Using Thermal Neutron Imaging in Forest Products Research †

Abstract

1. Introduction

2. Materials and Methods

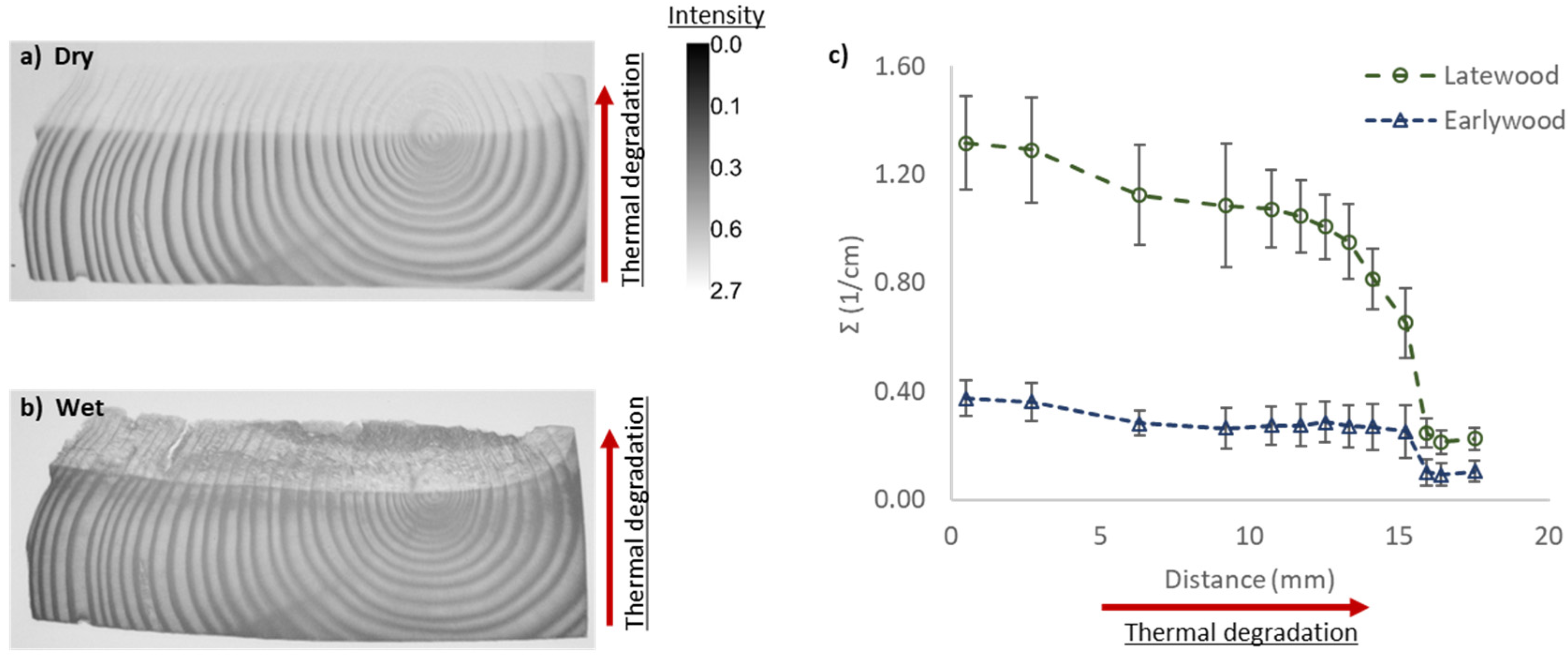

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jakes, J.E.; Arzola, X.; Bergman, R.; Ciesielski, P.; Hunt, C.G.; Rahbar, N.; Tshabalala, M.; Wiedenhoeft, A.C.; Zelinka, S.L. Not Just Lumber—Using Wood in the Sustainable Future of Materials, Chemicals, and Fuels. JOM 2016, 68, 2395–2404. [Google Scholar] [CrossRef]

- Langan, P.; Evans, B.R.; Foston, M.; Heller, W.T.; O’Neill, H.; Petridis, L.; Pingali, S.V.; Ragauskas, A.J.; Smith, J.C.; Urban, V.S.; et al. Neutron Technologies for Bioenergy Research. Ind. Biotechnol. 2012, 8, 209–216. [Google Scholar] [CrossRef]

- Kardjilov, N.; Festa, G. (Eds.) Neutron Methods for Archaeology and Cultural Heritage; Part of the Neutron Scattering Applications and Techniques Book Series; Springer International Publishing: Cham, Switzerland, 2017; ISBN 978-3-319-33161-4. [Google Scholar] [CrossRef]

- Odin, G.P.; Rouchon, V.; Ott, F.; Malikova, N.; Levitz, P.; Michot, L.J. Neutron imaging investigation of fossil woods: Non-destructive characterization of microstructure and detection of in situ changes as occurring in museum cabinets. Foss. Rec. 2017, 20, 95–103. [Google Scholar] [CrossRef][Green Version]

- Sonderegger, W.; Hering, S.; Mannes, D.; Vontobel, P.; Lehmann, E.; Niemz, P. Quantitative determination of bound water diffusion in multilayer boards by means of neutron imaging. Eur. J. Wood Wood Prod. 2010, 68, 341–350. [Google Scholar] [CrossRef][Green Version]

- Sonderegger, W.; Glaunsinger, M.; Mannes, D.; Volkmer, T.; Niemz, P. Investigations into the influence of two different wood coatings on water diffusion determined by means of neutron imaging. Eur. J. Wood Wood Prod. 2015, 73, 793–799. [Google Scholar] [CrossRef]

- Lanvermann, C.; Sanabria, S.J.; Mannes, D.; Niemz, P. Combination of neutron imaging (NI) and digital image correlation (DIC) to determine intra-ring moisture variation in Norway spruce. Holzforschung 2014, 68, 113–122. [Google Scholar] [CrossRef]

- Sedighi Gilani, M.; Abbasion, S.; Lehmann, E.; Carmeliet, J.; Derome, D. Neutron imaging of moisture displacement due to steep temperature gradients in hardwood. Int. J. Therm. Sci. 2014, 81, 1–12. [Google Scholar] [CrossRef]

- Islam, M.N.; Khan, M.A.; Alam, M.K.; Zaman, M.A.; Matsubayashi, M. Study of water absorption behavior in wood plastic composites by using neutron radiography techniques. Polym. Plast. Technol. Eng. 2003, 42, 925–934. [Google Scholar] [CrossRef]

- Mannes, D.; Lehmann, E.; Cherubini, P.; Niemz, P. Neutron imaging versus standard X-ray densitometry as method to measure tree-ring wood density. Trees Struct. Funct. 2007, 21, 605–612. [Google Scholar] [CrossRef]

- Sonderegger, W.; Mannes, D.; Kaestner, A.; Hovind, J.; Lehmann, E. On-line monitoring of hygroscopicity and dimensional changes of wood during thermal modification by means of neutron imaging methods. Holzforschung 2015, 69, 87–95. [Google Scholar] [CrossRef]

- Ossler, F.; Santodonato, L.J.; Warren, J.M.; Finney, C.E.A.; Bilheux, J.C.; Mills, R.A.; Skorpenske, H.D.; Bilheux, H.Z. In situ monitoring of hydrogen loss during pyrolysis of wood by neutron imaging. Proc. Combust. Inst. 2019, 37, 1273–1280. [Google Scholar] [CrossRef]

- Goldstein, I.S.; Jeroski, E.B.; Lund, A.E.; Nielson, J.F.; Weater, J.M. Acetylation of Wood in Lumber Thickness. For. Prod. J. 1961, 11, 363–370. [Google Scholar]

- Ibach, R.E.; Clemons, C.M.; Schumann, R.L. WPCs with Reduced Moisture: Effects of Chemical Modification on Durability in the Laboratory and Field. In Proceedings of the 9th International Conference on Woodfiber-Plastic Composites, Madison, WI, USA, 21–23 May 2007; pp. 259–266. [Google Scholar]

- Ibach, R.E.; Rowell, R.M.; Lee, B.-G. Decay Protection Based on Moisture Exclusion Resulting From Chemical Modification of Wood. In Proceedings of the 5th Pacific Rim Bio-Based Composites Symposium, Canberra, Australia, 10–13 December 2000; pp. 197–204. [Google Scholar]

- Rasband, W.S.; ImageJ, U.S. National Institutes of Health, Bethesda, Maryland, USA. 1997–2018. Available online: https://imagej.nih.gov/ij/ (accessed on 5 November 2020).

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef] [PubMed]

- Mori, M.; Kuhara, S.; Kobayashi, K.; Suzuki, S.; Yamada, M.; Senoo, A. Non-destructive tree-ring measurements using a clinical 3T-MRI for archaeology. Dendrochronologia 2019, 57, 125630. [Google Scholar] [CrossRef]

- Carminati, C.; Boillat, P.; Schmid, F.; Vontobel, P.; Hovind, J.; Morgano, M.; Raventos, M.; Siegwart, M.; Mannes, D.; Gruenzweig, C.; et al. Implementation and assessment of the black body bias correction in quantitative neutron imaging. PLoS ONE 2019, 14, e0210300. [Google Scholar] [CrossRef] [PubMed]

- Gnatowski, M.; Ibach, R.; Leung, M.; Sun, G. Magnetic resonance imaging used for the evaluation of water presence in wood plastic composite boards exposed to exterior conditions. Wood Mater. Sci. Eng. 2015, 10, 94–111. [Google Scholar] [CrossRef]

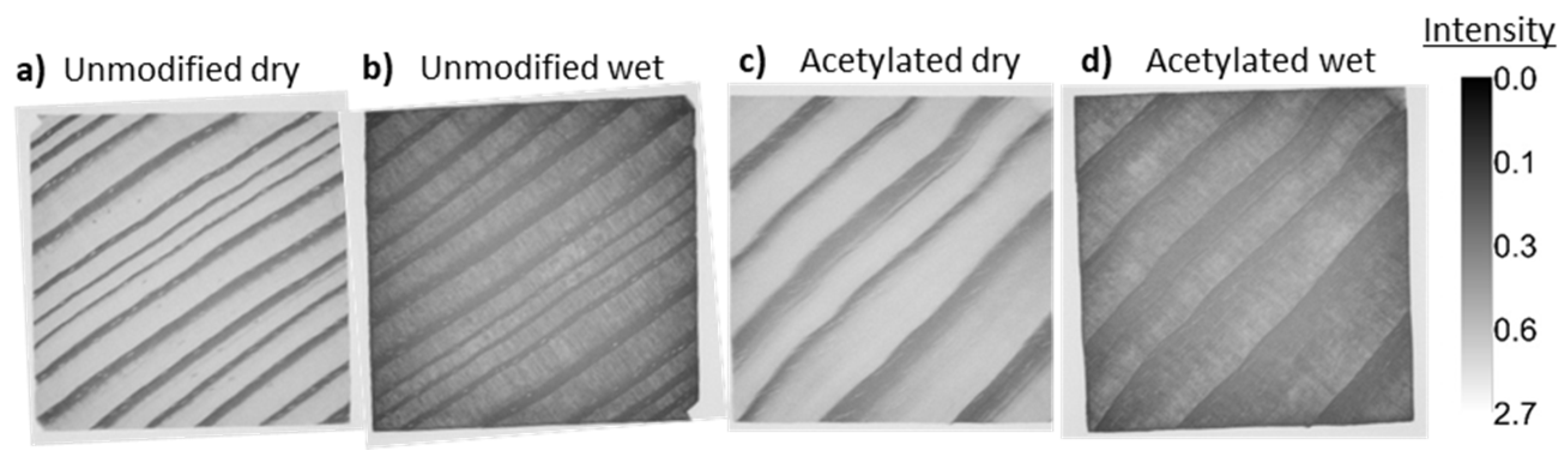

| Sample | ||

|---|---|---|

| Dry | Wet | |

| Unmodified Wood | 0.86 (0.15) 1 | 0.92 (0.33) 1 |

| 0.15 (0.04) 2 | 0.63 (0.21) 2 | |

| Acetylated Wood (20% WPG) | 0.71 (0.16) 1 | 0.75 (0.21) 1 |

| 0.16 (0.07) 2 | 0.60 (0.21) 2 | |

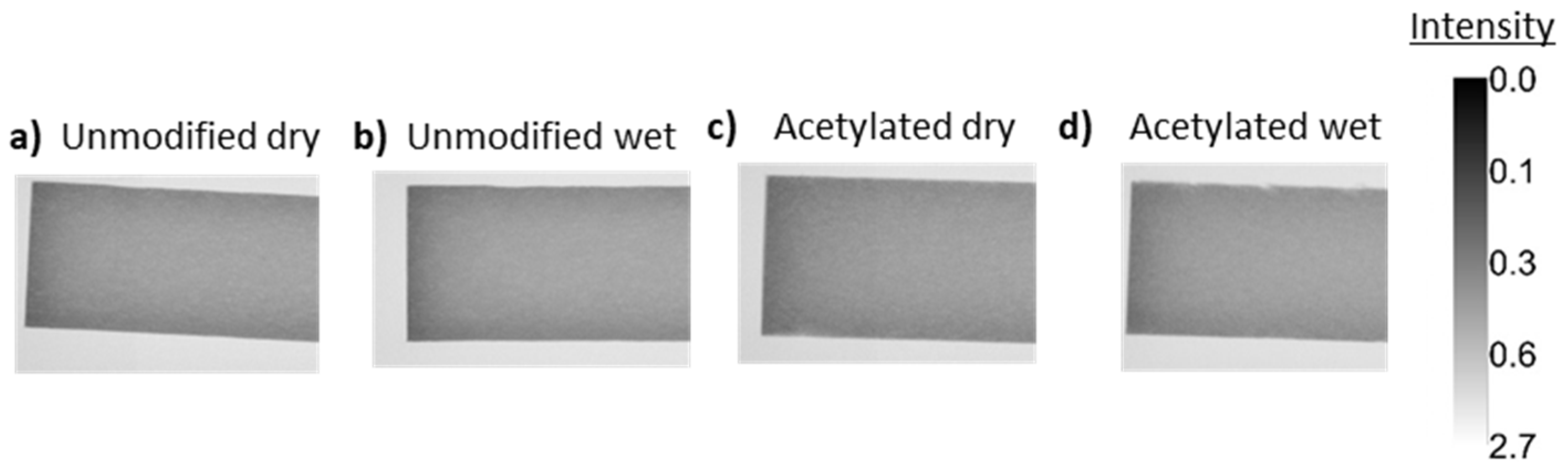

| Sample | ||

|---|---|---|

| Dry | Wet | |

| Unmodified WPC | 1.18 (0.04) 1 | 1.06 (0.20) 1 |

| 0.84 (0.07) 2 | 0.77 (0.06) 2 | |

| Acetylated WPC | 1.31 (0.24) 1 | 1.12 (0.20) 1 |

| 0.85 (0.07) 2 | 0.79 (0.05) 2 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Plaza, N.Z.; Ibach, R.E.; Hasburgh, L.E.; Taylor, M. Using Thermal Neutron Imaging in Forest Products Research. Environ. Sci. Proc. 2021, 3, 92. https://doi.org/10.3390/IECF2020-08082

Plaza NZ, Ibach RE, Hasburgh LE, Taylor M. Using Thermal Neutron Imaging in Forest Products Research. Environmental Sciences Proceedings. 2021; 3(1):92. https://doi.org/10.3390/IECF2020-08082

Chicago/Turabian StylePlaza, Nayomi Z., Rebecca E. Ibach, Laura E. Hasburgh, and Michael Taylor. 2021. "Using Thermal Neutron Imaging in Forest Products Research" Environmental Sciences Proceedings 3, no. 1: 92. https://doi.org/10.3390/IECF2020-08082

APA StylePlaza, N. Z., Ibach, R. E., Hasburgh, L. E., & Taylor, M. (2021). Using Thermal Neutron Imaging in Forest Products Research. Environmental Sciences Proceedings, 3(1), 92. https://doi.org/10.3390/IECF2020-08082