Multi-Scale Modelling of Particulate Composite †

Abstract

:1. Introduction

2. Background

2.1. Cenospheres

2.1.1. Morphology

2.1.2. Chemical Composition

2.1.3. Properties and Applications

2.2. Random Sequential Adsorption (RSA)

2.3. Representative Volume Element (RVE)

3. Research Gap

- The microstructural characteristic of such composites is not well understood. Multi-scale modelling that allows for exploring and developing this heterogeneous material is not found in the literature.

- An FE model to investigate the cenospheres interaction with the surrounding medium, the particle fracture and the damage evolution of the composite.

- The lightweight properties of these composites could be exploited in an application where dynamic loading is present, such as structures built on active seismic zones, wind loads on aeroplanes, dynamic loads due to waves on ships and ship motions, or impact loads if ships or a marine structure are hit by obstacles. Nevertheless, research on cenosphere composites under any form of dynamic loading is very scarce.

4. Objectives

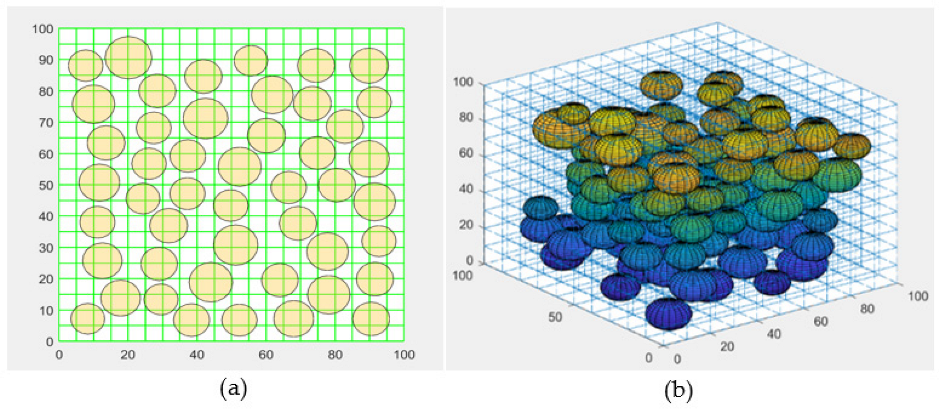

- To develop an algorithm in MATLAB to simulate the random sequential adsorption (RSA) of cenospheres in a 2D and 3D representative volume element (RVE).

- To develop a finite element model to simulate the RVE with periodic boundary conditions using ABAQUS and Python scripting.

- To validate the FE model by implementing a laboratory test on a cenosphere composite material within an acceptable margin of error. The laboratory tests include uniaxial tests and compressive strength tests to find the two elastic parameters: young’s modulus E and Poisson’s ratio v.

- To use the validated FE model for research applications that help in understanding and developing this composite material.

- To investigate the interaction between the cenosphere particles and the surrounding medium, and the damage evolution of the composite.

- To study the effect of cenosphere composites under dynamic and impact loading.

- To optimize the proportion of cenospheres in the matrix for maximum property performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Diamond, S. Particle morphologies in fly ash. Cem. Concr. Res. 1986, 16, 569–579. [Google Scholar] [CrossRef]

- Cardoso, R.; Shukla, A.; Bose, A. Effect of particle size and surface treatment on constitutive properties of polyester-cenosphere composites. J. Mater. Sci. 2002, 37, 603–613. [Google Scholar] [CrossRef]

- Ngu, L.-n.; Wu, H.; Zhang, D.-k. Characterization of ash cenospheres in fly ash from Australian power stations. Energy Fuels 2007, 21, 3437–3445. [Google Scholar] [CrossRef]

- Hirajima, T.; Petrus, H.; Oosako, Y.; Nonaka, M.; Sasaki, K.; Ando, T. Recovery of cenospheres from coal fly ash using a dry separation process: Separation estimation and potential application. Int. J. Miner. Process. 2010, 95, 18–24. [Google Scholar] [CrossRef]

- Ghosal, S.; Self, S.A. Particle size-density relation and cenosphere content of coal fly ash. Fuel 1995, 74, 522–529. [Google Scholar] [CrossRef]

- Hanif, A.; Lu, Z.; Li, Z. Utilization of fly ash cenosphere as lightweight filler in cement-based composites—A review. Constr. Build. Mater. 2017, 144, 373–384. [Google Scholar] [CrossRef]

- Beddu, S.; Zainoodin, M.M.; Muda, Z.C.; Mohamad, D.; Nazri, F.M.; Itam, Z.; Sadon, S.N. Characteristic Study on Malaysia Power Plant Fly Ash Cenosphere. In Proceedings of the 4th International Conference on Numerical Modelling in Engineering, Ghent, Belgium, 24–25 August 2021; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2019; pp. 1229–1237. [Google Scholar]

- Liu, X.; Zhang, M.-H.; Chia, K.S.; Yan, J.; Liew, J.R. Mechanical properties of ultra-lightweight cement composite at low temperatures of 0−60 °C. Cem. Concr. Compos. 2016, 73, 289–298. [Google Scholar] [CrossRef] [Green Version]

- Losiewicz, M.; Halsey, D.P.; Dews, S.J.; Olomaiye, P.; Harris, F.C. An investigation into the properties of micro-sphere insulating concrete. Constr. Build. Mater. 1996, 10, 583–588. [Google Scholar] [CrossRef]

- Huang, X.; Ranade, R.; Zhang, Q.; Ni, W.; Li, V.C. Mechanical and thermal properties of green lightweight engineered cementitious composites. Constr. Build. Mater. 2013, 48, 954–960. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, J.-Y.; Monteiro, P.J.; Zhang, M.-H. Development of ultra-lightweight cement composites with low thermal conductivity and high specific strength for energy efficient buildings. Constr. Build. Mater. 2015, 87, 100–112. [Google Scholar] [CrossRef]

- Bose, A.; Shukla, A. A Report on ”Processing of Cenosphere-Cement/Asphalt Composite Materials and Evaluation of Their Mechanical and Acoustic Properties”; Department of Chemical Engineering, University of Rhode Island: South Kingstown, Rhode Island, 2004. [Google Scholar]

- Chen, W.; Huang, Z. Experimental Study of the Mechanical Properties and Microstructures of Lightweight Toughness Cement-Based Composites. Materials 2019, 12, 3891. [Google Scholar] [CrossRef] [Green Version]

- Feder, J. Random sequential adsorption. J. Theor. Biol. 1980, 87, 237–254. [Google Scholar] [CrossRef]

- Stachurski, Z.H. Fundamentals of Amorphous Solids: Structure and Properties; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Böhm, H.J. A Short Introduction to Basic Aspects of Continuum Micromechanics; Cdl-Fmd Rep.; Vienna University of Technology: Vienna, Austria, 1998; Volume 3. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elbana, A.; Khennane, A.; Al-Deen, S.; Junaid, M.T. Multi-Scale Modelling of Particulate Composite. Environ. Sci. Proc. 2021, 12, 23. https://doi.org/10.3390/environsciproc2021012023

Elbana A, Khennane A, Al-Deen S, Junaid MT. Multi-Scale Modelling of Particulate Composite. Environmental Sciences Proceedings. 2021; 12(1):23. https://doi.org/10.3390/environsciproc2021012023

Chicago/Turabian StyleElbana, Abdalla, Amar Khennane, Safat Al-Deen, and Muhammad Talha Junaid. 2021. "Multi-Scale Modelling of Particulate Composite" Environmental Sciences Proceedings 12, no. 1: 23. https://doi.org/10.3390/environsciproc2021012023

APA StyleElbana, A., Khennane, A., Al-Deen, S., & Junaid, M. T. (2021). Multi-Scale Modelling of Particulate Composite. Environmental Sciences Proceedings, 12(1), 23. https://doi.org/10.3390/environsciproc2021012023