Modelling of Elevated Temperature Performance of Adhesives Used in Cross Laminated Timber: An Application of ANSYS Mechanical 2020 R1 Structural Analysis Software †

Abstract

:1. Introduction

- To determine the influence of the adhesive layer on thermal behaviour of CLT.

- To model the thermal behaviour of solid wood.

- To determine the mechanical properties of wood adhesives, especially loss in the adhesive bond strength due to rise in temperature.

2. Materials and Methods

2.1. Introduction and Materials’ Properties

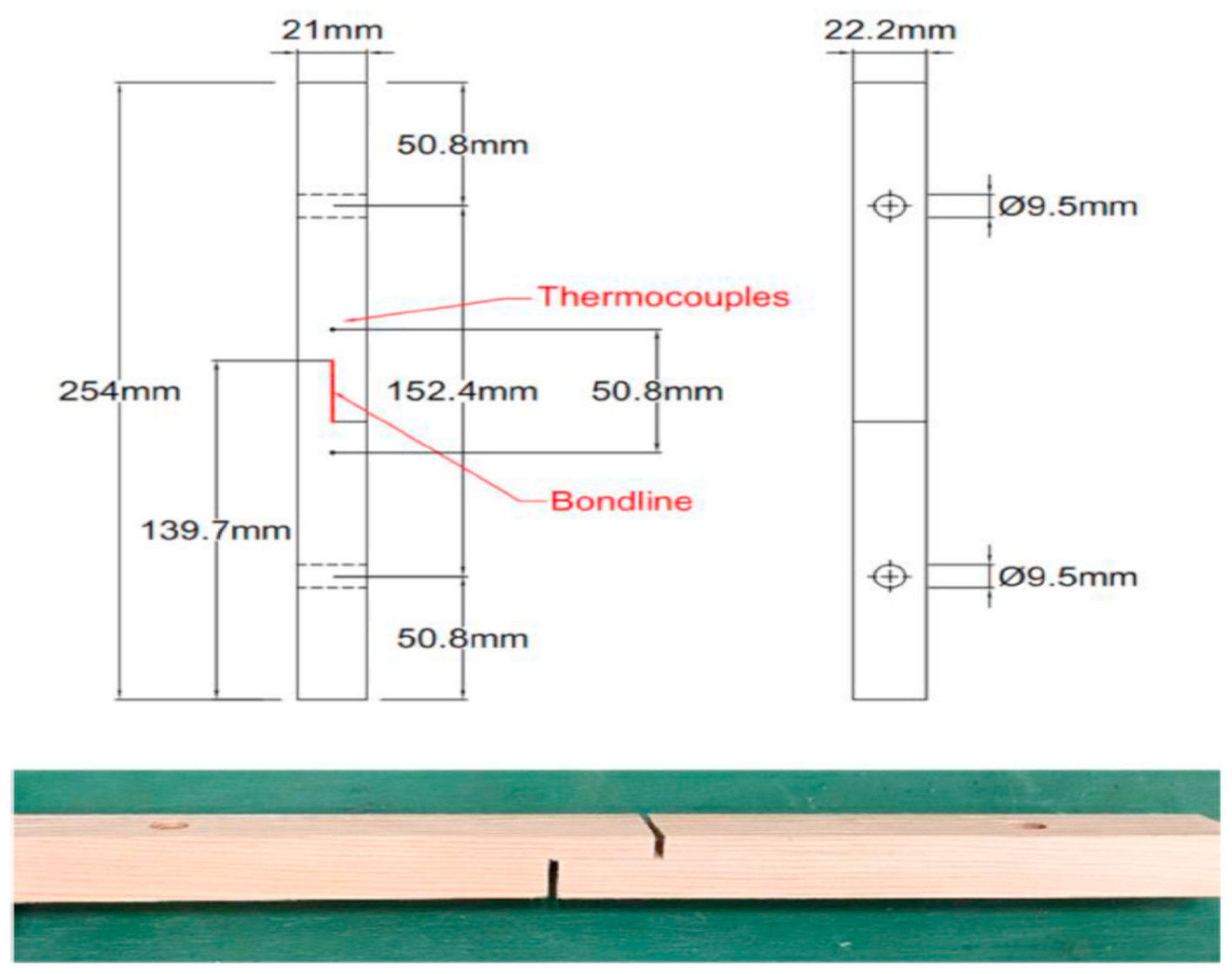

2.2. Thermal Model Analysis

2.2.1. Steady State Thermal Model

2.2.2. Analytical Model

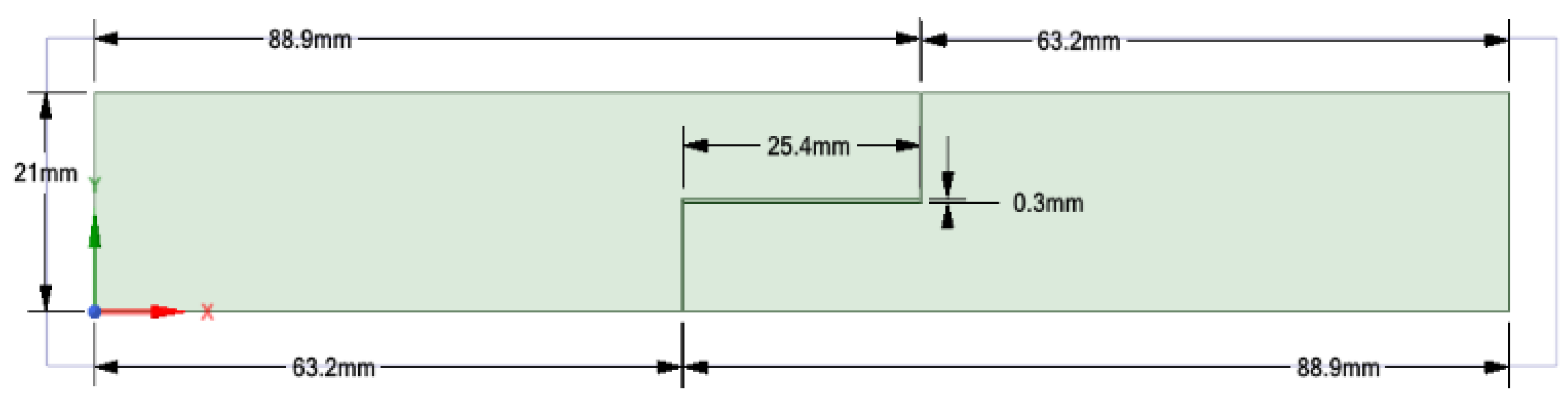

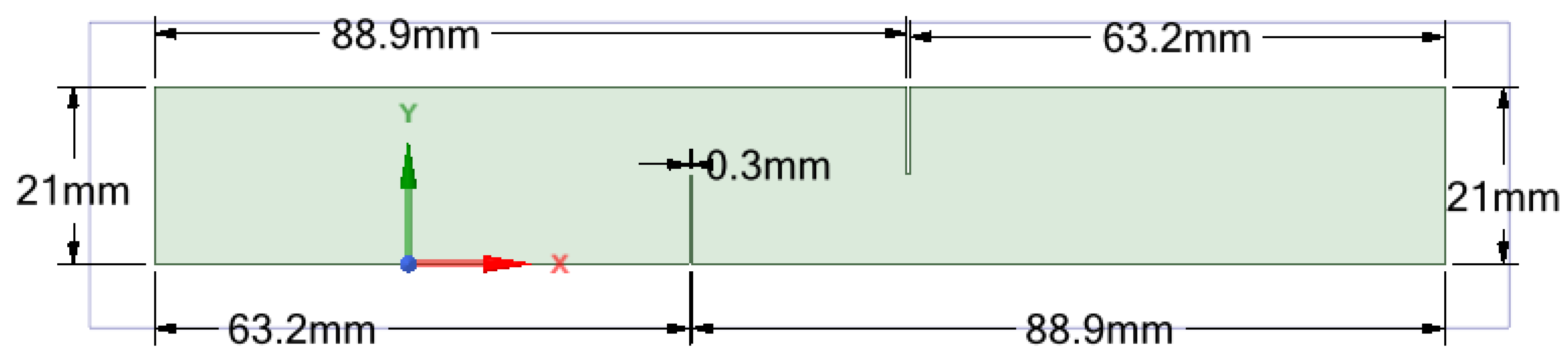

2.3. Thermal–Structural Behaviour of Wood

2.4. Thermal–Structural Behaviour of Adhesive Bond

3. Results and Analysis

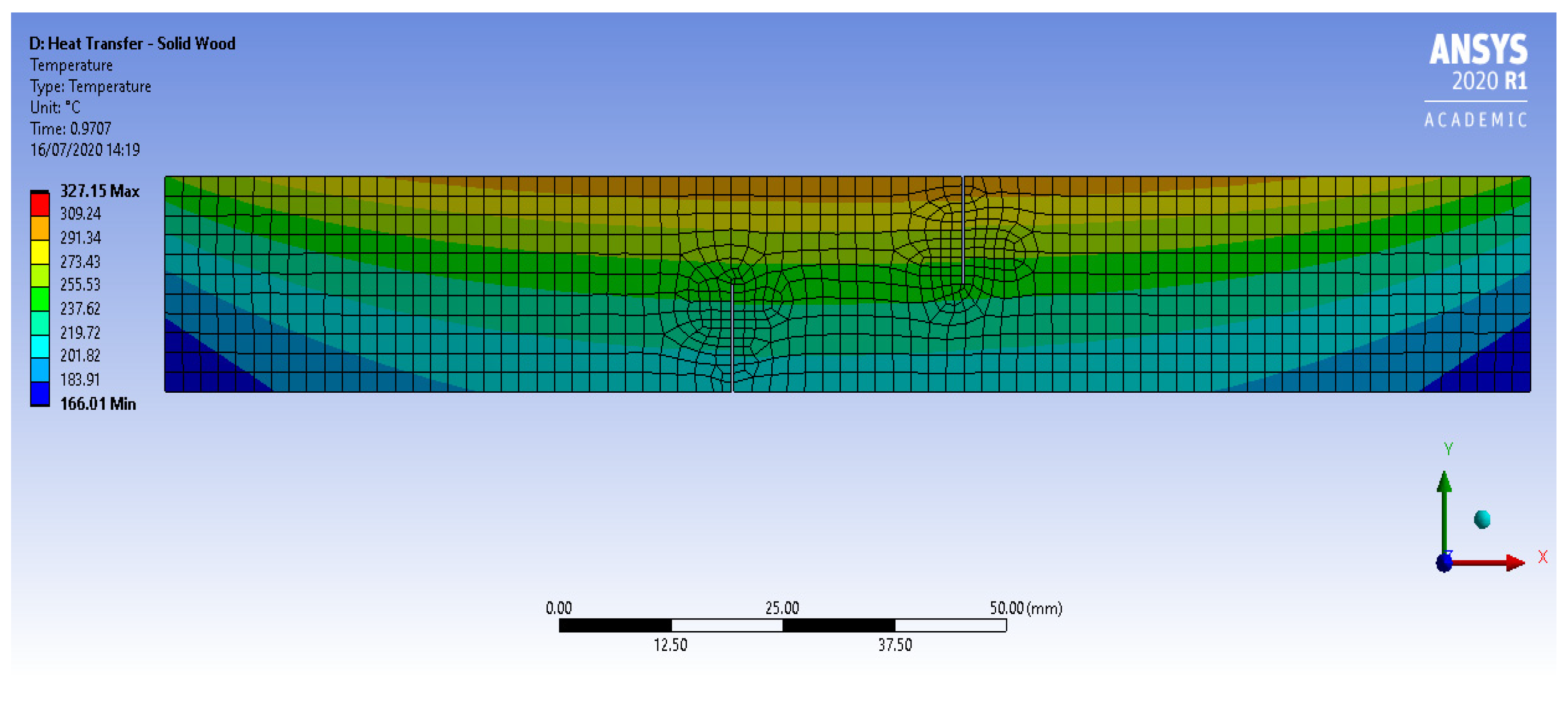

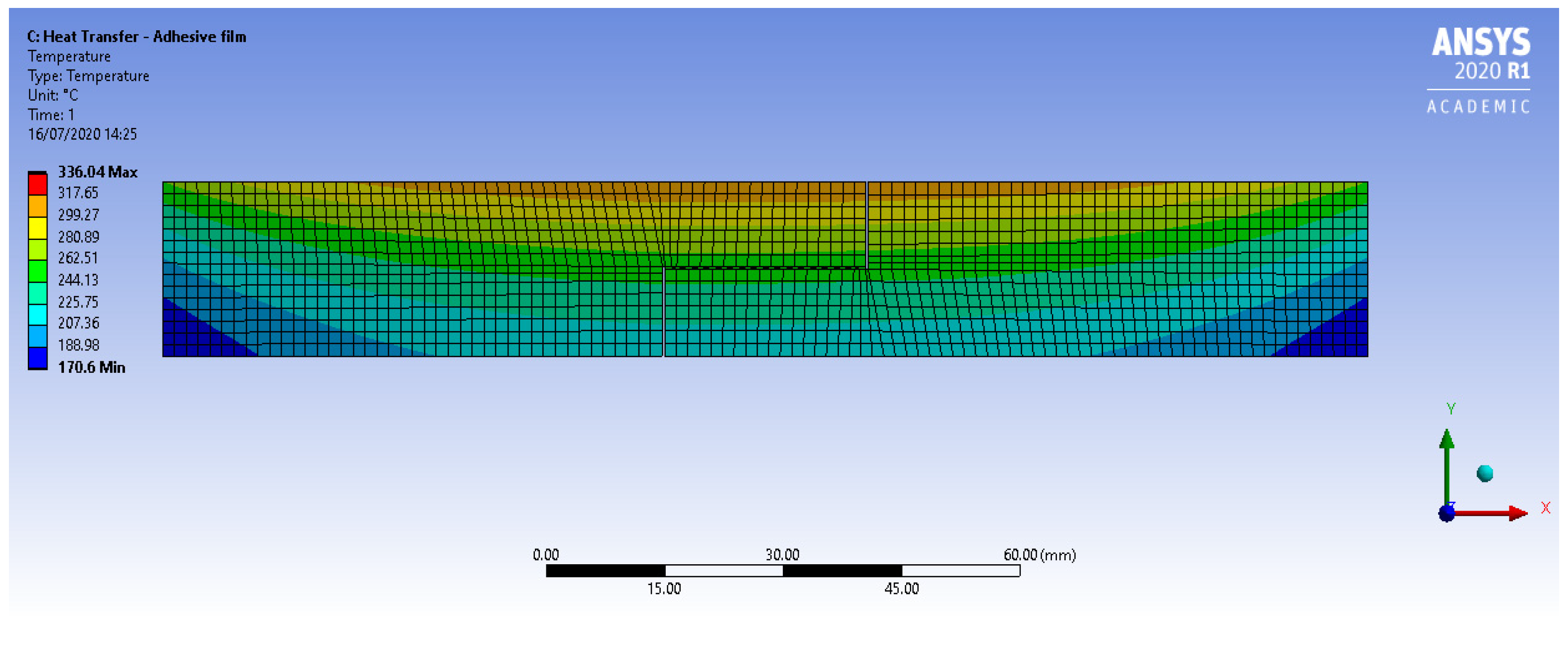

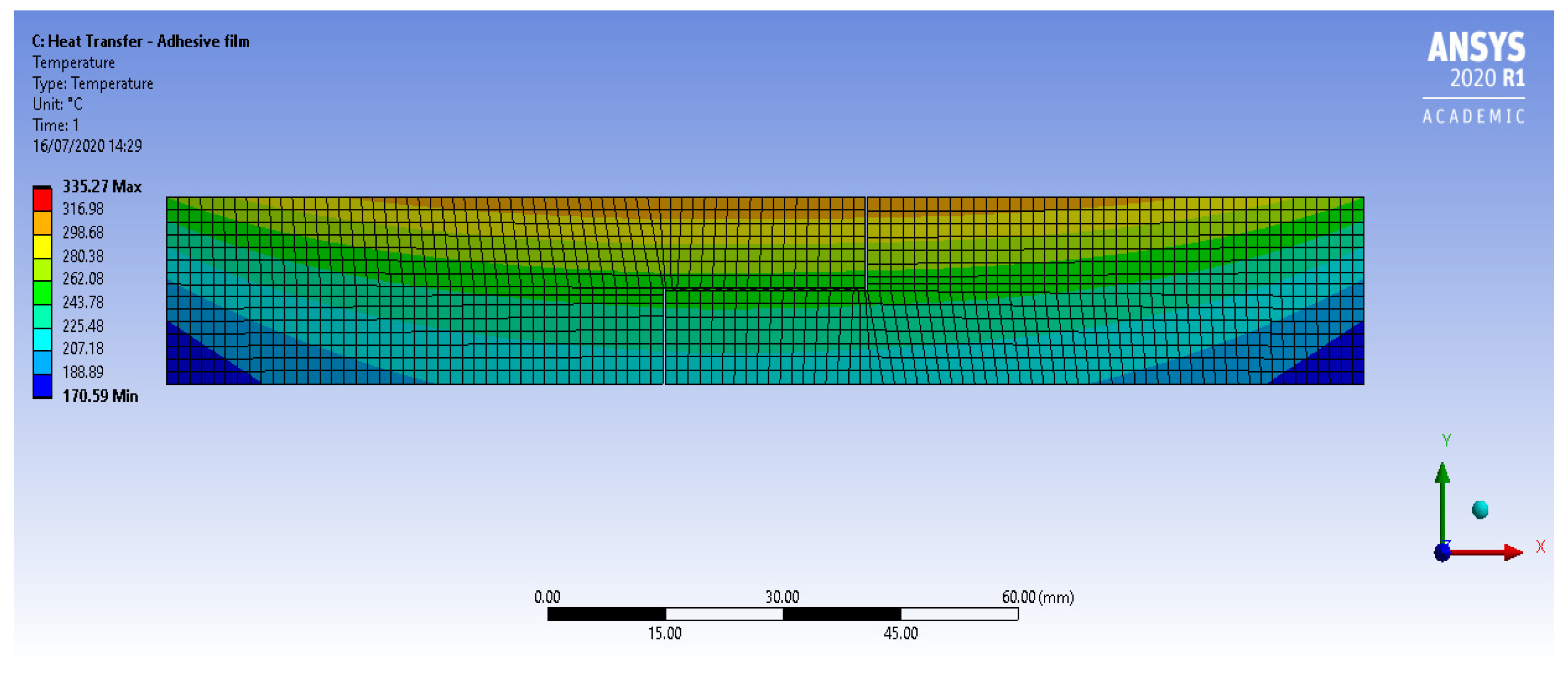

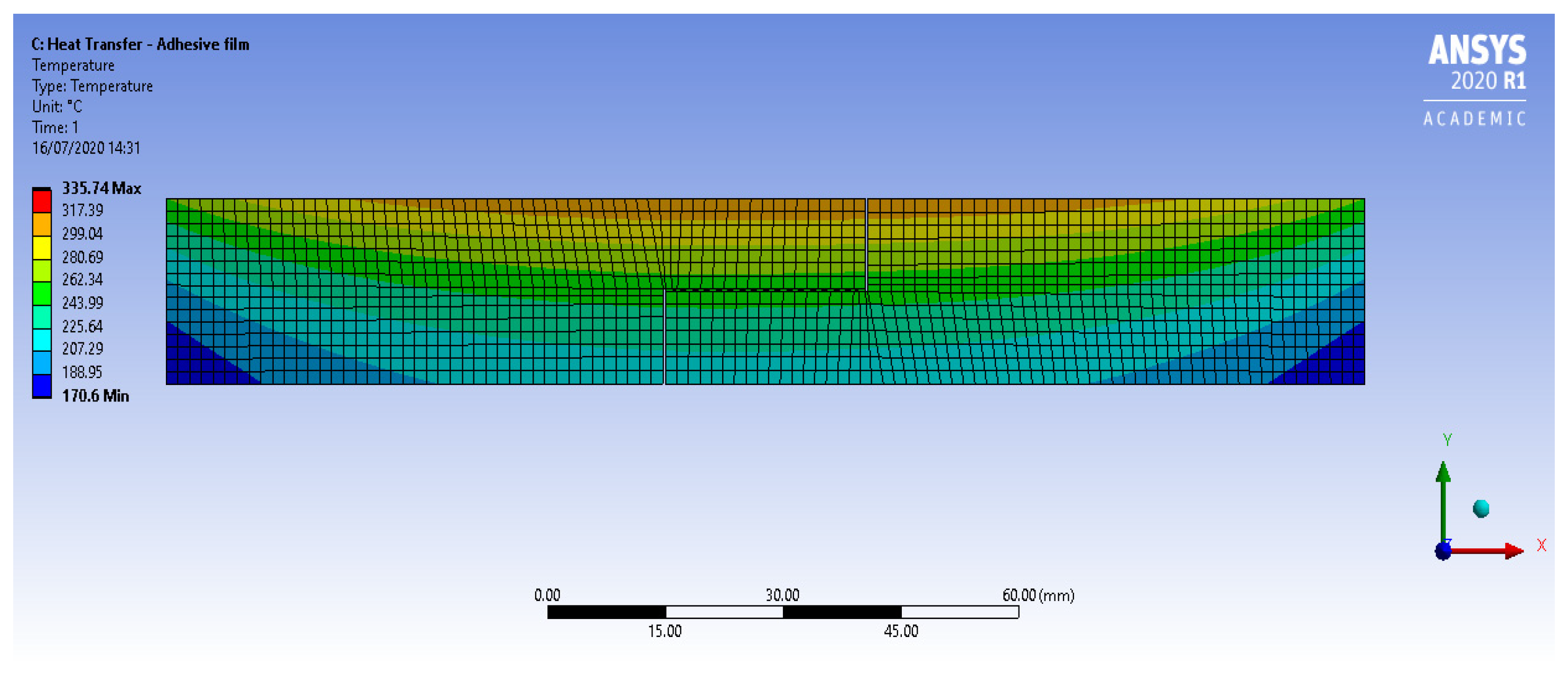

3.1. Steady State Thermal Model

3.2. Analytical Model

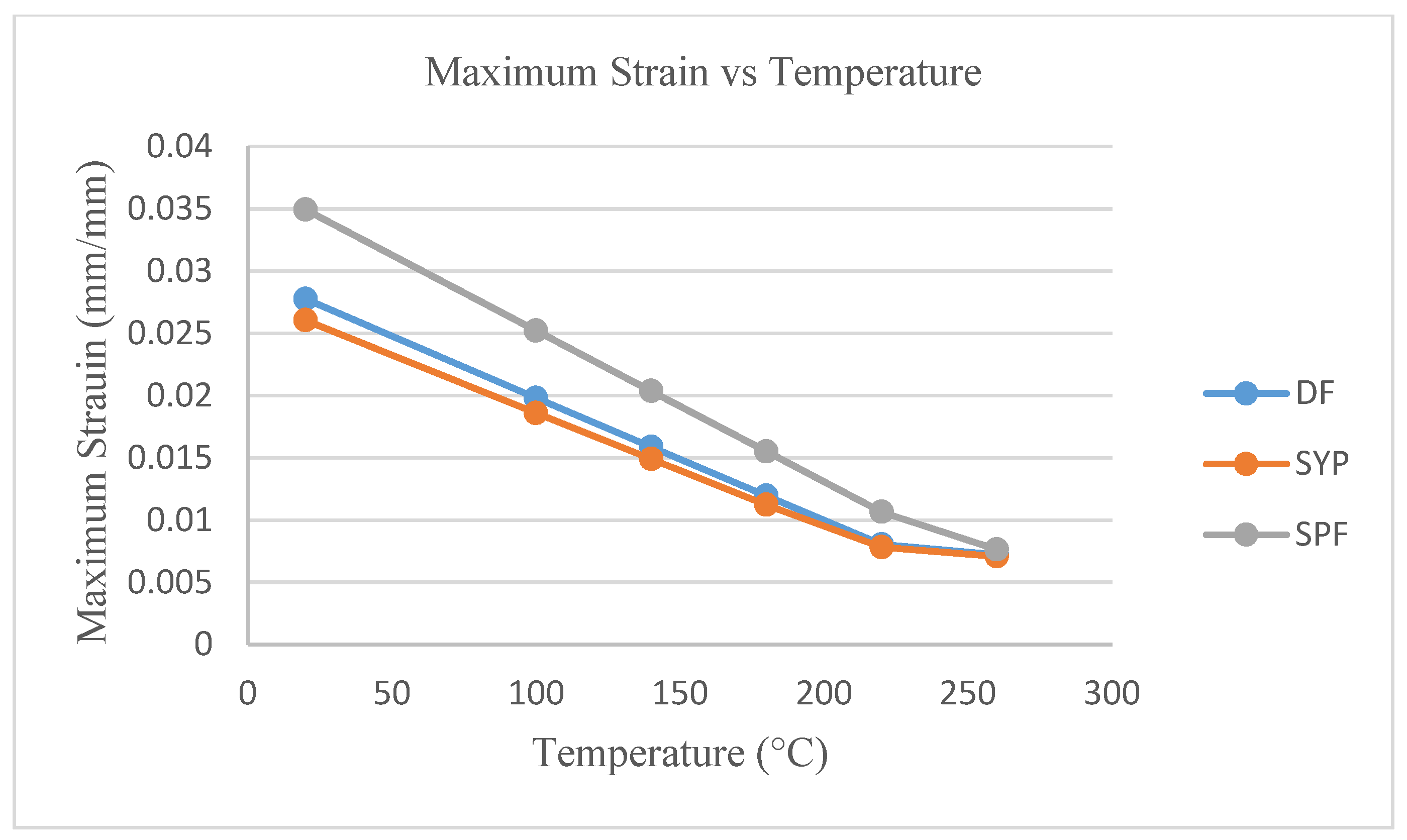

3.3. Thermal–Structural Behaviour of Wood

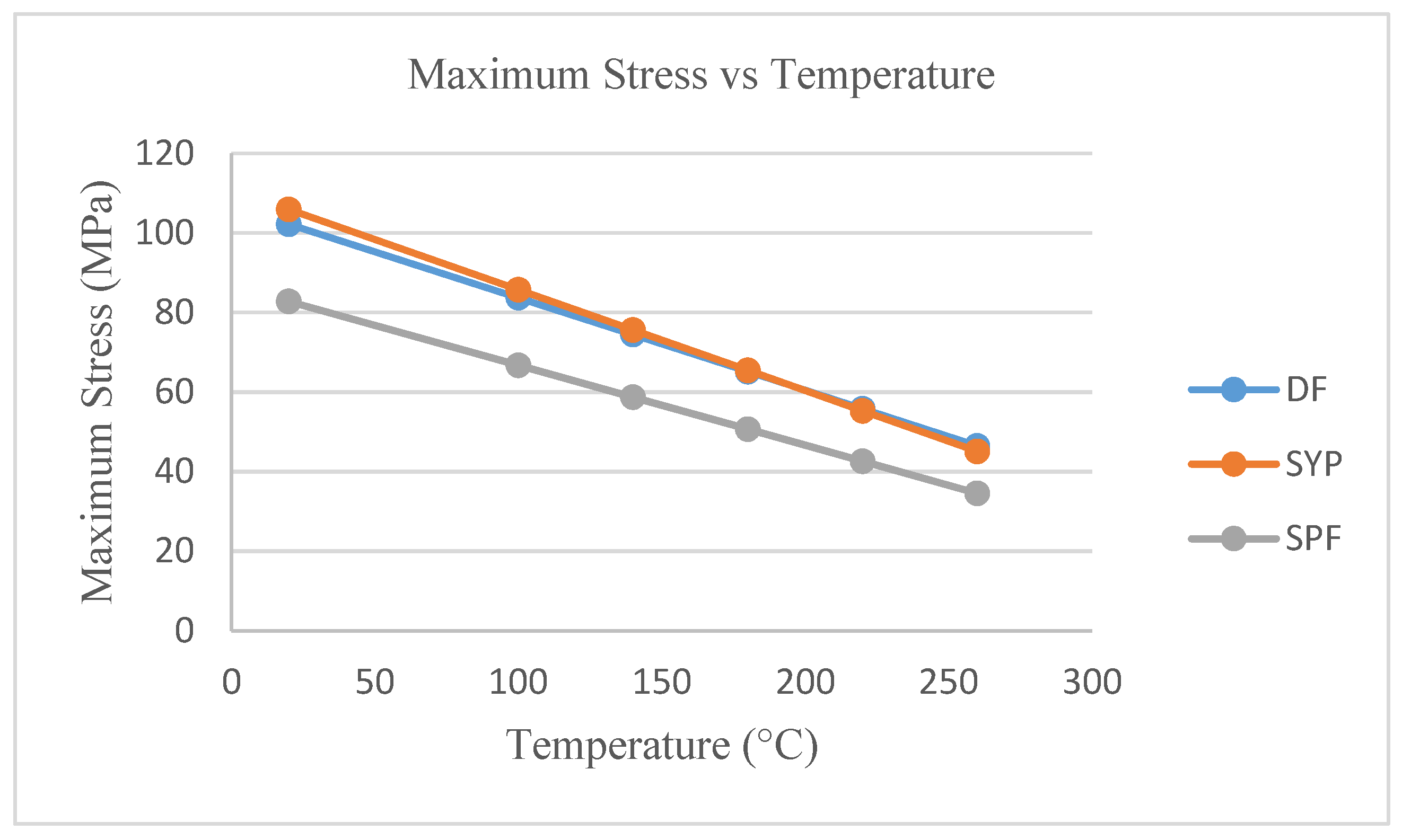

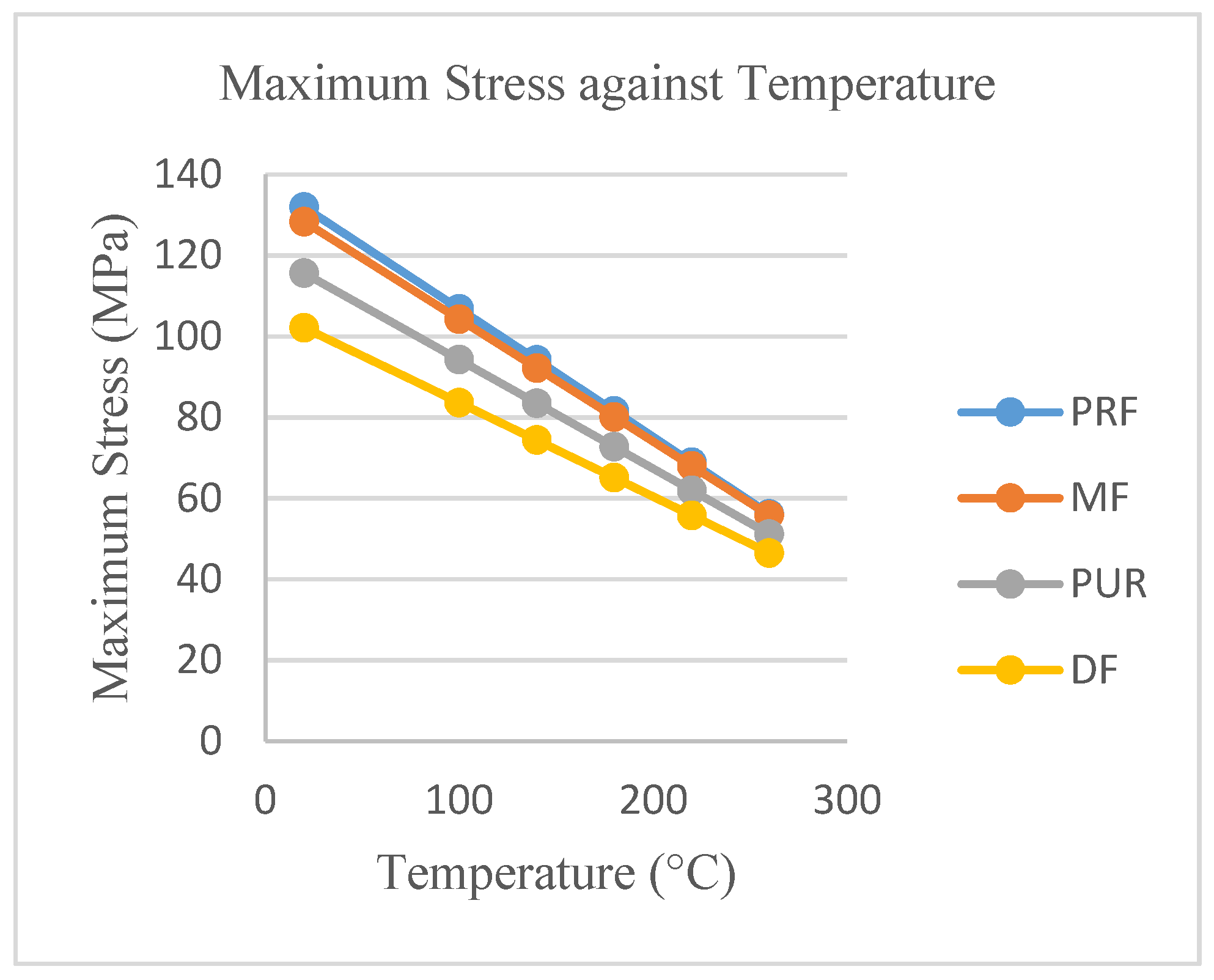

3.4. Thermal–Structural Behaviour of Adhesives

4. Discussion, Conclusions and Future Research

4.1. Discussion

4.1.1. To Determine the Influence of the Adhesive Layer on Thermal Behaviour of CLT

4.1.2. To Model the Thermal Behaviour of Solid Wood

4.1.3. To Determine the Mechanical Properties of Wood Adhesives, Especially Loss in the Adhesive Bond Strength due to Rise in Temperature

4.2. Conclusions

- The adhesive layer has little influence on the thermal properties of CLT and, therefore, the thermal properties of glued timber are the same as for solid timber. Wood adhesives have a significant influence on the structural properties of CLT.

- The stresses and strains of wood species decrease with increase in temperature.

- The stresses and strains of wood adhesives reduce with increase in temperature.

- PRF and MF are better structural adhesives than PUR.

- With accurate material properties, the thermal–structural behaviour of wooden structures can be analysed using ANSYS without having to carry out small-scale or large-scale experiments.

- Finally, the results from this research to a bigger extent support the experimental findings by Zelinka et al. [7].

4.3. Future Research

Funding

Acknowledgments

Conflicts of Interest

References

- Corfield, A. What Is Cross Laminated Timber (CLT)? Homebuilding & Renovating. 2020. Available online: https://www.homebuilding.co.uk/advice/cross-laminated-timber (accessed on 7 August 2020).

- European Cross-Laminated Timber Market: Industry Trends, O. European Cross-Laminated Timber Market Report and Forecast 2020–2025. 2020. Available online: https://www.imarcgroup.com/european-cross-laminated-timber-market (accessed on 7 August 2020).

- Liu, Y.; Guo, H.; Sun, C.; Chang, W.S. Assessing Cross Laminated Timber (CLT) as an Alternative Material for Mid-Rise Residential Buildings in Cold Regions in China-A Life-Cycle Assessment Approach. Sustainability 2016, 8, 1047. [Google Scholar] [CrossRef]

- Guo, H.; Liu, Y.; Meng, Y.; Huang, H.; Sun, C.; Shao, Y. A Comparison of the Energy Saving and Carbon Reduction Performance between Reinforced Concrete and Cross-Laminated Timber Structures in Residential Buildings in the Severe Cold Region of China. Sustainability 2017, 9, 1426. [Google Scholar] [CrossRef]

- Mallo, M.F.L.; Espinoza, O. Awareness, perceptions and willingness to adopt Cross-Laminated Timber by the architecture community in the United States. J. Clean. Prod. 2015, 94, 198–210. [Google Scholar] [CrossRef]

- Regents of the University of Minnesota and the Forest Products Management Development Institute. The Nature of Wood and Wood Products, A Self-Study Educational CD-ROM; University of Minnesota: Minneapolis, MN, USA, 2008. [Google Scholar]

- Zelinka, S.L.; Sullivan, K.; Pei, S.; Ottum, N.; Bechle, N.J.; Rammer, D.R.; Hasburgh, L.E. Small-scale tests on the performance of adhesives used in cross laminated timber (CLT) at elevated temperatures. Int. J. Adhes. Adhes. 2019, 95, 102436. [Google Scholar] [CrossRef]

- Zelinka, S.L.; Miyamoto, B.; Bechle, N.J.; Rammer, D. Small Scale Test to Measure the Strength of Adhesives at Elevated Temperatures for Use in Evaluating Adhesives for Cross Laminated Timber (CLT). In Wood & Fire Safety. WFS; Makovicka Osvaldova, L., Markert, F., Zelinka, S., Eds.; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Zelinka, S.; Pei, S.; Bechle, N.; Sullivan, K.; Ottum, N.; Rammer, D.; Hasburgh, L. Performance of wood adhesive for cross laminated timber under elevated temperatures. In Proceedings, WCTE 2018-World Conference on Timber Engineering; Korean Institute of Forest Science: Seoul, Korea, 2018; 7p. [Google Scholar]

- Wiesner, F. Structural Behaviour of Cross-Laminated Timber Elements in Fires. Ph.D. Thesis, The University of Edinburgh, Edinburgh, UK, 2015. Available online: https://hdl.handle.net/1842/36675. Available online: https://hdl.handle.net/1842/36675 (accessed on 7 August 2020).

- Kippenberg, G. Timber Comes First in Hackney. Electronic Article. 2017. Available online: https://www.ribaj.com/intelligence/innovation-timber (accessed on 7 August 2020).

- Load and Resistance Factor Design (LRFD). Manual for Engineered Wood Construction; APA-The Engineered Wood Association: Washington, DC, USA, 1996. [Google Scholar]

- Wood Handbook. Wood as an Engineering Material; General Technical Report FPL-GTR-113; Forest Products Laboratory, USDA Forest Service: Madison, WI, USA, 1999; p. 4. [Google Scholar]

- Wood Handbook. Wood as an Engineering Material; General Technical Report FPL-GTR-190; Forest Products Laboratory, USDA Forest Service: Madison, WI, USA, 2010. [Google Scholar]

- Aghayere, A.; Vigil, J. Structural Wood Design; CRC Press Inc: Boca Raton, FL, USA, 2017. [Google Scholar] [CrossRef]

- Goli, G.; Becherini, F.; Di Tuccio, M.C.; Bernardi, A.; Fioravanti, M. Thermal expansion of wood at different equilibrium moisture contents. J. Wood Sci. 2019, 65, 1–7. [Google Scholar] [CrossRef]

- ASHRAE. ASHRAE Handbook-Fundamentals; American Society of Heating, Refrigerating and Air-Conditioning Engineers IJlc: Atlanta, GA, USA, 1989. [Google Scholar]

- Charles, A. Harper. In Handbook of Plastics, Elastomers, and Composites, 4th ed.; McGRAW-ILL: New York, NY, USA, 2002. [Google Scholar]

- Sun, G.; Zhang, Z. Mechanical properties of melamine-formaldehyde microcapsules. J. Microencapsul. 2001, 18, 593–602. [Google Scholar] [PubMed]

- Martienssen, W.; Warlimont, H. Springer Handbook of Condensed Matter and Materials Data; Springer: New York, NY, USA, 2006. [Google Scholar]

- Konnerth, J.; Gindl, W.; Müller, U. Elastic properties of adhesive polymers. I. Polymer films by means of electronic speckle pattern interferometry. J. Appl. Polym. Sci. 2007, 103, 3936–3939. [Google Scholar] [CrossRef]

- Anegunta, S. Manufacture and Rehabilitation of Guard-Rail Posts Using Composites for Superior Performance. Master’s Thesis, Statler College of Engineering and Mineral Resources, Morgantown, WV, USA, 2000; p. 1031. Available online: https://researchrepository.wvu.edu/etd/1031 (accessed on 7 August 2020).

- Renault, A.; Jaouen, L.; Sgard, F.; Atalla, N. Direct quasistatic measurement of acoustical porous material Poisson ratio. In Proceedings of the 10e Congrès Français d’Acoustique, Lyon, France, 12–16 April 2010; p. hal-00534634. [Google Scholar]

- Kosky, P.; Balmer, R.; Keat, W.; Wise, G. Exploring Engineering, 3rd ed.; Elsevier/AP: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Lawrence, K.L. ANSYS Workbench Tutorial: Structural & Thermal Analysis Using the ANSYS Workbench Release 14 Environment; Schroff Development Corporation: Mission, KS, USA, 2012. [Google Scholar]

- Swedish Wood. The CLT Handbook. 2019. Available online: https://www.swedishwood.com/publications/list_of_swedish_woods_publications/the-clt-handbook/ (accessed on 8 May 2020).

- Klippel, M. Fire Safety of Bonded Structural Timber Elements. ETH Zürich. 2014. Available online: http://hdl.handle.net/20.500.11850/94679 (accessed on 7 August 2020).

- Craft, S.; Desjardins, R.; Richardson, L. Development of Small-scale Evaluation Methods for Wood Adhesives at Elevated Temperatures. In Proceedings of the 10th World Conference on Timber Engineering, Miyazaki, Japan, 2–5 June 2008. [Google Scholar]

- Frihart, C.R.; Hunt, C.G. Adhesives with wood materials: Bond formation and performance. In Wood handbook: Wood as an Engineering Material: Section 10. Centennial ed. General Technical Report FPL; GTR-190; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; p. 10. [Google Scholar]

- Clauβ, S.; Dijkstra, D.J.; Gabriel, J.; Kläusler, O.; Matner, M.; Meckel, W.; Niemz, P. Influence of the chemical structure of PUR prepolymers on thermal stability. Int. J. Adhes. Adhes. 2011, 31, 513–523. [Google Scholar] [CrossRef]

- Richter, K.; Lopez-Suevos, F. Thermal behavior of polyurethane adhesives bonded to wood: Identification of components to improve thermal stability by dynamic mechanical analysis. In Proceedings of the International Conference on Wood Adhesives, Lake Tahoe, NV, USA, 28–30 September 2009. [Google Scholar]

| Parameter | Douglas Fir (DF) | Southern Yellow Pine (SYP) | Spruce Pine Fir (SPF) |

|---|---|---|---|

| EL (MPa) | 14,740 | 13,530 | 9790 |

| ET (MPa) | 737 | 1055.34 | 577.61 |

| ER (MPa) | 1002.32 | 1528.89 | 1253.12 |

| VLR | 0.292 | 0.328 | 0.422 |

| VLT | 0.449 | 0.292 | 0.462 |

| VRT | 0.390 | 0.382 | 0.53 |

| GLR (MPa) | 943.36 | 1109.46 | 1213.96 |

| GLT (MPa) | 1149.72 | 1095.93 | 1174.8 |

| GRT (MPa) | 103.18 | 175.89 | 97.9 |

| Thermal Conductivity, W/(m°C) | 1.01 | 1.12 | 0.90 |

| Species | Radial (10−6 in/in/°F) | Tangential (10−6 in/in/°F) | Parallel (10−6 in/in/°F) |

|---|---|---|---|

| Douglas Fir-South | 14 | 19 | 1.9 |

| Southern Yellow Pine | 15 | 20 | 2.0 |

| Spruce Pine Fir | 13 | 18 | 1.8 |

| Elastic Properties | Melamine Formaldehyde (MF) | Phenol Resorcinol Formaldehyde (PRF) | Polyurethane (PUR) |

|---|---|---|---|

| Young’s Modulus (MPa) | 3200 | 3540 | 559 |

| Poisson’s Ratio | 0.33 | 0.443 | 0.351 |

| Coefficient of thermal expansion (CTE) (/°F·K) | 60 × 10−6 | 68 × 10−6 | 200 × 10−6 |

| Thermal Conductivity (W/m·K) | 0.5 | 0.146 | 0.209 |

| Specimen | Temperature Drop (°C) |

|---|---|

| Solid Wood-Douglas Fir (DF) | 18 |

| DF bonded with Phenol Resorcinol Formaldehyde (PRF) | 19 |

| DF bonded with Melamine Formaldehyde (MF) | 18 |

| DF bonded with Polyurethane (PUR) | 18 |

| Material | Heat Flux (W/m2) | Thermal Conductivity (Wm−1K−1) | TB (°C) | TC (°C) | Temperature Drop (°C) |

|---|---|---|---|---|---|

| Eurocode 5 Equation (Equation (1)) | |||||

| CLT-DF | 175 | 172 | 3 | ||

| Thermal Conductivity Equation (Equation (4)) | |||||

| Solid Wood-DF | 10,020 | 1.01 | 235 | 232 | 3 |

| Adhesive layer-PRF | 10,020 | 0.146 | 235 | 214 | 21 |

| Adhesive layer-MF | 10,020 | 0.5 | 235 | 229 | 6 |

| Adhesive layer-PUR | 10,020 | 0.209 | 235 | 220 | 15 |

| Temperature (°C) | Stress (MPa) | Strain (mm/mm) |

|---|---|---|

| 20 | 102 | 0.0278 |

| 100 | 83.7 | 0.0198 |

| 140 | 74.4 | 0.0159 |

| 180 | 65.1 | 0.0120 |

| 220 | 55.8 | 0.00805 |

| 260 | 46.5 | 0.00724 |

| Temperature (°C) | Stress (MPa) | Strain (mm/mm) |

|---|---|---|

| 20 | 115 | 0.0298 |

| 100 | 93.5 | 0.0213 |

| 140 | 82.5 | 0.0171 |

| 180 | 71.6 | 0.0128 |

| 220 | 60.5 | 0.00866 |

| 260 | 49.5 | 0.00703 |

| Temperature (°C) | Stress (MPa) | Strain (mm/mm) |

|---|---|---|

| 20 | 82.7 | 0.0349 |

| 100 | 66.7 | 0.0252 |

| 140 | 58.7 | 0.0204 |

| 180 | 50.6 | 0.0155 |

| 220 | 42.6 | 0.0107 |

| 260 | 34.5 | 0.00764 |

| Temperature (°C) | Stress (MPa) | Strain (mm/mm) |

|---|---|---|

| 20 | 131.95 | 0.069581 |

| 100 | 106.83 | 0.052427 |

| 140 | 94.215 | 0.043894 |

| 180 | 81.562 | 0.035399 |

| 220 | 68.872 | 0.026958 |

| 260 | 56.145 | 0.018615 |

| Temperature (°C) | Stress (MPa) | Strain (mm/mm) |

|---|---|---|

| 20 | 128.37 | 0.052469 |

| 100 | 104.28 | 0.039939 |

| 140 | 92.2 | 0.033707 |

| 180 | 80.095 | 0.027506 |

| 220 | 67.967 | 0.021352 |

| 260 | 55.815 | 0.015286 |

| Temperature (°C) | Stress (MPa) | Strain (mm/mm) |

|---|---|---|

| 20 | 115.67 | 0.15237 |

| 100 | 94.253 | 0.11392 |

| 140 | 83.515 | 0.094933 |

| 180 | 72.756 | 0.076201 |

| 220 | 61.976 | 0.057928 |

| 260 | 51.175 | 0.04066 |

| Experimental Results [7] | Simulation Results | |

|---|---|---|

| Stress |

|

|

| Strain |

|

|

| Experimental Results [7] | Simulation Results | |

|---|---|---|

| Stress |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okuni, I.M.; Bradford, T.E. Modelling of Elevated Temperature Performance of Adhesives Used in Cross Laminated Timber: An Application of ANSYS Mechanical 2020 R1 Structural Analysis Software. Environ. Sci. Proc. 2021, 3, 46. https://doi.org/10.3390/IECF2020-07902

Okuni IM, Bradford TE. Modelling of Elevated Temperature Performance of Adhesives Used in Cross Laminated Timber: An Application of ANSYS Mechanical 2020 R1 Structural Analysis Software. Environmental Sciences Proceedings. 2021; 3(1):46. https://doi.org/10.3390/IECF2020-07902

Chicago/Turabian StyleOkuni, Ivan Moses, and Tracy Ellen Bradford. 2021. "Modelling of Elevated Temperature Performance of Adhesives Used in Cross Laminated Timber: An Application of ANSYS Mechanical 2020 R1 Structural Analysis Software" Environmental Sciences Proceedings 3, no. 1: 46. https://doi.org/10.3390/IECF2020-07902

APA StyleOkuni, I. M., & Bradford, T. E. (2021). Modelling of Elevated Temperature Performance of Adhesives Used in Cross Laminated Timber: An Application of ANSYS Mechanical 2020 R1 Structural Analysis Software. Environmental Sciences Proceedings, 3(1), 46. https://doi.org/10.3390/IECF2020-07902