Thermoelectric (TE) devices are utilized for thermal energy harvesting, local cooling or heating, and temperature sensing. They have no mechanical structures, can be made flexible and present long operating lifetimes, making them useful for the Internet of Things (IoT) and wearable electronics.

Regarding TE sensors and detectors, one of the most important parameters to optimize is the thermal conductivity of the materials. The thermal losses in the device operation are critical since we want to heat up just one side of the material and have it maintaining the temperature gradient. Additionally, we want intelligible and fast responses to temperature changes which depends on the Seebeck coefficient (material property) and on the number of connected elements (device architecture) [

1].

This work presents TE detectors based on poly(dimethylsiloxane) (PDMS) and graphite (G) composites where both the material properties and the device architecture have been exploited.

PDMS is an elastomer widely used in several research areas, such as microfluidics or stretchable electronics, suitable as substrate or as composite matrix material. PDMS is highly flexible, and it can be easily molded with high resolution and aspect ratio, requiring low curing temperatures, and being chemically and thermally stable. Among other carbon allotropes, graphite is known to have a thermoelectric response when thermally stimulated and it is much cheaper when compared to carbon nanotubes and graphene. Graphite is widely available, ecofriendly, very resistant to heat and nearly inert in contact with almost any other material. The mixture of these two materials causes a low-cost and flexible composite, with TE properties, easy to process in terms of time and energy expenditure [

1].

Thermoelectric devices can assume vertical or planar structures, depending on how the heat flows and on the layout of the thermoelectric elements. In a previous published work, we reported, for the first time, the production of planar TE touch detectors based on PDMS:GFlakes composites. Here, we show the vertical assembling of TE devices, based on the same material, to be used for touch detection and temperature-sensing applications.

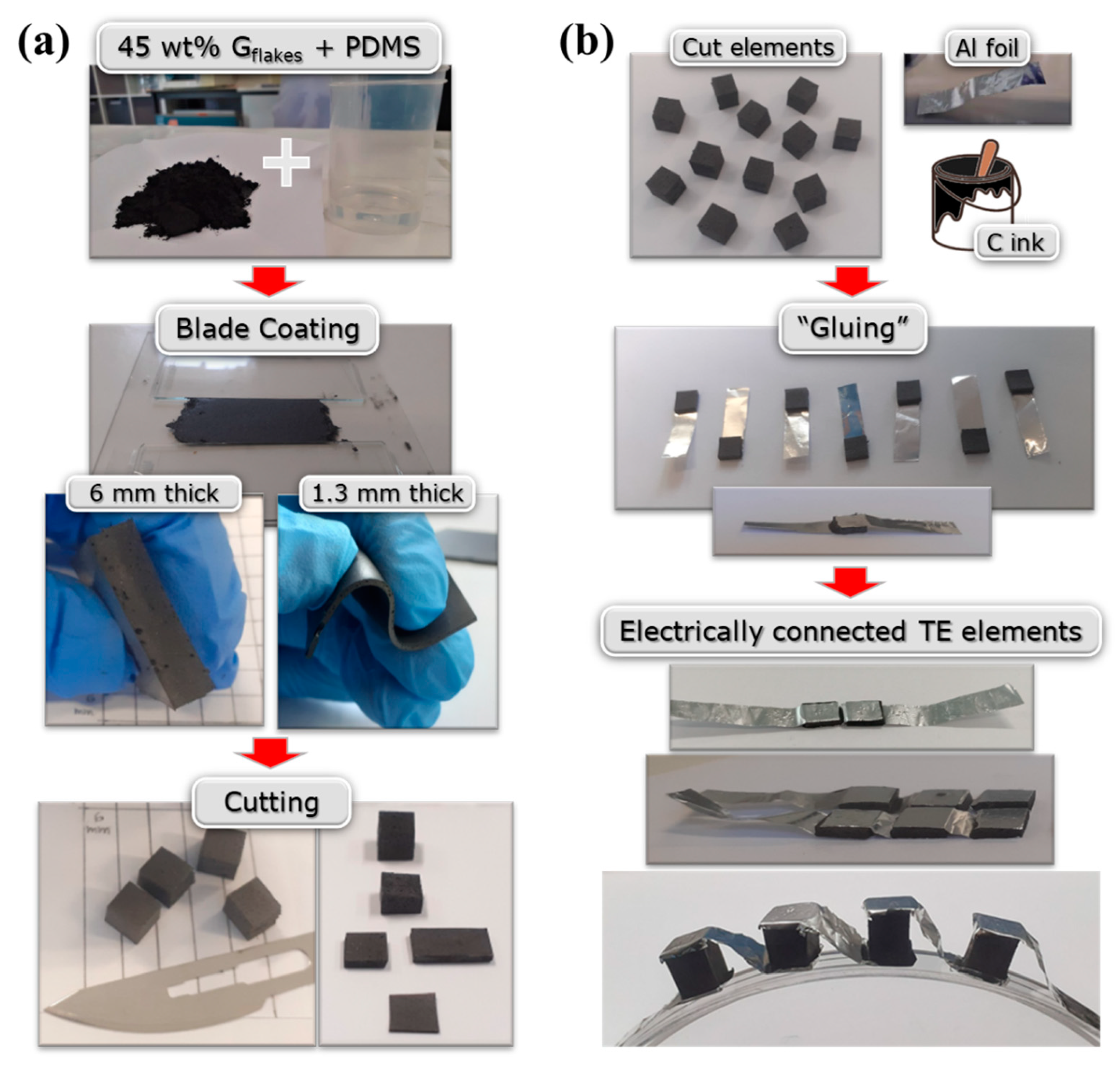

Figure 1 shows the thermoelectric devices’ manufacturing process, from the synthesis of the composite (a) to the device assembling (b). We can see photographs of each step to obtain vertical flexible thermoelectric devices. The PDMS:G

Flakes samples are prepared through a blade coating process, cut into small blocks with different thicknesses and areas (a) and connected with carbon ink + Al foil to form different thermoelectric detecting/sensing devices (b).

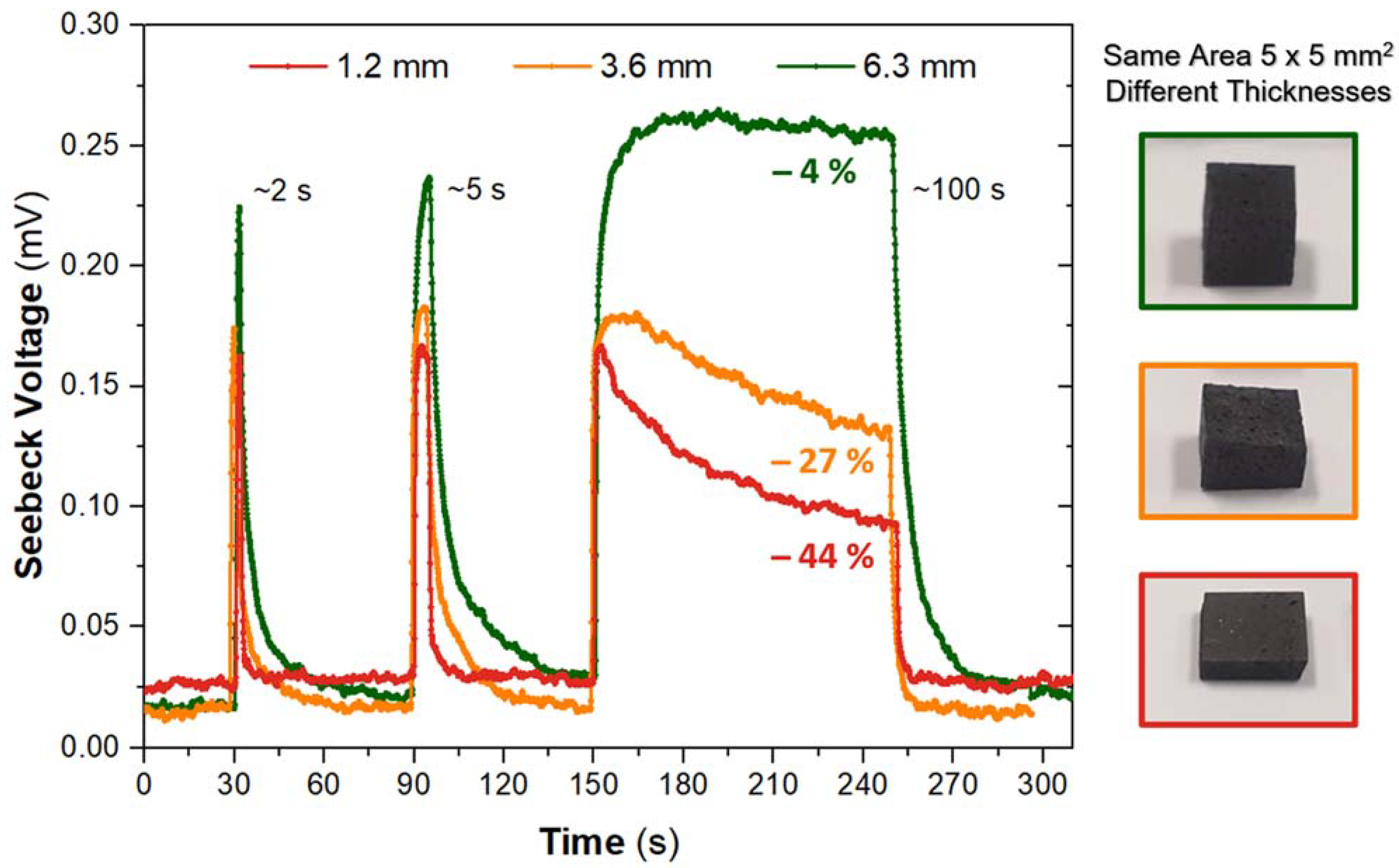

We studied the response to a gloved touch by using devices with single elements, with the same area, while changing their thicknesses, 1.2 mm, 3.6 mm, and 6.3 mm (

Figure 2), to compare the V

ON values (open circuit voltages when stimulated with temperature gradients), as well as rise and fall times. We conclude that for thicker elements, the maximum V

ON is higher, and it needs more time to be achieved but then it is stable for longer periods, while the thinner ones are faster, but they cannot sustain the temperature gradient for more than a few seconds.

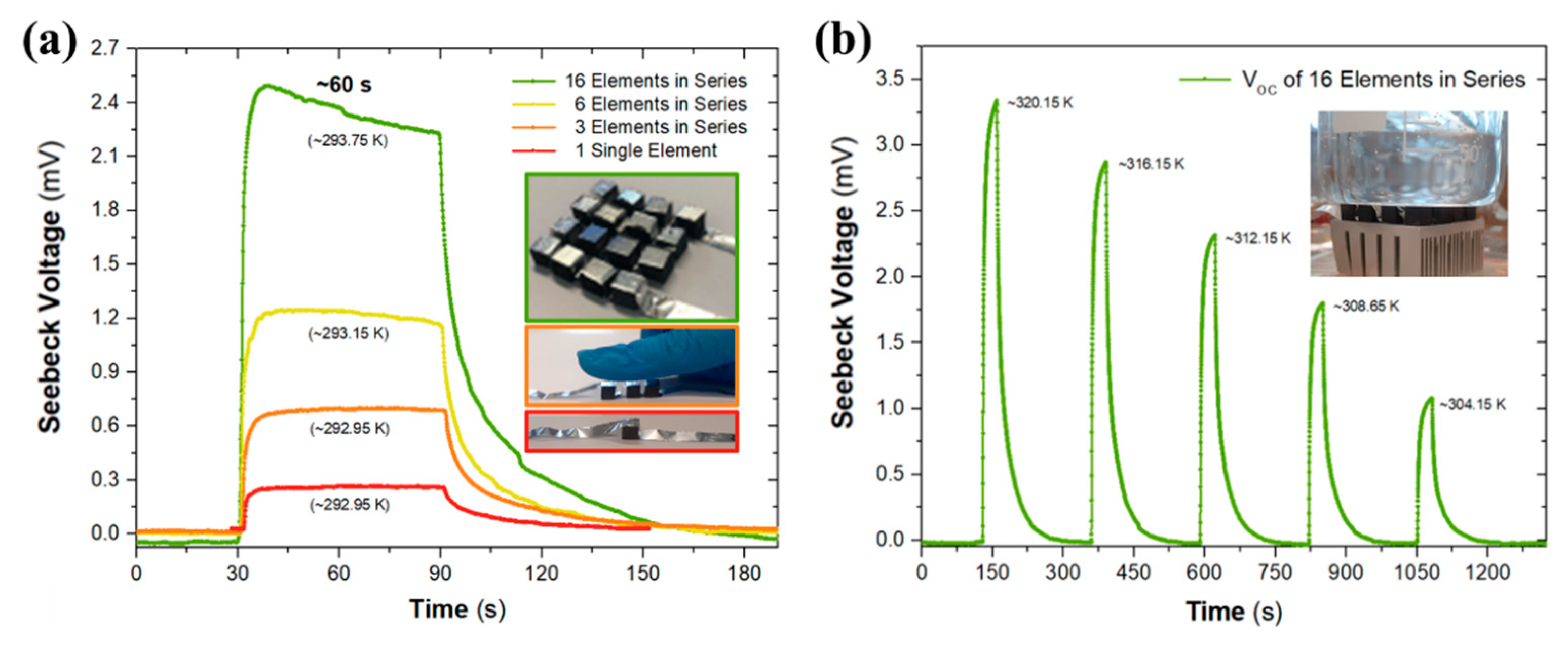

Since the thicker samples are able to maintain the V

ON for longer periods,

Figure 3a shows the results of gloved touches for 60 s for 1, 3, 6 and 16 electrically connected elements with 6 × 6 × 6.3 mm

3 of volume. As we can see, the V

ON response increases when more elements are electrically connected in series, since the Seebeck coefficient (S) of the device is the sum of each individual S. Due to its relevant thermoelectric signal, the device with 16 elements was submitted to hot water sensing, in which several water temperatures were tested, having discriminated V

ON values (

Figure 3b). The measured samples can be seen in the inset photographs.

All the detectors work well, with fast response and recovery times, returning to the initial VOFF values (open circuit voltages when there is no temperature gradient applied), allowing repeated thermal stimuli. The VON results reach 10−4 to 10−3 V even for the fastest touches and small temperature gradients, making these devices suitable for many different IoT applications.

Author Contributions

Conceptualization, J.F. and J.L.; methodology, J.F., J.L., E.M.F.V., J.H.C. and L.P.; validation, J.F., J.L., E.M.F.V. and L.P.; formal analysis, J.F., J.L., E.M.F.V. and L.P.; investigation, J.F. and E.M.F.V.; data curation, J.F., J.L., E.M.F.V. and L.P.; writing—original draft preparation, J.F. and E.M.F.V.; writing—review and editing, J.F., E.M.F.V., J.L., L.P., J.H.C., E.F. and R.M.; visualization, J.F., E.M.F.V., J.L. and L.P.; supervision, J.L. and L.P.; funding acquisition, L.P., E.M.F.V. and R.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financed by national funds from FCT-Fundação para a Ciência e a Tecnologia, I.P., in the scope of the projects LA/P/0037/2020, UIDP/50025/2020, and UIDB/50025/2020 of the Associate Laboratory Institute of Nanostructures, Nanomodelling and Nanofabrication–i3N, and by projects PTDC/NAN-MAT/32558/2017 and PTDC/CTM-PAM/4241/2020. E.V. thanks the FCT-Fundação para a Ciência e a Tecnologia, I.P., under the national support to R&D units grant, through the reference project UIDB/04436/2020 and UIDP/04436/2020. J.F. thanks the support from FCT-Fundação para a Ciência e a Tecnologia, I.P. through the PhD scholarship SFRH/BD/121679/2016 (Joana Figueira). This work has received funding from the European Union’s Horizon 2020 Research and Innovation Programme under the Grant Agreements Nos: 640598 (ERC-2014-STG NEW-FUN), 952169 (SYNERGY, H2020-WIDESPREAD-2020-5, CSA), and 101008701 (EMERGE, H2020-INFRAIA-2020-1).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Reference

- Figueira, J.; Loureiro, J.; Vieira, E.; Fortunato, E.; Martins, R.; Pereira, L. Flexible, scalable, and efficient thermoelectric touch detector based on PDMS and graphite flakes. Flex. Print. Electron. 2021, 6, 045018. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).