Abstract

The microalgae-microbial fuel cell (mMFC) enables us to perform secondary and tertiary treatment of domestic wastewater while simultaneously producing green electricity. In this work, the treatment of wastewater and producing electricity using a dual-chambered mMFC were demonstrated. Furthermore, the electricity produced by the mMFC was utilized to drive microbial electrolysis cell (MEC) for hydrogen synthesis. Primary domestic wastewater was treated in the anodic compartment of mMFC. Chemical oxygen demand (COD) removal of 67.2 and 54% was achieved in the anodic compartment of batch and continuous mode, respectively. Wetland-treated water was filled in the cathodic compartment, and Scenedesmus sp. was used as a catholyte. The overall voltage of 1.85 V was used to run a 1-L MEC. Industrial wastewater was treated with a COD removal of 73% in the MEC and biohydrogen was produced at a rate of 9.8 ± 0.2 mL L−1 d−1.

1. Introduction

Globally, around four hundred billion cubic meters of untreated wastewater is discharged each year []. Furthermore, the world’s energy need is increasing all the time. Most of our energy requirements are fulfilled by burning fossil fuels. The combustion of fossil fuels produces a large amount of carbon dioxide, which is a greenhouse gas that causes climate change. We need to shift to sustainable green energy sources now more than ever. Microalgae-microbial fuel cell (mMFC) has attracted attention as a long-term wastewater treatment technology as it does not require an external power supply for wastewater treatment (WWT). It uses exoelectrogens to convert the organic matter in wastewater to electricity, and domestic wastewater contains 2–5 kWh/m3 of energy []. In addition, mMFCs can be used in a variety of WWT applications because their biofilm contains not only electroactive microorganisms but also non-electroactive microorganisms such as fermentative, sulfate-reducing, nitrate-reducing, denitrifying, and aerobic microorganisms, which can be used for a variety of functions ranging from the breakdown of complex organics to fermentation []. Microbial electrolysis cell (MEC) is a modification of MFC that treats industrial wastewater when operated under anaerobic conditions and produces biohydrogen, which is an excellent green fuel.

In addition to producing bioelectricity and value-added products from microalgal biomass, the microbial fuel cells based on microalgae are effective systems for removing CO2, nitrogen, and phosphorus from wastewater. These mMFCs have been demonstrated to be effective for the removal of N and P through the symbiotic relationship between microalgae and bacteria in wastewater treatment together with power generation. Since mechanical aeration would otherwise require power, the oxygen produced by microalgae during the day eliminates the need for mechanical aerators []. MEC systems need external power at an electrical potential substantially lower than the theoretical one utilized in water electrolysis to create hydrogen. A conventional power source, photovoltaics, wind power, thermoelectric generators, and MFCs are all potential options for external power sources [].

In this study, mMFCs were used to perform secondary and tertiary wastewater treatment and produce electricity []. The secondary wastewater treatment was done in the anodic compartment that contained sludge, whereas the tertiary treatment was performed in the cathodic compartment containing microalgae. A detailed comparison of the batch mode mMFC and continuous flow mMFC was also performed in this study. On the other hand, the main objective of using MEC was to consume the electricity provided by the mMFCs to produce hydrogen using the microbial phenomenon. The MEC also helped in treating industrial wastewater, since high-strength wastewater containing large amounts of COD is required for the synthesis of hydrogen [].

2. Materials and Methods

2.1. Construction of mMFC and MEC

For mMFC, a two-compartment H-shaped prototype made of acrylic sheets was used. Graphite rods, abraded by sandpaper to increase the surface area, were used as electrodes. Cation exchange membrane (CMI-7000s), which was soaked in a 5% NaCl solution for 12 h prior to its usage, was used as a separator. The working volume of mMFC was 1700 mL and the total volume was 2000 mL. The anodes and cathodes were connected to complete the circuit with low-resistance white copper wires. A stirrer was used to keep the algae in suspension and LED bulbs were used to provide light for the growth of algae. A peristaltic pump was also used to provide a continuous flow to the continuous flow mMFC.

For MEC, a 1000 mL stock bottle was used with similar graphite electrodes as for mMFC. The working volume was 900 mL and the total volume was 1000 mL. Gas syringes and pipes were used for the collection of hydrogen.

2.2. Inoculum and Substrate for mMFC and MEC

For mMFC, 30% activated sludge was obtained from the I-9 wastewater treatment plant, and Islamabad was used to perform secondary treatment of domestic wastewater in the anodic compartment. In the cathodic compartment, microalgae (Scenedesmus sp.) was used to perform tertiary treatment of domestic wastewater as a photosynthetic electrolyte. The primary treated domestic wastewater from the membrane bio-reactor (MBR) plant of National University of Sciences and Technology (NUST) was used in the anodic compartment whereas wetland-treated wastewater was used in the cathodic compartment.

For MEC, 20% anaerobic sludge was mixed with 5% cow dung to treat synthetic food industrial wastewater with an initial COD value of 10,000 mg/L.

The obtained sludge was acclimatized to anaerobic conditions before being used in both mMFC and MEC.

2.3. Operation of mMFC and MEC

For mMFC, one mMFC was run in the continuous flow mode (MFC-C) and two in the batch mode (MFC-B). The mMFC was operated at a lab scale under ambient temperature. In the anodic compartment, a pH of 7 was maintained whereas a pH of 7.5 was maintained in the cathodic compartment. The hydraulic retention time (HRT) was 24 h for both MFC-B and MFC-C.

MEC was also operated at a lab scale under ambient temperature in the batch mode. The HRT was 10 days and a pH of 4.5–5.5 was maintained to suppress the growth of methanogens. The MEC was sparged with N2 gas prior to the start of each batch to ensure there was no oxygen present to be combined with the produced hydrogen.

The mMFCs were linked in series with the copper wires to get the combined voltage supplied to the MEC. A combined voltage of 1.8–1.9 V of all three mMFCs was provided to the MEC.

2.4. Analysis and Calculations

The closed reflux titrimetric method was used to obtain COD. pH was measured by using a Hach multimeter (Model-156). The values of orthophosphate and ammonium nitrogen were obtained using the ascorbic acid method and the salicylate method, respectively []. The water samples from both compartments of mMFC were obtained via the valves positioned at the center of the respective compartments. The water was stirred to ensure proper mixing prior to obtaining the samples. A digital multimeter was used to obtain the open circuit voltage whereas a datalogger (Picolog 6) was used to continuously obtain voltages in a closed circuit when a resistor of 470 Ω was used. The polarization curves were obtained by varying the resistances from 1 MΩ to 1 Ω. The voltages corresponding to these resistances were obtained and the current was calculated for each value using Ohm’s law. By dividing the current by the surface area of the anode, the current density was obtained to be 0.0024 m2. Power and power density were calculated using the formulas in Equations (1) and (2), respectively. For algae growth, a UV-visible spectrophotometer (PG Model T6OU, PG Instruments, UK) was used to measure the optical density (OD) at 680 nm []. The coulombic efficiency (CE) was found using the formula reported in [].

where V is the voltage drop across each resistor, I is the corresponding current, and A is the surface area of the anode.

3. Results and Discussion

3.1. Sludge and Wastewater Characteristics

The sludge had a pH of 6.5–7, total solid (TS) of 15–25%, volatile solid of 30–35% of TS, moisture content (MC) of 75–85%, oxidation reduction potential (ORP) of −360 to −380 mV, and TKN of 1800–2500 mg/L. The primary treated domestic wastewater used in mMFCs had an initial COD of 240 mg O2/L (varying for each day), orthophosphate of 18.5 mg/L, turbidity of 136 NTU, conductivity of 1636 µs/cm, pH of 7.3, TSS of 20 mg/L, TDS of 780 mg/L, ammonia nitrogen of 50 mg/L, nitrate nitrogen of 11.4 mg/L, nitrite nitrogen of 1.6 mg/L, and organic nitrogen of 20.16 mg/L.

3.2. Results of mMFC

The maximum open circuit voltage (OCV) was 784 mV in MFC-B whereas the maximum OCV was 723 mV in MFC-C.

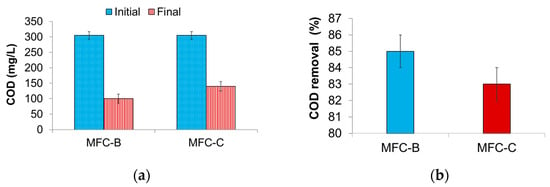

As shown in Figure 1a, the COD decreased in the anodic chamber of both MFC-B and MFC-C. The initial COD was 305 mg/L for both MFC-B and MFC-C. The final COD was 100 mg/L for the batch mode, and the removal efficiency was thus 67.2%. In the case of the continuous flow mode, the final COD was 140 mg/L, and the removal efficiency was thus 54%. There was a difference of 13.2% in the removal efficiency. The possible reason for the high COD removal in the batch mode was that there was more time available for the microorganisms to consume the already existing COD, whereas in the continuous flow mode, new COD was pumped in the reactor continuously. Another similar study quoted their COD removal efficiency to be in the similar range of 50 to 65% []. Figure 1b shows the COD removal in the cathodic chamber. The removal from the cathodic chamber was 85% in MFC-B and 83% in MFC-C.

Figure 1.

(a): COD removal from the anodic chamber. (b): COD removal from the cathodic chamber.

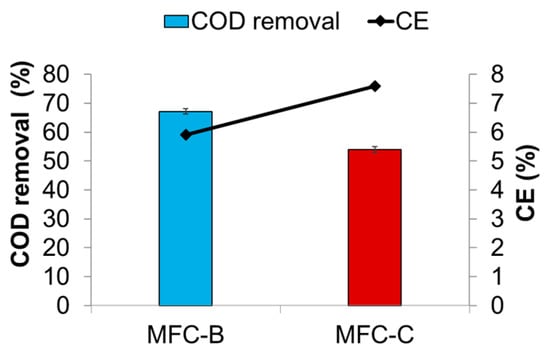

The CE indicates the amount of COD removed to be utilized for electricity. As shown in Figure 2, the COD removal was 67.2% in the batch mode while the CE was around 5.8%. In the continuous flow mode, the COD removal was 54% whereas the CE was around 7.7%. A difference of 1.9% was noted and MFC-C had higher CE despite having less removal efficiency. It is worth noting that the values of CE were quite low in comparison to the values of COD removal for both systems, indicating that a greater number of electrons were lost.

Figure 2.

Coulombic efficiency (CE) in MFC-B and MFC-C.

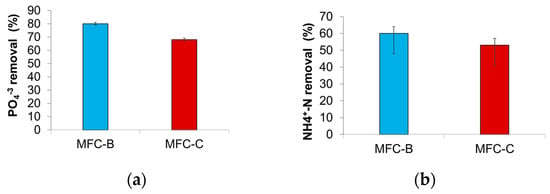

Figure 3a shows that the orthophosphate removal of MFC-B was 80% whereas it was 68% for MFC-C. MFC-B was able to achieve a high orthophosphate removal of 12% as compared to MFC-C. Figure 3b shows that an ammonium nitrogen removal percentage of 60% was achieved in the batch mode and it was around 57% in the continuous flow mode.

Figure 3.

(a): Orthophosphate removal in the cathodic chamber. (b): Ammonium-N removal in the cathodic chamber.

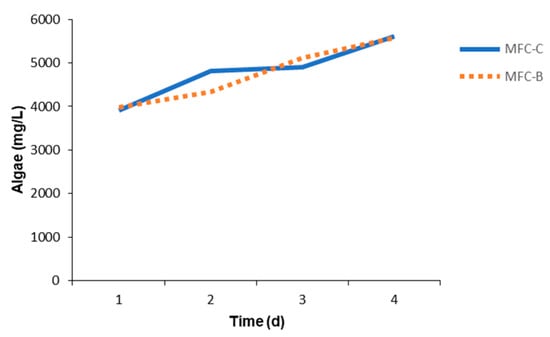

In Figure 4, an increasing trend can be seen in algal growth. The dotted line shows algal growth in MFC-B and the solid line shows algal growth in MFC-C. There was a similar trend in both mMFCs starting at around 4900 mg/L and growing to about 5700 mg/L in four days.

Figure 4.

Algal growth in the cathodic chamber.

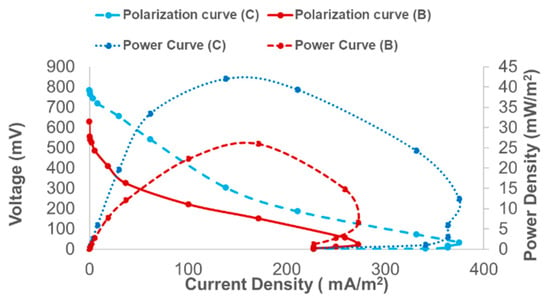

Figure 5 shows the polarization and power curves for MFC-B and MFC-C. The maximum current density was 375 mA/m2 in MFC-C and 272.2 mA/m2 in MFC-B. The maximum power density was 42 mW/m2 in MFC-C and 25.9 mW/m2 in MFC-B. By calculating the slopes of the polarization curves, the internal resistance was obtained to be 867.875 Ω in MFC-C and 847.250 Ω in MFC-B. In the continuous flow mode, the internal resistance is more than that in the batch mode, and the power density and current density were also greater. This may be due to the microbial configuration of sludge in the continuous flow mode, in which it was possible that the number of current-producing bacteria was greater in the continuous flow mode than in the batch mode.

Figure 5.

Polarization and power curves.

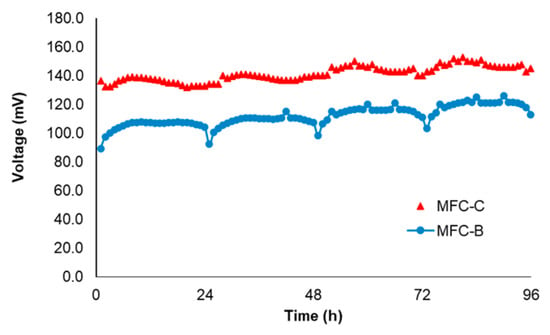

As shown in Figure 6, the voltage in the continuous flow mode was greater than in the batch mode. In the batch mode, there were dips in the values of voltage after every 24 h, indicating that the batch has ended and most of the COD has been consumed. In addition, the maximum value was achieved in the middle of the batch in the batch mode and the value steadily decreased towards the end of the batch after every 24 h. The curve of the continuous flow mode was relatively steady because of the continuous feed. Thus, COD was always available to the microorganisms, and voltage was constantly produced.

Figure 6.

Voltage vs. time graph of MFC-B and MFC-C with a resistor of 470 Ω.

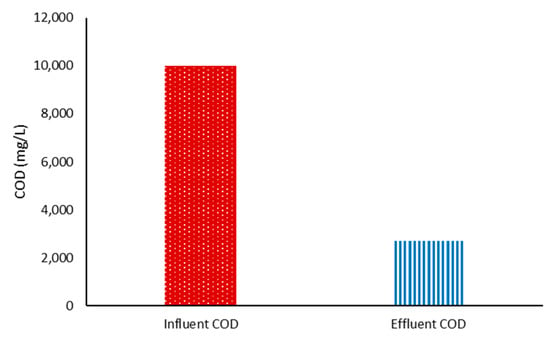

3.3. Results of MEC

Figure 7 shows a decrease in the value of COD of wastewater in MEC. The initial COD of the wastewater was 10,000 mg/L and after running a batch of 10 days, the value had decreased to 2700 mg/L, indicating a removal efficiency of 73%. The voltage provided by the mMFCs initiated a forceful current and was utilized to reduce the protons into hydrogen []. The average hydrogen production rate at the same time was 9.8 ± 0.2 mL L−1 d−1.

Figure 7.

COD Removal in MEC.

4. Conclusions

In this work, three mMFCs (each with a working volume of 1.7 L) were run and compared in the batch mode and continuous flow mode. The system could be applied for both secondary and tertiary treatment as depicted by the results. The secondary treatment was performed as the organics were removed, and the tertiary treatment was performed as nutrient removal was achieved using algae. The COD removal was greater in MFC-B, but MFC-C had a greater CE. OCV was similar in both systems. However, in a closed circuit, MFC-C had a greater voltage output. The combined voltage was enough to power the MEC and the results showed that the supplied voltage overcame its potential barrier, and thus, the hydrogen was produced along with the treatment of wastewater.

Author Contributions

Conceptualization, B.M., S.A., U.R. and Z.S.; methodology, B.M. and Z.U.; software, B.M., Z.U. and S.A.; validation, B.M., S.A., U.R., Z.U. and Z.S.; formal analysis, B.M. and Z.U.; investigation, B.M., S.A., U.R. and Z.U.; resources, S.A. and Z.S.; data curation, B.M., S.A., Z.U. and Z.S.; writing—original draft preparation, B.M.; writing—review and editing, B.M., Z.S. and Z.U.; visualization, B.M., S.A., Z.S. and Z.U.; supervision, Z.U. and Z.S.; project administration, Z.U. and Z.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ritchie, H. Max Roser and Pablo Rosado—“Energy”. 2022. Available online: https://ourworldindata.org/energy (accessed on 15 December 2022).

- Yu, J.; Cho, S.; Kim, S.; Cho, H.; Lee, T. Comparison of Exoelectrogenic Bacteria Detected Using Two Different Methods: U-tube Microbial Fuel Cell and Plating Method. Microbes Environ. 2012, 27, 49–53. [Google Scholar] [CrossRef] [PubMed]

- Logan, B.E.; Hamelers, B.; Rozendal, R.; Schröder, U.; Keller, J.; Freguia, S.; Aelterman, P.; Verstraete, W.; Rabaey, K. Microbial Fuel Cells: Methodology and Technology. Environ. Sci. Technol. 2006, 40, 5181–5192. [Google Scholar] [CrossRef] [PubMed]

- Arun, S.; Sinharoy, A.; Pakshirajan, K.; Lens, P.N. Algae based microbial fuel cells for wastewater treatment and recovery of value-added products. Renew. Sustain. Energy Rev. 2020, 132, 110041. [Google Scholar] [CrossRef]

- Aboelela, D.; Soliman, M.A. Hydrogen production from microbial electrolysis cells powered with microbial fuel cells. J. King Saud Univ.-Eng. Sci. 2022. [Google Scholar] [CrossRef]

- Sun, M.; Sheng, G.-P.; Zhang, L.; Xia, C.; Mu, Z.-X.; Liu, X.-W.; Wang, H.-L.; Yu, H.-Q.; Qi, R.; Yu, T.; et al. An MEC-MFC-Coupled System for Biohydrogen Production from Acetate. Environ. Sci. Technol. 2008, 42, 8095–8100. [Google Scholar] [CrossRef] [PubMed]

- Saleem, S.; Zeshan; Iftikhar, R.; Zafar, M.I.; Sohail, N.F. Growth kinetics of microalgae cultivated in different dilutions of fresh leachate for sustainable nutrient recovery and carbon fixation. Biochem. Eng. J. 2022, 178, 108299. [Google Scholar] [CrossRef]

- Ullah, Z.; Zeshan, S. Effect of substrate type and concentration on the performance of a double chamber microbial fuel cell. Water Sci. Technol. 2019, 81, 1336–1344. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).