1. Introduction

India’s domestic energy consumption has increased from 80 TWh in 2000 to 186 TWh in 2012 and constitutes 22% of total current electrical consumption [

1]. An increase of 400% in the aggregate floor area of buildings, with 20 billion m

2 of new building floor area, is expected by 2030 [

2]. Furthermore, due to the constant increase in the Indian Gross Domestic Product (GDP), consumer purchasing power is predicted to grow, leading to greater expectations of comfort in buildings [

3]. Most of the southern Indian cities are in the warm–humid coastal belt where the summer mean temperature varies between 25 and 35 °C and the winter mean temperature varies between 20 and 30 °C, with mean relative humidity ranging as high as 70–90% across the year [

4]. These conditions in buildings make them highly vulnerable to mould growth [

5].

The World Health Organisation in 2014 [

6] defined dampness as “any visible, measurable or perceived outcome of excess moisture that causes problems in buildings, such as mould, leaks, material degradation, mould odour, directly measured excess moisture (in terms of relative humidity or moisture content) or microbial growth”.

The mould growth index (MGI) is a mathematical empirical model that predicts mould growth on building construction material as a function of substrate material, temperature and relative humidity. MGI indicates the intensity of growth using an easy-to-understand seven-point scale ranging from 0 to 6, where 0 suggests no mould growth and 6 suggests very heavy and tight growth [

7]. The MGI has been summarized in

Table 1.

The prevalence of indoor dampness is estimated to affect 10–50% of indoor environments in India now and in the near future. Additionally, 75% of the buildings constructed in India suffer from some kind of waterproofing problem [

6]. The amount of water on or in materials is the most important trigger of the growth of microorganisms, including fungi, actinomycetes and other bacteria. Water can leak into buildings as a result of heavy rain or sewer system overflow. Additionally, water vapor can be produced by human activities, such as cooking, laundering or showering, and then condense on cold surfaces, such as outer walls, windows or furniture. Damp or water-damaged building materials are at high risk of mould growth, potentially resulting in health problems for the occupants and the deterioration of the buildings. This dampness not only promotes mould growth, but also degrades the thermo-physical property of the construction materials and, furthermore, adds on to the cooling load in all the building typologies [

8].

This study aims to assess the MGI of a commercial building with an autoclaved aerated concrete (AAC) wall assembly located in Mangalore, India. The objectives of this research are to:

Conduct a Heat and Mass Transfer (HAMT) study for the selected building construction assembly using the EnergyPlus (version 9.3) software and Python;

Analyse the MGI for the selected building construction assemblies and recognise favourable conditions for mould growth.

2. Materials and Methods

A 5-zone model with core-perimeter zones has been selected as a representative of the low-rise commercial building model for the study. The perimeter zone is kept at 5 m as per ECBC 2017 recommendations. The exterior wall assembly is considered to be a 230 mm AAC wall assembly with 15 mm of cement plaster on both sides.

The HAMT solver of EnergyPlus (EP) has been referred for the study to compute the MGI. EP possesses the potential to generate hourly surface hygrothermal conditions [

9,

10]. The hygrothermal performance of the selected wall assembly has been identified as per the ISO 12571:2013 [

11].

For the purpose of this study, we have used mathematical models and equations, as specified in ASHRAE 160–2009 [

12]. The initial value of the mould growth index (M for short) shall be zero (M = 0 at time t = 0). The mould index shall be accumulated for each hour using the following equation:

where M

t = mould growth index for the current hour; M

t−1 = mould growth index for the previous hour; and ΔM = change in the mould growth index calculated for each hour using Equation (6-4) or Equation (6-7) reported in ASHARE 160–2009, according to the conditions specified in the same standard. The database for hygrothermal properties has been identified, and an EP Python script to calculate the Mould Growth Index (MGI) has been developed.

3. Results

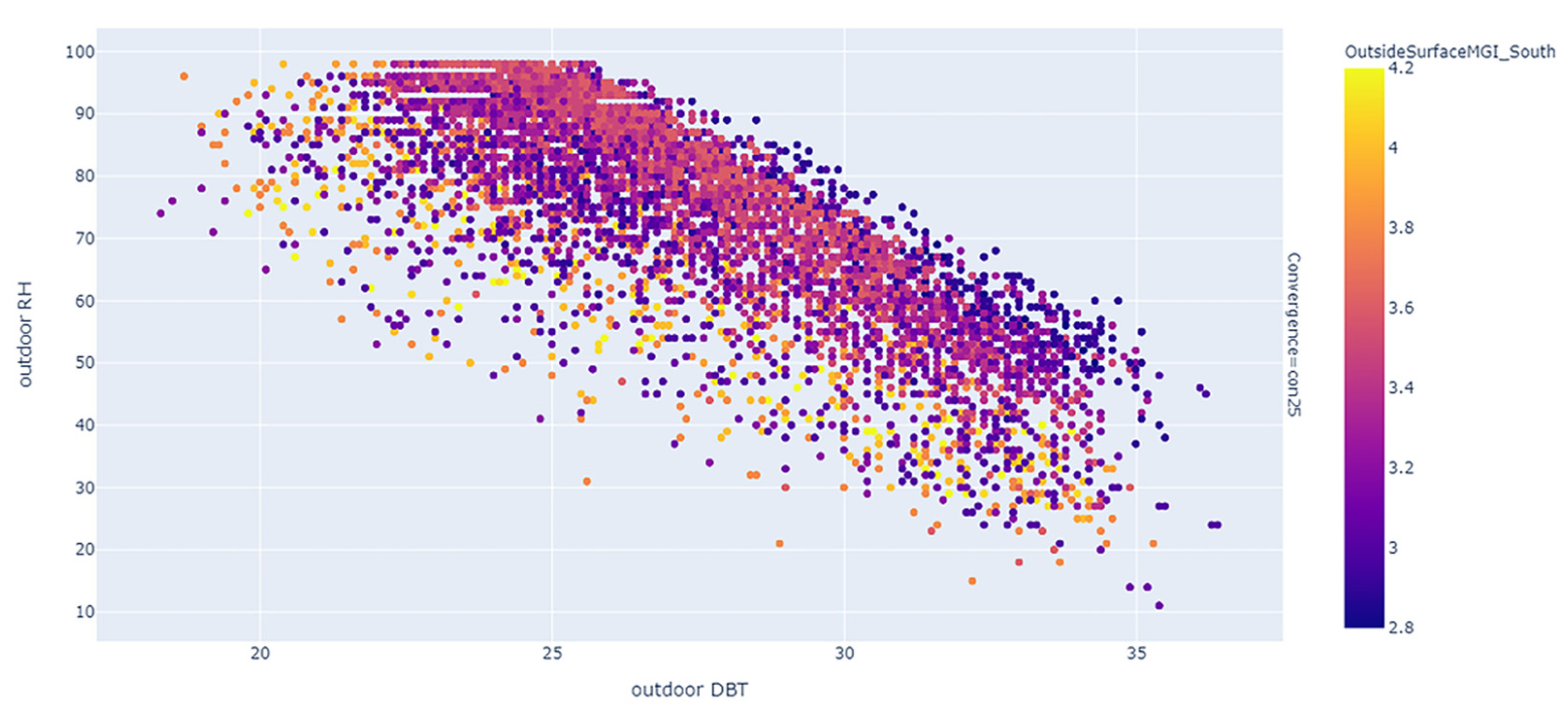

It is important to identify the error in the results of the MGI calculation, and this could be achieved by identifying appropriate warm-up days for the calculation of the MGI. Hence, for the purpose of these HAMT simulations, we have considered including 1, 6, 12, 25, 50 and 100 warm-up days. For ease of understanding, we have calculated the MGI for the south façade of the building and shown its relationship with the outside surface dry-bulb temperature (DBT) and the outside surface relative humidity (RH). The results suggest that the required convergence is achieved when the number of warm-up days are kept at 25 days, beyond which the model tends to over-predict the MGI. In higher convergence scenarios, we can observe a minimum MGI starting from 4, while for lower convergence, the minimum MGI starts from 0. With a higher number of convergences runs, the initial moisture content becomes high, which does not occur usually in new buildings.

Figure 1 suggests that an MGI of 4 to 6 can be expected on the AAC wall assembly when the surface temperature and surface relative humidity are in the range of 25–30 °C and 60–100% RH, respectively. Additionally, it was also observed that the MGI tends to be in the range of 3 to 4 when outdoor DBT and outdoor RH are in the range of 20–30 °C and 60–100% RH, respectively.

The MGI in the investigated commercial building in the Mangalore region ranges from 2.8 to 4.2. The surface temperature with surface RH of the material plays a very important role in the mould growth index, followed by outdoor DBT and RH, global horizontal radiation, as well as diffused horizontal radiation.

4. Discussion

This paper summarizes the method and process to be followed for modelling mould growth in building envelopes using HAMT in the EnergyPlus engine. The mould growth on a building has been attributed to outdoor DBT and RH; however, this is only partially true. It has been identified in this research that outdoor surface temperature and RH, along with the hygrothermal property of a material, play a crucial role in mould growth on a material. Additionally, the radiation falling on each surface, along with the time for which the moisture exists on a material surface, also plays an important role in mould growth. The annual mean MGI for the AAC assembly is 3.5, which suggests that mould growth is visible and will cover about 30–70% of the surface area. This is only for the first year and, over the life of the building, it can be expected to reach an MGI of 6, which suggests that mould growth will be very heavy and experience tight growth. This data can be used to identify and apply the appropriate moisture barrier to avoid water seepage and water stagnation on the buildings in the warm and humid climate of Mangalore. Furthermore, it was also observed that the database for the hygrothermal properties of the local building material in India is lacking and needs to be measured. Additionally, it is also important to note here that the data and results presented here are purely simulated, and that the on-site conditions might vary. This study will help the material manufacturers as well the building architects and developers to make appropriate design decisions to construct a mould-free building.

Author Contributions

Conceptualization, S.D.; methodology, S.D. and N.V.S.K.M.; software, N.V.S.K.M.; validation, S.D. and N.V.S.K.M.; formal analysis, S.D. and N.V.S.K.M.; investigation, S.D. and N.V.S.K.M.; resources, S.D., N.V.S.K.M. and G.P.; data curation, N.V.S.K.M.; writing—original draft preparation, S.D., N.V.S.K.M. and G.P.; writing—review and editing, S.D., N.V.S.K.M. and G.P.; visualization, N.V.S.K.M.; supervision, G.P.; project administration, S.D.; funding acquisition, S.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

Authors would like to acknowledge the Nitte Institute of Architecture (NITTE DU), Mangalore, KA, IN, and their Director, Vinod Aranha, for providing material support, NIA’s Building Science Lab and motivation for working towards this project.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Central Electricity Authority of India. Growth of Electricity Sector in India from 1947–2020; Central Electricity Authority of India: New Delhi, India, 2020. [Google Scholar]

- Kumar, S.; Kamath, M.; Deshmukh, A.; Sarraf, S.; Seth, S.; Walia, A. Energy Conservation and Commercialization (ECO-III). In Performance Based Rating and Energy Performance Benchmarking for Commercial Buildings in India; USAID: Washington, DC, USA, 2010. [Google Scholar]

- Rawal, R.; Shukla, Y.; Didwania, S.; Singh, M.; Mewada, V.; Galsar, M. Residential buildings in india: Energy use projections and savings potentials. Growth 2014, 800, 1000. [Google Scholar]

- Kumar, S.; Khan, A.; Bajpai, A.; Rao, G.S.; Mathur, J.; Chamberlain, L.; Thomas, P.C.; Rawal, R.; Kapoor, R.; Tetali, S.; et al. User Guide Energy Conservation Building Code, 2nd ed.; Bureau of Energy Efficiency: New Delhi, India, 2011. [Google Scholar]

- World Health Organisation. WHO Guidelines for Indoor Air Quality: Dampness and Mould; World Health Organization: Copenhagen, Denmark, 2009. [Google Scholar]

- World Health Organisation. WHO Guidelines for Indoor Air Quality: Dampness and Mould; World Health Organisation: Geneva, Switzerland, 2014. [Google Scholar]

- Viitanen, H. Factors affecting mould growth on kiln dried wood. In Proceedings of the COST E15 Conference, Helsinki, Finland, 11–13 June 2001; pp. 1–8. [Google Scholar]

- Stephenson, L.D.; Heffron, A.; Mehnert, B.B.; Alvey, J.B.; Boddu, V.; Gao, E.J.; Lawrence, D.J.; Kumar, A. Prediction of Long Term Degradation of Insulating Materials; US Army Corps of Engineers: Washington, DC, USA, 2015. [Google Scholar]

- Antretter, F.; Simon, P. HAMT extension for EnergyPlus encompasses moisture sources due to air leakage. In Proceedings of the ASHRAE Winter Conference, Atlanta, GA, USA, 12–16 January 2019. [Google Scholar]

- Simon, P.; Philip, B.; Som, S.; Joshua, N.; Mark, A. State-of-the-Art for Hygrothermal Simulation Tools; Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, 2017. [Google Scholar]

- ISO 12571:2013; Hygrothermal Performance of Building Materials and Products—Determination of Hygroscopic Sorption Properties. European Committee for Standardization: Brussels, Belgium, 2013.

- ASHRAE Standard 160-2009; Criteria for Moisture-Control Design Analysis in Buildings. American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2009.

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).