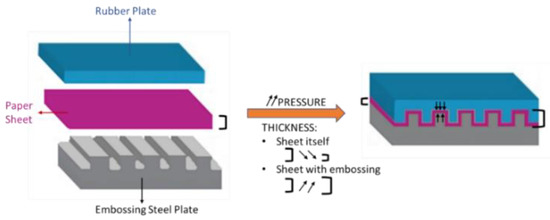

At this moment, the importance of tissue paper should be highlighted because of its high production increase in the last 10 years at a rate of 3.6% per year. Tissue paper is a product composed with virgin and/or recycled fibers, manufactured with low grammage, creped, and depending on the application, embossed. Embossing is a converting process in which the surface of a tissue paper sheet is changed under high pressure, allowing different functions such as toilet paper, kitchen towels, napkins, and facial paper. In this work, the authors intend to study how the embossing pressure affects the main properties of tissue paper, using a laboratory embossing system (see Figure 1) with two embossing patterns as shown in Figure 2. To perform this work, industrial base tissue paper (only creped) from two different Portuguese factories were used. Both papers are composed of a mixture of bleached hardwood (Eucalyptus globulus) and softwood (Pinus) kraft pulps, with hardwood being present in greater quantities. These two papers were selected because they have a very similar grammage and because the respective paper machines operate differently. The industrial base tissue paper designated by A was produced on a machine with a double headbox and steel creping blade, and the industrial base tissue paper designated by B was produced on a machine with a single headbox and ceramic creping blade.

Figure 1.

Schematic of the embossing process with pressure action effects.

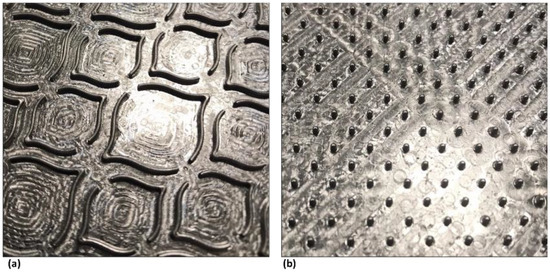

Figure 2.

Photographs of steel embossing plates: (a) deco embossing and (b) micro embossing.

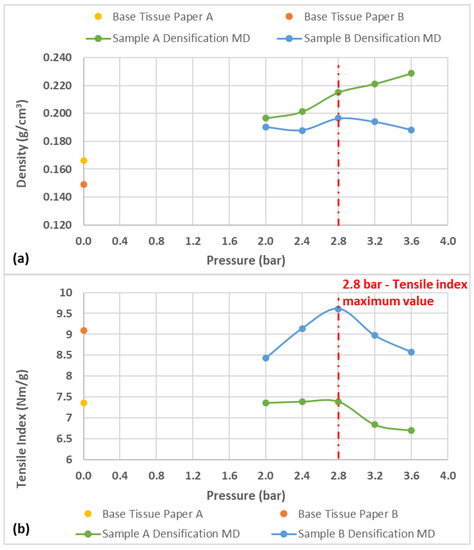

The behavior of the density and mechanical strength of the two samples for different pressures and without embossing patterns was studied. The effect of pressure when densifying the paper sheet provides a gain in mechanical strength as shown in Figure 3.

Figure 3.

Results obtained for: (a) density and (b) tensile index with the pressure increase in the base tissue paper densification of the samples A and B.

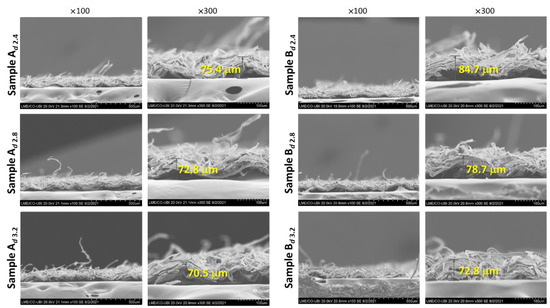

Looking at the cross-section Scanning Electron Microscope (SEM) images in Figure 4, it is clear that in both cases, with increasing pressure, crepe waves decrease its height. In the case of sample B, the visible destruction of the crepe wave should be noted. These images corroborate the results discussed above in which sample B has a more fragile fibrous sheet structure.

Figure 4.

SEM images of cross-sections in samples A and B, at two magnifications (×100 and ×300), at pressures 2.4, 2.8, and 3.2 bar. In the images with x300 magnification, the distances from the base to the crepe of the crepe wave are shown.

As a result, there is an optimal pressure for the embossing process, where the effect of pressure when densifying the paper sheet can be advantageous, as the gain in mechanical strength can counterbalance the losses with the embossing operation. The liquid interaction with the different densified paper structures was also considered in this study to evaluate the spreading dynamic.

As expected, the structural properties of the paper sheet are more affected by the micro embossing pattern than by the deco. It should be noted that the structural property most affected is thickness, where, for the micro embossing pattern, an increase of 147% was obtained, while for the deco embossing pattern, it remained practically constant with increasing pressure. As the remaining structural properties are directly related to the thickness, they did not undergo major changes for the deco embossing pattern, but for the micro embossing pattern, the changes were in accordance with those obtained for the thickness. These findings were verified in both samples, A and B.

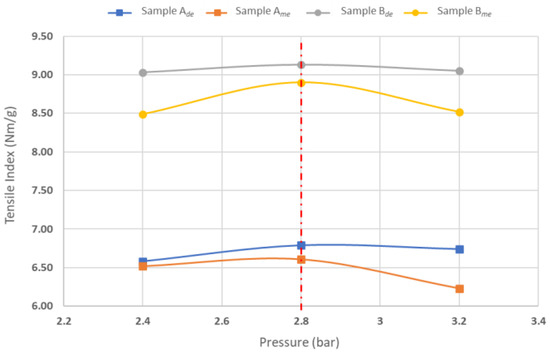

The mechanical strength behavior with the pressure for the two embossing patterns in samples A and B are represented in Figure 5.

Figure 5.

Results obtained for the tensile index, with the pressure increase in samples A and B with deco and micro embossing.

Comparing the industrial toilet base tissue paper with and without embossing, for the micro embossing pattern, we obtained a loss of about 10% and 2% for sample A and B, respectively. Regarding the embossing deco pattern, as expected, this loss is smaller, obtaining about 8% and 0% for samples A and B, respectively. These results are in line with what was previously discussed, proving that the densification of the sheet was advantageous so that the loss of mechanical properties by the embossing operation was minimized for the pressure of 2.8 bar.

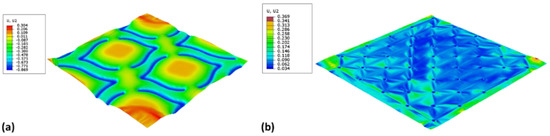

This behavior was also studied using the Explicit Finite Element Method (FEM), considering densification as an associative isotropic hardening associate with an anisotropic elasto-plastic model. This model was implemented as a VUMAT (Vectored User MATerial), which is linked to Commercial Finite Element Software AbaqusTM version 6.14 (Waltham, MA, USA) to simulate the embossing process. The displacement fields can be observed in Figure 6 for both embossing patterns.

Figure 6.

Displacement fields for both embossing patterns: (a) deco and (b) micro.

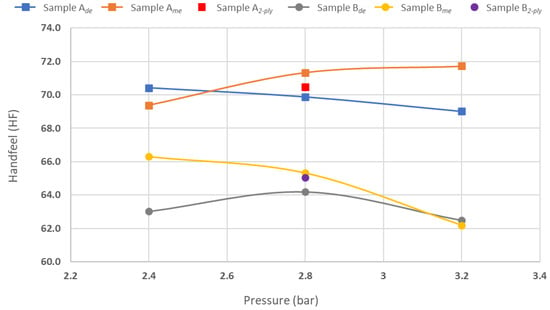

Finally, Figure 7 shows the behavior of the important softness property with embossing pressure for the two patterns alone and combined in a final 2-ply product.

Figure 7.

Results obtained for handfeel (HF), with the pressure increase in samples A and B with deco and micro embossing.

The handfeel (HF)value for a 2-ply final product with the two patterns can be located between the HF values obtained for each pattern separately. Furthermore, the embossing deco pattern, in both cases, has lower HF values than the micro pattern. Contrary to what happens with mechanical strength, it is not at 2.8 bar that the highest HF values are obtained. It is only for the case of the embossing deco pattern of sample B that the highest HF value is obtained for the pressure of 2.8 bar. Comparing the HF of industrial toilet base tissue paper with and without embossing, for the micro embossing pattern, a loss of about 9% and 12% was obtained for samples A and B, respectively. Regarding the embossing deco pattern, as expected, this loss was slightly higher, obtaining about 11% and 13% for samples A and B, respectively.

In conclusion, an optimum pressure was achieved at 2.8 bar to this embossing laboratory set-up for both embossing patterns. The two embossing patterns present different behaviors, but both demonstrate losses in mechanical and softness properties. At the end, to achieve a final product with excellent quality, it is important to make a compromise between the various properties.

Author Contributions

FEM analysis, M.L.R. and A.C.V.; investigation, J.C.V.; simulation supervision, M.L.R. and A.C.V.; data curation, J.C.V., A.d.O.M.; writing—original draft preparation, J.C.V., A.d.O.M., M.L.R., A.C.V.; writing—review and editing, J.C.V., A.d.O.M., M.L.R., A.C.V., A.M.C., P.T.F. and A.P.C.; supervision, P.T.F. and A.P.C.; project pivot, A.M.C. All authors have read and agreed to the published version of the manuscript.

Funding

The authors gratefully acknowledge the funding of this work that was carried out under the Project InPaCTus—Innovative Products and Technologies from Eucalyptus, Project Nº 21874 funded by Portugal 2020 through European Regional Development Fund (ERDF) in the frame of COMPETE 2020 nº 246/AXIS II/2017. The authors are also very grateful for the support given by research unit Fiber Materials and Environmental Technologies (FibEnTech-UBI), on the extent of the project reference UIDB/00195/2020, and by the Center for Mechanical and Aerospace Science and Technologies (C-MAST-UBI), on the extent of the project reference UIDB/00151/2020, both funded by the Fundação para a Ciência e a Tecnologia, IP/MCTES through national funds (PIDDAC).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).