digestion with food waste or fat, oil, and grease (FOG) can improve methane yield by 20–50% by providing additional readily biodegradable organics [18].

Process stability is crucial in anaerobic digestion, with optimal C/N ratios between 20:1 and 30:1 to prevent ammonia inhibition [19]. The presence of heavy metals, sulfides, or excessive organic loading can lead to process imbalances, reducing biogas output. Upgraded biogas (biomethane) can be injected into the natural gas grid or used as a vehicle fuel, with energy recovery potential ranging from 6 to 7 kWh per cubic meter of methane [20]. Advanced pre-treatment methods such as thermal hydrolysis or enzymatic hydrolysis can enhance digestion efficiency, increasing methane yield by 10–30% while improving sludge dewaterability [15].

In WWTPs, the role of AD extends beyond merely reducing sludge production for ease of handling. The biogas generated from anaerobic digestion processes is a valuable resource with multiple potential applications [21]. Therefore, it is crucial for WWTPs to assess various options for utilizing biogas and choose the most suitable one based on their site-specific conditions.

Each utilization pathway comes with its own set of costs and benefits, as well as varying degrees of environmental and social advantages biogas, the gas produced during anaerobic digestion, typically consists of approximately 60 to 75% methane (CH4) by volume, along with 25 to 30% CO2, and trace amounts of water vapor, N2, H2, H2S, and other gases.

The efficient production of biogas serves as a key indicator of the progress and effectiveness of anaerobic digestion within the reactor, making it a valuable by-product of the overall digestion process. For WWTPs treating domestic wastewater of normal strength, the average gas yield typically falls within the range of 15 to 22 m3 per 103 persons per day [14]. Gas production rates can exhibit significant variations depending on factors such as the biological activity in the digester and the quantity of volatile solids available in the sludge feed.

Another popular alternative is to process the biogas to eliminate carbon dioxide and moisture, thereby elevating the methane content from its initial range of 50–60% to an impressive 99%.

The particles eliminated during the wastewater treatment process can be broken down to create biogas. This biogas potential is approximately one cubic foot of digester gas per 100 gallons of wastewater, according to EPA calculations. According to research conducted by the Water Environment Research Foundation, the Water Environment Federation, and the National Association of Clean Water Agencies, energy produced from WWTPs in the United States may be able to supply 12% of the country’s electricity needs. Additionally, this might encourage the production of renewable natural gas (RNG) for automobiles. Only roughly 1200 of the more than 16,000 WWTPs in the US have anaerobic digesters. In total, 860 of them are equipped to use their biogas on-site [22].

There is substantial potential for producing biogas and/or biomethane in every part of the world, and by 2040, there will be 40% more sustainable feedstocks available for these uses [23].

According to Marinho (2019) [24], biomethane has the potential to reduce emissions of greenhouse gases responsible for the greenhouse effect by up to 300%. This substantial reduction in emissions underscores its environmental advantages. Moreover, it is noted to be more economically advantageous in many cases. When compared to diesel fuel, biomethane significantly reduces the emission of greenhouse gases, thereby making a substantial contribution to the mitigation of global warming. This reduction in greenhouse gas emissions is a key advantage, aligning with environmental sustainability goals and demonstrating the potential for biomethane to be a more environmentally friendly alternative in the transportation sector.

Biogas Composition and Purification Technologies

Methane (CH4) and carbon dioxide (CO2) make up the majority of biogas, with trace amounts of other gases including hydrogen sulfide (H2S), ammonia (NH3), water vapor (H2O), and volatile organic compounds (VOCs) also present. The feedstock and the circumstances of digestion affect the usual composition of biogas. In anaerobic digestion of sewage sludge, biogas generally contains 50–70% CH4, 30–50% CO2, 0.1–3% H2S, and 2–7% H2O [14,20]. The presence of H2S is particularly problematic as it is highly corrosive and toxic, requiring effective removal before biogas utilization.

The removal of CO2 is necessary when upgrading biogas to biomethane (purity > 97% CH4) for injection into the natural gas grid or use as vehicle fuel. Common CO2 removal methods include water scrubbing, amine scrubbing, pressure swing adsorption (PSA), and membrane separation. Water scrubbing operates at 4–10 bar and removes CO2 based on its higher solubility in water, achieving methane concentrations of >97% [25]. Amine scrubbing uses chemical solvents such as monoethanolamine (MEA) or methyldiethanolamine (MDEA) to selectively absorb CO2, achieving high efficiency (>99% CO2 removal) but requiring high regeneration energy [26].

Hydrogen sulfide (H2S) is commonly removed using biological, chemical, and adsorption-based methods. Biological desulfurization relies on sulfide-oxidizing bacteria (e.g., Thiobacillus) in an aerobic reactor to convert H2S into elemental sulfur or sulfate [27]. Chemical scrubbing involves iron-based solutions (e.g., FeCl3 or NaOH) to convert H2S into stable compounds. Adsorption methods, such as activated carbon or iron oxide (Fe2O3) beds, are widely used for low-concentration H2S removal (<1000 ppm) [28]. Advanced methods, such as membrane technology and cryogenic separation, are emerging for high-purity biomethane production, achieving CH4 concentrations of >99% with minimal energy consumption [29].

Efficient biogas purification enhances its energy value and usability while reducing environmental emissions. The purified biomethane has an energy content of ~35.8–39.8 MJ/m3, comparable to natural gas [26]. The choice of purification technology depends on cost, efficiency, and end-use requirements, with an increasing preference for low-energy and sustainable methods such as membrane separation and biological desulfurization.

Biogas, a gas combination of methane, carbon dioxide (CO2), and trace quantities of other gases, is created when organic matter is anaerobically digested in an oxygen-deficient environment. The kind of feedstock and the production process used can affect the precise makeup of biogas. The following are the main technologies used to produce biogas;

Biodigesters: These are sealed systems, such as tanks or containers, where naturally existing microbes break down organic material combined with water. Usually, impurities and surplus moisture are eliminated before biogas is used.

Landfill gas recovery systems: At landfills, biogas is created when municipal solid waste (MSW) breaks down anaerobically. Pipes and extraction wells can be used to gather this gas, and compressors are frequently used to move it to a central collection location.

Wastewater treatment plants: These establishments are capable of removing solids, organic materials, and nutrients such as phosphorus and nitrogen from sewage sludge. Sewage sludge can be utilized as an input for anaerobic digestion to produce biogas with further treatment.

Biogas primarily consists of methane (CH4, approximately 50–60%) and carbon dioxide (CO2, around 40%), with trace amounts of impurities such as nitrogen (N2), hydrogen sulfide (H2S), and water vapor (H2O). The composition of these components fluctuates depending on the feedstock used. To utilize biogas as a vehicle fuel, a two-step process of cleaning and upgrading (mainly involving CO2 removal) is essential. This process achieves two main objectives: reducing harmful contaminants and increasing the gas’s energy content. As a result, biogas can be efficiently adopted as an alternative to traditional fuels, particularly natural gas [30].

As a result of this compositional heterogeneity, biogas’s lower heating value (LHV) varies from around 16 megajoules per cubic meter (MJ/m3) to 28 MJ/m3 or more. Depending on its particular composition and use, biogas can be used directly to produce heat and power or as a culinary energy source [23].

Compressed natural gas (CNG) is recognized as a viable substitute for conventional transportation fuels such as diesel and gasoline. Because natural gas has a high octane value (4110), engines may have a higher compression ratio, which increases thermal efficiency. The decrease in vehicle emissions is an additional advantage of using CNG. Natural gas has the lowest carbon-to-hydrogen ratio of any hydrocarbon fuel, which significantly lowers carbon-based emissions (CO, CO2, and HC). Well-to-wheel greenhouse gas emissions for fossil natural gas decreased from around 93 g/MJ for gasoline and diesel to approximately 74 g/MJ, per a modeling study. Furthermore, CNG is a lead-free fuel. Currently, there are over 8.7 million CNG vehicles on the road, primarily in Argentina, Pakistan, Brazil, India, Russia, Iran, and Italy. Ten to twenty percent of all fleets in some nations, such as Argentina and Italy, are CNG-powered. In contrast to the 120,000 gas stations in the US, there are only around 1000 public and private CNG stations, and the number of CNG stations is expected to grow quickly [31,32,33,34].

Compressing cleaned biogas with 97% CH4 purity yields Bio-CNG, which is quite comparable to ordinary CNG. Compressed biomethane is another name for bio-CNG. The performance of a constant-speed internal combustion engine using CNG and Bio-CNG was evaluated by Chandra et al. [35], who stated that the engines’ braking power output, specific gas consumption, and thermal efficiency were comparable. Subramanian et al. [36] indicated that there is no discernible difference between CNG and Bio-CNG in terms of vehicle emissions and fuel efficiency. Biogas’s lifecycle greenhouse gas emissions have been demonstrated to be 80% lower than those of gasoline since it is made from renewable resources or waste [37].

The purified form of biogas is referred to as bio-substitute natural gas (BioSNG) [38]. BioSNG can be seamlessly integrated into the natural gas grid for broader utilization or used as fuel for natural gas vehicles. Several Swedish cities have already adopted BioSNG for public transport buses, effectively replacing diesel and reducing dependency on fossil fuels. This transition represents a sustainable solution to combat air pollution [39].

Renewable methane has the potential to replace natural gas in current car fleets, lowering emissions of air pollutants including NOX and greenhouse gases (GHGs). Future renewable methane production may come from gasification of biomass, renewable electricity-powered methane synthesis, or power-to-gas. Currently, the majority of renewable methane is produced by processes that capture the gas from the anaerobic decomposition of organic matter. The performance and availability of the feedstocks used to create gas have a significant influence on the GHG impact of renewable methane as well as the potential scope of its adoption [40].

Depending on the feedstock, biogas’s methane concentration varies; generally speaking, biogas made from sewage sludge has a greater methane percentage than biogas from other sources.

Lower methane values may serve as an indicator of potential microbiological issues within the process, which could result from factors such as temperature fluctuations or overloading.

Typically, the methane content in biogas falls within a range of 63% to 67% CH4, based on findings from studies by Bachmann (2009), Kind et al. (2012), and Kolisch (2010) [41,42,43].

However, efficient biogas production becomes meaningful only when the produced biogas is effectively utilized. The parameter “utilization of the produced biogas” quantifies the proportion of the generated biogas that is used for power, heat, or biofuel production, with the remaining portion typically being flared.

The optimal range for the utilization of produced biogas is generally between 95% and 99% [44]. This indicates that minimizing the flaring of biogas and maximizing its conversion into useful forms of energy is a key goal for sustainable biogas production.

As global urbanization accelerates, the demand for sustainable energy solutions in transportation is becoming increasingly urgent. The transportation sector accounts for ~25% of global CO2 emissions, with heavy reliance on fossil fuels such as diesel and gasoline [45]. Biogas, derived from wastewater treatment plants (WWTPs), represents a promising renewable energy source capable of significantly reducing emissions while promoting waste valorization. Anaerobic digestion (AD) of sewage sludge not only stabilizes waste but also generates biogas with a methane content ranging from 55% to 65%, depending on feedstock composition and digestion conditions [13].

Despite its potential, the large-scale integration of biogas into urban transportation presents several technical and economic challenges. Biogas upgrading is essential to remove CO2 (typically 30–45%) and hydrogen sulfide (H2S, 0.1–3%) to achieve a methane purity of >97%, making it suitable for use as compressed biomethane (Bio-CNG) [20]. However, upgrading technologies such as pressure swing adsorption (PSA), water scrubbing, and amine scrubbing require substantial infrastructure investments, with estimated costs ranging from €500,000 to €2 million per refueling station, depending on capacity and location [46]. Additionally, modifying existing diesel buses for biomethane operation involves engine and fuel system retrofitting, with costs estimated at $25,000 per vehicle [47].

This study explores the technical feasibility, energy potential, and environmental impact of integrating wastewater-derived biogas into municipal transportation systems. Unlike previous research that focuses primarily on biogas production and purification, this work examines the challenges of real-world implementation, including infrastructure requirements, policy barriers, and economic considerations. By addressing these key factors, this study contributes to the broader discussion on decarbonizing urban transport and advancing circular economy principles through waste-to-energy strategies.

The primary objectives of this study are twofold: (1) to analyze the biogas production process within wastewater treatment facilities, highlighting key operational parameters and energy yields; and (2) to conduct a comparative analysis of the environmental impacts of biogas-powered buses versus conventional diesel buses, focusing on emissions reduction, energy efficiency, and broader environmental impacts.

The study aims to contribute to the growing discourse on renewable energy solutions in urban settings by advancing circular economy principles and reducing the carbon footprint of municipal transportation systems. To achieve these objectives, a comprehensive analysis of the wastewater generated in Adana Province was conducted, assessing its biogas potential and evaluating the environmental impacts of utilizing this biogas in the municipal fleet.

2. Adana Wastewater Treatment Plants

In the service area of Adana Province, based on the latest census data, the total population stands at 2,258,718. In 2021, approximately 185,497,216 m3 of wastewater was generated within this area. That year, the Seyhan Wastewater Treatment Plant, operated by the Wastewater Treatment Department, processed 56,512,757 m3 of wastewater, while the Yüreğir Plant handled 25,294,690 m3.

The Ceyhan Plant treated 11,778,592 m3, the Kozan Plant processed 8,030,000 m3, the Karaisalı Plant treated 451,762 m3, and the Yumurtalık Plant processed 328,500 m3, bringing the total volume of wastewater treated in Adana service area to 102,396,301 m3. In 2021, a total of 5,394,346 Nm3 of biogas was generated from wastewater treatment processes, producing 10,001,480 kWe of electrical energy. This energy production contributed approximately 7,500,000 TL back to the national economy [48].

At the Seyhan Wastewater Treatment Plant, which has been designed with a full biological treatment approach, sludge treatment is an integral part of the process. This facility utilizes methane gas, which is generated from the sludge, to produce electrical energy, a resource that proves valuable throughout the year, including both summer and winter seasons. Considering the fluctuating energy demands across different seasons, the plant manages to fulfill approximately 70% of its electrical energy requirements. On a daily basis, the facility generates an average of 80–90 tons of sludge, and this sludge contains around 25% dry matter. Following the treatment process, the sludge undergoes dewatering and is subsequently stored within the facility’s designated storage area.

However, it is important to note that the final disposal of the sludge is handled in collaboration with the Sofulu Integrated Solid Waste Facility. Following temporary on-site storage and dewatering, the sludge is sent to the Sofulu facility for controlled, long-term storage. Interestingly, the sludge’s dryness level rises dramatically throughout the summer, up to 90%, which can support more sustainable and effective storage methods. This all-encompassing strategy for managing sludge guarantees efficient wastewater treatment while improving energy generation and residual material handling.

The main facility for gathering and cleaning wastewater from the districts of Yüreğir and Sarıçam is the Yüreğir Wastewater Treatment Plant. The entire biological treatment process served as the foundation for the design of this cutting-edge facility. This wastewater treatment plant’s sustainable approach to sludge treatment is one of its noteworthy qualities. Electrical energy is produced by using methane gas, a byproduct of the sludge treatment process. Throughout the year, even in the summer and winter, this energy source is beneficial. The facility can really fulfill around 60% of its electrical energy demands thanks to it, which increases energy efficiency. On a daily basis, the facility processes an average of 50–60 tons of sludge, with this sludge containing approximately 25% dry matter. To manage this sludge effectively, it is extracted and then subjected to a drying process. The drying is achieved by spreading the sludge on the designated empty areas reserved for expansion within the facility. Once properly dried, the sludge is transported and disposed of at the Sofulu Solid Waste Storage Area, which belongs to the Metropolitan Municipality of Adana.

Table 1 shows the yearly amount of wastewater treated in Adana Province (m3).

Table 1.

Wastewater treated by year (m3) in Adana Province.

This comprehensive approach to wastewater and sludge management at the Yüreğir Wastewater Treatment Plant highlights a commitment to both environmental responsibility and resource efficiency. It not only ensures the proper treatment of wastewater but also maximizes energy production and optimizes the handling of residual materials, contributing to the sustainability of the region’s infrastructure.

The Ceyhan Wastewater Treatment Plant is situated in the northwest of the Kelemeti District within the Ceyhan District. It covers an expansive area of 77,000 square meters. This wastewater treatment facility was established with a forward-looking approach, considering two stages of development. The first stage is expected to be operational by 2025, while the second stage is designed to be fully functional, taking into account the target year of 2040.

Table 2 presents the yearly amount of biogas and electricity production for Adana city.

Table 2.

Biogas and electricity production by year for Adana.

A noteworthy aspect of this wastewater treatment plant is its innovative approach to energy generation. It harnesses biogas that is produced during the disposal of the resulting sludge as a source of electrical energy. This sustainable practice significantly contributes to the facility’s power needs, and in fact, a substantial portion of the plant’s electrical energy requirements are met through this biogas generation process. Furthermore, plans are in place to enhance the facility’s energy production capabilities by constructing additional facilities on-site. This expansion will not only increase electrical energy generation but also allow for the surplus energy to be transferred to the main electrical grid, contributing to the broader energy supply in the region. This approach aligns with a commitment to both wastewater treatment and sustainable energy practices, promoting environmental responsibility and resource efficiency. The study quantified the potential impacts through a life cycle assessment, highlighting the environmental advantages of using biomethane as a road transport fuel compared to traditional fossil fuels when performing the same transportation function. This underscores the potential for biomethane to contribute to environmental sustainability in the transportation sector [49].

3. Materials and Methods

This research focused on evaluating biogas derived from wastewater as a renewable energy source for transportation. Adana Province’s Seyhan, Yüreğir, and Ceyhan wastewater treatment plants provided detailed information on biogas production rates as part of the primary data collection process. The technique included meticulous documentation of annual wastewater quantities, a chemical analysis of the biogas produced, the use of the biogas to power municipal buses (ages 15–24), and an evaluation of the application’s environmental benefits. In addition, the research aimed to assess the feasibility of retrofitting current automobiles, calculate the possible financial and environmental advantages, and create a strategic implementation strategy. By combining these methods, the study offers a comprehensive examination of biogas production from wastewater treatment facilities and explores its potential as a sustainable energy source for urban transportation. Table 3 presents the age distribution of diesel-powered buses in the municipal fleet assessed in this study. Buses aged 15 to 24 years were selected for conversion to a bio-methane fuel system due to their high diesel consumption and lower fuel efficiency.

Table 3.

Age distribution of buses in the municipal fleet (2022).

The biogas composition analysis was conducted on samples collected from the wastewater treatment facility to determine the concentrations of methane (CH4), carbon dioxide (CO2), oxygen (O2), nitrogen (N2), hydrogen (H2), carbon monoxide (CO), and hydrogen sulfide (H2S), as well as the net calorific value (NCV). A biogas compact analyzer was used for the biogas composition analysis. Biogas samples were collected directly from the anaerobic digesters using a probe and a heated sampling line to prevent condensation and maintain sample integrity. To ensure sensor accuracy, the gas was conditioned prior to analysis using built-in moisture separators, coolers, or dryers, effectively removing water vapor and particulates. The system automatically adjusted for environmental variations to minimize measurement errors. Methane (CH4) and carbon dioxide (CO2) components were quantified using Non-Dispersive Infrared (NDIR) spectroscopy. This method relies on the fact that CH4 and CO2 absorb infrared light at specific wavelengths, allowing for precise concentration determination. The NDIR analyzer was calibrated using certified reference gases before each measurement cycle.

Electrochemical sensors were utilized to measure O2 and H2S concentrations. These sensors detect gases through electrochemical reactions that generate electrical signals proportional to gas concentration. Periodic calibration with standard gas mixtures ensured sensor accuracy.

A thermal conductivity detector (TCD) was used to determine the levels of H2 and N2, as they possess distinct thermal conductivity properties compared to other gases in the sample. Carbon monoxide (CO) was analyzed using an electrochemical sensor designed to detect low CO concentrations with high sensitivity.

The net calorific value (NCV) of biogas was estimated based on the measured CH4 and CO2 concentrations using established empirical correlations. The energy content was expressed in mega-joules per cubic meter (MJ/m3) to evaluate the fuel potential of the biogas.

Measurement data were processed in real time and displayed using digital protocols such as Modbus or analog signals (4–20 mA), enabling seamless integration with external monitoring systems. The analyzer was designed for harsh operating conditions, with corrosion-resistant components ensuring durability in environments containing high levels of H2S and moisture.

These methodologies provided precise, continuous, and reliable monitoring of the biogas composition, facilitating its evaluation as a potential alternative energy source for transportation and other applications.

Hydrogen sulfide (H2S) is a major contaminant in biogas, with high concentrations in untreated gas. High H2S levels (ranging from 100 to 5000 ppm) pose severe corrosion risks for engines and lead to the formation of sulfur oxides (SOX) during combustion, which contribute to air pollution and acid rain [13]. If left unaddressed, H2S leads to severe engine corrosion and toxic sulfur emissions. To mitigate these issues, a biological scrubber system was utilized, operating under controlled conditions with sulfide-oxidizing bacteria (e.g., Thiobacillus spp.) that convert H2S into elemental sulfur or sulfate.

The biogas purification system in Adana is designed to remove hydrogen sulfide (H2S) and ensure its usability for energy applications. The purification process involves iron-based chemical precipitation, dry chemical iron oxide desulfurization, and biological scrubbing to achieve gas quality improvement.

Iron salts, such as iron sulfate (FeSO4) or iron chloride (FeCl3), are dosed into the system to react with H2S, forming insoluble iron sulfide (FeS). This compound is separated from the biogas stream, reducing H2S concentrations to acceptable levels.

A dry chemical desulfurization unit utilizing iron oxide-based media is implemented to further remove H2S from biogas. The desulfurization unit consists of a stainless steel reactor tank, desulfurization mass (iron oxide-based adsorbent material), and a biogas–air mixture control system. In the desulfurization process, the H2S-containing biogas enters through the lower conical section of the unit. The gas then passes through the desulfurization mass, where H2S is adsorbed and converted into a stable form. The treated biogas exits from the upper section of the unit. The desulfurization mass remains active until sulfur loading reaches 25% by weight, after which it requires replacement or regeneration.

In addition to chemical methods, a biological scrubber system is utilized for H2S removal. The system employs sulfide-oxidizing bacteria, which convert H2S into elemental sulfur or sulfate, reducing its concentration to environmentally acceptable levels. This biological process operates under controlled conditions, ensuring optimal microbial activity and efficient desulfurization.

Following purification, the biogas is utilized to power generators, facilitating an effective energy recovery process. Future advancements may include the integration of CO2 separation technologies for the production of transportation-grade biomethane.

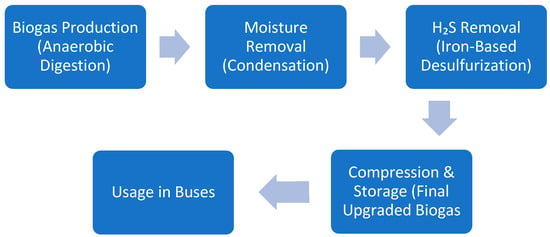

To enhance the methane content in biogas and upgrade it to bio-methane standards, the following flowchart system is presented in Figure 1.

Figure 1.

Flowchart of biogas utilization in buses.

Figure 1 illustrates the sequential stages of biogas purification for use as a transportation fuel. The process begins with biogas collection from anaerobic digestion of wastewater sludge, followed by moisture removal to protect downstream equipment. Hydrogen sulfide (H2S) is eliminated using chemical or biological desulfurization methods, ensuring safety and reducing engine corrosion risks. The purified methane is ready for use as fuel in municipal buses and can be compressed under pressure. By increasing methane purity to over 90% and reducing CO2 to below 5%, this purification method enhances the energy content and suitability of biogas as an alternative to fossil fuels.

These purification techniques extend the lifespan of engine components, lower maintenance costs, and improve overall fuel efficiency. Moreover, reducing H2S levels ensures that biogas combustion remains environmentally friendly, minimizing emissions and enhancing sustainability in municipal transportation.

4. Results

The biogas produced at the Adana wastewater treatment plants shows great potential as a fuel source for municipal buses, provided it undergoes targeted purification to remove impurities and increase methane content. Table 4 shows the biogas content from the three wastewater treatment plants averaged. The average biogas of three plants currently contain 65% methane, which is a strong starting point for energy production, but its efficiency as a fuel is diminished by the presence of carbon dioxide (30%) and hydrogen sulfide (H2S) at a high concentration of 5000–5500 ppm.

Table 4.

Biogas content from Adana’s wastewater treatment plants.

The high H2S content is especially problematic, as it can cause significant corrosion in engines and emit harmful sulfur compounds upon combustion. Therefore, this study’s main objective is to increase the methane concentration while removing H2S and reducing CO2, creating a cleaner, more energy-dense fuel suitable for use in buses.

Unprocessed biogas undergoes cleaning before upgrading, as impurities present can damage the upgrading systems. For instance, hydrogen sulfide (H2S) is highly corrosive, and particulates can lead to mechanical abrasion. Certain contaminants, like siloxanes, pose issues when biogas is used in combustion engines. The methods and points of removal for various impurities in raw biogas vary according to the digestion and upgrading technologies in use, as well as the gas quality standards. Biogas with H2S levels around 3000 ppm can be chemically treated to reduce impurities to < 30 ppm for further processing in the upgrading unit. An alternative method involves injecting oxygen (O2) or air into the digester to enable hydrogen sulfide removal via biological oxidation. Oxygen is often favored over air to avoid the introduction of nitrogen (N2), which is challenging to remove from biogas. If air is used, introducing N2 may require additional propane during grid injection to raise the biomethane’s calorific value to match that of natural gas. Biogas facility operators need to be mindful of the impurities and applicable limits when determining effective impurity removal methods.

Following these purification procedures, it was obtained that the methane concentration would surpass 90%, while CO2 would drop to less than 5% and H2S levels would fall below 10 parts per million. The net calorific value of the resultant biogas would rise from around 25 MJ/kg to 35 MJ/kg, which is equivalent to that of conventional fuels. With a lower environmental effect and comparable energy performance to fossil fuels, this purified biogas would be an excellent fuel source for buses.

There are several financial and environmental advantages to using purified biogas in city buses. Compared to conventional fuels like diesel, the higher methane concentration and fewer impurities would enhance combustion efficiency, lower greenhouse gas emissions, and generate fewer pollutants. Removing corrosive H2S also means reduced engine wear and maintenance costs, further enhancing the economic viability of biogas as a transportation fuel. Additionally, converting biogas into vehicle fuel supports a circular economy, turning waste into a valuable resource, reducing reliance on imported fossil fuels, and aligning with Adana City’s goals under its Sustainable Energy and Climate Action Plan [50,51].

This study estimates the biogas consumption required to operate a fleet of diesel buses in Adana, utilizing the biogas produced from the city’s wastewater treatment facilities.

The annual biogas production from the wastewater treatment plants in Adana is approximately 5,394,346 Nm3 in 2021. This study explores the feasibility of using biogas as an alternative fuel for a fleet of 83 diesel buses, specifically targeting those aged 15–24 years.

The total annual mileage for 83 buses is calculated as follows:

Total mileage/annually = 83 buses × 30,000 km/year = 2,490,000 km/year

Based on an average fuel consumption of 0.48 L per km [52], the annual diesel consumption is estimated as follows:

2,490,000 km × (0.48 L/km) = 1,195,200 L/year (diesel consumption)

An average daily biogas usage of approximately 0.739 m3 of biogas/km for a bus was used for this study. These data were employed in estimating the number of buses that could be powered by biogas. That means for a year and for 83 biogas buses annually, there is 1,840,110 m3 of biogas that is needed. That amount equals the ~34% of biogas production per year [53].

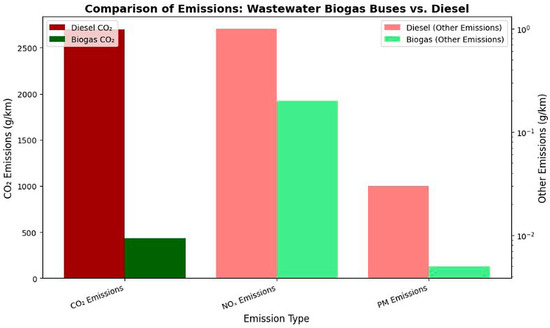

Given the total annual biogas production of 5,394,346 Nm3, this biogas volume is sufficient to meet the fuel requirements of the bus fleet, indicating a feasible pathway for sustainable transportation in the region. Table 5 and Figure 2 present a side-by-side comparison of key environmental impact parameters for diesel-powered and biogas-powered municipal buses. The results demonstrate that using purified biogas as a transportation fuel significantly reduces CO2 emissions by 84%, nitrogen oxides (NOX) by 80%, and particulate matter (PM) by 84.4% while maintaining energy efficiency. Advanced combustion techniques are required to minimize methane emissions associated with biogas combustion. These findings highlight the environmental benefits of transitioning to biogas-fueled transportation in urban areas.

Table 5.

Comparative environmental impact of diesel and biogas buses.

Figure 2.

Comparison of emissions: wastewater biogas buses vs. diesel.

Following purification, the methane concentration increased from 65% to above 90%, while CO2 was reduced to below 5% and H2S to less than 10 ppm. This improvement enhanced the net calorific value (NCV) from 25 MJ/kg to 35 MJ/kg, making the purified biogas comparable to conventional fossil fuels. Given Adana’s total annual biogas production of 5,394,346 Nm3, the estimated energy output is approximately 192,000 GJ, which could replace ~1.2 million liters of diesel annually, reducing CO2 emissions by approximately 7000 tons per year. These findings confirm the feasibility of using purified biogas as a sustainable fuel alternative.

This study not only confirms the viability of wastewater-derived biogas as a transportation fuel but also highlights its environmental and economic advantages. Compared to conventional fossil fuels, purified biogas reduces CO2 emissions by 84%, NOX emissions by 80%, and PM emissions by 84.4%. The findings align with previous research on biogas upgrading but provide a more practical perspective by integrating purification, energy potential calculations, and transportation applications. The adoption of such systems in municipal fleets could significantly contribute to urban decarbonization efforts and circular economy principles. Further studies will focus on optimizing purification efficiency and assessing the long-term economic viability of large-scale implementation.

4.1. Economic Feasibility: Cost Comparison of Biogas and Diesel

The economic feasibility of biogas as a transportation fuel presents significant long-term advantages over diesel. While diesel fuel prices fluctuate due to global market dynamics, biogas production costs remain relatively stable and predictable. Studies indicate that biogas production costs typically range between 0.40 and 0.60 USD/Nm3, making it 30–50% more cost-effective than diesel in the long run [14].

For instance, the annual production of 5,394,346 Nm3 of biogas from wastewater treatment plants in Adana is sufficient to fuel 83 municipal buses. Considering that 1 Nm3 of biogas provides an energy equivalent to approximately 0.6 L of diesel, the transition from diesel to biogas could significantly reduce fuel expenses [13]. Moreover, utilizing locally produced biogas reduces dependence on imported fossil fuels, contributing to economic resilience and energy security.

4.2. Environmental Impact Analysis

4.2.1. Long-Term Benefits for Air Quality and Climate Change Mitigation

The adoption of biogas as a transportation fuel has significant long-term environmental benefits, particularly in urban air quality improvement and climate change mitigation. By replacing diesel with biomethane, municipal buses can achieve an 84% reduction in CO2 emissions, equating to an estimated 15,000–18,000 metric tons of CO2 reduction per year in Adana’s public transportation sector. This substantial reduction aligns with global climate commitments, such as the Paris Agreement, and contributes to municipal decarbonization goals.

In addition to CO2 mitigation, particulate matter (PM) emissions decrease by 84.4%, which significantly improves urban air quality and reduces the risk of respiratory diseases. Nitrogen oxide (NOX) emissions, a major contributor to smog and acid rain, are reduced by 80%, directly benefiting public health and the environment.

Beyond local air quality benefits, biogas utilization contributes to circular economy principles by transforming organic waste into a high-value energy resource. The integration of wastewater-derived biogas into urban transportation exemplifies waste-to-energy solutions, reducing landfill dependency while creating a renewable fuel alternative.

4.2.2. Risks and Limitations

Despite its numerous advantages, biogas adoption in urban transportation presents certain challenges. One primary limitation is scalability, as expanding biogas-based public transportation requires significant infrastructure investments, technological advancements, and policy support. Additionally, biogas production rates vary due to fluctuations in organic waste availability, wastewater treatment efficiency, and seasonal feedstock variations. Ensuring a consistent and stable fuel supply may require advanced storage solutions or hybrid energy models incorporating solar or hydrogen technologies.

Another significant challenge is retrofitting older diesel buses to operate on biomethane. While new buses designed for compressed biomethane operation are available, adapting existing fleets requires engine modifications, fuel system upgrades, and investments in fueling infrastructure. The economic feasibility of such transitions must be weighed against potential government incentives, carbon pricing policies, and long-term fuel cost savings.

4.2.3. Policy Implications and Future Outlook

The findings of this study hold significant policy implications for cities seeking to reduce fossil fuel dependency and transition to sustainable transportation systems. Municipal governments and policymakers should consider incentivizing biogas infrastructure development through subsidies, tax exemptions, and carbon credits to accelerate adoption. Moreover, public–private partnerships (PPPs) can play a crucial role in scaling up biogas production and fueling infrastructure.

Future research should focus on optimizing purification technologies, improving biogas distribution networks, and assessing large-scale economic feasibility. Additionally, cross-city collaborations could explore replicating Adana’s biogas integration model in other municipalities, providing a scalable blueprint for waste-to-energy solutions in urban mobility. By aligning with circular economy principles, reducing greenhouse gas emissions, and enhancing energy security, biogas-powered transportation offers a replicable, long-term solution for cities worldwide.

5. Conclusions

This study evaluated the potential of biogas, specifically biomethane, as a viable alternative biofuel for municipal transportation. Given the increasing environmental concerns related to fossil fuel dependency and rising greenhouse gas emissions, transitioning to biomethane presents a sustainable and economically viable solution. The need for scaling up renewable fuel adoption is particularly critical as cities worldwide seek to diversify their energy sources and reduce their carbon footprint. Our findings indicate that replacing diesel buses with biomethane-powered buses in Adana can achieve an 84% reduction in CO2 emissions, an 84.4% decrease in particulate matter emissions, and an 80% reduction in nitrogen oxide (NOX) emissions. Furthermore, the methane purity of biogas can be increased to over 90%, with a net calorific value enhancement from 25 MJ/kg to 35 MJ/kg, making it a high-quality fuel suitable for large-scale urban transportation. The study also demonstrated a 34% potential diesel fuel replacement in Adana’s municipal bus fleet, reinforcing the feasibility of biogas as a key contributor to clean energy transitions.

To fully realize the potential of biomethane as a long-term sustainable transportation fuel, future work should focus on scaling up biogas utilization, and expanding its adoption beyond municipal buses to include taxis, commercial fleets, and heavy-duty transport. Additionally, integrating biogas with other renewable energy systems, such as hybrid models combining biogas with solar or hydrogen fuel technologies, could further enhance efficiency and sustainability. Optimizing purification technologies, particularly in CO2 and H2S removal, will also be crucial for maximizing fuel quality and yield. Furthermore, policy and infrastructure development is necessary, including government incentives and regulatory frameworks to support widespread biomethane adoption and expand fueling infrastructure for broader accessibility.

This approach not only benefits Adana but also serves as a scalable model for other cities seeking to transition towards low-carbon, renewable transportation systems. By leveraging wastewater-derived biogas, urban areas can enhance energy security, reduce air pollution, and contribute to global climate change mitigation efforts. Future studies should explore cross-city implementation strategies, economic incentives, and public–private partnerships to accelerate the shift towards biogas-powered sustainable transportation networks. These improvements lead to significant reductions in greenhouse gas emissions and air pollutants, reinforcing the environmental and economic benefits of biogas utilization. Future research should focus on optimizing purification methods and scaling up implementation to maximize sustainability impacts.

Funding

This research received no external funding.

Data Availability Statement

No additional data are available online.

Conflicts of Interest

The author declares no conflicts of interest.

References

- You, V.; Kakinaka, M. Modern and Traditional Renewable Energy Sources and CO2 Emissions in Emerging Countries. Environ. Sci. Pollut. Res. 2022, 29, 17695–17708. [Google Scholar] [CrossRef] [PubMed]

- Ritchie, H.; Samborska, V.; Roser, M. Urbanization. Available online: https://ourworldindata.org/urbanization (accessed on 28 November 2024).

- Aydin, K.; Ün, Ç. Development of Solid Waste Management System for Adana Metropolitan Municipality. In Exergy for a Better Environment and Improved Sustainability, 2nd ed.; Aloui, F., Dincer, I., Eds.; Green Energy and Technology; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Luttenberger, L.R. Waste Management Challenges in Transition to Circular Economy—Case of Croatia. J. Clean. Prod. 2020, 256, 120495. [Google Scholar] [CrossRef]

- Tshemese, Z.; Deenadayalu, N.; Linganiso, L.Z.; Chetty, M. An Overview of Biogas Production from Anaerobic Digestion and the Possibility of Using Sugarcane Wastewater and Municipal Solid Waste in a South African Context. Appl. Syst. Innov. 2023, 6, 13. [Google Scholar] [CrossRef]

- Song, G.; Li, Y. The Effect of Reinforcing the Concept of Circular Economy in West China Environmental Protection and Economic Development. Procedia Environ. Sci. 2012, 12, 785–792. [Google Scholar] [CrossRef][Green Version]

- Ün, Ç. Enhancing Sewage Sludge Treatment with Hydrothermal Processing: A Case Study of Adana City. Sustainability 2024, 16, 4174. [Google Scholar] [CrossRef]

- Miguel, N.; Sarasa, J.; López, A.; Gómez, J.; Mosteo, R.; Ormad, M.P. Study of Evolution of Microbiological Properties in Sewage Sludge-Amended Soils: A Pilot Experience. Int. J. Environ. Res. Public Health 2020, 17, 6696. [Google Scholar] [CrossRef]

- Straub, T.M.; Pepper, I.L.; Gerba, C.P. Hazards from Pathogenic Microorganisms in Land-Disposed Sewage Sludge. In Reviews of Environmental Contamination and Toxicology; Ware, G.W., Ed.; Springer: New York, NY, USA, 1993; Volume 132. [Google Scholar]

- Kelley, W.D.; Martens, D.C.; Reneau, R.B.; Simpson, T.W. Agricultural Use of Sewage Sludge: A Literature Review; Virginia Water Resources Research Center: Blacksburg, VA, USA, 1984. [Google Scholar]

- Vitenko, T.; Marynenko, N.; Kramar, I. Characteristics of sewage sludge composition for agricultural use. Econ. Environ. 2023, 85, 296–307. [Google Scholar] [CrossRef]

- IEA Bioenergy, Sustainable Biogas Production in Municipal Wastewater Treatment Plants. Available online: https://task37.ieabioenergy.com/wp-content/uploads/sites/32/2022/02/Wastewater_biogas_grey_web-1.pdf (accessed on 28 November 2024).

- Appels, L.; Baeyens, J.; Degrève, J.; Dewil, R. Principles and potential of the anaerobic digestion of waste-activated sludge. Prog. Energy Combust. Sci. 2008, 34, 755–781. [Google Scholar] [CrossRef]

- Tchobanoglous, G.; Burton, F.L.; Stensel, H.D.; Metcalf & Eddy Inc. Wastewater Engineering: Treatment and Reuse, 5th ed.; McGraw-Hill: New York, NY, USA, 2014. [Google Scholar]

- Carrère, H.; Dumas, C.; Battimelli, A.; Batstone, D.J.; Delgenès, J.P.; Steyer, J.P.; Ferrer, I. Pretreatment methods to improve sludge anaerobic degradability: A review. J. Hazard. Mater. 2010, 183, 1–15. [Google Scholar] [CrossRef]

- Ward, A.J.; Hobbs, P.J.; Holliman, P.J.; Jones, D.L. Optimisation of the anaerobic digestion of agricultural resources. Bioresour. Technol. 2008, 99, 7928–7940. [Google Scholar] [CrossRef]

- Zhang, W.; Wei, Y.; Liu, J.; Xie, H.; Wang, W.; Zhang, L. Methane production from fresh and aged dewatered sewage sludge: Effects of thermal hydrolysis and microbial community. Bioresour. Technol. 2017, 244, 840–849. [Google Scholar] [CrossRef]

- Mata-Alvarez, J.; Dosta, J.; Macé, S.; Astals, S. Codigestion of solid wastes: A review of its uses and perspectives including modeling. Crit. Rev. Biotechnol. 2014, 34, 83–93. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Cheng, J.J.; Creamer, K.S. Inhibition of anaerobic digestion process: A review. Bioresour. Technol. 2008, 99, 4044–4064. [Google Scholar] [CrossRef] [PubMed]

- Weiland, P. Biogas production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 85, 849–860. [Google Scholar] [CrossRef]

- Venkatesh, G.; Elmi, R.A. Economic-Environmental Analysis of Handling Biogas from Sewage Sludge Digesters in WWTPs for Energy Recovery: Case Study of Bekkelaget WWTP in Oslo (Norway). Energy 2013, 58, 220–235. [Google Scholar] [CrossRef]

- Renewable Natural Gas Production. Available online: https://afdc.energy.gov/fuels/natural-gas-renewable (accessed on 28 November 2024).

- International Energy Agency. Outlook for Biogas and Biomethane, Prospects for Organic Growth. Available online: https://iea.blob.core.windows.net/assets/03aeb10c-c38c-4d10-bcec-de92e9ab815f/Outlook_for_biogas_and_biomethane.pdf (accessed on 28 November 2024).

- Use of Biomethane in the Fleet of Heavy Vehicles. Available online: https://www.canalbioenergia.com.br/uso-de-biometano-em-frota-de-veiculos/ (accessed on 28 November 2024).

- Ryckebosch, E.; Drouillon, M.; Vervaeren, H. Techniques for transformation of biogas to biomethane. Biomass Bioenergy 2011, 35, 1633–1645. [Google Scholar] [CrossRef]

- Petersson, A.; Wellinger, A. Biogas upgrading technologies–developments and innovations. IEA Bioenergy 2009, 20, 1–19. [Google Scholar]

- Muñoz, R.; Meier, L.; Diaz, I.; Jeison, D. A review on the state-of-the-art of physical/chemical and biological technologies for biogas upgrading. Rev. Environ. Sci. Biotechnol. 2015, 14, 727–759. [Google Scholar] [CrossRef]

- Kapdi, S.S.; Vijay, V.K.; Rajesh, S.K.; Prasad, R. Biogas scrubbing, compression and storage: Perspective and prospectus in Indian context. Renew. Energy 2005, 30, 1195–1202. [Google Scholar] [CrossRef]

- Sun, Q.; Li, H.; Yan, J.; Liu, L.; Yu, Z.; Yu, X. Selection of appropriate biogas upgrading technology-a review of biogas cleaning, upgrading and utilization. In Renewable and Sustainable Energy Reviews; Elsevier: Amsterdam, The Netherlands, 2015; Volume 51, pp. 521–532. [Google Scholar] [CrossRef]

- Ün, Ç. A Sustainable Approach to the Conversion of Waste into Energy: Landfill Gas-to-Fuel Technology. Sustainability 2023, 15, 14782. [Google Scholar] [CrossRef]

- Bordelanne, O.; Montero, M.; Bravin, F.; Prieur-Vernat, A.; Oliveti-Selmi, O.; Pierre, H.; Papadopoulo, M.; Muller, T. Biomethane CNG Hybrid: A Reduction by More Than 80% of the Greenhouse Gases Emissions Compared to Gasoline. J. Nat. Gas Sci. Eng. 2011, 3, 617–624. [Google Scholar] [CrossRef]

- Jensen, J. Biomethane for Transportation-Opportunities for Washington State, Western Washington Clean Cities Coalition. Available online: https://www.westcoastcollaborative.org/files/reports/biomethane_transportation_opportunities_wa.pdf (accessed on 28 November 2024).

- Åhman, M. Biomethane in the Transport Sector: An Appraisal of the Forgotten Option. Energy Policy 2010, 38, 208–217. [Google Scholar] [CrossRef]

- U.S. and Canadian Natural Gas Vehicle Market Analysis: Compressed Natural Gas Infrastructure—Final Report, TIAX. Available online: https://www.ourenergypolicy.org/wp-content/uploads/2012/05/11_1803_anga_module5_cng_dd10.pdf (accessed on 28 November 2024).

- Chandra, R.; Vijay, V.K.; Subbarao, P.M.V.; Khura, T.K. Performance Evaluation of a Constant Speed IC Engine on CNG, Methane Enriched Biogas, and Biogas. Appl. Energy 2011, 88, 3969–3977. [Google Scholar] [CrossRef]

- Subramanian, K.A.; Mathad, V.C.; Vijay, V.K.; Subbarao, P.M.V. Comparative Evaluation of Emission and Fuel Economy of an Automotive Spark Ignition Vehicle Fuelled with Methane Enriched Biogas and CNG Using Chassis Dynamometer. Appl. Energy 2013, 105, 17–29. [Google Scholar] [CrossRef]

- Yang, L.; Ge, X.; Wan, C.; Yu, F.; Li, Y. Progress and perspectives in converting biogas to transportation fuels. Renew. Sustain. Energy Rev. 2014, 40, 1133–1152. [Google Scholar] [CrossRef]

- Bidart, C.; Fröhling, M.; Schultmann, F. Electricity and Substitute Natural Gas Generation from the Conversion of Wastewater Treatment Plant Sludge. Appl. Energy 2014, 113, 404–413. [Google Scholar] [CrossRef]

- Olsson, L.; Fallde, M. Waste(d) Potential: A Socio-Technical Analysis of Biogas Production and Use in Sweden. J. Clean. Prod. 2015, 98, 107–115. [Google Scholar] [CrossRef]

- BioCNG. CNG Fuel Emissions Reductions. Available online: https://www.biocng.us/cng-fuel/emissions-reductions/ (accessed on 28 November 2024).

- Bachmann, N. Vorteile und Grenzen der Vergärung von leicht abbaubaren Industrie- und Lebensmittelabfällen in Abwasserreinigungsanlagen. Available online: https://www.aramis.admin.ch/Default?DocumentID=62354&Load=true (accessed on 28 November 2024).

- Kind, E.; Levy, G.A. Energieeffizienz und Energieproduktion auf ARA; Holinger Ag: Baden, Switzerland, 2012. [Google Scholar]

- Hansen, J.; Kolisch, G.; Hobus, I.; Osthoff, T. Steigerung der Energieeffizienz auf kommunalen Kläranlagen, eine Ergebnisbetrachtung zu durchgeführten Energieanalysen. Korresp. Abwasser Abfall 2010, 57, 1028–1032. [Google Scholar]

- Energie in ARA: Leitfaden zur Energieoptimierung auf Abwasserreinigungsanlagen. Available online: https://vsa.ch/Mediathek/energie-in-ara/ (accessed on 28 November 2024).

- International Energy Agency (IEA). Transport sector CO2 emissions. IEA Glob. Energy Review 2021. Available online: https://www.iea.org/reports/global-energy-review-2021 (accessed on 18 February 2025).

- Scarlat, N.; Dallemand, J.F.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Aemetis Biogas and APG Demonstrate Low-Cost Conversion of Diesel Trucks to Utilize up to 65% Renewable Natural Gas. Available online: https://www.aemetis.com/aemetis-biogas-and-apg-demonstrate-low-cost-conversion-of-diesel-trucks-to-utilize-up-to-65-renewable-natural-gas/ (accessed on 18 February 2025).

- ASKI. Adana Metropolitan Municipality—Adana Water and Sewerage Administration Activity Report; ASKI: Adana, Turkey, 2022. [Google Scholar]

- Menegheti, G.; Pereira, R.B.; Piekarski, C.M.; de Francisco, A.C.; Sydney, E.B.; Bittencourt, J.V.M. Utilization of Biogas from Solid Waste in the Production of Biomethane and Its Use as Biofuel in the Transport Sector; Baskar, C., Ramakrishna, S., Baskar, S., Sharma, R., Chinnappan, A., Sehrawat, R., Eds.; Handbook of Solid Waste Management; Springer: Singapore, 2022. [Google Scholar] [CrossRef]

- Sustainable Energy and Climate Action Plan (SECAP) of Adana City, Republic of Türkiye, Ministry of Environment, Urbanization and Climate Change & Adana Metropolitan Municipality & World Bank & Sustainable Cities & ILBANK & EU & ARUP Publications. Available online: https://www.adana.bel.tr/panel/uploads/eplani_v/files/adana-buyuksehir-belediyesi-surdurulebilir-enerji-ve-iklim-eylem-plani-2024-2025.pdf (accessed on 18 February 2025).

- Ün, Ç. Investigation and mitigation studies of transportation-based greenhouse gas emissions in Adana city. In Sustainability of Natural Resources’ Efficiency; Guldal, S., Ed.; Iksad Publications: Ankara, Turkey, 2022; pp. 105–128. ISBN 978-625-8213-08-9. Available online: https://scholar.google.com.tr/citations?view_op=view_citation&hl=tr&user=oqjmYCoAAAAJ&citation_for_view=oqjmYCoAAAAJ:q3oQSFYPqjQC (accessed on 18 February 2025).

- Ün, Ç. Investigation of Alternative Vehicle Applications for Reducing Greenhouse Gas Emissions in Urban Public Transport: The Case of Adana Province. Eur. Mech. Sci. 2023, 7, 220–229. [Google Scholar] [CrossRef]

- Souza, S.N.; Santos, R.F.; Fracaro, G.P.M. Potential for the Production of Biogas in Alcohol and Sugar Cane Plants for Use in Urban Buses in Brazil. In Proceedings of the World Renewable Energy Congress, Linköping, Sweden, 8–13 May 2011. [Google Scholar]

- Biogas Buses ‘Better Value’ than Electric. Available online: https://www.europeanbiogas.eu/biogas-buses-better-value-electric/ (accessed on 18 February 2024).

- Report on Diesel- and Alternative-Fuel Bus Trials. Available online: https://assets.gov.ie/69312/eadd09d7dd5a49f698dbb4a77db4c78c.pdf (accessed on 18 February 2025).

- Introducing Biogas and Particulate Filters for Buses. Available online: https://civitas.eu/mobility-solutions/introducing-biogas-and-particulate-filters-for-buses (accessed on 18 February 2025).

- Case Study: Bio-Bus A Step Change in Sustainable Transport. Available online: https://www.geneco.uk.com/case-studies/bio-bus/ (accessed on 18 February 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).