1. Introduction

Microgrids have gained significant popularity due to the increasing demand for a plentiful supply of reliable, affordable, and clean energy. Governments are establishing regulations to ensure not only a constant supply of power but also that electricity is produced in an environmentally friendly and clean manner. In many linked electricity networks, microgrids have come to play a crucial role. They seem to hold the best hope for the future of sustainable energy globally, as they have expanded from small to large sizes. Both grid-connected and off-grid (islanded) modes of operation are possible for the microgrid. The island functioning of the microgrid might be particularly problematic due to the fluctuation and erratic nature of RESs, since it is impossible to maintain it in a stable state for an extended period without outside assistance [

1,

2]. To ensure the microgrid’s smooth operation, an energy storage system (ESS) can be utilized as an aid [

3]. Nevertheless, the grid aids the grid-connected microgrid when the renewable energy system (RES) varies or when load oscillations take place. An ESS may store energy during high-power generation periods and release it once the load surpasses the power generated, thereby mitigating the power oscillations produced by an RES [

4,

5]. Due to their technical advantages and ability to supply power as well as energy density, battery energy storage systems (BESSs) are most suitable for use in power systems. The functionality of a BESS as an energy reserve is directly linked to its technical attributes, such as depth of discharge (DoD), state of charge (SoC), power concentration, and self-discharge rates [

6]. Therefore, introducing BESSs considering their technical attributes to ensure an optimal and flexible operation according to rating and size turns out to be a primary concern for the economical development of microgrids.

To guarantee the reliability, safety, and financial gains of the microgrid, determining an ideal BESS size is quite important. In communities without access to the electrical grid, cost-effective power scheduling coupled with the correct sizing of the BESS is crucial for rural electrification projects. Several researchers have studied the BESS’s functioning and scheduling, but work continues to be conducted on the system’s design and ideal size estimation to create a low-cost setup with few power losses [

7]. Considering these facts, when formulating the optimization problem, we took the BESS’s life expectancy and depth of discharge into account. For the battery to operate optimally, it is necessary to consider its size and lifespan. We developed an approach that assesses a permissible range of DoD for a better life cycle and flexible operation of the BESS under several cautiously chosen scenarios. The hourly electricity demand and wind energy generation of a typical modest residential area with a peak load of around 160 kW were used to evaluate the developed strategy. By considering the outcomes of the three distinct research situations, we guarantee that the proposed approach is accurate and provides possible solutions. This approach can reduce the microgrid’s overall operating cost. Since the operation of the battery in a wind-based microgrid is much more intermittent than when it is used with other RESs or under normal circumstances, performing the economic power dispatch of energy sources in accordance with load requirements at each hour is mandatory.

2. Literature Review

Electricity demand is increasing globally each day due to rapid urbanization, technological advancements, and the growing reliance on digital infrastructure. As a result, the strain on energy grids continues to intensify, requiring innovative solutions for sustainable energy generation. Even if this trend continues, it is possible that the world’s energy consumption may double by 2100 [

8]. Governments are under tremendous pressure to provide consistent, dependable, and sustainable energy due to the need to sustain rapid economic growth at the same rate as the increase in population, particularly in emerging countries [

9]. High reliance on local or imported fossil fuels has detrimental environmental repercussions, along with the risks connected to future energy security and the competitiveness of power generation in terms of cost [

10]. Governments all over the globe are now reconsidering their energy policies in an effort to speed up the shift to greater reliance on renewable energy sources [

11].

RESs have become crucial resources for generating power due to the progressive depletion of fossil fuel resources over the last few years [

12]. However, there are differences in the distribution of renewable energy sources and the investments made by various nations in implementing hybrid microgrids. As anticipated, a nation’s power policies have a direct bearing on the quantity and quality of the energy produced. The power distribution paradigm has shifted towards a decentralized structure by merging renewable energy sources with utility grids, which has led to the study of hybrid microgrids [

13].

The growing use of RESs in microgrids has made maintaining grid stability and ensuring optimal performance more difficult. Battery energy storage systems (BESSs) are frequently used in microgrids. Depending on the configuration used and the intended use, the BESS can be deployed anywhere along the grid [

14]. As a crucial part of any microgrid, the BESS can tackle the off-grid operational scenario by providing renewable production sources, including PV and wind power generation, an uninterruptible source of power in the shape of a UPS (uninterruptible power supply) [

15]. Additionally, the BESS can store electricity from the utility and sell it to customers during times of high rates, when the electricity generation cost is comparatively lower. Microgrid operators benefit economically to a considerable extent. Additionally, the ESS can assist in stabilizing the microgrid’s voltage as well as the frequency level in the wake of load disturbances, enhancing the grid’s power quality [

16]. It is essential to maximize the benefits of BESSs to enhance the adaptability and commercial viability of microgrids [

17]. To achieve this, the use of metaheuristic algorithms has garnered considerable interest due to their effective handling of challenging optimization problems.

Several approaches have been proposed in the literature to determine the optimal size of a BESS in microgrids. BESS sizing problems are typically formulated using a similar methodology because demand, the BESS, and all power sources are generally included. Since cost minimization or profit maximization are typical definitions of optimization problems, both conventional optimization methods and metaheuristic approaches can be used to solve them. Traditional optimization methods, such as linear programming and mixed-integer linear programming (MILP), have been extensively used for battery sizing [

18]. These methods provide precise solutions but are computationally intensive for large-scale, nonlinear, and multi-objective problems. Additionally, they struggle to adapt to uncertainties in renewable energy sources (RESs), such as wind power fluctuations [

18,

19].

Metaheuristic algorithms, known for their flexibility and capability to handle complex nonlinear optimization problems, have gained popularity in BESS sizing. For instance, Particle Swarm Optimization (PSO) is widely used due to its simplicity and fast convergence. However, it often suffers from premature convergence and may get trapped in local optima, especially in high-dimensional problems [

20]. The Grey Wolf Optimizer (GWO), inspired by the social hierarchy of wolves, addresses some of PSO’s limitations by balancing exploration and exploitation. Yet, its performance can degrade when applied to dynamic and uncertain environments, like wind-based microgrids [

21].

Firefly Optimization (FFO) has been applied to determine the optimal battery capacity and energy scheduling. Despite its robustness, FFO’s performance is highly sensitive to parameter tuning and may require extensive computational effort to achieve optimal results [

22]. Similarly, the Whale Optimization Algorithm (WOA) has been employed for microgrid optimization, but it faces challenges in maintaining diversity in the solution space, which can reduce its effectiveness over time [

23,

24]. The Coyote Optimization Algorithm (COA), a comparatively newer approach, shows potential for solving complex optimization problems. However, there is limited research on its scalability and robustness in real-world microgrid applications [

25].

Stochastic programming approaches have also been employed to account for uncertainties in renewable energy generation, particularly wind power [

26]. These methods aim to minimize operational costs by considering probabilistic scenarios. However, their computational complexity increases significantly with the number of uncertain variables, making them less practical for real-time applications.

Although a number of earlier works have employed the genetic algorithm (GA) technique to address the optimal sizing of BESSs, particularly wind-penetrated microgrids, these studies often overlook the influence of battery depth of discharge (DoD) on the systems’ performance and lifespan. The GA is a versatile algorithm capable of addressing multi-objective optimization problems. However, its performance can be sensitive to crossover and mutation parameters, leading to slower convergence or suboptimal solutions [

27]. To address these drawbacks, our proposed approach incorporates the DoD constraint, enhancing the economic and technical viability of the BESS solution in a wind-based microgrid.

Renewable energy source (RES)-based microgrids, particularly those integrated with wind energy, face challenges due to the inherent variability and unpredictability of wind energy, which directly impact system reliability and stability. For example, during periods of low wind, power generation from wind turbines decreases markedly. Should these conditions align with elevated demand, the system may experience load-shedding or blackouts. Although diesel generators are often used as backup power sources, they present both economic and environmental challenges. Addressing these challenges, this paper presents an innovative and efficient optimization framework for the concurrent sizing of batteries and economic dispatch in wind-based microgrids. This method uniquely integrates the DoD of the battery storage system into the optimization process to improve economic performance and battery lifespan. A GA is employed to address the multi-objective optimization problem, focusing on minimizing the total scheduling cost while determining the optimal battery size. The suggested method decreases operating costs while ensuring environmentally sustainable and dependable microgrid operation by incorporating battery degradation metrics into the decision-making process.

The main features of the work include the following:

An efficient optimization framework that, under changing load and wind conditions, simultaneously establishes an ideal battery size and cost-effective dispatch for wind-based microgrids.

Battery degradation and lifecycle cost are taken into consideration by incorporating DoD constraints into dispatch optimization.

Extensive case studies have shown 40–50% cost savings in microgrid operating costs and electricity costs compared to traditional dispatch strategies.

A workable approach that gives grid operators and energy planners an affordable and environmentally friendly tool for raising the operational effectiveness of microgrids driven by renewable energy.

3. Methodology

In this section, we attempted to show how we created a model by using a mathematical formula to determine the ideal BESS size for the microgrid’s economical and adaptable functioning. The primary objective of this study is to minimize the objective function, and we demonstrated the limitations and requirements of the objective function. The ideal size of the BESS will be provided by minimizing the objective function, which will also reduce the overall system cost. For all calculations, character simulations, and economic evaluation of the suggested model, we operate in the MATLAB 2020b software environment.

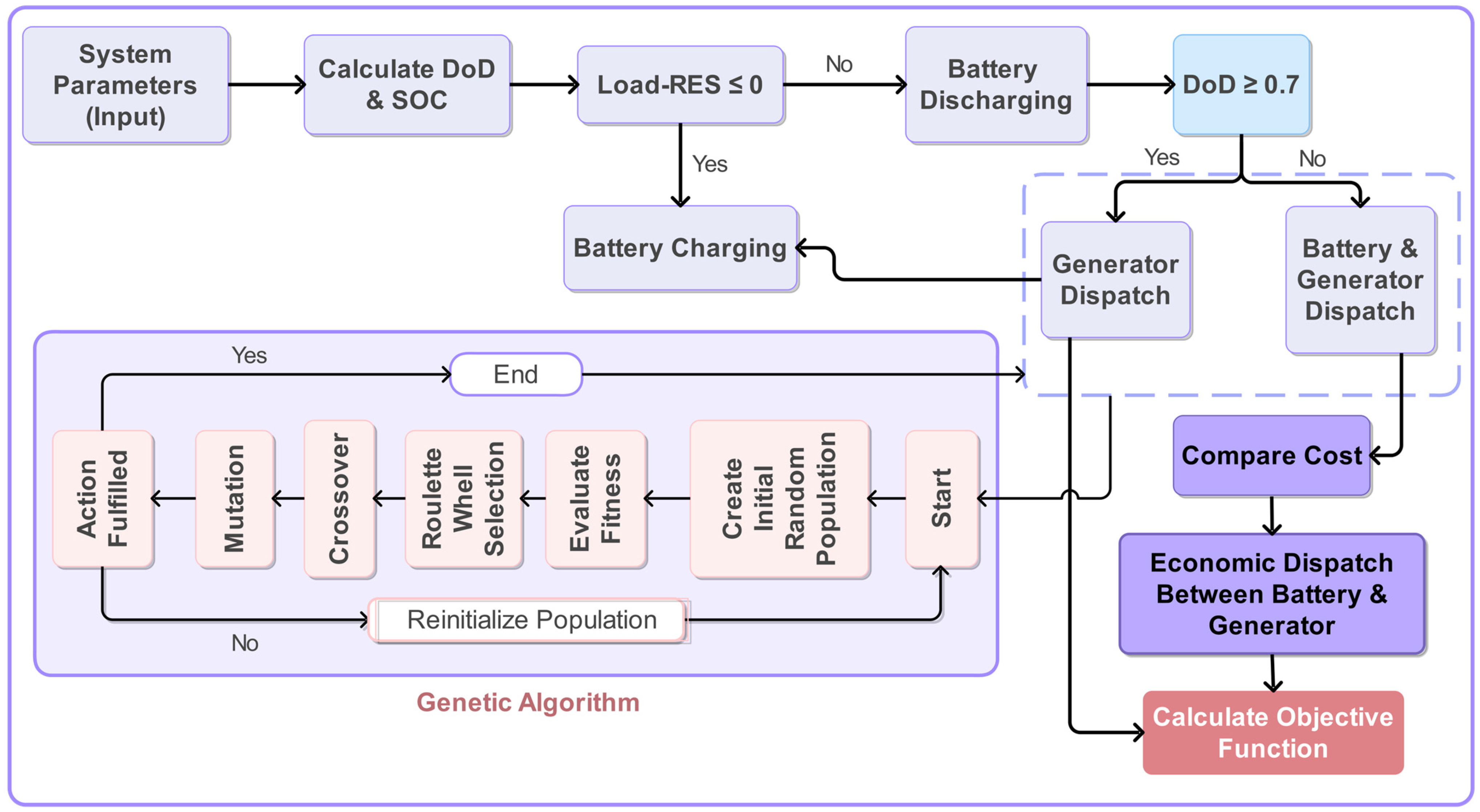

The proposed framework utilizes the GA algorithm to determine the optimal power management strategy at hourly intervals, thereby calculating the appropriate battery size based on the load requirement. When demand exceeds supply, the algorithm delivers electricity from the BESS or generators as needed. Although the operational cost is ultimately reliant on the DoD of the battery, the suggested method distributes the best possible amount of electricity from wind turbines and diesel generators based on the load demand at a specific hour and the cost equations for all sources. The algorithm also permits the use of generators to charge the battery in situations such as when the cost of the BESS is greater than that of the generator and the battery DoD is above a certain value. Every hour, the battery’s state of charge (SoC) is calculated, and thus the system determines whether the battery should be charged or drained. For an ideal battery size, the overall operating cost of the microgrid will be minimized using the stated power resource scheduling technique. The size range of the batteries is 100 to 150 kWh. Considering this knowledge, we now go through how the GA algorithm does optimization.

The following three operational cases provide a summary of the tactics used to research the study’s goals:

Case A: BESS unplugged mode: The system is operating without battery energy storage.

Case B: BESS plugged mode: The system is operating with a fixed battery capacity of 100 kWh.

Case C: BESS plugged mode: The system is operating with an optimized battery capacity.

3.1. Proposed Microgrid System

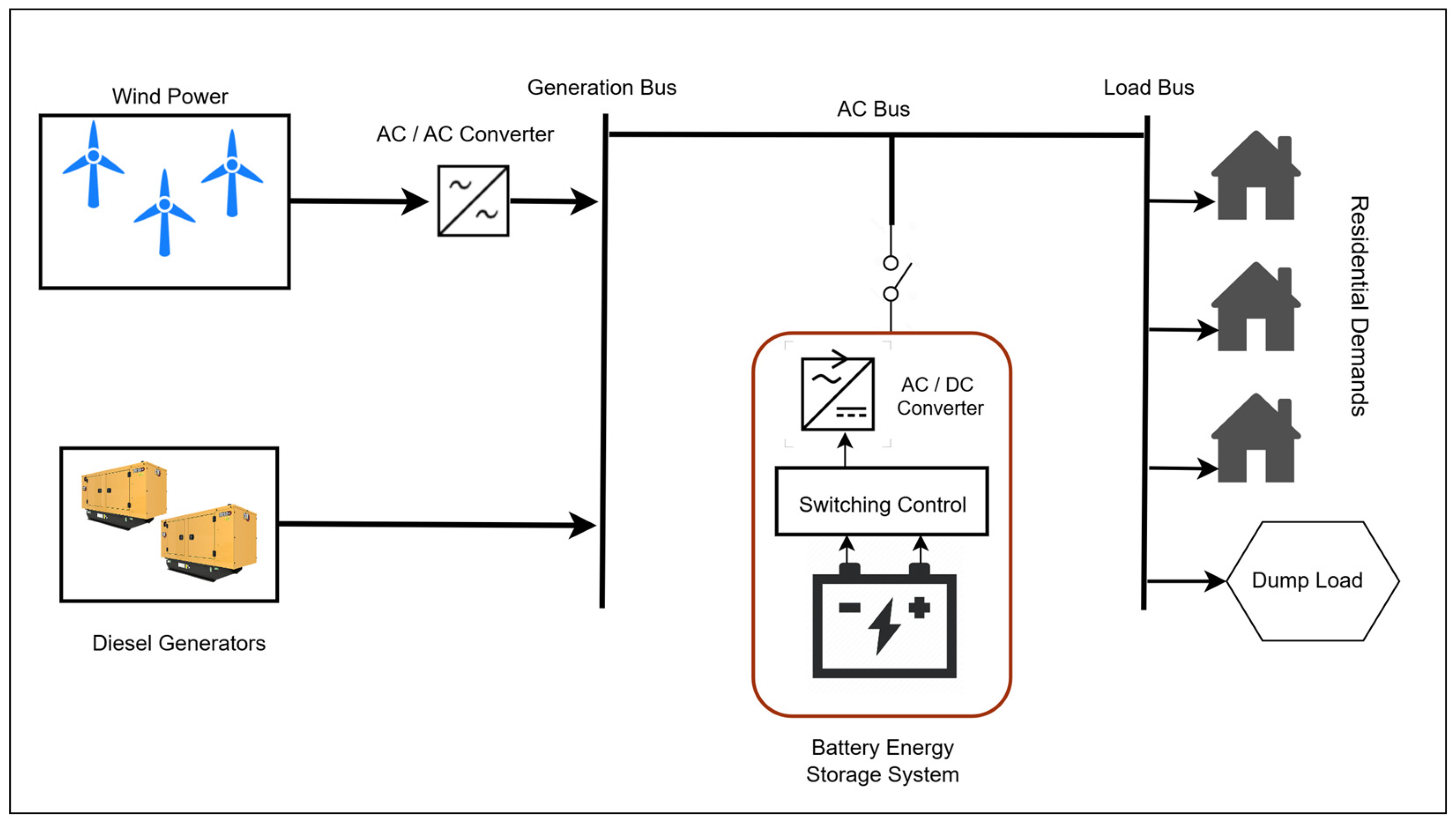

The microgrid design depicted in

Figure 1 is considered when defining the problem in this study. The microgrid is designed in a way that it may switch between operating with a BESS connection and without a BESS connection.

The generator bus connects the AC bus to three diesel generators and is the only source of the RES, wind power. Furthermore, the load bus links the residential load demand to the AC bus. When the load power requirement is satisfied and the BESS is fully charged, the extra power is used by a dump load attached to the load bus. By doing this, the BESS is not overcharged and the network cables are not stretched too much. The switch serves as a direct link between the BESS and the AC bus. The use of the converter topologies and their control are outside the purview of this study because it is presumed that the battery has the configuration of a converter and switching controller inside the BESS unit.

3.2. Wind Power Model

The output power of a wind turbine is expressed by (1) [

28]. The wind speed and hourly electricity output are related by the wind power model equation.

where v

r is the rated wind speed, V

CI is the cut-in wind speed, V

co is the cut-out wind speed,

is the rated power of the wind plant, and vt is the wind speed at time t. Equation (3) provides the entire cost of the electricity dispersed by the wind power facility during period T [

29].

where i

r and ly are the interest rate and expected battery life of the wind power plant, respectively, and IC

w is the initial cost of the wind power plant. The capital recovery factor, or CRF, is obtained using (2).

3.3. Generator Model

Regarding dispatch power, the cost for a diesel generator, i, at a specific time, t, is expressed as (4) [

30]. This presupposes that a diesel generator is being used and that it will be the microgrid’s secondary source of power generation. Wind energy serves as the main energy source.

where a

i, b

i, and c

i are the coefficients for the ith generator, and P

g,i(t) is the power delivered by the generator i at time t. The number of generators under consideration is N.

3.4. Battery Energy Storage Model

In accordance with its widespread availability and sophisticated technology, the BESS is one of the most well-liked ESSs [

30]. Since every technology has different power and energy characteristics, the application is the main indicator of the type of BESS to choose. Lithium-ion batteries were chosen for conducting this research because of their long lifespan, high efficiency, and high energy density, making them one of the best BESS kinds for storing renewable energy [

31].

It has been established that the battery’s life cycle affects the cost analysis of a BESS [

28,

29,

32]. The battery’s depth of discharge (DoD) affects the cycle life [

33]. As a result, the DoD also affects how much the BESS costs. Equations (5)–(7) provide the battery DoD (DoD

b(t)), life cycle for a specific DoD (l(t)), and battery cost (C

b).

where C

b,cap denotes the cost of the original battery capacity.

Equation (8) [

29] represents the state of charge (SoC), which is the status of battery capacity provided:

The unit optimization time () in these equations is likewise assumed to be 1 h. In this study, the battery’s efficiency is specified as the product of the battery’s charging efficiency and its discharging efficiency.

3.5. Objective Function

The aforementioned power management technique is put into practice to create a microgrid with an ideal battery size and daily economic scheduling. Battery capital costs play a significant role in determining battery size. By reducing both the daily microgrid scheduling cost (SC

D) (10) [

29] and the total cost per day (TCPD) of the BESS, the ideal BESS size is found. The entire operating cost (OC) of the microgrid (9) [

29], as shown in the formula, serves as its goal function.

Here, the cost of charging and discharging the battery storage is added to the cost of arranging power from three diesel generators to fulfill the day’s load demand. In the current study, the number N is assumed to be 3, and the time period T is specified as 24 h. The TCPD of battery storage (11) [

29] is a function of the initial cost of the battery and the annual maintenance cost taken into consideration throughout the battery’s lifespan. The overall expense of the microgrid will be reduced with the optimal battery size.

In this optimization problem, the objective function is to minimize the operational cost (OC), defined as the sum of the daily scheduling cost (SCD) and the total cost per day of the BESS (TCPDBESS). Since TCPDBESS remains constant for a given battery capacity, the optimization is driven by SCD. Consequently, the design variables of the problem are as follows:

Generator dispatch power at each time step which influences the generator fuel cost.

Battery scheduling cost , associated with the charging and discharging operations of the storage system.

These design variables are iteratively updated by the genetic algorithm until the minimum operational cost is obtained.

3.6. Constraints

Meeting the constraints that follow has allowed the microgrid’s energy management operation to be optimized.

3.6.1. ESS Constraints

Equation (12) [

34] provides an expression for the energy used in charging and discharging batteries. Positive P

batt indicates that the battery is charging, whereas negative P

batt specifies that the battery is discharging. The corresponding restriction (13–15) [

35] sets a minimum and maximum value for battery power. Battery power determines whether the battery is being charged or discharged; it is positive when the battery is being discharged and negative when it is being recharged. The battery’s operational condition is indicated by the binary variable

. The battery avoids the simultaneous charging and discharging function at any time frame by only discharging when

is 1 and charging when

is 0.

and

, respectively, display the greatest amount of power that the battery storage has been able to charge and discharge during period t. Each interval’s battery capacity falls between the minimum

and maximal

levels (16). In this study, the upper and lower bounds for energy storage capacity were chosen at 90% and 15%, respectively.

3.6.2. Diesel Generator Constraints

The maximum and lower limits of each diesel generator (17) must be respected when generating electricity using them.

3.6.3. Power Balance Constraints

The equilibrium between supply and demand is the main restraint on the electricity system. The microgrid has to maintain power flow balance at each time step, as defined by Equation (18).

where P

L(t) represents the load’s power consumption at time t.

5. Results and Discussion

In the preceding section, a model is presented for finding out the economic dispatch of energy sources on an hourly basis and the optimal size of a battery energy storage system (BESS). Our objective is to minimize the daily operating cost of the system, enabling further flexible and economical operation, by utilizing a genetic algorithm as a metaheuristic approach. The MATLAB coding environment was used as the primary software for the whole optimization.

5.1. System Parameters

A relatively low-voltage microgrid comprising three diesel-powered generators and a lithium-ion battery is proposed to demonstrate the effectiveness of the proposed strategy. Additionally, a 150 kW wind renewable energy source (RES) is employed. The parameters for diesel generators in

Table 1 derived from [

38] and the BESS data in

Table 2, including its lifetime, initial capital cost, maintenance cost, and interest rate, were derived from [

29]. MATLAB (R2020b) software was used to develop the proposed approach, which was then run on a personal computer with a Core i3 processor operating at 2.7 GHz and 8 GB RAM. The simulation’s computations took roughly 2 min and 15 s to complete.

We present a typical residential load profile and the wind power data used to evaluate the proposed technique in

Figure 3. The system load was modeled as a 24 h time-series demand curve discretized on an hourly basis. The maximum demand was normalized to about 170 kW, and the curve was shaped to represent realistic residential consumption behavior, characterized by higher demand in the evening and lower demand during the early morning. The adopted profile was adapted from a standard residential dataset and assumed to remain constant across days without seasonal variation. This simplified but representative model enables a realistic assessment of the optimization framework while ensuring computational efficiency.

As shown in

Figure 3, the demand exceeds the output of the RES for the majority of the day. The generators and the BESS provide the remaining electricity required to meet demand during these times. Instead, during those rare occasions when the generation of RESs surpasses the demand, the BESS gets charged with the additional electricity. When necessary, for instance, the generators might be utilized for charging the BESS in order to maintain their state of charge (SoC) at a considerable level for smooth and efficient functioning. This strategy is economically favorable, as generator operation is less costly compared to frequent deep discharging of the BESS, which accelerates degradation. The BESS must therefore work at an ideal SoC in order to maintain its state of health and extend its life expectancy.

It is thought that the array of battery storage employed in the microgrid system will be initially charged to 75% SoC.

Generator and Battery Energy Storage Parameters

The required parameters of the three diesel generators are listed in

Table 1 and parameters of battery energy storage listed in

Table 2.

5.2. Case A: BESS Unplugged Mode: System Is Operating Without Battery Energy Storage

In this case, battery energy storage is not used for microgrid operation. As a result, there will be no TCPD cost, and its only objective role will be to schedule the microgrid’s economic activities daily. The load demand must always be met by diesel generators and RESs. There are, however, some circumstances where diesel and renewable generators cannot handle the necessary load, leading to an imbalance of power between supply and demand. Due to the system’s imbalance brought on by this power mismatch, load shedding will cause a power outage. The penalty for load shedding is taken into consideration when calculating how much the microgrid’s scheduling costs will increase. The excess power from the RESs will, however, be used as a dump load when the RES power is greater than the loads.

Table 3 describes the detailed hourly load demand and dispatch data. The load profile and generation curve for the dispersed sources are displayed in

Figure 4. The figure shows that load shedding occurs when the generation and the load are out of balance in the hours between 8–15 and 17–19. A power imbalance can lead to a system power outage and significantly affect the power network. When there is a power outage, the microgrid must operate more frequently and more expensively, which raises overall operating expenses.

To handle these difficulties, the generators’ installed capacity might be increased. The cost would be considerably higher, and the overall system reliability would drop significantly. In addition, increasing the number of installed generators or their capacity results in an undesirable increase in greenhouse gas emissions. Alternative tactics must therefore be investigated.

5.3. Case B: BESS Plugged Mode: System Is Operating with a Fixed Battery Capacity of 100 kWh

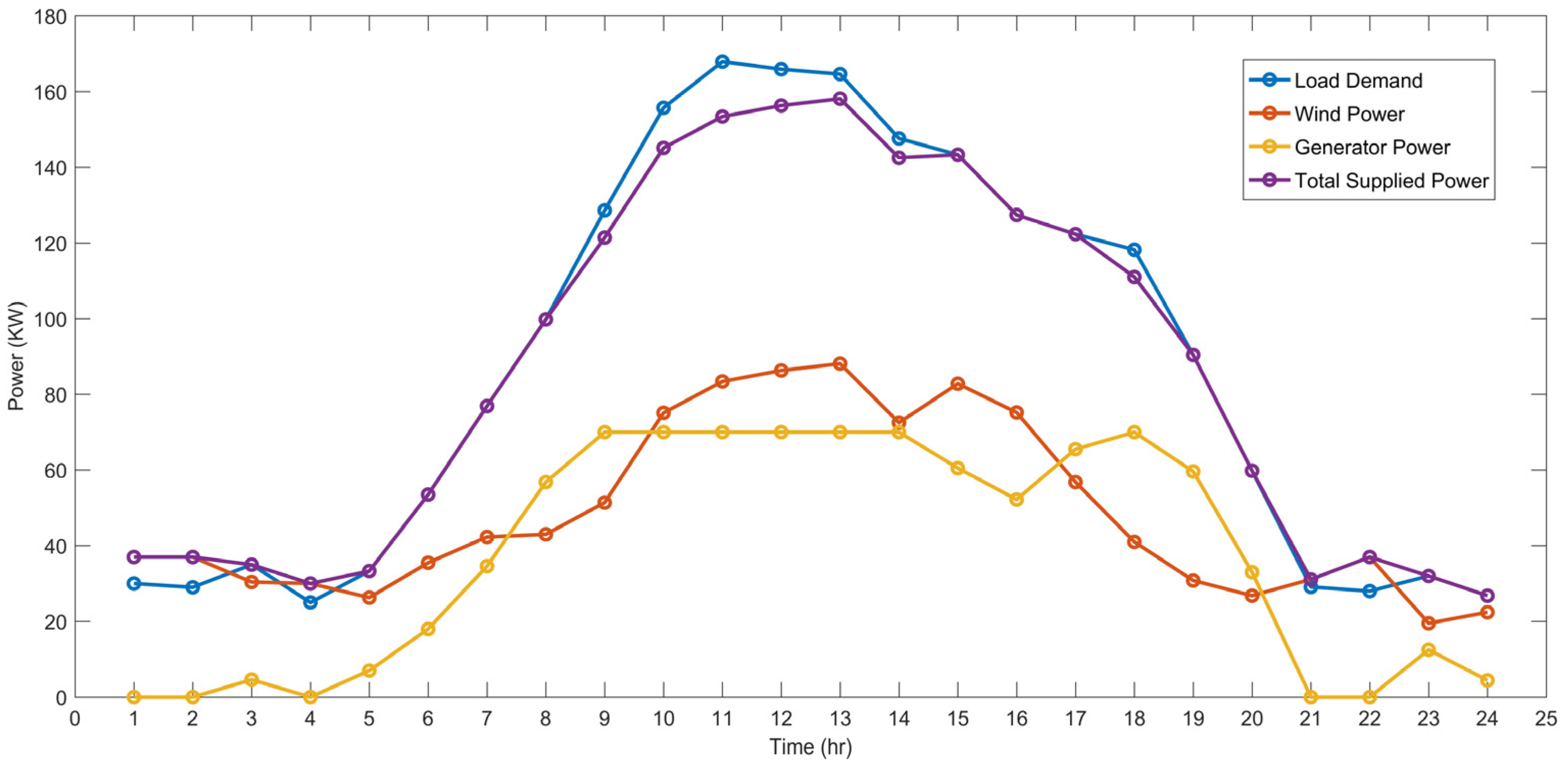

The microgrid system must have battery storage, since the load demand cannot always be met by renewable energy sources and diesel generators. In this instance, a 100 kWh battery is implemented in the system. The size of the battery is selected so that the generation and the load are always exactly in balance. Battery discharge occurs when battery cost is less than generator cost; battery charging occurs when battery cost rises.

In this instance, the microgrid’s daily scheduling cost is projected to be USD 126.25, whereas the battery’s TCPD is USD 70.90.

Figure 5 graphically represented the hourly load demand and dispatch data for all of the available sources.

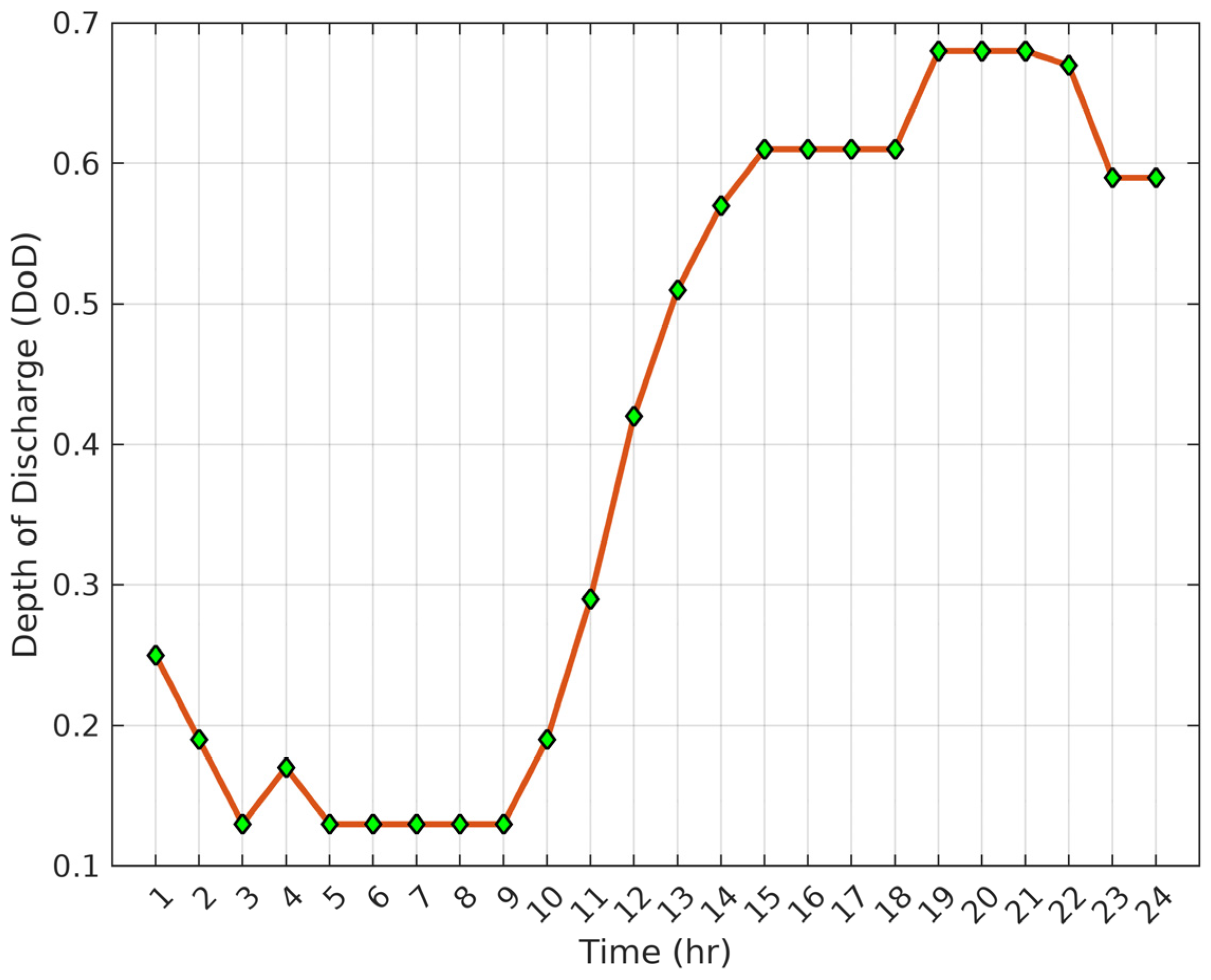

Figure 6 depicts the battery DoD for this scenario. It is clear from the figure that, in some circumstances, the DoD rises above 70%. As a result, the battery must operate at a high cost and experience shorter lifespans, which also affects the overall system flexibility. A high DoD indicates that the BESS is being operated beyond the permitted SoC limits, which is undesirable for the BESS’s healthy operation. Additionally, the charge level of the battery is low at the end of the day, which can have an impact on the device’s performance the following day.

Figure 5 shows how the microgrid’s dispersed resources are all operating with 100 kWh batteries. The diesel generator represents the total power dispatch from the three diesel generators in this diagram. The generator always supplies power according to the requirements, but considering the generation cost and the battery DoD state. During times of peak demand, the BESS might be seen in action. For instance, due to an increasing supply of wind power, battery storage charges from 1:00 to 2:00 and at 4:00, and discharges from 21:00 to 22:00.

Between 15:00 and 19:00, the BESS charges once more due to our algorithm, which is designed such that when the battery DoD crosses the 70% mark, the system will charge the BESS at a minimum of 8 kW to preserve battery health. The maximum demand, which happens at hour 11, cannot be fed by diesel engine output or wind power alone, even though both have increased. To satisfy this need, the BESS must release some energy. This observation indicates the microgrid’s ability to operate with some degree of flexibility. A noteworthy finding is that all three generators’ outputs are zero between 1:00 to 5:00 and 19:00 h, due to the drop in demand and the corresponding rise in the energy generated by wind. Additionally, between hours 9 and 13, the BESS power indicates a high rise in demand combined with a drop in wind energy. In order to prevent overstressing the battery, this type of operation signifies that the battery will only start charging when demand is lower than the quantity of renewable energy available or when the battery DoD crosses a certain threshold, though it might have damaged the battery. The battery’s power distribution during charging and discharging over a 24 h period is shown in

Figure 7.

Table 4 describes the detailed hourly load demand and dispatch data for all of the sources, which we graphically represented in

Figure 5. The generation data of all individual generators has also been shown in that table. From this table, it was easier for us to understand the overall load and generation scenarios on an hourly basis. The unpredictable behavior of wind power sources made the microgrid demand and generation scenarios more complex.

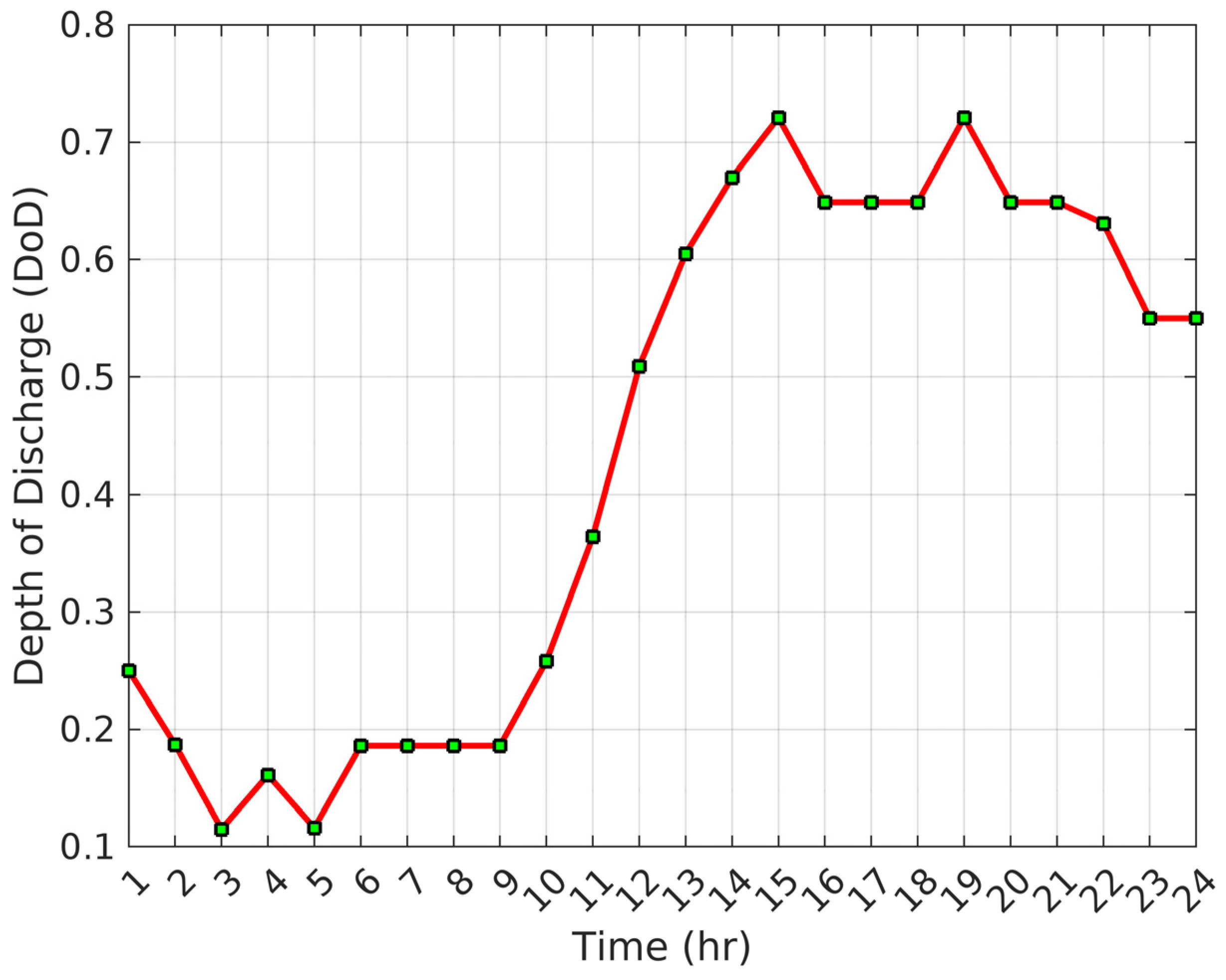

5.4. Case C: BESS Plugged Mode: System Is Operating with an Optimized Battery Capacity

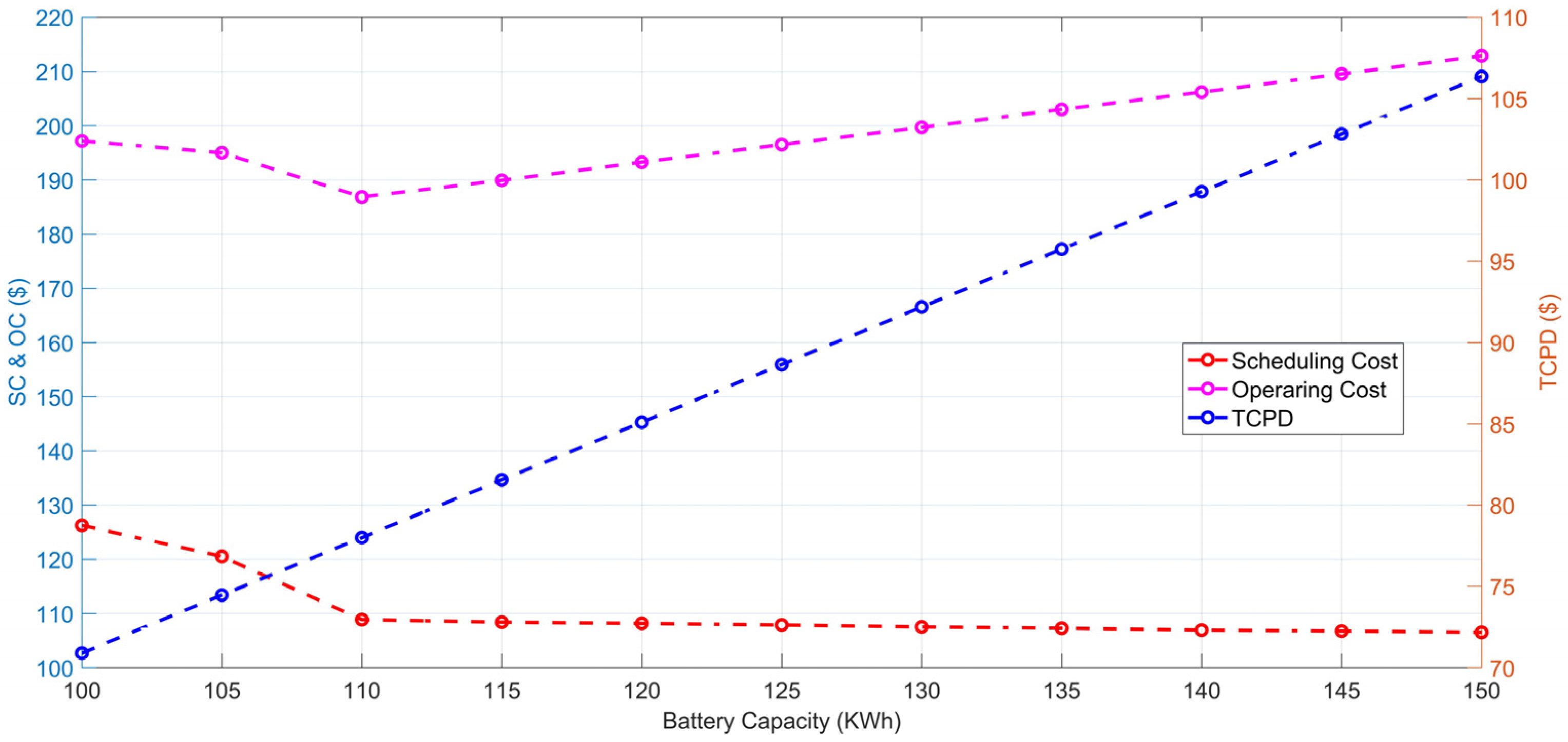

Here, the optimal battery size is taken into consideration to guarantee the system’s economical and effective operation. In a range of battery sizes, we looked for the one that would provide the lowest operating cost while simultaneously providing extended battery lifespan and flexibility. With a 5 kWh step size, the battery’s capacity goes from 100 kWh to 150 kWh. We took into consideration the power balance calculation and other constraints in order to determine the ideal size. It was determined that 110 kWh was the battery’s ideal capacity. The scheduling cost and TCPD totaled USD 108.84 and USD 78.001, respectively, for this scenario. Due to the microgrid’s optimal operation, both costs were lower compared to those reported in case B.

Figure 8 illustrates the power delivered from the wind turbine, generators, and BESS at any given time, and the load demand was always satisfied. Given its maximum output limit and reduced price, Generator 1 was given the highest priority among all three generators.

Figure 9 shows an optimized representation of the DoD.

Figure 10 depicts each generator’s separate power dispatch. Furthermore, comparable to example B, every generator is shifted to meet the changes in wind energy output and demand. In case B, when the capacity of the energy storage, i.e., battery, was not optimized, the battery was substantially exhausted to fulfill the demand. But in this case, the DoD stays within the battery’s targeted working range. The BESS was run on an hourly basis, much like case B describes, and its DoD followed a similar shape but never increased as it did in case B. The battery must be charged in the following cycle if the DoD is to remain over 70%; otherwise, its cost will be greater compared to that of the generators. A longer battery life is guaranteed when using the battery within the expected DoD range. The battery’s power distribution during charging and discharging over a 24 h period is shown in

Figure 11. Battery power is measured as a negative value when the battery is in charging state and shows a positive value when the battery is being discharged. It was obvious that the battery was discharged for most of the time when the load demand was higher. This suggests that the BESS is operating adaptably and effectively. At any given time, the maximum discharging power is set at 25 kW, while the maximum charging power is set at 8.89 kW.

Table 5 describes the detailed hourly load demand and dispatch data for all of the sources.

As the genetic algorithm is a metaheuristic optimization method, repeated runs may yield slightly different solutions. To assess the robustness of the GA in the proposed framework, we performed 10 independent simulations for the case of optimized battery sizing (110 kWh). The minimum, mean, maximum, and standard deviation of the final objective function values are presented in

Table 6. The results show that the variation across runs is relatively small, with a standard deviation of 0.0428. This demonstrates that the GA provides consistent convergence behavior for the problem under study.

5.5. Cost Comparison for Different Battery Sizes

Here, in

Table 7, we have shown the daily scheduling cost (SC) and total cost per day (TCPD) for battery sizes and summarized them to get operational cost. From the table, it is clear that the operating cost is minimum for a battery size of 110 kwh, so it was chosen as our optimized battery size.

Figure 12 visualizes the table data for a better understanding of the calculated data.

5.6. Technical Analysis Between Fixed and Optimized Battery Size

After determining the optimal battery sizing, the question is what changes will occur in the grid compared to its previous size. Does the optimized battery really contribute to the flexible and economic operation of the microgrid? From

Table 8, we observe that the average DoD value for the optimized battery size has decreased significantly compared to the previous one, resulting in a longer battery lifespan. A longer lifespan is one of the significant parameters for understanding the performance of the BESS.

From

Table 8, it is clear that when we used a randomly chosen battery size, i.e., 100 kWh in the microgrid, the lifecycle of the battery was 1349, which was comparatively much less than the 1425 lifecycle of the optimized battery size, i.e., 110 kWh.

More lifecycles ensure more usability of a battery, which ensures greater economic efficiency; as a result, the replacement time of the battery in the microgrid will be longer.

5.7. Comparison of Proposed Algorithm with Other Algorithms

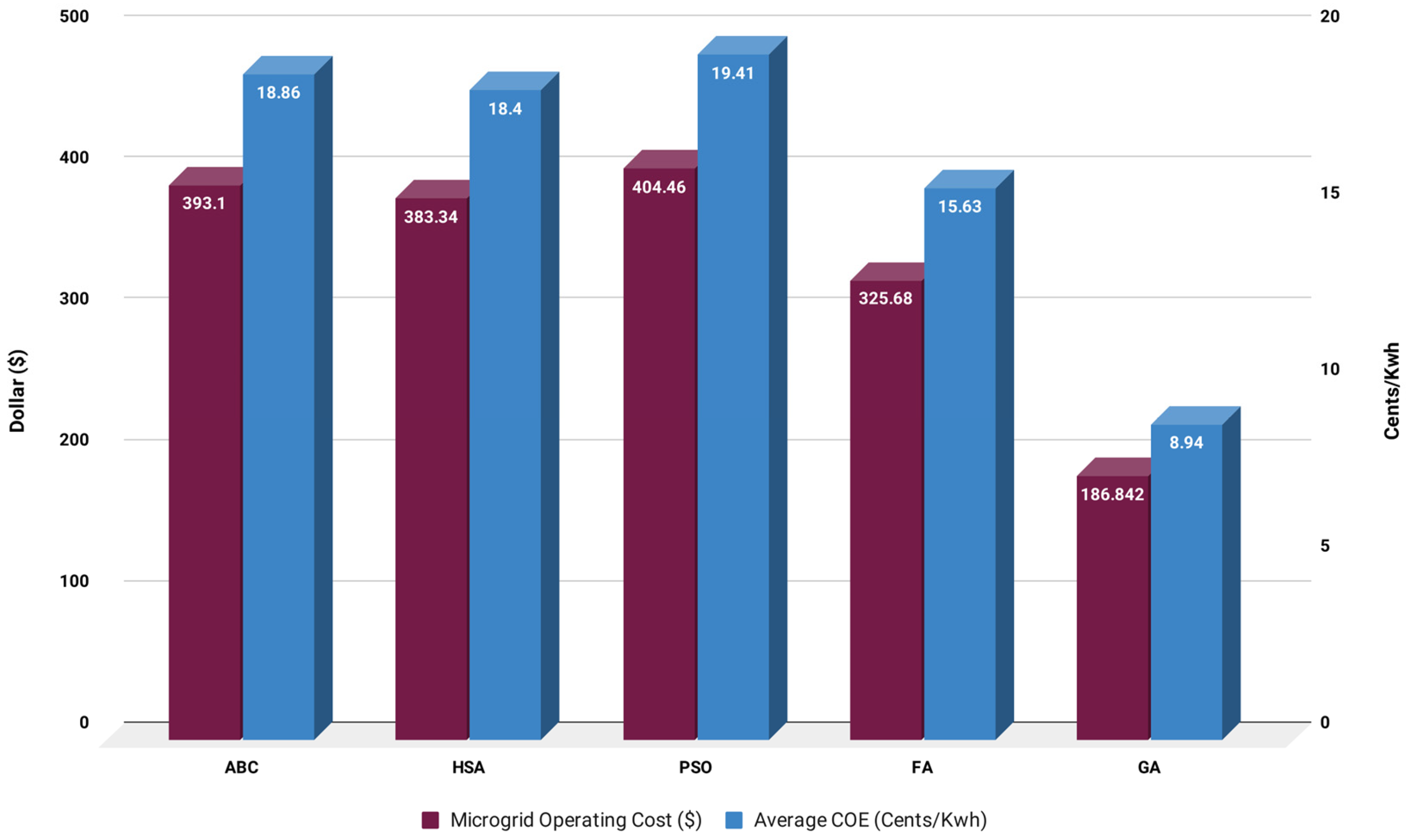

Figure 13 displays the microgrid’s operating costs and cost of electricity (CoE) for various algorithms, clearly demonstrating the robustness of our proposed algorithm, GA, in comparison to other algorithms. The comparison is performed by implementing the other methods, which are Artificial Bee Colony (ABC), Harmony Search Algorithm (HAS), Particle Swarm Optimization (PSO), and Firefly Algorithm (FA), using the parameters mentioned above.

Figure 13 shows that in comparison to other methods, our suggested method lowers both operational cost and CoE by 40–50%. The cost of electricity (CoE) is a measure of the hybrid microgrid’s economic profitability. It is calculated as the ratio of the total cost of all energy sources to the total daily load.

6. Conclusions

As the contribution of renewable energy sources to the global energy supply is growing rapidly, the optimal sizing of BESSs in microgrids has become a crucial factor in ensuring sustainable service. A system without a BESS faces uncertainty, which can lead to load shedding and the inability to utilize surplus renewable energy. Economic dispatch between generators and the BESS, considering battery degradation cost, was performed in this study. An optimization framework was developed to optimize economic scheduling and find the optimal battery size. The key point of our proposed method is to consider battery DoD as the microgrid’s operational cost, which is ultimately reliant on it. Meanwhile, lower operational costs result in the best possible battery sizing. The study’s outcomes indicate that operating with a fixed battery size results in higher costs and reduced stability, as the battery DoD often exceeds permissible limits, thereby shortening the battery lifespan. Our research reveals that while extending BESS capacity incurs higher costs, it does not always result in higher operational expenses. The proposed GA-based optimization method applied to a wind-powered microgrid under varying load conditions demonstrates a 40–50% reduction in operating costs and cost of electricity (CoE) compared to traditional dispatch strategies. Moreover, it enhances battery lifespan by minimizing deep discharge cycles, which in turn reduces maintenance and replacement costs. Additionally, this study offers a flexible framework that can be adapted to various microgrid configurations, regardless of location or renewable energy integration, thereby making a valuable contribution to the optimization of hybrid energy systems. In the future, a real-time online optimization framework will be developed that considers both solar PV and wind energy integration with microgrids.