Abstract

Since retrofitting existing natural gas-fired (NGF) power plants is an essential strategy for enhancing their efficiency and controlling greenhouse gas emissions, this paper compares the carbon footprint of natural gas-fired power generation from an NGF power plant in Brazil (BR-NGF) with and without retrofitting. The former scenario entails retrofitting the BR-NGF power plant with combined-cycle gas turbine (CCGT) technology. In contrast, the latter involves continuing the BR-NGF power plant operation with open-cycle gas turbine (OCGT) technology. Our analysis considers the BR-NGF power plant’s life cycle (construction, operation, and decommissioning) and the natural gas’ life cycle (natural gas extraction and processing, liquefaction, liquefied natural gas transportation, regasification, and combustion). Moreover, it is based on data from primary and secondary sources, mainly the Ecoinvent database and the ReCiPe 2016 method. For OCGT, the results showed that the BR-NGF power plant and the natural gas life cycles are responsible for 620.87 gCO2eq./kWh and 178.58 gCO2eq./kWh, respectively. For CCGT, these values are 450.04 gCO2eq./kWh and 129.30 gCO2eq./kWh. Our findings highlight the relevance of the natural gas’ life cycle, signaling additional opportunities for reducing the overall carbon footprint of natural gas-fired power generation.

1. Introduction

Climate change is one of the most pertinent environmental challenges of our time, sparking widespread international concern due to its far-reaching consequences [1]. The energy sector is the chief contributor to anthropogenic greenhouse gas (GHG) emissions, which are the driving force behind climate change [2]. Consequently, companies within the energy sector have been actively striving to reduce their GHG emissions, enhance resilience, and align with societal and market expectations.

In this sense, a global shift towards a low-carbon economy is driven by the increasing use of renewable energy sources like solar photovoltaic (PV) and wind power generation [3]. In this context, natural gas emerges as a promising player in the global energy system [4], offering a more environmentally friendly alternative among fossil energy sources [5]. Its role becomes even more crucial in ensuring energy supply, particularly with the growing use of intermittent energy sources, such as solar PV and wind [6].

Despite the disruption caused by Russia’s invasion of Ukraine, the natural gas market has shown resilience. In 2022, natural gas-fired power generation remained steady, maintaining its share of approximately 23% in global electricity generation. This stability also kept its carbon dioxide (CO2) emissions at 2021 levels. However, the more optimistic projections for renewable energy sources suggest a potential slowdown in natural gas demand growth. According to the International Energy Agency (IEA), the expected growth rate for natural gas demand between 2022 and 2030 is significantly lower than the 2.2% average growth rate observed between 2010 and 2021 [7].

In Brazil, the natural gas-fired power generation share was 5.3% of the national electricity matrix in 2023, marking an 8% decline from 2022. This decrease is attributed to reduced energy consumption, decreased dispatch from gas-fired (NGF) power plants, and a slowdown in steel production [8]. The Ten-Year Energy Expansion Plan (PDE as in its Portuguese acronym) projects a 34% increase in natural gas-fired power generation over the next decade, reaching approximately 7% of total domestic electricity generation by 2031 [6].

As the worldwide economy transitions towards a decarbonized future, the energy sector must adopt some strategies to address climate change, such as retrofitting existing power plants. In natural gas-fired power generation, this strategy often involves incorporating carbon capture and storage (CCS) technologies, reducing the amount of GHG released into the atmosphere [9,10]. Furthermore, converting NGF power plants from open-cycle gas turbines (OCGT) to combined-cycle gas turbines (CCGT) enhances their thermal efficiency, enabling more electricity to be generated from the same amount of natural gas [11]. It is noteworthy that, unlike converting OCGT to CCGT, retrofitting existing NGF power plants with CCS technologies enables near-zero GHG emissions from their operation stage, reducing the carbon footprint of their electricity generation [12].

Another strategy is to assess the GHG emissions associated with energy generation from a life cycle perspective [1]. This means analyzing the GHG emissions from the extraction and processing of raw materials through manufacturing, distribution, use, reuse, maintenance, and recycling to the final disposal. This holistic approach makes it possible to identify and prevent the transfer of GHG emissions between the different stages, processes, or geographical areas within the life cycle of energy generation [13].

By pointing out the outlooks for expanding the energy sector over the next ten years in Brazil, PDEs focus mainly on cost-effective energy scenarios and generating and transmitting electricity without fully considering sustainability issues. Although the PDEs address climate change, biodiversity conservation, water consumption, etc., these socio-environmental issues are not considered from a life cycle perspective and do not influence the selection of energy projects for the next decade [13].

Furthermore, Brazil’s natural gas-fired power generation carbon footprint has not received sufficient attention regarding detailed investigations. Existing life cycle-based studies have primarily focused on the overall Brazilian electricity matrix, overlooking specific characteristics of individual energy sources [14,15]. Sakamoto and colleagues [16] have conducted more detailed assessments of the environmental impact of natural gas supply in the country, considering both the current and future scenarios. However, important questions about natural gas-fired power generation still need to be answered. These questions revolve around the potential for retrofitting NGF power plants to reduce GHG emissions and the environmental performance disparities between OCGT and CCGT technologies.

The present paper is part of a comprehensive research and development (R&D) project undertaken by the Brazilian Electric Energy Research Center (CEPEL) for a company in the national electricity sector. It is dedicated to developing a methodology for conducting carbon footprint studies on power generation technologies in the Brazilian context. In particular, this paper focuses on analyzing the impact of retrofitting power plants on the carbon footprint of natural gas-fired power generation, comparing the OCGT and CCGT configurations of a NGF power plant in Brazil, referred to as the BR-NGF power plant.

2. Materials and Methods

2.1. An Overview of Natural Gas-Fired Power Generation

2.1.1. Open-Cycle Gas Turbine

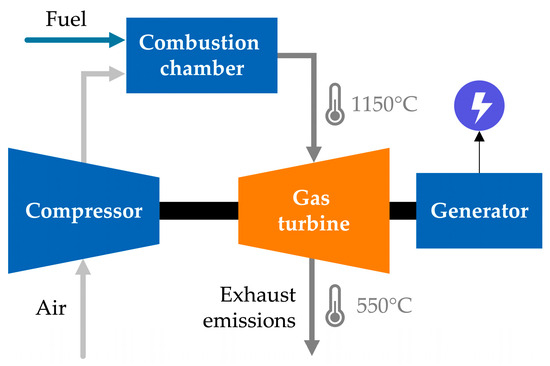

The OCGT follows the Rankine cycle. In this cycle, atmospheric air is compressed and then passed through the combustor, where natural gas combustion occurs. The heat energy generated is transformed into mechanical work in the gas turbine. Part of this work drives the compressor, while the remainder is converted into electricity through the generator. The residual working flow is subsequently released into the atmosphere [17] (Figure 1). Natural gas-fired power generation using OCGT technology achieves electrical efficiency ranging from 35% to 42% when operating at full load [18]. This configuration accounts for approximately 32% of Brazil’s total natural gas-fired power capacity [19].

Figure 1.

Scheme of a natural gas-fired power generation through OCGT. Source: elaborated by the authors, based on IEMA [20].

2.1.2. Combined-Cycle Gas Turbine

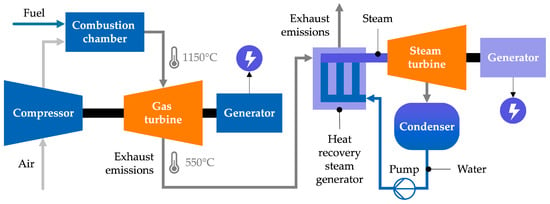

The CCGT is characterized by the utilization of one Brayton and one Rankine cycle. Like the OCGT, the process starts with the combustion of natural gas with air, producing hot gas that expands in the gas turbine. However, in the CCGT, the exhaust from the turbine (500 to 650 °C) is directed into the heat recovery steam generator (HRSG) to produce hot steam for the steam turbine, generating additional electricity. In this cycle, water is the working flow that is continuously recirculated through the steam turbine (Figure 2) [17]. The CCGT stands out with its electrical efficiency, ranging from 52% to 60% [18]. This allows for increased power output at equivalent fuel costs compared to OCGT [11]. In Brazil, this configuration represents around 65% of the total natural gas-fired power capacity [19].

Figure 2.

Scheme of a natural gas-fired power generation through CCGT. Source: elaborated by the authors, based on IEMA [20].

Note that the ambient conditions influence the operation of NGF power plants, mainly those with CCGT technology. In tropical regions, some equipment used in these power plants operates in suboptimal conditions due to high relative humidity and ambient temperature. This is particularly relevant for Brazil, which spans different climate zones, from tropical to temperate, leading to varying efficiencies in NGF power plants [21,22].

2.2. Carbon Footprint

Various footprints have emerged in the environmental sector in the last two decades, each focusing on a distinct environmental issue. However, they all share a common foundation—the life cycle perspective. These environmental tools can be applied to assess a wide range of targets, including products, services, organizations, individuals, sites, and countries [23].

The carbon footprint is focused on climate change and uses an indicator expressed in terms of CO2 equivalent (CO2eq.) to address the direct and indirect GHG emissions related to, for example, the entire value chain of a product or service. This indicator represents the concentration of CO2 that would cause the same radiative forcing as a given GHG [2,23].

Regarding energy generation, the carbon footprint covers the direct and indirect GHG emissions associated with the entire life cycle of the power plant, including construction, operation, and decommissioning, as well as the life cycle of any fuel used [24]. In line with ISO 14067 [25], conducting a carbon footprint analysis involves following the steps of a Life Cycle Assessment (LCA): (i) goal and scope definition, (ii) life cycle inventory (LCI) analysis, (iii) life cycle impact assessment (LCIA), and (iv) interpretation.

A carbon footprint analysis can be an enlightening first step into life cycle thinking for the general public. For policy and decision-makers, it often serves as a key to unlocking the concept and methodology of LCA [23].

2.3. Case Study

2.3.1. BR-NGF Power Plant Presentation

BR-NGF is a gas-fired power plant located in Brazil that has undergone two configurations in recent years. Initially, it operated with OCGT technology, featuring two gas turbines with an installed capacity of 350 MW. Subsequently, it was upgraded to CCGT technology with an installed capacity of 514 MW and is currently operational. The upgraded configuration integrates the two existing gas turbines from the OCGT system with two HRSG, one steam turbine, one condenser, and an additional generator, among other components.

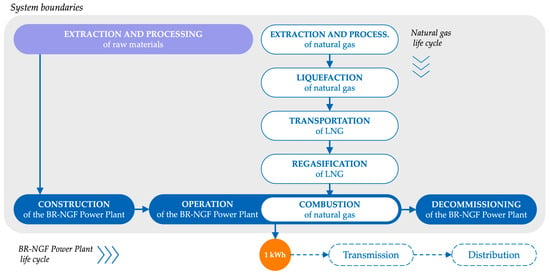

A comparative study must obtain information on OCGT and CCGT technologies at an equivalent quality level. In this sense, our analysis is based on the same system boundary in the carbon footprint calculation for both configurations of the BR-NGF power plant. It considers the following two life cycles: the BR-NGF power plant’s life cycle and natural gas’ life cycle. The former includes the construction, operation, and decommissioning stages, while the latter encompasses natural gas extraction and processing, liquefaction, liquefied natural gas (LNG) transportation, regasification, and combustion stages. Figure 3 shows the system boundary for calculating the carbon footprint of the BR-NGF power plant, considering OCGT and CCGT configurations.

Figure 3.

Scheme of the system boundaries considered in the carbon footprint analysis. Source: elaborated by the authors.

The natural gas utilized for electricity generation is sourced from Nigeria and imported as LNG, as per details provided by the BR-NGF power plant operational technical team. It is essential to note that, according to PDE 2031 [6], there are the following four options for the origin of natural gas destined for NGF power plants in Brazil: (i) domestic onshore production, (ii) domestic offshore production, (iii) import of LNG by sea, and (iv) import via gas pipelines.

2.3.2. Electricity Generation Scenarios

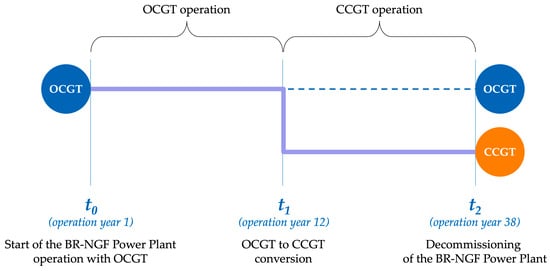

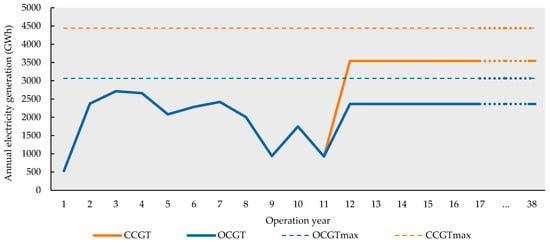

Figure 4 illustrates the time frame for comparing the carbon footprints of the BR-NGF power plant in the OCGT and CCGT configurations. The BR-NGF power plant began operating with OCGT in 2012, denoted as (or operation year 1). It started operating with CCGT in 2023, represented by (or operation year 12). Transitioning from OCGT to CCGT increased thermodynamic efficiency and electricity generation from the same amount of natural gas. Finally, (or operation year 38) represents the end of the BR-NGF power plant’s operation in 2050, including the termination of the activities of the two gas turbines and the steam turbine. It is important to note that a useful life of 38 years was adopted for the BR-NGF power plant.

Figure 4.

Scheme of the time frame defined to compare the BR-NGF power plant’s carbon footprints with OCGT and CCGT configurations. Source: elaborated by the authors.

From this time frame, it is possible to compare two specific scenarios. The first one is the hypothetical scenario, which consists of the continued operation of the BR-NGF power plant with the OCGT configuration and is represented by (solid line) and (dashed line). The second one is the actual scenario, which corresponds to the continued operation of the BR-NGF power plant with the new CCGT configuration and is represented by (solid line) and (solid line) (see Figure 4).

It is essential to highlight that regular maintenance and replacing components can extend the useful life of gas turbines. In the present analysis, equipment replacement and maintenance costs were not considered. However, maintenance costs significantly influence the dispatchability of a NGF power plant, consequently affecting the electricity generation from the OCGT to CCGT configurations.

The criteria used to determine the end of the gas turbines’ operation were based on the predictions of restrictions on using fossil fuels to generate electricity to combat global climate change and achieve a carbon-neutral status for the Brazilian electricity sector by 2050. Therefore, even if the gas turbines remain operational after 2050, our analysis assumes they will be decommissioned by then.

For , the electricity generated by the BR-NGF power plant was obtained from a primary data source, specifically from the National Electric System Operator (ONS) [26]. Similarly, data on natural gas consumption were retrieved from historical data stored by Emisfera [27]. Emisfera is a tool used in the Brazilian electricity sector to develop the GHG emissions inventory using data from primary sources. It collects site-specific data through direct contact with organizations and companies [27]. On the other hand, GHG emissions data were estimated based on the emissions factors defined by the Intergovernmental Panel on Climate Change (IPCC) [28] (see Table 1).

Table 1.

Operation data for the BR-NGF power plant with OCGT configuration in .

During in the OCGT and CCGT systems, natural gas consumption and GHG emissions in the BR-NGF power plant’s operation stage are the same as in . However, the electricity generated varies for each configuration. Therefore, for OCGT, an average operating regime of the two gas turbines was calculated from the seven years most representative of the period (operation years 2, 3, 4, 5, 6, 7, and 8), excluding outliers. This average operating regime was then used for the period . For the CCGT, electricity generation in was estimated based on conversion efficiencies of 0.36 and 0.54 for the OCGT and CCGT technologies, respectively.

Figure 5 compares the annual electricity generation scenarios (in GWh) for the OCGT and the CCGT. The focus is on the difference between these two configurations. The solid blue line represents the measured electricity generation values in the OCGT, while the orange solid line represents the CCGT generation. The dashed lines indicate the maximum annual generation potential for both configurations.

Figure 5.

Comparison between the annual electricity generation for OCGT and CCGT. Source: elaborated by the authors.

2.3.3. Life Cycle Inventory

This case study focuses on the primary material and energy inputs for the construction stage of the BR-NGF power plant’s OCGT and CCGT configurations. This involved examining construction materials such as reinforced concrete and steel structures, as well as metals, plastics, and insulating materials. Additionally, it considers energy inputs, including the consumption of diesel oil and energy from electricity and heat (see Table 2). Due to a lack of data from primary sources, the elementary flows considered in the construction stage were estimated by adapting LCIs from existing NGF power plants in the Ecoinvent 3.5 database [29]. To do this, the installed capacities of the NGF power plants were taken as a parameter to scale down or up the quantities of inputs and outputs.

Table 2.

LCI for OCGT and CCGT considering the BR-NGF power plant’s life cycle.

In the operation stage, the main elementary flows are direct CO2 emissions and electricity generation. It is worth noting that the absolute amount of 53,845,141.00 tCO2 remains unchanged when transitioning from OCGT to CCGT because there is no need for additional natural gas burning. However, there is a stark contrast in electricity generation, which significantly increases from 86,844,924.00 to 119,931,620.00 MWh (see Table 2). This increase characterizes the energy gain achieved with the implementation of CCGT, which significantly improves the intensity of its GHG emissions indicator. The calculation of natural gas consumption and electrical energy generated during the plant operation was based on data stored by Emisfera [27] and the ONS [26] data, respectively.

It is important to note that the existing literature lacks comprehensive information on accounting for GHG emissions during the decommissioning stage. However, Meng and Dillingham [30] suggest that this stage has minimal impact on the overall GHG emissions in the life cycle of natural gas-fired power generation. Consequently, a conservative estimate of 6% contribution from the decommissioning stage to the total life cycle GHG emissions was adopted, primarily due to the challenges of obtaining accurate data for this stage.

Transportation is necessary to move inputs and products from one stage to another in a product system’s life cycle. Accurate accounting for transport activities is not always straightforward, as it requires the mapping of the original suppliers of inputs and the future waste destinations. Therefore, this case study adopted the transport activities provided by the Ecoinvent 3.5 database [29] for the LCIs used in the BR-NGF power plant’s life cycle. These activities are quantified using ton-kilometer (tkm).

In our assessment of the carbon footprint of natural gas, we based our hypothesis on 100% LNG imported from Nigeria. This information was gathered through direct contact with the BR-NGF power plant team. Thus, this analysis, as illustrated in Figure 3, includes the following stages: (i) extraction and processing of onshore associated gas in Nigeria, (ii) liquefaction of natural gas, (iii) transportation of LNG from Nigeria to Brazil, and (iv) regasification to enter the natural gas into the gas pipeline system.

Given the characteristics of onshore associated gas production in Nigeria, which has resulted in substantial losses due to fugitive emissions [10,31], the GHG emissions originating from natural gas processing were deemed inconsequential and combined with the emissions from natural gas extraction. The data for natural gas production in Nigeria include specific information sourced from the Ecoinvent 3.5 database [29]. For instance, CH4 fugitive emissions during the extraction and processing stage correspond to 0.0190 m3, and natural gas consumption as an energy source in the liquefaction stage is equivalent to 4.118 MJ per m3 of natural gas delivered by the regasification stage. To put this in perspective, these values are 0.0017 m3 and 1.630 MJ for Brazil, 0.0005 m3 and 0.600 MJ for Bolivia—one of Brazil’s leading natural gas suppliers—and 0.0009 m3 and 1.140 MJ for a more comprehensive context defined as the “rest-of-the-world” (RoW) by the Ecoinvent 3.5 database [29]. Additionally, the GHG emissions from fugitive gas and energy consumption during transportation between Brazil’s regasification terminal and the BR-NGF power plant were regarded as negligible.

The energy inputs considered for the natural gas’ life cycle include the natural gas used to generate energy at different stages and the heavy fuel oil used for international shipping. The distance between Nigeria and Brazil was calculated in nautical miles (nm) and then converted into kilometers (km), which resulted in a distance of approximately 6500 km. As a result, the amount of 4.831 tkm of transportation was associated with each cubic meter (m3) of natural gas transported as LNG. Regarding direct emissions to air, this case study considers the release of natural gas through ventilation and flaring (see Table 3). Note that the input and output data used in the natural gas’ life cycle were obtained from secondary sources, specifically from the available literature and the Ecoinvent 3.5 database [29].

Table 3.

LCI for OCGT and CCGT considering the natural gas’ life cycle and 1.0 m3 of natural gas delivered by the regasification stage.

3. Results and Discussion

3.1. Life Cycle Impact Assessment

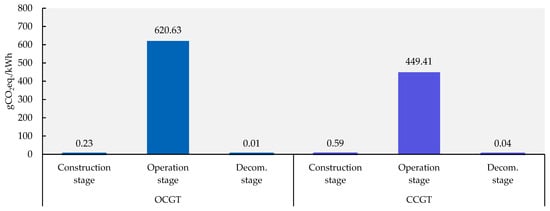

This section presents our comprehensive analysis of the carbon footprint of the natural gas-fired power generation through the BR-NGF power plant, considering the OCGT and CCGT configurations. Over an estimated useful life of 38 years, the OCGT and CCGT systems produced a total of 53,919,796.12 kgCO2eq. and 53,973,717.16 kgCO2eq., respectively. During the construction stage, the carbon footprints were recorded at 0.23 gCO2eq./kWh and 0.59 gCO2eq./kWh for OCGT and CCGT. Moving to the operation stage, these configurations are associated with 620.63 gCO2eq./kWh and 449.41 gCO2eq./kWh. Finally, in the decommissioning stage, it was estimated that 0.014 gCO2eq./kWh and 0.035 gCO2eq./kWh are emitted from OCGT and CCGT (see Table 4).

Table 4.

Carbon footprint results from generating 1 kWh of electricity from OCGT and CCGT, considering the BR-NGF power plant’s life cycle.

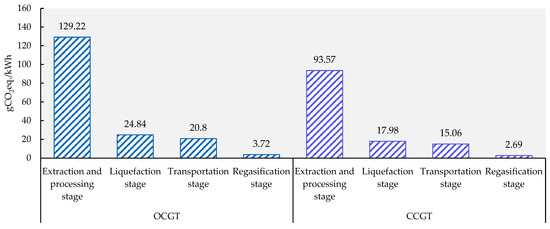

In the life cycle of natural gas, the carbon footprints for OCGT and CCGT configurations were as follows: 178.58 gCO2eq./kWh and 129.30 gCO2eq./kWh, respectively. The extraction and processing stage impacts were measured at 129.22 gCO2eq./kWh and 93.57 gCO2eq./kWh for these configurations. During the liquefaction stage, the carbon footprints were 24.84 gCO2eq./kWh for OCGT and 187.98 gCO2eq./kWh for CCGT. These results reached 20.80 gCO2eq./kWh and 15.06 gCO2eq./kWh for the transport stage. The regasification stage showed the lowest contribution to the carbon footprint of the life cycle of natural gas, with values of 3.72 gCO2eq./kWh and 2.69 gCO2eq./kWh for OCGT and CCGT, respectively (see Table 5).

Table 5.

Carbon footprint results from generating 1 kWh of electricity from OCGT and CCGT, considering the natural gas’ life cycle.

3.2. Interpretation

3.2.1. Analysis of Relevant Issues

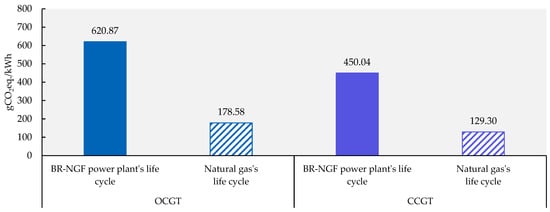

For OCGT, the life cycle of the BR-NGF power plant is responsible for 620.87 gCO2eq./kWh, while the life cycle of natural gas is responsible for 178.58 gCO2eq./kWh, which account for around 78% and 22% of total GHG emissions, respectively. In the case of the CCGT, the values for the life cycles of the BR-NGF power plant and natural gas are 450.04 gCO2eq./kWh and 129.30 gCO2eq./kWh, also corresponding to 78% and 22% of total GHG emissions from the life cycle of the natural gas-fired power generation. The OCGT reaches 799.45 gCO2eq./kWh, while the CCGT reaches 579.34 gCO2eq./kWh (see Figure 6).

Figure 6.

Carbon footprint comparison between 1 kWh of electricity generation from OCGT and CCGT considering the BR-NGF power plant and natural gas life cycles. Source: elaborated by the authors.

Therefore, transitioning from OCGT to CCGT has reduced the carbon footprint of the natural gas-fired power generation in the BR-NGF power plant by around 28%. Since the OCGT configuration accounts for approximately 32% of Brazil’s total natural gas-fired power capacity, retrofitting NGF power plants with CCGT technology has significant potential to reduce GHG emissions.

In the life cycle of the BR-NGF power plant, the operation stage accounts for over 99% of GHG emissions in both the OCGT and CCGT configurations. This is primarily due to CO2 emissions from natural gas combustion. On the other hand, the construction and decommissioning stages combined contribute to less than 1% of total GHG emissions in both OCGT and CCGT. During the construction stage of OCGT and CCGT, the main sources of GHG emissions are the use of construction materials (around 57%), energy consumption in the form of heat (around 25%), diesel (19%), and electricity (0.3%) (see Figure 7).

Figure 7.

Life cycle stages’ contribution to the carbon footprint of the BR-NGF power plant for OCGT and CCGT configurations. Source: elaborated by the authors.

When analyzing the natural gas’ life cycle, the extraction and processing stage stands out (around 72% in both cycles). Its GHG emissions are mainly due to the high levels of fugitive natural gas emissions in Nigeria [10,31]. Furthermore, the liquefaction and transport stages also play a relevant role in natural gas’ life cycle, contributing around 14% and 12% of GHG emissions, respectively. The regasification stage contributed 2% to the carbon footprint of the natural gas’ life cycle (see Figure 8).

Figure 8.

Life cycle stages’ contribution to the carbon footprint of natural gas for OCGT and CCGT configurations. Source: elaborated by the authors.

The carbon footprint of the natural gas’ life cycle includes contributions from various stages. Fugitive emissions and natural gas input during the extraction and processing stage comprise 58% and 14% of the total GHG emissions, respectively. Using natural gas in the liquefaction stage contributes 14% to the carbon footprint. In the transportation stage, 12% of GHG emissions are attributed to fuel consumption, 4% associated with burning and production of heavy fuel oil, and 8% with the consumption of transported LNG. The remaining 2% of GHG emissions are from activities related to the regasification stage, in which 93% of emissions correspond to LNG consumption and 7% to electricity consumption.

When it comes to the GHG contribution to the carbon footprint of the natural gas’ life cycle, it is important to understand the role of each gas. For the OCGT and CCGT, the emissions of 129.30 gCO2eq./kWh and 178.58 gCO2eq./kWh are mainly formed by approximately 37% CO2, 59% CH4, and 4% N2O. While CH4 emissions are predominant only during natural gas extraction and processing, it is CO2 that presents more significant emissions across all life cycle stages due to the combustion of fossil fuels. Despite its high GWP, N2O did not present significant amounts in any process at any stage of natural gas’ life cycle.

3.2.2. Sensitivity Analysis

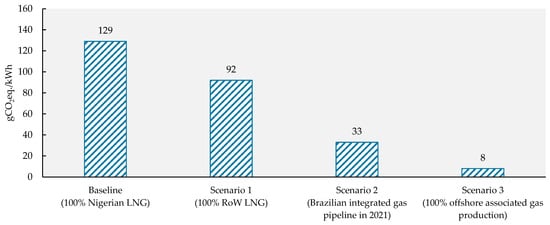

In this case study, a sensitivity analysis was performed on the carbon footprint of the natural gas’ life cycle, specifically focusing on the CCGT configuration. This analysis was carried out in two steps. According to the National Agency of Petroleum, Natural Gas, and Biofuels (ANP), Brazil imports LNG from several countries apart from Nigeria, such as the United States, Qatar, and Trinidad and Tobago, among others [32]. Therefore, the first step of this sensitivity analysis assessed the effects of switching from importing LNG from Nigeria (Baseline) to a RoW scenario (Scenario 1), which reflects the average global natural gas production from the Ecoinvent 3.5 database [29]. As a result, Nigeria’s high fugitive emissions, which position it as the seventh largest gas flaring country in the world [10], increase the life cycle GHG emissions of its LNG (around 129 gCO2eq./kWh) by approximately 40% compared to LNG from Scenario 1 (around 92 gCO2eq./kWh). Note that both values attributed to the natural gas’ life cycle from LNG are close to 100 gCO2eq./kWh, reported by Turconi and colleagues [33] as a lower benchmark for LNG.

The second step of this sensitivity analysis delved into the origin of natural gas and considered two alternative scenarios to 100% LNG from Nigerian onshore associated gas production. The first one considered an approximation of the natural gas supply in the Brazilian integrated gas pipeline in 2021 as follows: offshore associate gas (47%), onshore non-associated gas (31%), and onshore associate gas (22%) (Scenario 2) [32]. In contrast, the second one assumed that the natural gas was sourced from offshore associate gas production (Scenario 3). This production did not involve the liquefaction and regasification stages in the natural gas supply chain [29].

In Figure 9, the scenarios considered for the CCGT show a significant variation in the GHG emission from natural gas’ life cycle, ranging from 8 to 129 gCO2eq./kWh. This wide range, exceeding 1500%, underscores the significant impact of the natural gas’ life cycle on the carbon footprint of natural gas-fired power generation. This impact can lead to variations of over 20% for CCGT and approximately 15% for OCGT in the final results. These findings underscore the pivotal role of legislation in supporting less carbon-intensive electricity generation. For instance, implementing a measure to quantify and restrict the amount of embodied carbon in natural gas could lead to replacing natural gas from Nigeria with an alternative.

Figure 9.

Carbon footprint comparison between the scenarios defined for the natural gas’ life cycle in the CCGT configuration. Source: elaborated by the authors.

3.2.3. Limitations

The limitations of the present study stem from the reliance on secondary sources in the entire life cycle of natural gas-fired power generation from the OCGT and CCGT configurations. Specifically, the study was hindered by challenges in accessing technical information from the OCGT and CCGT projects and by the fact that CCGT was yet to be in operation at the time of this study. This impacted the assessment of construction materials; energy inputs; transport activities; CO2, CH4, and N2O emissions during the operation stage; and GHG emissions associated with the decommissioning stage of the BR-NGF power plant.

Another limitation concerns the assumption that natural gas consumption in CCGT remains the same as that of OCGT. The electricity generation scenario for CCGT was based on maintaining the average natural gas consumption from 2012 to the present. The CCGT electricity generation scenario was based on maintaining the average natural gas consumption from 2012 to the present. However, it is possible to create electricity generation scenarios using the chain of optimization models for the generation expansion and operational planning of the Brazilian Interconnected System to ascertain whether the cost changes involved in the BR-NGF power plant operation (converting from OCGT to CCGT) would lead to significant changes in the dispatch. This is particularly pertinent for our study as the dispatch regime of a NGF power plant reportedly impacts its carbon footprint, according to Spath and Mann [34].

Given that the ambient conditions affect the operation of NGF power plants, particularly those using CCGT technology [21,22], our results are not generalizable to the NGF power plants located in other climate zones. However, our findings could be used as a reference to support more sustainable natural gas-fired power generation.

4. Conclusions

This paper analyzed the impact of retrofitting power plants on the carbon footprint of natural gas-fired power generation, comparing the OCGT and CCGT configurations of the BR-NGF power plant in Brazil. For this purpose, our analysis considered two life cycles, namely the BR-NGF power plant’s life cycle (construction, operation, and de-commissioning stages) and natural gas’ life cycle (natural gas extraction and processing, liquefaction, LNG transportation, regasification, and combustion stages).

The carbon footprint results showed that the BR-NGF power plant and the natural gas life cycles are responsible for 620.87 gCO2eq./kWh and 178.58 gCO2eq./kWh for the OCGT. In the case of the CCGT, these values are 450.04 gCO2eq./kWh and 129.30 gCO2eq./kWh. Our findings indicated that the transition from OCGT to CCGT improved the BR-NGF power plant’s environmental performance, considering only the GHG emissions and similar dispatch regimes for both configurations. They also highlighted the relevance of the natural gas’ life cycle in terms of GHG emissions, signaling additional opportunities for reducing the overall carbon footprint of natural gas-fired power generation in Brazil.

Furthermore, our sensitivity analysis revealed significant variations in the carbon footprint of natural gas-fired power generation. Changing the country of origin of LNG could reduce 28% to 94% of the GHG emissions from the natural gas’ life cycle for the CCGT configuration. This impact can lead to variations of over 20% for the CCGT and approximately 15% for the OCGT in the carbon footprint of natural gas-fired power generation with the BR-NGF power plant. These findings are relevant considering the possibility of using carbon capture technology to reduce GHG emissions during power plant operation. Consequently, the largest percentage of the carbon footprint of natural gas-fired power generation would shift to the natural gas’ life cycle.

Finally, future studies should prioritize obtaining more primary data from OCGT and CCGT configurations. Since the CCGT was not in operation during our research, collecting primary operational data on the BR-NGF power plant will be essential. Additionally, it would be beneficial to conduct scenario analyses using optimization models for generation expansion and operational planning. These analyses will provide insights into the impact of cost changes associated with the conversion from an OCGT to a CCGT and the variations in the dispatch regimes on the carbon footprint of natural gas-fired power generation.

Author Contributions

Conceptualization, D.M. and K.C.G.; methodology, D.M., J.G.L., I.R., A.M.M. and J.L.S.A.; software, J.G.L.; validation, D.M. and K.C.G.; formal analysis, D.M., J.G.L., I.R., A.M.M. and J.L.S.A.; investigation, D.M., J.G.L., I.R., A.M.M. and J.L.S.A.; writing—original draft preparation, J.G.L.; writing—review and editing, D.M., J.G.L. and K.C.G.; visualization, J.G.L.; supervision, D.M.; project administration, D.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

The authors gratefully acknowledge the support of the Brazilian Electric Energy Research Center (CEPEL).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yaman, C. A Review on the Process of Greenhouse Gas Inventory Preparation and Proposed Mitigation Measures for Reducing Carbon Footprint. Gases 2024, 4, 18–40. [Google Scholar] [CrossRef]

- IPCC. IPCC Fifth Assessment Report: Climate Change 2014 (AR5)—Synthesis Report; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Matos, D.; Lassio, J.G.; Castelo Branco, D.; Pereira Júnior, A.O. Perspectives for Expansion of Concentrating Solar Power (CSP) Generation Technologies in Brazil. Energies 2022, 15, 9286. [Google Scholar] [CrossRef]

- Egging-Bratseth, R. A Techno-Economic Perspective on Natural Gas and Its Value Chain. Gases 2020, 1, 1–18. [Google Scholar] [CrossRef]

- Ghosh, S.; Majumder, R.; Chatterjee, B. Natural Gas Matters: LNG and India’s Quest for Clean Energy. Gases 2024, 4, 1–17. [Google Scholar] [CrossRef]

- Brazil. The Ten-Yeat Energy Expansion Plan 2031; Ministry of Mines and Energy: Brasília, Brazil, 2022.

- IEA. World Energy Outlook 2023; IEA: Paris, France, 2023. [Google Scholar]

- Brazil. Brazilian Energy Balance 2023; Ministry of Mines and Energy: Brasília, Brazil, 2024.

- Zarei, M.; Cherif, A.; Khaligh, V.; Yoon, T.; Lee, C.-J. Techno-Economic Assessment of Amine-Based CO2 Capture Process at Coal-Fired Power Plants: Uncertainty Analysis. ACS Sustain. Chem. Eng. 2023, 11, 14901–14912. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2019; IEA: Paris, France, 2019. [Google Scholar]

- Islam, M.M.; Hasanuzzaman, M.; Pandey, A.K.; Rahim, N.A. Modern Energy Conversion Technologies. In Energy for Sustainable Development; Elsevier: Amsterdam, The Netherlands, 2020; pp. 19–39. [Google Scholar]

- Elias, R.S.; Wahab, M.I.M.; Fang, L. Retrofitting Carbon Capture and Storage to Natural Gas-Fired Power Plants: A Real-Options Approach. J. Clean. Prod. 2018, 192, 722–734. [Google Scholar] [CrossRef]

- Lassio, J.G.; Magrini, A.; Castelo Branco, D. Life Cycle-Based Sustainability Indicators for Electricity Generation: A Systematic Review and a Proposal for Assessments in Brazil. J. Clean. Prod. 2021, 311, 127568. [Google Scholar] [CrossRef]

- Barros, M.V.; Piekarski, C.M.; De Francisco, A.C. Carbon Footprint of Electricity Generation in Brazil: An Analysis of the 2016–2026 Period. Energies 2018, 11, 1412. [Google Scholar] [CrossRef]

- La Picirelli de Souza, L.; Eduardo Silva Lora, E.; Rajabi Hamedani, S.; Escobar Palacio, J.C.; Cioccolanti, L.; Villarini, M.; Comodi, G.; Colantoni, A. Life Cycle Assessment of Prospective Scenarios Maximizing Renewable Resources in the Brazilian Electricity Matrix. Renew. Energy Focus 2023, 44, 1–18. [Google Scholar] [CrossRef]

- Sakamoto, H.; Maciel, M.; Henrique Cardoso, F.; Kulay, L. Energy and Environmental Contributions for Future Natural Gas Supply Planning in Brazil. Energy Technol. 2020, 8, 1900976. [Google Scholar] [CrossRef]

- Darabkhani, H.G.; Varasteh, H.; Bazooyar, B. Oxyturbine Power Cycles and Gas-CCS Technologies. In Carbon Capture Technologies for Gas-Turbine-Based Power Plants; Elsevier: Amsterdam, The Netherlands, 2023; pp. 39–74. [Google Scholar]

- ETSAP. Gas-Fired Power. ETSAP. 2012. Available online: https://iea-etsap.org/E-TechDS/PDF/E02-gas_fired_power-GS-AD-gct_FINAL.pdf (accessed on 3 September 2024).

- MME. Supplementary Information to the Monthly Monitoring Bulletin of the Natural Gas Industry; Ministry of Mines and Energy: Brasília, Brazil, 2023.

- IEMA. Thermoelectricity in Focus: Use of Water in Thermoelectric Power Plants; IEMA: São Paulo, Brazil, 2016. [Google Scholar]

- Arrieta, F.R.P.; Lora, E.E.S. Influence of Ambient Temperature on Combined-Cycle Power-Plant Performance. Appl. Energy 2005, 80, 261–272. [Google Scholar] [CrossRef]

- Junior, N.P.; Gazoli, J.R.; Sete, A.; Velasquez, R.M.G.; Hunt, J.D.; Bindemann, F.T.; Wounnsoscky, W.; de Freitas, M.A.V.; de Ávila Condessa, G.; Ismail, K.A.R. Climate Impact on Combined Cycle Thermoelectric Power Plant in Hot and Humid Regions. Results Eng. 2023, 19, 101342. [Google Scholar] [CrossRef]

- Rosenbaum, R.K.; Hauschild, M.Z.; Boulay, A.-M.; Fantke, P.; Laurent, A.; Núñez, M.; Vieira, M. Life Cycle Impact Assessment. In Life Cycle Assessment; Hauschild, M., Rosenbaum, R., Olsen, S., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 167–270. [Google Scholar]

- Laurent, A.; Espinosa, N.; Hauschild, M.Z. LCA of Energy Systems. In Life Cycle Assessment; Hauschild, M., Rosenbaum, R., Olsen, S., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 633–668. ISBN 9783319564753. [Google Scholar]

- ISO 14067:2013; Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification and Communication. International Organization for Standardization: Geneva, Switzerland, 2013.

- ONS. Operation History—Power Generation. 2024. Available online: https://www.ons.org.br/Paginas/resultados-da-operacao/historico-da-operacao/geracao_energia.aspx (accessed on 3 September 2024).

- CEPEL. EMISFERA Platform—Emissions Calculation and Analysis Tool; CEPEL: Rio de Janeiro, Brazil, 2018. [Google Scholar]

- Gommes, D.; Watterson, J. Chapter 2: Stationary Combustion 2006 IPCC Guidelines for National Greenhouse Gas Inventories 2.1 Volume 2: Energy 2.2; IPCC: Geneva, Switzerland, 2006. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Meng, F.; Dillingham, G. Life Cycle Analysis of Natural Gas-Fired Distributed Combined Heat and Power versus Centralized Power Plant. Energy Fuels 2018, 32, 11731–11741. [Google Scholar] [CrossRef]

- Abdulsamad, A.; George-Ikoli, T. Strengthening Methane Emissions Reduction in Nigeria’s Oil and Gas Sector. 2024. Available online: https://resourcegovernance.org/sites/default/files/2024-07/strengthening-methane-emissions-reduction-in-nigeria%E2%80%99s-oil-and-gas-sector-6552.pdf (accessed on 3 September 2024).

- ANP. Consolidated Production Report 2021: Oil and Natural Gas Production; ANP: Rio de Janeiro, Brazil, 2022. [Google Scholar]

- Turconi, R.; Boldrin, A.; Astrup, T. Life Cycle Assessment (LCA) of Electricity Generation Technologies: Overview, Comparability and Limitations. Renew. Sustain. Energy Rev. 2013, 28, 555–565. [Google Scholar] [CrossRef]

- Spath, P.; Mann, M. Life Cycle Assessment of a Natural Gas Combined—Cycle Power Generation System; National Renewable Energy Lab.(NREL): Golden, CO, USA, 2000.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).