An Investigation of Digital Technology Implementation in Off-Site Construction with a Focus on Efficiency Improvement †

Abstract

:1. Introduction

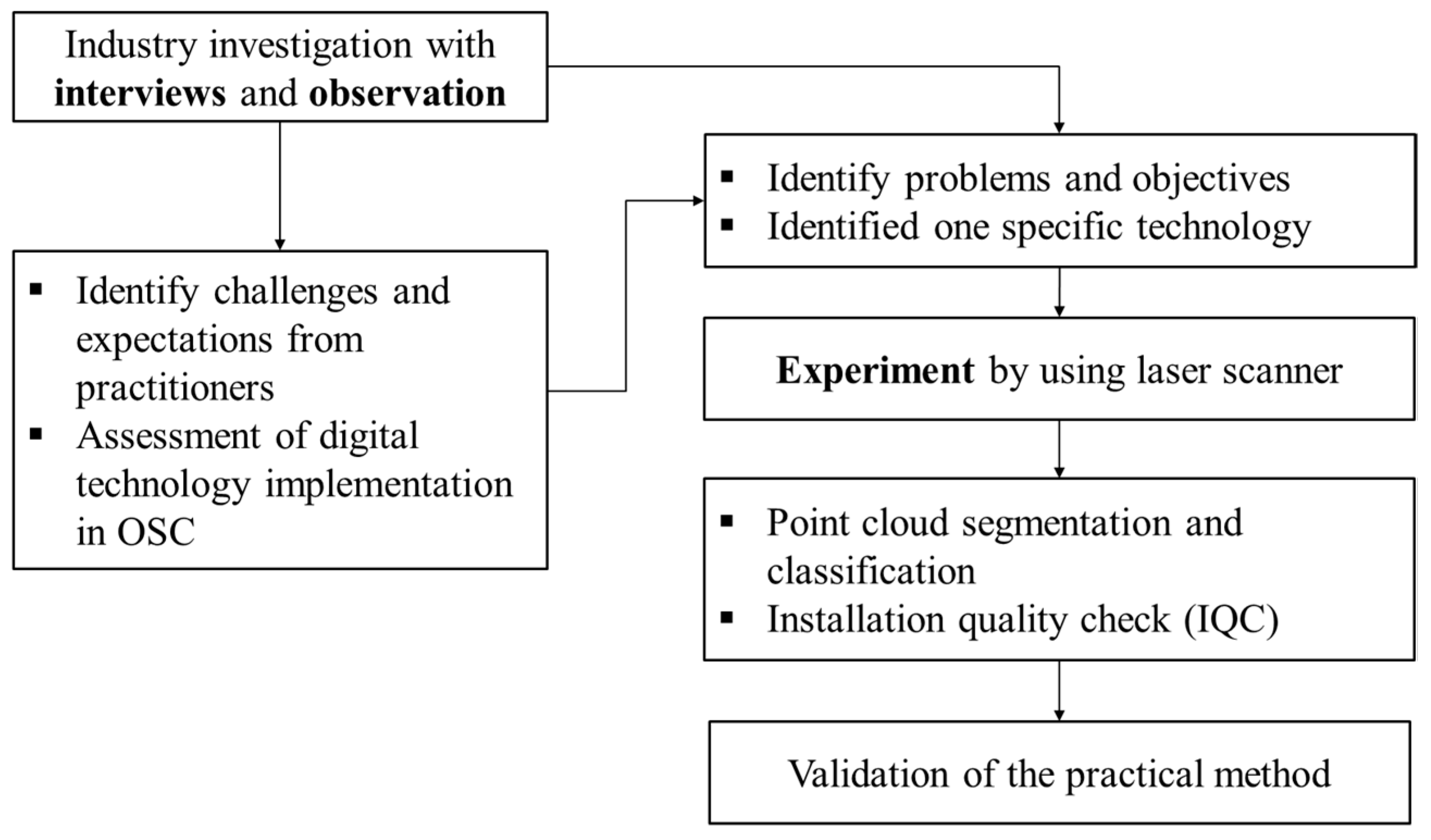

2. Methodology

3. Results

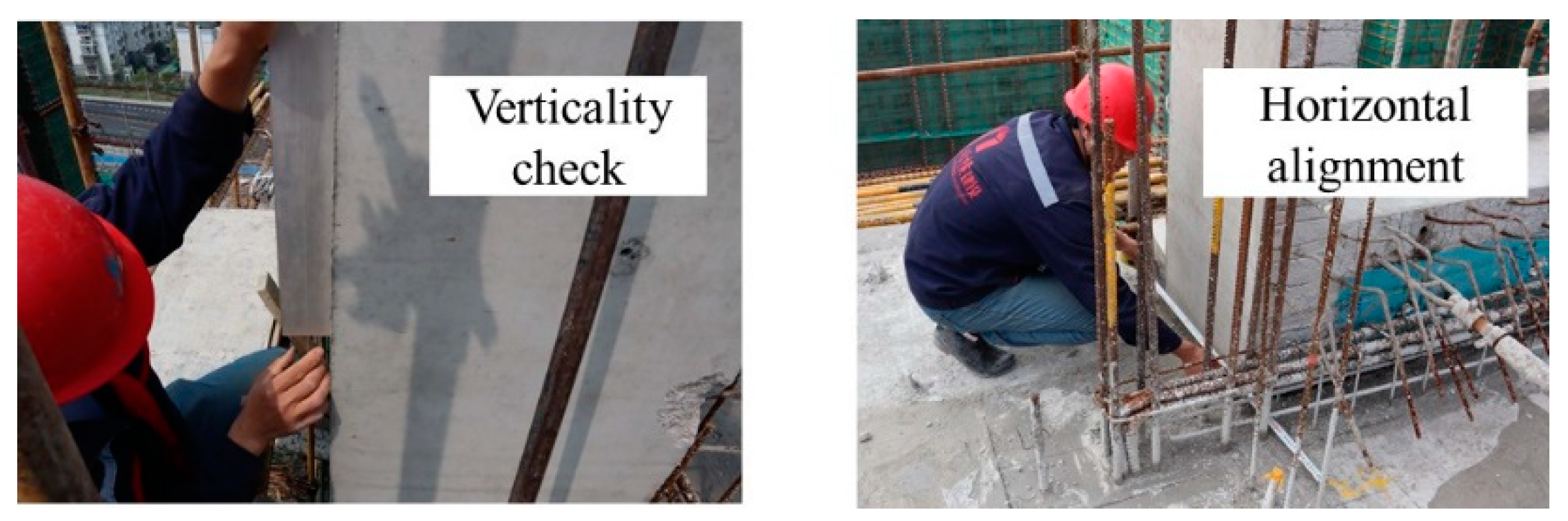

3.1. Findings of the Industry Investigation

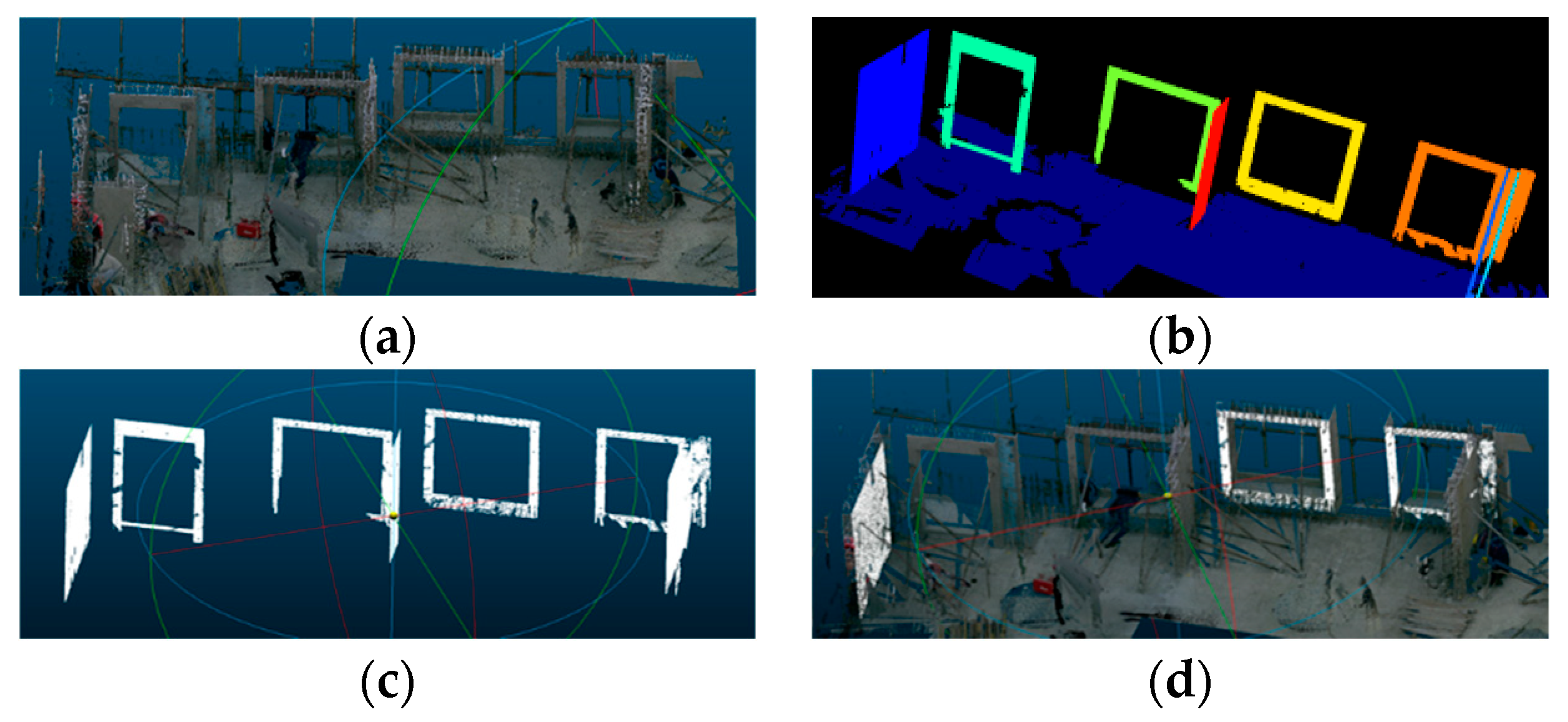

3.2. Findings of Using Laser Scanning

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0. Buildings 2020, 10, 204. [Google Scholar] [CrossRef]

- Li, C.Z.; Hong, J.; Xue, F.; Shen, G.Q.; Xu, X.; Mok, M.K. Schedule risks in prefabrication housing production in Hong Kong: A social network analysis. J. Clean Prod. 2016, 134, 482–494. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Singh, G.; Lu, M.; Bouferguene, A.; Al-Hussein, M. BIM-based automated design and planning for boarding of light-frame residential buildings. Autom. Constr. 2018, 89, 235–249. [Google Scholar] [CrossRef]

- Yin, X.; Liu, H.; Chen, Y.; Al-Hussein, M. Building information modelling for off-site construction: Review and future directions. Autom. Constr. 2019, 101, 72–91. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Costin, A.; Wang, C. Challenges of Migrating from Desktop-based BIM in Construction. In Proceedings of the 33rd International Symposium on Automation and Robotics in Construction (ISARC 2016), Auburn, AL, USA, 18–21 July 2016; pp. 934–942. [Google Scholar]

- Luo, L.; Jin, X.; Shen, G.Q.P.; Wang, Y.; Liang, X.; Li, X.; Li, C.Z. Supply Chain Management for Prefabricated Building Projects in Hong Kong. J. Manag. Eng. 2020, 36, 05020001. [Google Scholar] [CrossRef]

- Sepasgozar, S.; Wang, C.; Shirowzhan, S. Challenges and Opportunities for Implementation of Laser Scanners in Building Construction. In Proceedings of the 33rd International Symposium on Automation and Robotics in Construction (ISARC 2016), Auburn, AL, USA, 18–21 July 2016; pp. 742–751. [Google Scholar]

- Sepasgozaar, S.M.E.; Shirowzhan, S.; Wang, C. A Scanner Technology Acceptance Model for Construction Projects. Procedia Eng. 2017, 180, 1237–1246. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.C.; Zlatanova, S.; Sepasgozar, S.; Aleksandrov, M. Onsite Quality Check for Installation of Prefabricated Wall Panels Using Laser Scanning. Buildings 2021, 11, 412. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. An Investigation of Digital Technology Implementation in Off-Site Construction with a Focus on Efficiency Improvement. Environ. Sci. Proc. 2021, 12, 8. https://doi.org/10.3390/environsciproc2021012008

Wang M, Wang CC, Sepasgozar S, Zlatanova S. An Investigation of Digital Technology Implementation in Off-Site Construction with a Focus on Efficiency Improvement. Environmental Sciences Proceedings. 2021; 12(1):8. https://doi.org/10.3390/environsciproc2021012008

Chicago/Turabian StyleWang, Mudan, Cynthia Changxin Wang, Samad Sepasgozar, and Sisi Zlatanova. 2021. "An Investigation of Digital Technology Implementation in Off-Site Construction with a Focus on Efficiency Improvement" Environmental Sciences Proceedings 12, no. 1: 8. https://doi.org/10.3390/environsciproc2021012008

APA StyleWang, M., Wang, C. C., Sepasgozar, S., & Zlatanova, S. (2021). An Investigation of Digital Technology Implementation in Off-Site Construction with a Focus on Efficiency Improvement. Environmental Sciences Proceedings, 12(1), 8. https://doi.org/10.3390/environsciproc2021012008