Abstract

The present research focuses on heat recovery from hot kitchen wastewater to fulfil the dual objective of reducing energy consumption and CO2 emissions, while simultaneously improving the fat, oil and grease (FOG) removal efficiency of the grease trap (GT). A GT was retrofitted with a novel heat exchanger design (termed as a hybrid GT device) to enhance wastewater thermal recovery and FOG removal capabilities. Hot wastewater containing FOG was assessed in a full-scale experimental GT. The governing parameters of temperature, mass flow rate and FOG content were monitored. Results indicate that the hybrid GT improves FOG removal performance by lowering the temperature of GT hot wastewater by approximately 25%. The hybrid GT enables improvement in energy efficiency and cost savings for commercial kitchens/wastewater generators, lowering the carbon footprint and cost of food preparation.

1. Introduction

The EU assertion of wastewater energy recognized as a non-conventional/green energy source has attracted researchers to focus on developing new ways to recycle the wasted heat in wastewater. These wastewater heat recovery technologies could lower the carbon footprint of hot-water-related activities to meet the EU net-zero carbon emission targets by reducing the total energy required for water heating sectors [1]. Based on the recent data, about two-thirds of water heating requirements are derived from conventional fuels (oil, wood pellets, etc.) in Ireland and the UK [2]. Only a small part of this is powered using renewable energy sources from fuel, such as biomass boilers, solar energy, etc. The recovered wastewater heat can be utilized to preheat the incoming cold freshwater by circulating it through heat exchangers [3]. This preheating of cold water then requires a reduced amount of energy to attain desired temperatures, which vary based on various hot-water-based applications [4].

The residential and commercial building sectors share more than a quarter of the total energy consumption and 17% of global carbon emissions. The water heating sector consumes around 20% of the global energy consumption. The commercial and domestic sectors alone consume about 50% of the energy required for water heating and steam generation for several heating applications [4]. Water heating requirements in domestic and commercial sectors share a very large energy potential, which requires optimum energy management to attain effective thermal efficiency for minimum building heating expenditure. In colder countries such as the UK, Ireland, Canada, etc., a major part of the total energy associated with water heating in the hospitality sector is utilized in applications such as hotels, kitchens, cafes, restaurants, etc. Commercial food and drink preparation in kitchens consumes about 50% of the UK’s total hot water demand [5], and the predicted data on the available recoverable thermal potential from this element of wastewater for the UK were estimated at about 1.4 TWh/year [6].

Thermal recovery from wastewater benefits the user by reducing the total water heating energy demand and lowering the water heating expenditure due to significant energy saving, which has a direct impact on decreasing the operating costs for commercial users with hot water needs [7]. Numerous technologies have been proposed by researchers for effective thermal management to capture the heat embedded in hot wastewater. Selimli et al. (2019) conducted a practical investigation to evaluate the heat recovery potential from the household kitchen dishwasher. A fin-mounted tube heat exchanger was tested for enhanced thermal recovery. It saved 57 kWh of energy and 21 kg of greenhouse gas emission per year [8]. A heat exchanger with a spiral shape coil was tested to examine heat recovery potential in a storage-based wastewater system [9] which was capable of harnessing about 60% of the total wastewater heat. Greater thermal recovery capabilities of the system were seen for lower mass flow rates [9].

Many techniques were proposed for enhanced wastewater heat recovery; despite this, there is a need to explore more in order to find the most effective and economical method for heat recovery [10]. Nagpal et al. [10] reviewed waste heat recovery from sewer/drain wastewater and pointed out the need and scope of wastewater thermal recovery at various levels, including at component, building, sewer and wastewater treatment plant levels, based on the wastewater flow and embedded energy potential within it.

The waste heat to be recovered from wastewater at the component level is usually carried out by installing a heat exchanger in the vicinity of different hot-water-based appliances. However, the amount of heat recovered is quite low, and the heat exchanger retrofitting cost could not economically be justified [10]. Greater wastewater volume flow rate availability discharged from several applications at building level increases the scope for economically viable heat recovery by retaining the hot wastewater for a specific period of time to capture the maximum possible amount of heat embedded in wastewater via a wastewater storage vessel. In commercial or industrial kitchens/food preparation, a grease trap is a common on-site treatment process which already provides a storage vessel of hot wastewater.

The present research examines the novel recovery of heat from kitchen wastewater in a grease trap (GT) or grease interceptor. A hybrid GT heat recovery system was designed in which the GT is retrofitted with a heat recovery unit and experimentally tested. The performance of the hybrid GT is assessed under different amounts of vegetable oil added to the wastewater to simulate wastewater containing fat, oil and grease (FOG) and to predict the system’s thermal recovery capabilities.

2. Methodology

A medium-sized, commercially available GT system (see Figure 1) was integrated with a heat recovery unit to capture the waste heat embedded in the kitchen wastewater. This involved retrofitting the GT with a coil-type heat exchanger. The GT in question comprised two chambers separated by a baffle under which the wastewater flows. The principle of operation of the GT is one where through an increase retention time in the wastewater and reduced water velocities, FOG is separated out from the wastewater and held in the top layer of the GT due to buoyancy, and heavier particles are also settled to the bottom of the tank.

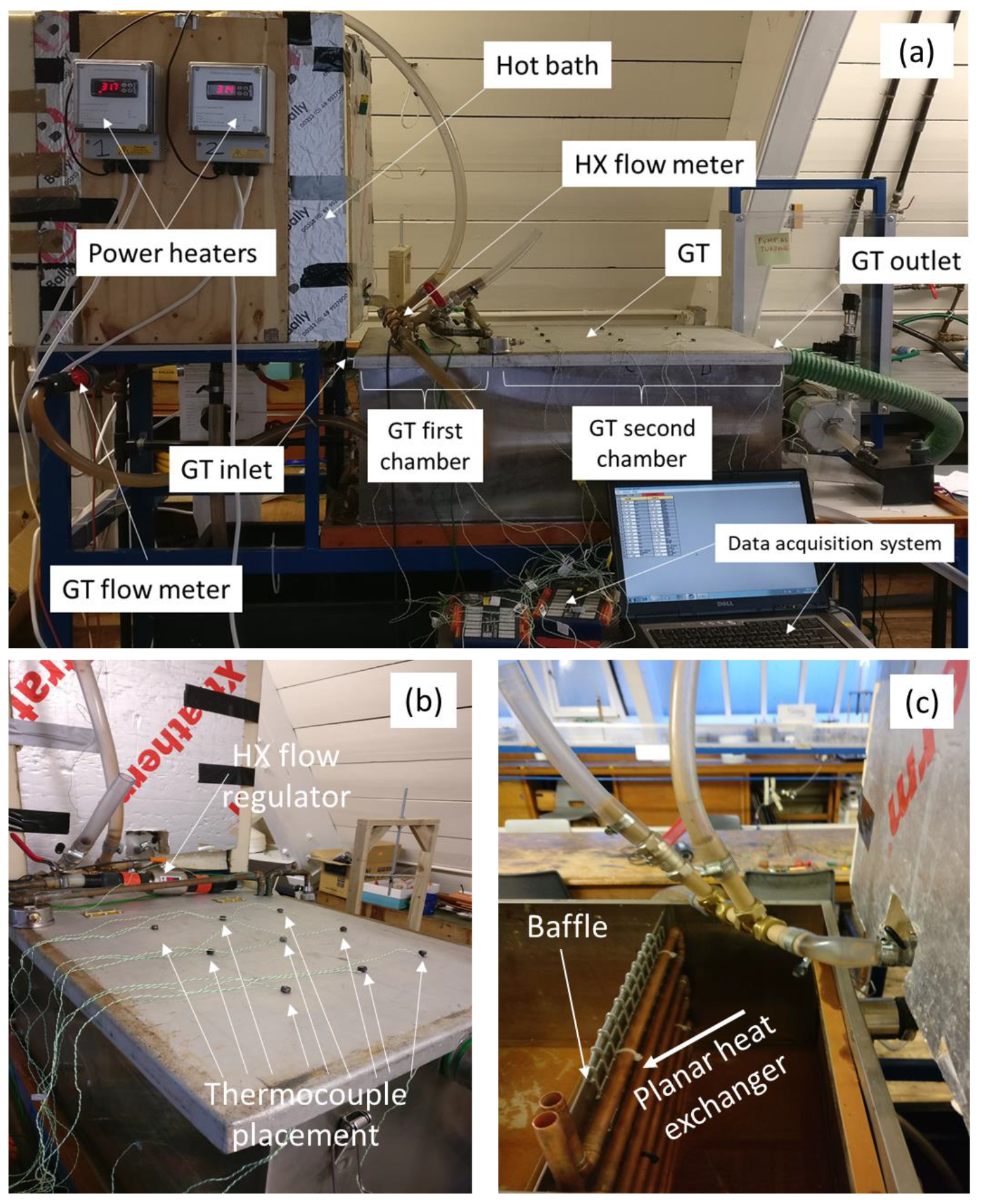

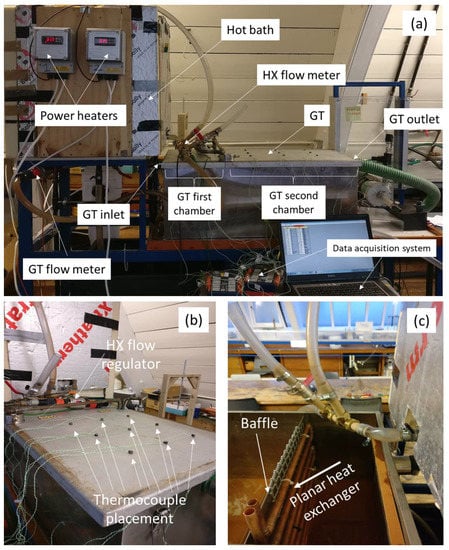

Figure 1.

Laboratory setup of the grease trap system retrofitted with planar-type thermal recovery unit. Various views are presented, namely: (a) mini-commercial hybrid GT side view, (b) front view and (c) planar heat exchanger unit.

A vertical serpentine shape heat exchanger (HX) made of hollow copper pipe with a circular cross-section was retrofitted inside the GT. The HX is displayed in Figure 1c placed vertically inside the GT. The images of the experimental setup are shown in Figure 1. The hot wastewater inside the GT was fed through a hot water bath fitted with two heavy-duty coil-type heaters used to heat the wastewater to a required GT inlet temperature.

The flow rate of the wastewater at the inlet of the GT could be varied using a flow control valve as shown in Figure 1a. Clean water at ambient temperature was used to flow through the HX to recapture heat from the higher-temperature wastewater accumulated inside the GT. The flow of clean water could also be adjusted via an HX flow regulator (see in Figure 1b). The HX was placed vertically 40 mm above the bottom of the GT and was clamped to the existing GT baffle wall on the upstream side (refer to Figure 1c). The baffle is placed at a small distance from the GT inlet and is part of the original GT design. A vertical clearance between the baffle bottom surface and the GT bottom was maintained along the GT width to allow wastewater to flow past the baffle towards the GT outlet section unimpeded. During the experiments, water was used initially containing vegetable oil in an attempt to simulate real kitchen wastewater containing FOG. In the present research, the preliminary results with known quantities of vegetable oil (VO) added to the hot water was considered as wastewater coming into the GT. VO was gradually added to the wastewater and data recorded for each addition of VO volumes to examine the impact of thermal recovery for each case. The impact of the HX design on the improvement of FOG removal will be examined in a subsequent study and is outside the scope of this current work. Furthermore, future work will also include the addition of other forms of FOG aside from vegetable oil to the experimental system (i.e., butter, lard, etc.).

The thermal performance of the system was assessed in terms of temperature at the outlet of the GT (TGo) and HX (THo) with respect to the GT inlet and HX inlet temperature, respectively. The temperatures were measured using K-type thermocouples and recorded using a data acquisition system (Keithley-DAQ 6510). The thermocouples were calibrated at freezing and boiling points of water. The temperature was measured at 16 different locations to capture the thermal distribution of the entire system, shown in Figure 1b. Measurements were recorded at regular intervals for each case at the time of attainment of steady state. The temperature measurement possesses an accuracy of ±0.1 °C.

The mass flow rates of the GT and HX were monitored using a magnetic-inductive flow meter (IFM electronics gmbh-SM8000). The mass flow rate of both the GT and HX were set to the desired values with the help of the flow adjustment valve. The flow meter has an accuracy of ±0.0017 kg/s.

A sequential procedure was followed to obtain thermal recovery trends across a wide range of the amount of VO added to the GT. This was assessed in terms of the impact of VO addition on temperature for both the GT and HX. All cases were conducted for a constant GT and HX fluid flow rate of 0.033 kg/s and 0.0408 kg/s for the GT wastewater and HX freshwater, respectively. This allowed us to assess the thermal performance variation for each case. The prototype was operated with the wastewater containing vegetable oil from only 20 mL up to 9.6 l. The vegetable oil floated at the top of the wastewater liquid surface in the GT during experiments.

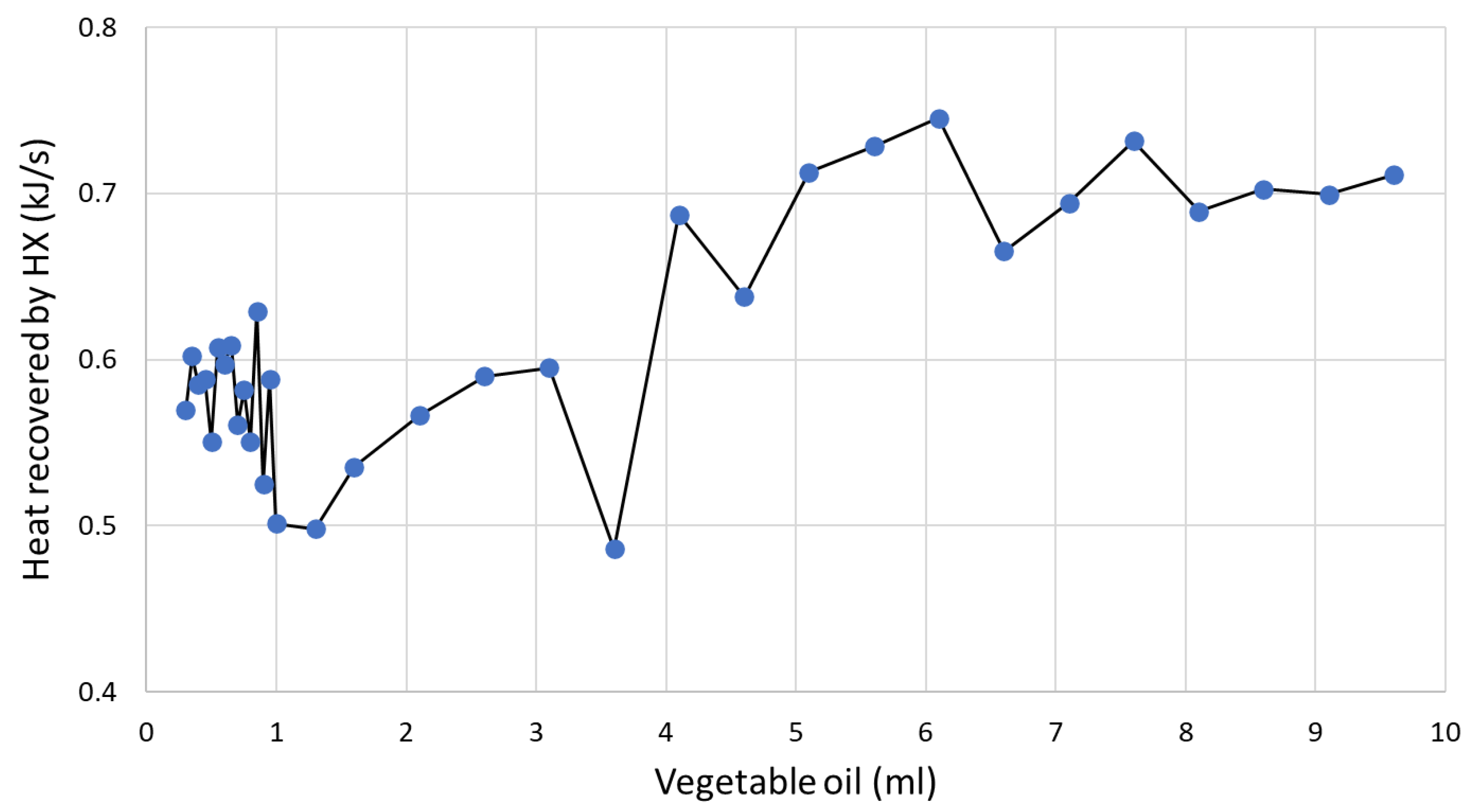

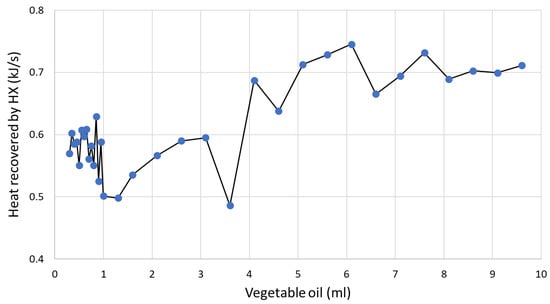

The vegetable oil was a commercially available domestic product in Ireland. The amount of VO added to the wastewater and its impact on wastewater heat recovery is shown in Figure 2. In each case, the thermal performance was evaluated based on the values of GT inlet temperature (TGi), GT outlet temperature (TGo), GT mass flow rate (), HX inlet temperature (THi), HX outlet temperature (THo), HX mass flow rate () and ambient temperature in the laboratory (Ta). The data recorded for each case during experimentation took about 3–4 h of continuous operation, required for the system to reach steady state. The amount of heat recovery was calculated using the expression below:

where the temperature gradient denotes the HX fluid temperature difference between the HX outlet and the HX inlet, i.e., (THo − THi).

Figure 2.

The amount of heat recovery variation with respect to vegetable oil addition in the GT wastewater.

During experimentation, the data measurements were recorded once the system attained steady state, i.e., where there were negligible parametric variations observed with time. At the start-up of the experimental system (starting from room temperature), about 3–4 h of continuous operation was needed for the system to stabilize the thermal and flow parameters and to attain steady state. Negligible variation in the thermal and flow parameters represents the arrival of the steady state where the performance of the system was recorded using the data acquisition system. For intermediate cases conducted after start-up, an additional 3–4 h of continuous operation was a requirement to obtain steady state again at new operating points.

3. Results

Initially, the thermal recovery performance of the system was assessed against different amounts of vegetable oil added to the GT wastewater. It was observed that increasing VO content in the wastewater brought an improvement in the GT wastewater heat recovery at rapid rate (refer to Figure 2). An approximate 50% increase in thermal recovery was observed due to the formation of a thick oil layer at the top of the wastewater surface which acted like insulation layer minimizing the heat loss to the surrounding air from the top of the GT lid. The formation of this VO layer on the water surface in the GT is part of the normal operation of a GT but improves the performance of the hybrid GT system compared with clean water. The increasing heat recovery with the increase in VO content proves to be beneficial in terms of waste energy saving.

The heat recovery obtained by the thermal recovery unit of the hybrid GT system was assessed. The lower GT wastewater outlet temperature denoted more thermal recovery by the heat exchanging unit. This hybrid GT also induced the retention of a greater amount of FOG in the first chamber of the GT (see Figure 1a) due to the lower temperature of the wastewater within this chamber (which contained the heat exchanger). The trapped amount of FOG in the first chamber of the GT attenuates the movement of the FOG reaching the second chamber of the GT (see Figure 1a). This consequently minimizes the amount of FOG discharged into the sewer system due to reduction in the volume heat content in the GT first chamber. High thermal recovery from wastewater induces a higher retention of FOG in the first GT chamber and minimizes the FOG level at the GT outlet. The fresh cold water flowing through the HX coils reduces the temperature of the GT wastewater near to the HX coil walls. The maximum amount of heat recovery was enhanced by about 50% and keeps growing on the higher side with the addition of more oil to the GT wastewater. This experimental testing is ongoing, and the preliminary results here with the vegetable oil will be expanded on in future work with the addition of other common types of FOG.

The preliminary hybrid GT results show that its impact could result in the requirement to redesign the GT, as the second chamber is often the larger one, intended to capture most of the FOG. The grease removal efficiency may also be on the higher side when wastewater contains two-phase fatty matter as opposed to just VO. Deposition of the FOG layer at the top of the wastewater surface behaves like an insulation layer, which lessens the heat loss from the GT top to the surrounding environment and results in higher wastewater heat recovery. The resulting treated wastewater contains low FOG content, which would reduce the frequency of sewer maintenance requirements downstream. Furthermore, energy saving achieved will reduce the amount of fossil fuels need for water heating, and hence carbon footprint. In the case of this experimental hybrid GT system, the maximum energy recovery amounted to 0.75 kW from an electrical heat input of 5.4 kW.

4. Discussion and Conclusions

A medium-sized GT system coupled with a heat recovery unit to recover waste heat from kitchen wastewater was experimentally investigated. This hybrid GT system considered in the present research was tested for wastewater containing vegetable oil. The thermal characteristics of the system were examined against different amounts of vegetable oil in the wastewater. The outcomes show that thermal recovery from wastewater improves with thickness of the oil layer at the free wastewater surface, which acts as insulation and attenuates heat loss from the system to the local surroundings. About a 50% increase in heat recovery from the wastewater containing vegetable oil was observed. This research is ongoing and in its preliminary phase. Phase-change matter (such as butter) in the wastewater may aid in retaining higher amounts of FOG in the first chamber of the GT and minimize the FOG amount that reaches the GT outlet. In the next phase, the phase-change matter such as butter and lard, which are very common in food preparations in commercial kitchens, will be under observation and will bring further understanding and development to the recovery of heat and improvement of grease removal in grease trap systems.

Author Contributions

Conceptualization, A.M. and A.P.S.; methodology, A.M. and A.P.S.; validation, A.P.S.; formal analysis, A.P.S.; resources, A.M.; writing—original draft preparation, A.P.S.; writing—review and editing, A.M.; visualization, A.P.S.; supervision, A.M.; project administration, A.M.; funding acquisition, A.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the European Regional Development Funds, Interreg Ireland-Wales Programme (2014–2020) through the Dwr Uisce Project (80910).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available on request.

Conflicts of Interest

The authors declare no conflict of interest in any form.

References

- Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2018.328.01.0082.01.ENG (accessed on 21 December 2018).

- Spriet, J.; McNabola, A. Decentralized drain water heat recovery from commercial kitchens in the hospitality sector. Energy Build. 2019, 194, 247–259. [Google Scholar] [CrossRef]

- Pochwat, K.; Kordana-Obuch, S.; Starzec, M.; Piotrowska, B. Financial analysis of the use of two horizontal drain water heat recovery units. Energies 2020, 13, 4113. [Google Scholar] [CrossRef]

- Spriet, J.; McNabola, A.; Neugebauer, G.; Stoeglehner, G.; Ertl, T.; Kretschmer, F. Spatial and temporal considerations in the performance of wastewater heat recovery systems. J. Clean. Prod. 2020, 247, 119583. [Google Scholar] [CrossRef]

- Schestak, I.; Spriet, J.; Styles, D.; Williams, A.P. Emissions down the drain: Balancing life cycle energy and greenhouse gas savings with resource use for heat recovery from kitchen drains. J. Environ. Manag. 2020, 271, 110988. [Google Scholar] [CrossRef]

- Dawson, A.F.M.; Kalinske, A.A.; Sewage, S.; Journal, W.; May, N. Design and Operation of Grease Interceptors Symposium on grease removal. Sew. Work. J. 2017, 16, 482–489. [Google Scholar]

- Alnahhal, S.; Spremberg, E. Contribution to Exemplary In-House Wastewater Heat Recovery in Berlin, Germany. Procedia CIRP 2016, 40, 35–40. [Google Scholar] [CrossRef]

- Selimli, S.; Karabas, T.; Taskin, Y.; Karatas, M.B. Experimental study of the performance of heat recovery by a fin and tube heat exchange tank attached to the dishwasher greywater line. Sustain. Energy Technol. Assess. 2019, 36, 100552. [Google Scholar] [CrossRef]

- Torras, S.; Oliet, C.; Rigola, J.; Oliva, A. Drain water heat recovery storage-type unit for residential housing. Appl. Therm. Eng. 2016, 103, 670–683. [Google Scholar] [CrossRef]

- Nagpal, H.; Spriet, J.; Murali, M.; McNabola, A. Heat Recovery from Wastewater—A Review of Available Resources. Water 2021, 13, 1274. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).