1. Introduction

Water treatment technologies play an increasingly important role in the efforts to meet the demand for improved drinking water globally. With organic, inorganic, and microbes as the major contaminants for many drinking water sources, especially in low- and middle-income countries, disinfection is central to the advancement of water treatment processes [

1,

2,

3]. Disinfection is a crucial step in the water treatment process that prevents or reduces the risk of waterborne illnesses and ensures the safety of drinking water [

4]. Several disinfection techniques including chloramination, pasteurization, chlorination, chlorine dioxide, and ozonation are used in the treatment of water. But due to concerns over cost-effectiveness, overdose of chemicals, disinfection by-products, and health, there is a shift towards solar water disinfection [

5,

6]. According to studies, ultraviolet (UV) is an efficient method of water disinfection. UV radiation exhibits effective disinfection capacity against a variety of pathogenic bacteria and has been widely used throughout the world [

3,

7]. Unlike chemical disinfection, UV radiation also functions as a chemical-free process with a broad-spectrum antimicrobial agent and no risk of overdosing [

4,

8,

9]. Solar water disinfection systems (SODISs) that solely depend on UV radiation from the sun as argued by Afitiri et al. [

10] are therefore the most suitable alternative water treatment technologies for populations lacking improved water systems and reliable energy.

However, many pathogenic micro-organisms as reported in several studies, evolve to develop efficient deoxyribonucleic acid (DNA) repair mechanisms in order to counteract the lethal effects of UV-induced damages [

11]. This according to studies often occurs either through photoreactivation or dark repair [

12,

13]. In photoreactivation, the photolyase enzyme specifically binds to the cyclobutane pyrimidine dimers (CPDs) and reverses the damage using the energy of light within the range of 310–480 nm. Dark repair on the other hand replaces the damaged DNA with new, undamaged nucleotides as the efficiency of the UV irradiation reduces or becomes totally unavailable [

14,

15]. These microbial evolution processes and the development of resistance increasingly challenge UV as the only disinfection method. Moreover, its capacity for scaling to meet the growing needs of larger populations is limited by its characteristically slower disinfection rates. Recent evidence also shows the risk of bacteria regrowth during post-treatment water storage and the quality of the water to be treated [

16,

17,

18,

19]. Optimizing UV to address these emerging challenges is now of growing importance.

The integration of photocatalysts into conventional SODIS systems can increase both the disinfection efficiency and organics degradation to improve the quality of the water [

10,

20]. Photocatalysts integration into conventional SODIS significantly influences the required time for complete disinfection of contaminants in relation to UV alone, non-recovery of inactivated organisms, as well as the inactivation of UV-resistant micro-organisms [

10,

21,

22,

23]. Studies in this respect argue for the availability of suitable catalysts (reagents), sunlight availability and intensity as well as simple operational designs to effectively enhance photocatalyst adoption in UV disinfection processes. Hence, more research tailored towards this scope is novel and imperative.

One of the most widely studied photocatalysts for water disinfection has been TiO

2; hence, the literature extensively affirms its application to completely disinfect microbial contaminants to increase water access [

24,

25,

26]. When the TiO

2 in water is exposed to light energy equal to or greater than its band gap (λ < 385 nm), it induces the generation of holes (h

+) and hydroxyl (OH

•) in the valence band and electrons (e−) and superoxide ions (•O

2−) in the conduction band [

12]. As OH

• and •O

2− radicals are produced on the surface of TiO

2, they immediately interact with the organism’s outer surface until they penetrate into its cells [

27,

28,

29]. Compared to the •O

2− that are long-lived and cannot penetrate the cell membrane, the OH

• radicals are short-lived, highly toxic towards micro-organisms, and capable of oxidizing organic compounds and their diffusion from the TiO

2 surface into the solution is minimal. Hence, OH

• radicals are the key species in the photocatalytic oxidation process [

12,

30,

31].

The reported remarkable achievement in the use of photocatalysts such as TiO

2 in solar water disinfection is a result of the huddle effect provided by the photon energy from the UV light and the chemical energy from the OH

• radicals generated from the surface of the UV irradiated TiO

2. The UV light inhibits the normal replication of DNA and also bacterial mutations. The cumulative effect of the UV and the OH

• radicals becomes highly toxic towards micro-organisms leading to the perturbation of different cellular processes and finally to the death of microbial species [

12,

32]. In the disinfection of microbial species, UV of a suitable wavelength is needed to match the energy gap of the photoactive TiO

2 for the huddle effect to occur [

10,

33].

Laboratory demonstrations provide a first-hand opportunity to investigate suitable catalysts and UV intensity and radiation on the disinfection of pathogenic bacterial species in unimproved drinking water sources. The most commonly used artificial sources of UV light for laboratory-scale studies are conventional mercury, low-pressure (LP) and medium-pressure (MP) UV lamps, and broadband UV-A lamps. These lamps, however, are disadvantaged as they are characterized by fixed wavelength, short bulb lifetime, low energy efficiency, and environmental pollution due to mercury [

12,

34].

In the past decade, a new UV source called an ultraviolet light-emitting diode (UV-LED) emerged and has shown the potential to replace conventional UV mercury lamps in water disinfection [

4,

7,

35]. UV-LED applications for water disinfection are characterized by different wavelengths whose emission wavelengths are approximately 300–400 nm (near-ultraviolet light-emitting diodes) and approximately 200–300 nm (deep-ultraviolet LEDs) [

12,

36]. Additional advantages of UV-LEDs in water disinfection over mercury lamps include no disposal problem (LEDs do not contain mercury), compact and robust design, more durability in transit and during handling, faster start-up time (no warm-up time), ability to turn on and off with high frequencies, lower voltages, low power requirements, potential for higher energy efficiency, potential for longer lifetimes, and reduced frequency of replacement among others [

37,

38,

39].

Li et al. [

4] evaluated the comparison of UV-LED and low-pressure UV for water disinfection. Photoreactivation and dark repair of

Escherichia coli (

E. coli) revealed the distinct roles of different UV lights in the disinfection and reactivation of

E. coli. Li et al. [

4] concluded that, based on the output power of 280 nm LEDs (two times more than that of 265 nm LEDs) and the reactivation performance, 280 nm LEDs were a better choice for inactivating

E. coli. However, studies on more micro-organisms and 365 nm wavelengths are nascent. Similarly, few studies in the literature have evaluated the use of UV-LED/TiO

2 disinfection systems for different microbial species in water. Studies in these regards are necessary for a more comprehensive understanding of UV disinfection based on LEDs and adoption in rural settings that still depend on contaminated water sources.

The use of UV for drinking water disinfection is known for no harmful disinfection by-products. Yet, the disinfection process remains time-consuming and limited to the disinfection of one or two microbial species for most studies in the literature. In this study, the disinfection of four different bacteria species (Salmonella senftenberg (S. senftenberg), Bacillus subtilis (B. subtilis), Staphylococcus aureus (S. aureus) and E. coli using UV under laboratory conditions (UV-LED of 365 nm wavelength) was evaluated and the UV disinfection process optimized using photocatalyst (TiO2). The increasing order of disinfection between the studied microbial contaminants was determined. Additionally, the cumulative effects of UV and different masses (0.02 g, 0.04 g, 0.08 g, and 0.16 g TiO2) of the photocatalyst were assessed and compared to inform future applications in field scale demonstrations for improved water access for households.

4. Discussion

This study evaluated the disinfection of

S. aureus, S. senftenberg, B. subtilis, and

E. coli using UV-LED (365 nm) and the optimization of the disinfection with different masses of photocatalyst (TiO

2). Additionally, the order of disinfection of the different bacteria species was assessed. No bacterial disinfection was observed under dark conditions. The no inactivation of the bacterial species under dark conditions indicates that the photolytic or photocatalytic disinfection observed is exclusively attributed to the UV light derived from UV-LED. We found that porous glass TiO

2 photocatalyst alone in the dark had no effect on the disinfection of all the studied microbial organisms. UV radiation drives the disinfection of microbial organisms and its availability with TiO

2 in water produces OH

• and •O

2− radicals for the photocatalytic oxidation process to produce a huddle effect that kills micro-organisms [

12,

39]. Hence, without photon energy from UV light, photocatalysts alone cannot remarkably disinfect microbial water contaminants.

The UV-LED radiation had disinfection effects on all the studied bacteria species. The results from this study also demonstrated that 365 nm UV-LED alone is not efficient for micro-organisms’ disinfection and hence affirms one of the key findings from Song et al. [

7]. These align with findings from previous studies on the use of UV-LED for water disinfection [

9,

36,

38]. Hijnen et al. [

41] found that for UV disinfection, DNA or RNA is the key target in a variety of organisms which comes in two major classes of mutagenic DNA lesions induced by UV irradiation—cyclobutane pyrimidine dimers (CPDs) and 6–4 photoproducts (6–4 PPs) [

4,

13]. The UV light inhibits the normal replication of DNA and also bacterial mutations, hence leading to perturbation of different cellular processes and finally to the death of microbial species [

5,

7,

24].

Disinfection with UVA (315–400 nm) radiation alone is known to be less efficient. Our observations of low disinfection rates with UV alone for all four bacteria species further supported this. However, the integration of UVA radiation with TiO

2 photocatalyst efficiently disinfects micro-organisms through the production of reactive oxygen species [

42]. As UVA-LEDs are known for their high output power feature, they are desirable for photocatalytic disinfection with TiO

2 [

7]. For instance, the “residual disinfecting effect”, a phenomenon where

E. coli attains further disinfection even after a photocatalytic process, as observed in previous studies, shows this high output in disinfection rates [

43]. Such residual disinfection effects are known for the cumulative damage of cellular components by reactive oxygen species or stable oxidants, such as H

2O

2, which could prevent the reproduction of damaged micro-organisms [

7,

44,

45,

46].

The results support the use of the porous glass-embedded TiO

2 for efficient water disinfection. The disinfection of the pathogenic micro-organisms (

S. aureus, S. senftenberg, B. subtilis, and

E. coli.) under UV-LED irradiation was enhanced with the addition of the porous glass TiO

2 photocatalyst. The studied micro-organisms when subjected only to UV light recorded very low log reduction and were able to repair after 24 h post-treatment storage. The use of TiO

2 in suspension is efficient due to the large surface area of the catalyst available for the reaction. Studies in the literature show that TiO

2 photocatalysts significantly influence the required time for complete disinfection of contaminants in relation to UV alone and non-recovery of disinfected microbial organisms [

10,

16,

21,

22,

23,

47], which is further confirmed in this study. The major reactive oxygen species (ROS), hydroxyl radicals, and hydrogen peroxide induce oxidative damage to DNA, proteins, and cell membranes and cause growth delays in micro-organisms [

7,

13]. Comparatively, this process requires more time than the direct damage produced by UVC (less than 280 nm) radiation [

7,

48]. Nonetheless, microbial species disinfection with UVA is believed to be irreparable, whereas the damage by UVC is reparable through DNA repair mechanisms [

43,

49].

The presence of some of the microbial species after 360 min of the experiments indicates their great resistance to stressful conditions, especially

B. subtilis. This resistance is reflected at the same time by the ability of these micro-organisms to regrow after post-treatment storage in the dark for 24 h and after being exposed to UV radiation that could affect their stability or rate of reproduction. This indicates the capability of micro-organisms to outlive the UV disinfection process as reported in similar studies [

16,

50,

51]. The experimental treatments without TiO

2 recorded a regrowth of bacterial species after 24 h of post-treatment storage. The establishment of the cellular repair mechanism was beyond the scope of this study. Nonetheless, bacteria recover by means of some of the documented cellular repair mechanisms such as photoreactivation, nucleotide excision repair, mutagenic DNA repair, and recombination DNA repair, thus permitting their recovery and the manifestation of the regrowth phenomenon [

52].

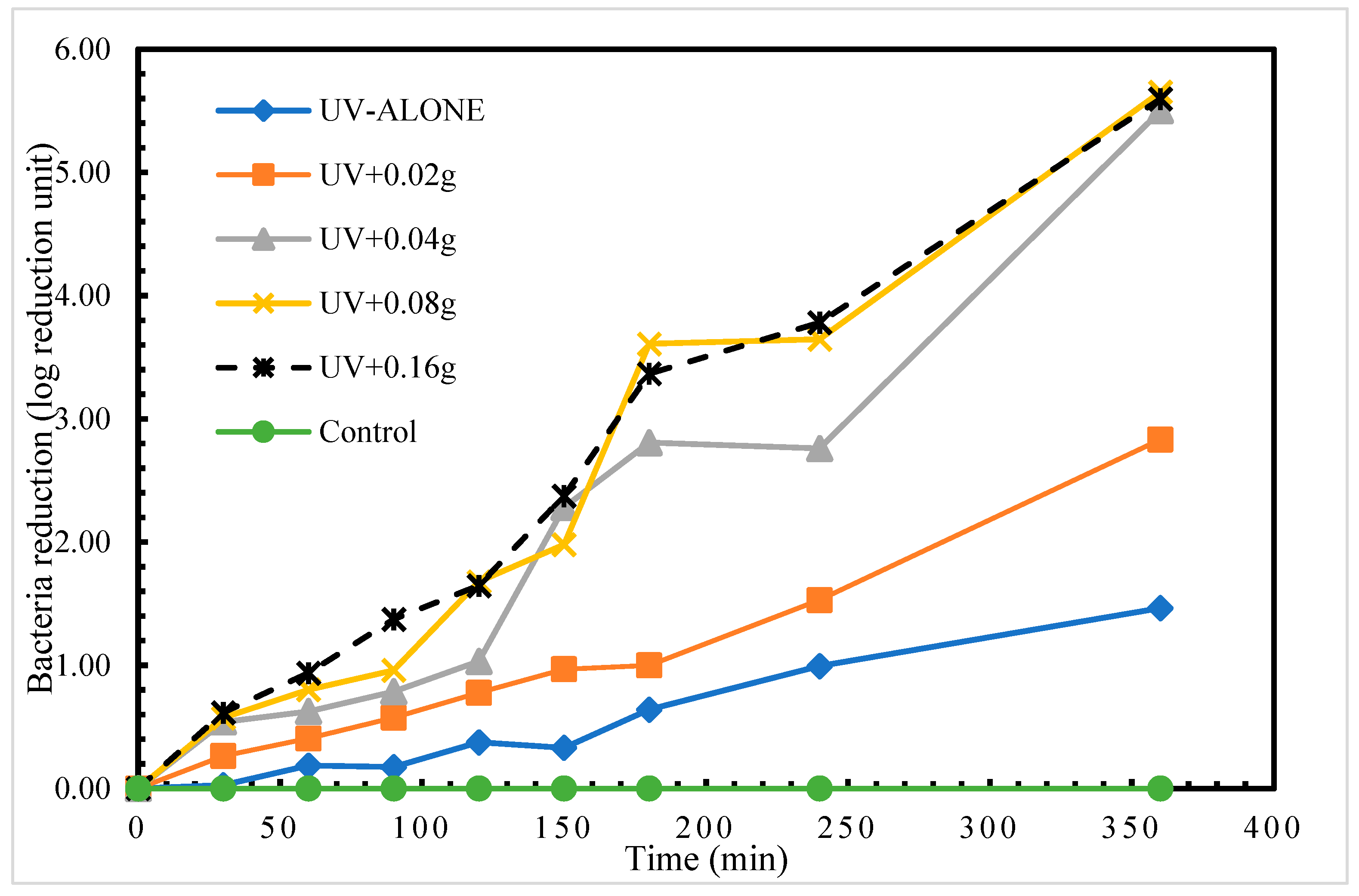

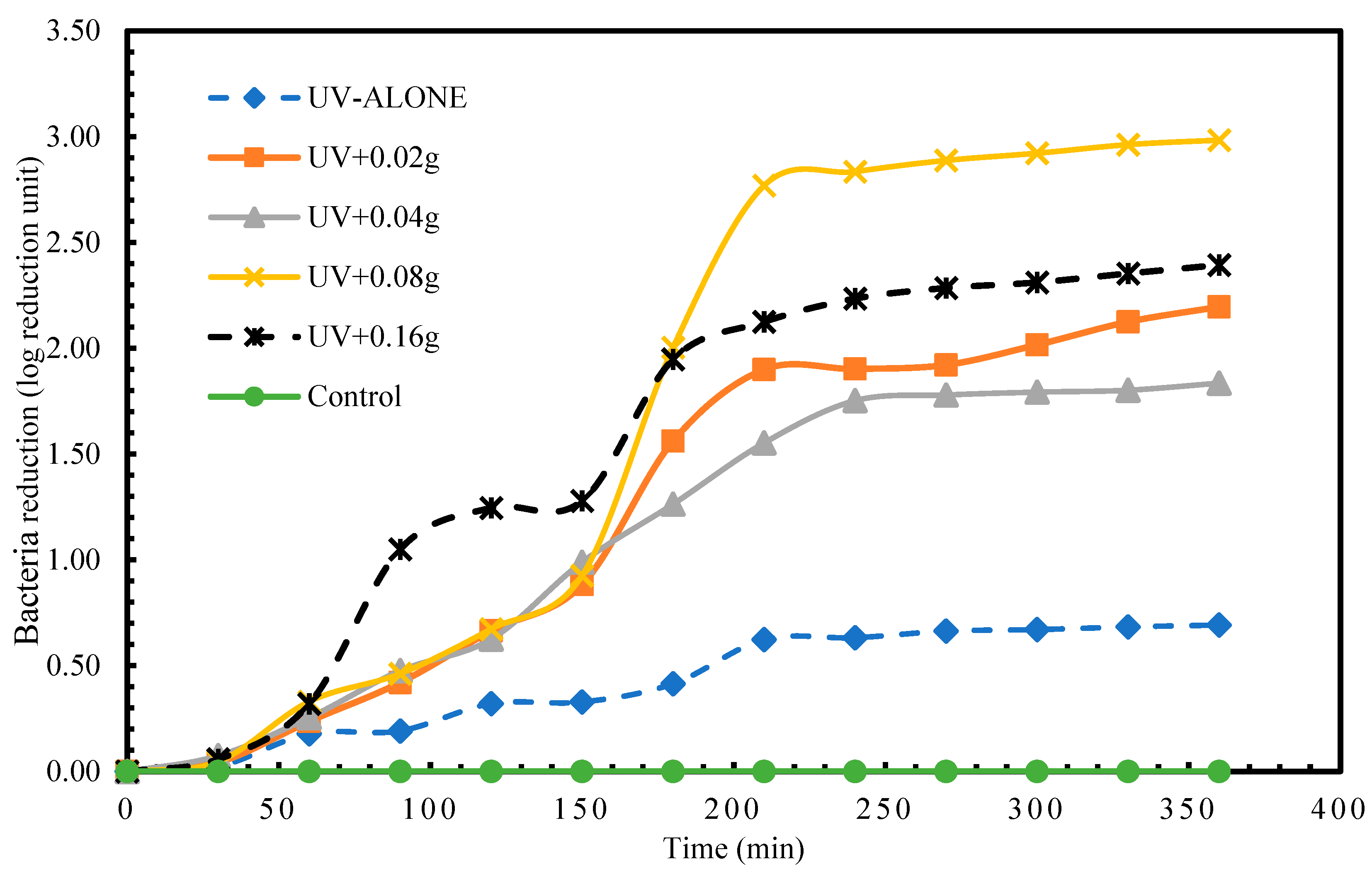

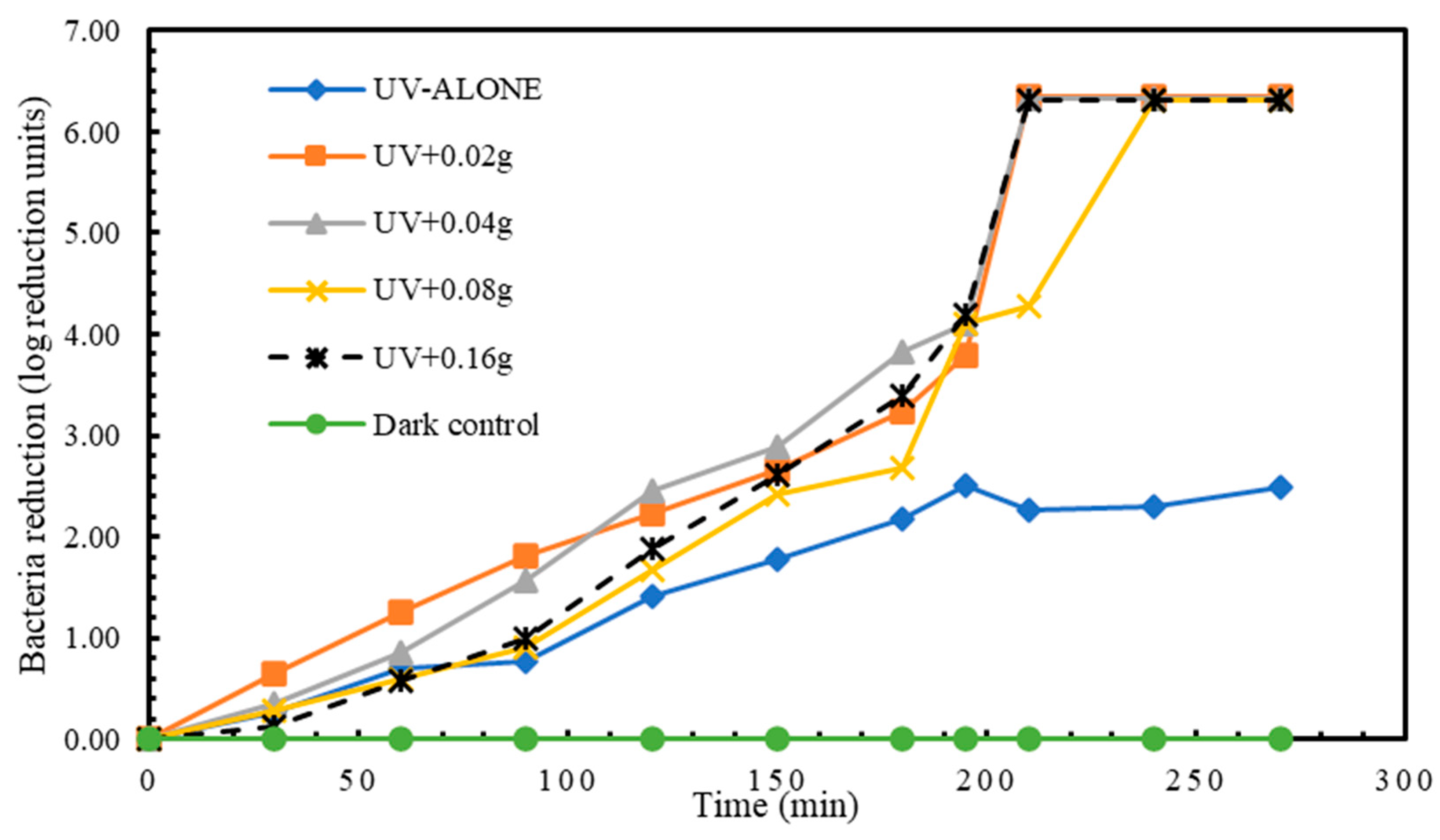

The maximum log reduction of 5.65, 3.85, 2.98, and 6.35 were obtained with treatments with 0.08 g, 0.04 g, 0.08 g, and 0.02 g of the TiO

2, respectively, for the corresponding bacterial species

S. aureus,

S. senftenberg,

B. subtilis, and

E. coli. The disinfection in log reduction units increased over the irradiation time. These findings therefore mean that the addition of TiO

2 in suspension leads to an increase in the disinfection of the bacterial species within a shorter period of time which can be attributed to the increase in the OH

• generated from the surface of the UV irradiated TiO

2 [

53]. However, as the higher mass of the TiO

2 is introduced, a point is reached where disinfection of the bacterial species decreases. This therefore indicates a detrimental effect that can be attributed to either a screening effect of excess TiO

2 particles on the surface of the bacterial species [

12,

54] or the accumulation of OH

• radicals which readily dimerize and react to form hydroperoxyl radicals, which does not contribute to the inactivation process due to their less reactivity [

31]. Analogous results to these findings were also reported in previous studies [

12,

29,

55,

56,

57].

E. coli disinfection achieved the highest log reduction among the studied micro-organisms supporting related works in the literature on

E. coli disinfection using UV-LEDs of different wavelengths (255, 265, 272, 275, and 280 nm) with a reported log reduction range of 3.4–4.0 log reduction units [

48,

49,

58,

59]. The findings from this study with respect to the disinfection of

E. coli are similar to the works of Hamamoto et al. [

60] and Mori et al. [

61], who applied UV radiation of 365 nm for the disinfection of

E. coli and obtained higher log reduction of 5.7 and 3.9 log reduction units, respectively. Xiong and Hu [

43] in their study established a 3 log reduction unit for

E. coli disinfection using TiO

2 photocatalytic disinfection with a 365 nm UV-LED. The higher log reduction obtained for

E. coli within a relatively shorter time compared to the other studied bacterial species could have been due to the high flow of photons which directly attack the

E. coli bacteria and thus preventing its self-defense and auto-repair mechanisms from taking place leading to accelerated disinfection [

12,

29].

E. coli therefore demonstrates a more sensitive mechanism to the UV and a huddle effect is expected even at low irradiance from the light source.

After 24 h post-treatment storage, no dark repair was detected in all the TiO

2 photocatalyst treatments. The repressed photoreactivation and dark repair in TiO

2 photocatalysis could be attributed to the severe damage of the DNA by the UV photon due to high UV dose and severe damage of the cell membrane and oxidative attack of intracellular components by the OH

• generated from the surface of the UV irradiated TiO

2 that could have led to subsequent cell death [

12,

62].

Statistically significant associations were established between the compared means of the four studied bacteria species (

S. aureus,

S. senftenberg,

B. subtilis, and

E. coli). The comparison of micro-organism response to UV-LEDs in this study, as well as the literature works, revealed that some micro-organisms may be sensitive to different UV sources, likely due to the difference in the UV source radiation patterns and the fluence rates. The order of disinfection of the studied bacteria is consistent with previous works by Wang et al. [

63] that demonstrated bacterial inactivation in the order of

E. coli,

S. aureus, and

B. subtilis. Disinfection studies on several micro-organisms using UV-LED of the same wavelengths and comparable fluence rates still show considerable discrepancies among the published results [

6,

7,

64].

5. Conclusions

Direct photolytic and TiO2 photocatalytic disinfection of four different bacterial species were assessed using UV-LED of wavelength 365 nm. The optimization of the UV disinfection under different masses of the TiO2 photocatalyst was evaluated. Additionally, the order of disinfection of the different bacteria species was assessed. The findings demonstrated that the application of UV alone was not efficient for micro-organisms’ disinfection; however, the integration of UV and TiO2 photocatalyst optimized the disinfection of S. aureus, S. senftenberg, B. subtilis, and E. coli in water. The TiO2 alone had no effect on the disinfection of the pathogenic bacteria species. It was revealed that UV radiation of wavelength 365 nm for the disinfection of S. aureus, S. senftenberg, B. subtilis, and E. coli achieved 1.46, 1.26, 0.69, and 2.49 log reduction units, respectively. Apparently, the UV irradiation for the disinfection of the studied microbial species required more exposure time of not less than 6 h for efficient disinfection. The optimization with TiO2 photocatalyst gave corresponding disinfections of 5.65, 3.85, 2.98, and 6.35 log reduction units for S. aureus, S. senftenberg, B. subtilis, and E. coli. The disinfection calculated and reported in a log reduction of the bacteria species in increasing order was B. subtilis < S. senftenberg < S. aureus < E. coli. The findings provide key implications and new insights into the studied bacteria species and the future application of porous glass TiO2 to enhance bacteria disinfection using UV light. It is recommended that future studies investigate the stability of the photocatalyst after the degradation processes, the photocatalyst regeneration, the degradation mechanism, the availability, cost-effectiveness, health implications of the use of porous glass TiO2, and possible adoption in water treatment.