Magnesium and its alloys are considered promising candidates to replace bioinert metallic materials, such as titanium alloys and stainless steels, currently used in the manufacture of temporary implants for trauma. Magnesium alloys are fully biodegradable in the human body, making a second surgery to remove the implant unnecessary. In addition, they have an elastic modulus similar to that of bone, minimizing the stress-shielding effect, and have osteoconductive properties, which contribute to bone regeneration. The biggest obstacle to the wide use of magnesium alloys as a biodegradable material for orthopedic applications is related to the control of biodegradation rates and little knowledge regarding the effects of biodegradation on the structural integrity of the material. Computer modeling plays an important role in the design of orthopedic implants for osteosynthesis. In the case of biodegradable metals, a computational approach is necessary to predict the effects of degradation on the structural integrity of the implant and its ability to stabilize the bone fracture, avoiding trial and error approaches.

In the present work, the mechanical behavior of the magnesium alloy WE43 was simulated using a von Mises elastoplastic model with isotropic hardening, coupled to a continuous damage model to phenomenologically simulate corrosion and its impacts on the structural characteristics of the material. The corrosion phenomenological model was implemented through the development of a material subroutine (VUMAT) for use with the commercial finite element program Abaqus/Explicit. Corrosion was considered a multi-mechanism phenomenon, incorporating a pitting mechanism and the stress corrosion cracking mechanism. Both corrosion mechanisms were implemented using a non-local average formulation, to reduce the influence of mesh geometry. The pitting corrosion model was calibrated based on data obtained from mechanical characterization and in vitro degradation tests of WE43 magnesium wires. It was able to accurately capture both the linear strength reduction of the specimen as well as the non-linear degradation rate observed experimentally.

The corrosion rate of the material when immersed in simulated body fluid (SBF) was measured through the hydrogen evolution method. Furthermore, to determine the effect of corrosion on the mechanical properties of the material after immersion in SBF, three specimens were tensile tested for each degradation stage: 6 h, 12 h, 24 h, 48 h, 72 h, and 168 h. The specimens were wires of Ø0.84 mm × 84 mm. Specimens were chemically cleaned with 20% chromic acid, followed by a cleaning stage in an ultrasonic bath with ethanol and distilled water, and finally dried in an oven at 50 °C. Then, a protective layer of polytetrafluoroethylene (PTFE) was applied on both ends of the specimens, 17 mm in length. PTFE acts as a barrier between the surface of the material and the SBF, restricting the corrosion area to 50 mm of the central region of the specimen. This was carried out to ensure that failure during the tensile test occurred in this central region. The surface area subject to corrosion was 1.32 cm

2, having a ratio between the volume of electrolyte and the surface area of 50 mL/cm

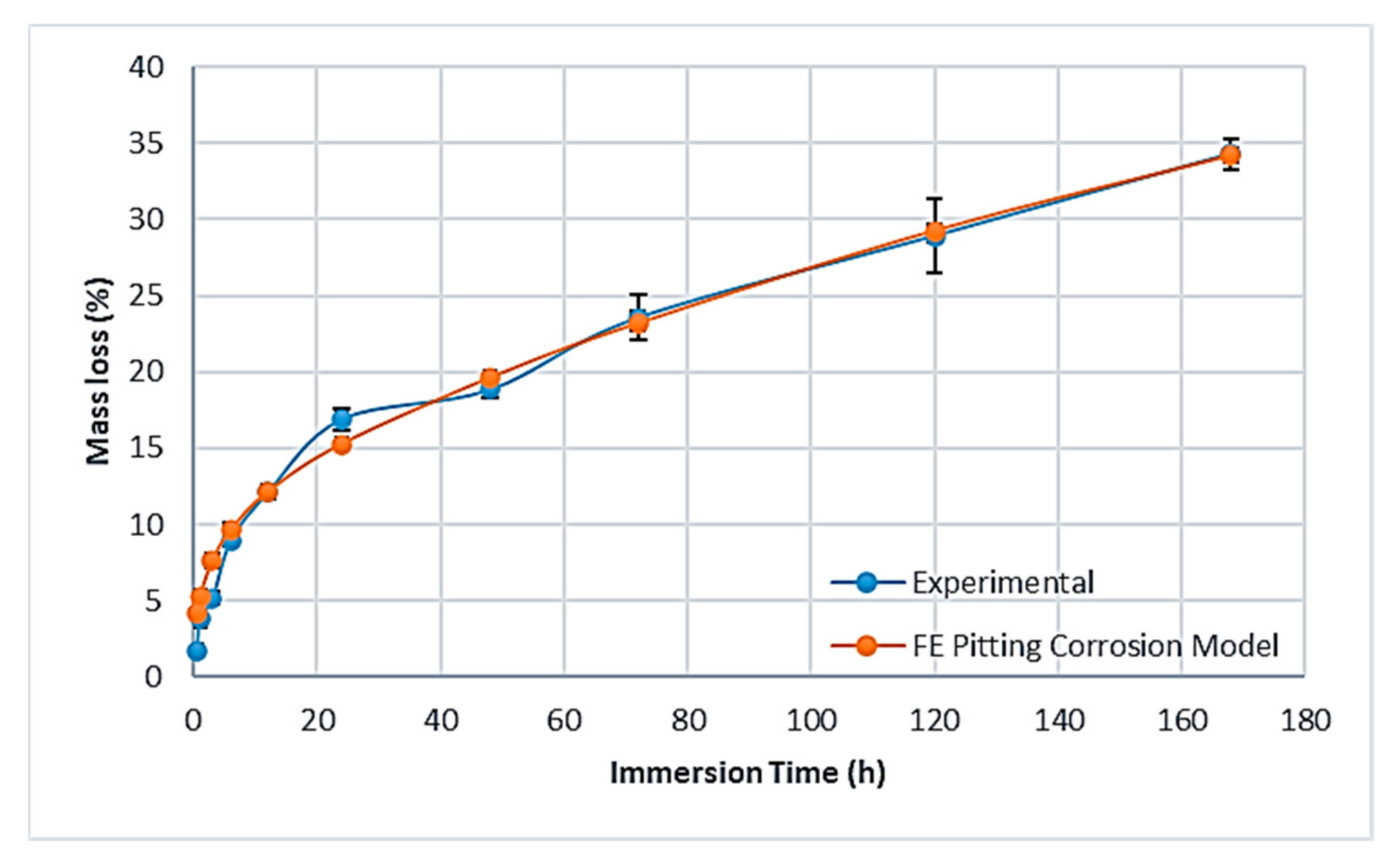

2. The mass loss during corrosion time can be observed in

Figure 1. In

Figure 2, it is possible to observe the surface corrosion after immersion in SBF after 168 h. The reduction in mechanical properties can be observed in

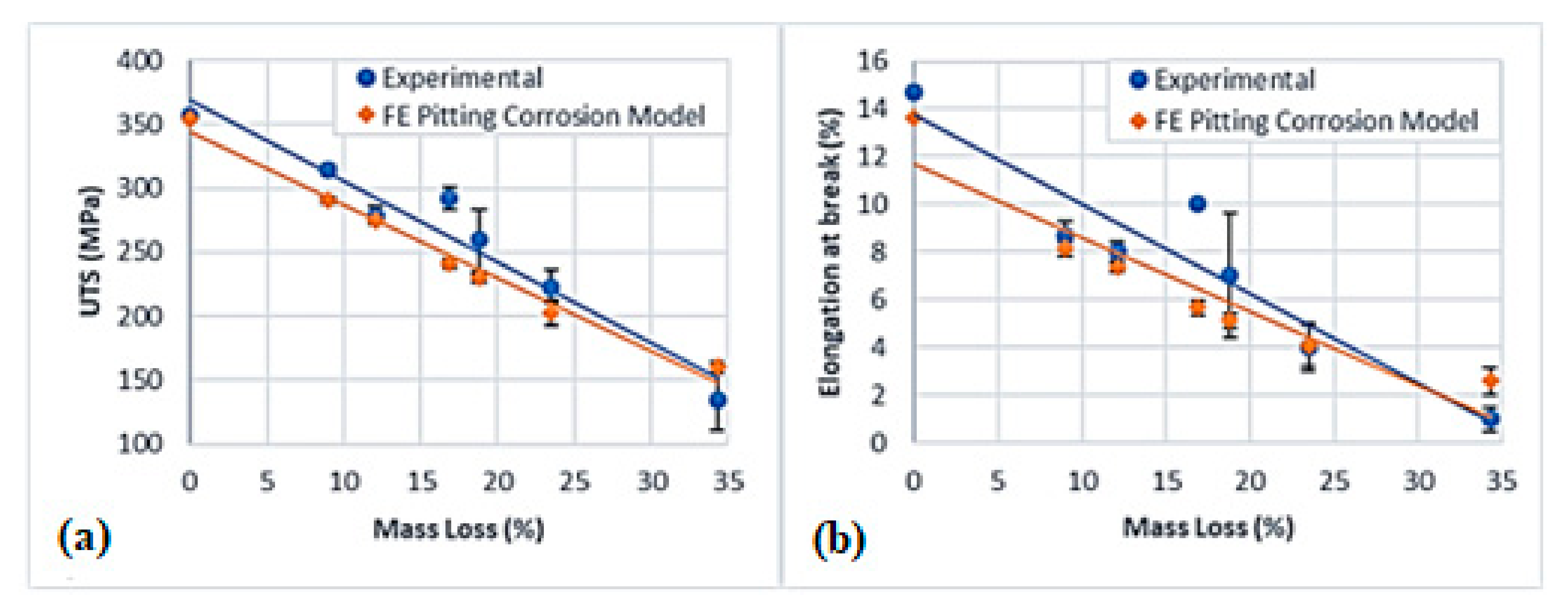

Figure 3.

After the initial determination of the parameters, each scenario was simulated three times, with different random starting seeds being provided for the Weibull distribution, through the RANDOM_SEED subroutine present in FORTRAN 90, resulting in three distributions different from the initial values of the pits. It follows that the variable corrosion kinetic parameter, together with the other calibrated parameters, allowed the developed model to present a high degree of correspondence, in relation to the Mass Loss vs. Immersion Time curve, highly corresponding to that found experimentally.

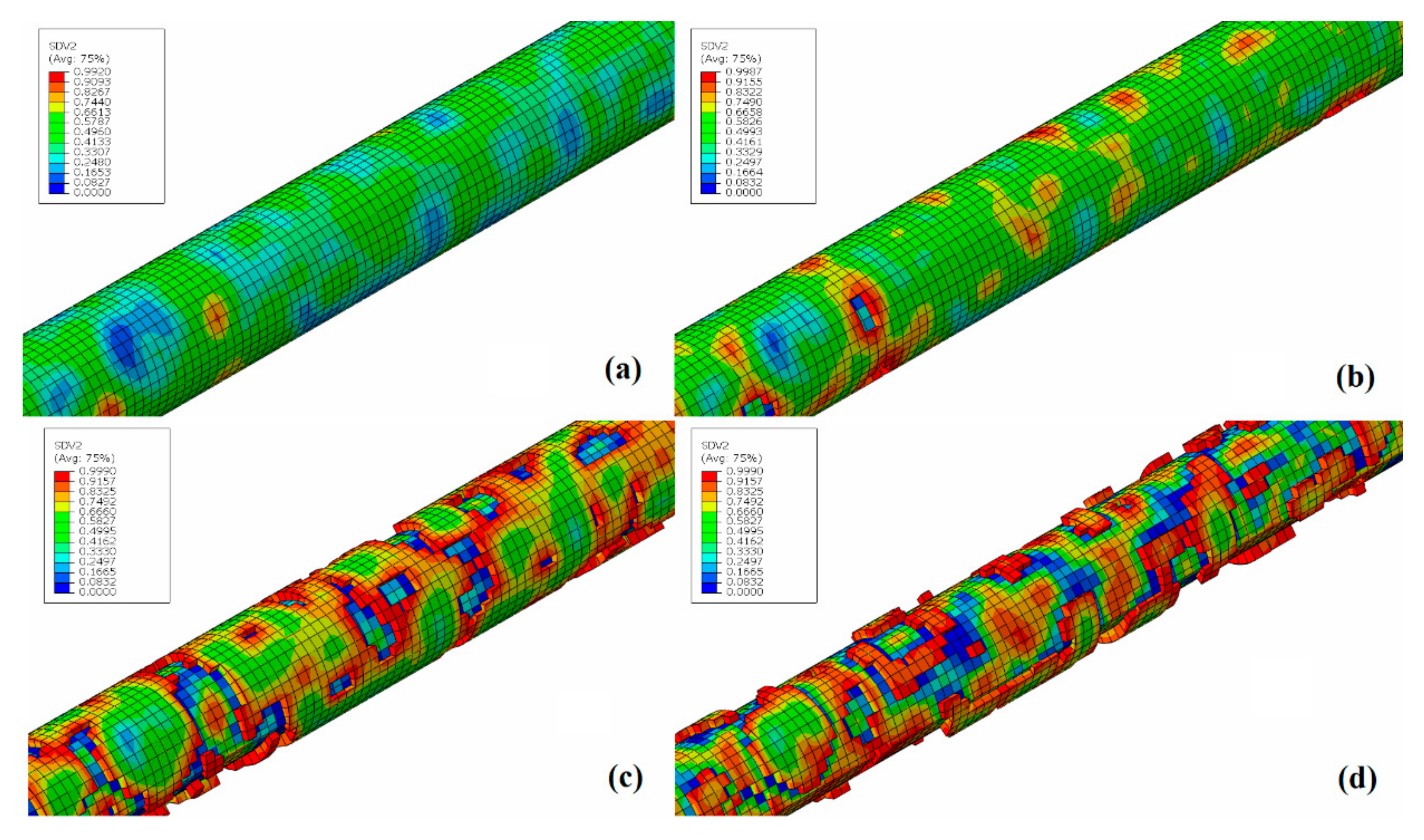

Figure 4 shows the specimen used during calibration of specimens in the different stages of corrosion.

The average result of the three corrosion simulations was used in the comparison with the values found experimentally and is shown in

Figure 1. As can be seen from

Figure 1, the calibrated pitting corrosion model can accurately represent the variable corrosion rate observed in the corrosion experiment, as well as provide the same average corrosion rate found experimentally. Additionally, from

Figure 3 it is possible to note that the pitting corrosion model can accurately capture the linear reduction in material structural integrity, represented in the form of UTS and elongation at break, observed from corrosion experiments.

The influence of stress corrosion cracking on the corrosion pattern and its effect on material integrity, investigated through the multi-mechanism model, was shown to have secondary relevance, when compared to the localized pitting corrosion mechanism, even for stresses around 75% of the yield stress of the material.

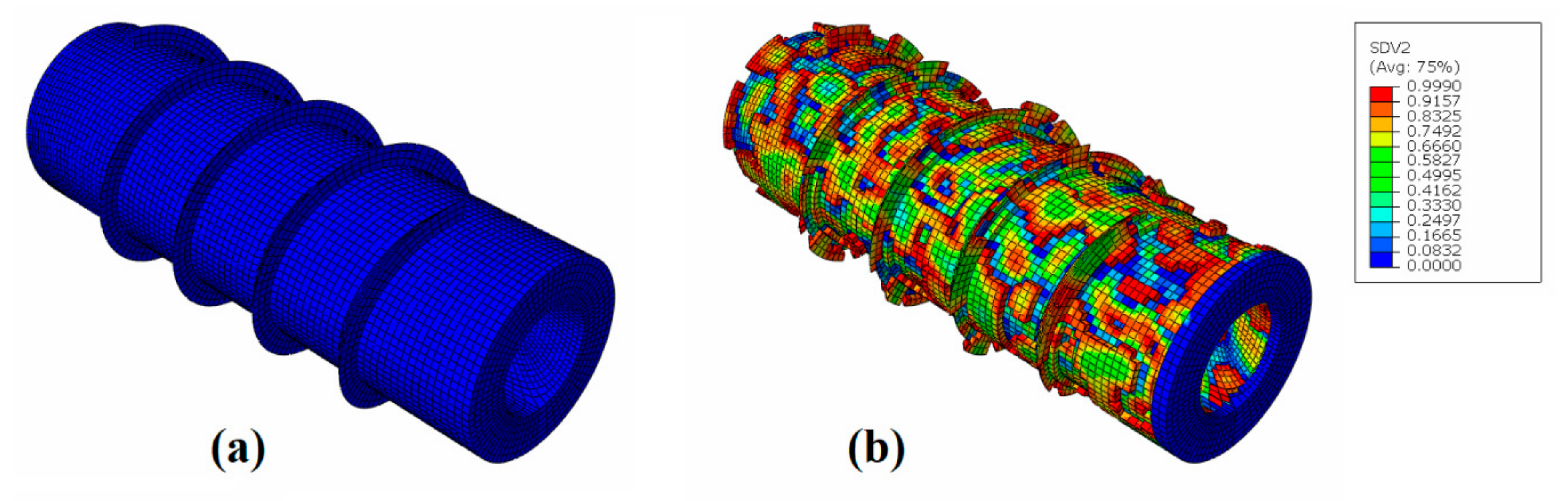

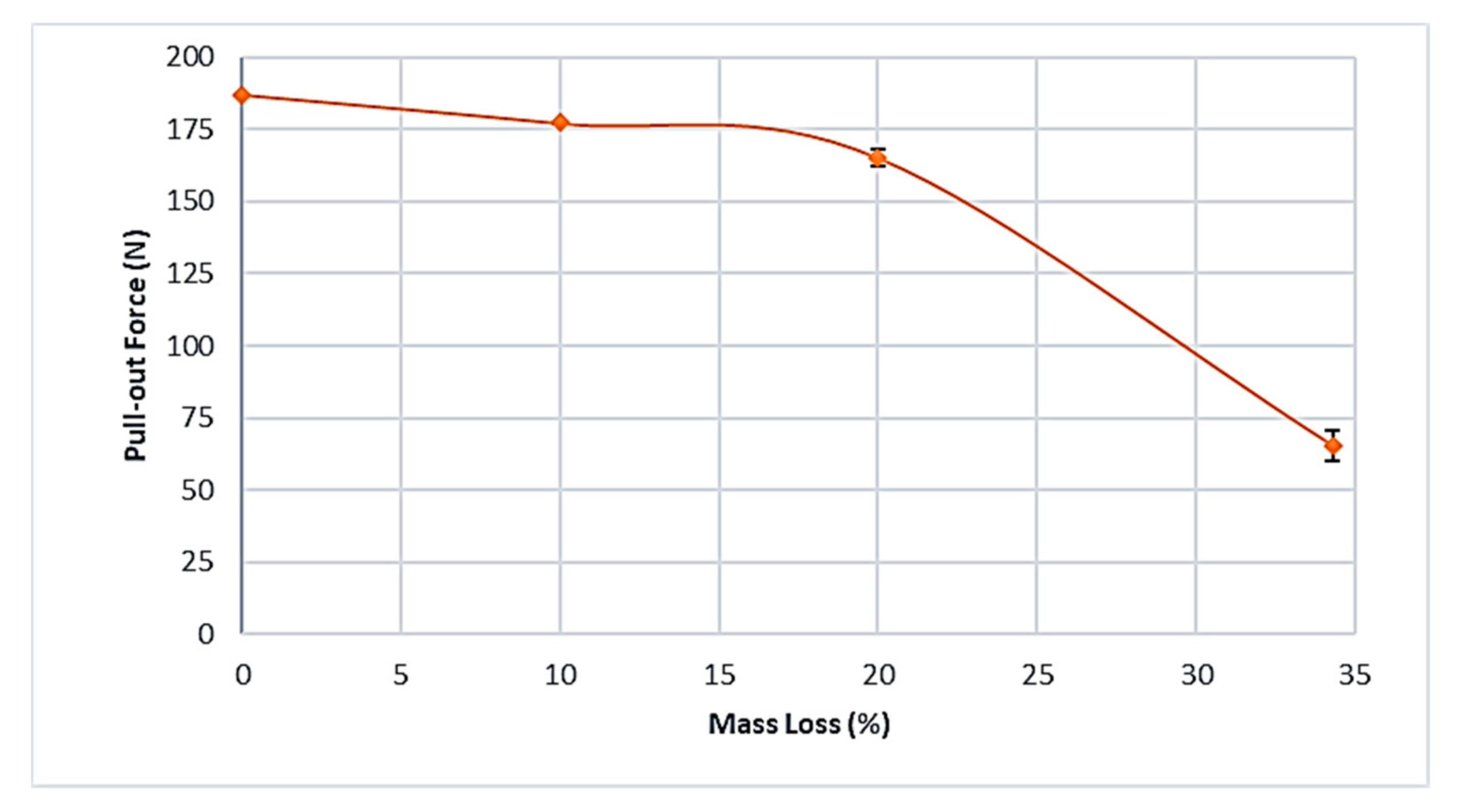

The corrosion model was applied to a case study involving the pull-out test of orthopedic screws and was able to capture the loss of fixation strength as corrosion evolves.

Figure 5 presents the orthopedic screw in its intact state and after 168 h of corrosion, equivalent to a mass loss of 34.3%.

The proposed numerical model proved to be an efficient tool to evaluate the structural integrity of biodegradable magnesium alloys, which can be used in future works for the design of orthopedic implants. In

Figure 6, it is possible to observe that the pull-out force has a non-linear evolution with the mass loss. Each scenario was simulated three times, with different random starting seeds being supplied to the Weibull distribution, resulting in three different distributions of the initial values of the pits.

In future works, we intend to study the influence of stress applied during corrosion on the mass loss and in reduction in mechanical properties.

Author Contributions

Conceptualization, F.S. and A.C.V.; methodology, F.S. and M.L.R.; software, F.S.; validation, M.L.R.; formal analysis, A.C.V.; investigation, F.S.; resources, F.S.; data curation, F.S.; writing—original draft preparation, F.S.; writing—review and editing, A.C.V.; visualization, F.S.; supervision, M.L.R.; project administration, M.L.R.; funding acquisition, A.C.V. and M.L.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Center for Mechanical and Aerospace Science and Technologies (C-MAST-UBI), on the extent of the project reference UIDB/00151/2020, funded by the Fundação para a Ciência e a Tecnologia, IP/MCTES through Portuguese national funds (PIDDAC).

Institutional Review Board Statement

Not applicable for studies not involving humans or animals.

Informed Consent Statement

Not applicable for studies not involving humans.

Conflicts of Interest

The authors declare no conflict of interest.

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).