Abstract

This study aims to analyze the addition of widely available, cheap, and biologically based residues, such as charcoal fines, in the production of polymeric biocomposites reinforced with natural fibers subjected to UV-C radiation. The addition of charcoal fines was 0, 10, 20, 30% in the polymeric matrix of the biocomposites. The mechanical and chemical properties of the biocomposites were evaluated. The flexural strength was more resistant when subjected to UV-C radiation with 20% filling. These results attest that biocomposites with the addition of vegetative charcoal fines are less susceptible to photodegradation.

1. Introduction

Currently, polymer composites reinforced with natural fibers are gaining attention worldwide due to environmental concerns and the advantages of natural fibers over the traditional synthetic fibers used in composites. In this conception, many studies have been based on the use of industrial waste that has the potential to obtain new materials. Often used in the steel industry, charcoal is one of the oldest and most well-known materials in the world. However, as it is a highly fragile material, it generates significant amounts of fines that, in most cases, do not have an adequate destination and constitute a problem to be solved. In this sense, we believe that these residues can be used as raw materials for new product development, as a reinforcement agent in the production of polymeric biocomposites, and used in various industrial applications. Carbon filler is an important component of polymer composites due to its favorable properties and the possibility of modification that, when combined with suitable polymer matrices, have a positive effect on improving electrical properties, polymer resistance to environmental factors, and resistance UV-C dilation [1,2]. Epoxy resin, for example, performs several other functions in biocomposites, such as protecting against abrasion and the environment [3,4,5].

In the action of solar radiation, polymeric materials undergo oxidative chemical reactions that result in material degradation, causing loss of brightness, color change, loss of transparency, formation of cracks, mechanical and physical fragility [1,6,7]. Although the photodegradation mechanism of most polymers is well established, the behavior of polymer composites against UV-C radiation is still a field to be explored. This study aims to investigate the mechanical and chemical properties of the effect of UV-C radiation on polymeric biocomposites with and without charcoal fines. Thus, we investigate the residues of charcoal fines as reinforcement, aiming to use it as a raw material for the production of carbonaceous biocomposites.

2. Materials and Methods

For the production of charcoal, wood from a ten-year-old Eucalyptus saligna plantation was used. For this purpose, wood samples were fragmented in a Wiley knife mill and previously dried in an oven at 105 ± 2 °C. The pyrolysis was carried out in a metallic reactor inside a muffle furnace, at an initial temperature of 30 °C and a final temperature of 400 °C, the heating rate of 10 °C.min−1, until reaching the final temperature, where they remained for 120 min. The production of charcoal fines on a laboratory scale passed in the MA-500 model ball mill for three hours. For homogenization of the samples, the charcoal fines were sieved obtaining a final granulometry of 100 mesh (0.154 mm). A polymer compound was made with an epoxy resin matrix in addition to charcoal fines with percentage participation of 10%, 20%, 30% of the composition. A sample containing 100% epoxy resin was produced. The effect of degradation under UV-C radiation on chemical and mechanical properties was evaluated using a photodegradation chamber apparatus, where the biocomposites were exposed for 360 h. To determine the mechanical property of flexural strength was determined from ASTM D 7264M-21 standard [8]. Fourier transform infrared spectroscopy (FTIR) analysis was recorded in a Bruker spectrometer, model Tensor 27, by the attenuated total reflectance (ATR) technique. The samples were scanned in the range of 4000–600 cm−1 with a resolution of 4 cm−1. In this analysis, 32 scans were collected for each FTIR spectrum.

Data Analysis

Data were submitted to normality (Shapiro–Wilk) and homoscedasticity (Bartlett) tests. The analysis of variance was performed following a completely randomized design, with four response variables related to the proportion of charcoal added (0, 10, 20 and 30%). To identify the significant differences in relation to some dependent variables, the regression model adjustment that best predicted the behavior of the data was performed. Tests were performed at 95% probability. Standard deviation measures of dispersion were provided to understand the confidence interval obtained for each variable studied better.

3. Results

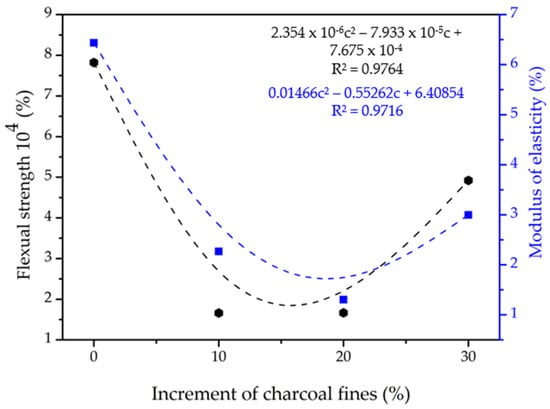

The effect of adding coal fines on the flexural strength (specifically the modulus of rupture and elasticity) and FTIR spectra of polymeric biocomposites were evaluated. The mechanical properties of biocomposites after being subjected to UV-C radiation are shown in Figure 1. Figure 1 shows the modulus of rupture (MOR) values, corresponding to 7.82 × 104%, 1.66 × 104%, 1.66 × 104%, 4.92 × 104% (0%, 10%, 20% and 30% addition, respectively), and modulus of rupture (MOE) values of 6.67, 2.27%, 1.30%, and 3.0% (0%, 10%, 20% and 30% addition, respectively).

Figure 1.

Flexural strength analyzing the modulus of rupture and elasticity of the biocomposites in the respective study proportions.

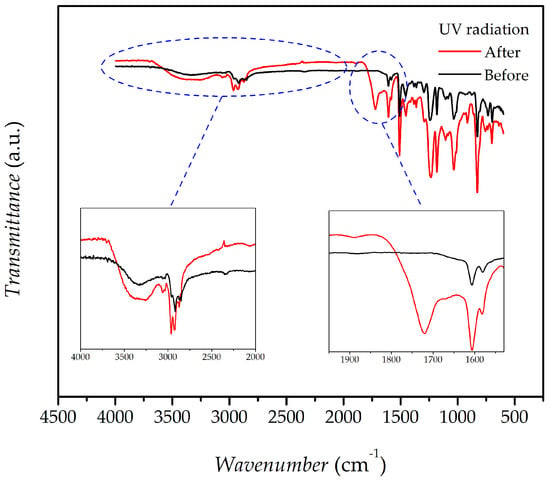

FTIR spectroscopy is a powerful tool to analyze the photodegradation effect caused by UV light on the polymeric matrices. In Figure 2, we compared both FTIR spectra of the epoxy resin before and after 360 h of UV irradiation, and we observed the chemical changes in the epoxy resin structure. The characteristic bands of epoxy resin are present in the spectra, such as the peaks at 3045 cm−1 (symmetrical and asymmetrical C–H stretch in aromatic), in the range of 1600–1460 cm−1 (C–C stretching vibration in aromatic), 1295 cm−1 (asymmetrical –CH2 deformation), 1237 cm−1 (asymmetrical aromatic C–O stretch), 1181 cm−1 (asymmetrical aliphatic C–O stretch), 1030 cm−1 (symmetrical aromatic C–O stretch), 916 cm−1 (epoxide ring vibrations), and 827 cm−1 (–CH out of plane deformation in aromatic) [9]. Moreover, bands assigned to hydroxyl and carbonyl groups were also observed in the 3100–3700 cm−1 and 1800–1600 cm−1 spectral regions, respectively. In particular, the absorption peaks located in the last-mentioned wavenumber regions were enhanced in the FTIR spectrum of irradiated epoxy resin, indicating the photodegradation process. In addition, the effect of UV irradiation on the epoxy resin can be considered due to the appearance of the absorption bands in the range of 3400–2400 cm−1, which correspond to carboxylic acids [10].

Figure 2.

FTIR spectra of epoxy resin before and after UV irradiation.

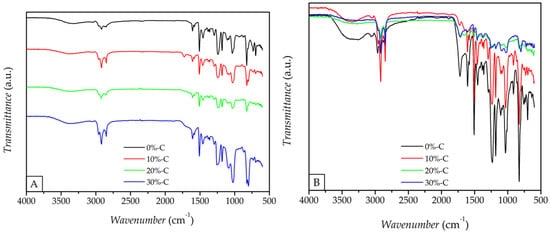

The FTIR spectra of 10, 20 and 30% of the charcoal fines and epoxy resin biocomposites before and after UV irradiation are shown in Figure 3. The FTIR spectrum profiles of the unordered composites are very similar to those obtained for epoxy resin fresh and no noticeable differences were caused by the addition of charcoal fines fill. However, the greatest changes are observed when the FTIR spectra of the irradiated composites were compared to the FTIR spectrum of UV-irradiated epoxy resin, mainly as to the intensity of signals attributed to the carbonyl and hydroxyl peaks. It is evident that smaller amounts of carbonyl (1800–1600 cm−1) and hydroxyl (3100–3700 cm−1) groups were generated during the UV degradation of the composites than of the epoxy resin, since less pronounced peaks were recorded in the composite spectra. No evidence of the formation of carboxylic acids was detected in the FTIR spectra of composites, suggesting a preservation effect provided by the biocarbon additive.

Figure 3.

FTIR spectrum of epoxy resin and 10, 20 and 30% of epoxy-charcoal fines biocomposites: (A) before and (B) after UV irradiation.

4. Discussion

The polymer composite without the addition of carbon fines showed a higher loss of strength after exposure to UV-C radiation when compared to treatments with 10 and 20% addition of charcoal fines. Note that the increase in certain quantities of charcoal fines will minimize the loss of resistance of the material when subjected to photodegradation radiation, corroborating the trends found in the literature. Flexural properties showed greater strength in 20% of charcoal fines. Filler particles obstruct the sliding of polymer matrix chains and this leads to increased flexural properties of the biocomposites [6]. However, with the addition of more filler, such as 30%, the properties decreased, similar to that found by [6]. Such an event can be attributed to the weak polymer–fiber interaction, voids, and weak dispersion of fibers in the matrix [6]. However, it also depends on other factors, such as size, shape, and type of filler material [11,12,13]. Carbon filling is an important component of polymer biocomposites, due to its favorable properties and the possibility of modification, which, in combination with suitable polymer matrices, has a positive effect on the mechanical properties and improvement in the resistance of polymers to actors environmental and UV-C radiation [1]. Related studies obtained good results obtained with carbon filling, which significantly increased the mechanical strength of the material [1,7,14].

The FTIR analysis allowed us to evaluate the chemical changes caused by the photodegradation of epoxy resin as well as the beneficial effect of biocarbon addition on the material. As observed in the FTIR spectrum of the UV irradiated epoxy resin (Figure 2), the intensities of the carbonyl group (1800–1600 cm−1) increased, which reveals a relative degree of photodegradation. The carbonyl species are generated as a result of β-scission from the alkoxy radicals produced by recombination of alkyl radicals in the first steps of UV radiation exposition [15]. Another evidence of epoxy resin degradation is the presence of bands assigned to carboxylic acids (3400–2400 cm−1). These species can be formed as a result of C–C dissociation bonds in the presence of oxygen and UV light [16]. The FTIR spectra of the composites after the UV irradiation showed a decrease in the signal intensities of degradation bands, probably due to the low contents of carbonyl, hydroxyl, and carboxylic acids in the polymeric chain. These results attested that the composites were less susceptible to photodegradation. The protection effect of biocarbon may be summarized in terms of an antioxidant effect, probably via an efficient catalytic decomposition free radical scavenger. Although the FTIR analysis has shown that the addition of carbon avoided the degradation of the polymer chain, it was not possible to obtain information about the suitable carbon/resin ratio.

5. Conclusions

It was found that the analyzed charcoal fines can be used as reinforcement for polymer matrices, due to their stability against UV-C radiation, resulting in improved mechanical properties. Further studies on chemical, elemental and microstructural properties are recommended, in addition to the use of charcoal fines at different pyrolysis temperatures and particle sizes.

Author Contributions

F.M.D. performed the laboratory experiments, analyzed the data and prepared the manuscript. A.K.S.P., Á.M.d.S., E.C.d.S., M.P.O., D.P., L.P.R.P. and A.F.D.J. provided critical feedback, review and editing of the manuscript. D.P. and L.P.R.P. strongly assisted in the execution and review of chemical analyses. A.F.D.J. and F.M.D. designed the study and administered the project. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

The authors thank the Espírito Santo Research and Innovation Foundation (FAPES), the Biomass Energy Laboratory (LEB), the Central Laboratory of Analytics II and the Mechanics and Materials Laboratory (LABMAT) of the Federal University of Espírito Santo (UFES) for carrying out the analysis of the materials.

Conflicts of Interest

The authors declare that they do not have a financial conflict of interest; however, the product developed in this manuscript is under a patent process with government agencies in Brazil.

References

- Polok-Rubiniec, M.; Włodarczyk-Fligier, A. Polypropylene matrix composite with charcoal filler. J. Achiev. Mater. Manuf. Eng. 2020, 2, 60–66. [Google Scholar] [CrossRef]

- Nazarpour-Fard, H.; Rad-Moghadam, K.; Shirini, F.; Hosain Beheshty, M.; Hosein Asghari, G. Reinforcement of epoxy resin/carbon fiber composites by carboxylated carbon nanotubes: A dynamic mechanical study. Polimery 2018, 63, 253–263. [Google Scholar] [CrossRef]

- Akaluzia, R.O.; Edoziuno, F.O.; Adediran, A.A.; Odoni, B.U.; Edibo, S.; Olayanju, T.M.A. Evaluation of the effect of reinforcement particle sizes on the impact and hardness properties of hardwood charcoal particulate-polyester resin composites. Mater. Today Proc. 2021, 38, 570–577. [Google Scholar] [CrossRef]

- Jagadeesh, V.; Venkatasubbaiah, K.; Lakshumu Naidu, A. Experimental study on mechanical behavior of natural hybrid composites filled with ground nut shell ash. Mech. Mech. Eng. 2019, 23, 218–227. [Google Scholar] [CrossRef]

- Reddy, S.; Xu, X.; Guo, T.; Zhu, R.; He, L.; Ramakrishana, S. Allotropic carbon (graphene oxide and reduced graphene oxide) based biomaterials for neural regeneration. Curr. Opin. Biomed. Eng. 2018, 6, 120–129. [Google Scholar] [CrossRef]

- Das, S.C.; Ashek-E-Khoda, S.; Sayeed, M.A.; Paul, D.; Dhar, S.A.; Grammatikos, S.A. On the use of wood charcoal filler to improve the properties of natural fiber reinforced polymer composites. Mater. Today Proc. 2021, 44, 926–929. [Google Scholar] [CrossRef]

- Huang, J.; Mao, C.; Zhu, Y.; Jiang, W.; Yang, X. Control of carbon nanotubes at the interface of a co-continuous immiscible polymer blend to fabricate conductive composites with ultralow percolation thresholds. Carbon N. Y. 2014, 73, 267–274. [Google Scholar] [CrossRef]

- American Society for Testing Materials—ASTM. D 7264M-15; Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2021.

- Maity, P.; Kasisomayajula, S.; Parameswaran, V.; Basu, S.; Gupta, N. Improvement in surface degradation properties of polymer composites due to pre-processed nanometric alumina fillers. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 63–72. [Google Scholar] [CrossRef]

- Nikafshar, S.; Zabihi, O.; Ahmadi, M.; Mirmohseni, A.; Taseidifar, M.; Naebe, M. The Effects of UV Light on the Chemical and Mechanical Properties of a Transparent Epoxy-Diamine System in the Presence of an Organic UV Absorber. Materials 2017, 10, 180. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.T.; Das, S.C.; Saha, J.; Paul, D.; Islam, M.T.; Rahman, M.; Khan, M.A. Effect of Coconut Shell Powder as Filler on the Mechanical Properties of Coir-polyester Composites. Chem. Mater. Eng. 2017, 5, 75–82. [Google Scholar] [CrossRef]

- Xanthos, M. Functional Fillers for Plastics, 1st ed.; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2005; pp. 5–19. [Google Scholar]

- Dahal, R.K.; Acharya, B.; Saha, G.; Bissessur, R.; Dutta, A.; Farooque, A. Biochar as a filler in glassfiber reinforced composites: Experimental study of thermal and mechanical properties. Compos. Part B Eng. 2019, 175, 107169. [Google Scholar] [CrossRef]

- Yui, H.; Wu, G.; Sano, H.; Sumita, M.; Kino, K. Morphology and electrical conductivity of injection-molded polypropylene/carbon black composites with addition of high-density polyethylene. Polymer 2006, 47, 3599–3608. [Google Scholar] [CrossRef]

- Peña, J.M.; Allen, N.S.; Edge, M.; Liauw, C.M.; Valange, B. Studies of synergism between carbon black and stabilisers in LDPE photodegradation. Polym. Degrad. Stab. 2001, 72, 259–270. [Google Scholar] [CrossRef]

- Ghasemi-Kahrizsangi, A.; Neshati, J.; Shariatpanahi, H.; Akbarinezhad, E. Improving the UV degradation resistance of epoxy coatings using modified carbon black nanoparticles. Prog. Org. Coatings 2015, 85, 199–207. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).