Utilization of Waste Glass Powder in Cement Mortar †

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Physical and Mechanical Properties

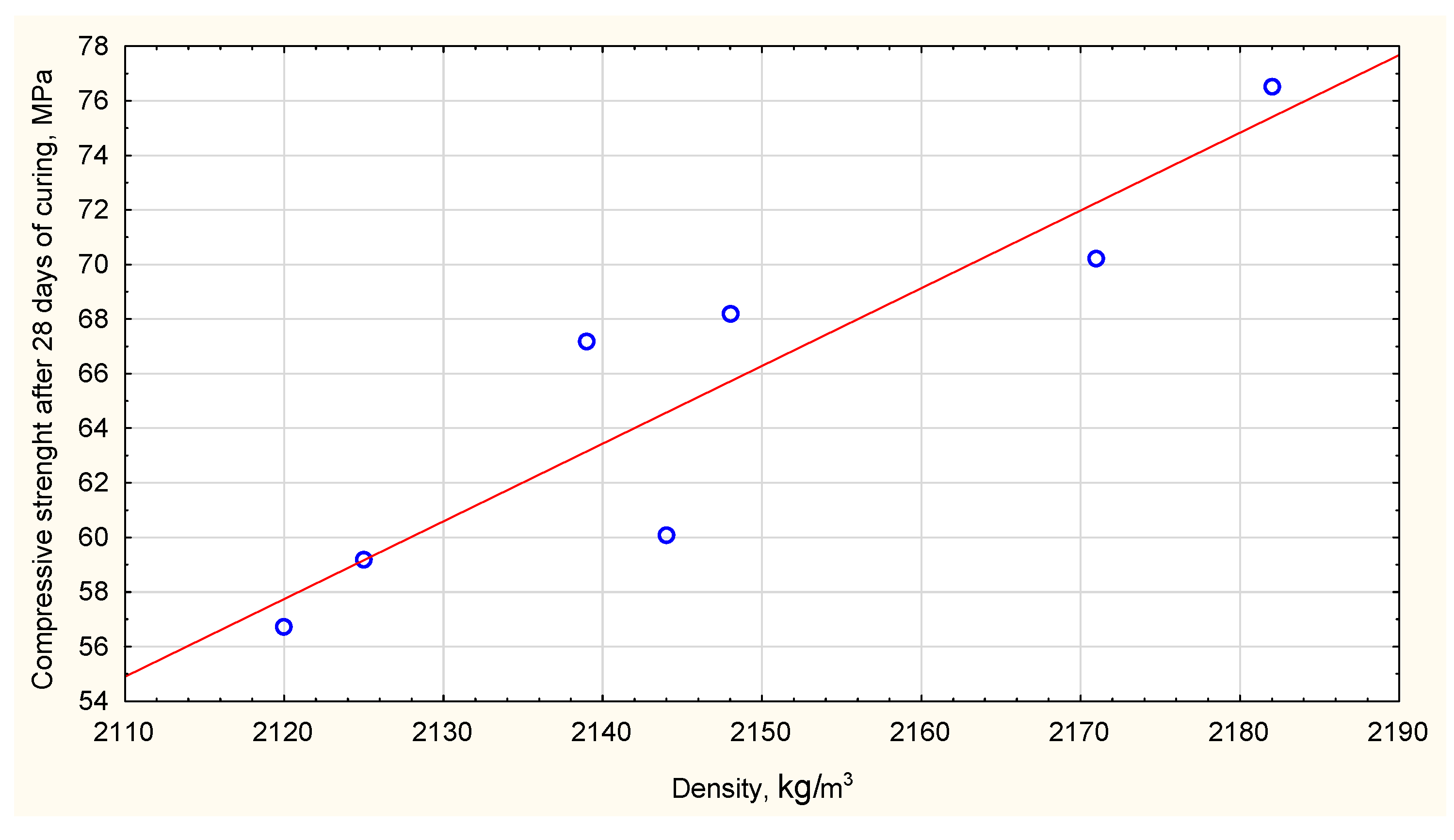

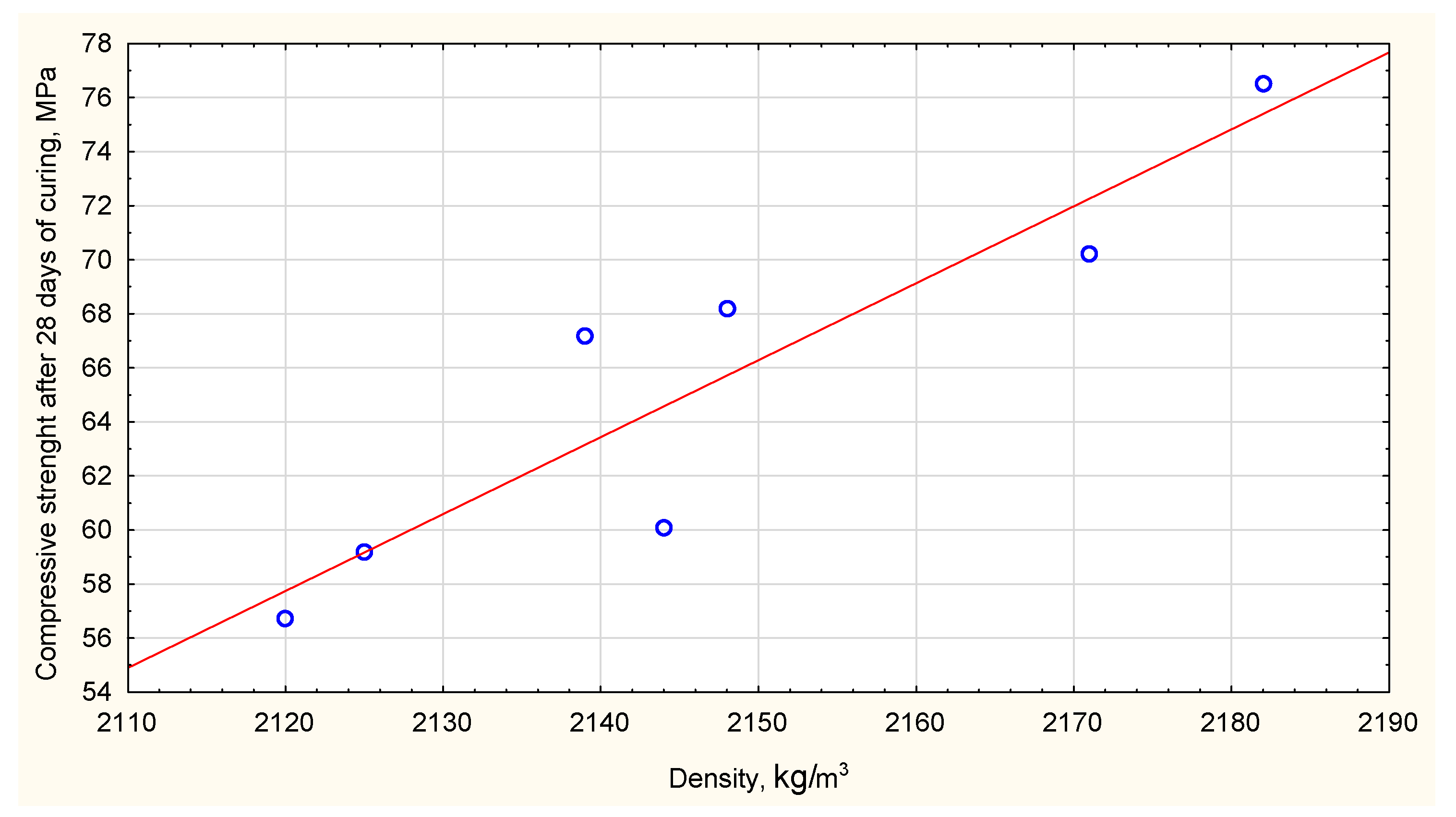

3.2. Relationship between Physical and Mechanical Properties and the Density of Hardened Mortar

4. Conclusions

- 1.

- The obtained linear regression equations illustrate the relationships between the density and compressive strength, and between the density and flexural strength at 28 days. These relationships were expressed by linear regression equations with a correlation coefficient r > 0.914.

- 2.

- The test results revealed that waste glass powder can be used in small amounts of cement-based mortars to reduce the amount of cement and to utilize waste glass. A higher performance, modified cement-based mortar can be produced for civil engineering applications by replacing 5 % with waste glass powder.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abhay, S.; Shashivendra, D. Mechanical performance of lean mortar mixes comprising glass powder as cement replacement. Compliance Eng. J. 2019, 10. Available online: https://www.researchgate.net/publication/343083546 (accessed on 13 March 2021).

- Aliabdo, A.A.; Elmoaty, M.A.; Elmoaty, A.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Madandoust, R.; Ghavidel, R. Mechanical properties of concrete containing waste glass powder and rice husk ash. Biosyst. Eng. 2013, 116, 113–119. [Google Scholar] [CrossRef]

- Wang, H.Y.; Zeng, H.; Wu, J.Y. A study on the macro and micro properties of concrete with LCD glass. Constr. Build. Mater. 2014, 50, 664–670. [Google Scholar] [CrossRef]

- Khmiri, A.; Chaabouni, M.; Samet, B. Chemical behaviour of ground waste glass when used as partial cement replacement in mortars. Constr. Build. Mater. 2013, 44, 74–80. [Google Scholar] [CrossRef]

- Carsana, M.; Frassoni, M.; Bertolinia, L. Comparison of ground waste glass with other supplementary cementitious materials. Cem. Concr. Compos. 2014, 45, 39–45. [Google Scholar] [CrossRef]

- Calmona, J.L.; Sauera, A.S.; Vieiraa, G.L.; Teixeira, J.E.S.L. Effects of windshield waste glass on the properties of structural repair mortars. Cem. Concr. Compos 2014, 53, 88–96. [Google Scholar] [CrossRef]

- Madandousta, R.; Ranjbara, M.M.; Moghadamb, H.A.; Mousavi, S.Y. Mechanical properties and durability assessment of rice husk ash concrete. Biosyst. Eng. 2011, 110, 144–152. [Google Scholar] [CrossRef]

- Cassar, J.; Camilleri, J. Utilisation of imploded glass in structural concrete. Constr. Build. Mater. 2012, 29, 299–307. [Google Scholar] [CrossRef]

- Sadiqul Islam, G.M.; Rahman, M.H.; Kazi, N. Waste glass powder as partial replacement of cement for sustainable concrete practice. Int. J. Sustain. Built Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef] [Green Version]

- Tamanna, N.; Tuladhar, R. Sustainable Use of Recycled Glass Powder as Cement Replacement in Concrete. Open Waste Manag. J. 2020, 13, 1–13. Available online: https://openwastemanagementjournal.com/VOLUME/13/PAGE/1/ (accessed on 13 March 2021). [CrossRef]

| Waste Glass Powder, % | 0 | 5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|---|

| CEM I 42.5 R, % | 26.9 | 25.6 | 24.3 | 22.9 | 21.6 | 20.2 | 18.9 |

| Glass powder, % | 0.1 | 1.4 | 2.7 | 4.1 | 5.4 | 6.8 | 8.1 |

| Sand, % | 60.6 | 60.6 | 60.6 | 60.6 | 60.6 | 60.6 | 60.6 |

| Water, % | 12.4 | 12.4 | 12.4 | 12.4 | 12.4 | 12.4 | 12.4 |

| Waste Glass Powder, % | 0 | 5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|---|

| Density, kg/m³ | 2171 | 2182 | 2148 | 2139 | 2144 | 2125 | 2120 |

| Flexural strength, MPa | 6.3 | 7.1 | 6.2 | 5.9 | 5.6 | 5.4 | 4.6 |

| Compressive strength, MPa | 70.2 | 76.5 | 68.2 | 67.2 | 60.1 | 59.2 | 56.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagrockienė, D.; Barkauskas, K. Utilization of Waste Glass Powder in Cement Mortar. Environ. Sci. Proc. 2021, 9, 25. https://doi.org/10.3390/environsciproc2021009025

Nagrockienė D, Barkauskas K. Utilization of Waste Glass Powder in Cement Mortar. Environmental Sciences Proceedings. 2021; 9(1):25. https://doi.org/10.3390/environsciproc2021009025

Chicago/Turabian StyleNagrockienė, Džigita, and Kęstutis Barkauskas. 2021. "Utilization of Waste Glass Powder in Cement Mortar" Environmental Sciences Proceedings 9, no. 1: 25. https://doi.org/10.3390/environsciproc2021009025

APA StyleNagrockienė, D., & Barkauskas, K. (2021). Utilization of Waste Glass Powder in Cement Mortar. Environmental Sciences Proceedings, 9(1), 25. https://doi.org/10.3390/environsciproc2021009025